cooling CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1439 of 1938

(18) Remove the 3 previously loosened bolts

attaching the front bracket to the power steering

pump and separate the power steering pump from

the front bracket prior to removing the pump from

the vehicle.

(19) The power steering pump is removed from the

vehicle by pulling it out through the exhaust tunnel

area in the floor pan of the vehicle.

INSTALL

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel are of the vehicle.

(2) Install the power steering pump on its cast

mounting bracket and loosely install nut to hold

pump in place (Fig. 9).

(3) Install the front bracket on the power steering

pump and loosely install the 3 mounting bolts (Fig.

10). Then install the nut and bolt attaching the front

bracket to the cast bracket (Fig. 10).

(4) Tighten the 3 power steering pump mounting

bolts (Fig. 10) to a torque of 54 N´m (40 ft. lbs.).

NOTE: Before installing power steering fluid pres-

sure hose on power steering pump, inspect the

O-ring on the pressure hose for damage and

replace if necessary.

(5) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 8). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(6) Install the power steering fluid, low pressure

return hose on the power steering pump low pressure

fitting (Fig. 8).Be sure hose clamps are properly

reinstalled.

(7) Install the power steering fluid supply hose

from the power steering fluid reservoir, on the power

steering pump fluid fitting (Fig. 7).Be sure hose is

clear of accessory drive belts all hose clamps

are properly reinstalled.

(8) Install the power steering pump drive belt on

pulley. See Cooling, Group 7 for detailed installation

procedure.

(9) Install the accessory drive splash shield (Fig.

6).

(10) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig. 5).

(11) Install a screw type hose clamp on the power

steering hose to steel tube connection.Be sure hose

clamps are properly reinstalled.Tighten the screw

clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 5). This is requiredto prevent the overheating of the power steering

hoses.

(12) When used, properly position the protective

heat sleeves on the power steering hoses (Fig. 5).

Then, tie strap the heat sleeves to the power steering

hoses to keep them in their proper position.

(13) Install the exhaust pipe on the exhaust man-

ifold. Install all exhaust system hangers/isolators on

the exhaust system brackets.

(14) Connect the oxygen sensor wiring harness to

the vehicle wiring harness. Install wiring harness

grommet in the floor pan of the vehicle.

(15) Lower vehicle.

(16) Adjust the power steering pump drive belt.

See Cooling, Group 7 for detailed adjustment proce-

dure.

(17) Tighten the top nut and bottom bolt on the

power steering pump front mounting bracket (Fig. 3)

to a torque of 54 N´m (40 ft. lbs.).

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use MoparT, Power

Steering Fluid, or equivalent.

(18) Fill the remote power steering pump fluid res-

ervoir to correct fluid level.

(19) Install cap on power steering fluid reservoir.

(20) Connect the negative battery cable on the

negative battery post.

(21) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

3.0 LITER POWER STEERING PUMP

REMOVE

WARNING: POWER STEERING OIL, ENGINE COM-

PONENTS AND THE EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

(1) Remove the (-) negative battery cable from the

battery and isolate cable.

(2) Remove cap from power steering fluid reser-

voir.

(3) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

NSSTEERING 19 - 13

REMOVAL AND INSTALLATION (Continued)

Page 1440 of 1938

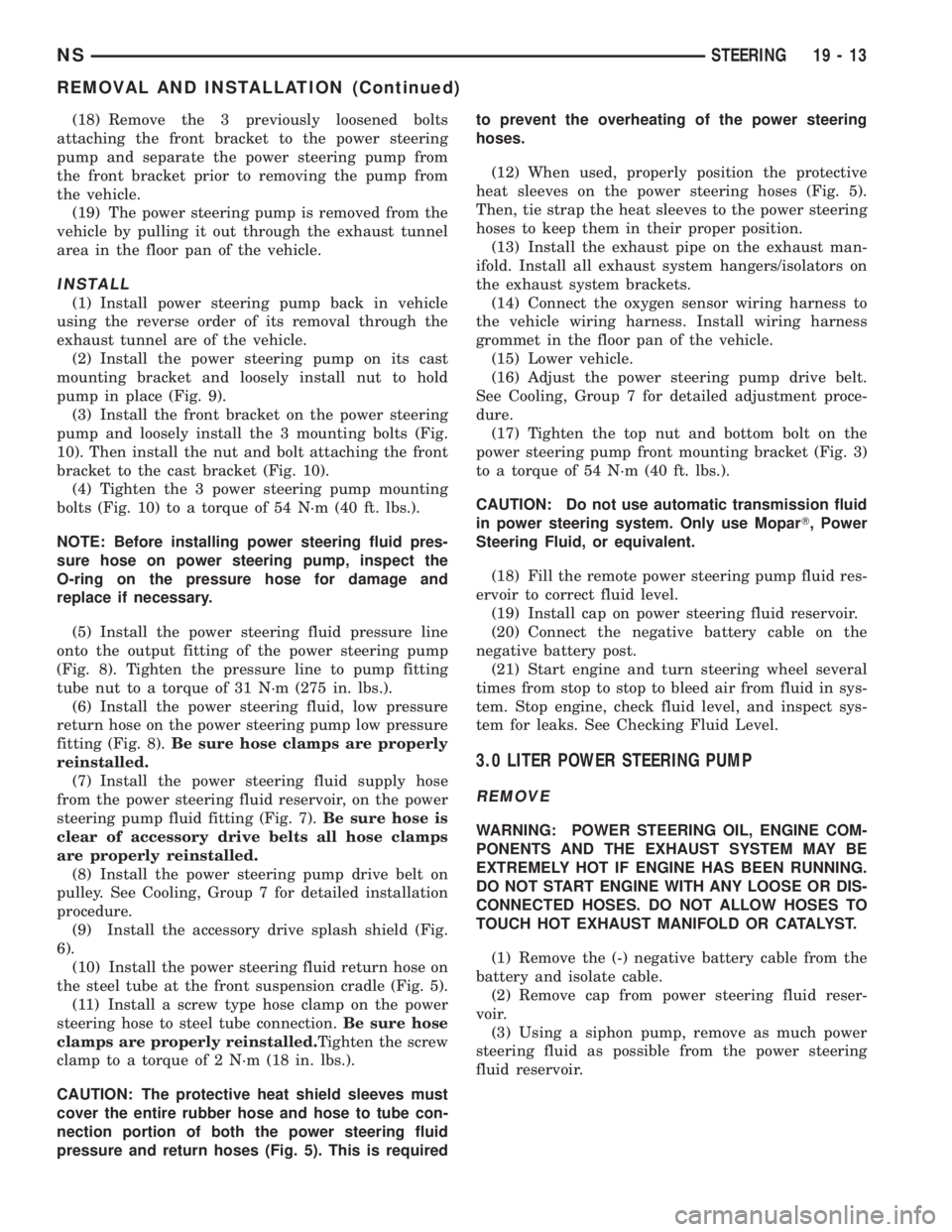

(4) Remove the serpentine accessory drive belt

from the engine (Fig. 11). See Cooling, Group 7 for

detailed removal procedure.

(5) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting, in the Lubri-

cation and Maintenance section of this service man-

ual for the required lifting procedure.

(6) Disconnect the oxygen sensor wiring harness

from the vehicle wiring harness. Access to connection

at vehicle wiring harness is through the oxygen sen-

sor wiring harness grommet in the floor pan of the

vehicle.

NOTE: The exhaust system needs to be removed

from the engine to allow for an area to remove the

power steering pump from the vehicle.

(7) Remove the catalytic converter from the

exhaust manifold. Then remove all the exhaust sys-

tem hangers/isolators from the brackets on the

exhaust system.

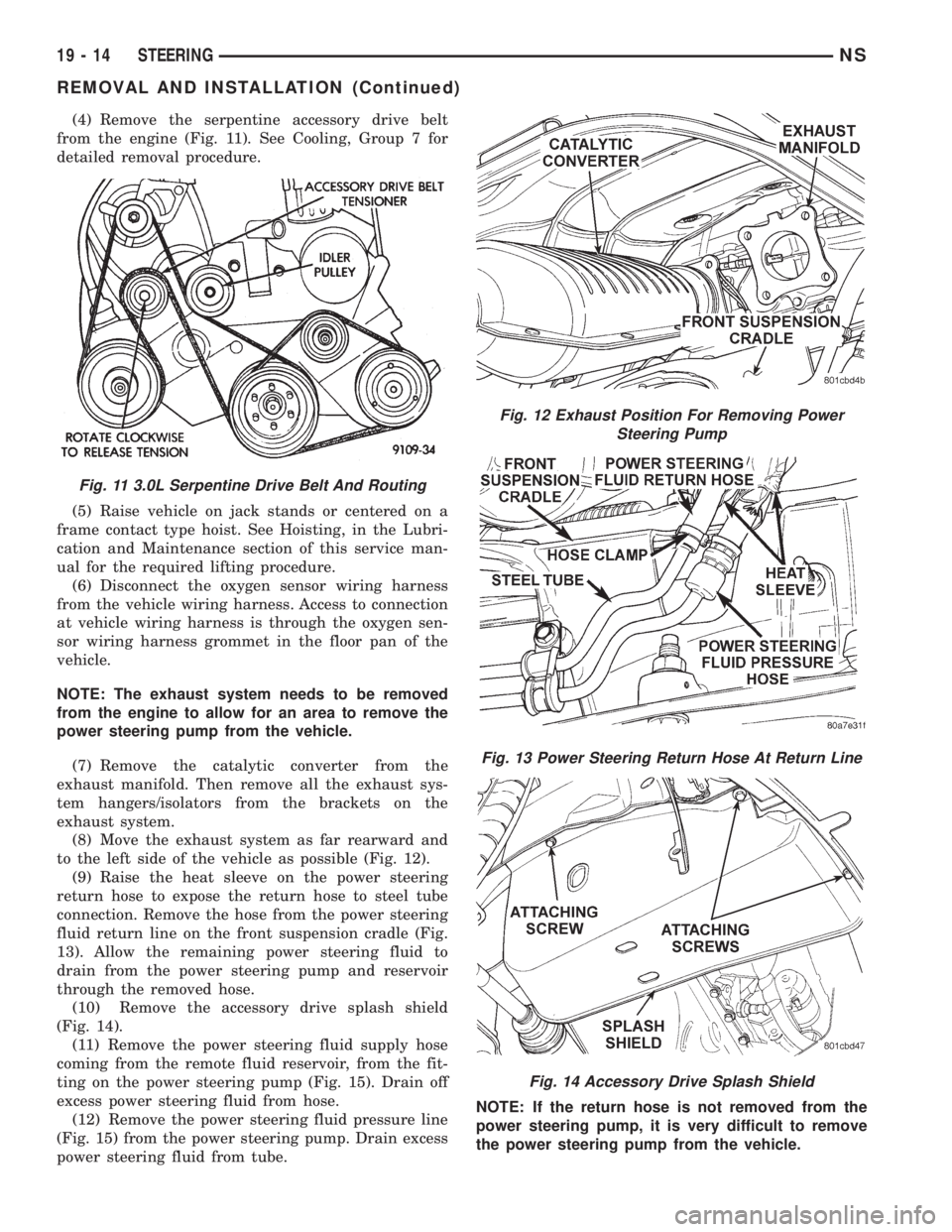

(8) Move the exhaust system as far rearward and

to the left side of the vehicle as possible (Fig. 12).

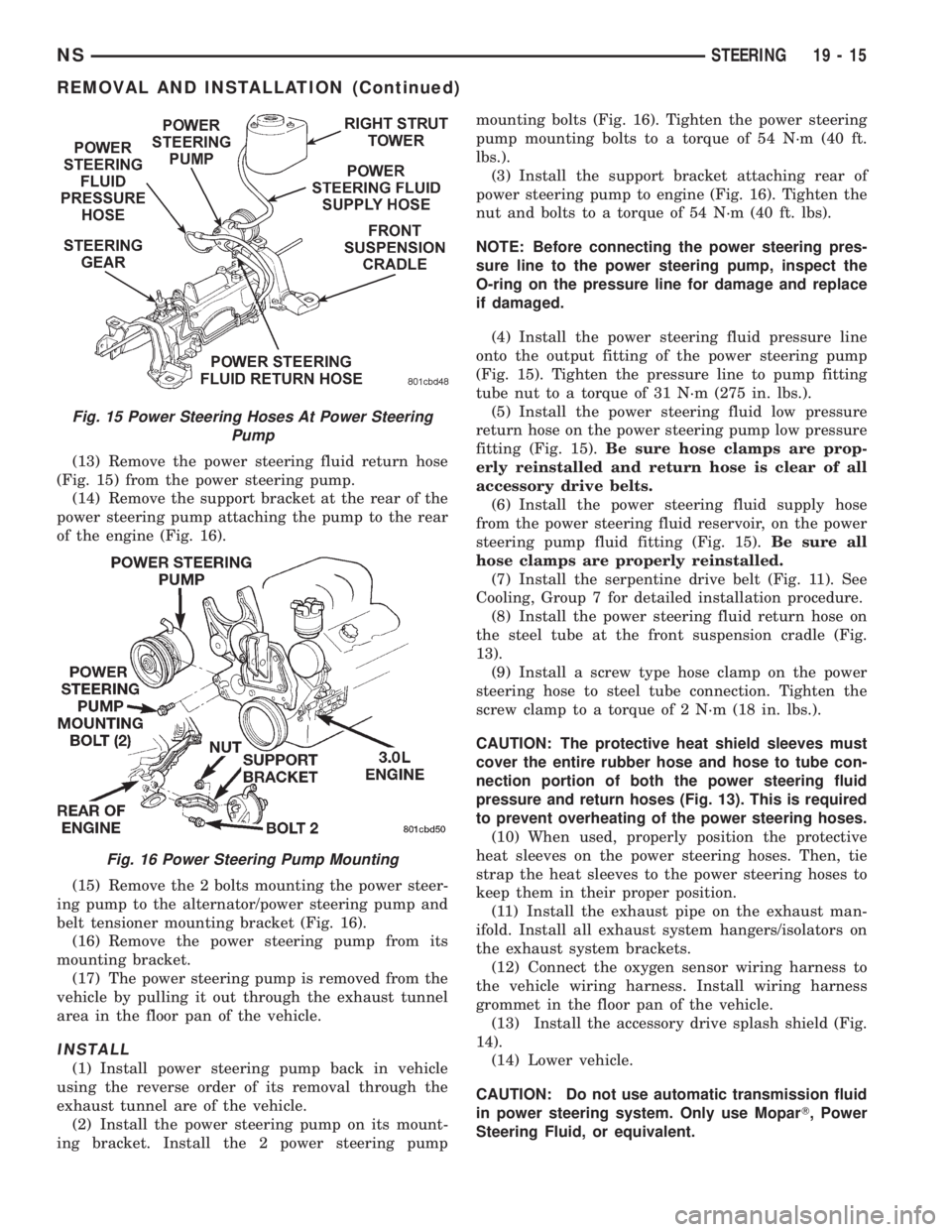

(9) Raise the heat sleeve on the power steering

return hose to expose the return hose to steel tube

connection. Remove the hose from the power steering

fluid return line on the front suspension cradle (Fig.

13). Allow the remaining power steering fluid to

drain from the power steering pump and reservoir

through the removed hose.

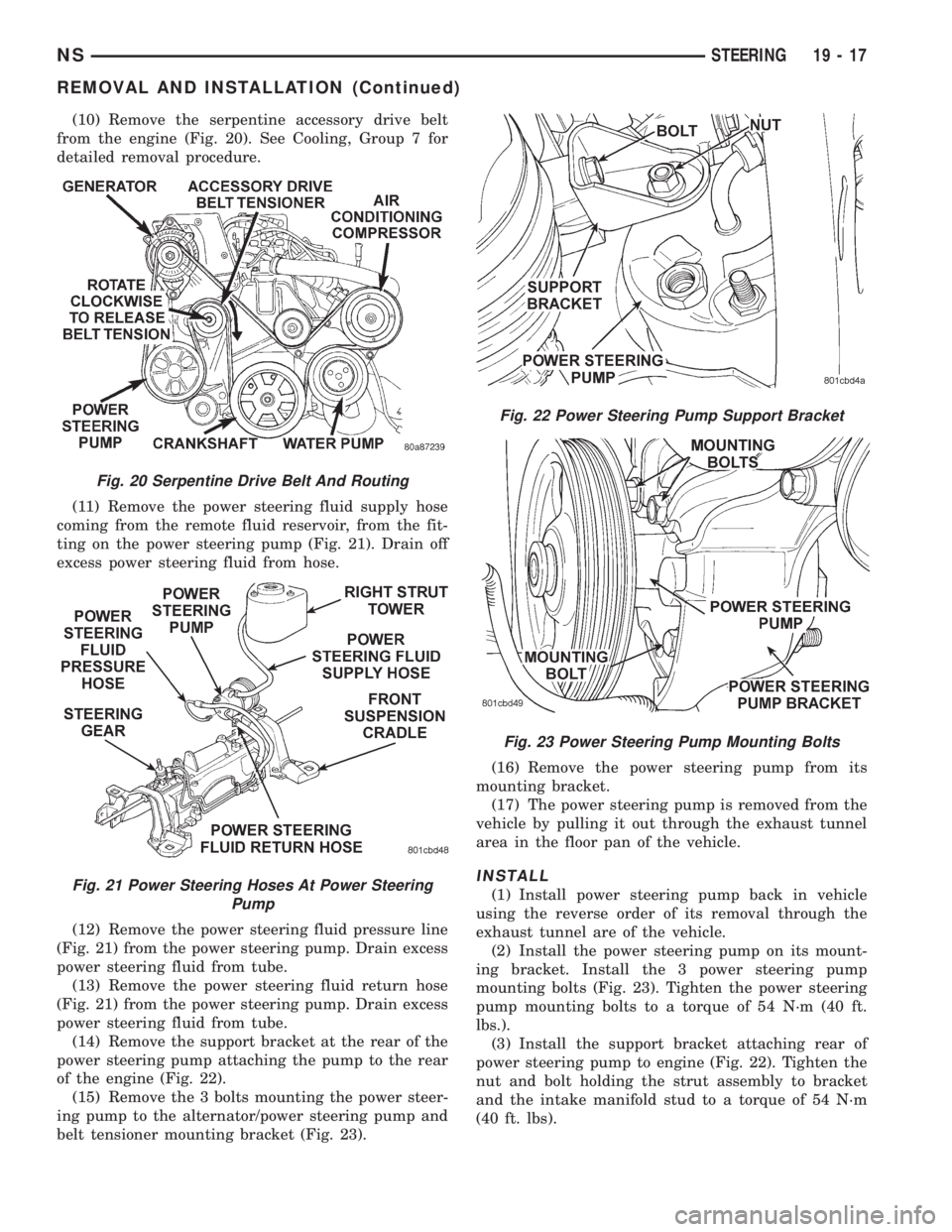

(10) Remove the accessory drive splash shield

(Fig. 14).

(11) Remove the power steering fluid supply hose

coming from the remote fluid reservoir, from the fit-

ting on the power steering pump (Fig. 15). Drain off

excess power steering fluid from hose.

(12) Remove the power steering fluid pressure line

(Fig. 15) from the power steering pump. Drain excess

power steering fluid from tube.NOTE: If the return hose is not removed from the

power steering pump, it is very difficult to remove

the power steering pump from the vehicle.

Fig. 11 3.0L Serpentine Drive Belt And Routing

Fig. 12 Exhaust Position For Removing Power

Steering Pump

Fig. 13 Power Steering Return Hose At Return Line

Fig. 14 Accessory Drive Splash Shield

19 - 14 STEERINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1441 of 1938

(13) Remove the power steering fluid return hose

(Fig. 15) from the power steering pump.

(14) Remove the support bracket at the rear of the

power steering pump attaching the pump to the rear

of the engine (Fig. 16).

(15) Remove the 2 bolts mounting the power steer-

ing pump to the alternator/power steering pump and

belt tensioner mounting bracket (Fig. 16).

(16) Remove the power steering pump from its

mounting bracket.

(17) The power steering pump is removed from the

vehicle by pulling it out through the exhaust tunnel

area in the floor pan of the vehicle.

INSTALL

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel are of the vehicle.

(2) Install the power steering pump on its mount-

ing bracket. Install the 2 power steering pumpmounting bolts (Fig. 16). Tighten the power steering

pump mounting bolts to a torque of 54 N´m (40 ft.

lbs.).

(3) Install the support bracket attaching rear of

power steering pump to engine (Fig. 16). Tighten the

nut and bolts to a torque of 54 N´m (40 ft. lbs).

NOTE: Before connecting the power steering pres-

sure line to the power steering pump, inspect the

O-ring on the pressure line for damage and replace

if damaged.

(4) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 15). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(5) Install the power steering fluid low pressure

return hose on the power steering pump low pressure

fitting (Fig. 15).Be sure hose clamps are prop-

erly reinstalled and return hose is clear of all

accessory drive belts.

(6) Install the power steering fluid supply hose

from the power steering fluid reservoir, on the power

steering pump fluid fitting (Fig. 15).Be sure all

hose clamps are properly reinstalled.

(7) Install the serpentine drive belt (Fig. 11). See

Cooling, Group 7 for detailed installation procedure.

(8) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig.

13).

(9) Install a screw type hose clamp on the power

steering hose to steel tube connection. Tighten the

screw clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 13). This is required

to prevent overheating of the power steering hoses.

(10) When used, properly position the protective

heat sleeves on the power steering hoses. Then, tie

strap the heat sleeves to the power steering hoses to

keep them in their proper position.

(11) Install the exhaust pipe on the exhaust man-

ifold. Install all exhaust system hangers/isolators on

the exhaust system brackets.

(12) Connect the oxygen sensor wiring harness to

the vehicle wiring harness. Install wiring harness

grommet in the floor pan of the vehicle.

(13) Install the accessory drive splash shield (Fig.

14).

(14) Lower vehicle.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use MoparT, Power

Steering Fluid, or equivalent.

Fig. 15 Power Steering Hoses At Power Steering

Pump

Fig. 16 Power Steering Pump Mounting

NSSTEERING 19 - 15

REMOVAL AND INSTALLATION (Continued)

Page 1443 of 1938

(10) Remove the serpentine accessory drive belt

from the engine (Fig. 20). See Cooling, Group 7 for

detailed removal procedure.

(11) Remove the power steering fluid supply hose

coming from the remote fluid reservoir, from the fit-

ting on the power steering pump (Fig. 21). Drain off

excess power steering fluid from hose.

(12) Remove the power steering fluid pressure line

(Fig. 21) from the power steering pump. Drain excess

power steering fluid from tube.

(13) Remove the power steering fluid return hose

(Fig. 21) from the power steering pump. Drain excess

power steering fluid from tube.

(14) Remove the support bracket at the rear of the

power steering pump attaching the pump to the rear

of the engine (Fig. 22).

(15) Remove the 3 bolts mounting the power steer-

ing pump to the alternator/power steering pump and

belt tensioner mounting bracket (Fig. 23).(16) Remove the power steering pump from its

mounting bracket.

(17) The power steering pump is removed from the

vehicle by pulling it out through the exhaust tunnel

area in the floor pan of the vehicle.

INSTALL

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel are of the vehicle.

(2) Install the power steering pump on its mount-

ing bracket. Install the 3 power steering pump

mounting bolts (Fig. 23). Tighten the power steering

pump mounting bolts to a torque of 54 N´m (40 ft.

lbs.).

(3) Install the support bracket attaching rear of

power steering pump to engine (Fig. 22). Tighten the

nut and bolt holding the strut assembly to bracket

and the intake manifold stud to a torque of 54 N´m

(40 ft. lbs).

Fig. 20 Serpentine Drive Belt And Routing

Fig. 21 Power Steering Hoses At Power Steering

Pump

Fig. 22 Power Steering Pump Support Bracket

Fig. 23 Power Steering Pump Mounting Bolts

NSSTEERING 19 - 17

REMOVAL AND INSTALLATION (Continued)

Page 1444 of 1938

NOTE: Before installing power steering pressure

hose on power steering pump, inspect the O-ring

on the power steering pressure hose for damage

and replace if required.

(4) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 21). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(5) Install the power steering fluid, low pressure

return hose on the power steering pump low pressure

fitting (Fig. 21).Be sure hose clamps are prop-

erly reinstalled.

(6) Install the power steering fluid supply hose

from the power steering fluid reservoir, on the power

steering pump fluid fitting (Fig. 21).Be sure hose is

clear of accessory drive belts and all hose

clamps are properly reinstalled.

(7) Install the serpentine drive belt (Fig. 20). See

Cooling, Group 7 for detailed installation procedure.

(8) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig.

18).

(9) Install a screw type hose clamp on the power

steering hose to steel tube connection.Be sure hose

clamps are properly reinstalled.Tighten the screw

clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 18). This is required

to keep the power steering hoses from becoming

overheated.

(10) When used, properly position the protective

heat sleeves on the power steering hoses (Fig. 18).

Then, tie strap the heat sleeves to the power steering

hoses to keep them in their proper position.

(11) Install the exhaust pipe on the exhaust man-

ifold. Install all exhaust system hangers/isolators on

the exhaust system brackets.

(12) Connect the oxygen sensor wiring harness to

the vehicle wiring harness. Install wiring harness

grommet in the floor pan of the vehicle.

(13) Install the accessory drive splash shield (Fig.

19).

(14) Lower vehicle.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use MoparT, Power

Steering Fluid, or equivalent.

(15) Fill the remote power steering pump fluid res-

ervoir to correct fluid level.

(16) Install cap on power steering fluid reservoir.(17) Connect the negative battery cable on the

negative battery post.

(18) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

POWER STEERING FLUID RESERVOIR TO PUMP

SUPPLY HOSE

REMOVE

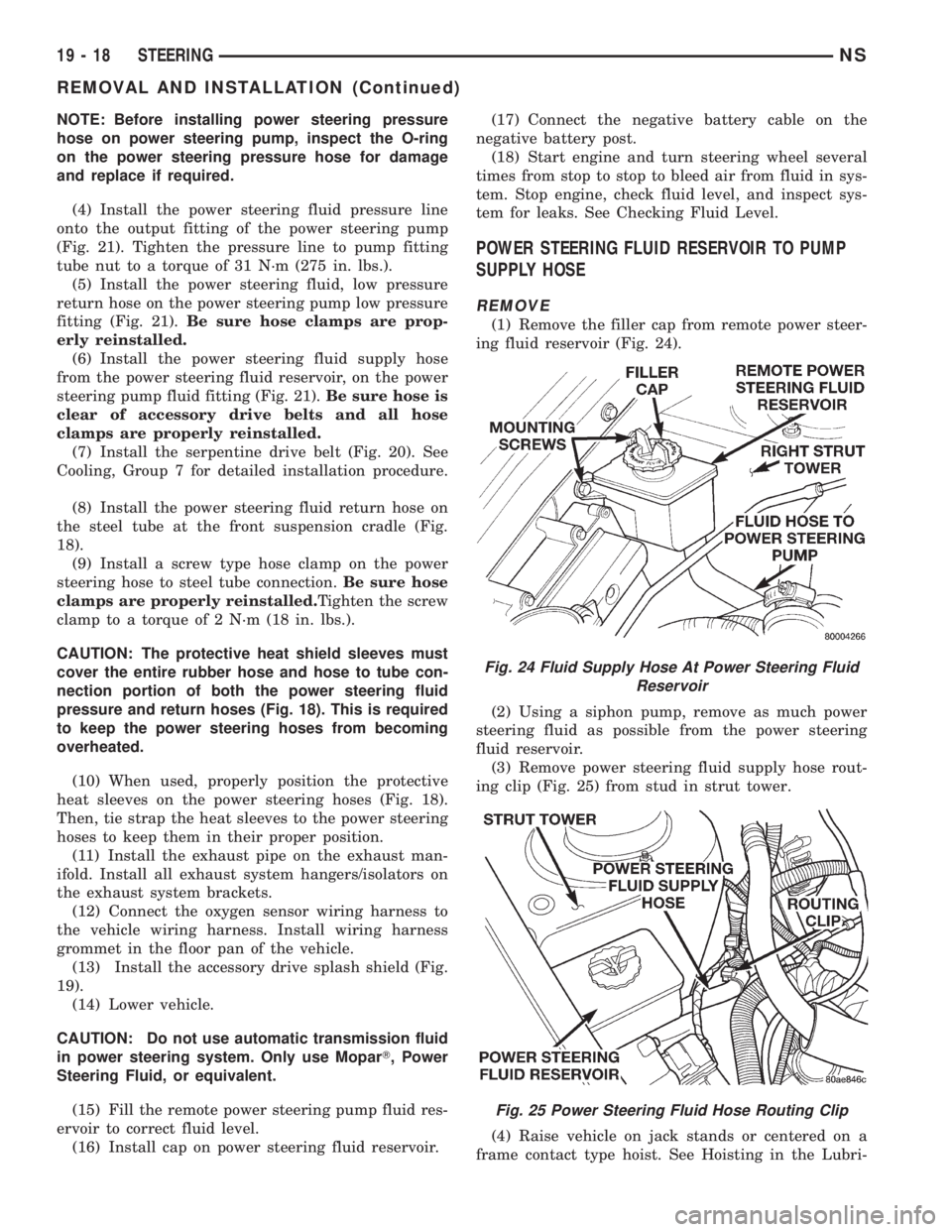

(1) Remove the filler cap from remote power steer-

ing fluid reservoir (Fig. 24).

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) Remove power steering fluid supply hose rout-

ing clip (Fig. 25) from stud in strut tower.

(4) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

Fig. 24 Fluid Supply Hose At Power Steering Fluid

Reservoir

Fig. 25 Power Steering Fluid Hose Routing Clip

19 - 18 STEERINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1474 of 1938

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.

(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine and turn

the steering wheel slowly from lock to lock.

(8) Stop the engine and check the fluid level and

refill as required.

(9) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

REMOVAL AND INSTALLATION

POWER STEERING PUMPÐ2.5L DIESEL

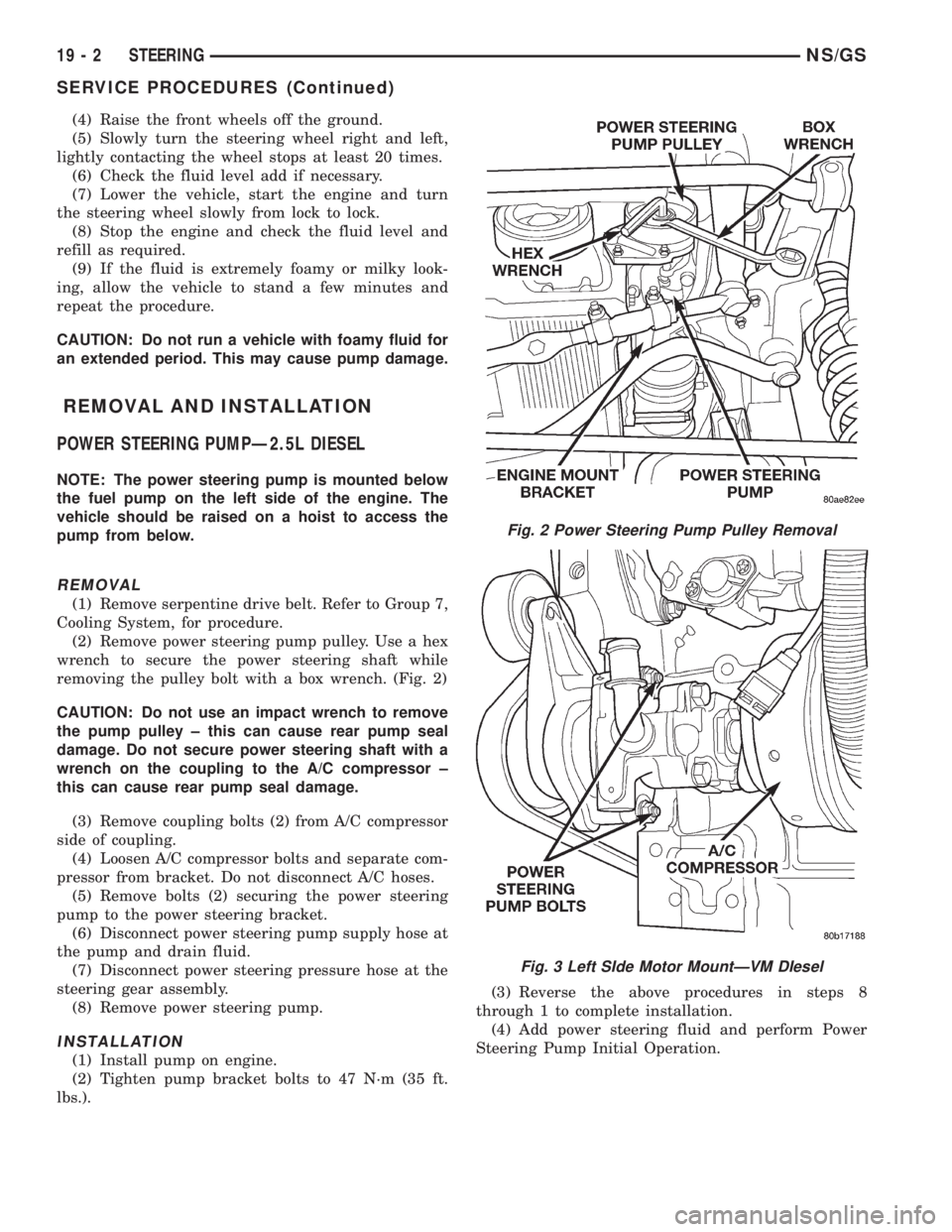

NOTE: The power steering pump is mounted below

the fuel pump on the left side of the engine. The

vehicle should be raised on a hoist to access the

pump from below.

REMOVAL

(1) Remove serpentine drive belt. Refer to Group 7,

Cooling System, for procedure.

(2) Remove power steering pump pulley. Use a hex

wrench to secure the power steering shaft while

removing the pulley bolt with a box wrench. (Fig. 2)

CAUTION: Do not use an impact wrench to remove

the pump pulley ± this can cause rear pump seal

damage. Do not secure power steering shaft with a

wrench on the coupling to the A/C compressor ±

this can cause rear pump seal damage.

(3) Remove coupling bolts (2) from A/C compressor

side of coupling.

(4) Loosen A/C compressor bolts and separate com-

pressor from bracket. Do not disconnect A/C hoses.

(5) Remove bolts (2) securing the power steering

pump to the power steering bracket.

(6) Disconnect power steering pump supply hose at

the pump and drain fluid.

(7) Disconnect power steering pressure hose at the

steering gear assembly.

(8) Remove power steering pump.

INSTALLATION

(1) Install pump on engine.

(2) Tighten pump bracket bolts to 47 N´m (35 ft.

lbs.).(3) Reverse the above procedures in steps 8

through 1 to complete installation.

(4) Add power steering fluid and perform Power

Steering Pump Initial Operation.

Fig. 2 Power Steering Pump Pulley Removal

Fig. 3 Left SIde Motor MountÐVM DIesel

19 - 2 STEERINGNS/GS

SERVICE PROCEDURES (Continued)

Page 1476 of 1938

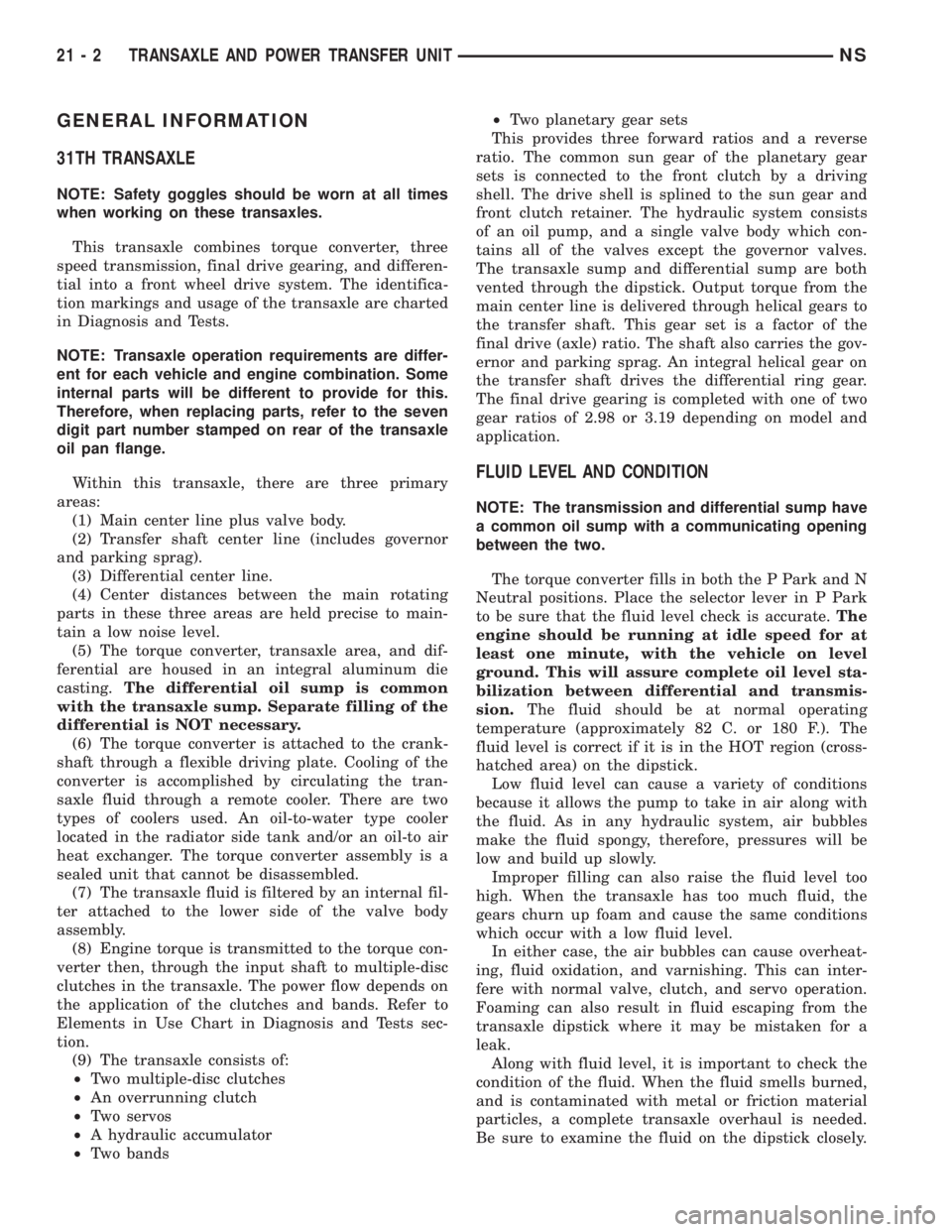

GENERAL INFORMATION

31TH TRANSAXLE

NOTE: Safety goggles should be worn at all times

when working on these transaxles.

This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system. The identifica-

tion markings and usage of the transaxle are charted

in Diagnosis and Tests.

NOTE: Transaxle operation requirements are differ-

ent for each vehicle and engine combination. Some

internal parts will be different to provide for this.

Therefore, when replacing parts, refer to the seven

digit part number stamped on rear of the transaxle

oil pan flange.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

(4) Center distances between the main rotating

parts in these three areas are held precise to main-

tain a low noise level.

(5) The torque converter, transaxle area, and dif-

ferential are housed in an integral aluminum die

casting.The differential oil sump is common

with the transaxle sump. Separate filling of the

differential is NOT necessary.

(6) The torque converter is attached to the crank-

shaft through a flexible driving plate. Cooling of the

converter is accomplished by circulating the tran-

saxle fluid through a remote cooler. There are two

types of coolers used. An oil-to-water type cooler

located in the radiator side tank and/or an oil-to air

heat exchanger. The torque converter assembly is a

sealed unit that cannot be disassembled.

(7) The transaxle fluid is filtered by an internal fil-

ter attached to the lower side of the valve body

assembly.

(8) Engine torque is transmitted to the torque con-

verter then, through the input shaft to multiple-disc

clutches in the transaxle. The power flow depends on

the application of the clutches and bands. Refer to

Elements in Use Chart in Diagnosis and Tests sec-

tion.

(9) The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The drive shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump, and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor of the

final drive (axle) ratio. The shaft also carries the gov-

ernor and parking sprag. An integral helical gear on

the transfer shaft drives the differential ring gear.

The final drive gearing is completed with one of two

gear ratios of 2.98 or 3.19 depending on model and

application.

FLUID LEVEL AND CONDITION

NOTE: The transmission and differential sump have

a common oil sump with a communicating opening

between the two.

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground. This will assure complete oil level sta-

bilization between differential and transmis-

sion.The fluid should be at normal operating

temperature (approximately 82 C. or 180 F.). The

fluid level is correct if it is in the HOT region (cross-

hatched area) on the dipstick.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, the air bubbles can cause overheat-

ing, fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and servo operation.

Foaming can also result in fluid escaping from the

transaxle dipstick where it may be mistaken for a

leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed.

Be sure to examine the fluid on the dipstick closely.

21 - 2 TRANSAXLE AND POWER TRANSFER UNITNS

Page 1538 of 1938

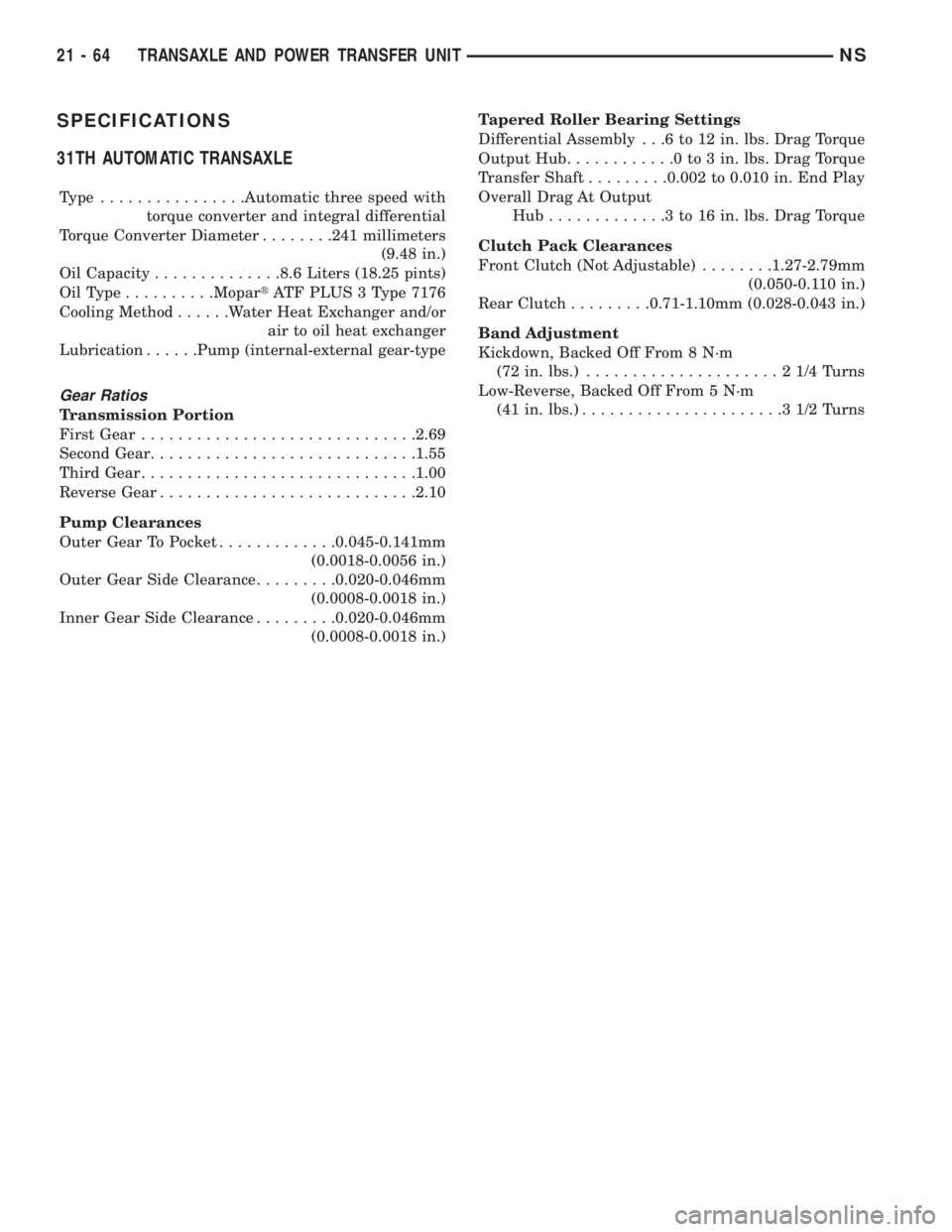

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE

Type ................Automatic three speed with

torque converter and integral differential

Torque Converter Diameter........241 millimeters

(9.48 in.)

Oil Capacity..............8.6 Liters (18.25 pints)

OilType..........MopartATF PLUS 3 Type 7176

Cooling Method......Water Heat Exchanger and/or

air to oil heat exchanger

Lubrication......Pump (internal-external gear-type

Gear Ratios

Transmission Portion

First Gear..............................2.69

Second Gear.............................1.55

Third Gear..............................1.00

Reverse Gear............................2.10

Pump Clearances

Outer Gear To Pocket.............0.045-0.141mm

(0.0018-0.0056 in.)

Outer Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Inner Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)Tapered Roller Bearing Settings

Differential Assembly . . .6 to 12 in. lbs. Drag Torque

Output Hub............0to3in.lbs. Drag Torque

Transfer Shaft.........0.002 to 0.010 in. End Play

Overall Drag At Output

Hub.............3to16in.lbs. Drag Torque

Clutch Pack Clearances

Front Clutch (Not Adjustable)........1.27-2.79mm

(0.050-0.110 in.)

Rear Clutch.........0.71-1.10mm (0.028-0.043 in.)

Band Adjustment

Kickdown, Backed Off From 8 N´m

(72 in. lbs.).....................21/4Turns

Low-Reverse, Backed Off From 5 N´m

(41 in. lbs.)......................31/2Turns

21 - 64 TRANSAXLE AND POWER TRANSFER UNITNS

Page 1544 of 1938

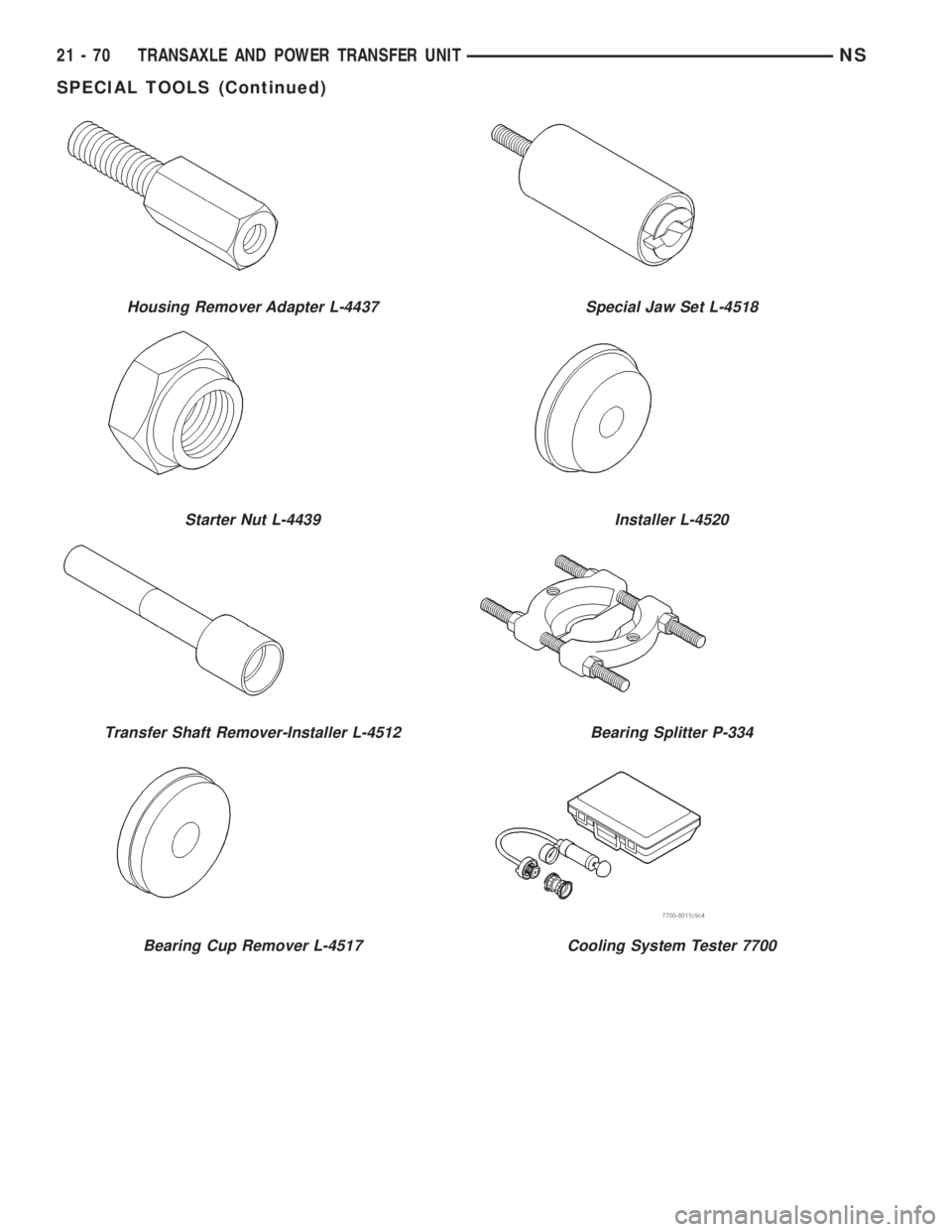

Housing Remover Adapter L-4437

Starter Nut L-4439

Transfer Shaft Remover-Installer L-4512

Bearing Cup Remover L-4517

Special Jaw Set L-4518

Installer L-4520

Bearing Splitter P-334

Cooling System Tester 7700

21 - 70 TRANSAXLE AND POWER TRANSFER UNITNS

SPECIAL TOOLS (Continued)

Page 1546 of 1938

OPERATION

The gear ratios for the 41TE transaxle are as fol-

lows:

²1stÐ2.84

²2ndÐ1.57

²3rdÐ1.00

²ODÐ0.69

²ReverseÐ2.21

Final Drive Ratio is dependent on which engine

option is selected.

²2.4 Liter: 3.91 FDR

²3.3 Liter: 3.62 FDR

²3.8 Liter: 3.45 FDR

The torque converter clutch is available in 2nd,

direct, or overdrive gear;. The shift lever is conven-

tional with six positions: P, R, N, OD, 3, and L avail-

able. When OD is selected the transaxle shifts

through all four speeds with torque converter clutch

available in overdrive. This position is recommended

for most driving. The 3 position is tailored for use in

hilly or mountainous driving. When 3 is selected, the

transmission uses only 1st, 2nd, and direct gears

with 2nd-direct shift delayed to 40 mph or greater.

When operating in 3 or L positions torque converter

clutch application occurs in direct gear. This

improves transmission cooling under heavy loads. If

high engine coolant temperature occurs, the torque

converter clutch will also engage in 2nd gear. The L

position provides maximum engine braking for

descending steep grades. Unlike most current tran-

saxles, upshifts are provided to 2nd or direct gear at

peak engine speeds if the accelerator is depressed.

This provides engine over-speed protection and max-

imum performance.

FLUID LEVEL AND CONDITION

NOTE: The transmission and differential sump have

a common oil sump with an opening between the

two.

The torque converter fills in both the (P) Park and

(N) Neutral positions. Place the selector lever in (P)

Park to check the fluid level.The engine should be

running at idle speed for at least one minute,

with the vehicle on level ground. This will

assure complete oil level stabilization between

differential and transmission.The fluid should be

at normal operating temperature (approximately 82

C. or 180 F.). The fluid level is correct if it is in the

HOTregion (cross-hatched area) on the oil level indi-

cator.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, the air bubbles can cause overheat-

ing, fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed.

Be sure to examine the fluid on the dipstick closely.

If there is any doubt about its condition, drain out a

sample for a double check.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

the 41TE transaxle. MOPARtATF PLUS 3 (Auto-

matic Transmission FluidÐtype 7176) should be used

to aid in assuring optimum transmission perfor-

mance. Fluids of the type labeled DEXRON II Auto-

matic Transmission Fluid arenot recommended.It

is important that the transmission fluid be main-

tained at the prescribed level using the recommended

fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the

addition of any fluids to the transaxle, other than the

fluid listed above. An exception to this policy is the

use of special dyes to aid in detecting fluid leaks. The

use of transmission sealers should be avoided, since

they may adversely affect seals.

DESCRIPTION AND OPERATION

CLUTCH AND GEAR

The transaxle consists of:

²Three multiple disc input clutches

²Two multiple disc grounded clutches

²Four hydraulic accumulators

²Two planetary gear sets

This provides four forward ratios and a reverse

ratio. The input clutch-apply pistons were designed

with centrifugally balanced oil cavities so that quick

response and good control can be achieved at any

speed. A push/pull piston is incorporated for two of

the three input clutches.

21 - 72 TRANSAXLE AND POWER TRANSFER UNITNS

GENERAL INFORMATION (Continued)