ECU CHRYSLER VOYAGER 1996 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1565 of 1938

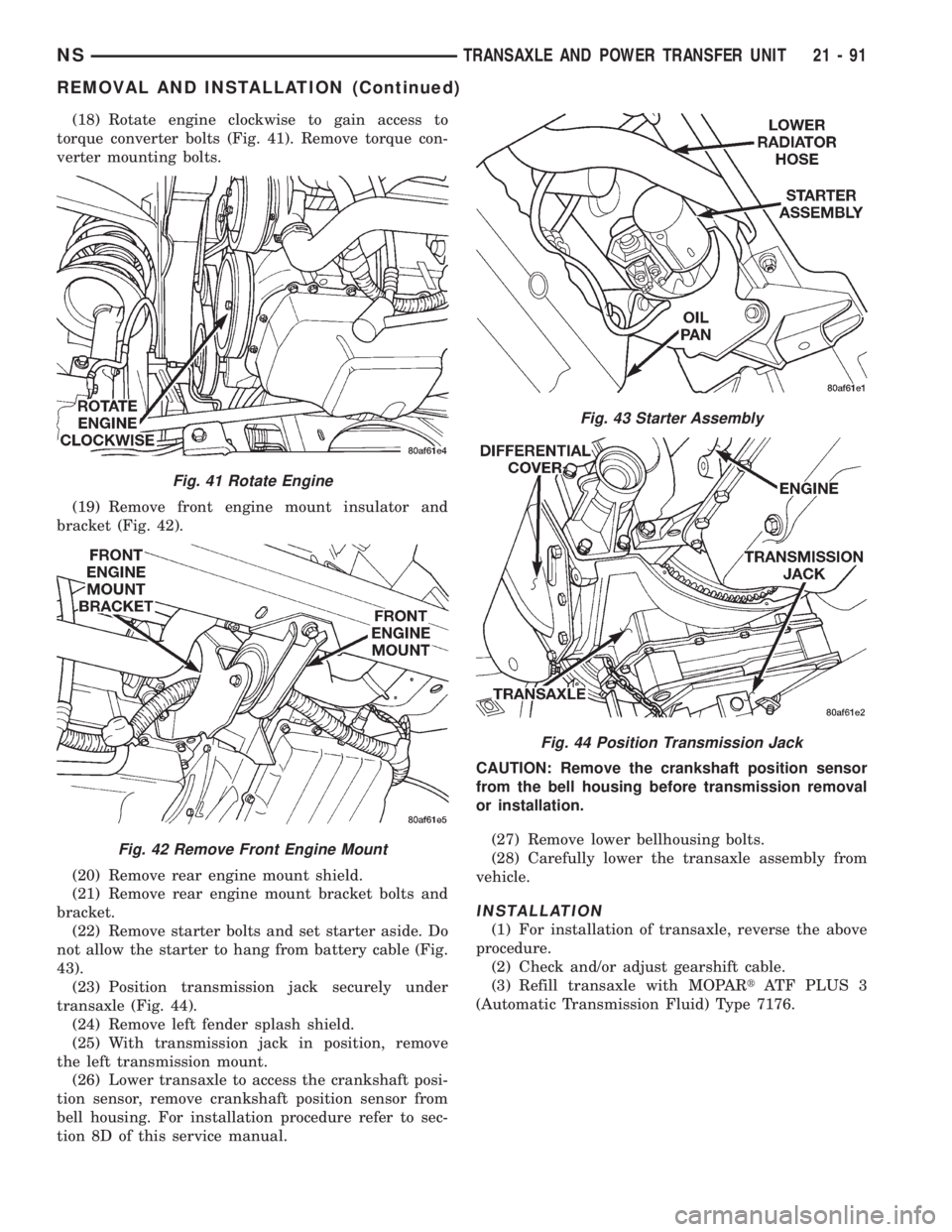

(18) Rotate engine clockwise to gain access to

torque converter bolts (Fig. 41). Remove torque con-

verter mounting bolts.

(19) Remove front engine mount insulator and

bracket (Fig. 42).

(20) Remove rear engine mount shield.

(21) Remove rear engine mount bracket bolts and

bracket.

(22) Remove starter bolts and set starter aside. Do

not allow the starter to hang from battery cable (Fig.

43).

(23) Position transmission jack securely under

transaxle (Fig. 44).

(24) Remove left fender splash shield.

(25) With transmission jack in position, remove

the left transmission mount.

(26) Lower transaxle to access the crankshaft posi-

tion sensor, remove crankshaft position sensor from

bell housing. For installation procedure refer to sec-

tion 8D of this service manual.CAUTION: Remove the crankshaft position sensor

from the bell housing before transmission removal

or installation.

(27) Remove lower bellhousing bolts.

(28) Carefully lower the transaxle assembly from

vehicle.

INSTALLATION

(1) For installation of transaxle, reverse the above

procedure.

(2) Check and/or adjust gearshift cable.

(3) Refill transaxle with MOPARtATF PLUS 3

(Automatic Transmission Fluid) Type 7176.

Fig. 41 Rotate Engine

Fig. 42 Remove Front Engine Mount

Fig. 43 Starter Assembly

Fig. 44 Position Transmission Jack

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 91

REMOVAL AND INSTALLATION (Continued)

Page 1668 of 1938

DIFFERENTIAL BEARING RETAINER AXLE

SEAL

REMOVAL

(1) Remove axle shaft. Refer to Group 2, Suspen-

sion and Driveshafts for service procedures.

(2) Insert a flat±blade pry tool into the axle seal

bore.

(3) Using the pry tool, carefully pop out the seal

taking care not to nick the seal bore.

INSTALLATION

(1) Clean axle shaft seal bore of any excess seal-

ant.

(2) Align axle shaft seal with axle shaft seal bore.

(3) Position axle seal at extension housing.

(4) Using Tool L-4520 and Tool C-4171, tap seal

into position.

SHIFT SHAFT SEALS

It isnotnecessary to remove the shift shaft cover

from the transaxle to service the shift shaft seals.

REMOVAL

(1) Remove the shift lever from the seal that is to

be serviced. Refer to shift lever removal for service

procedure.

(2) Using a pick tool, pry up on the shift shaft seal

and remove seal from bore.

INSTALLATION

(1) Position new shift shaft seal in bore.

(2) Install shift shaft seal into bore using an

appropriate size deep±well socket.

TRANSAXLE

The following items can be serviced without remov-

ing the transaxle from the vehicle:

²Gearshift housing

²5th speed synchronizer

²5th speed gear

²Roller detents and springs

²Speedometer pinion

²Vehicle speed sensor

²Bearing retainer plate.

²All external covers

²Shift shaft seals

²Axle shaft seals

To service any other component of the A-598 tran-

saxle you must remove it from the vehicle.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove air intake hose. Disconnect air mass

meter connector.

(3) Remove intercooler hose.(4) Remove connectors for back-up lamp (Fig. 28)

and crank position sensor (Fig. 29).

(5) Remove crank position sensor (2.5L VM Diesel

only).

(6) Remove wiring harness bracket at transaxle

(Fig. 30).

(7) Remove crossover and shift selector cables (Fig.

31).

(8) Remove the two top bolts at the rear engine

mount bracket.

(9) Remove bolts securing the coolant reservoir to

the top of the engine. Move the coolant reservoir out

of the way.

(10) Install an engine support chain to the cylinder

head assembly (Fig. 32).

Fig. 28 Back-up Lamp Connector

Fig. 29 Crankshaft Position Sensor

21 - 12 A±598 MANUAL TRANSAXLENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1731 of 1938

BODY

CONTENTS

page page

BODY COMPONENT SERVICE.............. 22

GENERAL SERVICE INFORMATION........... 1

PAINT.................................. 2SEATS .................................. 9

STATIONARY GLASS....................... 4

GENERAL SERVICE INFORMATION

INDEX

page

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS...... 1

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use

when welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

Chrysler Corporation uses many different types of

push-in fasteners to secure the interior and exterior

trim to the body. Most of these fasteners can be

reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

NSBODY 23 - 1

Page 1734 of 1938

STATIONARY GLASS

INDEX

page page

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS................... 4

REMOVAL AND INSTALLATION

BODY SIDE/SLIDING DOOR STATIONARY

GLASS............................... 6REAR WINDOW.......................... 7

WINDSHIELD............................ 4

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

URETHANE ADHESIVES ARE APPLIED AS A SYS-

TEM. USE GLASS CLEANER, GLASS PREP SOL-

VENT, GLASS PRIMER, PVC (VINYL) PRIMER AND

PINCHWELD (FENCE) PRIMER PROVIDED BY THE

ADHESIVE MANUFACTURER. IF NOT, STRUCTURAL

INTEGRITY COULD BE COMPROMISED.

CHRYSLER DOES NOT RECOMMEND GLASS

ADHESIVE BY BRAND. TECHNICIANS SHOULD

REVIEW PRODUCT LABELS AND TECHNICAL DATA

SHEETS, AND USE ONLY ADHESIVES THAT THEIR

MANUFACTURES WARRANT WILL RESTORE A

VEHICLE TO THE REQUIREMENTS OF FMVSS 212.

TECHNICIANS SHOULD ALSO INSURE THAT PRIM-

ERS AND CLEANERS ARE COMPATIBLE WITH THE

PARTICULAR ADHESIVE USED.

BE SURE TO REFER TO THE URETHANE MANU-

FACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

It is difficult to salvage a windshield during the

removal operation. The windshield is part of the

structural support for the roof. The urethane bonding

used to secure the windshield to the fence is difficult

to cut or clean from any surface. If the moldings are

set in urethane, it would also be unlikely they could

be salvaged. Before removing the windshield, check

the availability of the windshield and moldings from

the parts supplier.

REMOVAL AND INSTALLATION

WINDSHIELD

The urethane adhesive holding the windshield to

the opening pinch weld (fence) can be cut using a

sharp cold knife from the exterior of the vehicle.

Using the cold knife method is effective if the wind-

shield is already broken. If the glass must be sal-

vaged, cutting the urethane adhesive from the

interior of the vehicle using a reciprocating or oscil-

lating power knife is recommended.

WINDSHIELD REMOVAL ± EXTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove windshield wiper arms.

(3) Remove cowl cover.

(4) Remove A-pillar trim panels.

(5) Disconnect wire connectors to windshield

defroster grid.

(6) Place protective covers over instrument panel

and hood.

(7) Remove windshield molding (Fig. 1). Using pli-

ers, pull outward on molding at the bottom of A-pil-

lars.

(8) Using a sharp cold knife, cut urethane adhe-

sive holding the windshield to the A-pillars, roof

header and cowl pinch weld fences (Fig. 2). A power

cutting device can be used if available.

(9) Remove windshield from vehicle.

23 - 4 BODYNS

Page 1754 of 1938

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during highcrosswinds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

Wind noise can also be caused by improperly fitted

exterior moldings or body ornamentation. Loose

moldings can flutter, creating a buzzing or chattering

noise. An open cavity or protruding edge can create a

whistling or howling noise. Inspect the exterior of the

vehicle to verify that these conditions do not exist.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If component

alignment or sealing is necessary, refer to the appro-

priate section of this group for proper procedures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

SERVICE PROCEDURES

HEAT STAKING

(1) Remove trim panel.

(2) Bend or move the trim panel components at

the heat staked joints. Observe the heat staked loca-

tions and/or component seams for looseness.

(3) Heat stake the components.

(a) If the heat staked or component seam loca-

tion is loose, hold the two components tightly

together and using a soldering gun with a flat tip,

melt the material securing the components

together. Do not over heat the affected area, dam-

age to the exterior of the trim panel may occur.

(b) If the heat staked material is broken or miss-

ing, use a hot glue gun to apply new material to

the area to be repaired. The panels that are being

heat staked must be held together while the apply-

ing the glue. Once the new material is in place, it

23 - 24 BODYNS

DIAGNOSIS AND TESTING (Continued)

Page 1762 of 1938

INSTALLATION

NOTE: The screws attaching the door latch to the

door end frame have nylon patches on the threads.

All screws must be replaced when the latch has

been removed.

(1) Place door latch in position on door end frame.

(2) Install screws to hold door latch to door end

frame.

(3) Insert linkage into door latch.

(4) Engage clips to hold linkage to door latch.

(5) Connect wire connector into power door lock

motor, if equipped.

(6) Insert a hex wrench through the elongated hole

located in the door shut face above the latch.

(7) Loosen allen head screw.

(8) Pull outward on the outside door handle and

release.

(9) Tighten allen head screw.

(10) Verify door latch and power door lock opera-

tion.

(11) Install water shield and front door trim panel.

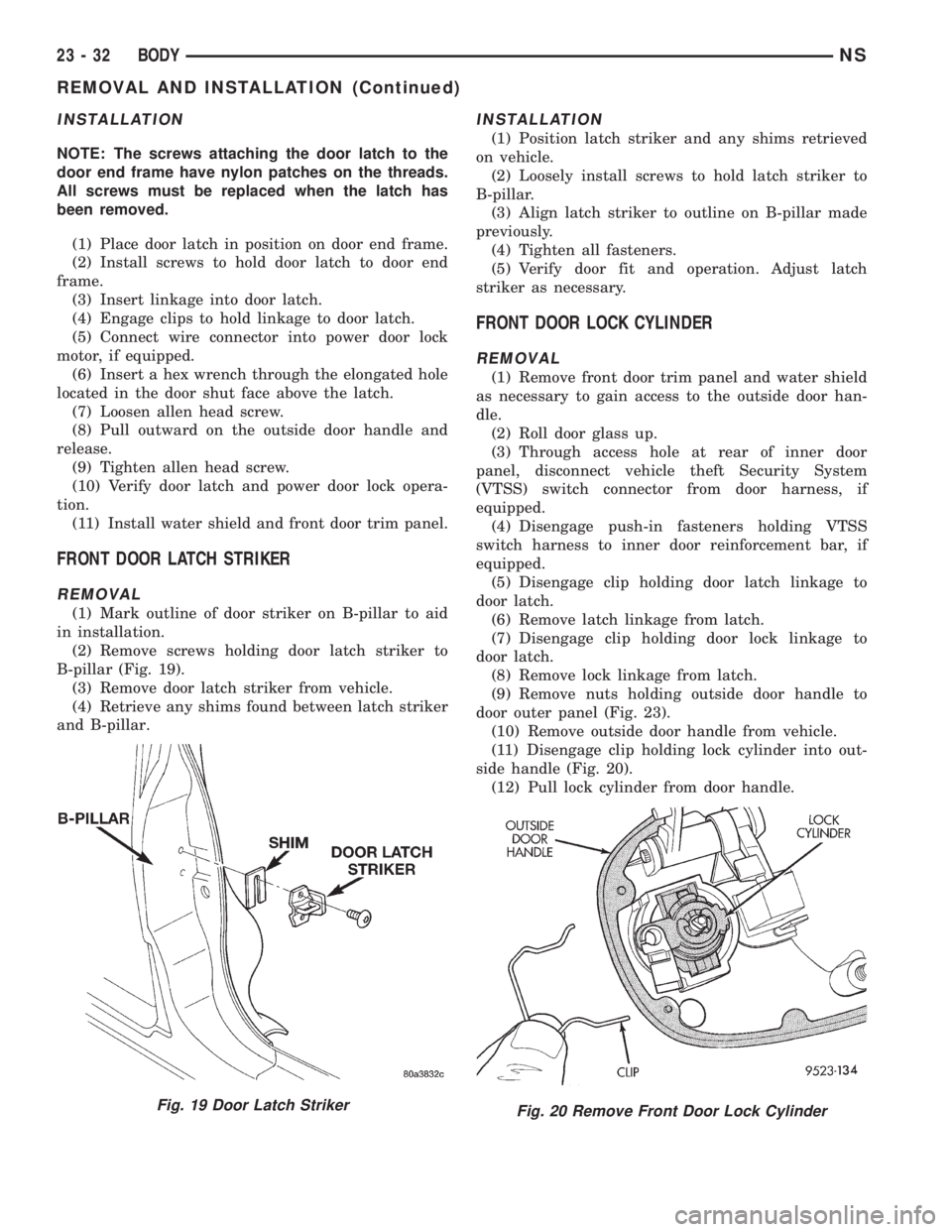

FRONT DOOR LATCH STRIKER

REMOVAL

(1) Mark outline of door striker on B-pillar to aid

in installation.

(2) Remove screws holding door latch striker to

B-pillar (Fig. 19).

(3) Remove door latch striker from vehicle.

(4) Retrieve any shims found between latch striker

and B-pillar.

INSTALLATION

(1) Position latch striker and any shims retrieved

on vehicle.

(2) Loosely install screws to hold latch striker to

B-pillar.

(3) Align latch striker to outline on B-pillar made

previously.

(4) Tighten all fasteners.

(5) Verify door fit and operation. Adjust latch

striker as necessary.

FRONT DOOR LOCK CYLINDER

REMOVAL

(1) Remove front door trim panel and water shield

as necessary to gain access to the outside door han-

dle.

(2) Roll door glass up.

(3) Through access hole at rear of inner door

panel, disconnect vehicle theft Security System

(VTSS) switch connector from door harness, if

equipped.

(4) Disengage push-in fasteners holding VTSS

switch harness to inner door reinforcement bar, if

equipped.

(5) Disengage clip holding door latch linkage to

door latch.

(6) Remove latch linkage from latch.

(7) Disengage clip holding door lock linkage to

door latch.

(8) Remove lock linkage from latch.

(9) Remove nuts holding outside door handle to

door outer panel (Fig. 23).

(10) Remove outside door handle from vehicle.

(11) Disengage clip holding lock cylinder into out-

side handle (Fig. 20).

(12) Pull lock cylinder from door handle.

Fig. 19 Door Latch StrikerFig. 20 Remove Front Door Lock Cylinder

23 - 32 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1763 of 1938

INSTALLATION

(1) Engage clip into outside handle to hold lock

cylinder.

(2) With link arm toward rear of vehicle, push lock

cylinder into door handle until clip snaps into place

(Fig. 21).

(3) Insert lock linkage into door latch.

(4) Engage clip to hold door lock linkage to latch.

(5) Insert latch linkage into door latch.

(6) Engage clip to hold door latch linkage to latch.

(7) Install push-in fasteners to hold VTSS switch

harness to inner door reinforcement bar, if equipped.

(8) Connect VTSS switch connector into door har-

ness, if equipped.

(9) Verify door latch operation.

(10) Install water shield and door trim panel.

FRONT DOOR OUTER BELT MOLDING

REMOVAL

(1) Remove door trim panel.

(2) Roll door glass down.

(3) Using a hook tool, disengage interlocking lip at

the base of the inward edge of the belt molding (Fig.

22).

(4) Remove belt molding from door.

INSTALLATION

(1) Place belt molding in position on door.

(2) Engage interlocking lip at the base of the

inward edge of the belt molding on door panel.

(3) Install door trim panel.

FRONT DOOR OUTSIDE HANDLE

REMOVAL

(1) Remove front door trim panel and water shield

as necessary to gain access to the outside door han-

dle.

(2) Roll door glass up.(3) Through access hole at rear of inner door

panel, disconnect vehicle theft Security System

(VTSS) switch connector from door harness, if

equipped.

(4) Disengage push-in fasteners holding VTSS

switch harness to inner door reinforcement bar, if

equipped.

(5) Disengage clip holding door latch linkage to

door latch.

(6) Remove latch linkage from latch.

(7) Disengage clip holding door lock linkage to

door latch.

(8) Remove lock linkage from latch.

(9) Remove nuts holding outside door handle to

door outer panel (Fig. 23).

(10) Remove outside door handle from vehicle.

Fig. 21 Install Front Door Lock Cylinder

Fig. 22 Front Door Outer Belt Molding

Fig. 23 Front Door Outside Handle

NSBODY 23 - 33

REMOVAL AND INSTALLATION (Continued)

Page 1771 of 1938

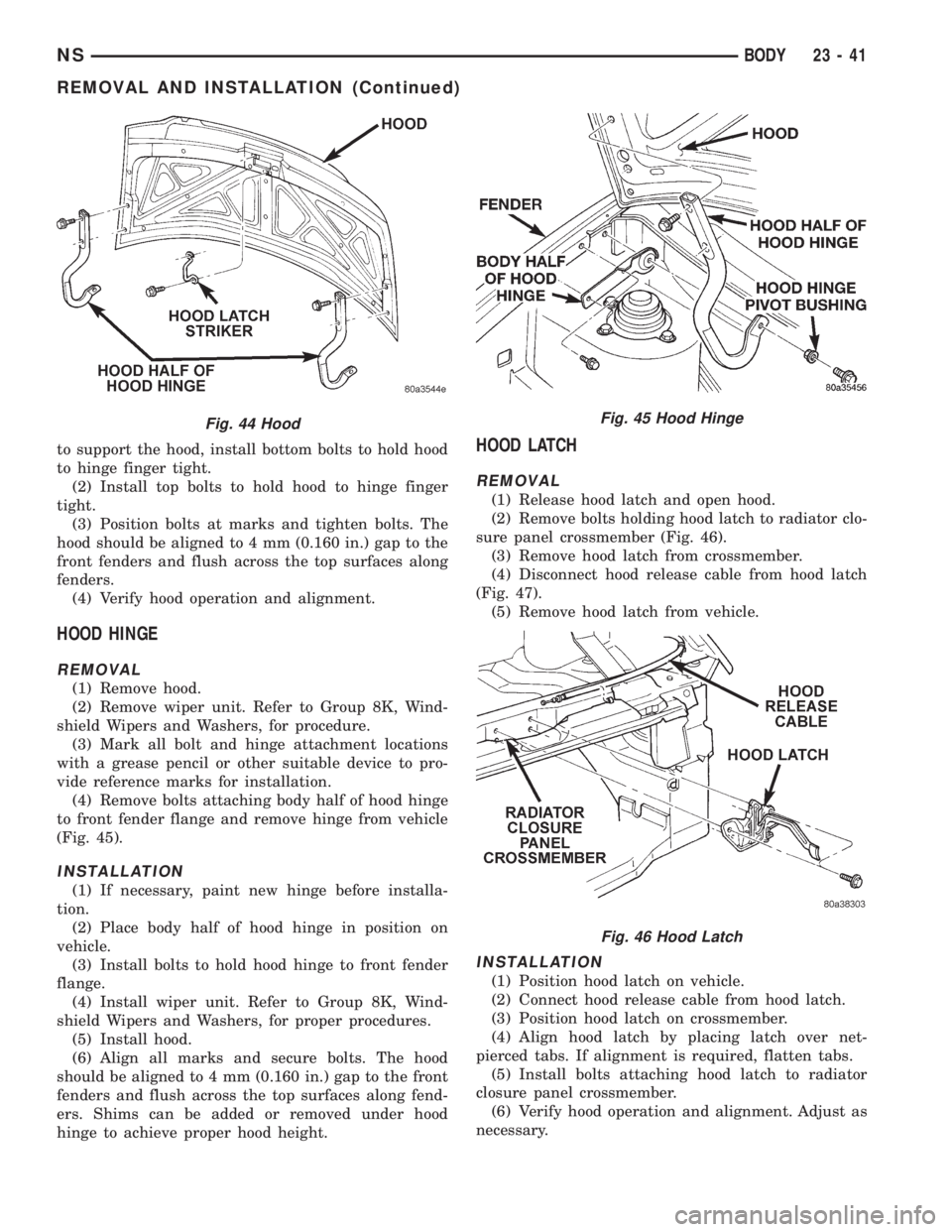

to support the hood, install bottom bolts to hold hood

to hinge finger tight.

(2) Install top bolts to hold hood to hinge finger

tight.

(3) Position bolts at marks and tighten bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders.

(4) Verify hood operation and alignment.

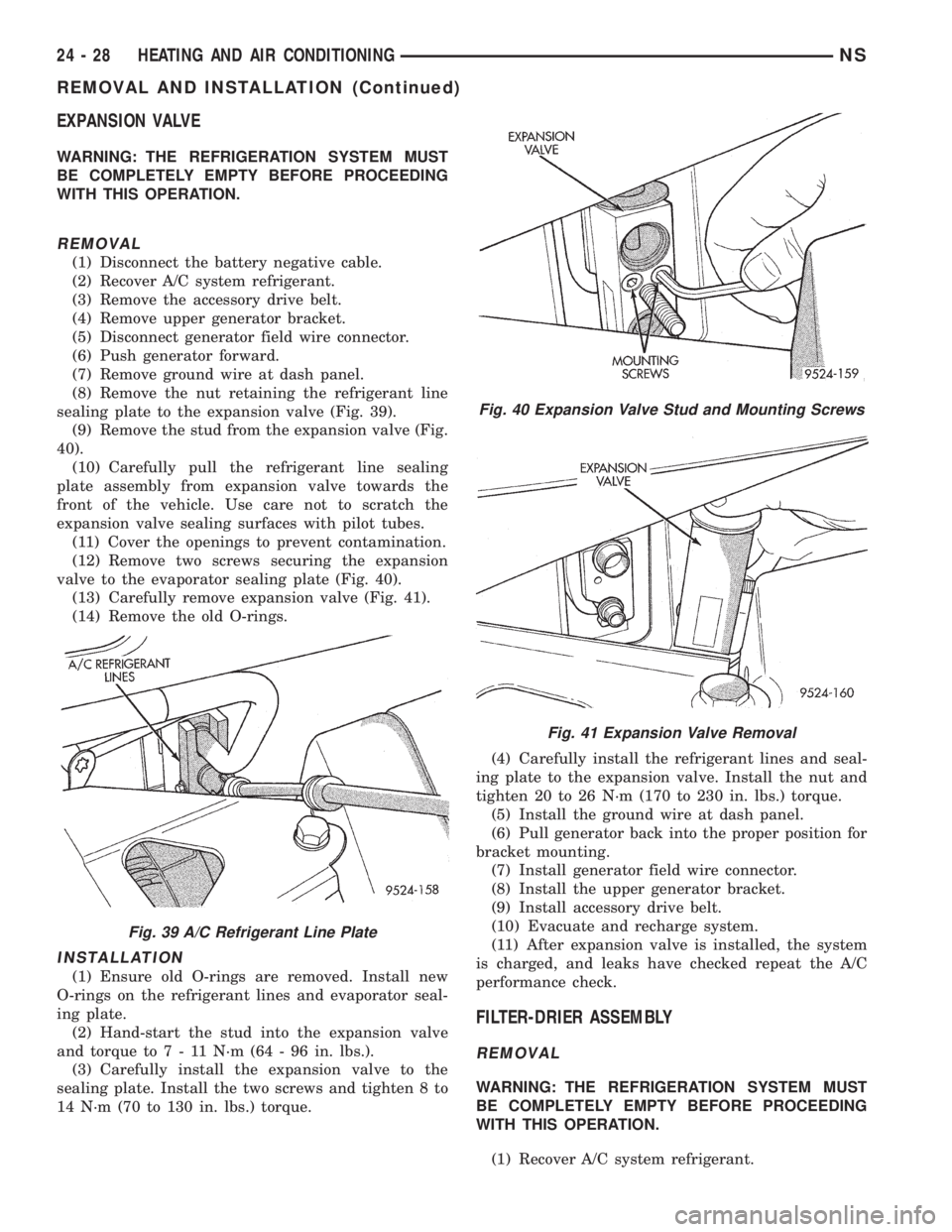

HOOD HINGE

REMOVAL

(1) Remove hood.

(2) Remove wiper unit. Refer to Group 8K, Wind-

shield Wipers and Washers, for procedure.

(3) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation.

(4) Remove bolts attaching body half of hood hinge

to front fender flange and remove hinge from vehicle

(Fig. 45).

INSTALLATION

(1) If necessary, paint new hinge before installa-

tion.

(2) Place body half of hood hinge in position on

vehicle.

(3) Install bolts to hold hood hinge to front fender

flange.

(4) Install wiper unit. Refer to Group 8K, Wind-

shield Wipers and Washers, for proper procedures.

(5) Install hood.

(6) Align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers. Shims can be added or removed under hood

hinge to achieve proper hood height.

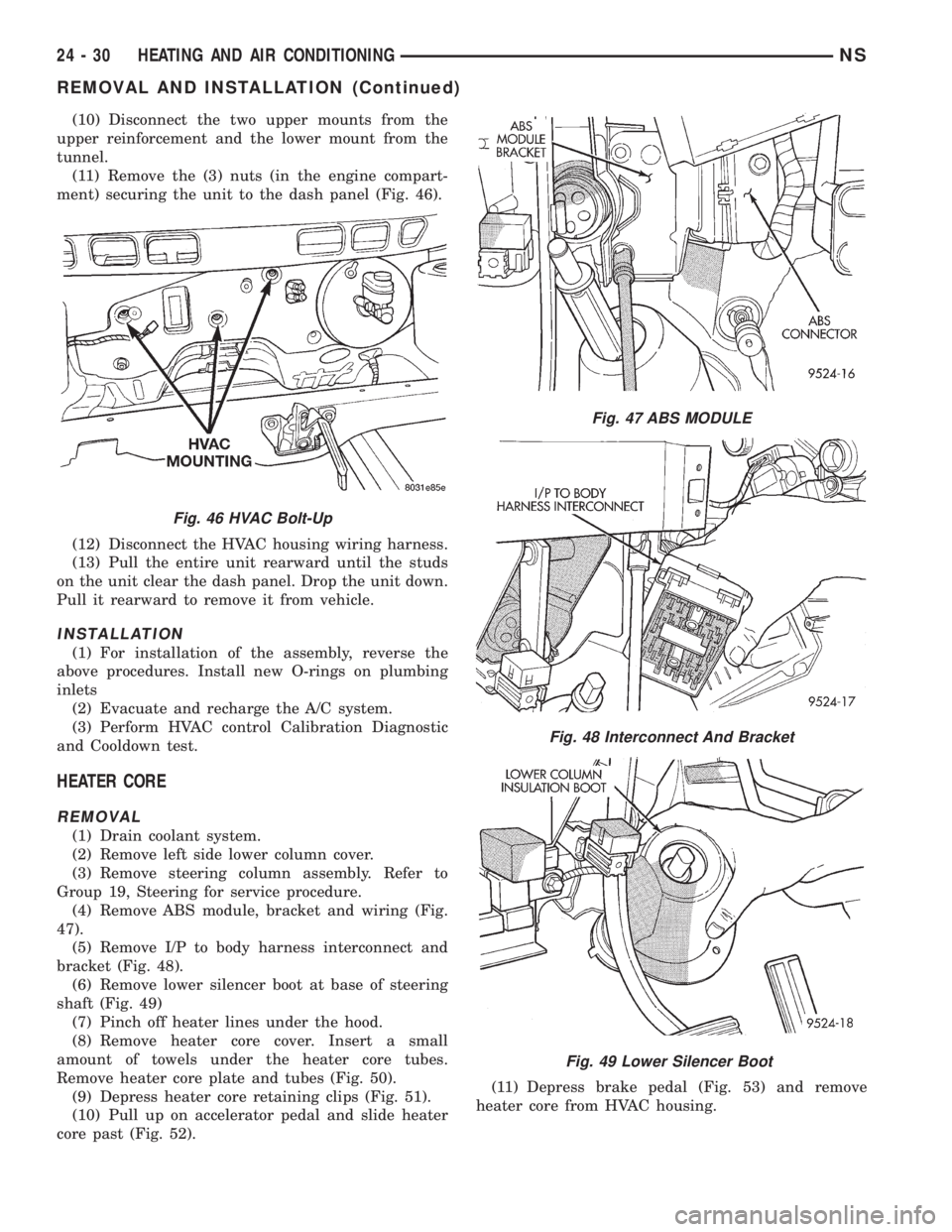

HOOD LATCH

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts holding hood latch to radiator clo-

sure panel crossmember (Fig. 46).

(3) Remove hood latch from crossmember.

(4) Disconnect hood release cable from hood latch

(Fig. 47).

(5) Remove hood latch from vehicle.

INSTALLATION

(1) Position hood latch on vehicle.

(2) Connect hood release cable from hood latch.

(3) Position hood latch on crossmember.

(4) Align hood latch by placing latch over net-

pierced tabs. If alignment is required, flatten tabs.

(5) Install bolts attaching hood latch to radiator

closure panel crossmember.

(6) Verify hood operation and alignment. Adjust as

necessary.

Fig. 44 HoodFig. 45 Hood Hinge

Fig. 46 Hood Latch

NSBODY 23 - 41

REMOVAL AND INSTALLATION (Continued)

Page 1844 of 1938

EXPANSION VALVE

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Recover A/C system refrigerant.

(3) Remove the accessory drive belt.

(4) Remove upper generator bracket.

(5) Disconnect generator field wire connector.

(6) Push generator forward.

(7) Remove ground wire at dash panel.

(8) Remove the nut retaining the refrigerant line

sealing plate to the expansion valve (Fig. 39).

(9) Remove the stud from the expansion valve (Fig.

40).

(10) Carefully pull the refrigerant line sealing

plate assembly from expansion valve towards the

front of the vehicle. Use care not to scratch the

expansion valve sealing surfaces with pilot tubes.

(11) Cover the openings to prevent contamination.

(12) Remove two screws securing the expansion

valve to the evaporator sealing plate (Fig. 40).

(13) Carefully remove expansion valve (Fig. 41).

(14) Remove the old O-rings.

INSTALLATION

(1) Ensure old O-rings are removed. Install new

O-rings on the refrigerant lines and evaporator seal-

ing plate.

(2) Hand-start the stud into the expansion valve

and torque to7-11N´m(64-96in.lbs.).

(3) Carefully install the expansion valve to the

sealing plate. Install the two screws and tighten 8 to

14 N´m (70 to 130 in. lbs.) torque.(4) Carefully install the refrigerant lines and seal-

ing plate to the expansion valve. Install the nut and

tighten 20 to 26 N´m (170 to 230 in. lbs.) torque.

(5) Install the ground wire at dash panel.

(6) Pull generator back into the proper position for

bracket mounting.

(7) Install generator field wire connector.

(8) Install the upper generator bracket.

(9) Install accessory drive belt.

(10) Evacuate and recharge system.

(11) After expansion valve is installed, the system

is charged, and leaks have checked repeat the A/C

performance check.

FILTER-DRIER ASSEMBLY

REMOVAL

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

(1) Recover A/C system refrigerant.

Fig. 39 A/C Refrigerant Line Plate

Fig. 40 Expansion Valve Stud and Mounting Screws

Fig. 41 Expansion Valve Removal

24 - 28 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1846 of 1938

(10) Disconnect the two upper mounts from the

upper reinforcement and the lower mount from the

tunnel.

(11) Remove the (3) nuts (in the engine compart-

ment) securing the unit to the dash panel (Fig. 46).

(12) Disconnect the HVAC housing wiring harness.

(13) Pull the entire unit rearward until the studs

on the unit clear the dash panel. Drop the unit down.

Pull it rearward to remove it from vehicle.

INSTALLATION

(1) For installation of the assembly, reverse the

above procedures. Install new O-rings on plumbing

inlets

(2) Evacuate and recharge the A/C system.

(3) Perform HVAC control Calibration Diagnostic

and Cooldown test.

HEATER CORE

REMOVAL

(1) Drain coolant system.

(2) Remove left side lower column cover.

(3) Remove steering column assembly. Refer to

Group 19, Steering for service procedure.

(4) Remove ABS module, bracket and wiring (Fig.

47).

(5) Remove I/P to body harness interconnect and

bracket (Fig. 48).

(6) Remove lower silencer boot at base of steering

shaft (Fig. 49)

(7) Pinch off heater lines under the hood.

(8) Remove heater core cover. Insert a small

amount of towels under the heater core tubes.

Remove heater core plate and tubes (Fig. 50).

(9) Depress heater core retaining clips (Fig. 51).

(10) Pull up on accelerator pedal and slide heater

core past (Fig. 52).(11) Depress brake pedal (Fig. 53) and remove

heater core from HVAC housing.

Fig. 46 HVAC Bolt-Up

Fig. 47 ABS MODULE

Fig. 48 Interconnect And Bracket

Fig. 49 Lower Silencer Boot

24 - 30 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)