ECU CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1859 of 1938

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES

When diagnosing electrical problems in the auxil-

iary rear heater or rear A/C system, refer to Group

8W, Wiring Diagrams.

When diagnosing problems in the auxiliary sys-

tems, refer to diagnostic sections for front heater A/C.

REMOVAL AND INSTALLATION

AIR DISTRIBUTION DUCT-A/C

REMOVAL

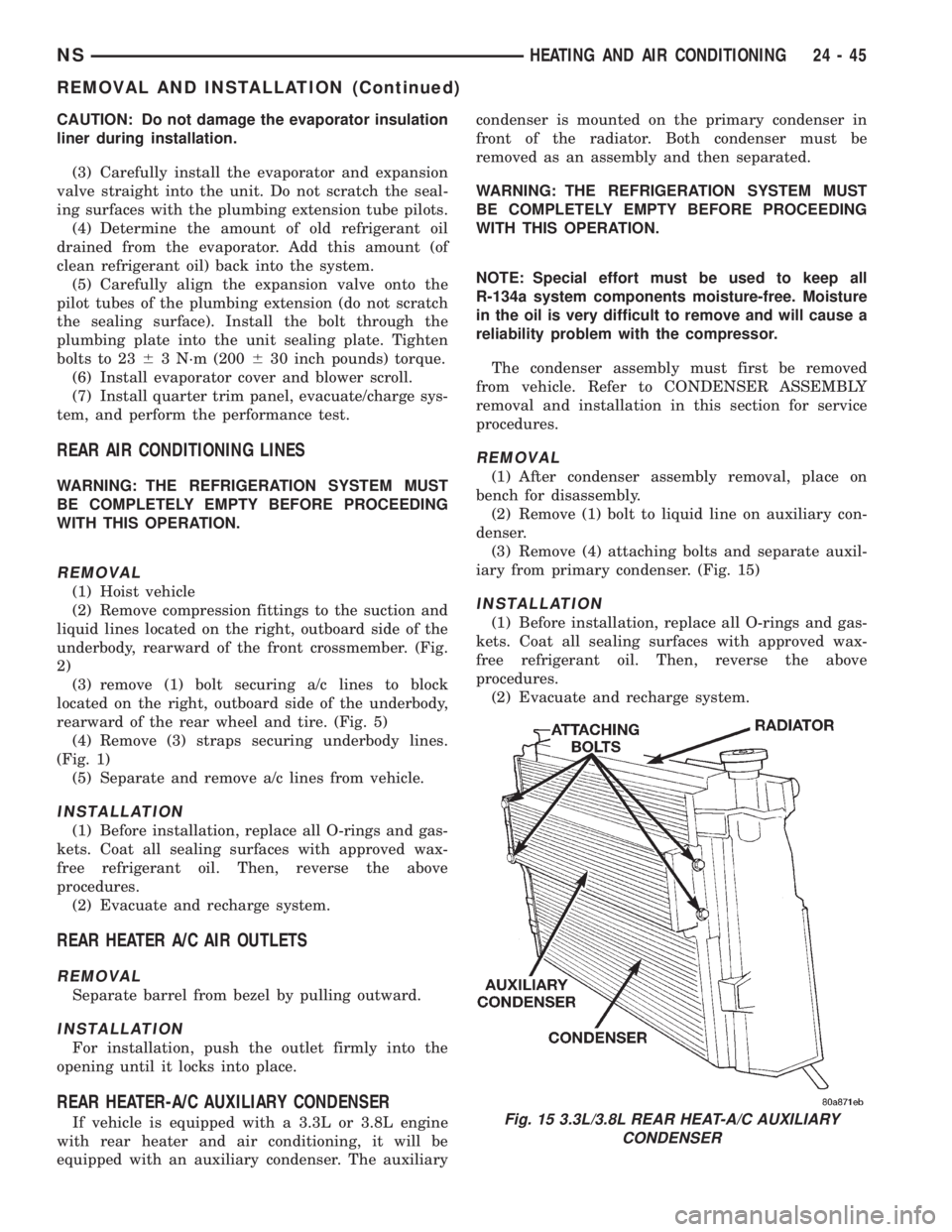

(1) Remove quarter trim panel, D-pillar, and head-

liner (Fig. 8). Refer to Group 23, Body.

(2) Remove screws securing D-pillar duct to quar-

ter panel. Pull duct up and away from unit.

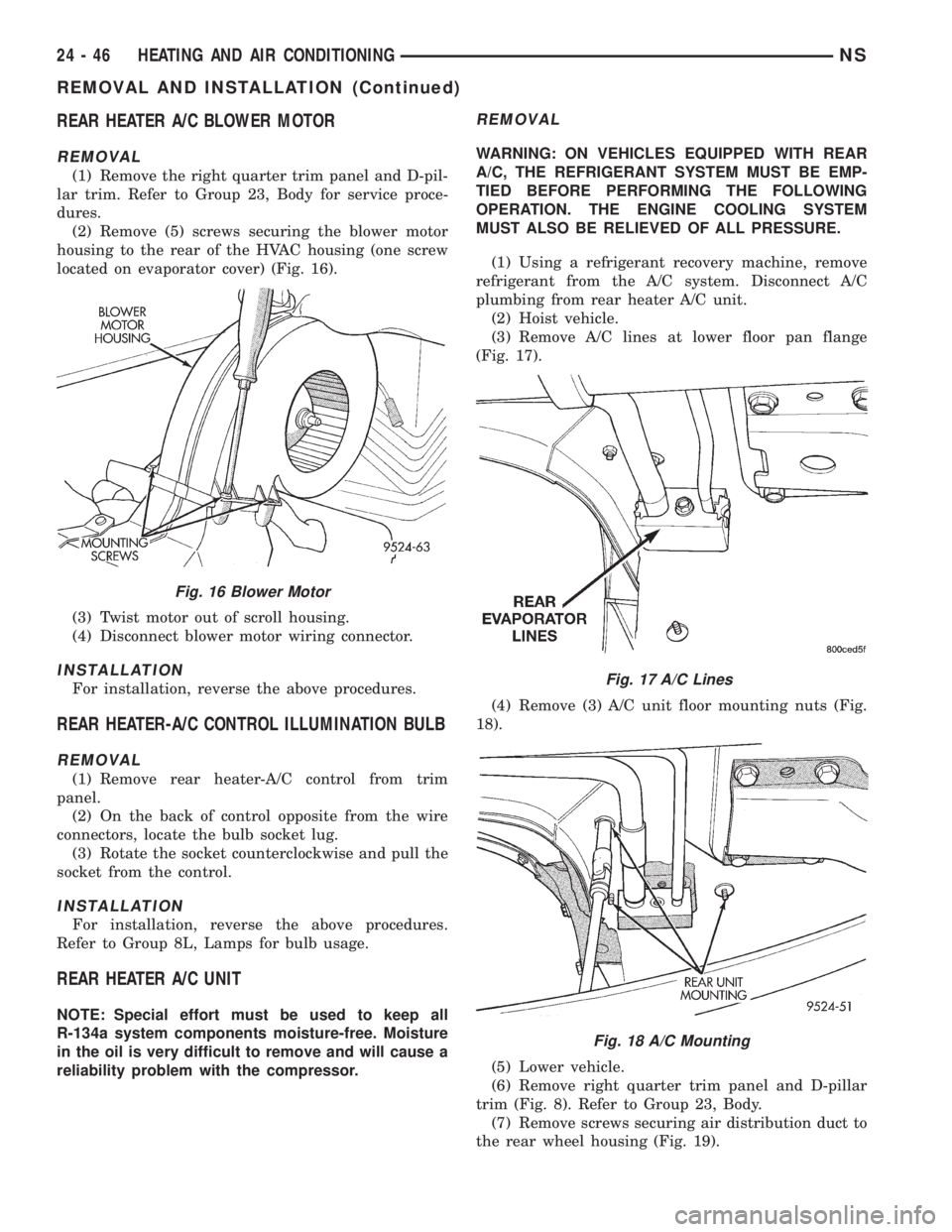

(3) Remove screws securing duct to rear header

(Fig. 9).

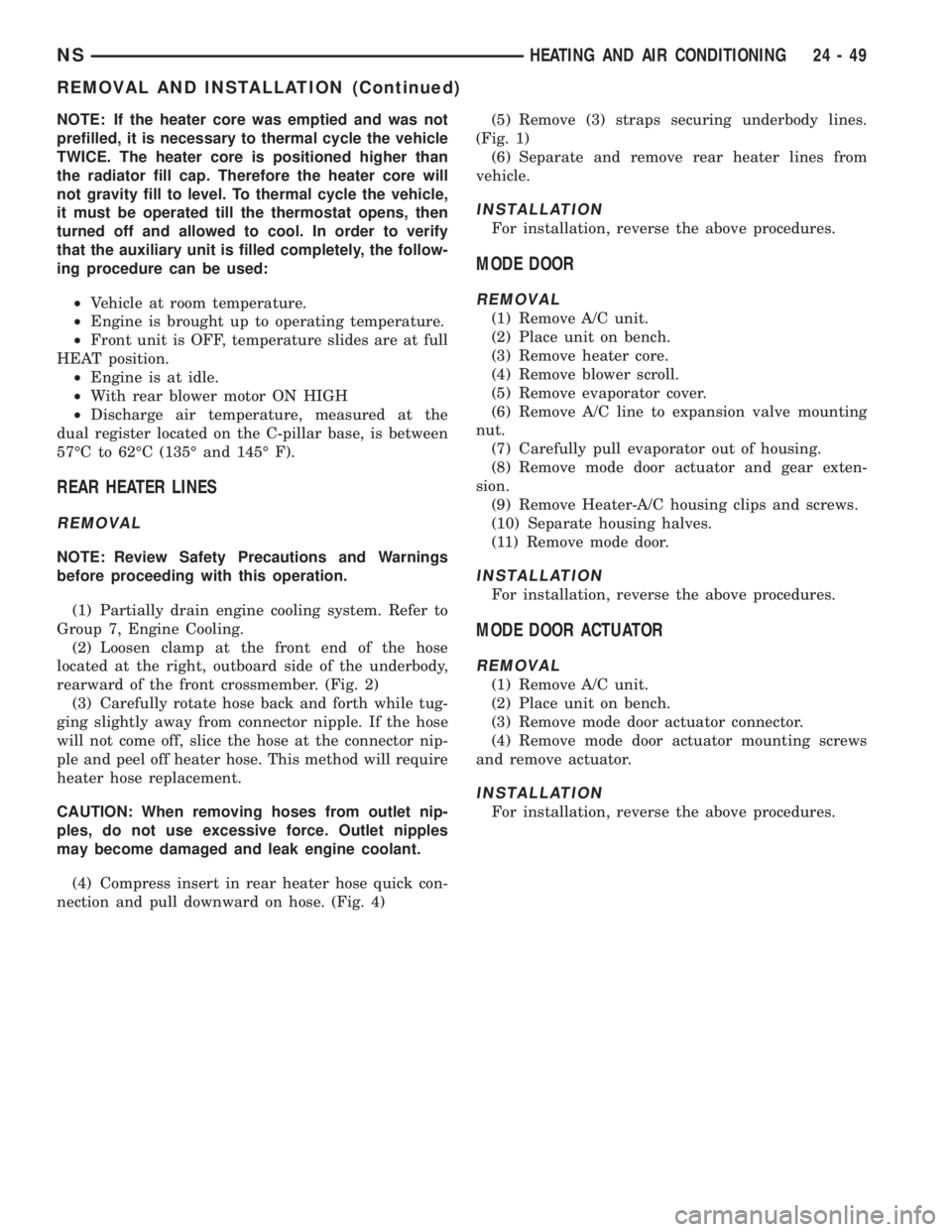

(4) Remove screws securing duct to right and left

rails (Fig. 10).

INSTALLATION

For installation, reverse the above procedures.

AIR DISTRIBUTION DUCT-HEATER

REMOVAL

(1) Remove quarter trim panel and D-pillar (Fig.

8) and (Fig. 11). Refer to Group 23, Body.

(2) Remove screws securing lower heat duct to

housing.

INSTALLATION

For installation, reverse the above procedures.

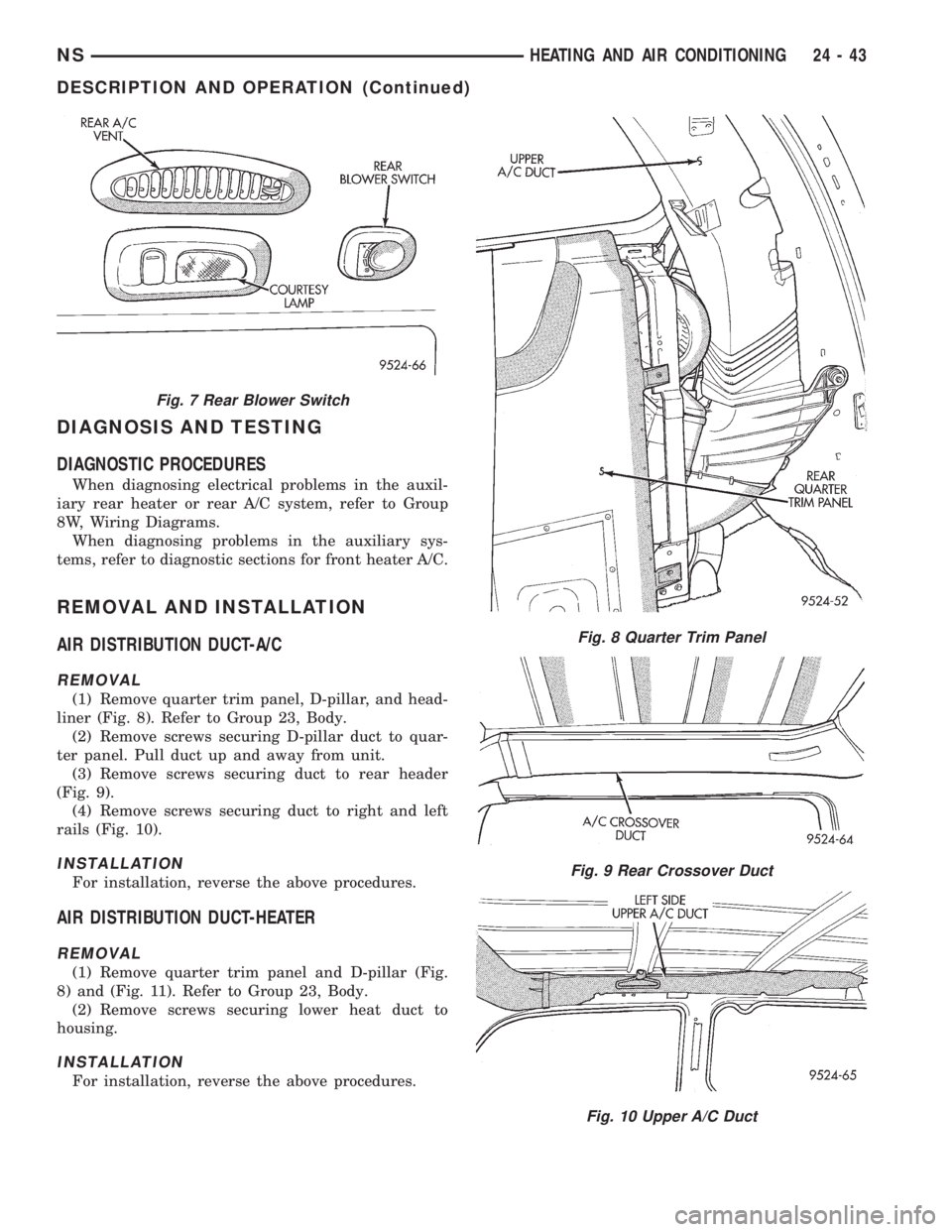

Fig. 7 Rear Blower Switch

Fig. 8 Quarter Trim Panel

Fig. 9 Rear Crossover Duct

Fig. 10 Upper A/C Duct

NSHEATING AND AIR CONDITIONING 24 - 43

DESCRIPTION AND OPERATION (Continued)

Page 1861 of 1938

CAUTION: Do not damage the evaporator insulation

liner during installation.

(3) Carefully install the evaporator and expansion

valve straight into the unit. Do not scratch the seal-

ing surfaces with the plumbing extension tube pilots.

(4) Determine the amount of old refrigerant oil

drained from the evaporator. Add this amount (of

clean refrigerant oil) back into the system.

(5) Carefully align the expansion valve onto the

pilot tubes of the plumbing extension (do not scratch

the sealing surface). Install the bolt through the

plumbing plate into the unit sealing plate. Tighten

bolts to 2363 N´m (200630 inch pounds) torque.

(6) Install evaporator cover and blower scroll.

(7) Install quarter trim panel, evacuate/charge sys-

tem, and perform the performance test.

REAR AIR CONDITIONING LINES

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

REMOVAL

(1) Hoist vehicle

(2) Remove compression fittings to the suction and

liquid lines located on the right, outboard side of the

underbody, rearward of the front crossmember. (Fig.

2)

(3) remove (1) bolt securing a/c lines to block

located on the right, outboard side of the underbody,

rearward of the rear wheel and tire. (Fig. 5)

(4) Remove (3) straps securing underbody lines.

(Fig. 1)

(5) Separate and remove a/c lines from vehicle.

INSTALLATION

(1) Before installation, replace all O-rings and gas-

kets. Coat all sealing surfaces with approved wax-

free refrigerant oil. Then, reverse the above

procedures.

(2) Evacuate and recharge system.

REAR HEATER A/C AIR OUTLETS

REMOVAL

Separate barrel from bezel by pulling outward.

INSTALLATION

For installation, push the outlet firmly into the

opening until it locks into place.

REAR HEATER-A/C AUXILIARY CONDENSER

If vehicle is equipped with a 3.3L or 3.8L engine

with rear heater and air conditioning, it will be

equipped with an auxiliary condenser. The auxiliarycondenser is mounted on the primary condenser in

front of the radiator. Both condenser must be

removed as an assembly and then separated.

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

The condenser assembly must first be removed

from vehicle. Refer to CONDENSER ASSEMBLY

removal and installation in this section for service

procedures.

REMOVAL

(1) After condenser assembly removal, place on

bench for disassembly.

(2) Remove (1) bolt to liquid line on auxiliary con-

denser.

(3) Remove (4) attaching bolts and separate auxil-

iary from primary condenser. (Fig. 15)

INSTALLATION

(1) Before installation, replace all O-rings and gas-

kets. Coat all sealing surfaces with approved wax-

free refrigerant oil. Then, reverse the above

procedures.

(2) Evacuate and recharge system.

Fig. 15 3.3L/3.8L REAR HEAT-A/C AUXILIARY

CONDENSER

NSHEATING AND AIR CONDITIONING 24 - 45

REMOVAL AND INSTALLATION (Continued)

Page 1862 of 1938

REAR HEATER A/C BLOWER MOTOR

REMOVAL

(1) Remove the right quarter trim panel and D-pil-

lar trim. Refer to Group 23, Body for service proce-

dures.

(2) Remove (5) screws securing the blower motor

housing to the rear of the HVAC housing (one screw

located on evaporator cover) (Fig. 16).

(3) Twist motor out of scroll housing.

(4) Disconnect blower motor wiring connector.

INSTALLATION

For installation, reverse the above procedures.

REAR HEATER-A/C CONTROL ILLUMINATION BULB

REMOVAL

(1) Remove rear heater-A/C control from trim

panel.

(2) On the back of control opposite from the wire

connectors, locate the bulb socket lug.

(3) Rotate the socket counterclockwise and pull the

socket from the control.

INSTALLATION

For installation, reverse the above procedures.

Refer to Group 8L, Lamps for bulb usage.

REAR HEATER A/C UNIT

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH REAR

A/C, THE REFRIGERANT SYSTEM MUST BE EMP-

TIED BEFORE PERFORMING THE FOLLOWING

OPERATION. THE ENGINE COOLING SYSTEM

MUST ALSO BE RELIEVED OF ALL PRESSURE.

(1) Using a refrigerant recovery machine, remove

refrigerant from the A/C system. Disconnect A/C

plumbing from rear heater A/C unit.

(2) Hoist vehicle.

(3) Remove A/C lines at lower floor pan flange

(Fig. 17).

(4) Remove (3) A/C unit floor mounting nuts (Fig.

18).

(5) Lower vehicle.

(6) Remove right quarter trim panel and D-pillar

trim (Fig. 8). Refer to Group 23, Body.

(7) Remove screws securing air distribution duct to

the rear wheel housing (Fig. 19).

Fig. 16 Blower Motor

Fig. 17 A/C Lines

Fig. 18 A/C Mounting

24 - 46 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1865 of 1938

NOTE: If the heater core was emptied and was not

prefilled, it is necessary to thermal cycle the vehicle

TWICE. The heater core is positioned higher than

the radiator fill cap. Therefore the heater core will

not gravity fill to level. To thermal cycle the vehicle,

it must be operated till the thermostat opens, then

turned off and allowed to cool. In order to verify

that the auxiliary unit is filled completely, the follow-

ing procedure can be used:

²Vehicle at room temperature.

²Engine is brought up to operating temperature.

²Front unit is OFF, temperature slides are at full

HEAT position.

²Engine is at idle.

²With rear blower motor ON HIGH

²Discharge air temperature, measured at the

dual register located on the C-pillar base, is between

57ÉC to 62ÉC (135É and 145É F).

REAR HEATER LINES

REMOVAL

NOTE: Review Safety Precautions and Warnings

before proceeding with this operation.

(1) Partially drain engine cooling system. Refer to

Group 7, Engine Cooling.

(2) Loosen clamp at the front end of the hose

located at the right, outboard side of the underbody,

rearward of the front crossmember. (Fig. 2)

(3) Carefully rotate hose back and forth while tug-

ging slightly away from connector nipple. If the hose

will not come off, slice the hose at the connector nip-

ple and peel off heater hose. This method will require

heater hose replacement.

CAUTION: When removing hoses from outlet nip-

ples, do not use excessive force. Outlet nipples

may become damaged and leak engine coolant.

(4) Compress insert in rear heater hose quick con-

nection and pull downward on hose. (Fig. 4)(5) Remove (3) straps securing underbody lines.

(Fig. 1)

(6) Separate and remove rear heater lines from

vehicle.

INSTALLATION

For installation, reverse the above procedures.

MODE DOOR

REMOVAL

(1) Remove A/C unit.

(2) Place unit on bench.

(3) Remove heater core.

(4) Remove blower scroll.

(5) Remove evaporator cover.

(6) Remove A/C line to expansion valve mounting

nut.

(7) Carefully pull evaporator out of housing.

(8) Remove mode door actuator and gear exten-

sion.

(9) Remove Heater-A/C housing clips and screws.

(10) Separate housing halves.

(11) Remove mode door.

INSTALLATION

For installation, reverse the above procedures.

MODE DOOR ACTUATOR

REMOVAL

(1) Remove A/C unit.

(2) Place unit on bench.

(3) Remove mode door actuator connector.

(4) Remove mode door actuator mounting screws

and remove actuator.

INSTALLATION

For installation, reverse the above procedures.

NSHEATING AND AIR CONDITIONING 24 - 49

REMOVAL AND INSTALLATION (Continued)

Page 1891 of 1938

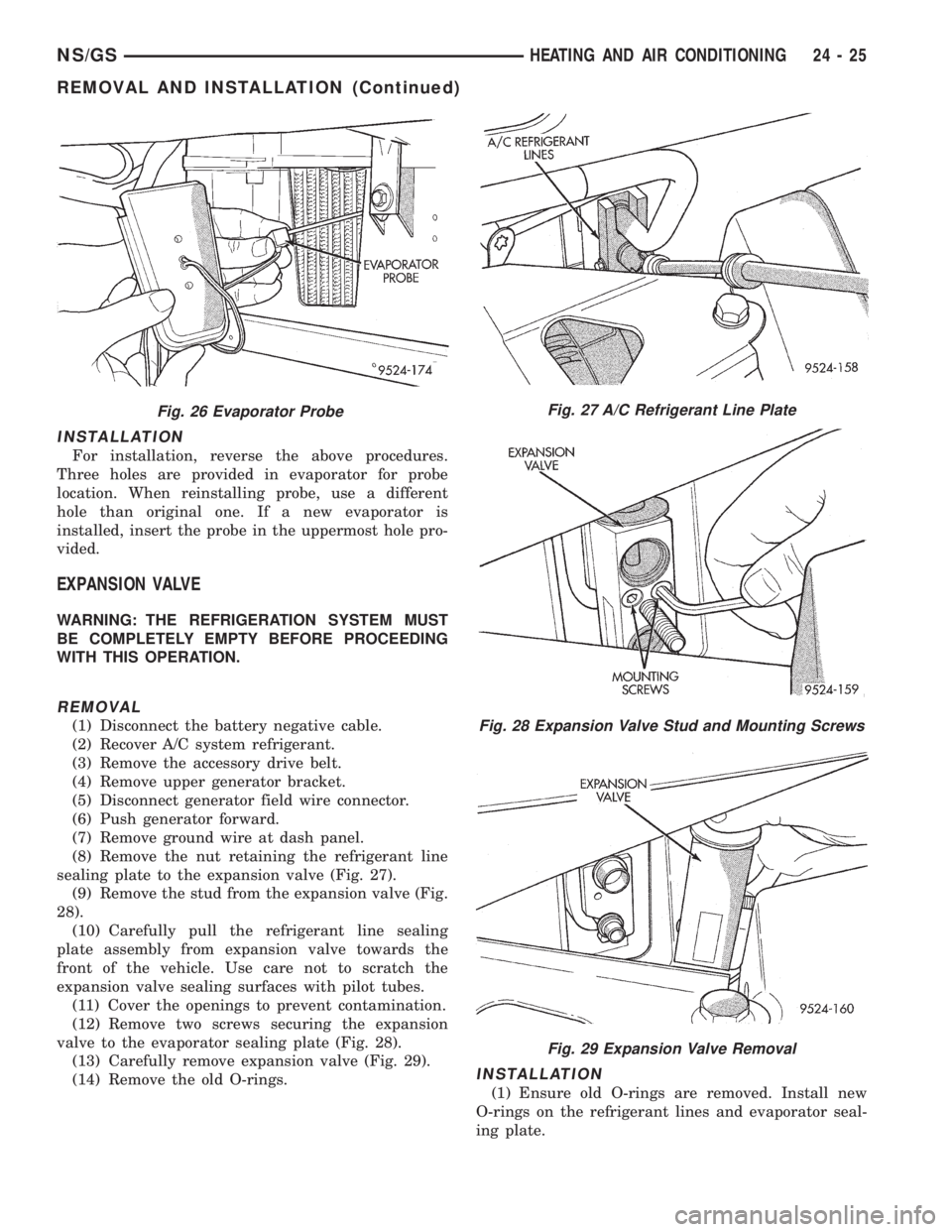

INSTALLATION

For installation, reverse the above procedures.

Three holes are provided in evaporator for probe

location. When reinstalling probe, use a different

hole than original one. If a new evaporator is

installed, insert the probe in the uppermost hole pro-

vided.

EXPANSION VALVE

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Recover A/C system refrigerant.

(3) Remove the accessory drive belt.

(4) Remove upper generator bracket.

(5) Disconnect generator field wire connector.

(6) Push generator forward.

(7) Remove ground wire at dash panel.

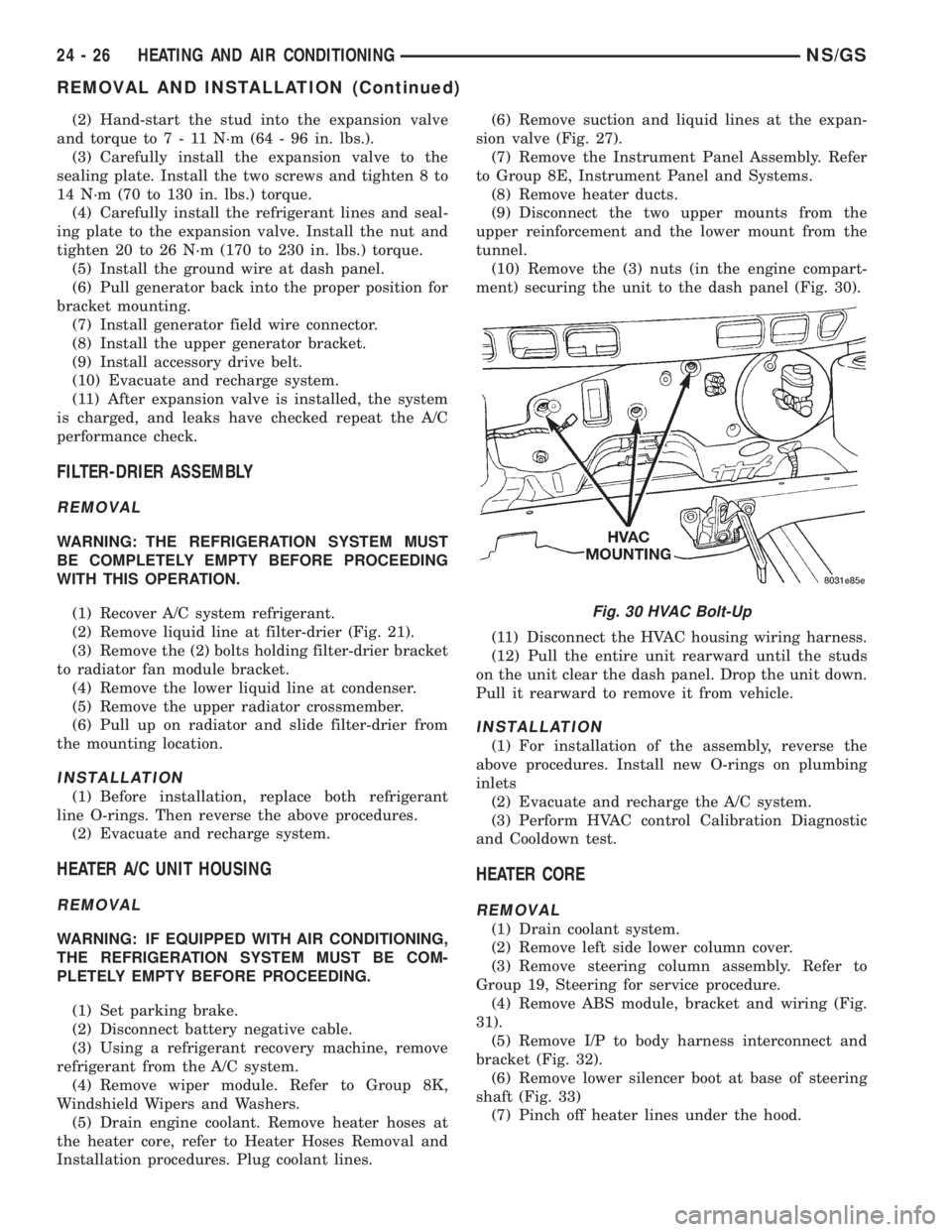

(8) Remove the nut retaining the refrigerant line

sealing plate to the expansion valve (Fig. 27).

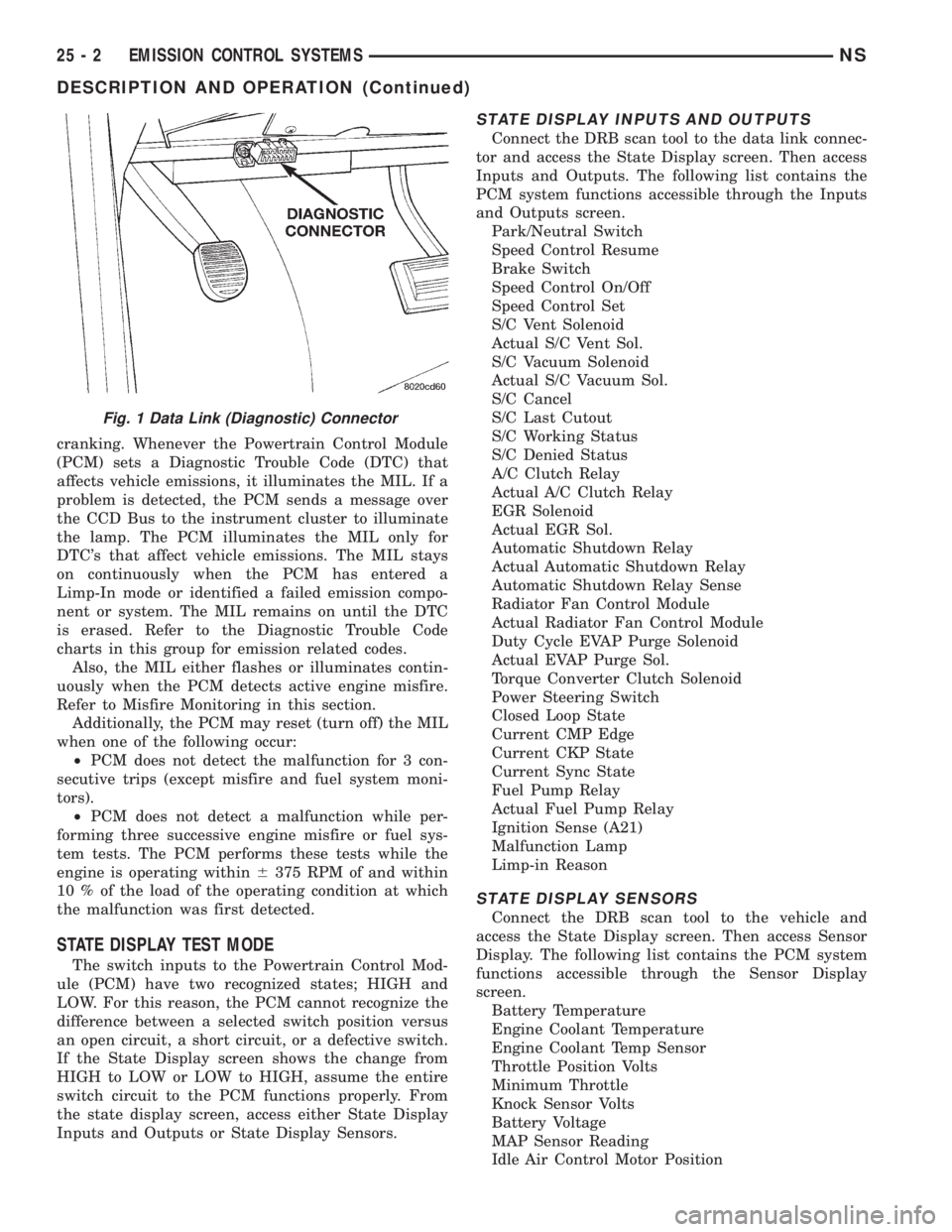

(9) Remove the stud from the expansion valve (Fig.

28).

(10) Carefully pull the refrigerant line sealing

plate assembly from expansion valve towards the

front of the vehicle. Use care not to scratch the

expansion valve sealing surfaces with pilot tubes.

(11) Cover the openings to prevent contamination.

(12) Remove two screws securing the expansion

valve to the evaporator sealing plate (Fig. 28).

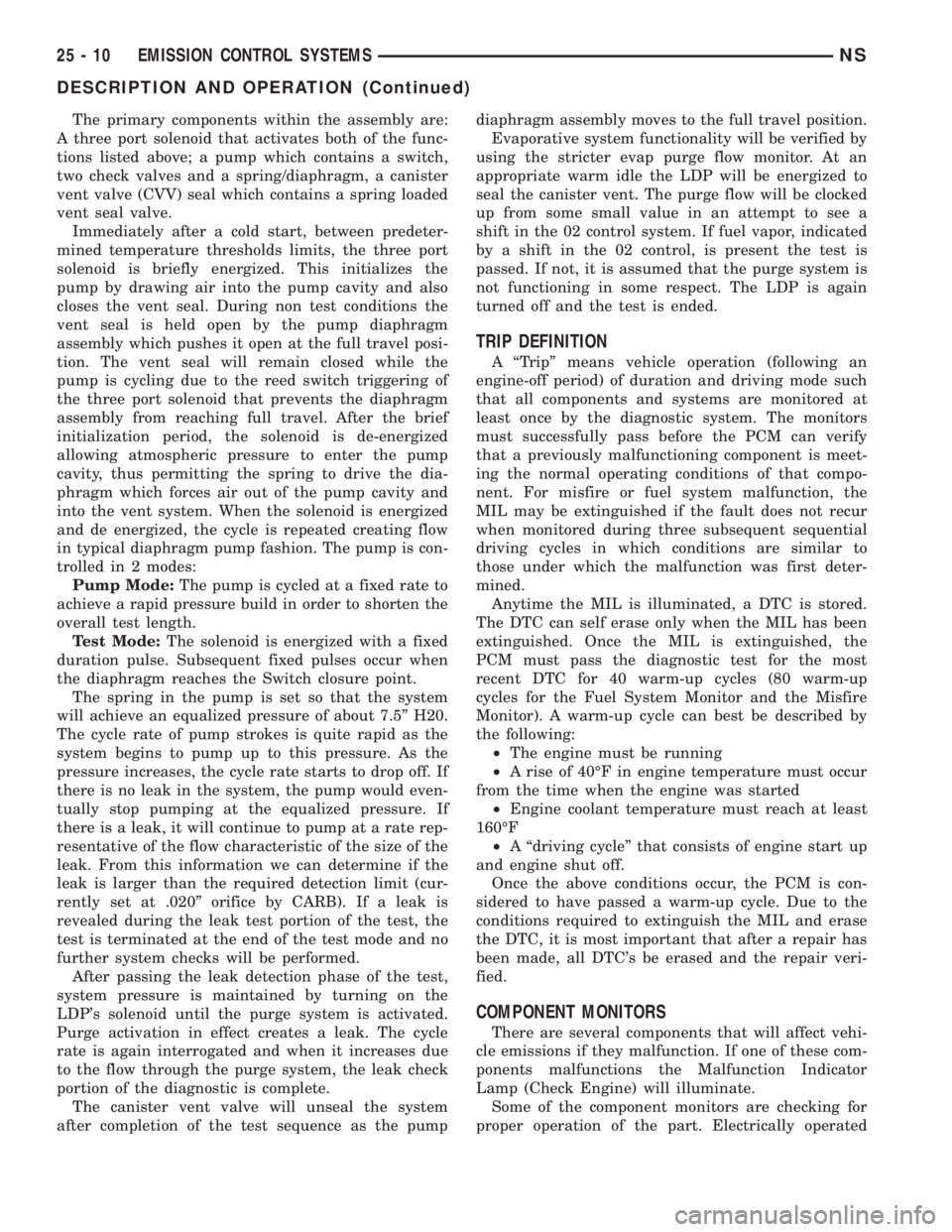

(13) Carefully remove expansion valve (Fig. 29).

(14) Remove the old O-rings.

INSTALLATION

(1) Ensure old O-rings are removed. Install new

O-rings on the refrigerant lines and evaporator seal-

ing plate.

Fig. 26 Evaporator ProbeFig. 27 A/C Refrigerant Line Plate

Fig. 28 Expansion Valve Stud and Mounting Screws

Fig. 29 Expansion Valve Removal

NS/GSHEATING AND AIR CONDITIONING 24 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1892 of 1938

(2) Hand-start the stud into the expansion valve

and torque to7-11N´m(64-96in.lbs.).

(3) Carefully install the expansion valve to the

sealing plate. Install the two screws and tighten 8 to

14 N´m (70 to 130 in. lbs.) torque.

(4) Carefully install the refrigerant lines and seal-

ing plate to the expansion valve. Install the nut and

tighten 20 to 26 N´m (170 to 230 in. lbs.) torque.

(5) Install the ground wire at dash panel.

(6) Pull generator back into the proper position for

bracket mounting.

(7) Install generator field wire connector.

(8) Install the upper generator bracket.

(9) Install accessory drive belt.

(10) Evacuate and recharge system.

(11) After expansion valve is installed, the system

is charged, and leaks have checked repeat the A/C

performance check.

FILTER-DRIER ASSEMBLY

REMOVAL

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

(1) Recover A/C system refrigerant.

(2) Remove liquid line at filter-drier (Fig. 21).

(3) Remove the (2) bolts holding filter-drier bracket

to radiator fan module bracket.

(4) Remove the lower liquid line at condenser.

(5) Remove the upper radiator crossmember.

(6) Pull up on radiator and slide filter-drier from

the mounting location.

INSTALLATION

(1) Before installation, replace both refrigerant

line O-rings. Then reverse the above procedures.

(2) Evacuate and recharge system.

HEATER A/C UNIT HOUSING

REMOVAL

WARNING: IF EQUIPPED WITH AIR CONDITIONING,

THE REFRIGERATION SYSTEM MUST BE COM-

PLETELY EMPTY BEFORE PROCEEDING.

(1) Set parking brake.

(2) Disconnect battery negative cable.

(3) Using a refrigerant recovery machine, remove

refrigerant from the A/C system.

(4) Remove wiper module. Refer to Group 8K,

Windshield Wipers and Washers.

(5) Drain engine coolant. Remove heater hoses at

the heater core, refer to Heater Hoses Removal and

Installation procedures. Plug coolant lines.(6) Remove suction and liquid lines at the expan-

sion valve (Fig. 27).

(7) Remove the Instrument Panel Assembly. Refer

to Group 8E, Instrument Panel and Systems.

(8) Remove heater ducts.

(9) Disconnect the two upper mounts from the

upper reinforcement and the lower mount from the

tunnel.

(10) Remove the (3) nuts (in the engine compart-

ment) securing the unit to the dash panel (Fig. 30).

(11) Disconnect the HVAC housing wiring harness.

(12) Pull the entire unit rearward until the studs

on the unit clear the dash panel. Drop the unit down.

Pull it rearward to remove it from vehicle.

INSTALLATION

(1) For installation of the assembly, reverse the

above procedures. Install new O-rings on plumbing

inlets

(2) Evacuate and recharge the A/C system.

(3) Perform HVAC control Calibration Diagnostic

and Cooldown test.

HEATER CORE

REMOVAL

(1) Drain coolant system.

(2) Remove left side lower column cover.

(3) Remove steering column assembly. Refer to

Group 19, Steering for service procedure.

(4) Remove ABS module, bracket and wiring (Fig.

31).

(5) Remove I/P to body harness interconnect and

bracket (Fig. 32).

(6) Remove lower silencer boot at base of steering

shaft (Fig. 33)

(7) Pinch off heater lines under the hood.

Fig. 30 HVAC Bolt-Up

24 - 26 HEATING AND AIR CONDITIONINGNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1906 of 1938

cranking. Whenever the Powertrain Control Module

(PCM) sets a Diagnostic Trouble Code (DTC) that

affects vehicle emissions, it illuminates the MIL. If a

problem is detected, the PCM sends a message over

the CCD Bus to the instrument cluster to illuminate

the lamp. The PCM illuminates the MIL only for

DTC's that affect vehicle emissions. The MIL stays

on continuously when the PCM has entered a

Limp-In mode or identified a failed emission compo-

nent or system. The MIL remains on until the DTC

is erased. Refer to the Diagnostic Trouble Code

charts in this group for emission related codes.

Also, the MIL either flashes or illuminates contin-

uously when the PCM detects active engine misfire.

Refer to Misfire Monitoring in this section.

Additionally, the PCM may reset (turn off) the MIL

when one of the following occur:

²PCM does not detect the malfunction for 3 con-

secutive trips (except misfire and fuel system moni-

tors).

²PCM does not detect a malfunction while per-

forming three successive engine misfire or fuel sys-

tem tests. The PCM performs these tests while the

engine is operating within6375 RPM of and within

10 % of the load of the operating condition at which

the malfunction was first detected.

STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRB scan tool to the data link connec-

tor and access the State Display screen. Then access

Inputs and Outputs. The following list contains the

PCM system functions accessible through the Inputs

and Outputs screen.

Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

S/C Vent Solenoid

Actual S/C Vent Sol.

S/C Vacuum Solenoid

Actual S/C Vacuum Sol.

S/C Cancel

S/C Last Cutout

S/C Working Status

S/C Denied Status

A/C Clutch Relay

Actual A/C Clutch Relay

EGR Solenoid

Actual EGR Sol.

Automatic Shutdown Relay

Actual Automatic Shutdown Relay

Automatic Shutdown Relay Sense

Radiator Fan Control Module

Actual Radiator Fan Control Module

Duty Cycle EVAP Purge Solenoid

Actual EVAP Purge Sol.

Torque Converter Clutch Solenoid

Power Steering Switch

Closed Loop State

Current CMP Edge

Current CKP State

Current Sync State

Fuel Pump Relay

Actual Fuel Pump Relay

Ignition Sense (A21)

Malfunction Lamp

Limp-in Reason

STATE DISPLAY SENSORS

Connect the DRB scan tool to the vehicle and

access the State Display screen. Then access Sensor

Display. The following list contains the PCM system

functions accessible through the Sensor Display

screen.

Battery Temperature

Engine Coolant Temperature

Engine Coolant Temp Sensor

Throttle Position Volts

Minimum Throttle

Knock Sensor Volts

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Fig. 1 Data Link (Diagnostic) Connector

25 - 2 EMISSION CONTROL SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)

Page 1914 of 1938

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non test conditions the

vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling due to the reed switch triggering of

the three port solenoid that prevents the diaphragm

assembly from reaching full travel. After the brief

initialization period, the solenoid is de-energized

allowing atmospheric pressure to enter the pump

cavity, thus permitting the spring to drive the dia-

phragm which forces air out of the pump cavity and

into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow

in typical diaphragm pump fashion. The pump is con-

trolled in 2 modes:

Pump Mode:The pump is cycled at a fixed rate to

achieve a rapid pressure build in order to shorten the

overall test length.

Test Mode:The solenoid is energized with a fixed

duration pulse. Subsequent fixed pulses occur when

the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5º H20.

The cycle rate of pump strokes is quite rapid as the

system begins to pump up to this pressure. As the

pressure increases, the cycle rate starts to drop off. If

there is no leak in the system, the pump would even-

tually stop pumping at the equalized pressure. If

there is a leak, it will continue to pump at a rate rep-

resentative of the flow characteristic of the size of the

leak. From this information we can determine if the

leak is larger than the required detection limit (cur-

rently set at .020º orifice by CARB). If a leak is

revealed during the leak test portion of the test, the

test is terminated at the end of the test mode and no

further system checks will be performed.

After passing the leak detection phase of the test,

system pressure is maintained by turning on the

LDP's solenoid until the purge system is activated.

Purge activation in effect creates a leak. The cycle

rate is again interrogated and when it increases due

to the flow through the purge system, the leak check

portion of the diagnostic is complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pumpdiaphragm assembly moves to the full travel position.

Evaporative system functionality will be verified by

using the stricter evap purge flow monitor. At an

appropriate warm idle the LDP will be energized to

seal the canister vent. The purge flow will be clocked

up from some small value in an attempt to see a

shift in the 02 control system. If fuel vapor, indicated

by a shift in the 02 control, is present the test is

passed. If not, it is assumed that the purge system is

not functioning in some respect. The LDP is again

turned off and the test is ended.

TRIP DEFINITION

A ªTripº means vehicle operation (following an

engine-off period) of duration and driving mode such

that all components and systems are monitored at

least once by the diagnostic system. The monitors

must successfully pass before the PCM can verify

that a previously malfunctioning component is meet-

ing the normal operating conditions of that compo-

nent. For misfire or fuel system malfunction, the

MIL may be extinguished if the fault does not recur

when monitored during three subsequent sequential

driving cycles in which conditions are similar to

those under which the malfunction was first deter-

mined.

Anytime the MIL is illuminated, a DTC is stored.

The DTC can self erase only when the MIL has been

extinguished. Once the MIL is extinguished, the

PCM must pass the diagnostic test for the most

recent DTC for 40 warm-up cycles (80 warm-up

cycles for the Fuel System Monitor and the Misfire

Monitor). A warm-up cycle can best be described by

the following:

²The engine must be running

²A rise of 40ÉF in engine temperature must occur

from the time when the engine was started

²Engine coolant temperature must reach at least

160ÉF

²A ªdriving cycleº that consists of engine start up

and engine shut off.

Once the above conditions occur, the PCM is con-

sidered to have passed a warm-up cycle. Due to the

conditions required to extinguish the MIL and erase

the DTC, it is most important that after a repair has

been made, all DTC's be erased and the repair veri-

fied.

COMPONENT MONITORS

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (Check Engine) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

25 - 10 EMISSION CONTROL SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)

Page 1923 of 1938

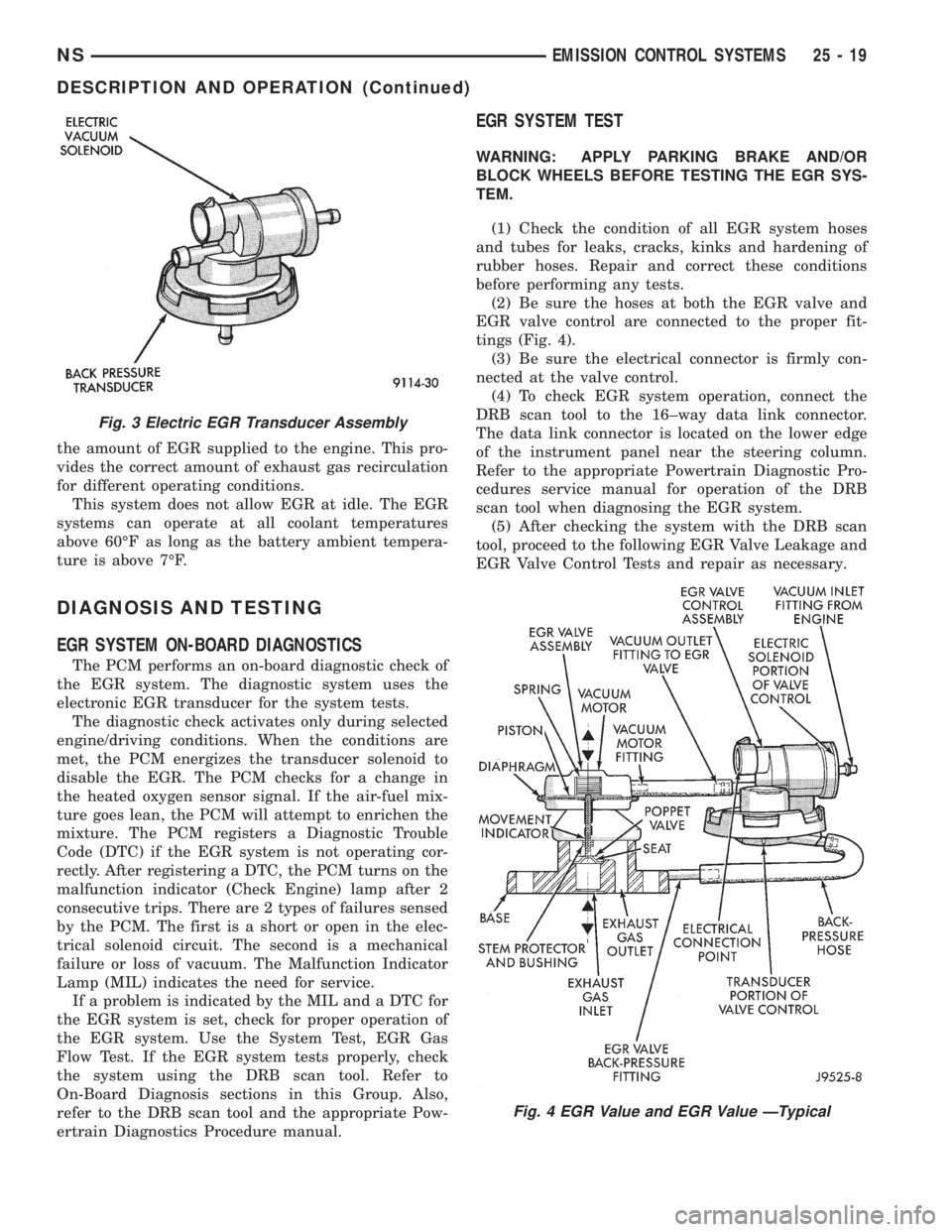

the amount of EGR supplied to the engine. This pro-

vides the correct amount of exhaust gas recirculation

for different operating conditions.

This system does not allow EGR at idle. The EGR

systems can operate at all coolant temperatures

above 60ÉF as long as the battery ambient tempera-

ture is above 7ÉF.

DIAGNOSIS AND TESTING

EGR SYSTEM ON-BOARD DIAGNOSTICS

The PCM performs an on-board diagnostic check of

the EGR system. The diagnostic system uses the

electronic EGR transducer for the system tests.

The diagnostic check activates only during selected

engine/driving conditions. When the conditions are

met, the PCM energizes the transducer solenoid to

disable the EGR. The PCM checks for a change in

the heated oxygen sensor signal. If the air-fuel mix-

ture goes lean, the PCM will attempt to enrichen the

mixture. The PCM registers a Diagnostic Trouble

Code (DTC) if the EGR system is not operating cor-

rectly. After registering a DTC, the PCM turns on the

malfunction indicator (Check Engine) lamp after 2

consecutive trips. There are 2 types of failures sensed

by the PCM. The first is a short or open in the elec-

trical solenoid circuit. The second is a mechanical

failure or loss of vacuum. The Malfunction Indicator

Lamp (MIL) indicates the need for service.

If a problem is indicated by the MIL and a DTC for

the EGR system is set, check for proper operation of

the EGR system. Use the System Test, EGR Gas

Flow Test. If the EGR system tests properly, check

the system using the DRB scan tool. Refer to

On-Board Diagnosis sections in this Group. Also,

refer to the DRB scan tool and the appropriate Pow-

ertrain Diagnostics Procedure manual.

EGR SYSTEM TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE TESTING THE EGR SYS-

TEM.

(1) Check the condition of all EGR system hoses

and tubes for leaks, cracks, kinks and hardening of

rubber hoses. Repair and correct these conditions

before performing any tests.

(2) Be sure the hoses at both the EGR valve and

EGR valve control are connected to the proper fit-

tings (Fig. 4).

(3) Be sure the electrical connector is firmly con-

nected at the valve control.

(4) To check EGR system operation, connect the

DRB scan tool to the 16±way data link connector.

The data link connector is located on the lower edge

of the instrument panel near the steering column.

Refer to the appropriate Powertrain Diagnostic Pro-

cedures service manual for operation of the DRB

scan tool when diagnosing the EGR system.

(5) After checking the system with the DRB scan

tool, proceed to the following EGR Valve Leakage and

EGR Valve Control Tests and repair as necessary.

Fig. 3 Electric EGR Transducer Assembly

Fig. 4 EGR Value and EGR Value ÐTypical

NSEMISSION CONTROL SYSTEMS 25 - 19

DESCRIPTION AND OPERATION (Continued)