radiator CHRYSLER CARAVAN 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 247 of 2339

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING SYSTEM

PRESSURE CAP TESTING

Dip the pressure cap in water. Clean any deposits

off the vent valve or its seat and apply cap to end of

the Pressure Cap Test Adaptor that is included with

the Cooling System Tester 7700 (Fig. 17). Working

the plunger, bring the pressure to 104 kPa (15 psi) on

the gauge. If the pressure cap fails to hold pressure

of at least 97 kPa (14 psi), replace the pressure cap.

CAUTION: The Cooling System Tester Tool is very

sensitive to small air leaks that will not cause cool-

ing system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to the tool. Turn tool

upside down and recheck pressure cap to confirm

that cap is bad.

If the pressure cap tests properly while positioned

on Cooling System Tester (Fig. 17), but will not hold

pressure or vacuum when positioned on the filler

neck. Inspect the filler neck and cap top gasket for

irregularities that may prevent the cap from sealing

properly.

DIAGNOSIS AND TESTING - RADIATOR CAP

TO FILLER NECK SEAL

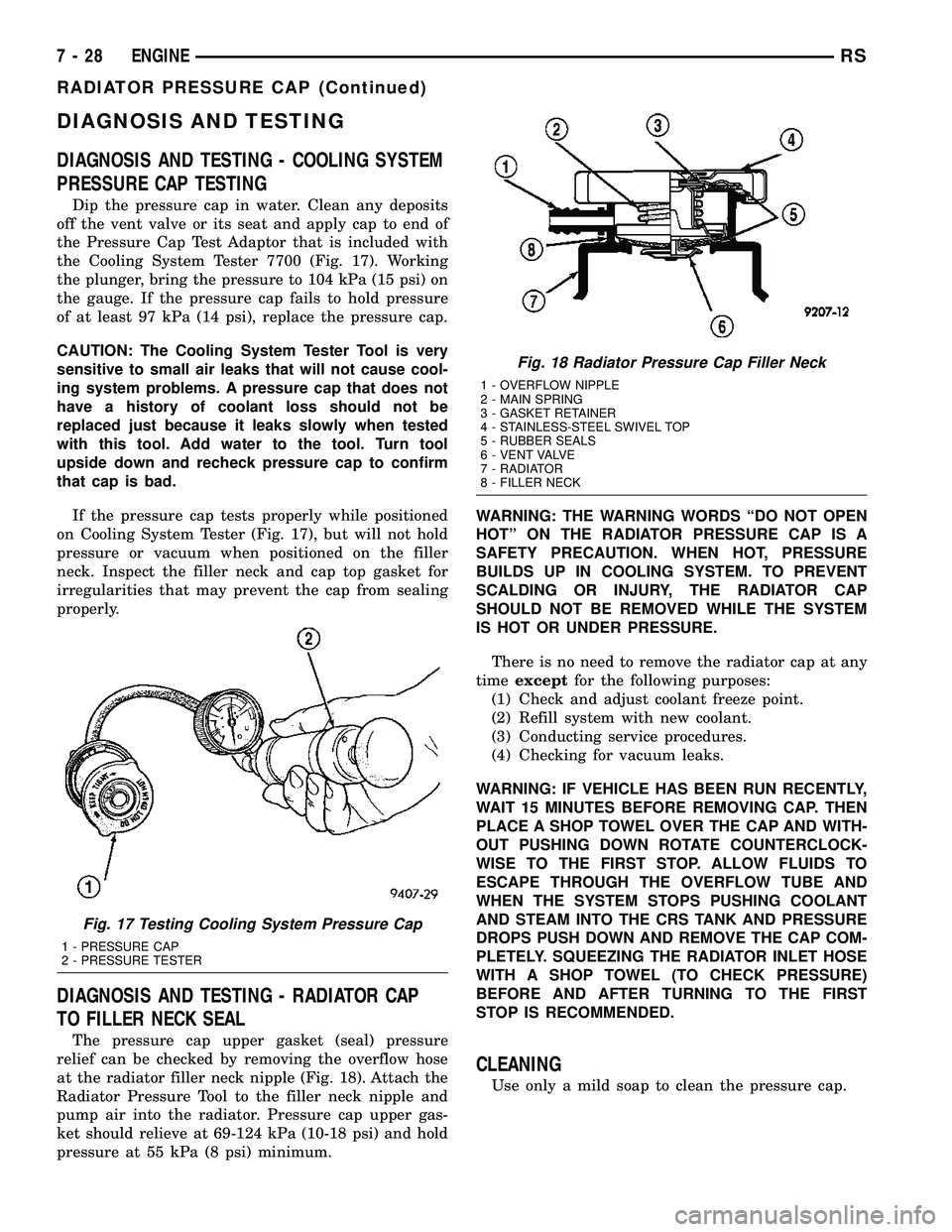

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 18). Attach the

Radiator Pressure Tool to the filler neck nipple and

pump air into the radiator. Pressure cap upper gas-

ket should relieve at 69-124 kPa (10-18 psi) and hold

pressure at 55 kPa (8 psi) minimum.WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

timeexceptfor the following purposes:

(1) Check and adjust coolant freeze point.

(2) Refill system with new coolant.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN

PLACE A SHOP TOWEL OVER THE CAP AND WITH-

OUT PUSHING DOWN ROTATE COUNTERCLOCK-

WISE TO THE FIRST STOP. ALLOW FLUIDS TO

ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COM-

PLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE)

BEFORE AND AFTER TURNING TO THE FIRST

STOP IS RECOMMENDED.

CLEANING

Use only a mild soap to clean the pressure cap.

Fig. 17 Testing Cooling System Pressure Cap

1 - PRESSURE CAP

2 - PRESSURE TESTER

Fig. 18 Radiator Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - RADIATOR

8 - FILLER NECK

7 - 28 ENGINERS

RADIATOR PRESSURE CAP (Continued)

Page 248 of 2339

INSPECTION

Hold the cap in your hand,top side up(Fig. 19).

The vent valve at the bottom of the cap should open.

If the rubber gasket has swollen, preventing the

valve from opening, replace the cap.

Hold the cleaned cap in your hand,upside down.

If any light can be seen between vent valve and the

rubber gasket, replace the cap.Do not use a

replacement cap that has a spring to hold the

vent shut.

A replacement cap must be of the type designed for

coolant reserve systems. This design ensures coolant

return to the radiator.

RADIATOR FAN

DESCRIPTION

The dual radiator fans are mounted to the back

side of the radiator (Fig. 20). The radiator fan consist

of the fan blade, electric motor and a support shroud

which are all serviced as an assembly.

OPERATION

RADIATOR FAN OPERATION CHART

COOLANT TEMPERATURE A/C PRESSURE TRANSAXLE OIL

TEMPERATURE

Fan

Operation

Speeds:Initial Max Initial Max Initial Max

Fan On: 104ÉC

(220ÉF)110ÉC

(230ÉF) Fan

Speed

Duty-Cycles

(Ramps-up)

from 30% to

99%1,724 Kpa

(250 psi)2,068 Kpa

(300 psi) Fan

Speed

Duty-Cycles

(Ramps-up)

from 30% to

99%96ÉC (204ÉF) 111ÉC (232ÉF)

Fan Speed

Duty Cycles

(Ramps-up)

from 30% to

99%

Fan Off: 101ÉC

(214ÉF)Fan Speed

Duty-Cycles

(Ramps-

down) from

99% to 30%1,710 Kpa

(248 psi)Fan Speed

Duty-Cycles

(Ramps-

down) from

99% to 30%89ÉC (192ÉF) Fan Speed

Duty Cycles

(Ramps-down)

from 99% to

30%

Fig. 19 Cooling System Pressure Cap

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - RADIATOR

8 - FILLER NECK

RSENGINE7-29

RADIATOR PRESSURE CAP (Continued)

Page 249 of 2339

DIAGNOSIS AND TESTING - RADIATOR FAN MOTOR

RADIATOR FAN DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

NOISY RADIATOR FAN 1. Fan blade loose. 1. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

2. Fan blade striking a surrounding

object.2. Locate point of fan blade contact

and repair as necessary.

3. Air obstructions at radiator or A/C

condenser.3. Remove obstructions and/or

clean debris.

4. Electric fan motor defective. 4. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

ELECTRIC FAN MOTOR DOES

NOT OPERATE1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor, or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Defective A/C pressure

transducer.2. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

ELECTRIC RADIATOR FAN

OPERATES ALL THE TIME1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Check for low coolant level. 2. Add coolant as necessary.

3. Defective A/C pressure

transducer.3. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

REMOVAL

There are no repairs to be made to the fan or

shroud assembly. If the fan is warped, cracked, or

otherwise damaged, it must be replaced as an assem-

bly (Fig. 20).

(1) Remove the radiator upper crossmember. (Refer

to 23 - BODY/EXTERIOR/GRILLE OPENING REIN-

FORCEMENT - REMOVAL)

(2) Disconnect the radiator fan electrical connec-

tors.

(3) Remove radiator fan(s) retaining screw (Fig.

20).

(4) Remove the radiator fan(s) by lifting upward to

release from mounts.

INSTALLATION

(1) Install the radiator fan(s) into mounts and

attaching clips on the radiator.

(2) Install radiator fan(s) attaching screws (Fig.

20). Tighten to 5 N´m (45 in. lbs.).

(3) Connect the radiator fan(s) electrical connec-

tors.(4) Install the radiator upper support crossmem-

ber. (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - INSTALLATION)

Fig. 20 Radiator Fans

1 - SCREWS - RADIATOR FAN ATTACHING

2 - RADIATOR FAN - RIGHT

3 - MOUNT - RIGHT RADIATOR FAN

4 - CLIPS - RADIATOR FAN LOWER

5 - MOUNT - LEFT RADIATOR FAN

6 - RADIATOR FAN - LEFT

7 - 30 ENGINERS

RADIATOR FAN (Continued)

Page 250 of 2339

(5) Install the upper radiator mounts to the cross-

member bolts, if removed. Tighten to 8 N´m (70 in.

lbs.).

(6) Install the radiator upper hose to the support

clip (2.4L engine).

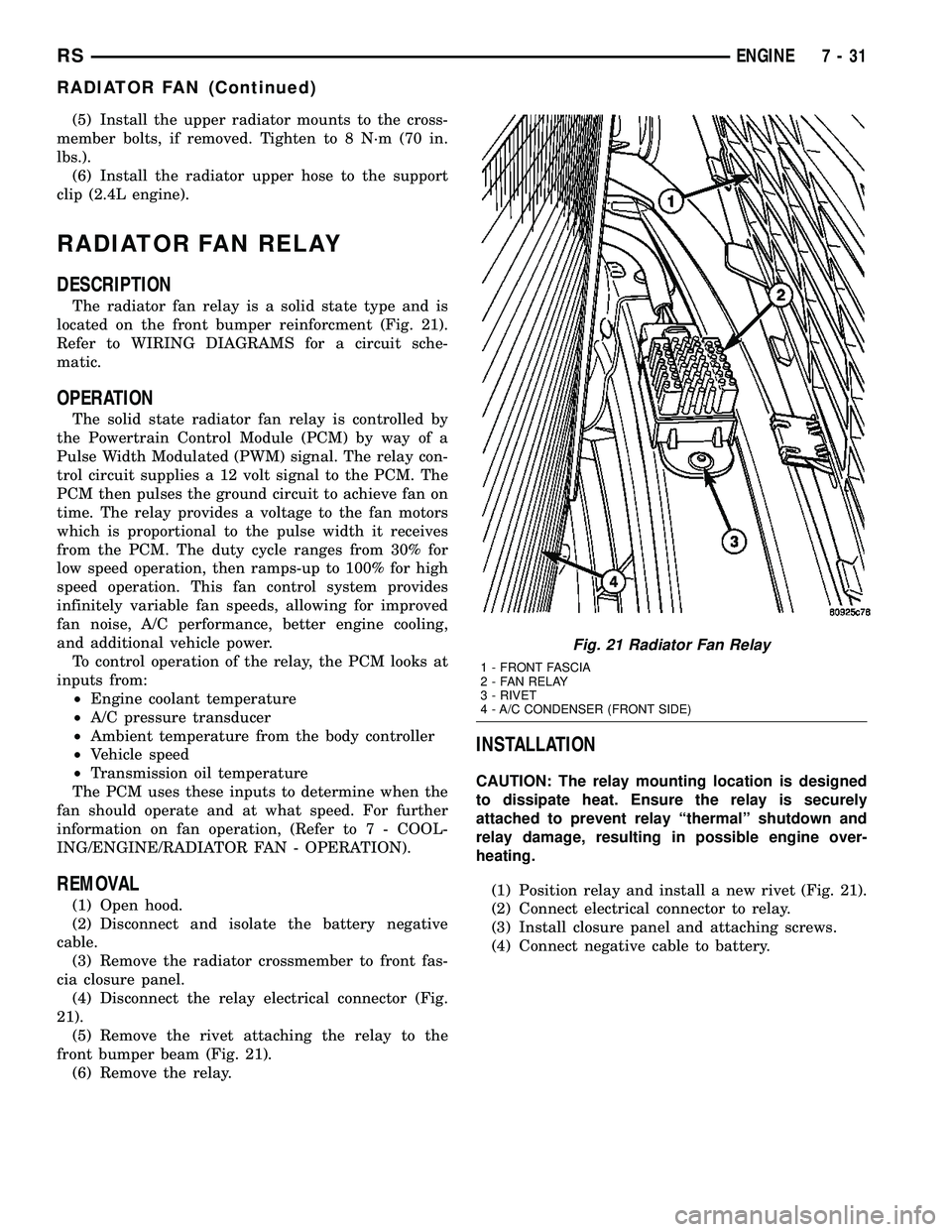

RADIATOR FAN RELAY

DESCRIPTION

The radiator fan relay is a solid state type and is

located on the front bumper reinforcment (Fig. 21).

Refer to WIRING DIAGRAMS for a circuit sche-

matic.

OPERATION

The solid state radiator fan relay is controlled by

the Powertrain Control Module (PCM) by way of a

Pulse Width Modulated (PWM) signal. The relay con-

trol circuit supplies a 12 volt signal to the PCM. The

PCM then pulses the ground circuit to achieve fan on

time. The relay provides a voltage to the fan motors

which is proportional to the pulse width it receives

from the PCM. The duty cycle ranges from 30% for

low speed operation, then ramps-up to 100% for high

speed operation. This fan control system provides

infinitely variable fan speeds, allowing for improved

fan noise, A/C performance, better engine cooling,

and additional vehicle power.

To control operation of the relay, the PCM looks at

inputs from:

²Engine coolant temperature

²A/C pressure transducer

²Ambient temperature from the body controller

²Vehicle speed

²Transmission oil temperature

The PCM uses these inputs to determine when the

fan should operate and at what speed. For further

information on fan operation, (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - OPERATION).

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the radiator crossmember to front fas-

cia closure panel.

(4) Disconnect the relay electrical connector (Fig.

21).

(5) Remove the rivet attaching the relay to the

front bumper beam (Fig. 21).

(6) Remove the relay.

INSTALLATION

CAUTION: The relay mounting location is designed

to dissipate heat. Ensure the relay is securely

attached to prevent relay ªthermalº shutdown and

relay damage, resulting in possible engine over-

heating.

(1) Position relay and install a new rivet (Fig. 21).

(2) Connect electrical connector to relay.

(3) Install closure panel and attaching screws.

(4) Connect negative cable to battery.

Fig. 21 Radiator Fan Relay

1 - FRONT FASCIA

2 - FAN RELAY

3 - RIVET

4 - A/C CONDENSER (FRONT SIDE)

RSENGINE7-31

RADIATOR FAN (Continued)

Page 255 of 2339

(7) Install drive belt shield.

(8) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

WATER PUMP INLET TUBE -

2.4L

DESCRIPTION

The 2.4L engine uses a metal tube to connect the

engine block to the lower radiator hose and heater

return (Fig. 31). The tube has an O-ring for block to

tube sealing and bolts attach the tube to the engine

block.

REMOVAL

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Remove radiator upper hose to access the hose

connections at the inlet tube.

(3) Remove radiator lower (Fig. 7) and heater

hoses from the inlet tube (Fig. 32).

(4) Remove the two fasteners that hold the inlet

tube to the block.

(5) Rotate tube while removing the tube from the

engine block.

INSTALLATION

(1) Inspect the O-ring for damage before installing

the tube into the cylinder block (Fig. 31).

(2) Lube O-ring with coolant and install inlet tube

into the cylinder block opening (Fig. 31).(3) Install the two inlet tube fasteners and tighten

to 12 N´m (105 in. lbs.).

(4) Connect the radiator lower hose (Fig. 7) and

heater hose to inlet tube (Fig. 32).

(5) Install the radiator upper hose.

(6) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

Fig. 30 Water Pump Seal

1 - WATER PUMP HOUSING

2 - SEAL

3 - IMPELLER

Fig. 31 Water Pump Inlet Tube - 2.4L Engine

1 - O-RING

2 - WATER PUMP INLET TUBE

Fig. 32 Water Pump Inlet Tube Hose Connections

1 - WATER PUMP INLET TUBE

2 - HOSE - HEATER RETURN

3 - COOLANT INLET

7 - 36 ENGINERS

WATER PUMP - 3.3/3.8L (Continued)

Page 256 of 2339

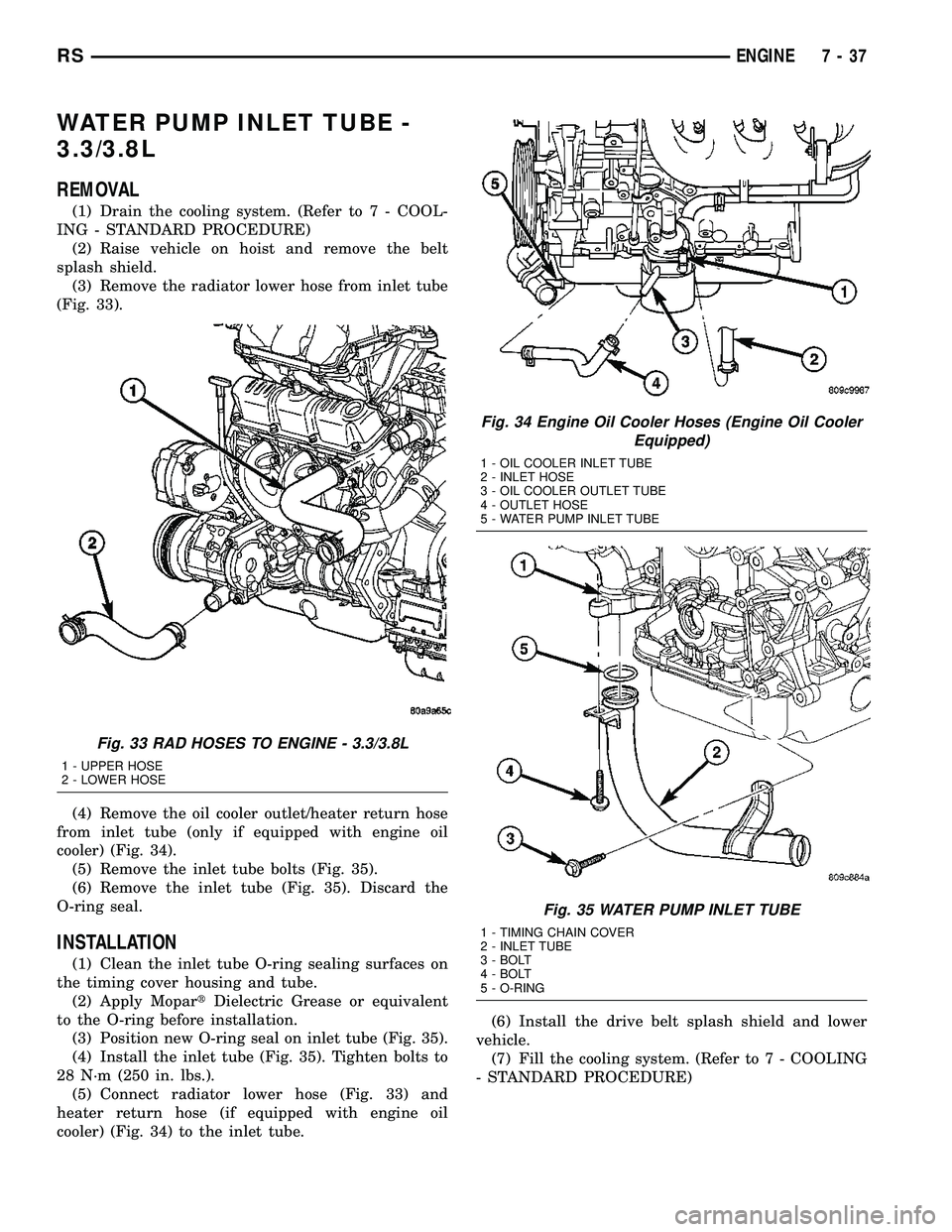

WATER PUMP INLET TUBE -

3.3/3.8L

REMOVAL

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Raise vehicle on hoist and remove the belt

splash shield.

(3) Remove the radiator lower hose from inlet tube

(Fig. 33).

(4) Remove the oil cooler outlet/heater return hose

from inlet tube (only if equipped with engine oil

cooler) (Fig. 34).

(5) Remove the inlet tube bolts (Fig. 35).

(6) Remove the inlet tube (Fig. 35). Discard the

O-ring seal.

INSTALLATION

(1) Clean the inlet tube O-ring sealing surfaces on

the timing cover housing and tube.

(2) Apply MopartDielectric Grease or equivalent

to the O-ring before installation.

(3) Position new O-ring seal on inlet tube (Fig. 35).

(4) Install the inlet tube (Fig. 35). Tighten bolts to

28 N´m (250 in. lbs.).

(5) Connect radiator lower hose (Fig. 33) and

heater return hose (if equipped with engine oil

cooler) (Fig. 34) to the inlet tube.(6) Install the drive belt splash shield and lower

vehicle.

(7) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

Fig. 33 RAD HOSES TO ENGINE - 3.3/3.8L

1 - UPPER HOSE

2 - LOWER HOSE

Fig. 34 Engine Oil Cooler Hoses (Engine Oil Cooler

Equipped)

1 - OIL COOLER INLET TUBE

2 - INLET HOSE

3 - OIL COOLER OUTLET TUBE

4 - OUTLET HOSE

5 - WATER PUMP INLET TUBE

Fig. 35 WATER PUMP INLET TUBE

1 - TIMING CHAIN COVER

2 - INLET TUBE

3 - BOLT

4 - BOLT

5 - O-RING

RSENGINE7-37

Page 258 of 2339

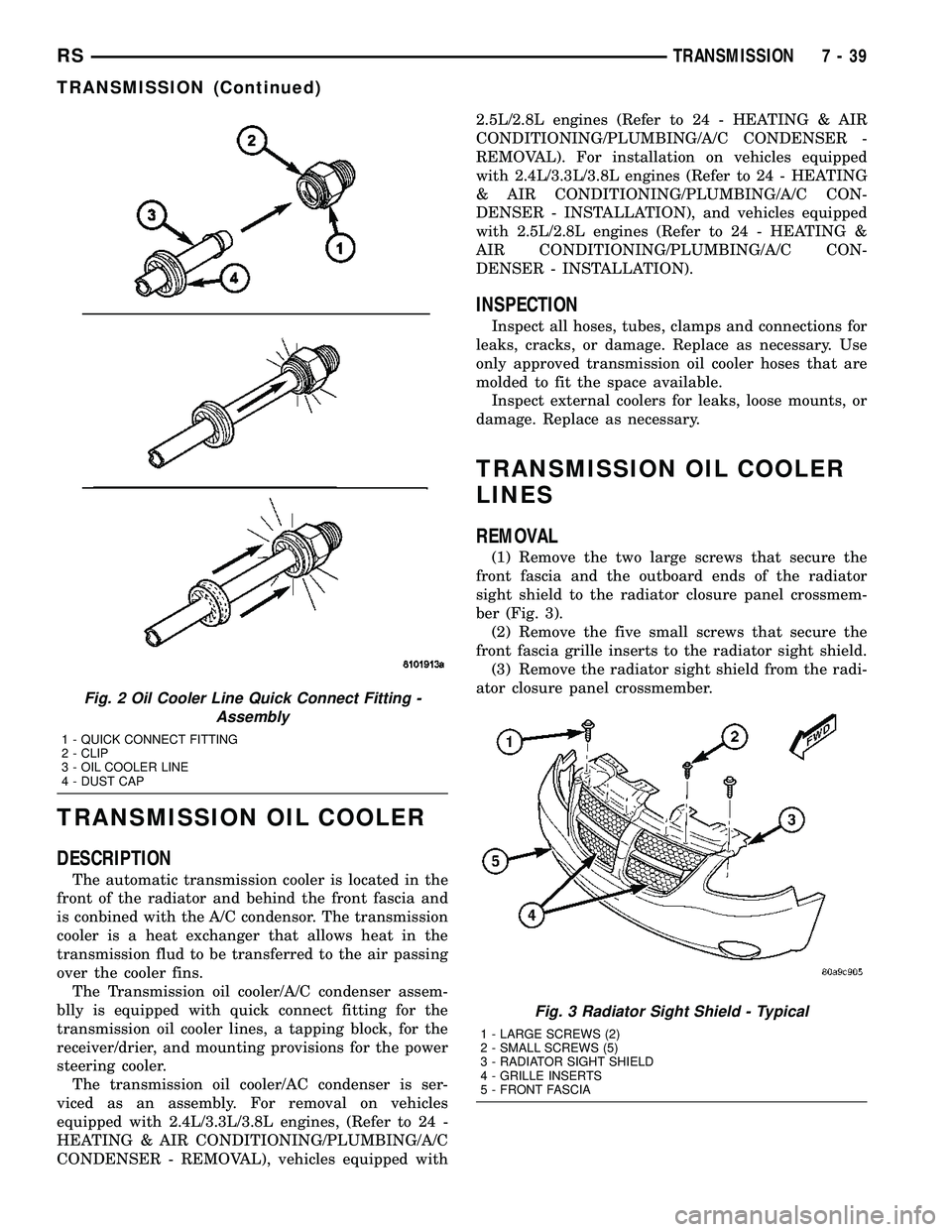

TRANSMISSION OIL COOLER

DESCRIPTION

The automatic transmission cooler is located in the

front of the radiator and behind the front fascia and

is conbined with the A/C condensor. The transmission

cooler is a heat exchanger that allows heat in the

transmission flud to be transferred to the air passing

over the cooler fins.

The Transmission oil cooler/A/C condenser assem-

blly is equipped with quick connect fitting for the

transmission oil cooler lines, a tapping block, for the

receiver/drier, and mounting provisions for the power

steering cooler.

The transmission oil cooler/AC condenser is ser-

viced as an assembly. For removal on vehicles

equipped with 2.4L/3.3L/3.8L engines, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

CONDENSER - REMOVAL), vehicles equipped with2.5L/2.8L engines (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/A/C CONDENSER -

REMOVAL). For installation on vehicles equipped

with 2.4L/3.3L/3.8L engines (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C CON-

DENSER - INSTALLATION), and vehicles equipped

with 2.5L/2.8L engines (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/A/C CON-

DENSER - INSTALLATION).

INSPECTION

Inspect all hoses, tubes, clamps and connections for

leaks, cracks, or damage. Replace as necessary. Use

only approved transmission oil cooler hoses that are

molded to fit the space available.

Inspect external coolers for leaks, loose mounts, or

damage. Replace as necessary.

TRANSMISSION OIL COOLER

LINES

REMOVAL

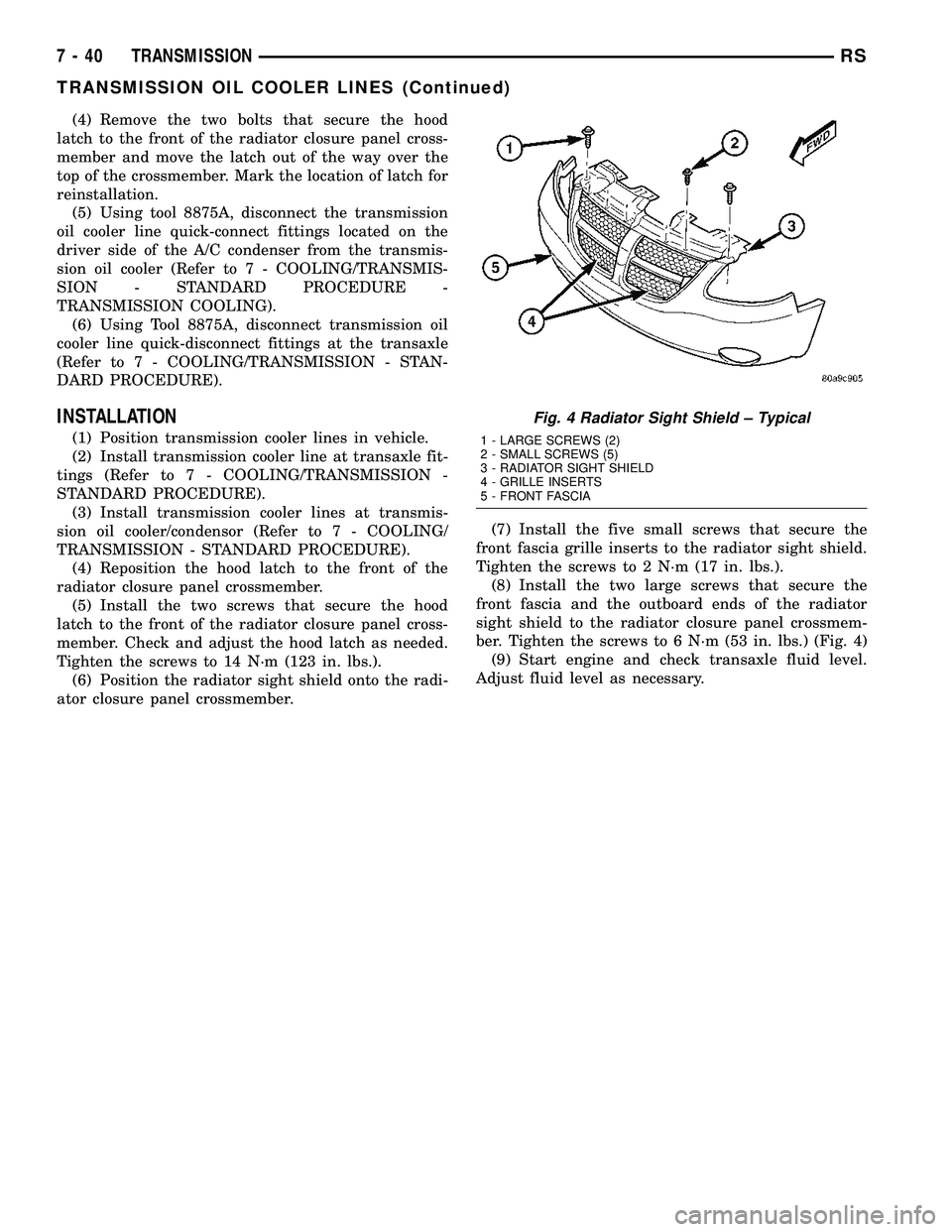

(1) Remove the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber (Fig. 3).

(2) Remove the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

(3) Remove the radiator sight shield from the radi-

ator closure panel crossmember.

Fig. 2 Oil Cooler Line Quick Connect Fitting -

Assembly

1 - QUICK CONNECT FITTING

2 - CLIP

3 - OIL COOLER LINE

4 - DUST CAP

Fig. 3 Radiator Sight Shield - Typical

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

RSTRANSMISSION7-39

TRANSMISSION (Continued)

Page 259 of 2339

(4) Remove the two bolts that secure the hood

latch to the front of the radiator closure panel cross-

member and move the latch out of the way over the

top of the crossmember. Mark the location of latch for

reinstallation.

(5) Using tool 8875A, disconnect the transmission

oil cooler line quick-connect fittings located on the

driver side of the A/C condenser from the transmis-

sion oil cooler (Refer to 7 - COOLING/TRANSMIS-

SION - STANDARD PROCEDURE -

TRANSMISSION COOLING).

(6) Using Tool 8875A, disconnect transmission oil

cooler line quick-disconnect fittings at the transaxle

(Refer to 7 - COOLING/TRANSMISSION - STAN-

DARD PROCEDURE).

INSTALLATION

(1) Position transmission cooler lines in vehicle.

(2) Install transmission cooler line at transaxle fit-

tings (Refer to 7 - COOLING/TRANSMISSION -

STANDARD PROCEDURE).

(3) Install transmission cooler lines at transmis-

sion oil cooler/condensor (Refer to 7 - COOLING/

TRANSMISSION - STANDARD PROCEDURE).

(4) Reposition the hood latch to the front of the

radiator closure panel crossmember.

(5) Install the two screws that secure the hood

latch to the front of the radiator closure panel cross-

member. Check and adjust the hood latch as needed.

Tighten the screws to 14 N´m (123 in. lbs.).

(6) Position the radiator sight shield onto the radi-

ator closure panel crossmember.(7) Install the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

Tighten the screws to 2 N´m (17 in. lbs.).

(8) Install the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber. Tighten the screws to 6 N´m (53 in. lbs.) (Fig. 4)

(9) Start engine and check transaxle fluid level.

Adjust fluid level as necessary.

Fig. 4 Radiator Sight Shield ± Typical

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

7 - 40 TRANSMISSIONRS

TRANSMISSION OIL COOLER LINES (Continued)

Page 363 of 2339

- DIAGNOSIS AND TESTING). If battery connec-

tions and battery charge is OK proceed to Step 2.

(2) Using a voltmeter, test for battery voltage at

both sides of horn fuse 7. If voltage is OK, on both

sides of fuse, proceed to Fuse OK. If voltage is OK,

on one side of fuse, the fuse is blown, proceed to Step

3.

(3) Using a suitable ammeter in place of the fuse,

test amperage draw of the horn circuit. If amperage

draw is greater than 20 amps without the horn

switch depressed, a grounded circuit exists between

the fuse and the horn relay. Proceed to Step 4. If

amperage draw is greater than 20 amps with the

horn switch depressed, a grounded circuit exists

between the horn relay and the horn. Proceed to step

Step 5.

(4) Remove the horn relay from the IPM. If the

amperage draw drops to 0 amps, the horn switch or

circuit is shorted. If the amperage draw does not

drop to 0 amps, repair short at the IPM.

(5) Disengage a wire connector from one of the

horns. If amperage drops and the connected horn

sounds, replace the faulty horn. If amperage does not

drop with both horns disconnected and the horn

switch depressed, proceed to Step 6.

(6) Using a continuity tester, with the horns dis-

connected test continuity of the X2 cavity of the horn

relay to ground. If continuity is detected, the circuit

is grounded between the Junction Block and the

horns. Locate and repair pinched harness.

FUSE OK

(1) Remove the horn relay from the intelligent

power module.

(2) Using a continuity tester, Depress horn switch

and test continuity from the X3 cavity of the horn

relay to ground.

(a) If continuity is detected, proceed to Step 3.

(b) If NO continuity, proceed to Step 4.

(3) Using a suitable jumper wire, jump across the

fuse F62 cavity and the X2 cavity of the horn relay in

the Junction Block.

(a) If the horn sounds, replace the horn relay.

(b) If the horn does not sound, proceed to Step 4.

(4) Remove airbag trim cover from steering wheel.

Refer to ELECTRICAL, RESTRAINTS.

(5) Test continuity across horn switch connectors

with horn switch depressed.

(a) If continuity is detected, repair open circuit

between the relay and the horn switch.

(b) If NO continuity, replace airbag trim cover.

(6) Install horn relay into intelligent power mod-

ule.

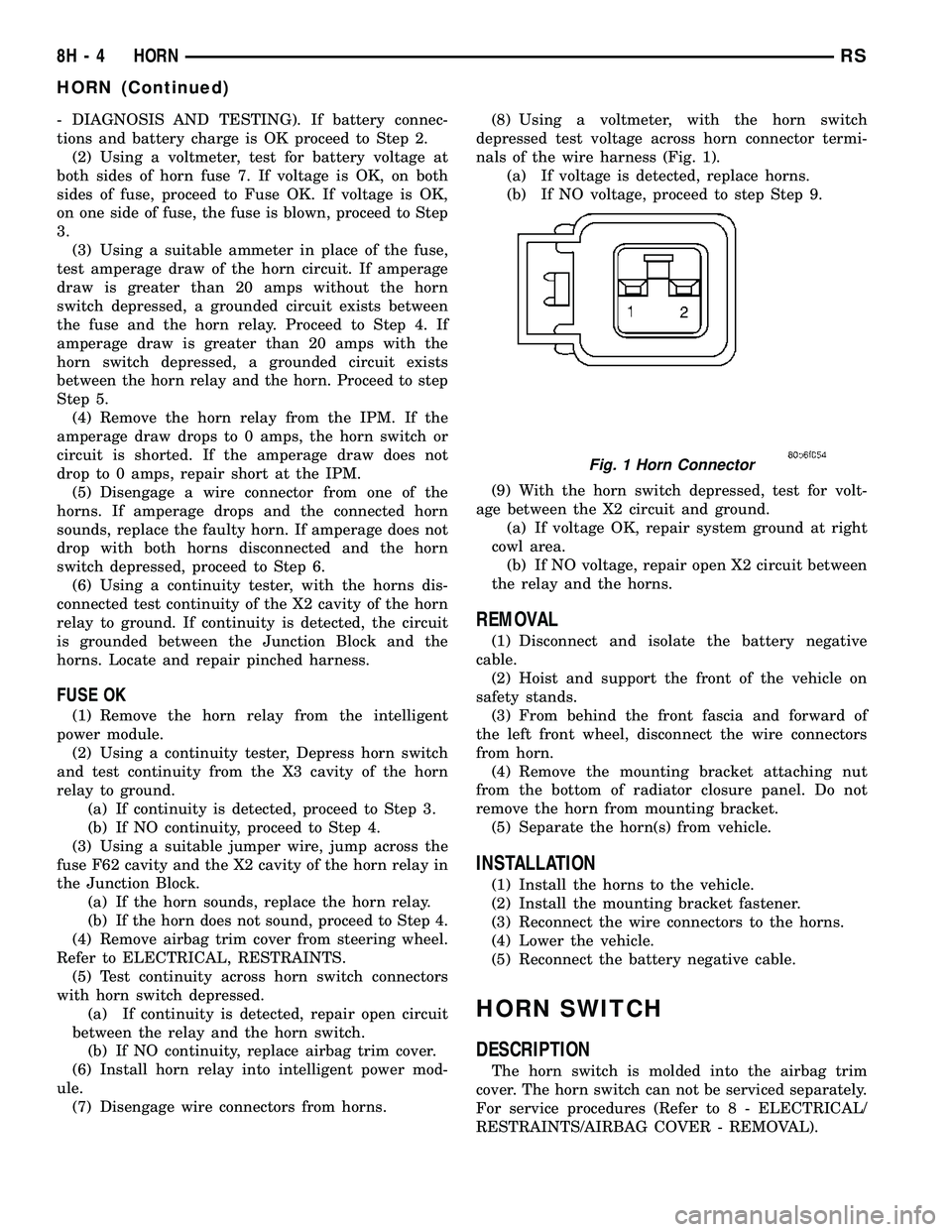

(7) Disengage wire connectors from horns.(8) Using a voltmeter, with the horn switch

depressed test voltage across horn connector termi-

nals of the wire harness (Fig. 1).

(a) If voltage is detected, replace horns.

(b) If NO voltage, proceed to step Step 9.

(9) With the horn switch depressed, test for volt-

age between the X2 circuit and ground.

(a) If voltage OK, repair system ground at right

cowl area.

(b) If NO voltage, repair open X2 circuit between

the relay and the horns.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Hoist and support the front of the vehicle on

safety stands.

(3) From behind the front fascia and forward of

the left front wheel, disconnect the wire connectors

from horn.

(4) Remove the mounting bracket attaching nut

from the bottom of radiator closure panel. Do not

remove the horn from mounting bracket.

(5) Separate the horn(s) from vehicle.

INSTALLATION

(1) Install the horns to the vehicle.

(2) Install the mounting bracket fastener.

(3) Reconnect the wire connectors to the horns.

(4) Lower the vehicle.

(5) Reconnect the battery negative cable.

HORN SWITCH

DESCRIPTION

The horn switch is molded into the airbag trim

cover. The horn switch can not be serviced separately.

For service procedures (Refer to 8 - ELECTRICAL/

RESTRAINTS/AIRBAG COVER - REMOVAL).

Fig. 1 Horn Connector

8H - 4 HORNRS

HORN (Continued)

Page 421 of 2339

STANDARD PROCEDURE

SETTING TRANSMITTER CODES

(1) Turn off the engine.

(2) Erase the codes by pressing the two outside

buttons. Release the buttons when the display con-

firms the operation (about 20 seconds).

(3) Choose one of the three buttons to train. Place

the hand-held transmitter within one inch of the uni-

versal transmitter and push the buttons on both

transmitters.

(4) Release both buttons. Your universal transmit-

ter is now ªtrainedº. To train the other buttons,

repeat Step 3 and Step 4. Be sure to keep your hand-

held transmitter in case you need to retrain the uni-

versal transmitter.

ERASING TRANSMITTER CODES

To erase the universal transmitter codes, simply

hold down the two outside buttons until the display

confirms the operation.

NOTE: Individual channels cannot be erased. Eras-

ing the transmitter codes will erase ALL pro-

grammed codes.

REMOVAL

(1) For the universal transmitter removal proce-

dure, (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE/COMPASS/MINI-TRIP COMPUTER -

REMOVAL.

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the over-

head console through ambient temperature messages

received from the Powertrain Control Module (PCM)

over the Programmable Communications Interface

(PCI) data bus circuit. The PCM receives a hard

wired input from the ambient temperature sensor.

The ambient temperature sensor is a variable resis-

tor mounted to a bracket that is secured with a screw

to the right side of the headlamp mounting module

grille opening, behind the radiator grille and in front

of the engine compartment.

For additional information on the PCM, (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION).

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent by the Powertrain Control Module (PCM). The

resistance in the sensor changes as temperature

changes, changing the temperature sensor signal cir-

cuit voltage to the PCM. Based upon the resistance

in the sensor, the PCM senses a specific voltage on

the temperature sensor signal circuit, which it is pro-

grammed to correspond to a specific temperature.

The PCM then sends the proper ambient tempera-

ture messages to the Electronic Vehicle Information

Center (EVIC)/Compass Mini-Trip Computer (CMTC)

over the Programmable Communication Interface

(PCI) data bus.

The thermometer function is supported by the

ambient temperature sensor, a wiring circuit, the

PCM, the PCI data bus, and the Electronics module.

If any portion of the ambient temperature sensor cir-

cuit fails, the PCM will self-diagnose the circuit.

The ambient temperature sensor circuit can also be

diagnosed manually (Refer to 8 - ELECTRICAL/

OVERHEAD CONSOLE/AMBIENT TEMP SENSOR

- DIAGNOSIS AND TESTING - AMBIENT TEM-

PERATURE SENSOR CIRCUIT). If the temperature

sensor and circuit are confirmed to be OK, but the

temperature display is inoperative or incorrect,

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

DIAGNOSIS AND TESTING) to determine the cause.

For complete circuit diagrams, refer to the appropri-

ate wiring information.

DIAGNOSIS AND TESTING

AMBIENT TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At room temperature (approx. 68ÉF),

the sensor resistance should be between 10-13 Kilo-

hms. The sensor resistance should be between these

two values at 68ÉF. If the resistance is out of range

replace the ambient temperature sensor.

AMBIENT TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector and the Powertrain Control Module

(PCM) wire harness connector.

8M - 12 OVERHEAD CONSOLERS

UNIVERSAL TRANSMITTER (Continued)