cooling CHRYSLER VOYAGER 1996 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1245 of 1938

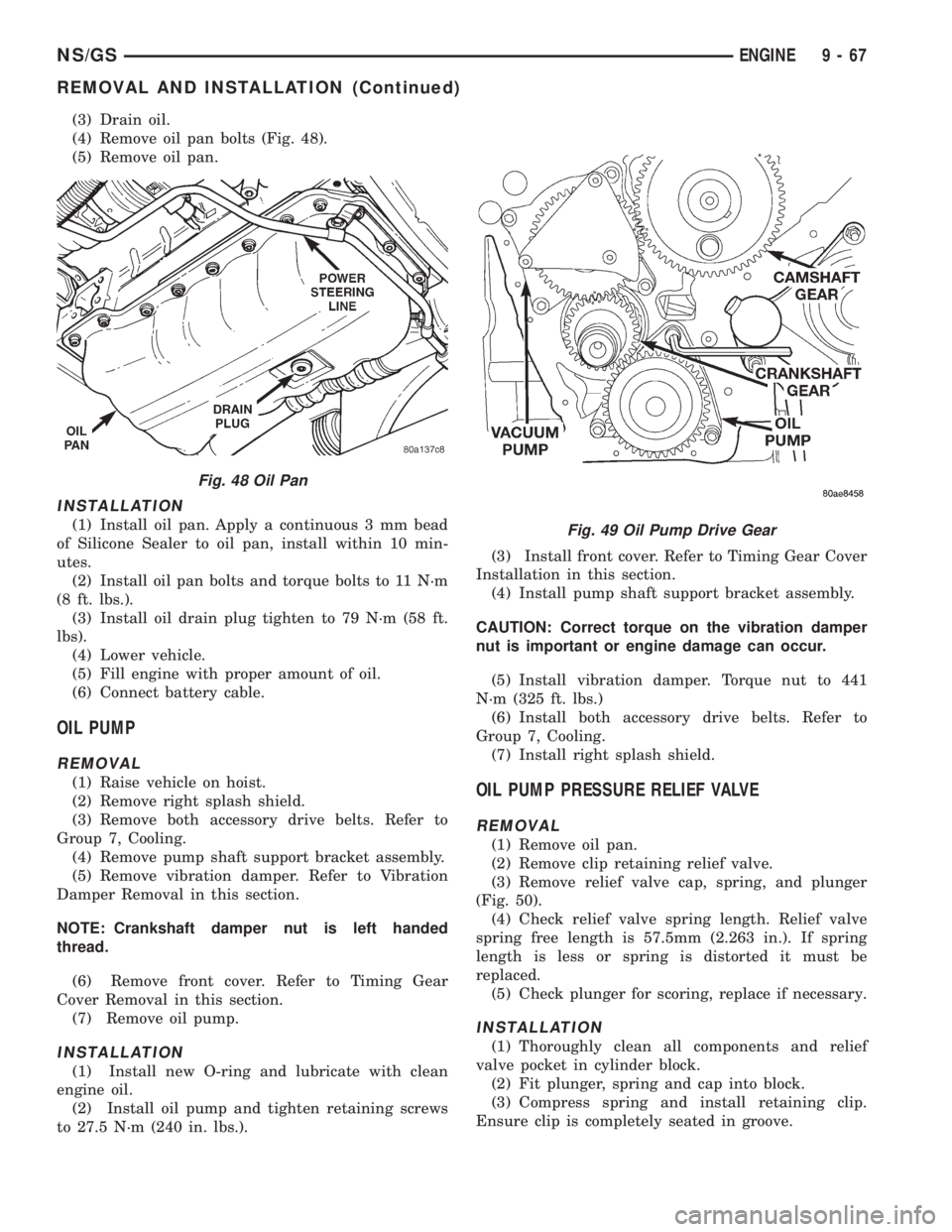

(3) Drain oil.

(4) Remove oil pan bolts (Fig. 48).

(5) Remove oil pan.

INSTALLATION

(1) Install oil pan. Apply a continuous 3 mm bead

of Silicone Sealer to oil pan, install within 10 min-

utes.

(2) Install oil pan bolts and torque bolts to 11 N´m

(8 ft. lbs.).

(3) Install oil drain plug tighten to 79 N´m (58 ft.

lbs).

(4) Lower vehicle.

(5) Fill engine with proper amount of oil.

(6) Connect battery cable.

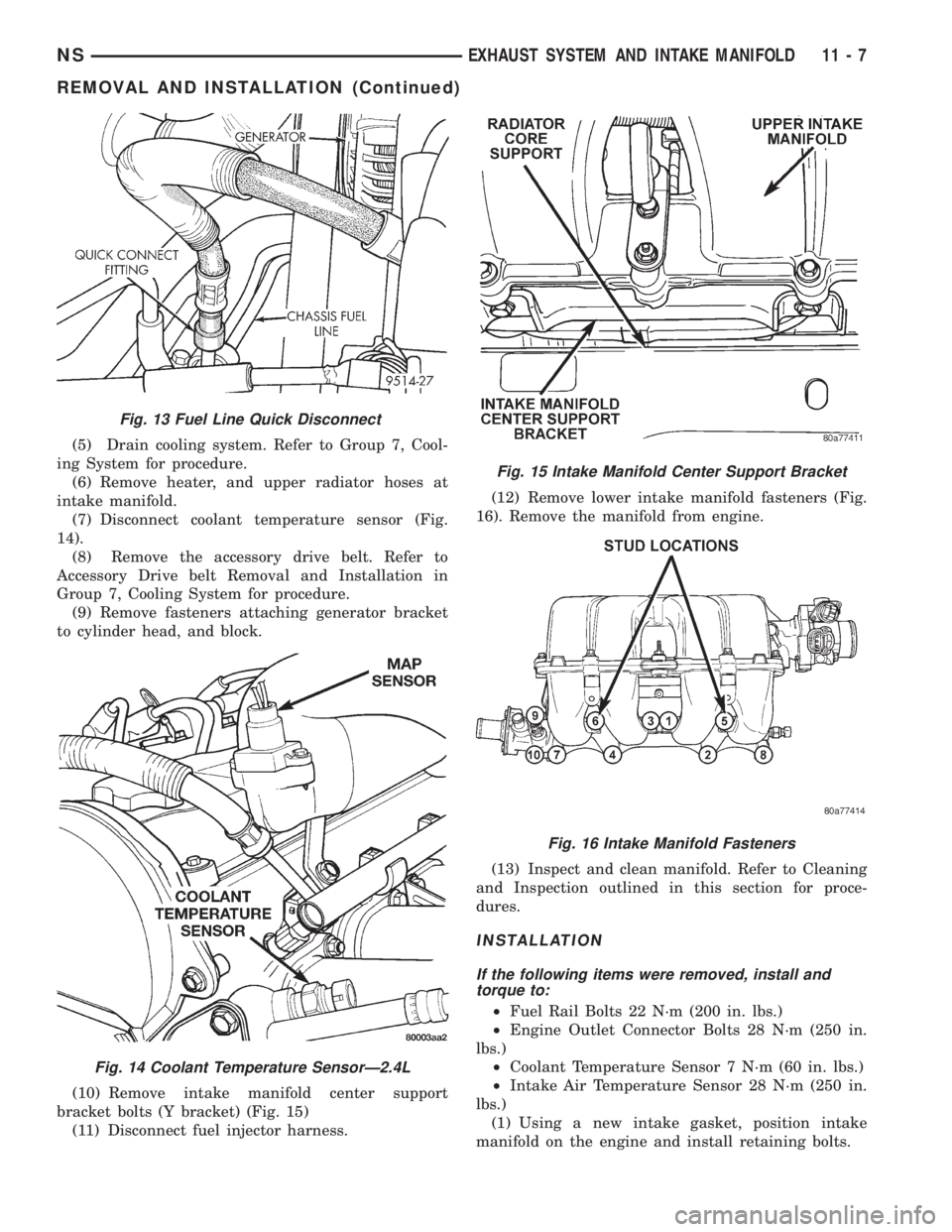

OIL PUMP

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove right splash shield.

(3) Remove both accessory drive belts. Refer to

Group 7, Cooling.

(4) Remove pump shaft support bracket assembly.

(5) Remove vibration damper. Refer to Vibration

Damper Removal in this section.

NOTE: Crankshaft damper nut is left handed

thread.

(6) Remove front cover. Refer to Timing Gear

Cover Removal in this section.

(7) Remove oil pump.

INSTALLATION

(1) Install new O-ring and lubricate with clean

engine oil.

(2) Install oil pump and tighten retaining screws

to 27.5 N´m (240 in. lbs.).(3) Install front cover. Refer to Timing Gear Cover

Installation in this section.

(4) Install pump shaft support bracket assembly.

CAUTION: Correct torque on the vibration damper

nut is important or engine damage can occur.

(5) Install vibration damper. Torque nut to 441

N´m (325 ft. lbs.)

(6) Install both accessory drive belts. Refer to

Group 7, Cooling.

(7) Install right splash shield.

OIL PUMP PRESSURE RELIEF VALVE

REMOVAL

(1) Remove oil pan.

(2) Remove clip retaining relief valve.

(3) Remove relief valve cap, spring, and plunger

(Fig. 50).

(4) Check relief valve spring length. Relief valve

spring free length is 57.5mm (2.263 in.). If spring

length is less or spring is distorted it must be

replaced.

(5) Check plunger for scoring, replace if necessary.

INSTALLATION

(1) Thoroughly clean all components and relief

valve pocket in cylinder block.

(2) Fit plunger, spring and cap into block.

(3) Compress spring and install retaining clip.

Ensure clip is completely seated in groove.

Fig. 48 Oil Pan

Fig. 49 Oil Pump Drive Gear

NS/GSENGINE 9 - 67

REMOVAL AND INSTALLATION (Continued)

Page 1269 of 1938

(5) Drain cooling system. Refer to Group 7, Cool-

ing System for procedure.

(6) Remove heater, and upper radiator hoses at

intake manifold.

(7) Disconnect coolant temperature sensor (Fig.

14).

(8) Remove the accessory drive belt. Refer to

Accessory Drive belt Removal and Installation in

Group 7, Cooling System for procedure.

(9) Remove fasteners attaching generator bracket

to cylinder head, and block.

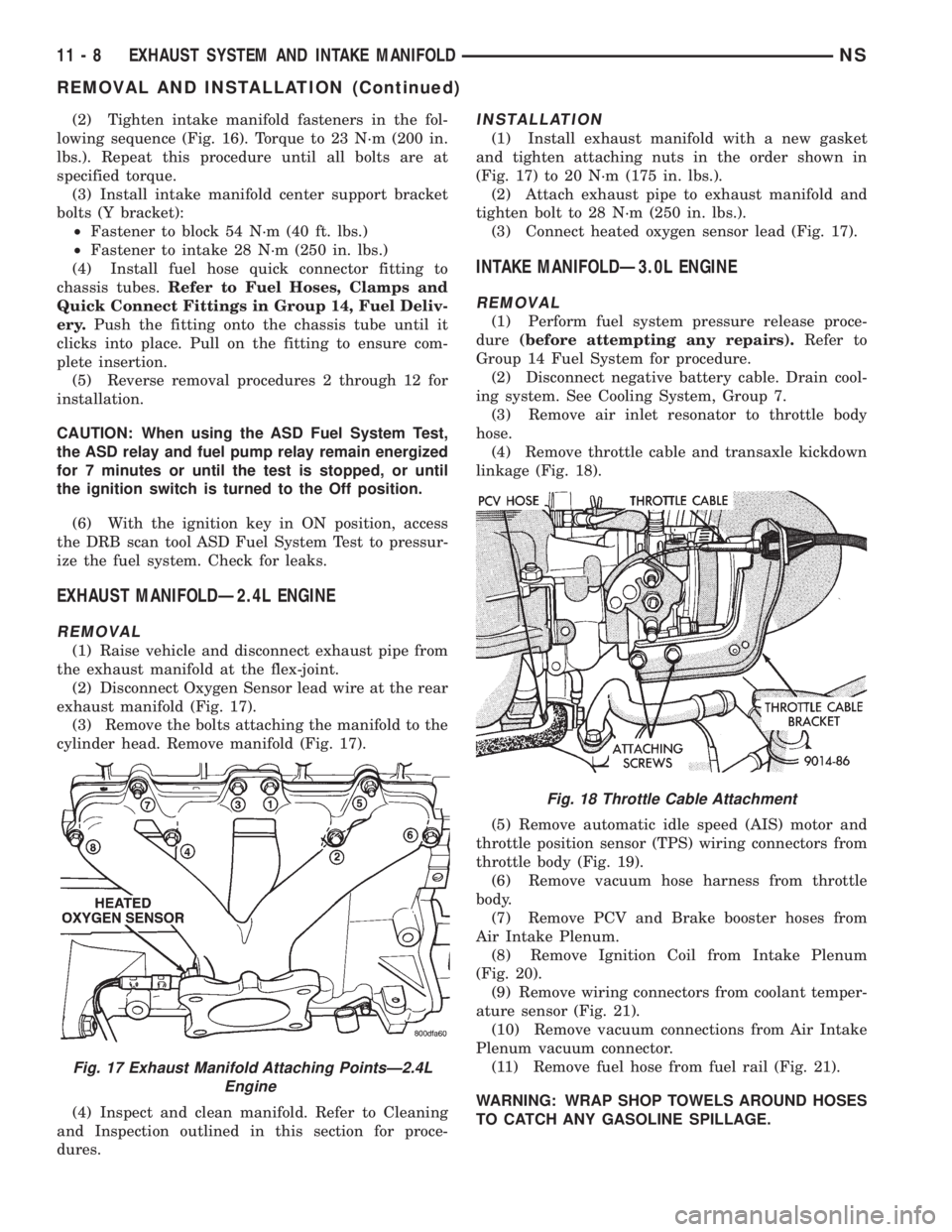

(10) Remove intake manifold center support

bracket bolts (Y bracket) (Fig. 15)

(11) Disconnect fuel injector harness.(12) Remove lower intake manifold fasteners (Fig.

16). Remove the manifold from engine.

(13) Inspect and clean manifold. Refer to Cleaning

and Inspection outlined in this section for proce-

dures.

INSTALLATION

If the following items were removed, install and

torque to:

²Fuel Rail Bolts 22 N´m (200 in. lbs.)

²Engine Outlet Connector Bolts 28 N´m (250 in.

lbs.)

²Coolant Temperature Sensor 7 N´m (60 in. lbs.)

²Intake Air Temperature Sensor 28 N´m (250 in.

lbs.)

(1) Using a new intake gasket, position intake

manifold on the engine and install retaining bolts.

Fig. 13 Fuel Line Quick Disconnect

Fig. 14 Coolant Temperature SensorÐ2.4L

Fig. 15 Intake Manifold Center Support Bracket

Fig. 16 Intake Manifold Fasteners

NSEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 7

REMOVAL AND INSTALLATION (Continued)

Page 1270 of 1938

(2) Tighten intake manifold fasteners in the fol-

lowing sequence (Fig. 16). Torque to 23 N´m (200 in.

lbs.). Repeat this procedure until all bolts are at

specified torque.

(3) Install intake manifold center support bracket

bolts (Y bracket):

²Fastener to block 54 N´m (40 ft. lbs.)

²Fastener to intake 28 N´m (250 in. lbs.)

(4) Install fuel hose quick connector fitting to

chassis tubes.Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in Group 14, Fuel Deliv-

ery.Push the fitting onto the chassis tube until it

clicks into place. Pull on the fitting to ensure com-

plete insertion.

(5) Reverse removal procedures 2 through 12 for

installation.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(6) With the ignition key in ON position, access

the DRB scan tool ASD Fuel System Test to pressur-

ize the fuel system. Check for leaks.

EXHAUST MANIFOLDÐ2.4L ENGINE

REMOVAL

(1) Raise vehicle and disconnect exhaust pipe from

the exhaust manifold at the flex-joint.

(2) Disconnect Oxygen Sensor lead wire at the rear

exhaust manifold (Fig. 17).

(3) Remove the bolts attaching the manifold to the

cylinder head. Remove manifold (Fig. 17).

(4) Inspect and clean manifold. Refer to Cleaning

and Inspection outlined in this section for proce-

dures.

INSTALLATION

(1) Install exhaust manifold with a new gasket

and tighten attaching nuts in the order shown in

(Fig. 17) to 20 N´m (175 in. lbs.).

(2) Attach exhaust pipe to exhaust manifold and

tighten bolt to 28 N´m (250 in. lbs.).

(3) Connect heated oxygen sensor lead (Fig. 17).

INTAKE MANIFOLDÐ3.0L ENGINE

REMOVAL

(1) Perform fuel system pressure release proce-

dure(before attempting any repairs).Refer to

Group 14 Fuel System for procedure.

(2) Disconnect negative battery cable. Drain cool-

ing system. See Cooling System, Group 7.

(3) Remove air inlet resonator to throttle body

hose.

(4) Remove throttle cable and transaxle kickdown

linkage (Fig. 18).

(5) Remove automatic idle speed (AIS) motor and

throttle position sensor (TPS) wiring connectors from

throttle body (Fig. 19).

(6) Remove vacuum hose harness from throttle

body.

(7) Remove PCV and Brake booster hoses from

Air Intake Plenum.

(8) Remove Ignition Coil from Intake Plenum

(Fig. 20).

(9) Remove wiring connectors from coolant temper-

ature sensor (Fig. 21).

(10) Remove vacuum connections from Air Intake

Plenum vacuum connector.

(11) Remove fuel hose from fuel rail (Fig. 21).

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY GASOLINE SPILLAGE.

Fig. 17 Exhaust Manifold Attaching PointsÐ2.4L

Engine

Fig. 18 Throttle Cable Attachment

11 - 8 EXHAUST SYSTEM AND INTAKE MANIFOLDNS

REMOVAL AND INSTALLATION (Continued)

Page 1273 of 1938

(10) Connect fuel line to fuel rail (Fig. 21). Torque

hose clamps to 1 N´m (10 in. lbs.).

(11) Connect vacuum harness to air intake ple-

num.

(12) Connect and coolant temperature sensor elec-

trical connector to sensor (Fig. 21).

(13) Connect PCV and brake booster supply hose

to intake plenum.

(14) Connect automatic idle speed (AIS) motor

and throttle position sensor (TPS) electrical connec-

tors (Fig. 19).

(15) Connect vacuum vapor harness to throttle

body (Fig. 19).

(16) Install throttle cable and transaxle kickdown

linkage (Fig. 18).

(17) Install air inlet resonator hose assembly to

throttle body.

(18) Install radiator to thermostat housing hose

and heater hose to heater pipe nipple.

(19) Fill cooling system. Refer to Filling the Cool-

ing System outlined in Group 7 Cooling System for

procedure.

(20) Connect negative battery cable.

(21) With the DRB Scan Tool use ASD Fuel Sys-

tem Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

The Auto Shutdown (ASD) Relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

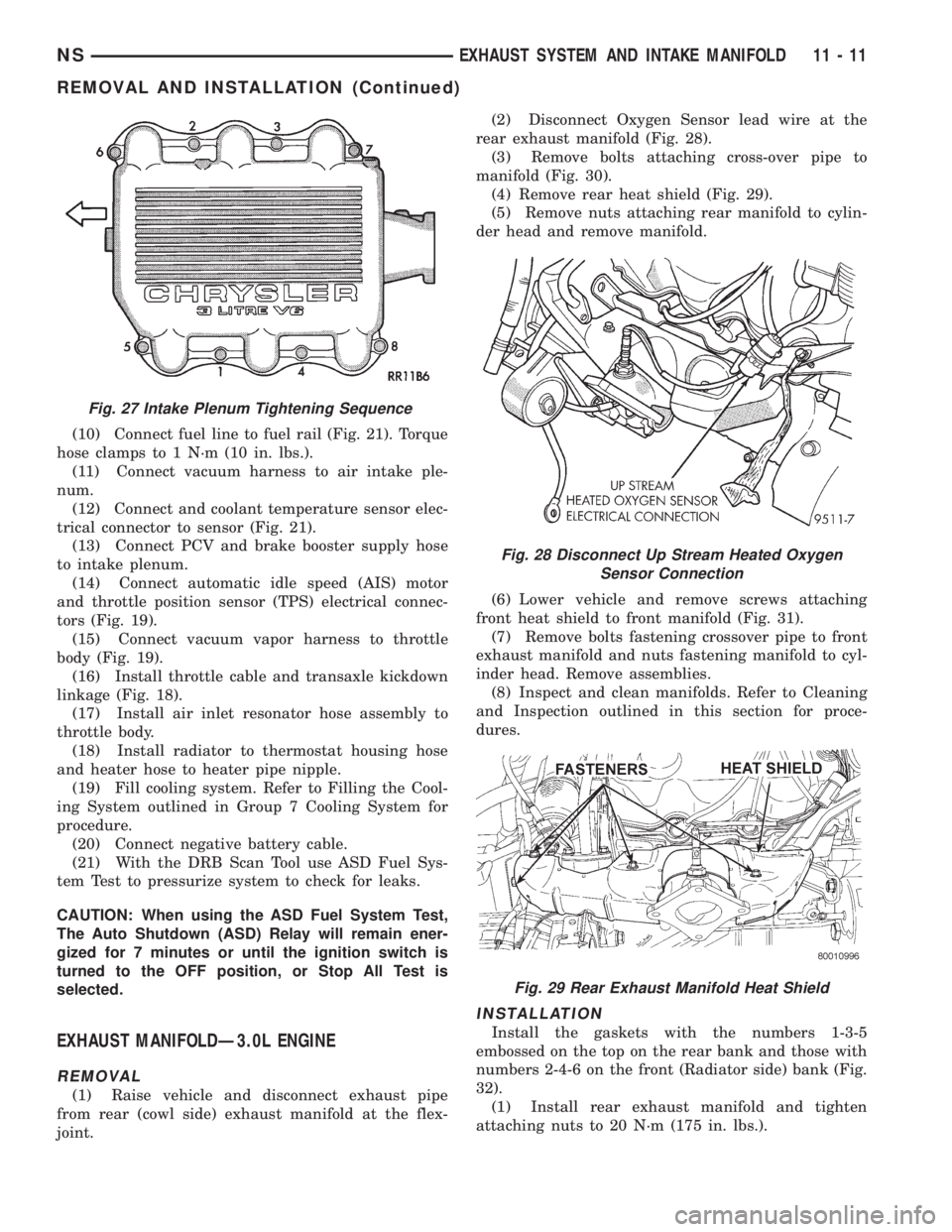

EXHAUST MANIFOLDÐ3.0L ENGINE

REMOVAL

(1) Raise vehicle and disconnect exhaust pipe

from rear (cowl side) exhaust manifold at the flex-

joint.(2) Disconnect Oxygen Sensor lead wire at the

rear exhaust manifold (Fig. 28).

(3) Remove bolts attaching cross-over pipe to

manifold (Fig. 30).

(4) Remove rear heat shield (Fig. 29).

(5) Remove nuts attaching rear manifold to cylin-

der head and remove manifold.

(6) Lower vehicle and remove screws attaching

front heat shield to front manifold (Fig. 31).

(7) Remove bolts fastening crossover pipe to front

exhaust manifold and nuts fastening manifold to cyl-

inder head. Remove assemblies.

(8) Inspect and clean manifolds. Refer to Cleaning

and Inspection outlined in this section for proce-

dures.

INSTALLATION

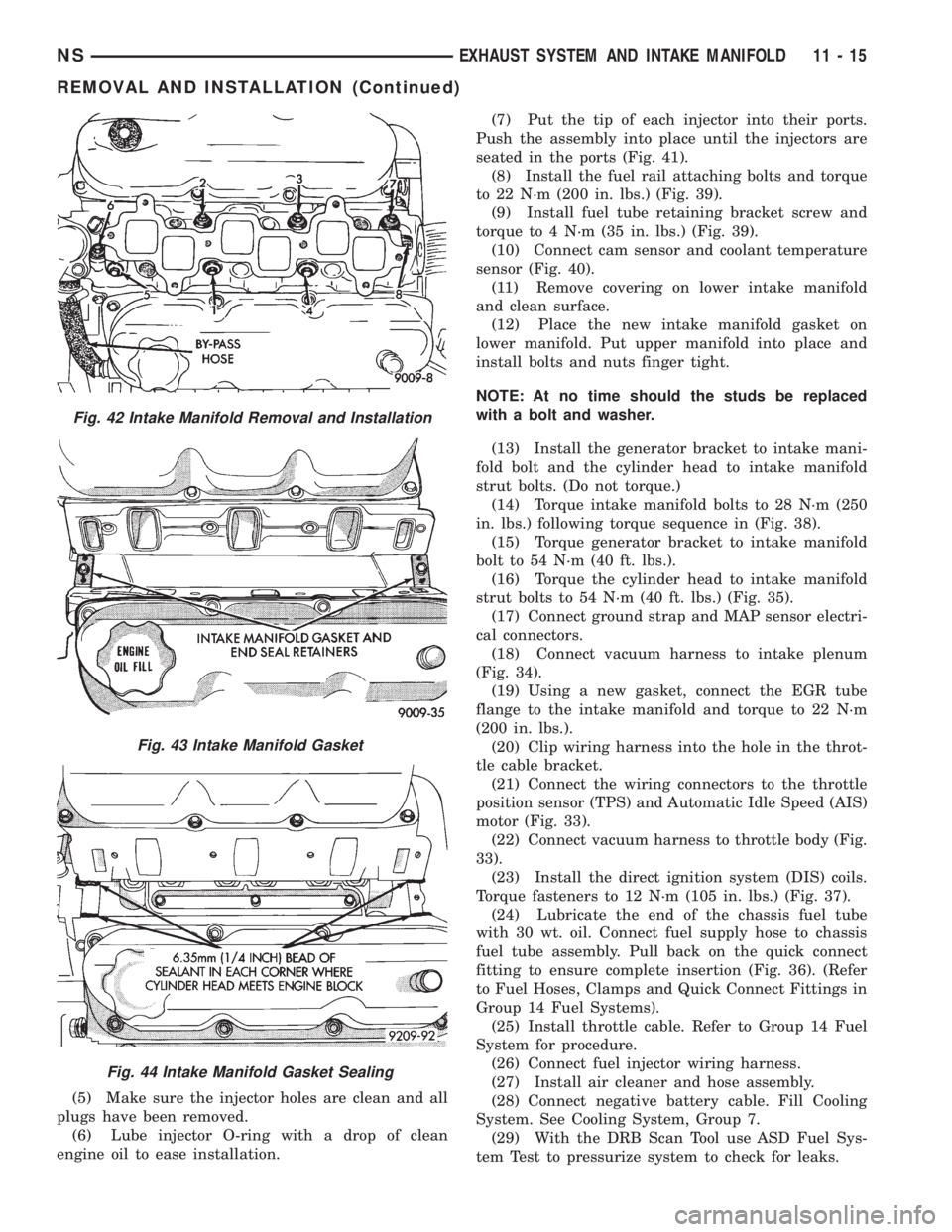

Install the gaskets with the numbers 1-3-5

embossed on the top on the rear bank and those with

numbers 2-4-6 on the front (Radiator side) bank (Fig.

32).

(1) Install rear exhaust manifold and tighten

attaching nuts to 20 N´m (175 in. lbs.).

Fig. 27 Intake Plenum Tightening Sequence

Fig. 28 Disconnect Up Stream Heated Oxygen

Sensor Connection

Fig. 29 Rear Exhaust Manifold Heat Shield

NSEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 11

REMOVAL AND INSTALLATION (Continued)

Page 1274 of 1938

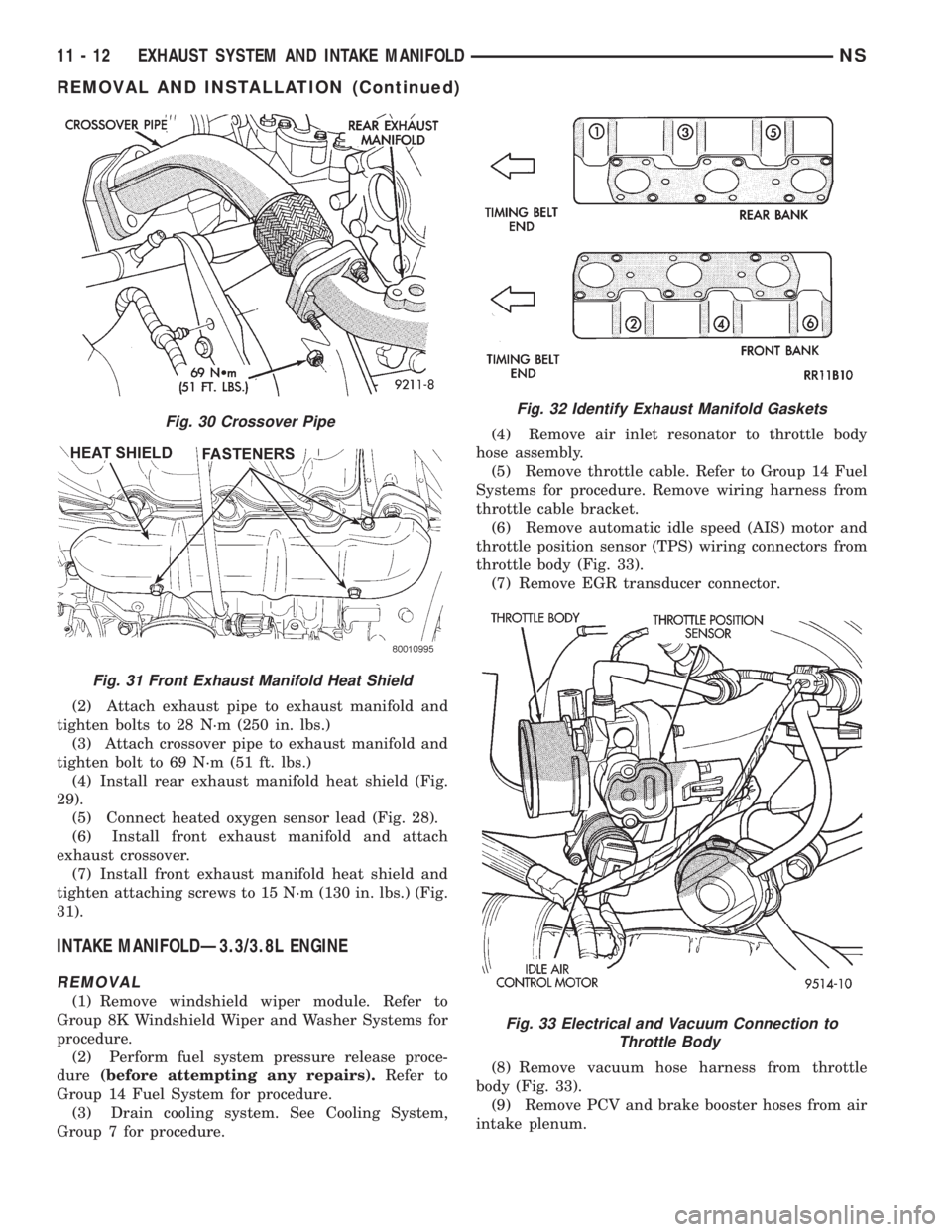

(2) Attach exhaust pipe to exhaust manifold and

tighten bolts to 28 N´m (250 in. lbs.)

(3) Attach crossover pipe to exhaust manifold and

tighten bolt to 69 N´m (51 ft. lbs.)

(4) Install rear exhaust manifold heat shield (Fig.

29).

(5) Connect heated oxygen sensor lead (Fig. 28).

(6) Install front exhaust manifold and attach

exhaust crossover.

(7) Install front exhaust manifold heat shield and

tighten attaching screws to 15 N´m (130 in. lbs.) (Fig.

31).

INTAKE MANIFOLDÐ3.3/3.8L ENGINE

REMOVAL

(1) Remove windshield wiper module. Refer to

Group 8K Windshield Wiper and Washer Systems for

procedure.

(2) Perform fuel system pressure release proce-

dure(before attempting any repairs).Refer to

Group 14 Fuel System for procedure.

(3) Drain cooling system. See Cooling System,

Group 7 for procedure.(4) Remove air inlet resonator to throttle body

hose assembly.

(5) Remove throttle cable. Refer to Group 14 Fuel

Systems for procedure. Remove wiring harness from

throttle cable bracket.

(6) Remove automatic idle speed (AIS) motor and

throttle position sensor (TPS) wiring connectors from

throttle body (Fig. 33).

(7) Remove EGR transducer connector.

(8) Remove vacuum hose harness from throttle

body (Fig. 33).

(9) Remove PCV and brake booster hoses from air

intake plenum.

Fig. 30 Crossover Pipe

Fig. 31 Front Exhaust Manifold Heat Shield

Fig. 32 Identify Exhaust Manifold Gaskets

Fig. 33 Electrical and Vacuum Connection to

Throttle Body

11 - 12 EXHAUST SYSTEM AND INTAKE MANIFOLDNS

REMOVAL AND INSTALLATION (Continued)

Page 1277 of 1938

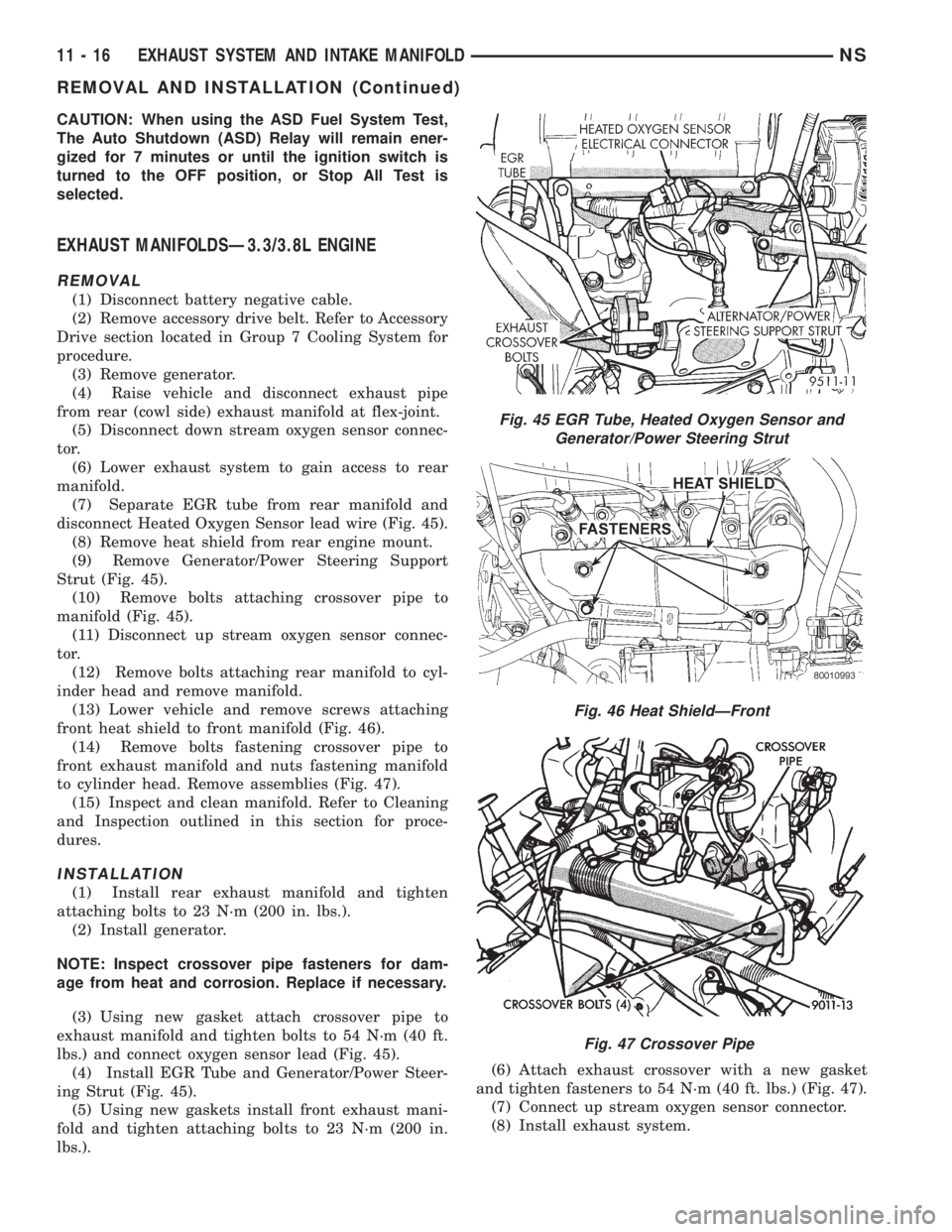

(5) Make sure the injector holes are clean and all

plugs have been removed.

(6) Lube injector O-ring with a drop of clean

engine oil to ease installation.(7) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports (Fig. 41).

(8) Install the fuel rail attaching bolts and torque

to 22 N´m (200 in. lbs.) (Fig. 39).

(9) Install fuel tube retaining bracket screw and

torque to 4 N´m (35 in. lbs.) (Fig. 39).

(10) Connect cam sensor and coolant temperature

sensor (Fig. 40).

(11) Remove covering on lower intake manifold

and clean surface.

(12) Place the new intake manifold gasket on

lower manifold. Put upper manifold into place and

install bolts and nuts finger tight.

NOTE: At no time should the studs be replaced

with a bolt and washer.

(13) Install the generator bracket to intake mani-

fold bolt and the cylinder head to intake manifold

strut bolts. (Do not torque.)

(14) Torque intake manifold bolts to 28 N´m (250

in. lbs.) following torque sequence in (Fig. 38).

(15) Torque generator bracket to intake manifold

bolt to 54 N´m (40 ft. lbs.).

(16) Torque the cylinder head to intake manifold

strut bolts to 54 N´m (40 ft. lbs.) (Fig. 35).

(17) Connect ground strap and MAP sensor electri-

cal connectors.

(18) Connect vacuum harness to intake plenum

(Fig. 34).

(19) Using a new gasket, connect the EGR tube

flange to the intake manifold and torque to 22 N´m

(200 in. lbs.).

(20) Clip wiring harness into the hole in the throt-

tle cable bracket.

(21) Connect the wiring connectors to the throttle

position sensor (TPS) and Automatic Idle Speed (AIS)

motor (Fig. 33).

(22) Connect vacuum harness to throttle body (Fig.

33).

(23) Install the direct ignition system (DIS) coils.

Torque fasteners to 12 N´m (105 in. lbs.) (Fig. 37).

(24) Lubricate the end of the chassis fuel tube

with 30 wt. oil. Connect fuel supply hose to chassis

fuel tube assembly. Pull back on the quick connect

fitting to ensure complete insertion (Fig. 36). (Refer

to Fuel Hoses, Clamps and Quick Connect Fittings in

Group 14 Fuel Systems).

(25) Install throttle cable. Refer to Group 14 Fuel

System for procedure.

(26) Connect fuel injector wiring harness.

(27) Install air cleaner and hose assembly.

(28) Connect negative battery cable. Fill Cooling

System. See Cooling System, Group 7.

(29) With the DRB Scan Tool use ASD Fuel Sys-

tem Test to pressurize system to check for leaks.

Fig. 42 Intake Manifold Removal and Installation

Fig. 43 Intake Manifold Gasket

Fig. 44 Intake Manifold Gasket Sealing

NSEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 15

REMOVAL AND INSTALLATION (Continued)

Page 1278 of 1938

CAUTION: When using the ASD Fuel System Test,

The Auto Shutdown (ASD) Relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

EXHAUST MANIFOLDSÐ3.3/3.8L ENGINE

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove accessory drive belt. Refer to Accessory

Drive section located in Group 7 Cooling System for

procedure.

(3) Remove generator.

(4) Raise vehicle and disconnect exhaust pipe

from rear (cowl side) exhaust manifold at flex-joint.

(5) Disconnect down stream oxygen sensor connec-

tor.

(6) Lower exhaust system to gain access to rear

manifold.

(7) Separate EGR tube from rear manifold and

disconnect Heated Oxygen Sensor lead wire (Fig. 45).

(8) Remove heat shield from rear engine mount.

(9) Remove Generator/Power Steering Support

Strut (Fig. 45).

(10) Remove bolts attaching crossover pipe to

manifold (Fig. 45).

(11) Disconnect up stream oxygen sensor connec-

tor.

(12) Remove bolts attaching rear manifold to cyl-

inder head and remove manifold.

(13) Lower vehicle and remove screws attaching

front heat shield to front manifold (Fig. 46).

(14) Remove bolts fastening crossover pipe to

front exhaust manifold and nuts fastening manifold

to cylinder head. Remove assemblies (Fig. 47).

(15) Inspect and clean manifold. Refer to Cleaning

and Inspection outlined in this section for proce-

dures.

INSTALLATION

(1) Install rear exhaust manifold and tighten

attaching bolts to 23 N´m (200 in. lbs.).

(2) Install generator.

NOTE: Inspect crossover pipe fasteners for dam-

age from heat and corrosion. Replace if necessary.

(3) Using new gasket attach crossover pipe to

exhaust manifold and tighten bolts to 54 N´m (40 ft.

lbs.) and connect oxygen sensor lead (Fig. 45).

(4) Install EGR Tube and Generator/Power Steer-

ing Strut (Fig. 45).

(5) Using new gaskets install front exhaust mani-

fold and tighten attaching bolts to 23 N´m (200 in.

lbs.).(6) Attach exhaust crossover with a new gasket

and tighten fasteners to 54 N´m (40 ft. lbs.) (Fig. 47).

(7) Connect up stream oxygen sensor connector.

(8) Install exhaust system.

Fig. 45 EGR Tube, Heated Oxygen Sensor and

Generator/Power Steering Strut

Fig. 46 Heat ShieldÐFront

Fig. 47 Crossover Pipe

11 - 16 EXHAUST SYSTEM AND INTAKE MANIFOLDNS

REMOVAL AND INSTALLATION (Continued)

Page 1279 of 1938

(9) Attach exhaust pipe to exhaust manifold using

new gasket and tighten bolts to 28 N´m (250 in. lbs.).

(10) Connect down stream oxygen sensor connec-

tor.

(11) Install front manifold heat shield and tighten

attaching screws to 12 N´m (105 in. lbs.) (Fig. 46).

(12) Install accessory drive belt. Refer to Accessory

Drive section located in Group 7 Cooling System for

procedure.

(13) Connect battery negative cable.

CLEANING AND INSPECTION

INTAKE MANIFOLD

INSPECTION

Check for:

²Damage and cracks of each section.

²Clogged water passages in end cross-overs (if

equipped).

²Check for cylinder head mounting surface distor-

tion using a straightedge and thickness gauge. Refer

to specifications for warpage specification.

CLEANING

Remove the gasket material from the manifold sur-

faces.

Be careful not to gouge or scratch the sealing sur-

face.

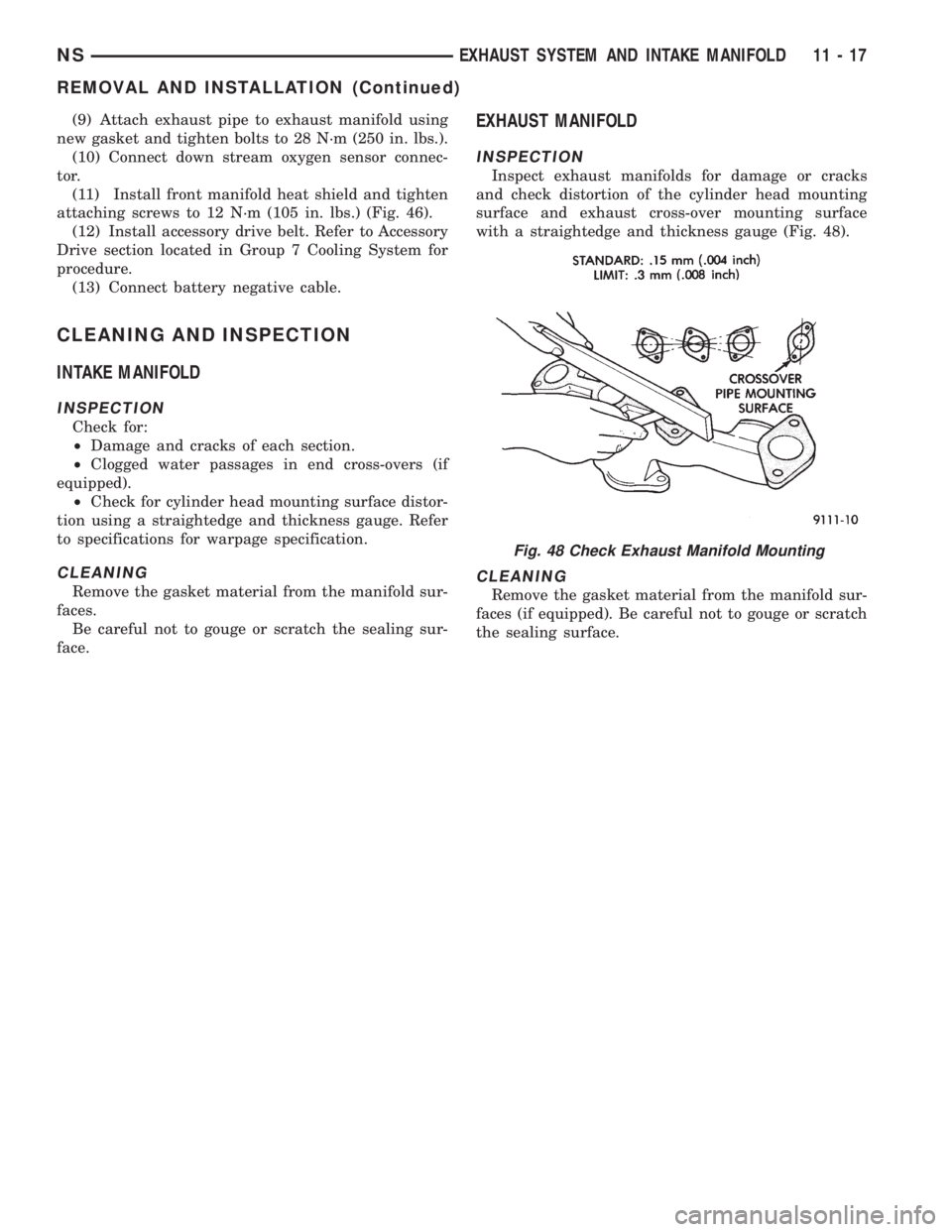

EXHAUST MANIFOLD

INSPECTION

Inspect exhaust manifolds for damage or cracks

and check distortion of the cylinder head mounting

surface and exhaust cross-over mounting surface

with a straightedge and thickness gauge (Fig. 48).

CLEANING

Remove the gasket material from the manifold sur-

faces (if equipped). Be careful not to gouge or scratch

the sealing surface.

Fig. 48 Check Exhaust Manifold Mounting

NSEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 17

REMOVAL AND INSTALLATION (Continued)

Page 1324 of 1938

THROTTLE BODY....................... 64

THROTTLE POSITION SENSOR............ 65

UPSTREAM OXYGEN SENSOR............. 68

SPECIFICATIONS

TORQUE.............................. 72SPECIAL TOOLS

FUEL................................. 72

GENERAL INFORMATION

INTRODUCTION

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

All inputs to the PCM are converted into signals.

The PCM can adapt its programming to meet chang-

ing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are the primary inputs that determine injec-

tor pulse width.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCMprogramming. Input from the oxygen (O2S) sensor is

not monitored during OPEN LOOP modes.

During CLOSED LOOP modes the PCM does mon-

itor the O2S sensor input. This input indicates to the

PCM whether or not the calculated injector pulse

width results in the ideal air/fuel ratio of 14.7 parts

air to 1 part fuel. By monitoring the exhaust oxygen

content through the O2S sensor, the PCM can fine

tune the injector pulse width. Fine tuning injector

pulse width allows the PCM to achieve optimum fuel

economy combined with low emissions.

The multi-port fuel injection system has the follow-

ing modes of operation:

²Ignition switch ON (zero RPM)

²Engine start-up

²Engine warm-up

²Cruise (Idle)

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes.

Under most operating conditions, the acceleration,

deceleration, and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the multi-port fuel injection system is acti-

vated by the ignition switch, the following actions

occur:

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the coolant temperature sen-

sor and throttle position sensor input. The PCM mod-

ifies fuel strategy based on this input.

When the key is in the ON position and the engine

is not running (zero rpm), the Automatic Shutdown

(ASD) relay and fuel pump relay are not energized.

Therefore battery voltage is not supplied to the fuel

pump, ignition coil, fuel injectors or oxygen sensor

heating element.

ENGINE START-UP MODE

This is an OPEN LOOP mode. The following

actions occur when the starter motor is engaged.

If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the ASD relay and fuel pump relay. These relays sup-

ply battery voltage to the fuel pump, fuel injectors,

14 - 30 FUEL SYSTEMNS

SPECIFICATIONS (Continued)

Page 1326 of 1938

IGNITION SWITCH OFF MODE

When the ignition switch is turned to the OFF

position, the following occurs:

²All outputs are turned off.

²No inputs are monitored.

²The PCM shuts down.

DESCRIPTION AND OPERATION

SYSTEM DIAGNOSIS

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information, refer to Group 25, Emission

Control Systems. See On-Board Diagnostics.

CCD BUS

Various controllers and modules exchange informa-

tion through a communications port called the CCD

Bus. The PCM transmits the malfunction indicator

(check engine) lamp On/Off signal, engine RPM and

vehicle load information on the CCD Bus.

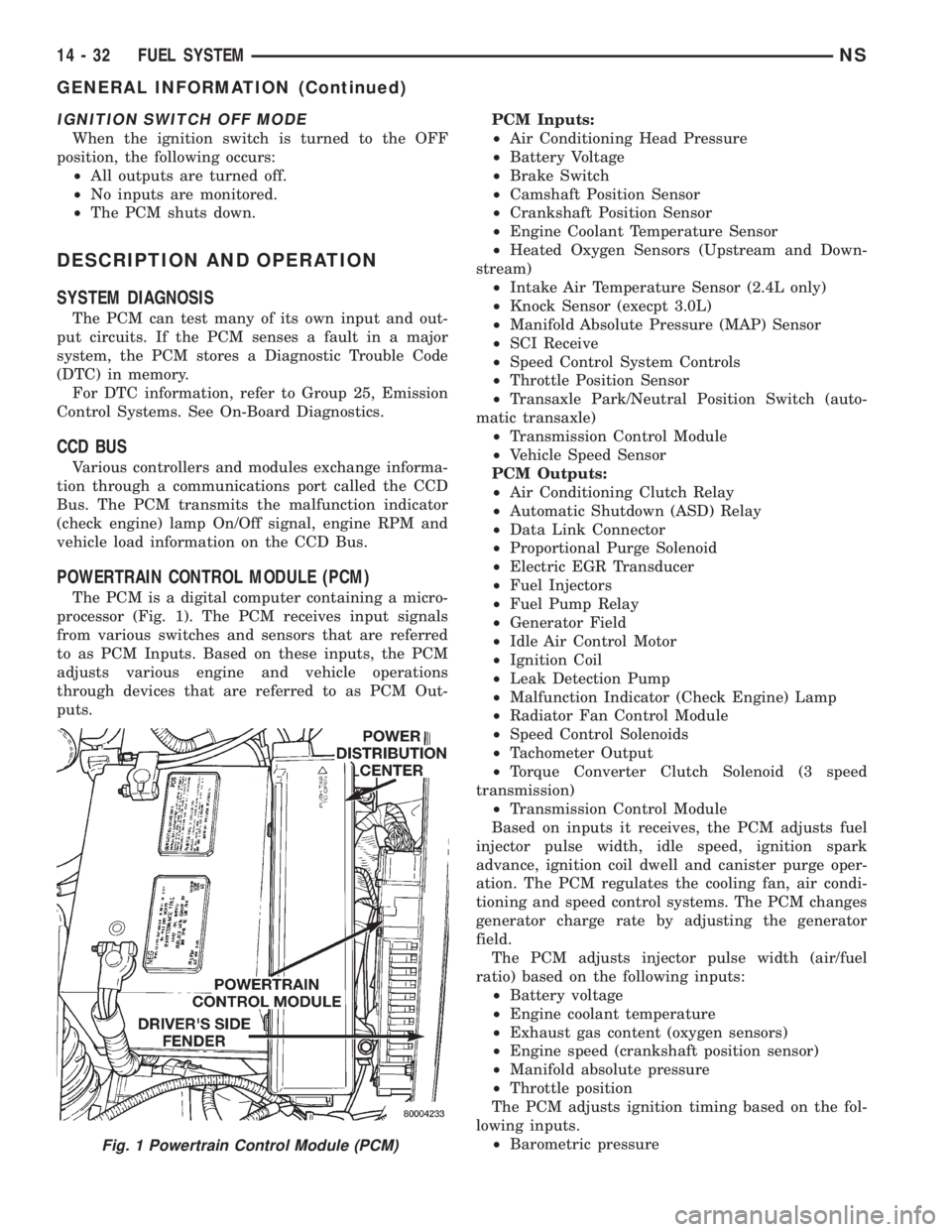

POWERTRAIN CONTROL MODULE (PCM)

The PCM is a digital computer containing a micro-

processor (Fig. 1). The PCM receives input signals

from various switches and sensors that are referred

to as PCM Inputs. Based on these inputs, the PCM

adjusts various engine and vehicle operations

through devices that are referred to as PCM Out-

puts.PCM Inputs:

²Air Conditioning Head Pressure

²Battery Voltage

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Engine Coolant Temperature Sensor

²Heated Oxygen Sensors (Upstream and Down-

stream)

²Intake Air Temperature Sensor (2.4L only)

²Knock Sensor (execpt 3.0L)

²Manifold Absolute Pressure (MAP) Sensor

²SCI Receive

²Speed Control System Controls

²Throttle Position Sensor

²Transaxle Park/Neutral Position Switch (auto-

matic transaxle)

²Transmission Control Module

²Vehicle Speed Sensor

PCM Outputs:

²Air Conditioning Clutch Relay

²Automatic Shutdown (ASD) Relay

²Data Link Connector

²Proportional Purge Solenoid

²Electric EGR Transducer

²Fuel Injectors

²Fuel Pump Relay

²Generator Field

²Idle Air Control Motor

²Ignition Coil

²Leak Detection Pump

²Malfunction Indicator (Check Engine) Lamp

²Radiator Fan Control Module

²Speed Control Solenoids

²Tachometer Output

²Torque Converter Clutch Solenoid (3 speed

transmission)

²Transmission Control Module

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark

advance, ignition coil dwell and canister purge oper-

ation. The PCM regulates the cooling fan, air condi-

tioning and speed control systems. The PCM changes

generator charge rate by adjusting the generator

field.

The PCM adjusts injector pulse width (air/fuel

ratio) based on the following inputs:

²Battery voltage

²Engine coolant temperature

²Exhaust gas content (oxygen sensors)

²Engine speed (crankshaft position sensor)

²Manifold absolute pressure

²Throttle position

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Barometric pressure

Fig. 1 Powertrain Control Module (PCM)

14 - 32 FUEL SYSTEMNS

GENERAL INFORMATION (Continued)