wheel CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 425 of 1938

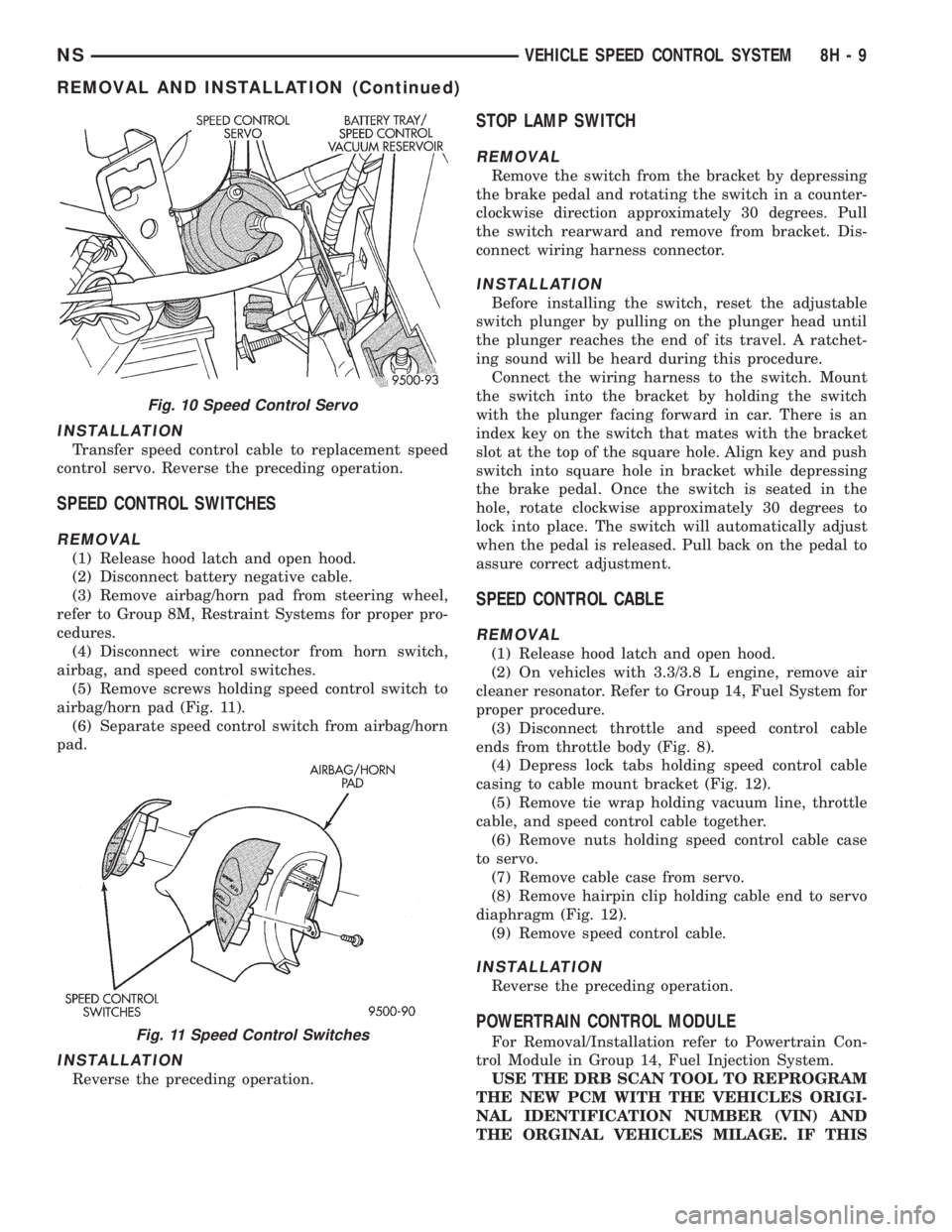

INSTALLATION

Transfer speed control cable to replacement speed

control servo. Reverse the preceding operation.

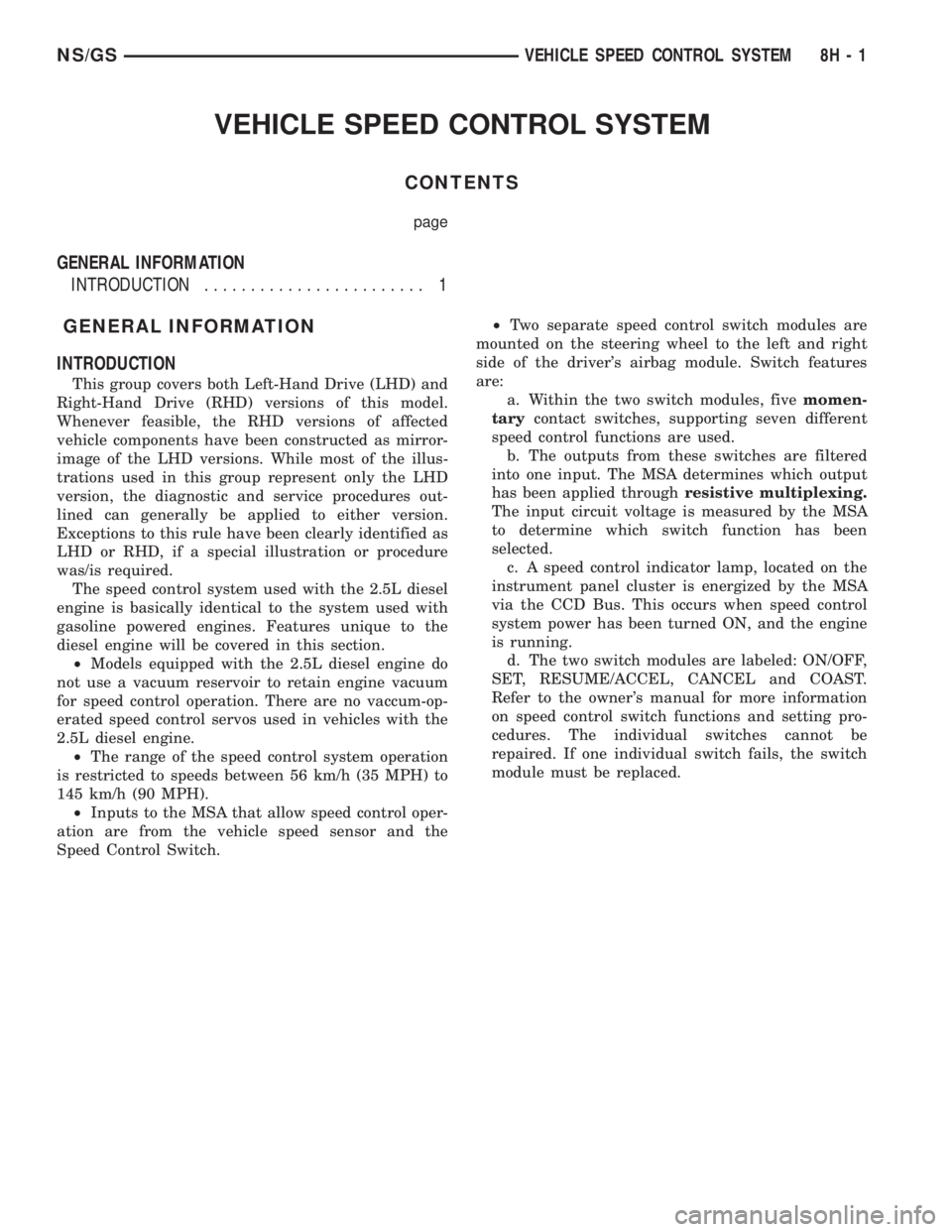

SPEED CONTROL SWITCHES

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable.

(3) Remove airbag/horn pad from steering wheel,

refer to Group 8M, Restraint Systems for proper pro-

cedures.

(4) Disconnect wire connector from horn switch,

airbag, and speed control switches.

(5) Remove screws holding speed control switch to

airbag/horn pad (Fig. 11).

(6) Separate speed control switch from airbag/horn

pad.

INSTALLATION

Reverse the preceding operation.

STOP LAMP SWITCH

REMOVAL

Remove the switch from the bracket by depressing

the brake pedal and rotating the switch in a counter-

clockwise direction approximately 30 degrees. Pull

the switch rearward and remove from bracket. Dis-

connect wiring harness connector.

INSTALLATION

Before installing the switch, reset the adjustable

switch plunger by pulling on the plunger head until

the plunger reaches the end of its travel. A ratchet-

ing sound will be heard during this procedure.

Connect the wiring harness to the switch. Mount

the switch into the bracket by holding the switch

with the plunger facing forward in car. There is an

index key on the switch that mates with the bracket

slot at the top of the square hole. Align key and push

switch into square hole in bracket while depressing

the brake pedal. Once the switch is seated in the

hole, rotate clockwise approximately 30 degrees to

lock into place. The switch will automatically adjust

when the pedal is released. Pull back on the pedal to

assure correct adjustment.

SPEED CONTROL CABLE

REMOVAL

(1) Release hood latch and open hood.

(2) On vehicles with 3.3/3.8 L engine, remove air

cleaner resonator. Refer to Group 14, Fuel System for

proper procedure.

(3) Disconnect throttle and speed control cable

ends from throttle body (Fig. 8).

(4) Depress lock tabs holding speed control cable

casing to cable mount bracket (Fig. 12).

(5) Remove tie wrap holding vacuum line, throttle

cable, and speed control cable together.

(6) Remove nuts holding speed control cable case

to servo.

(7) Remove cable case from servo.

(8) Remove hairpin clip holding cable end to servo

diaphragm (Fig. 12).

(9) Remove speed control cable.

INSTALLATION

Reverse the preceding operation.

POWERTRAIN CONTROL MODULE

For Removal/Installation refer to Powertrain Con-

trol Module in Group 14, Fuel Injection System.

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW PCM WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE ORGINAL VEHICLES MILAGE. IF THIS

Fig. 10 Speed Control Servo

Fig. 11 Speed Control Switches

NSVEHICLE SPEED CONTROL SYSTEM 8H - 9

REMOVAL AND INSTALLATION (Continued)

Page 427 of 1938

VEHICLE SPEED CONTROL SYSTEM

CONTENTS

page

GENERAL INFORMATION

INTRODUCTION........................ 1

GENERAL INFORMATION

INTRODUCTION

This group covers both Left-Hand Drive (LHD) and

Right-Hand Drive (RHD) versions of this model.

Whenever feasible, the RHD versions of affected

vehicle components have been constructed as mirror-

image of the LHD versions. While most of the illus-

trations used in this group represent only the LHD

version, the diagnostic and service procedures out-

lined can generally be applied to either version.

Exceptions to this rule have been clearly identified as

LHD or RHD, if a special illustration or procedure

was/is required.

The speed control system used with the 2.5L diesel

engine is basically identical to the system used with

gasoline powered engines. Features unique to the

diesel engine will be covered in this section.

²Models equipped with the 2.5L diesel engine do

not use a vacuum reservoir to retain engine vacuum

for speed control operation. There are no vaccum-op-

erated speed control servos used in vehicles with the

2.5L diesel engine.

²The range of the speed control system operation

is restricted to speeds between 56 km/h (35 MPH) to

145 km/h (90 MPH).

²Inputs to the MSA that allow speed control oper-

ation are from the vehicle speed sensor and the

Speed Control Switch.²Two separate speed control switch modules are

mounted on the steering wheel to the left and right

side of the driver's airbag module. Switch features

are:

a. Within the two switch modules, fivemomen-

tarycontact switches, supporting seven different

speed control functions are used.

b. The outputs from these switches are filtered

into one input. The MSA determines which output

has been applied throughresistive multiplexing.

The input circuit voltage is measured by the MSA

to determine which switch function has been

selected.

c. A speed control indicator lamp, located on the

instrument panel cluster is energized by the MSA

via the CCD Bus. This occurs when speed control

system power has been turned ON, and the engine

is running.

d. The two switch modules are labeled: ON/OFF,

SET, RESUME/ACCEL, CANCEL and COAST.

Refer to the owner's manual for more information

on speed control switch functions and setting pro-

cedures. The individual switches cannot be

repaired. If one individual switch fails, the switch

module must be replaced.

NS/GSVEHICLE SPEED CONTROL SYSTEM 8H - 1

Page 429 of 1938

TURN SIGNAL AND FLASHERS

CONTENTS

page page

GENERAL INFORMATION

COMBINATION FLASHER.................. 1

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

COMBINATION FLASHER / DAYTIME

RUNNING LAMPS (DRL) MODULE......... 2

COMBINATION FLASHER FUNCTION......... 1DIAGNOSIS AND TESTING

COMBINATION FLASHER WITH / WITHOUT

DAYTIME RUNNING LAMPS MODULEÐ

CIRCUIT DIAGNOSTICS.................. 3

TURN SIGNAL MULTI-FUNCTION SWITCH.... 2

REMOVAL AND INSTALLATION

COMBINATION FLASHER WITH / WITHOUT

DRL MODULE........................ 11

MULTI-FUNCTION SWITCH............... 11

GENERAL INFORMATION

INTRODUCTION

The turn signals are actuated with a lever on the

left side of the steering column just ahead of the

steering wheel. The signals are automatically turned

off by a canceling cam (two lobes molded to the clock-

spring mechanism). The cam comes in contact with

the cancel actuator on the turn signal (multi-func-

tion) switch assembly. Either cam lobe, pushing on

the cancel actuator, returns the switch to the OFF

position.

Lane change signaling is actuated by applying par-

tial turn signal stalk movement toward the direction

desired until the indicator lamps flashes in the

instrument cluster. When the switch stalk is released

the stalk will spring back into the neutral position

turning OFF the turn signal.

With the ignition switch ON and the turn signal

switch stalk actuated left or right, current flows

through the:

²Combination flasher

²Multi-function switch

²Turn indicator lamp

²Front and rear turn signal bulbs.

A chime will sound after the vehicle has traveled a

distance of approximately 0.5 mile with the turn sig-

nal ON.

COMBINATION FLASHER

The Turn Signal/Hazard Warning Flasher is a

module providing the vehicle with turn signal and

hazard warning functions and has been designed

with internal relays to take advantage of low current

switching requirements in the vehicle. It is plugged

into the Junction Block at position 4 (Fig. 1), where

all wiring associated with its operation is terminated.The Junction Block is adjacent to and left of the

steering column of the vehicle.

To gain access to the flasher, remove the lower

steering column cover and knee blocker. Refer to

Group 8E, Instrument Panel and Systems for

removal procedures.

DESCRIPTION AND OPERATION

COMBINATION FLASHER FUNCTION

The Turn Signal/Hazard Warning Flasher is a

module providing turn signal, hazard warning func-

tions and has been designed with internal relays to

Fig. 1 Combination Flasher Location

NSTURN SIGNAL AND FLASHERS 8J - 1

Page 439 of 1938

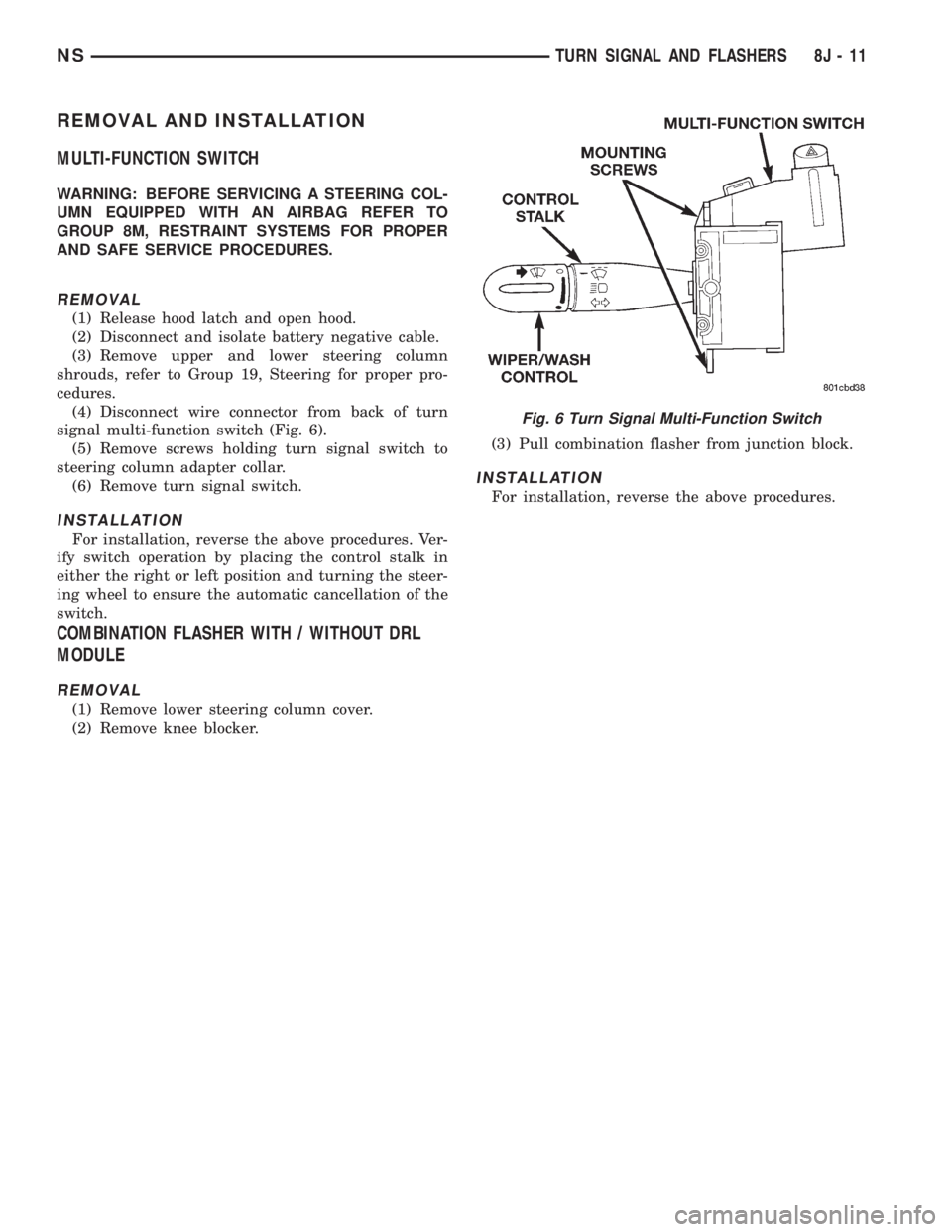

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH

WARNING: BEFORE SERVICING A STEERING COL-

UMN EQUIPPED WITH AN AIRBAG REFER TO

GROUP 8M, RESTRAINT SYSTEMS FOR PROPER

AND SAFE SERVICE PROCEDURES.

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect and isolate battery negative cable.

(3) Remove upper and lower steering column

shrouds, refer to Group 19, Steering for proper pro-

cedures.

(4) Disconnect wire connector from back of turn

signal multi-function switch (Fig. 6).

(5) Remove screws holding turn signal switch to

steering column adapter collar.

(6) Remove turn signal switch.

INSTALLATION

For installation, reverse the above procedures. Ver-

ify switch operation by placing the control stalk in

either the right or left position and turning the steer-

ing wheel to ensure the automatic cancellation of the

switch.

COMBINATION FLASHER WITH / WITHOUT DRL

MODULE

REMOVAL

(1) Remove lower steering column cover.

(2) Remove knee blocker.(3) Pull combination flasher from junction block.

INSTALLATION

For installation, reverse the above procedures.

Fig. 6 Turn Signal Multi-Function Switch

NSTURN SIGNAL AND FLASHERS 8J - 11

Page 444 of 1938

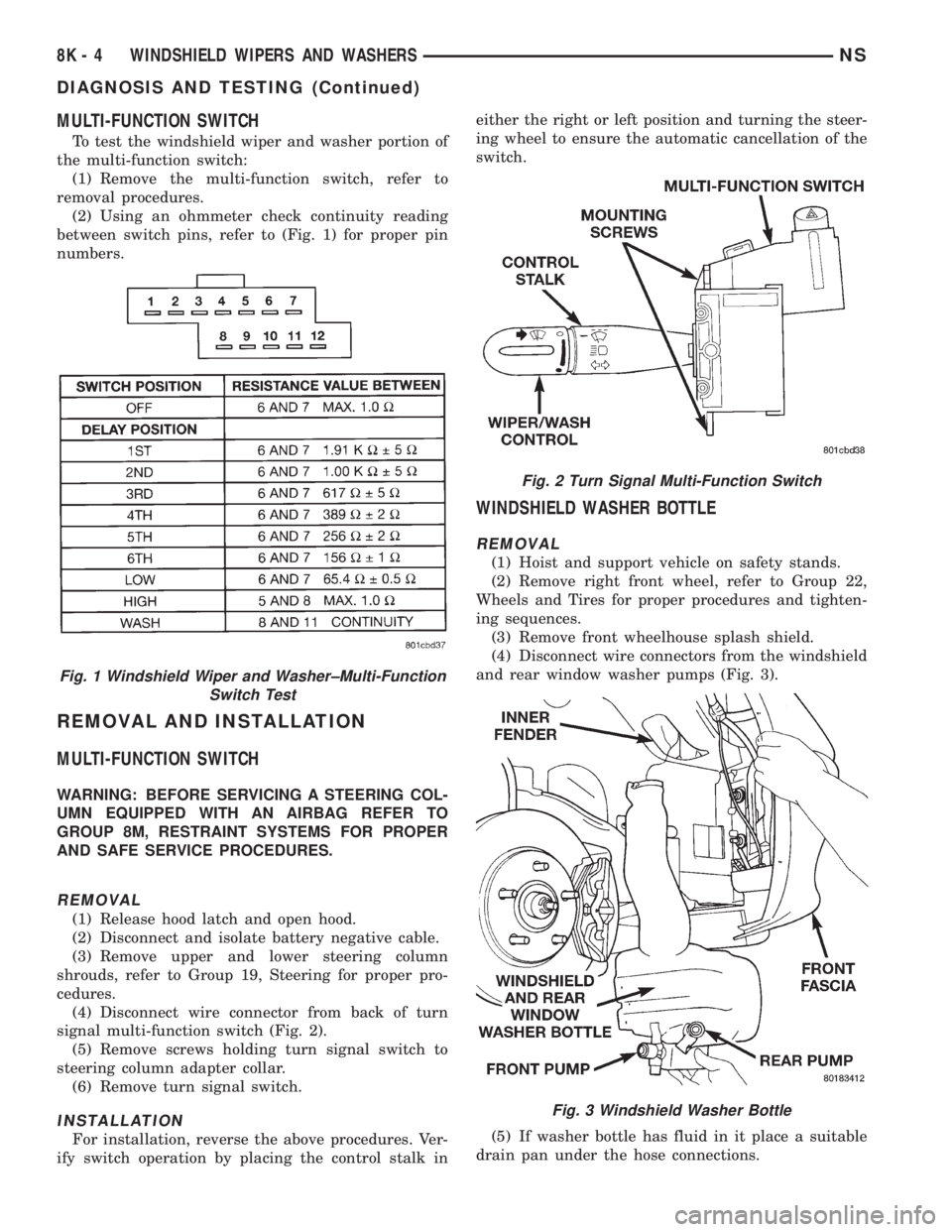

MULTI-FUNCTION SWITCH

To test the windshield wiper and washer portion of

the multi-function switch:

(1) Remove the multi-function switch, refer to

removal procedures.

(2) Using an ohmmeter check continuity reading

between switch pins, refer to (Fig. 1) for proper pin

numbers.

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH

WARNING: BEFORE SERVICING A STEERING COL-

UMN EQUIPPED WITH AN AIRBAG REFER TO

GROUP 8M, RESTRAINT SYSTEMS FOR PROPER

AND SAFE SERVICE PROCEDURES.

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect and isolate battery negative cable.

(3) Remove upper and lower steering column

shrouds, refer to Group 19, Steering for proper pro-

cedures.

(4) Disconnect wire connector from back of turn

signal multi-function switch (Fig. 2).

(5) Remove screws holding turn signal switch to

steering column adapter collar.

(6) Remove turn signal switch.

INSTALLATION

For installation, reverse the above procedures. Ver-

ify switch operation by placing the control stalk ineither the right or left position and turning the steer-

ing wheel to ensure the automatic cancellation of the

switch.

WINDSHIELD WASHER BOTTLE

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Remove right front wheel, refer to Group 22,

Wheels and Tires for proper procedures and tighten-

ing sequences.

(3) Remove front wheelhouse splash shield.

(4) Disconnect wire connectors from the windshield

and rear window washer pumps (Fig. 3).

(5) If washer bottle has fluid in it place a suitable

drain pan under the hose connections.

Fig. 1 Windshield Wiper and Washer±Multi-Function

Switch Test

Fig. 2 Turn Signal Multi-Function Switch

Fig. 3 Windshield Washer Bottle

8K - 4 WINDSHIELD WIPERS AND WASHERSNS

DIAGNOSIS AND TESTING (Continued)

Page 463 of 1938

(1) Connect wire connector into fog lamp wire har-

ness.

(2) Insert bulb into lamp so index notches on bulb

engage with bosses in lamp (Fig. 5).

(3) Hinge wire retainer clip over bulb base.

(4) Engage wire clip to hold bulb into lamp.

(5) Install rear cover on fog lamp.

(6) Install fog lamp on vehicle.

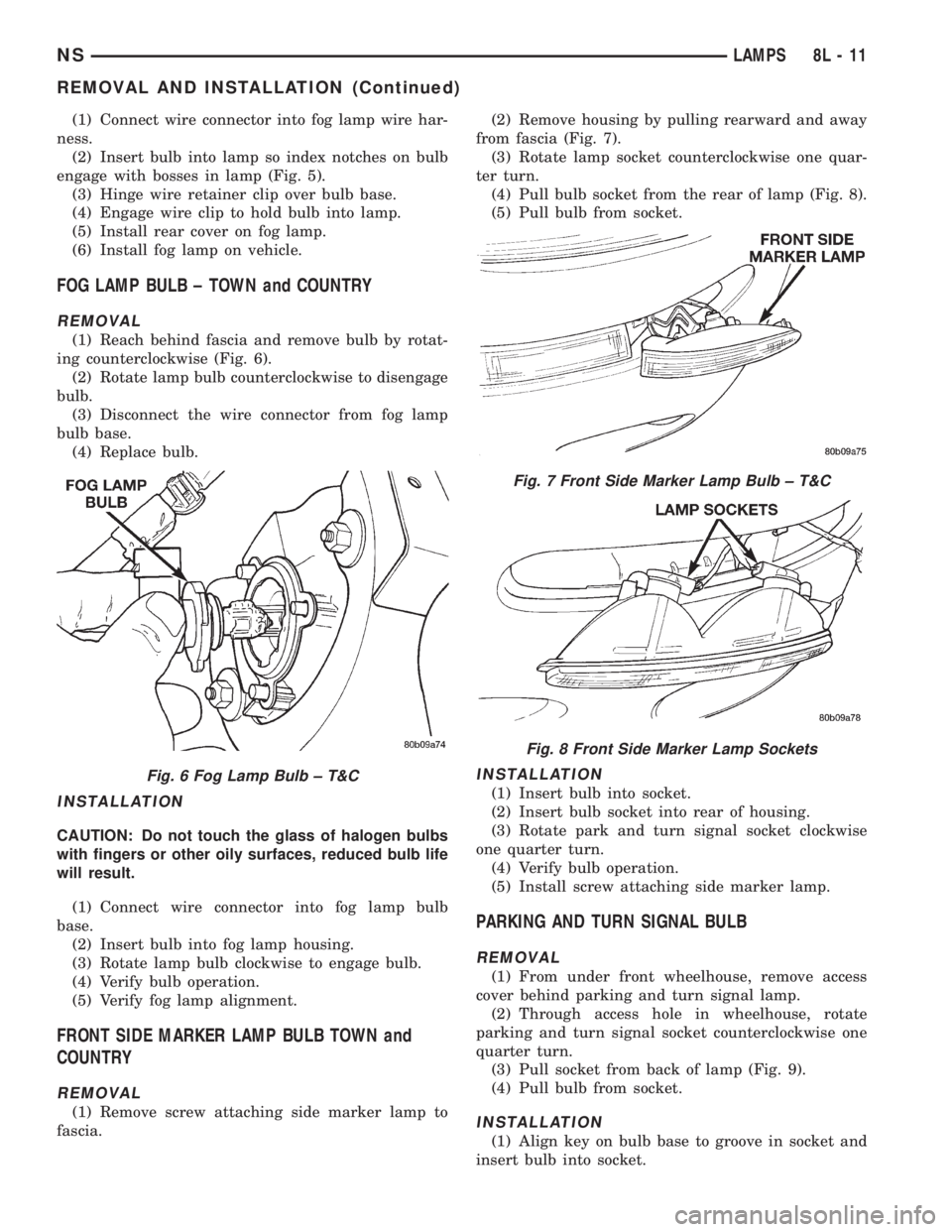

FOG LAMP BULB ± TOWN and COUNTRY

REMOVAL

(1) Reach behind fascia and remove bulb by rotat-

ing counterclockwise (Fig. 6).

(2) Rotate lamp bulb counterclockwise to disengage

bulb.

(3) Disconnect the wire connector from fog lamp

bulb base.

(4) Replace bulb.

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other oily surfaces, reduced bulb life

will result.

(1) Connect wire connector into fog lamp bulb

base.

(2) Insert bulb into fog lamp housing.

(3) Rotate lamp bulb clockwise to engage bulb.

(4) Verify bulb operation.

(5) Verify fog lamp alignment.

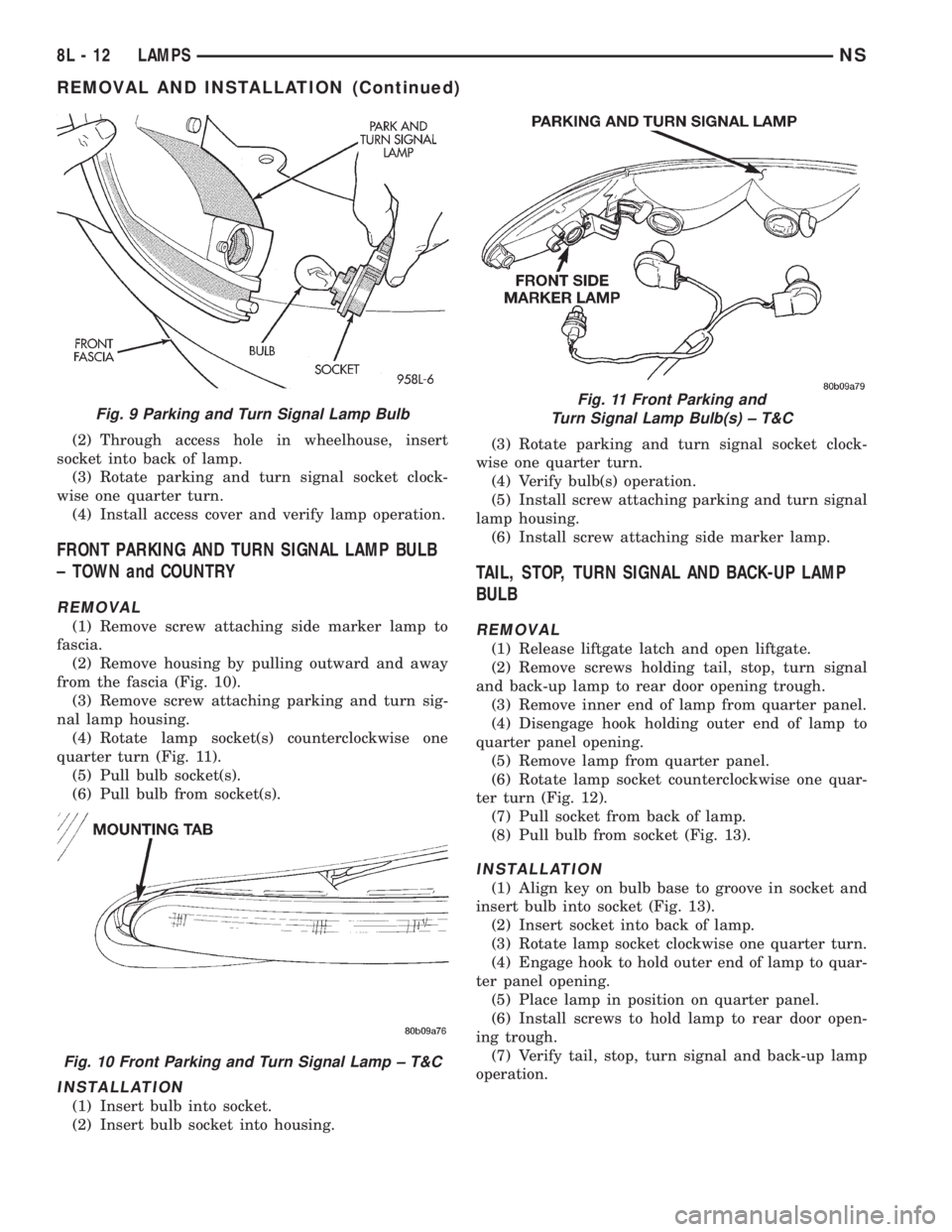

FRONT SIDE MARKER LAMP BULB TOWN and

COUNTRY

REMOVAL

(1) Remove screw attaching side marker lamp to

fascia.(2) Remove housing by pulling rearward and away

from fascia (Fig. 7).

(3) Rotate lamp socket counterclockwise one quar-

ter turn.

(4) Pull bulb socket from the rear of lamp (Fig. 8).

(5) Pull bulb from socket.

INSTALLATION

(1) Insert bulb into socket.

(2) Insert bulb socket into rear of housing.

(3) Rotate park and turn signal socket clockwise

one quarter turn.

(4) Verify bulb operation.

(5) Install screw attaching side marker lamp.

PARKING AND TURN SIGNAL BULB

REMOVAL

(1) From under front wheelhouse, remove access

cover behind parking and turn signal lamp.

(2) Through access hole in wheelhouse, rotate

parking and turn signal socket counterclockwise one

quarter turn.

(3) Pull socket from back of lamp (Fig. 9).

(4) Pull bulb from socket.

INSTALLATION

(1) Align key on bulb base to groove in socket and

insert bulb into socket.

Fig. 6 Fog Lamp Bulb ± T&C

Fig. 7 Front Side Marker Lamp Bulb ± T&C

Fig. 8 Front Side Marker Lamp Sockets

NSLAMPS 8L - 11

REMOVAL AND INSTALLATION (Continued)

Page 464 of 1938

(2) Through access hole in wheelhouse, insert

socket into back of lamp.

(3) Rotate parking and turn signal socket clock-

wise one quarter turn.

(4) Install access cover and verify lamp operation.

FRONT PARKING AND TURN SIGNAL LAMP BULB

± TOWN and COUNTRY

REMOVAL

(1) Remove screw attaching side marker lamp to

fascia.

(2) Remove housing by pulling outward and away

from the fascia (Fig. 10).

(3) Remove screw attaching parking and turn sig-

nal lamp housing.

(4) Rotate lamp socket(s) counterclockwise one

quarter turn (Fig. 11).

(5) Pull bulb socket(s).

(6) Pull bulb from socket(s).

INSTALLATION

(1) Insert bulb into socket.

(2) Insert bulb socket into housing.(3) Rotate parking and turn signal socket clock-

wise one quarter turn.

(4) Verify bulb(s) operation.

(5) Install screw attaching parking and turn signal

lamp housing.

(6) Install screw attaching side marker lamp.

TAIL, STOP, TURN SIGNAL AND BACK-UP LAMP

BULB

REMOVAL

(1) Release liftgate latch and open liftgate.

(2) Remove screws holding tail, stop, turn signal

and back-up lamp to rear door opening trough.

(3) Remove inner end of lamp from quarter panel.

(4) Disengage hook holding outer end of lamp to

quarter panel opening.

(5) Remove lamp from quarter panel.

(6) Rotate lamp socket counterclockwise one quar-

ter turn (Fig. 12).

(7) Pull socket from back of lamp.

(8) Pull bulb from socket (Fig. 13).

INSTALLATION

(1) Align key on bulb base to groove in socket and

insert bulb into socket (Fig. 13).

(2) Insert socket into back of lamp.

(3) Rotate lamp socket clockwise one quarter turn.

(4) Engage hook to hold outer end of lamp to quar-

ter panel opening.

(5) Place lamp in position on quarter panel.

(6) Install screws to hold lamp to rear door open-

ing trough.

(7) Verify tail, stop, turn signal and back-up lamp

operation.

Fig. 9 Parking and Turn Signal Lamp Bulb

Fig. 10 Front Parking and Turn Signal Lamp ± T&C

Fig. 11 Front Parking and

Turn Signal Lamp Bulb(s) ± T&C

8L - 12 LAMPSNS

REMOVAL AND INSTALLATION (Continued)

Page 498 of 1938

ACM monitors the system to determine the system

readiness. The ACM contains on-board diagnostics

and will light the AIRBAG warning lamp in the mes-

sage center when a problem occurs.

The driver and passenger airbag system is a safety

device designed to reduce the risk of fatality or seri-

ous injury, caused by a frontal impact of the vehicle.

The impact sensor provides verification of the

direction and severity of the impact. One impact sen-

sor is used. It is located inside the Airbag Control

Module (ACM) which is mounted on a bracket, just

forward of the center console. The impact sensor is

an accelerometer that senses deceleration. The decel-

eration pulses are sent to a microprocessor which

contains a decision algorithm. When an impact is

severe enough to require airbag protection, the ACM

micro processor sends a signal that completes the

electrical circuit to the driver and passenger airbags.

The sensor is calibrated for the specific vehicle and

reacts to the severity and direction of the impact.

CLOCKSPRING

The clockspring is snapped into a plastic mounting

platform on the steering column behind the steering

wheel. The clockspring is used to maintain a contin-

uous electrical circuit between the wiring harness

and the driver's airbag module. This assembly con-

sists of a flat ribbon like electrically conductive tape

which winds and unwinds with the steering wheel

rotation.

DRIVER AND PASSENGER AIRBAG MODULES

The Driver Airbag Module is located in the center

of the steering wheel. The Passenger Airbag Module

is located in the instrument panel above the glove

box (Fig. 1). The Driver Airbag Module cover contains

the horn switch, inflator device, and a fabric bag. The

airbag cover/horn switch is serviced separately from

the inflator and bag components. Refer to Group 8G,

Horns for proper service procedure for horn switch.

The Passenger Airbag Module is serviced as an

assembly.

WARNING: WHEN THE AIRBAG SYSTEM IS

DEPLOYED BECAUSE OF A COLLISION, THE FOL-

LOWING MUST BE REPLACED:

²COMPLETE STEERING COLUMN ASSEMBLY

²LOWER STEERING COUPLER

²STEERING WHEEL

²STEERING COLUMN CLOCKSPRING

²DRIVER AIRBAG COVER/HORN SWITCH

²DRIVER AIRBAG MODULE

²PASSENGER AIRBAG MODULE

²UPPER INSTRUMENT PANEL WITH PAD

DIAGNOSIS AND TESTING

AIRBAG SYSTEM TEST

(1) Disconnect and isolate the battery negative

cable.

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.

(2) Connect scan tool (DRB) to Data Link connec-

tor, located at left side of the steering column and at

the lower edge of the lower instrument panel.

(3) Turn the ignition key to ON position. Exit vehi-

cle with scan tool. Use the latest version of the

proper cartridge.

(4) After checking that no one is inside the vehicle,

connect the battery negative terminal.

(5) Using the scan tool, read and record active

diagnostic code data.

(6) Read and record any stored diagnostic codes.

(7) Refer to the proper Body Diagnostic Procedures

Manual if any diagnostic codes are found in Step 5 or

Step 6.

(8) Erase stored diagnostic codes if there are no

active diagnostic codes. If problems remain, diagnos-

tic codes will not erase. Refer to the Passive

Restraint Diagnostic Test Manual to diagnose the

problem.If airbag warning lamp either fails to

light, or goes on and stays on, there is a system

malfunction. Refer to the proper Body Diagnos-

tic Procedures Manual to diagnose the problem.

Fig. 1 Airbag Module Locations

8M - 2 RESTRAINT SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 501 of 1938

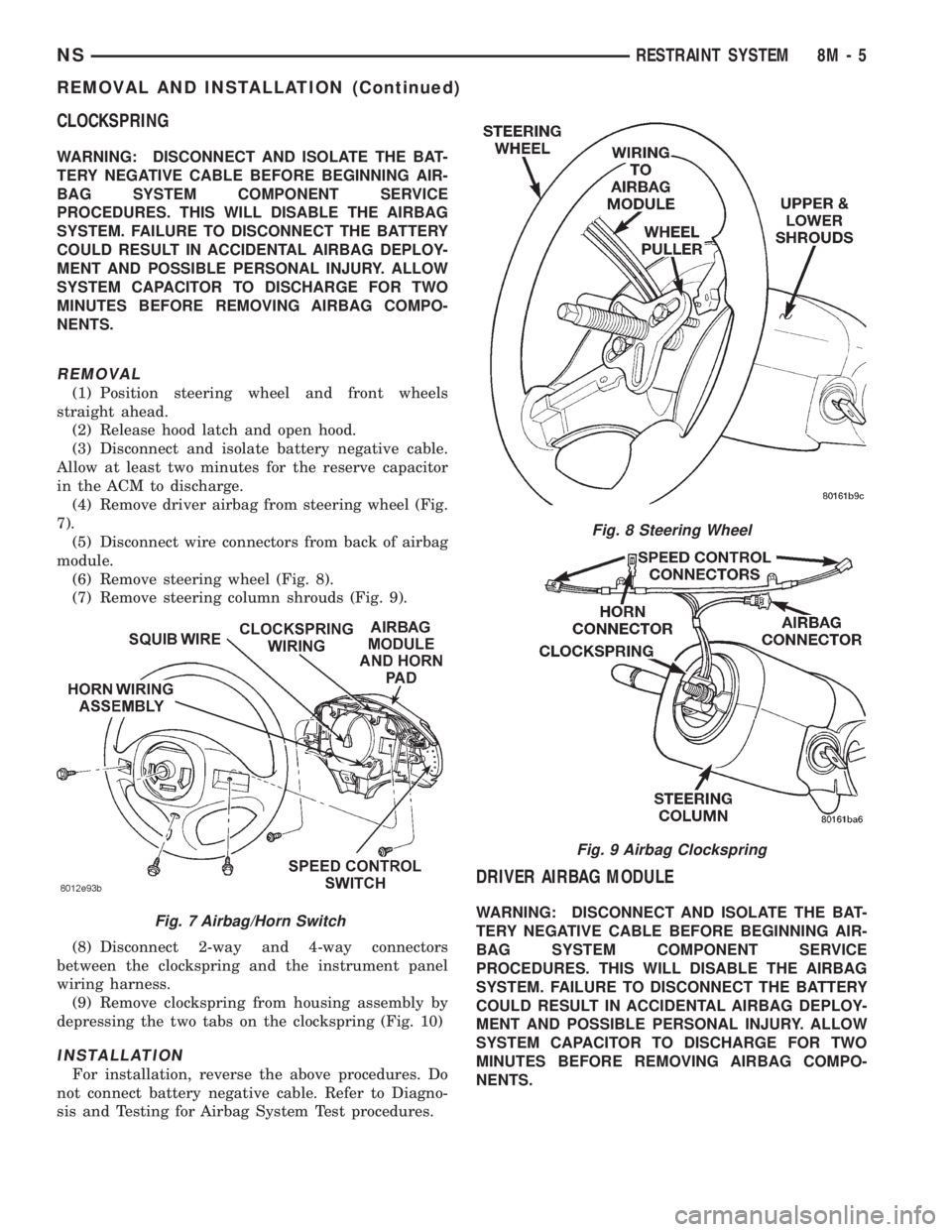

CLOCKSPRING

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood.

(3) Disconnect and isolate battery negative cable.

Allow at least two minutes for the reserve capacitor

in the ACM to discharge.

(4) Remove driver airbag from steering wheel (Fig.

7).

(5) Disconnect wire connectors from back of airbag

module.

(6) Remove steering wheel (Fig. 8).

(7) Remove steering column shrouds (Fig. 9).

(8) Disconnect 2-way and 4-way connectors

between the clockspring and the instrument panel

wiring harness.

(9) Remove clockspring from housing assembly by

depressing the two tabs on the clockspring (Fig. 10)

INSTALLATION

For installation, reverse the above procedures. Do

not connect battery negative cable. Refer to Diagno-

sis and Testing for Airbag System Test procedures.

DRIVER AIRBAG MODULE

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.Fig. 7 Airbag/Horn Switch

Fig. 8 Steering Wheel

Fig. 9 Airbag Clockspring

NSRESTRAINT SYSTEM 8M - 5

REMOVAL AND INSTALLATION (Continued)

Page 502 of 1938

DEPLOYED MODULE

The Driver Airbag Module and Driver Airbag Cov-

er/Horn Pad are serviced separately from eachother.

REMOVAL

(1) Disconnect battery negative cable. Allow at

least two minutes for the reserve capacitor in the

ACM to discharge.

(2) Clean powder residue from interior of vehicle,

refer to Cleanup Procedure.

(3) Remove three screws attaching Driver Airbag

Module to steering wheel (Fig. 7).

(4) Remove airbag module from steering wheel.

(5) Disconnect wire connectors from Airbag Mod-

ule, horn switch, and speed control switches.

(6) Adjust the steering wheel so that the tires are

in a straight ahead position. Remove steering wheel

(Fig. 8), refer to Group 19, Steering for proper proce-

dure.

(7) Disconnect the 2-way and 4-way connectors

between the clockspring and the instrument panel

wiring harness.

(8) Remove upper and lower steering column

shrouds.

(9) Remove clockspring from the housing assembly

by depressing the 2 tabs on the clockspring (Fig. 10).

(10) Remove screws holding speed control switches

to airbag cover and remove, if equipped.

INSTALLATION

For installation, reverse the above procedures. Do

not connect battery negative cable. Refer to Diagno-

sis and Testing for Airbag System Test procedures.

UNDEPLOYED

REMOVAL

(1) Disconnect battery negative cable. Allow at

least two minutes for the reserve capacitor in the

Airbag Control Module (ACM) to discharge.

(2) Remove screws attaching airbag/horn switch to

steering wheel (Fig. 7).

(3) Remove Driver Airbag Module from steering

wheel.

(4) Disconnect wire connectors from airbag mod-

ule, horn switch, and speed control switches, if

equipped.

(5) Remove screws holding vehicle speed control

switches to airbag cover and remove.

INSTALLATION

For installation, reverse the above procedures and

do not connect battery negative cable. Do not connect

battery negative cable. Refer to Diagnosis and Test-

ing for Airbag System Test procedures.

PASSENGER AIRBAG

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.

DEPLOYED MODULE

REMOVAL

(1) Disconnect and isolate battery negative cable.

Allow at least two minutes for the reserve capacitor

in the Airbag Control Module to discharge.

(2) Clean powder residue from interior of vehicle,

refer to Cleanup Procedure in this section.

(3) Remove instrument panel, refer to Group 8E,

Instrument Panel and Systems for proper proce-

dures.

(4) Remove all reusable components from the

upper instrument panel.

INSTALLATION

Transfer all reusable components to the new the

upper instrument panel.

(1) Install new Passenger Airbag Module into

instrument panel.

(2) Install airbag module attaching screws to the

instrument panel.

Fig. 10 Clockspring Locking Tabs

8M - 6 RESTRAINT SYSTEMNS

REMOVAL AND INSTALLATION (Continued)