key CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 998 of 1938

Component/

GroundColor Location Fig.

Left Rear

Reading LampGY At Lamp 17

Left Rear

Sliding Door

ContactBK LT B-Pillar 14

Left Rear

Sliding Door

Lock MotorBK At Motor N/S

Left Rear

SpeakerBK At Speaker 21

Left Rear Vent

MotorNAT At Motor 21

Left Rear Wheel

Speed SensorGY Center Rear of

Floor Pan16

Left Repeater

LampGY At Lamp N/S

Left Speed

Control SwitchLeft Side of

Steering Wheel

Pad11

Left Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Left Visor/Vanity

LampBK At Lamp 17

License Lamp GY At Lamps 23

Liftgate Ajar

SwitchBK At Latch 23

Liftgate

Arm/Disarm

SwitchGY At Key Cylinder 23

Liftgate Lock

MotorBK At Motor 23

LJ01 BK LT Quarter

Panel21

Low Note Horn BK LT Frame Rail 4

Low Washer

Fluid Level

SensorBK Bottom of

Reservior4

MAP Sensor

2.4LBK On Intake N/S

MAP Sensor

3.3L, 3.8LBK Near Throttle

Body9

Memort

Seat/Mirror

ModuleBK RT Front of

Floor Pan16

Memory Set

SwitchBL At Switch 19Component/

GroundColor Location Fig.

Message Center BL Rear of

Message

Center11

Mode Door

ActuatorBK LT Side of

HVAC15

Multi Function

SwitchBK Rear of Switch 11

Name Brand

Speaker RelayLT/GY LT of Steering

ColumnN/S

Output Shaft

Speed SensorGY Front of

Transmission7, 9

Overhead

ConsoleRD Front of

Console17

P18 GY RT of Steering

Column12

P30 BK RT Side of

HVAC10

P34 GY RT of Steering

Column12

P50 NAT Right Side of

HVAC Taped to

Harness10

Park Brake

SwitchNAT Top of Park

BrakeN/S

Park/Neutral

Positon SwitchBK Front of

TransmissionN/S

Passenger

AirbagYL Rear of Airbag 11

PDC C1 NAT Bottom of PDC 2

PDC C2 OR Bottom of PDC 2

PDC C3 DK/

GNBottom of PDC 2

PDC C4 BK Bottom of PDC 2

PDC C5 LT/GY Bottom of PDC 2

PDC C6 LT/GN Bottom of PDC 3

PDC C7 LT/GY Bottom of PDC 3

PDC C8 BL Bottom of PDC 3

Power Folding

Mirror SwitchBK At Switch N/S

Power Mirror

SwitchBK Rear of Switch 11

Power Steering

Pressure SwitchBK RT Side of

Engine

CompartmentN/S

8W - 90 - 34 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 999 of 1938

Component/

GroundColor Location Fig.

Powertrain

Control Module

C1BK LT Fender Side

Shield3

Powertrain

Control Module

C2BK LT Fender Side

Shield3

Radiator Fan

No.1BK At Motor N/S

Radiator Fan

No.2BK At Motor N/S

Radiator Fan

RelayBK LT Front Frame

Rail3

Radio C1 GY Rear of Radio 11

Radio C2 BK Rear of Radio 11

Radio C3 BK Rear of Radio 11

Radio Choke LT/GY Rear of Radio N/S

Rear A/C-

Heater UnitLT/GN RT Quarter

Panel22

Rear Blower

Front Control

SwitchBK Rear of Switch 11

Rear Blower

Rear Control

SwitchBK At Switch N/S

Rear Cigar

Lighter/Power

OutletBK LT Quarter

Panel21

Rear Dome

LampBK At Lamp N/S

Rear Washer

MotorBK Bottom of

Reservior4

Rear Window

DefoggerBK On Liftgate 23

Rear Wiper

MotorBK At Motor 23

Recirculation

Door ActuatorNAT RT Side of

HVAC15

Remote Keyless

Entry ModuleRD Top RT of I.P. 11

Right

Combination

RelayBK LT Quarter

PanelN/S

Right Door

Arm/Disarm

SwitchBK At Switch 19

Right Door

Courtesy LampBK At Lamp 19Component/

GroundColor Location Fig.

Right Door

SpeakerBK At Speaker 19

RF3 BK At Radiator Fan

ModuleN/S

Right Fog Lamp GY At Lamp 4

Right Front

Door Ajar

SwitchBK RT B-Pillar 12

Right Front

Door Lock

MotorBK At Motor 19

Right Front

Panel SpeakerBK At Speaker 11

Right Front

Park/Turn

Signal LampBK At Lamp 4

Right Front

Wheel Speed

SensorBK Right Fender

Side Shield4

Right Front

Window MotorRD At Motor 19

Right Headlamp BK At Lamp 4

Right Headlamp

Leveling MotorBK At Motor N/S

Right Liftgate

Flood LampBK At Lamp 23

Right Mid

Reading LampGY At Lamp 17

Right Power

Door Lock

SwitchBK At Switch 19

Right Power

Mirror C1RD At Mirror 11

Right Power

Mirror C2BL At Mirror 11

Right Power

Window SwitchBK At Switch 19

Right Rear

Lamp AssemblyBK At Lamp 22

Right Rear Door

Ajar SwitchBK RT C-Pillar N/S

Right Rear Pillar

SpeakerBK At Speaker 22

Right Rear

Reading LampGY At Lamp 17

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 35

DESCRIPTION AND OPERATION (Continued)

Page 1000 of 1938

Component/

GroundColor Location Fig.

Right Rear

Sliding Door

ContactBK RT B-Pillar 14

Right Rear

Sliding Door

Lock MotorBK At Motor N/S

Right Rear

SpeakerBK At Speaker 22

Right Rear Vent

MotorNAT At Motor 22

Right Rear

Wheel Speed

SensorGY Center Rear of

Floor Pan16

Right Repeater

LampGY At Lamp N/S

Right Speed

Control SwitchRight Side of

Steering Wheel

Pad11

Right Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Right Visor/

Vanity LampBK At Lamp 17

S02 BK Under Seat N/S

Seat Belt Switch BK RT B-Pillar N/S

Sentry Key

Immobilizer

ModuleBK Near Steering

Column at

Module11

Stop Lamp

SwitchGY Top of Brake

Pedal12

T05 BK LT Quarter

PanelN/S

T08 BK RT Quarter

PanelN/SComponent/

GroundColor Location Fig.

Throttle Position

SensorNAT On Throttle

Body5, 6, 7,

8, 9

Trailer Tow

ConnectorBK LT Quarter

PanelN/S

Transmission

Control ModuleBK RT Fender Side

Shield3

Transmission

Range SensorBK Top of

Transmission7. 9

Transmission

Control

SolenoidsBK Front of

Transmission7, 9

Turbine Speed

SensorGY Front of

Transmission7, 9

Turn Signal/

Hazard SwitchBK Part of

Multifunction

Switch11

Upstream

Heated Oxygen

SensorGY Rear of Engine 5, 6, 7,

8, 9

Vehicle Speed

Control ServoBK LT Rear of

Engine

Compartment5, 6, 7,

8, 9

Vehicle Speed

SensorBK Rear of

Transmission5, 6, 8

Windshield

Wiper SwitchBK Part of

Multifunction

Switch11

Wiper Module BK LT Side of

Engine2

8W - 90 - 36 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1081 of 1938

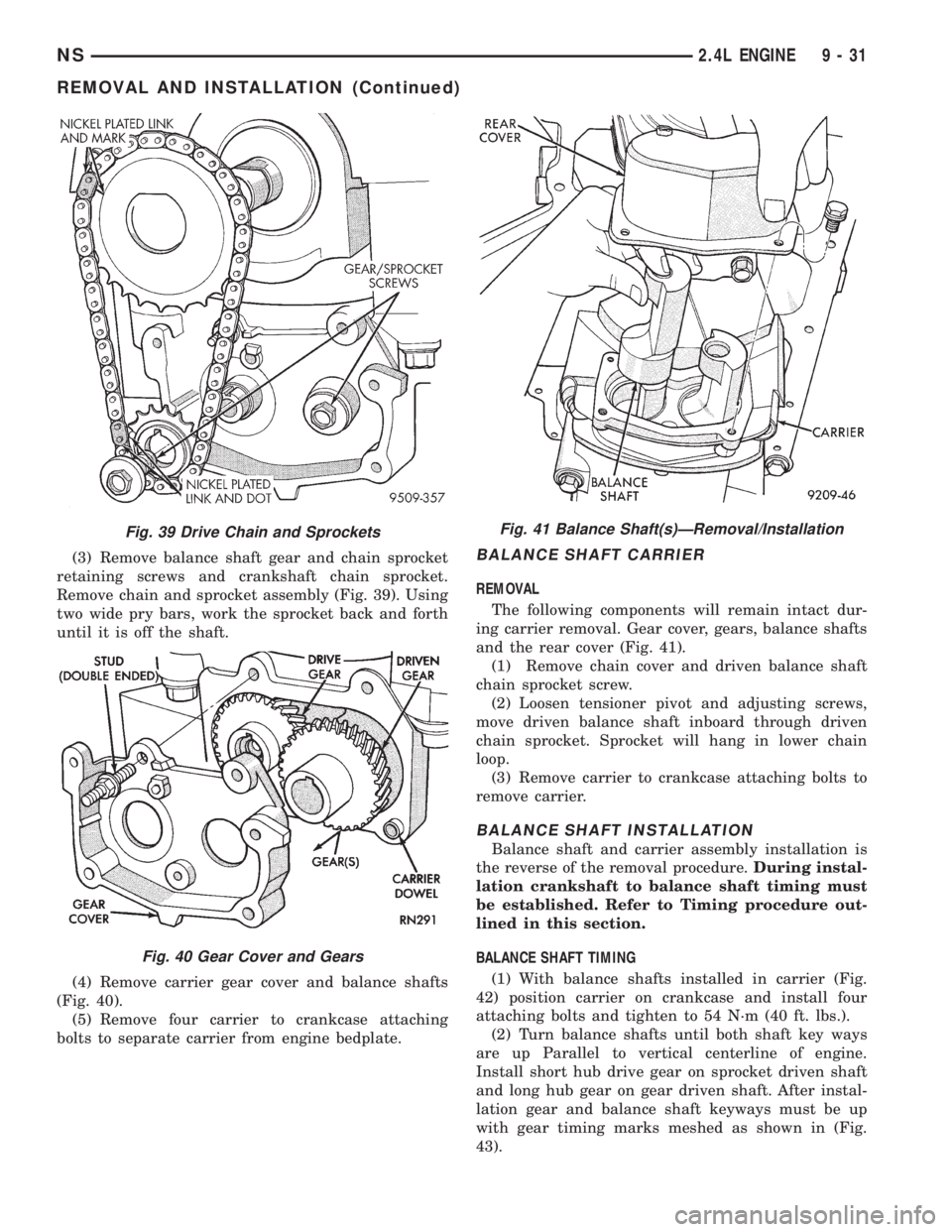

(3) Remove balance shaft gear and chain sprocket

retaining screws and crankshaft chain sprocket.

Remove chain and sprocket assembly (Fig. 39). Using

two wide pry bars, work the sprocket back and forth

until it is off the shaft.

(4) Remove carrier gear cover and balance shafts

(Fig. 40).

(5) Remove four carrier to crankcase attaching

bolts to separate carrier from engine bedplate.BALANCE SHAFT CARRIER

REMOVAL

The following components will remain intact dur-

ing carrier removal. Gear cover, gears, balance shafts

and the rear cover (Fig. 41).

(1) Remove chain cover and driven balance shaft

chain sprocket screw.

(2) Loosen tensioner pivot and adjusting screws,

move driven balance shaft inboard through driven

chain sprocket. Sprocket will hang in lower chain

loop.

(3) Remove carrier to crankcase attaching bolts to

remove carrier.

BALANCE SHAFT INSTALLATION

Balance shaft and carrier assembly installation is

the reverse of the removal procedure.During instal-

lation crankshaft to balance shaft timing must

be established. Refer to Timing procedure out-

lined in this section.

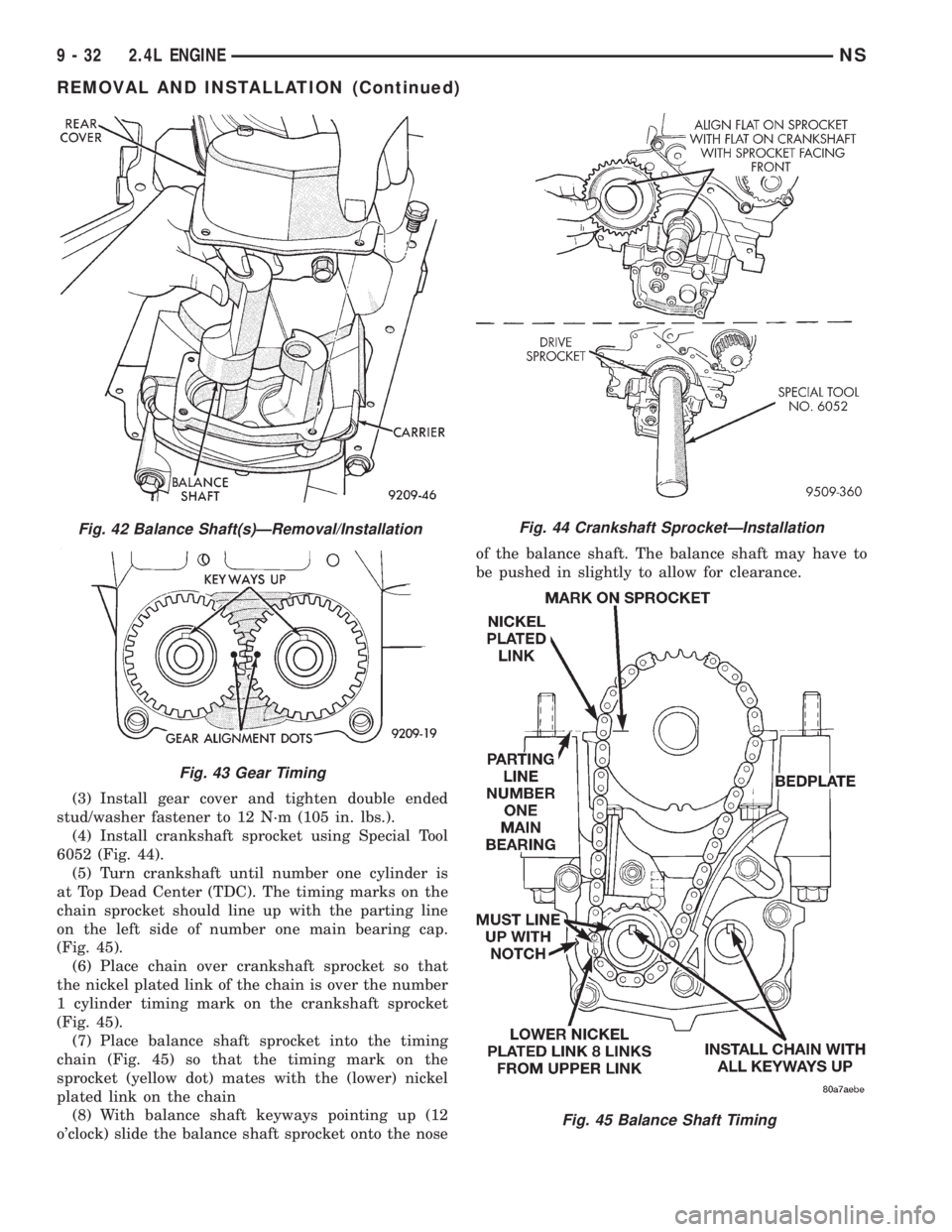

BALANCE SHAFT TIMING

(1) With balance shafts installed in carrier (Fig.

42) position carrier on crankcase and install four

attaching bolts and tighten to 54 N´m (40 ft. lbs.).

(2) Turn balance shafts until both shaft key ways

are up Parallel to vertical centerline of engine.

Install short hub drive gear on sprocket driven shaft

and long hub gear on gear driven shaft. After instal-

lation gear and balance shaft keyways must be up

with gear timing marks meshed as shown in (Fig.

43).

Fig. 39 Drive Chain and Sprockets

Fig. 40 Gear Cover and Gears

Fig. 41 Balance Shaft(s)ÐRemoval/Installation

NS2.4L ENGINE 9 - 31

REMOVAL AND INSTALLATION (Continued)

Page 1082 of 1938

(3) Install gear cover and tighten double ended

stud/washer fastener to 12 N´m (105 in. lbs.).

(4) Install crankshaft sprocket using Special Tool

6052 (Fig. 44).

(5) Turn crankshaft until number one cylinder is

at Top Dead Center (TDC). The timing marks on the

chain sprocket should line up with the parting line

on the left side of number one main bearing cap.

(Fig. 45).

(6) Place chain over crankshaft sprocket so that

the nickel plated link of the chain is over the number

1 cylinder timing mark on the crankshaft sprocket

(Fig. 45).

(7) Place balance shaft sprocket into the timing

chain (Fig. 45) so that the timing mark on the

sprocket (yellow dot) mates with the (lower) nickel

plated link on the chain

(8) With balance shaft keyways pointing up (12

o'clock) slide the balance shaft sprocket onto the noseof the balance shaft. The balance shaft may have to

be pushed in slightly to allow for clearance.

Fig. 42 Balance Shaft(s)ÐRemoval/Installation

Fig. 43 Gear Timing

Fig. 44 Crankshaft SprocketÐInstallation

Fig. 45 Balance Shaft Timing

9 - 32 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1270 of 1938

(2) Tighten intake manifold fasteners in the fol-

lowing sequence (Fig. 16). Torque to 23 N´m (200 in.

lbs.). Repeat this procedure until all bolts are at

specified torque.

(3) Install intake manifold center support bracket

bolts (Y bracket):

²Fastener to block 54 N´m (40 ft. lbs.)

²Fastener to intake 28 N´m (250 in. lbs.)

(4) Install fuel hose quick connector fitting to

chassis tubes.Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in Group 14, Fuel Deliv-

ery.Push the fitting onto the chassis tube until it

clicks into place. Pull on the fitting to ensure com-

plete insertion.

(5) Reverse removal procedures 2 through 12 for

installation.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(6) With the ignition key in ON position, access

the DRB scan tool ASD Fuel System Test to pressur-

ize the fuel system. Check for leaks.

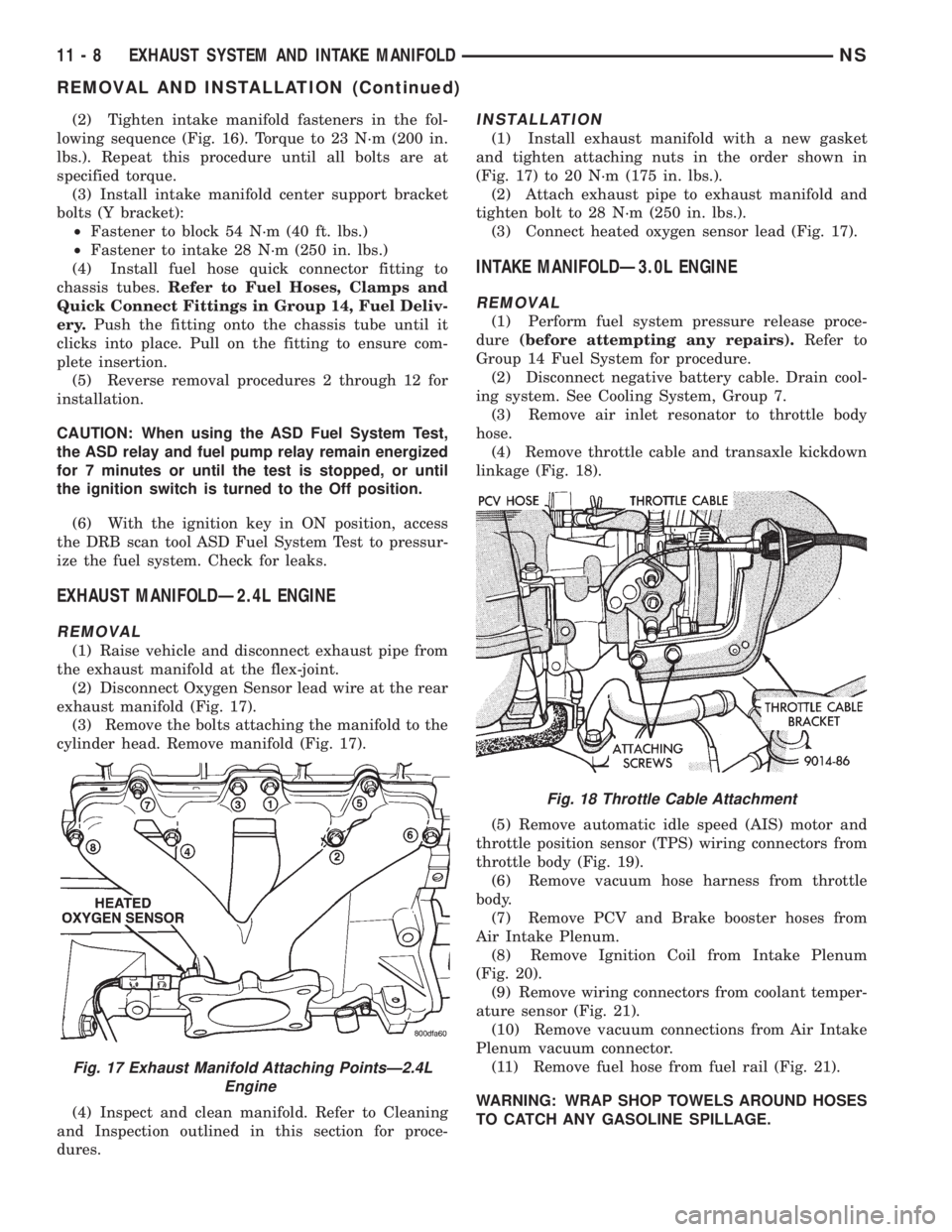

EXHAUST MANIFOLDÐ2.4L ENGINE

REMOVAL

(1) Raise vehicle and disconnect exhaust pipe from

the exhaust manifold at the flex-joint.

(2) Disconnect Oxygen Sensor lead wire at the rear

exhaust manifold (Fig. 17).

(3) Remove the bolts attaching the manifold to the

cylinder head. Remove manifold (Fig. 17).

(4) Inspect and clean manifold. Refer to Cleaning

and Inspection outlined in this section for proce-

dures.

INSTALLATION

(1) Install exhaust manifold with a new gasket

and tighten attaching nuts in the order shown in

(Fig. 17) to 20 N´m (175 in. lbs.).

(2) Attach exhaust pipe to exhaust manifold and

tighten bolt to 28 N´m (250 in. lbs.).

(3) Connect heated oxygen sensor lead (Fig. 17).

INTAKE MANIFOLDÐ3.0L ENGINE

REMOVAL

(1) Perform fuel system pressure release proce-

dure(before attempting any repairs).Refer to

Group 14 Fuel System for procedure.

(2) Disconnect negative battery cable. Drain cool-

ing system. See Cooling System, Group 7.

(3) Remove air inlet resonator to throttle body

hose.

(4) Remove throttle cable and transaxle kickdown

linkage (Fig. 18).

(5) Remove automatic idle speed (AIS) motor and

throttle position sensor (TPS) wiring connectors from

throttle body (Fig. 19).

(6) Remove vacuum hose harness from throttle

body.

(7) Remove PCV and Brake booster hoses from

Air Intake Plenum.

(8) Remove Ignition Coil from Intake Plenum

(Fig. 20).

(9) Remove wiring connectors from coolant temper-

ature sensor (Fig. 21).

(10) Remove vacuum connections from Air Intake

Plenum vacuum connector.

(11) Remove fuel hose from fuel rail (Fig. 21).

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY GASOLINE SPILLAGE.

Fig. 17 Exhaust Manifold Attaching PointsÐ2.4L

Engine

Fig. 18 Throttle Cable Attachment

11 - 8 EXHAUST SYSTEM AND INTAKE MANIFOLDNS

REMOVAL AND INSTALLATION (Continued)

Page 1301 of 1938

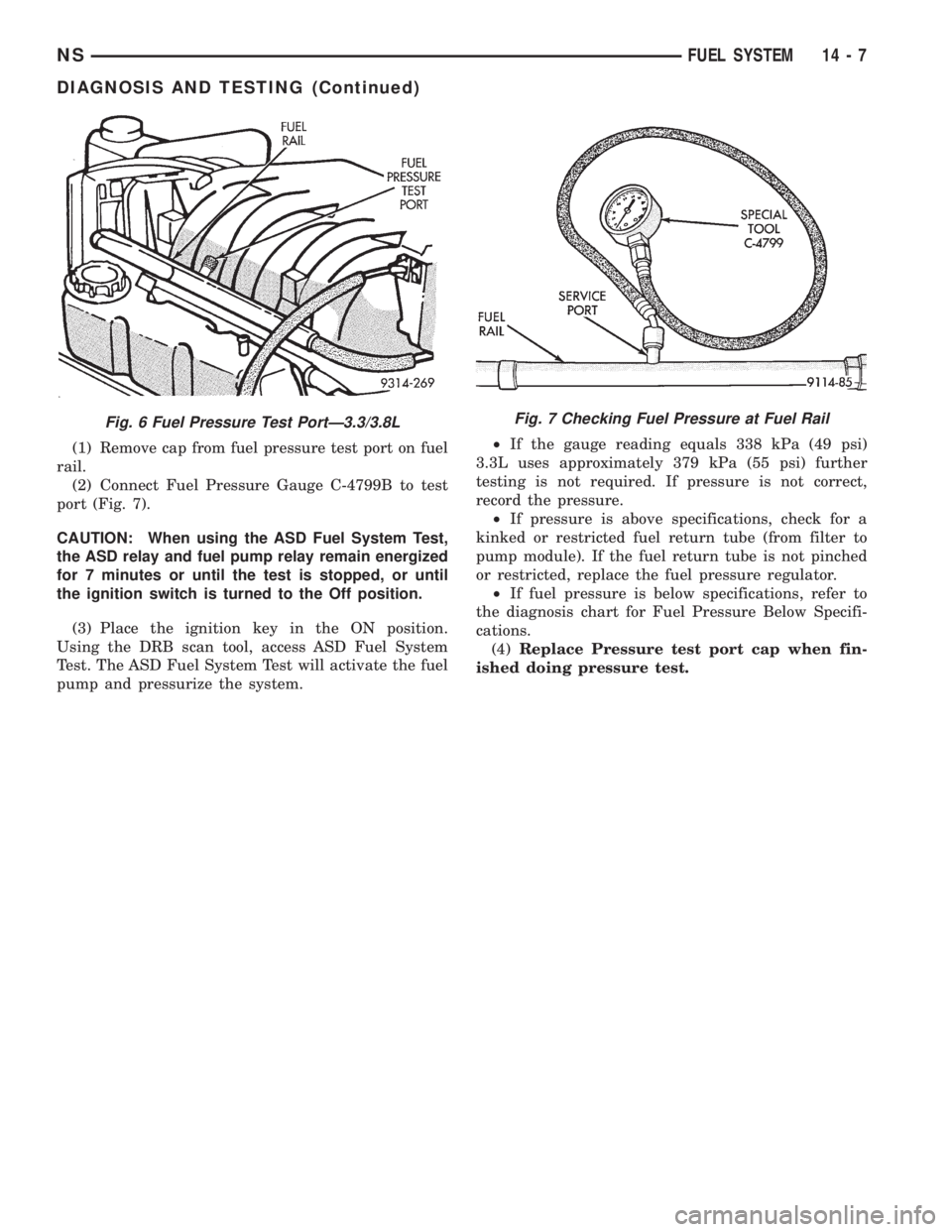

(1) Remove cap from fuel pressure test port on fuel

rail.

(2) Connect Fuel Pressure Gauge C-4799B to test

port (Fig. 7).

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(3) Place the ignition key in the ON position.

Using the DRB scan tool, access ASD Fuel System

Test. The ASD Fuel System Test will activate the fuel

pump and pressurize the system.²If the gauge reading equals 338 kPa (49 psi)

3.3L uses approximately 379 kPa (55 psi) further

testing is not required. If pressure is not correct,

record the pressure.

²If pressure is above specifications, check for a

kinked or restricted fuel return tube (from filter to

pump module). If the fuel return tube is not pinched

or restricted, replace the fuel pressure regulator.

²If fuel pressure is below specifications, refer to

the diagnosis chart for Fuel Pressure Below Specifi-

cations.

(4)Replace Pressure test port cap when fin-

ished doing pressure test.

Fig. 6 Fuel Pressure Test PortÐ3.3/3.8LFig. 7 Checking Fuel Pressure at Fuel Rail

NSFUEL SYSTEM 14 - 7

DIAGNOSIS AND TESTING (Continued)

Page 1305 of 1938

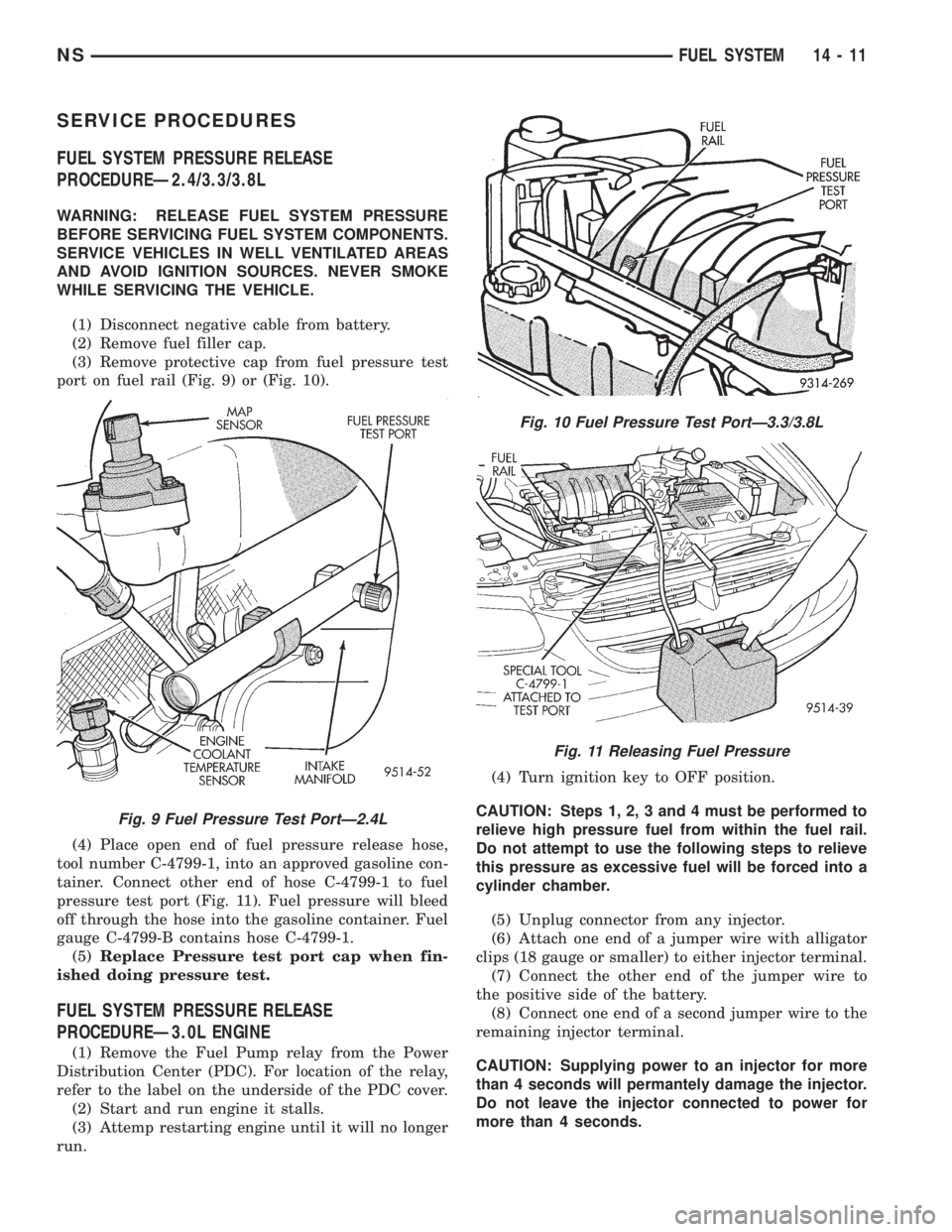

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.4/3.3/3.8L

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove protective cap from fuel pressure test

port on fuel rail (Fig. 9) or (Fig. 10).

(4) Place open end of fuel pressure release hose,

tool number C-4799-1, into an approved gasoline con-

tainer. Connect other end of hose C-4799-1 to fuel

pressure test port (Fig. 11). Fuel pressure will bleed

off through the hose into the gasoline container. Fuel

gauge C-4799-B contains hose C-4799-1.

(5)Replace Pressure test port cap when fin-

ished doing pressure test.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ3.0L ENGINE

(1) Remove the Fuel Pump relay from the Power

Distribution Center (PDC). For location of the relay,

refer to the label on the underside of the PDC cover.

(2) Start and run engine it stalls.

(3) Attemp restarting engine until it will no longer

run.(4) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within the fuel rail.

Do not attempt to use the following steps to relieve

this pressure as excessive fuel will be forced into a

cylinder chamber.

(5) Unplug connector from any injector.

(6) Attach one end of a jumper wire with alligator

clips (18 gauge or smaller) to either injector terminal.

(7) Connect the other end of the jumper wire to

the positive side of the battery.

(8) Connect one end of a second jumper wire to the

remaining injector terminal.

CAUTION: Supplying power to an injector for more

than 4 seconds will permantely damage the injector.

Do not leave the injector connected to power for

more than 4 seconds.

Fig. 9 Fuel Pressure Test PortÐ2.4L

Fig. 10 Fuel Pressure Test PortÐ3.3/3.8L

Fig. 11 Releasing Fuel Pressure

NSFUEL SYSTEM 14 - 11

Page 1313 of 1938

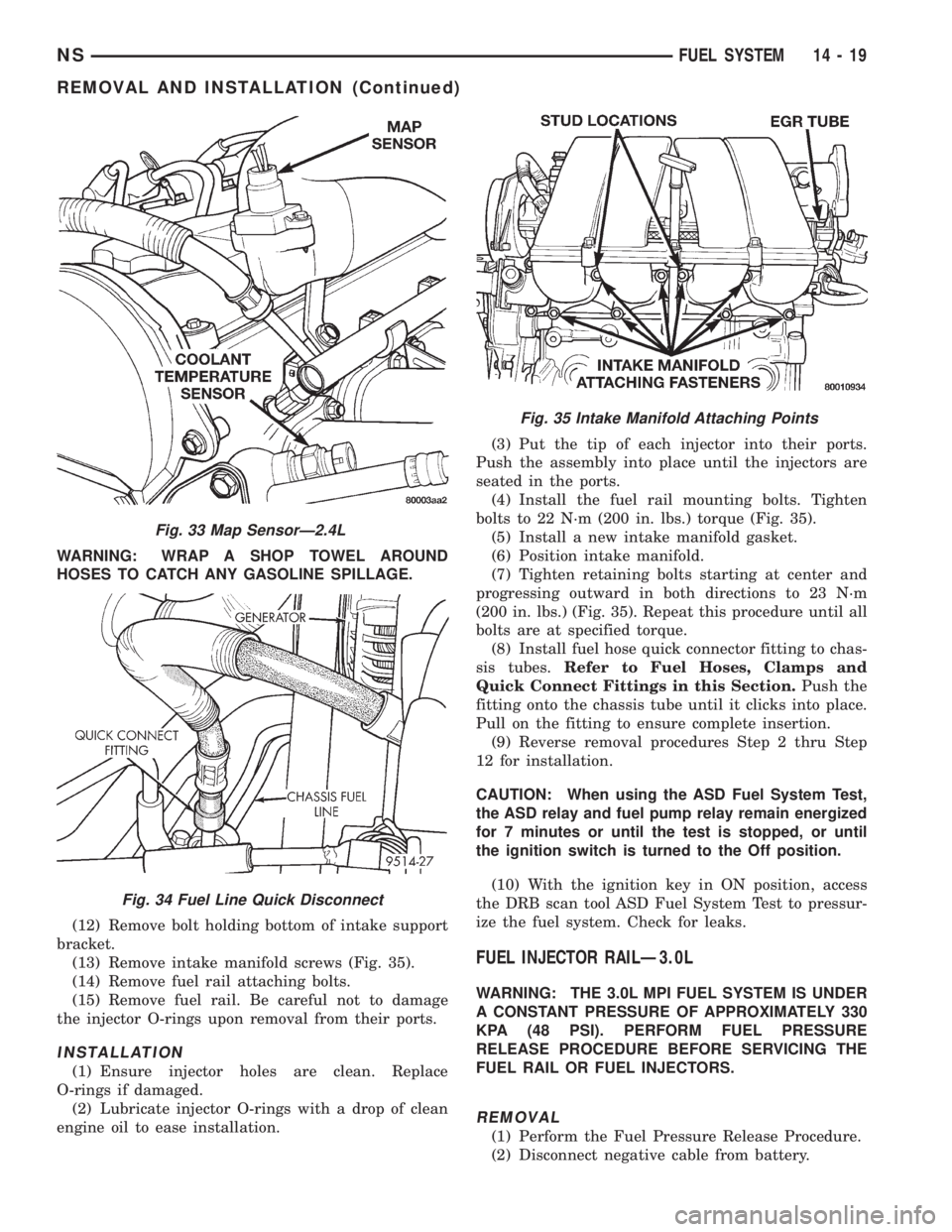

WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE.

(12) Remove bolt holding bottom of intake support

bracket.

(13) Remove intake manifold screws (Fig. 35).

(14) Remove fuel rail attaching bolts.

(15) Remove fuel rail. Be careful not to damage

the injector O-rings upon removal from their ports.

INSTALLATION

(1) Ensure injector holes are clean. Replace

O-rings if damaged.

(2) Lubricate injector O-rings with a drop of clean

engine oil to ease installation.(3) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports.

(4) Install the fuel rail mounting bolts. Tighten

bolts to 22 N´m (200 in. lbs.) torque (Fig. 35).

(5) Install a new intake manifold gasket.

(6) Position intake manifold.

(7) Tighten retaining bolts starting at center and

progressing outward in both directions to 23 N´m

(200 in. lbs.) (Fig. 35). Repeat this procedure until all

bolts are at specified torque.

(8) Install fuel hose quick connector fitting to chas-

sis tubes.Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in this Section.Push the

fitting onto the chassis tube until it clicks into place.

Pull on the fitting to ensure complete insertion.

(9) Reverse removal procedures Step 2 thru Step

12 for installation.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(10) With the ignition key in ON position, access

the DRB scan tool ASD Fuel System Test to pressur-

ize the fuel system. Check for leaks.

FUEL INJECTOR RAILÐ3.0L

WARNING: THE 3.0L MPI FUEL SYSTEM IS UNDER

A CONSTANT PRESSURE OF APPROXIMATELY 330

KPA (48 PSI). PERFORM FUEL PRESSURE

RELEASE PROCEDURE BEFORE SERVICING THE

FUEL RAIL OR FUEL INJECTORS.

REMOVAL

(1) Perform the Fuel Pressure Release Procedure.

(2) Disconnect negative cable from battery.

Fig. 33 Map SensorÐ2.4L

Fig. 34 Fuel Line Quick Disconnect

Fig. 35 Intake Manifold Attaching Points

NSFUEL SYSTEM 14 - 19

REMOVAL AND INSTALLATION (Continued)

Page 1315 of 1938

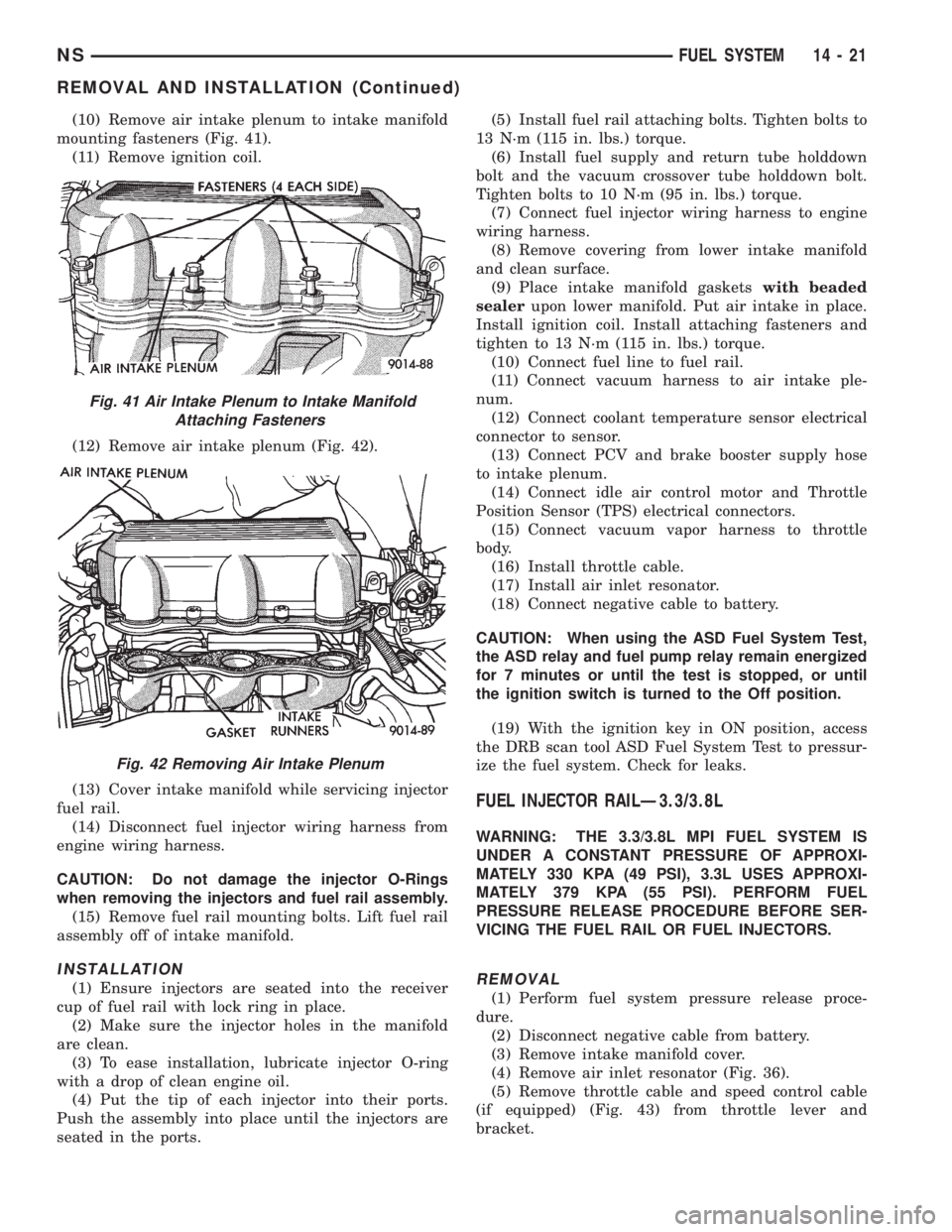

(10) Remove air intake plenum to intake manifold

mounting fasteners (Fig. 41).

(11) Remove ignition coil.

(12) Remove air intake plenum (Fig. 42).

(13) Cover intake manifold while servicing injector

fuel rail.

(14) Disconnect fuel injector wiring harness from

engine wiring harness.

CAUTION: Do not damage the injector O-Rings

when removing the injectors and fuel rail assembly.

(15) Remove fuel rail mounting bolts. Lift fuel rail

assembly off of intake manifold.

INSTALLATION

(1) Ensure injectors are seated into the receiver

cup of fuel rail with lock ring in place.

(2) Make sure the injector holes in the manifold

are clean.

(3) To ease installation, lubricate injector O-ring

with a drop of clean engine oil.

(4) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports.(5) Install fuel rail attaching bolts. Tighten bolts to

13 N´m (115 in. lbs.) torque.

(6) Install fuel supply and return tube holddown

bolt and the vacuum crossover tube holddown bolt.

Tighten bolts to 10 N´m (95 in. lbs.) torque.

(7) Connect fuel injector wiring harness to engine

wiring harness.

(8) Remove covering from lower intake manifold

and clean surface.

(9) Place intake manifold gasketswith beaded

sealerupon lower manifold. Put air intake in place.

Install ignition coil. Install attaching fasteners and

tighten to 13 N´m (115 in. lbs.) torque.

(10) Connect fuel line to fuel rail.

(11) Connect vacuum harness to air intake ple-

num.

(12) Connect coolant temperature sensor electrical

connector to sensor.

(13) Connect PCV and brake booster supply hose

to intake plenum.

(14) Connect idle air control motor and Throttle

Position Sensor (TPS) electrical connectors.

(15) Connect vacuum vapor harness to throttle

body.

(16) Install throttle cable.

(17) Install air inlet resonator.

(18) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(19) With the ignition key in ON position, access

the DRB scan tool ASD Fuel System Test to pressur-

ize the fuel system. Check for leaks.

FUEL INJECTOR RAILÐ3.3/3.8L

WARNING: THE 3.3/3.8L MPI FUEL SYSTEM IS

UNDER A CONSTANT PRESSURE OF APPROXI-

MATELY 330 KPA (49 PSI), 3.3L USES APPROXI-

MATELY 379 KPA (55 PSI). PERFORM FUEL

PRESSURE RELEASE PROCEDURE BEFORE SER-

VICING THE FUEL RAIL OR FUEL INJECTORS.

REMOVAL

(1) Perform fuel system pressure release proce-

dure.

(2) Disconnect negative cable from battery.

(3) Remove intake manifold cover.

(4) Remove air inlet resonator (Fig. 36).

(5) Remove throttle cable and speed control cable

(if equipped) (Fig. 43) from throttle lever and

bracket.

Fig. 41 Air Intake Plenum to Intake Manifold

Attaching Fasteners

Fig. 42 Removing Air Intake Plenum

NSFUEL SYSTEM 14 - 21

REMOVAL AND INSTALLATION (Continued)