battery CHRYSLER VOYAGER 1996 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 424 of 1938

VACUUM SUPPLY TEST

(1) Disconnect vacuum hose at the servo and

install a vacuum gauge in the hose (Fig. 7).

(2) Start engine and observe gauge at idle. Vac-

uum gauge should read at least ten inches of mer-

cury. Shut off engine, the vacuum should continue to

hold 10 inches of mercury.

(3) If vacuum does not meet this requirement,

check and correct the following vacuum leaks in the

vacuum lines, check valve, vacuum reservoir or poor

engine performance.

VEHICLE SPEED SENSOR

For diagnosis and testing of the Vehicle Speed Sen-

sor (VSS), refer to the appropriate Powertrain Diag-

nostic Procedures service manual. Also refer to the

DRB scan tool.

REMOVAL AND INSTALLATION

SPEED CONTROL SERVO

REMOVAL

(1) Release hood latch and open hood.

(2) On vehicles with 3.3/3.8 L engine, remove air

cleaner resonator. Refer to Group 14, Fuel System for

proper procedure.

(3) Disconnect the throttle and speed control cable

ends from throttle body (Fig. 8).

(4) Depress lock tabs holding speed control cable

casing to cable mount bracket (Fig. 9).(5) Disconnect vacuum line from nipple on air

intake plenum.

(6) Remove tie wrap holding vacuum line, throttle

cable, and speed control cable together.

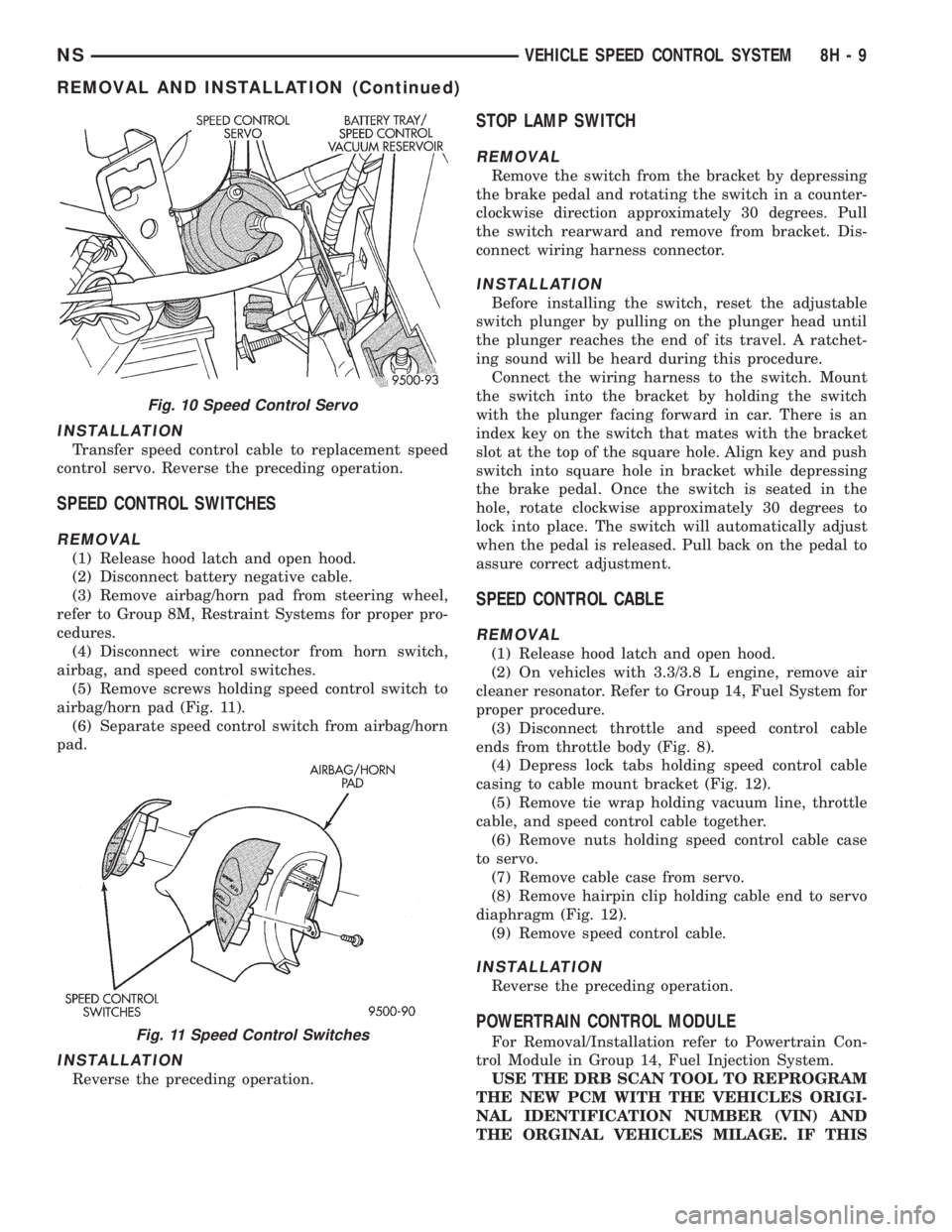

(7) Remove bolt holding speed control servo to side

of battery tray/vacuum reservoir (Fig. 10).

(8) Remove speed control servo from battery tray.

(9) Disconnect wire connector from speed control

servo.

(10) Disconnect vacuum line from speed control

servo that leads to the battery tray/vacuum reservoir.

(11) Remove speed control servo.

Fig. 7 Vacuum Gauge Test

Fig. 8 Speed Control Cable End

Fig. 9 Speed Control Cable Case and Vacuum

LineÐTypical

8H - 8 VEHICLE SPEED CONTROL SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 425 of 1938

INSTALLATION

Transfer speed control cable to replacement speed

control servo. Reverse the preceding operation.

SPEED CONTROL SWITCHES

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable.

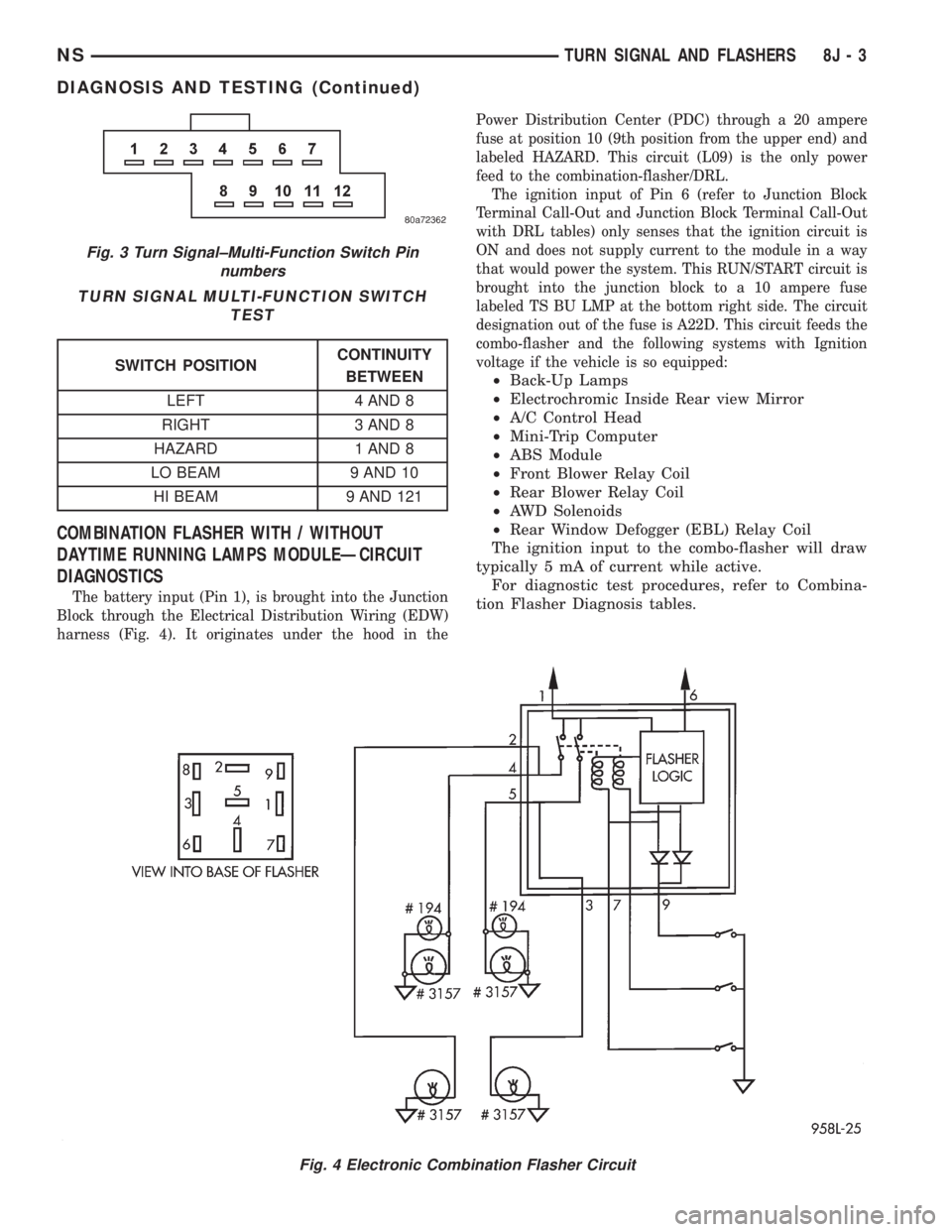

(3) Remove airbag/horn pad from steering wheel,

refer to Group 8M, Restraint Systems for proper pro-

cedures.

(4) Disconnect wire connector from horn switch,

airbag, and speed control switches.

(5) Remove screws holding speed control switch to

airbag/horn pad (Fig. 11).

(6) Separate speed control switch from airbag/horn

pad.

INSTALLATION

Reverse the preceding operation.

STOP LAMP SWITCH

REMOVAL

Remove the switch from the bracket by depressing

the brake pedal and rotating the switch in a counter-

clockwise direction approximately 30 degrees. Pull

the switch rearward and remove from bracket. Dis-

connect wiring harness connector.

INSTALLATION

Before installing the switch, reset the adjustable

switch plunger by pulling on the plunger head until

the plunger reaches the end of its travel. A ratchet-

ing sound will be heard during this procedure.

Connect the wiring harness to the switch. Mount

the switch into the bracket by holding the switch

with the plunger facing forward in car. There is an

index key on the switch that mates with the bracket

slot at the top of the square hole. Align key and push

switch into square hole in bracket while depressing

the brake pedal. Once the switch is seated in the

hole, rotate clockwise approximately 30 degrees to

lock into place. The switch will automatically adjust

when the pedal is released. Pull back on the pedal to

assure correct adjustment.

SPEED CONTROL CABLE

REMOVAL

(1) Release hood latch and open hood.

(2) On vehicles with 3.3/3.8 L engine, remove air

cleaner resonator. Refer to Group 14, Fuel System for

proper procedure.

(3) Disconnect throttle and speed control cable

ends from throttle body (Fig. 8).

(4) Depress lock tabs holding speed control cable

casing to cable mount bracket (Fig. 12).

(5) Remove tie wrap holding vacuum line, throttle

cable, and speed control cable together.

(6) Remove nuts holding speed control cable case

to servo.

(7) Remove cable case from servo.

(8) Remove hairpin clip holding cable end to servo

diaphragm (Fig. 12).

(9) Remove speed control cable.

INSTALLATION

Reverse the preceding operation.

POWERTRAIN CONTROL MODULE

For Removal/Installation refer to Powertrain Con-

trol Module in Group 14, Fuel Injection System.

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW PCM WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE ORGINAL VEHICLES MILAGE. IF THIS

Fig. 10 Speed Control Servo

Fig. 11 Speed Control Switches

NSVEHICLE SPEED CONTROL SYSTEM 8H - 9

REMOVAL AND INSTALLATION (Continued)

Page 426 of 1938

STEP IS NOT DONE A DIAGONSTIC TROUBLE

CODE (DTC) MAY BE SET.

VACUUM RESEROIR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove battery, Refer to Group 8B, for Battery

Removal/Installation

(3) Remove battery tray.

(4) Disconnect vacuum hoses from vacuum reser-

voir

INSTALLATION

(1) Connect vacuum hoses to vacuum reservoir.

(2) Install battery tray

(3) Install battery, Refer to Group 8B, for Battery

Removal/Installation.

(4) Connect negative cable to battery.

VEHICLE SPEED SENSOR

For Removal/Installation, refer to Vehicle Speed

Sensor in Group 14, Fuel Injections.

Fig. 12 Speed Control Cable

8H - 10 VEHICLE SPEED CONTROL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 431 of 1938

COMBINATION FLASHER WITH / WITHOUT

DAYTIME RUNNING LAMPS MODULEÐCIRCUIT

DIAGNOSTICS

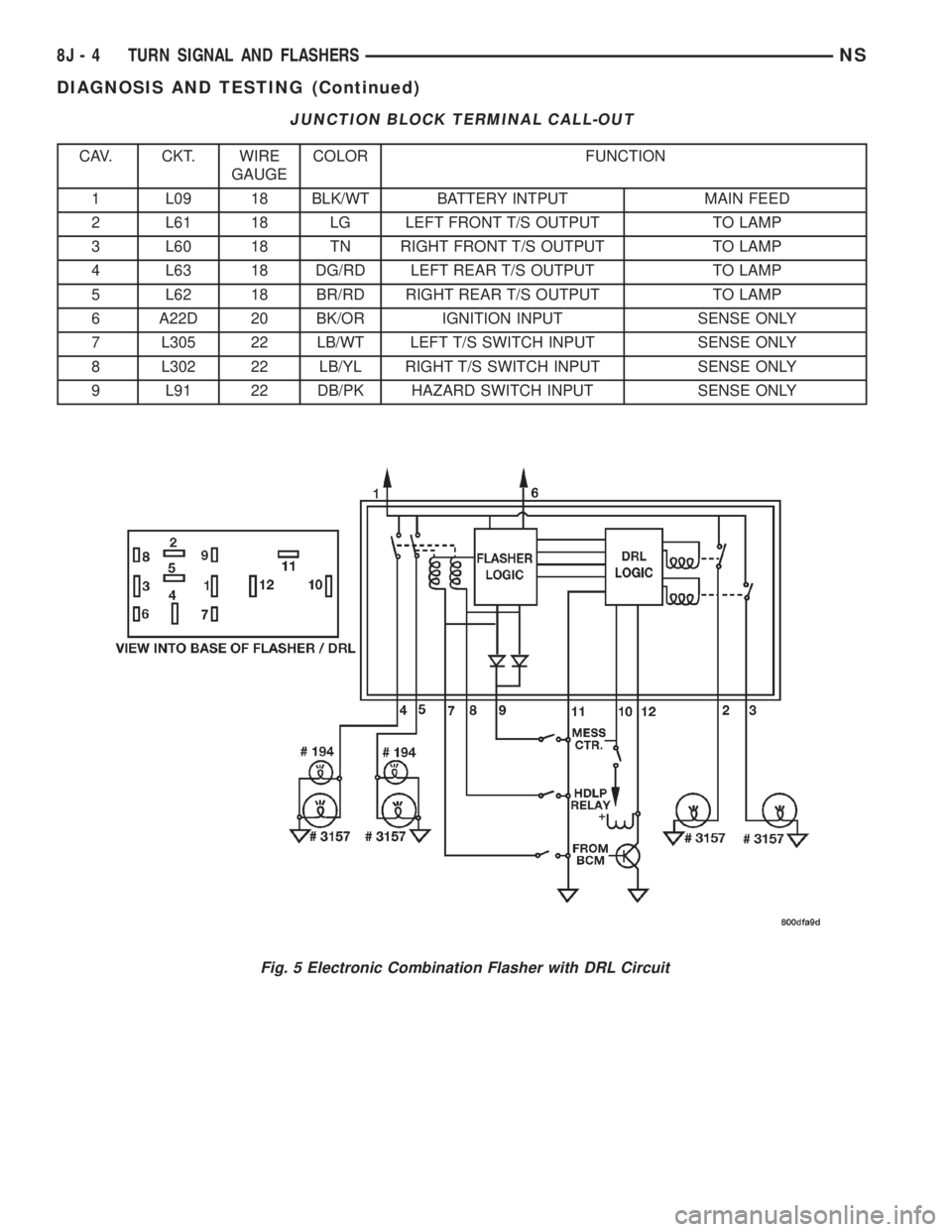

The battery input (Pin 1), is brought into the Junction

Block through the Electrical Distribution Wiring (EDW)

harness (Fig. 4). It originates under the hood in thePower Distribution Center (PDC) through a 20 ampere

fuse at position 10 (9th position from the upper end) and

labeled HAZARD. This circuit (L09) is the only power

feed to the combination-flasher/DRL.

The ignition input of Pin 6 (refer to Junction Block

Terminal Call-Out and Junction Block Terminal Call-Out

with DRL tables) only senses that the ignition circuit is

ON and does not supply current to the module in a way

that would power the system. This RUN/START circuit is

brought into the junction block to a 10 ampere fuse

labeled TS BU LMP at the bottom right side. The circuit

designation out of the fuse is A22D. This circuit feeds the

combo-flasher and the following systems with Ignition

voltage if the vehicle is so equipped:

²Back-Up Lamps

²Electrochromic Inside Rear view Mirror

²A/C Control Head

²Mini-Trip Computer

²ABS Module

²Front Blower Relay Coil

²Rear Blower Relay Coil

²AWD Solenoids

²Rear Window Defogger (EBL) Relay Coil

The ignition input to the combo-flasher will draw

typically 5 mA of current while active.

For diagnostic test procedures, refer to Combina-

tion Flasher Diagnosis tables.

Fig. 4 Electronic Combination Flasher Circuit

Fig. 3 Turn Signal±Multi-Function Switch Pin

numbers

TURN SIGNAL MULTI-FUNCTION SWITCH

TEST

SWITCH POSITIONCONTINUITY

BETWEEN

LEFT 4 AND 8

RIGHT 3 AND 8

HAZARD 1 AND 8

LO BEAM 9 AND 10

HI BEAM 9 AND 121

NSTURN SIGNAL AND FLASHERS 8J - 3

DIAGNOSIS AND TESTING (Continued)

Page 432 of 1938

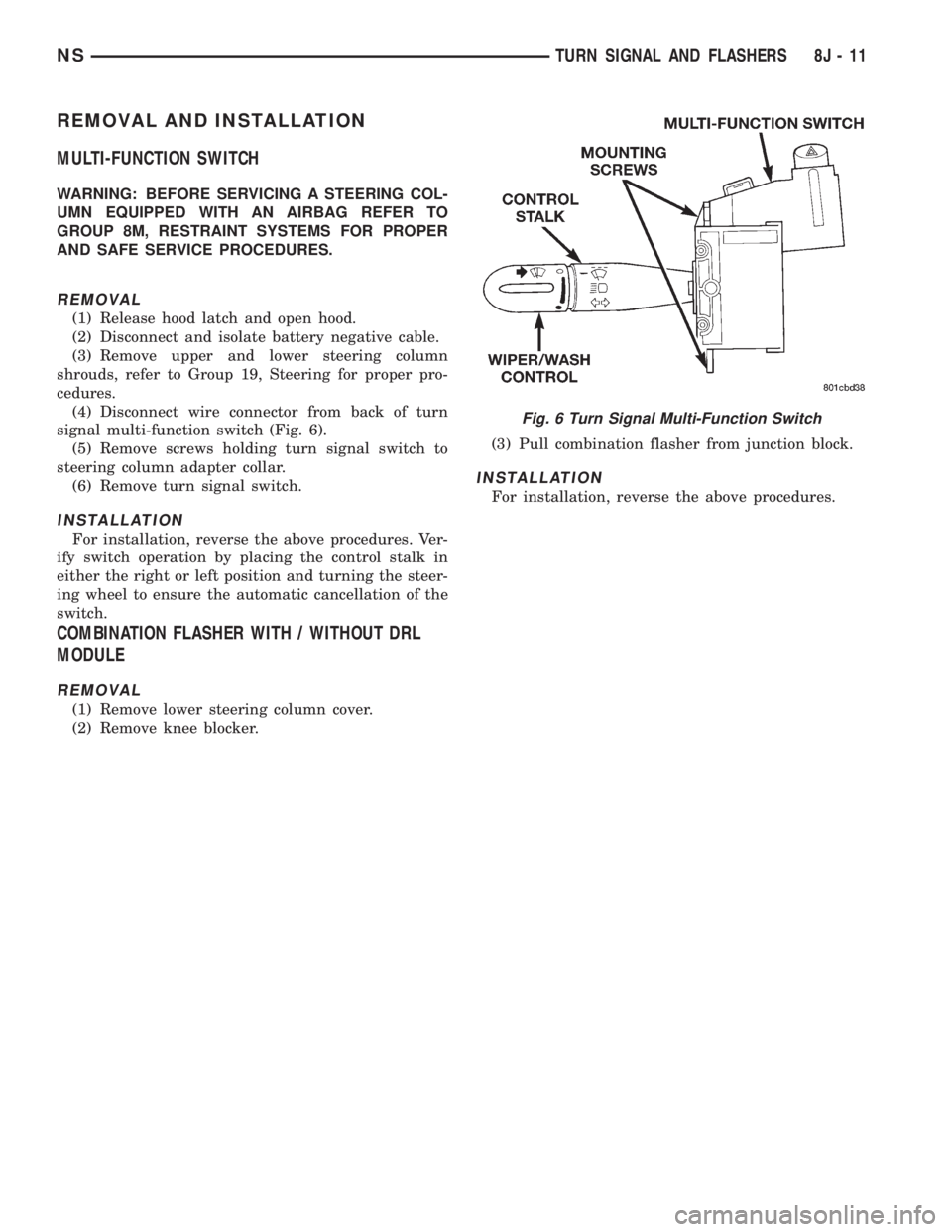

Fig. 5 Electronic Combination Flasher with DRL Circuit

JUNCTION BLOCK TERMINAL CALL-OUT

CAV. CKT. WIRE

GAUGECOLOR FUNCTION

1 L09 18 BLK/WT BATTERY INTPUT MAIN FEED

2 L61 18 LG LEFT FRONT T/S OUTPUT TO LAMP

3 L60 18 TN RIGHT FRONT T/S OUTPUT TO LAMP

4 L63 18 DG/RD LEFT REAR T/S OUTPUT TO LAMP

5 L62 18 BR/RD RIGHT REAR T/S OUTPUT TO LAMP

6 A22D 20 BK/OR IGNITION INPUT SENSE ONLY

7 L305 22 LB/WT LEFT T/S SWITCH INPUT SENSE ONLY

8 L302 22 LB/YL RIGHT T/S SWITCH INPUT SENSE ONLY

9 L91 22 DB/PK HAZARD SWITCH INPUT SENSE ONLY

8J - 4 TURN SIGNAL AND FLASHERSNS

DIAGNOSIS AND TESTING (Continued)

Page 433 of 1938

JUNCTION BLOCK TERMINAL CALL-OUT WITH DRL

CAV. CKT. WIRE

GAUGECOLOR FUNCTION

1 L09 18 BLK/WT BATTERY INTPUT MAIN FEED

2 L61 18 LG LEFT FRONT T/S OUTPUT TO LAMP

3 L60 18 TN RIGHT FRONT T/S OUTPUT TO LAMP

4 L63 18 DG/RD LEFT REAR T/S OUTPUT TO LAMP

5 L62 18 BR/RD RIGHT REAR T/S OUTPUT TO LAMP

6 A22D 20 BK/OR IGNITION INPUT SENSE ONLY

7 L305 22 LB/WT LEFT T/S SWITCH INPUT SENSE ONLY

8 L302 22 LB/YL RIGHT T/S SWITCH INPUT SENSE ONLY

9 L91 22 DB/PK HAZARD SWITCH INPUT SENSE ONLY

10 G09 22 GY/BK PARK BRAKE SWITCH INPUT SENSE ONLY

11 Z01 14 BK GROUND MAIN GRD.

12 L93 22 RD/YL HEADLAMP RELAY SWITCH

INPUTSENSE ONLY

NSTURN SIGNAL AND FLASHERS 8J - 5

DIAGNOSIS AND TESTING (Continued)

Page 439 of 1938

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH

WARNING: BEFORE SERVICING A STEERING COL-

UMN EQUIPPED WITH AN AIRBAG REFER TO

GROUP 8M, RESTRAINT SYSTEMS FOR PROPER

AND SAFE SERVICE PROCEDURES.

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect and isolate battery negative cable.

(3) Remove upper and lower steering column

shrouds, refer to Group 19, Steering for proper pro-

cedures.

(4) Disconnect wire connector from back of turn

signal multi-function switch (Fig. 6).

(5) Remove screws holding turn signal switch to

steering column adapter collar.

(6) Remove turn signal switch.

INSTALLATION

For installation, reverse the above procedures. Ver-

ify switch operation by placing the control stalk in

either the right or left position and turning the steer-

ing wheel to ensure the automatic cancellation of the

switch.

COMBINATION FLASHER WITH / WITHOUT DRL

MODULE

REMOVAL

(1) Remove lower steering column cover.

(2) Remove knee blocker.(3) Pull combination flasher from junction block.

INSTALLATION

For installation, reverse the above procedures.

Fig. 6 Turn Signal Multi-Function Switch

NSTURN SIGNAL AND FLASHERS 8J - 11

Page 441 of 1938

WINDSHIELD WIPERS AND WASHERS

CONTENTS

page page

REAR WIPER AND WASHER................ 9WINDSHIELD WIPERS AND WASHER......... 1

WINDSHIELD WIPERS AND WASHER

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES................ 1

FAILED PARK SWITCH.................... 2

MULTI-FUNCTION SWITCH................. 4

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH................. 4

WINDSHIELD WASHER BOTTLE............. 4

WINDSHIELD WIPER BLADE ELEMENT....... 6WINDSHIELD WIPER BLADE................ 5

WINDSHIELD WIPER MOTOR............... 6

WIPER ARM............................. 7

WIPER LINKAGE......................... 7

WIPER UNIT............................ 7

CLEANING AND INSPECTION

WIPER BLADES.......................... 8

ADJUSTMENTS

WIPER ARM ALIGNMENT.................. 8

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

SAFETY PRECAUTIONS. DISCONNECT THE NEGA-

TIVE CABLE FROM THE BATTERY BEFORE SER-

VICING COMPONENTS INVOLVING THE AIRBAG

SYSTEM. ACCIDENTAL DEPLOYMENT OF AIRBAG

AND PERSONAL INJURY CAN RESULT.

The windshield wipers can be operated with the

windshield wiper switch when the ignition switch is

in the RUN or ACCESSORY positions. The wind-

shield wiper system is protected by a 40 amp fuse (9)

located in the Power Distribution Center (PDC) in

the engine compartment. The windshield washer cir-

cuit is protected by a 6 amp fuse (9) located in the

Junction Block. The wiper motor has permanent

magnetic fields. The speeds are determined by cur-

rent flow to the appropriate set of brushes inside the

motor. The current flow is controlled by the multi-

function switch stalk mounted wiper switch, high

speed/low speed relays located in the PDC. The speed

sensitive intermittent wiper is controlled by the BodyControl Module (BCM). The intermittent mode, with

the vehicle traveling greater than 10.4 mph, has a

range of 0.5 to 18 seconds. With the vehicle traveling

less than 10.4 mph, and the time delay is not

adjusted, time delay doubles to a range of 1 to 36

seconds. The wiper arms will park at the base of the

windshield just above the cowl cover after the wiper

switch is turned OFF.

The windshield wiper motor and linkage is located

in an integral wiper unit at the rear of the engine

compartment. The wiper unit must be removed to

gain access to the wiper motor.

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES

The windshield wiper system operates in several

modes:

²Low and high speed normal wipe

²Speed sensitive intermittent wipe

²Wipe after wash

²Pulse wipe

²Park (switch OFF)

The windshield wiper circuits are continuously

monitored and controlled by the Body Control Mod-

NSWINDSHIELD WIPERS AND WASHERS 8K - 1

Page 442 of 1938

ule (BCM). If a problem occurs in the electronic com-

ponents, wiring, switch (except integral motor park

switch) and wiper motor a Diagnostic Trouble Code

(DTC) will be stored in the BCM memory. DTC's can

be retrieved using a scan tool (DRB). Refer to proper

Body Diagnostic Procedures manual for DTC descrip-

tions and retrieval information.

The windshield wiper park switch and circuit is

monitored by the BCM. The park switch and circuit

can be tested using the Wiper System Diagnosis

chart.

FAILED PARK SWITCH

If the wiper park switch has failed the windshield

wipers will operate as follows:SWITCH OFFÐWipers stop in current location

regardless of the park signal.

INTERMITTENT MODEÐWipers operate at low

speed for one or more extra wipes or continuously.

LOW SPEEDÐWipers operate at low speed.

HIGH SPEEDÐWipers operate at high speed.

PULSE WIPEÐWipers will not operate.

WIPE AFTER WASHÐWipers operate at low

speed in any mode setting. Wipers operate only while

wash button is depressed with switch in OFF mode,

wipers stop in mid-cycle when button is released.

The windshield wiper park switch and circuit is

monitored by the BCM. The park switch and circuit

can be tested using the Wiper System Diagnosis

table.

WIPER SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

WIPER BLADES DO NOT PARK

PROPERLY1. WIPER ARMS IMPROPERLY

PARKED.

2. WIPER ARMS ARE LOOSE ON

PIVOT SHAFT.

3. MOTOR CRANK LOOSE AT

OUTPUT SHAFT.1. REMOVE WIPER ARMS AND

REPARK. REFER TO WIPER ARM

REMOVAL AND INSTALLATION.

2. REMOVE WIPER ARM AND

REPARK. REFER TO WIPER ARM

REMOVAL AND INSTALLATION.

3. REMOVE WIPER ARM, RUN

WIPER MOTOR TO PARK

POSITION AND REMOVE THE

MODULE. WITHOUT ROTATING

THE MOTOR OUTPUT SHAFT,

REMOVE THE CRANK AND CLEAN

ANY FOREIGN MATTER FROM

THE MOTOR SHAFT. INSTALL THE

MOTOR CRANK IN ITS ORIGINAL

POSITION.

MOTOR STOPS IN ANY

POSITION WHEN THE SWITCH

IS TURNED OFF1. OPEN PARK CIRCUIT. 1. CHECK PARK SWITCH BY

DISCONNECTING THE WIRE

CONNECTOR AND APPLY

BATTERY VOLTAGE TO PIN 4.

PLACE A JUMPER WIRE FROM

PIN 2 TO PIN 3 AND THEN TO AN

EXTERNAL GROUND. REPLACE

MOTOR IF IT DOES NOT PARK.

MOTOR WILL NOT STOP WHEN

THE SWITCH IS TURNED OFF1. FAULTY SWITCH.

2. LOCK OF DYNAMIC BRAKE ON

WET GLASS.1. CHECK SWITCH IN LOW, HIGH

AND INTERMITTENT POSITION.

2. ENSURE PARK SWITCH HAS

CLEAN GROUND.

WIPER BLADES SLAP AGAINST

COWL SCREEN OR WINDOW

MOLDINGS.1. WIPER ARMS ARE PARKED

INCORRECTLY.1. PARK WIPER ARMS. REFER TO

WIPER ARM ADJUSTMENT.

8K - 2 WINDSHIELD WIPERS AND WASHERSNS

DIAGNOSIS AND TESTING (Continued)

Page 444 of 1938

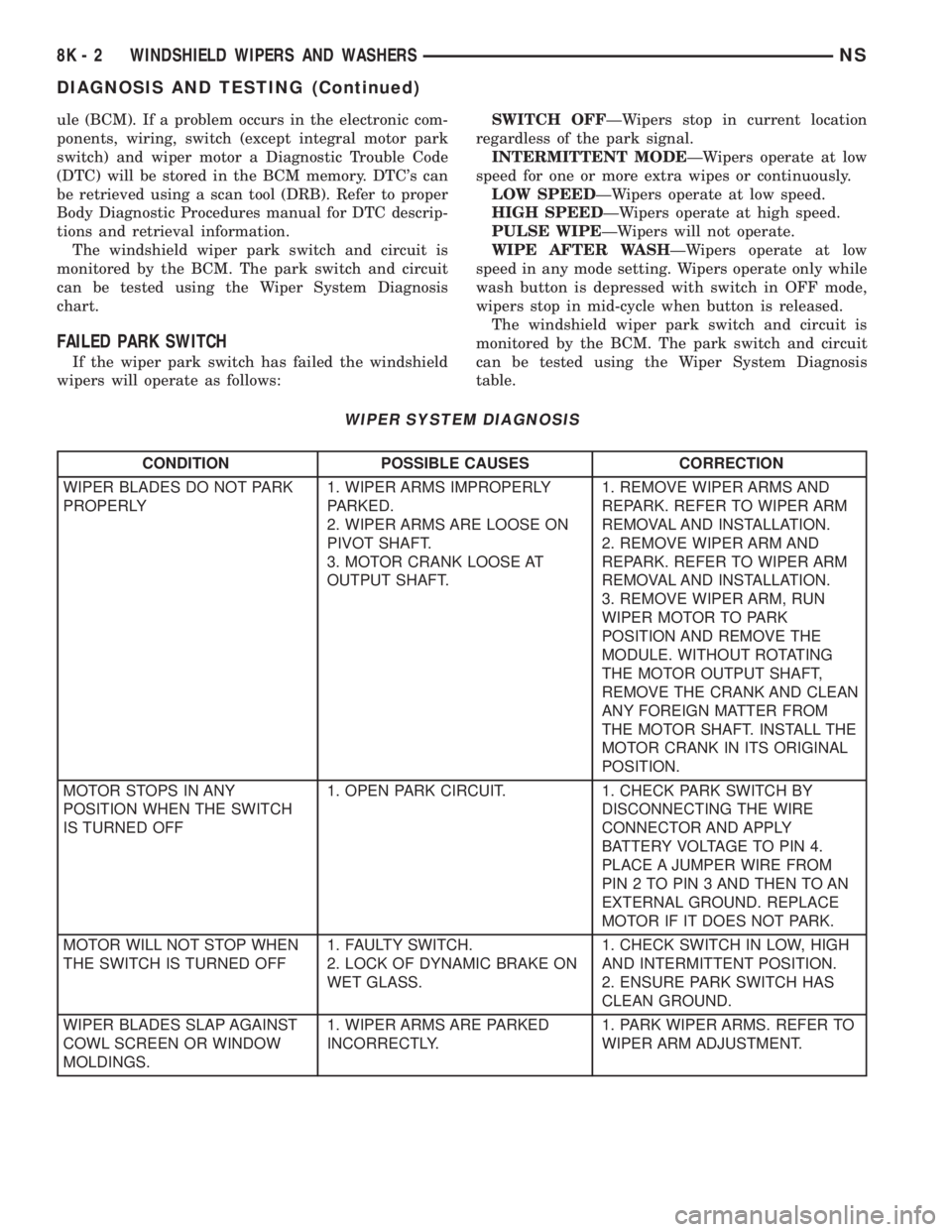

MULTI-FUNCTION SWITCH

To test the windshield wiper and washer portion of

the multi-function switch:

(1) Remove the multi-function switch, refer to

removal procedures.

(2) Using an ohmmeter check continuity reading

between switch pins, refer to (Fig. 1) for proper pin

numbers.

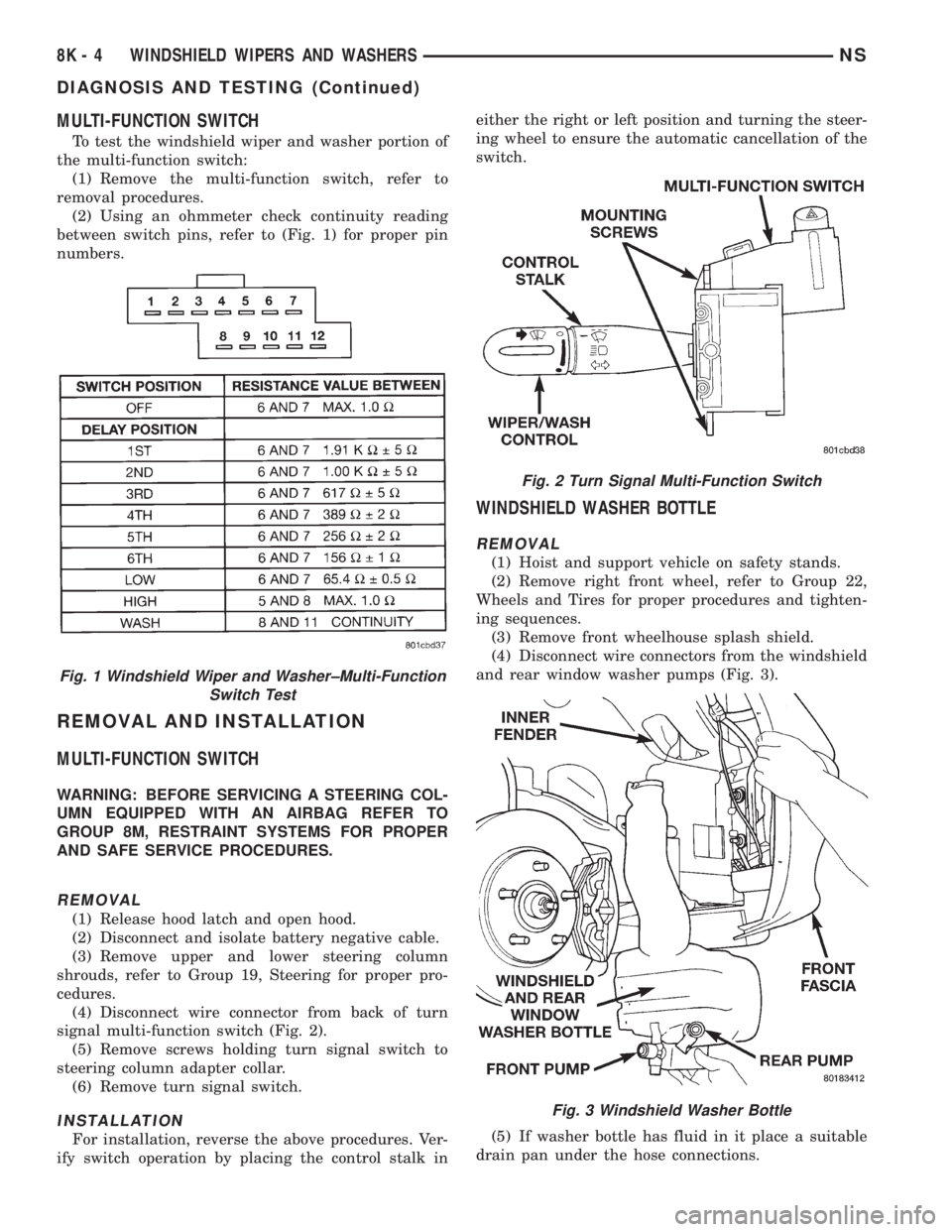

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH

WARNING: BEFORE SERVICING A STEERING COL-

UMN EQUIPPED WITH AN AIRBAG REFER TO

GROUP 8M, RESTRAINT SYSTEMS FOR PROPER

AND SAFE SERVICE PROCEDURES.

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect and isolate battery negative cable.

(3) Remove upper and lower steering column

shrouds, refer to Group 19, Steering for proper pro-

cedures.

(4) Disconnect wire connector from back of turn

signal multi-function switch (Fig. 2).

(5) Remove screws holding turn signal switch to

steering column adapter collar.

(6) Remove turn signal switch.

INSTALLATION

For installation, reverse the above procedures. Ver-

ify switch operation by placing the control stalk ineither the right or left position and turning the steer-

ing wheel to ensure the automatic cancellation of the

switch.

WINDSHIELD WASHER BOTTLE

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Remove right front wheel, refer to Group 22,

Wheels and Tires for proper procedures and tighten-

ing sequences.

(3) Remove front wheelhouse splash shield.

(4) Disconnect wire connectors from the windshield

and rear window washer pumps (Fig. 3).

(5) If washer bottle has fluid in it place a suitable

drain pan under the hose connections.

Fig. 1 Windshield Wiper and Washer±Multi-Function

Switch Test

Fig. 2 Turn Signal Multi-Function Switch

Fig. 3 Windshield Washer Bottle

8K - 4 WINDSHIELD WIPERS AND WASHERSNS

DIAGNOSIS AND TESTING (Continued)