CHRYSLER CROSSFIRE 2007 1.G Owners Manual

Manufacturer: CHRYSLER, Model Year: 2007, Model line: CROSSFIRE, Model: CHRYSLER CROSSFIRE 2007 1.GPages: 299, PDF Size: 8.26 MB

Page 241 of 299

Points to Remember

NOTE:

When the vehicle is stopped after a few miles/

kilometers of operation, you may observe vapor coming

from the front of the engine compartment. This is nor-

mally a result of moisture from rain, snow, or high

humidity accumulation on the radiator and being vapor-

ized when the thermostat opens, allowing hot water to

enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

²Do not overfill the coolant bottle.

²Check coolant freeze point in the system.

²If frequent coolant additions are required, or if the

level in the recovery bottle does not drop when the

engine cools, the cooling system should be pressure

tested for leaks.

²Maintain a coolant concentration of a minimum of 50%

ethylene glycol Extended Life Coolant and high qual-

ity water with recommended antifreeze for proper

corrosion protection of your engine cooling system

that contains aluminum components.

²Make sure that the radiator and coolant bottle hoses

are not kinked or obstructed.

²Keep the front of the radiator clean. If your vehicle has

air conditioning, keep the front of the condenser clean,

also.

²Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory coolant performance, poor fuel

economy, and increased emissions.

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, checking, tears, cuts, abrasions,

and excessive swelling indicate deterioration of the rub-

ber.

Pay particular attention to the hoses nearest to high heat

sources such as the exhaust manifold. Inspect hose rout-

ing to be sure hoses do not touch any heat source or

moving component that may cause heat damage or

mechanical wear.

MAINTAINING YOUR VEHICLE 241

7

Page 242 of 299

Insure nylon tubing in these areas has not melted or

collapsed. Inspect all hose connections such as clamps

and couplings to make sure they are secure and no leaks

are present. Components should be replaced immedi-

ately if there is any evidence of degradation that could

cause failure.

Brakes

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance section.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before a hose is replaced

based on leakage.

242 MAINTAINING YOUR VEHICLE

Page 243 of 299

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and at every

engine oil change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

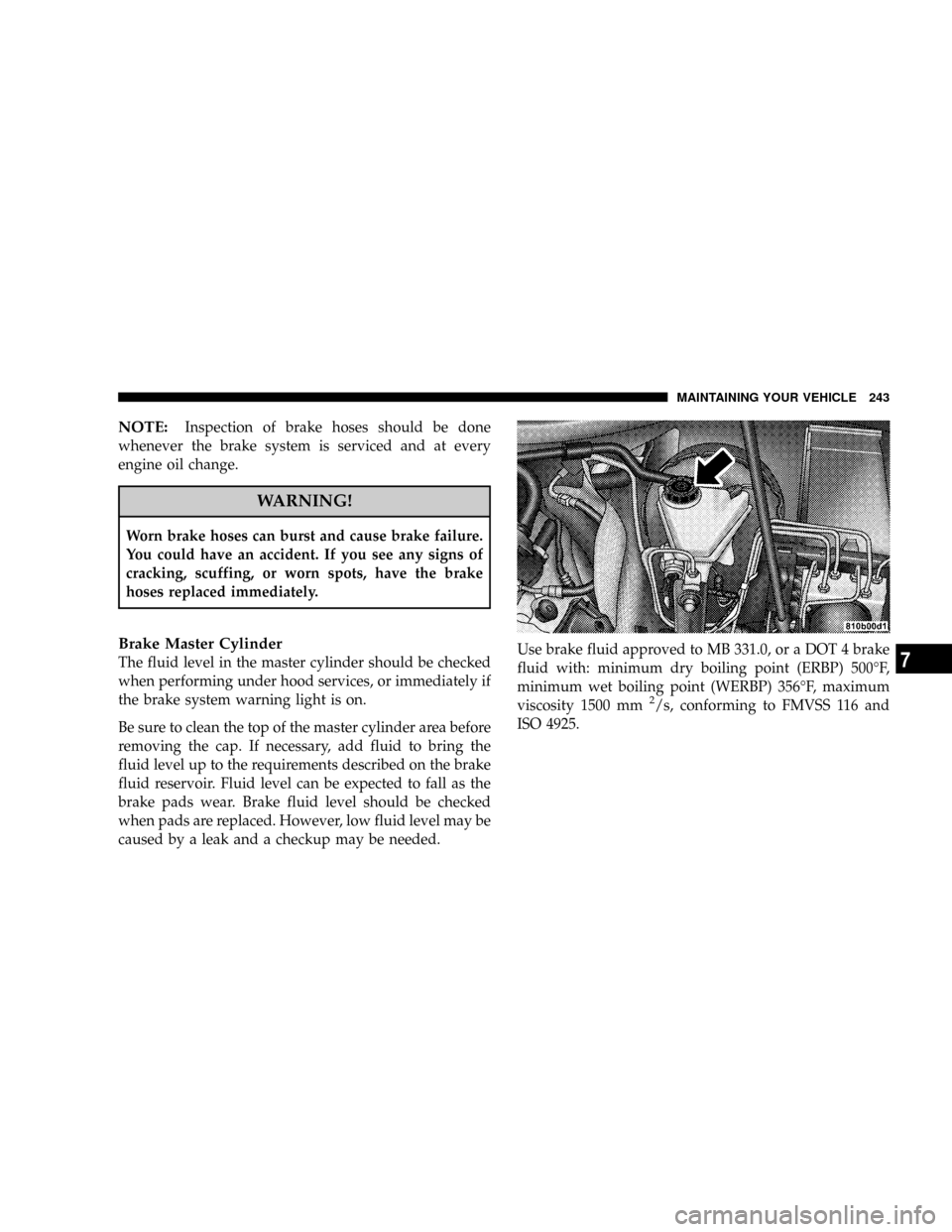

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning light is on.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

fluid reservoir. Fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be checked

when pads are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.Use brake fluid approved to MB 331.0, or a DOT 4 brake

fluid with: minimum dry boiling point (ERBP) 500ÉF,

minimum wet boiling point (WERBP) 356ÉF, maximum

viscosity 1500 mm

2/s, conforming to FMVSS 116 and

ISO 4925.

MAINTAINING YOUR VEHICLE 243

7

Page 244 of 299

WARNING!

Use of a brake fluid that may have a lower initial

boiling point or unidentified as to specification, may

result in sudden brake failure during hard prolonged

braking. You could have an accident.

WARNING!

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign mat-

ter. Use of contaminated fluid may result in reduced

brake performance or a sudden brake failure. You

could have an accident.

CAUTION!

Do not allow petroleum-based fluid to contaminate

the brake fluid as seal damage will result!

Automatic Transmission

The fluid in the automatic transmission should be

changed at 80,000 miles (129,000 km), along with the

transmission fluid filter. After that, the transmission fluid

is filled for life.

Selection of Lubricant

It is important that the proper lubricant is used in the

transmission to assure optimum transmission perfor-

mance. Use only ATF approved to MB 236.10, MB 236.12.

Synthetic Dexron IIItAutomatic Transmission Fluid may

be substituted. Refer to the Recommended Fluids, Lubri-

cants and Genuine Parts section for the correct fluid type.

It is important that the transmission fluid be maintained

at the prescribed level using the recommended fluid.

244 MAINTAINING YOUR VEHICLE

Page 245 of 299

CAUTION!

Using a transmission fluid other than the fluid rec-

ommended by DaimlerChrysler Corporation may

cause deterioration in transmission shift quality

and/or torque converter shudder. Using a transmis-

sion fluid other than that recommended by the

DaimlerChrysler Corporation will result in more

frequent fluid and filter changes. Refer to the Rec-

ommended Fluids, Lubricants and Genuine Parts

section for correct fluid type.

Fluid Level Check

Regular automatic transmission fluid level checks and

changes are not required. For this reason the dipstick is

omitted.

If you notice fluid loss or gear shift malfunction, have

your authorized dealer check the transmission fluid level.

Fluid and Filter Changes

Automatic transmission fluid and filter should be

changed at 80,000 miles (129,000 km). The fluid is then

filled for life.

NOTE:Refer to Section 8 of this manual for Mainte-

nance Schedules.

Manual Transmission

Selection of Lubricant

No fluid service is required. Use only fluid approved to

MB 236.2. SAE 5W-20 engine oil, meeting API SL or GF-3,

may be substituted. Refer to the Recommended Fluids,

Lubricants and Genuine Parts section for the correct fluid

type.

Fluid Level Check

Check the fluid level by removing the fill plug. The fluid

level should be between the bottom of the fill hole and a

point not more than 3/16 inch (4.76 mm) below the

bottom of the hole.

MAINTAINING YOUR VEHICLE 245

7

Page 246 of 299

CAUTION!

Do not overfill. Dirt and water in the transmission

can cause serious damage. To prevent dirt and water

from entering the transmission after checking or

replenishing fluid, make certain that the dipstick cap

is seated properly.

Add fluid, if necessary, to maintain the proper level.

Frequency of Fluid Change

Under normal operation conditions, the fluid installed at

the factory will give satisfactory lubrication for the life of

the vehicle. Fluid changes are not necessary unless the

lubricant has become contaminated with water. If con-

taminated with water, the fluid should be changed im-

mediately.

Special Additives

Do not add any fluid additives to the transmission. The

only exception to this policy is the use of special dyes toaid in detecting fluid leaks. The use of transmission

sealers should be avoided as this may adversely affect

seals.

Appearance Care and Protection from Corrosion

Protection of Body and Paint from Corrosion

Vehicle body protection requirements vary according to

geographic locations and usage. Chemicals that make

roads passable in snow and ice, and those that are

sprayed on trees and road surfaces during other seasons,

are highly corrosive to the metal in your vehicle. Outside

parking, which exposes your vehicle to airborne contami-

nants, road surfaces on which the vehicle is operated,

extreme hot or cold weather and other extreme condi-

tions will have an adverse effect on paint, metal trim, and

underbody protection.

The following maintenance recommendations will enable

you to obtain maximum benefit from the corrosion

resistance built into your vehicle.

What Causes Corrosion?

Corrosion is the result of deterioration or removal of

paint and protective coatings from your vehicle.

246 MAINTAINING YOUR VEHICLE

Page 247 of 299

The most common causes are:

²Road salt, dirt and moisture accumulation.

²Stone and gravel impact.

²Insects, tree sap and tar.

²Salt in the air near seacoast localities.

²Atmospheric fallout/industrial pollutants.

²Bird droppings.

Washing

²

Wash your vehicle regularly. Always wash your ve-

hicle in the shade using a mild car wash soap, and

rinse the panels completely with clear water.

²If insects, tar or other similar deposits have accumu-

lated on your vehicle, wash it as soon as possible.

²Use Mopartauto polish to remove road film and

stains and to polish your vehicle. Take care never to

scratch the paint.

²Avoid using abrasive compounds and power buffing

that may diminish the gloss or thin out the paint

finish.

CAUTION!

Do not use abrasive or strong cleaning materials such

as steel wool or scouring powder, which will scratch

metal and painted surfaces.

Special Care

²

If you drive on salted or dusty roads or if you drive

near the ocean, hose off the undercarriage at least once

a month.

²It is important that the drain holes in the lower edges

of the doors, rocker panels and rear liftgate / decklid

be kept clear and open.

²If you detect any stone chips or scratches in the paint,

touch them up immediately. The cost of such repairs is

considered the responsibility of the owner.

MAINTAINING YOUR VEHICLE 247

7

Page 248 of 299

²Use Moparttouch-up paint on scratches or chips as

soon as possible. Your dealer has touch-up paint to

match the color of your vehicle.

²If your vehicle is damaged due to an accident or

similar cause which destroys the paint and protective

coating, have your vehicle repaired as soon as pos-

sible. The cost of such repairs is considered the respon-

sibility of the owner.

²If you carry special cargo such as chemicals, fertilizers,

deicer salt, etc., be sure that such materials are well

packaged and sealed.

²Aluminum wheels should be cleaned regularly with

mild soap and water to prevent corrosion. To remove

heavy soil, select a non-abrasive, non-acidic cleaner.

Do not use scouring pads or metal polishes. Avoid

automatic car washes that use acidic solutions or harsh

brushes that may damage the wheels' protective fin-

ish.

Wheel And Wheel Trim Care

All wheels and wheel trim, especially Aluminum, should

be cleaned regularly, using mild soap and water tomaintain their luster and to prevent corrosion. Wash

them with the same soap solution as the body of your

vehicle. Rinse the wheels thoroughly.

When cleaning extremely dirty wheels, care must be

taken in the selection of tire and wheel cleaning chemi-

cals and equipment to prevent damage to the wheels.

Only MopartWheel Cleaners are recommended. Any of

the ªDO NOT USEº items listed below can damage

wheels and wheel trim.

DO NOT USE:

²Any abrasive cleaner

²Any abrasive cleaning pad (such as steel wool) or

abrasive brush

²Any cleaner that contains an acid which can react with

and discolor the chrome surface.

²Oven cleaner

²A car wash that uses carbide-tipped wheel cleaning

brushes or acidic solutions.

248 MAINTAINING YOUR VEHICLE

Page 249 of 299

CAUTION!

Many wheel cleaners contain acids that may harm the

wheel surface.

Interior Care

Use MopartFabric Cleaner to clean fabric upholstery

and carpeting.

Use MopartVinyl Cleaner to clean vinyl upholstery.

MopartVinyl Cleaner is specifically recommended for

vinyl trim.

Leather Seat Care and Cleaning

Leather is best preserved by regular cleaning with a

damp soft cloth. Small particles of dirt can act as an

abrasive and damage the leather surface and should be

removed immediately with a damp cloth. Stubborn soils

can be removed easily with a soft cloth and MopartTotal

Clean. Care should be taken to avoid soaking your

leather upholstery with any liquid. Please do not use

polishes, oils, cleaning fluids, solvents, detergents, orammonia based cleaners to clean your leather upholstery.

Application of a leather conditioner is not required to

maintain the original condition.

CAUTION!

The use of vinyl, leather or plastic protectants may

cause excessive gloss and/or discoloration of interior

trim parts.

WARNING!

Do not use volatile solvents for cleaning purposes.

Many are potentially flammable, and if used in

closed areas they may cause respiratory harm.

Cleaning Headlights

Your vehicle has plastic headlights that are lighter and

less susceptible to stone breakage than glass headlights.

Plastic is not as scratch resistant as glass and therefore

different lens cleaning procedures must be followed.

MAINTAINING YOUR VEHICLE 249

7

Page 250 of 299

To minimize the possibility of scratching the lenses and

reducing light output, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild soap solution fol-

lowed by rinsing.

Do not use abrasive cleaning components, solvents, steel

wool or other aggressive material to clean the lenses.

Glass Surfaces

All glass surfaces should be cleaned on a regular basis

with any commercial household-type glass cleaner.

Never use an abrasive-type cleaner. Use caution when

cleaning inside rear windows equipped with electric

defrosters. Do not use scrapers or other sharp instru-

ments which may scratch the elements.

Instrument Panel Cover

The instrument panel cover has a low glare surface which

minimizes reflections in the windshield. Do not use

protectants or other products which may cause undesir-

able reflections. Use soap and warm water to restore the

low glare surface.

Cleaning Plastic Instrument Cluster Lenses

The lenses in front of the instruments in the vehicle are

molded in clear plastic. When cleaning the lenses, care

must be taken to avoid scratching the plastic.

²Clean with a wet soft rag. A mild soap solution may be

used, but do not use high alcohol content or abrasive

cleaners. If soap is used, wipe clean with a clean damp

rag.

²Dry with a soft tissue.

Seat Belt Maintenance

Do not bleach, dye or clean the belts with chemical

solvents or abrasive cleaners. This will weaken the fabric.

If the belts need cleaning, use a mild soap solution or

lukewarm water. Do not remove the belts from the

vehicle to wash them.

Replace the belts if they appear frayed or worn or if the

buckles do not work properly.

250 MAINTAINING YOUR VEHICLE