wheel CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 211 of 1938

INSTALLATION

1. Position the slave cylinder assembly to the tran-

saxle deck and secure with the nut and washer

assemblies (2) and tighten to specifications (Fig. 14).

2. Make sure the slave cylinder pushrod is prop-

erly seated in the cup end of the clutch release lever.

3. Connect the quick connect coupling. Refer to the

ªQuick Connect Couplingº removal and installation

procedure in this section.

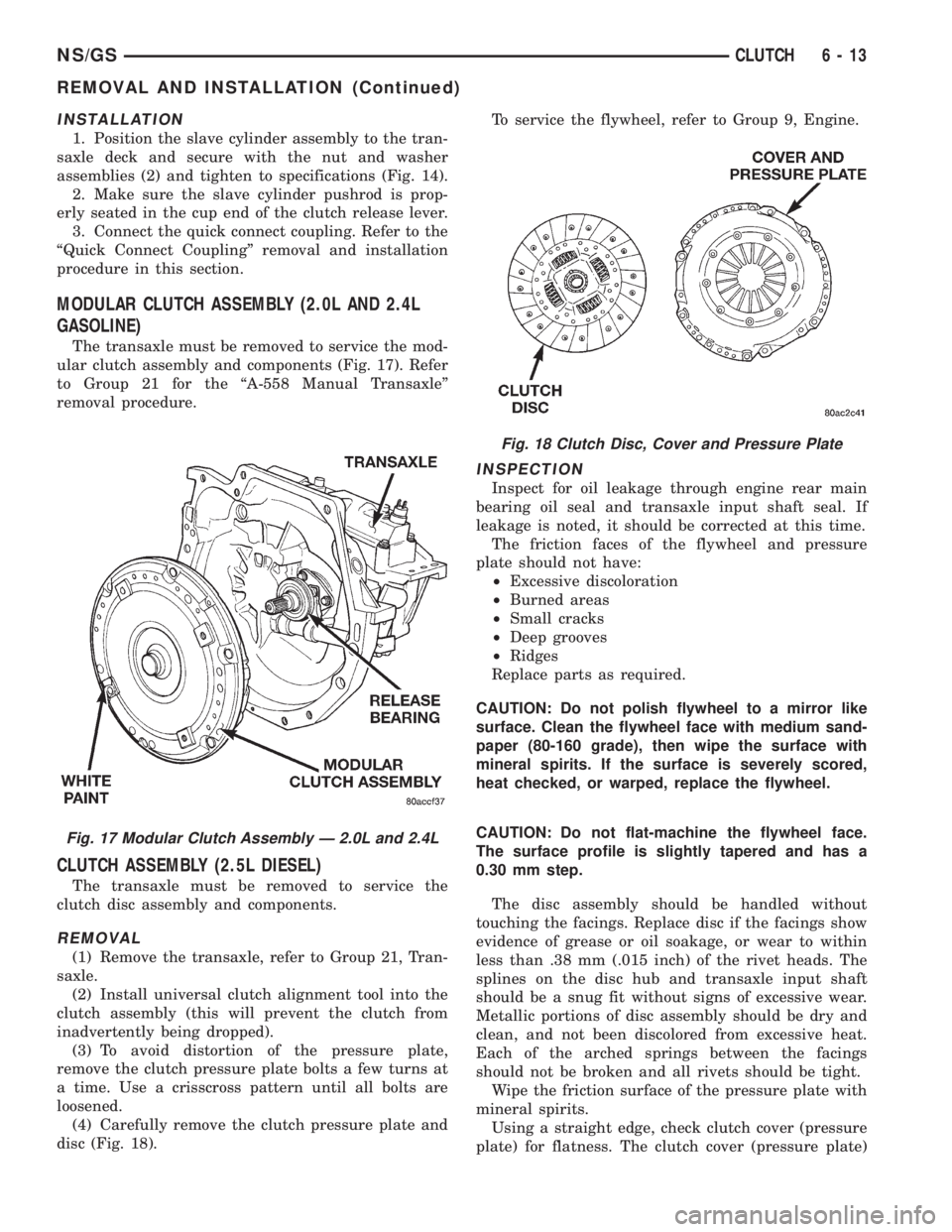

MODULAR CLUTCH ASSEMBLY (2.0L AND 2.4L

GASOLINE)

The transaxle must be removed to service the mod-

ular clutch assembly and components (Fig. 17). Refer

to Group 21 for the ªA-558 Manual Transaxleº

removal procedure.

CLUTCH ASSEMBLY (2.5L DIESEL)

The transaxle must be removed to service the

clutch disc assembly and components.

REMOVAL

(1) Remove the transaxle, refer to Group 21, Tran-

saxle.

(2) Install universal clutch alignment tool into the

clutch assembly (this will prevent the clutch from

inadvertently being dropped).

(3) To avoid distortion of the pressure plate,

remove the clutch pressure plate bolts a few turns at

a time. Use a crisscross pattern until all bolts are

loosened.

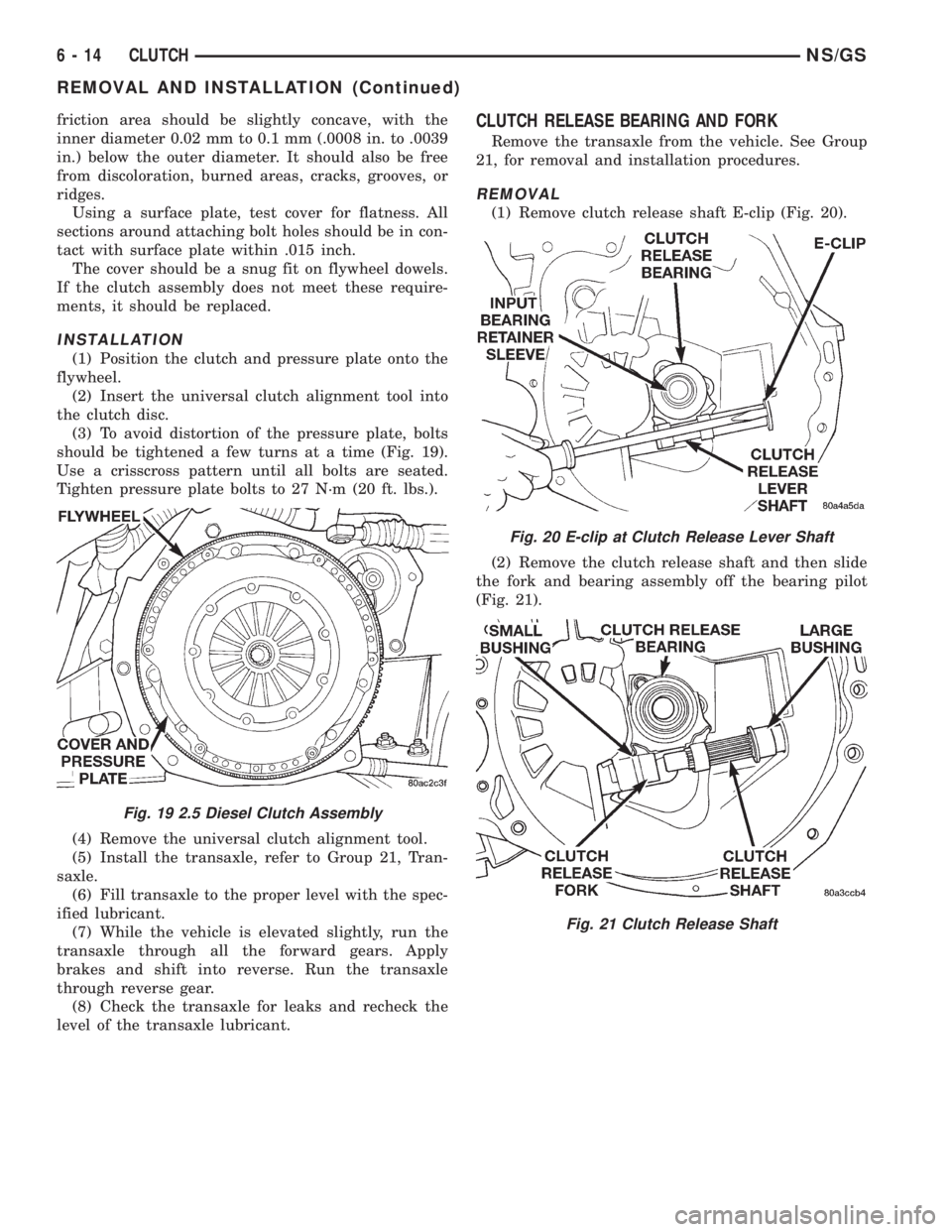

(4) Carefully remove the clutch pressure plate and

disc (Fig. 18).To service the flywheel, refer to Group 9, Engine.

INSPECTION

Inspect for oil leakage through engine rear main

bearing oil seal and transaxle input shaft seal. If

leakage is noted, it should be corrected at this time.

The friction faces of the flywheel and pressure

plate should not have:

²Excessive discoloration

²Burned areas

²Small cracks

²Deep grooves

²Ridges

Replace parts as required.

CAUTION: Do not polish flywheel to a mirror like

surface. Clean the flywheel face with medium sand-

paper (80-160 grade), then wipe the surface with

mineral spirits. If the surface is severely scored,

heat checked, or warped, replace the flywheel.

CAUTION: Do not flat-machine the flywheel face.

The surface profile is slightly tapered and has a

0.30 mm step.

The disc assembly should be handled without

touching the facings. Replace disc if the facings show

evidence of grease or oil soakage, or wear to within

less than .38 mm (.015 inch) of the rivet heads. The

splines on the disc hub and transaxle input shaft

should be a snug fit without signs of excessive wear.

Metallic portions of disc assembly should be dry and

clean, and not been discolored from excessive heat.

Each of the arched springs between the facings

should not be broken and all rivets should be tight.

Wipe the friction surface of the pressure plate with

mineral spirits.

Using a straight edge, check clutch cover (pressure

plate) for flatness. The clutch cover (pressure plate)

Fig. 17 Modular Clutch Assembly Ð 2.0L and 2.4L

Fig. 18 Clutch Disc, Cover and Pressure Plate

NS/GSCLUTCH 6 - 13

REMOVAL AND INSTALLATION (Continued)

Page 212 of 1938

friction area should be slightly concave, with the

inner diameter 0.02 mm to 0.1 mm (.0008 in. to .0039

in.) below the outer diameter. It should also be free

from discoloration, burned areas, cracks, grooves, or

ridges.

Using a surface plate, test cover for flatness. All

sections around attaching bolt holes should be in con-

tact with surface plate within .015 inch.

The cover should be a snug fit on flywheel dowels.

If the clutch assembly does not meet these require-

ments, it should be replaced.

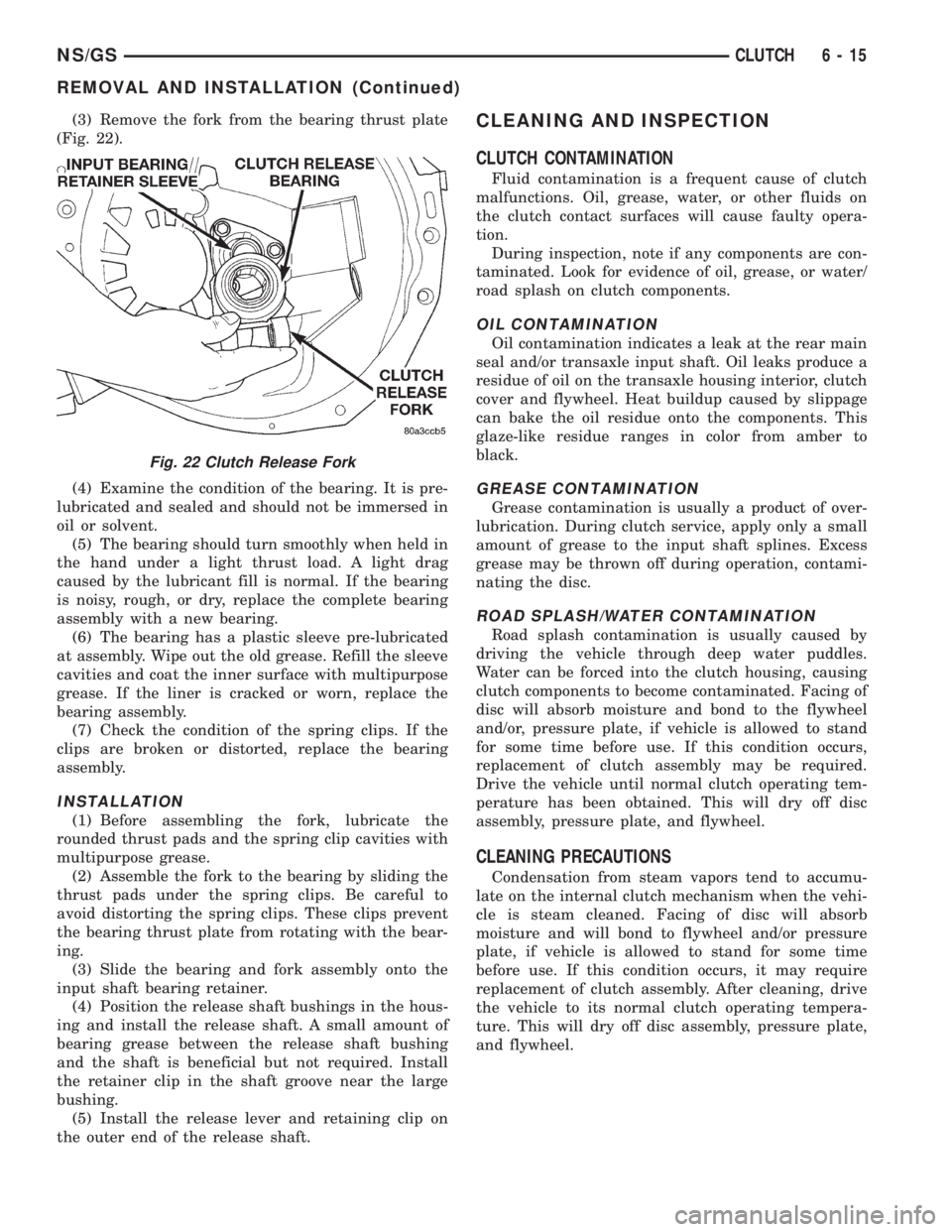

INSTALLATION

(1) Position the clutch and pressure plate onto the

flywheel.

(2) Insert the universal clutch alignment tool into

the clutch disc.

(3) To avoid distortion of the pressure plate, bolts

should be tightened a few turns at a time (Fig. 19).

Use a crisscross pattern until all bolts are seated.

Tighten pressure plate bolts to 27 N´m (20 ft. lbs.).

(4) Remove the universal clutch alignment tool.

(5) Install the transaxle, refer to Group 21, Tran-

saxle.

(6) Fill transaxle to the proper level with the spec-

ified lubricant.

(7) While the vehicle is elevated slightly, run the

transaxle through all the forward gears. Apply

brakes and shift into reverse. Run the transaxle

through reverse gear.

(8) Check the transaxle for leaks and recheck the

level of the transaxle lubricant.

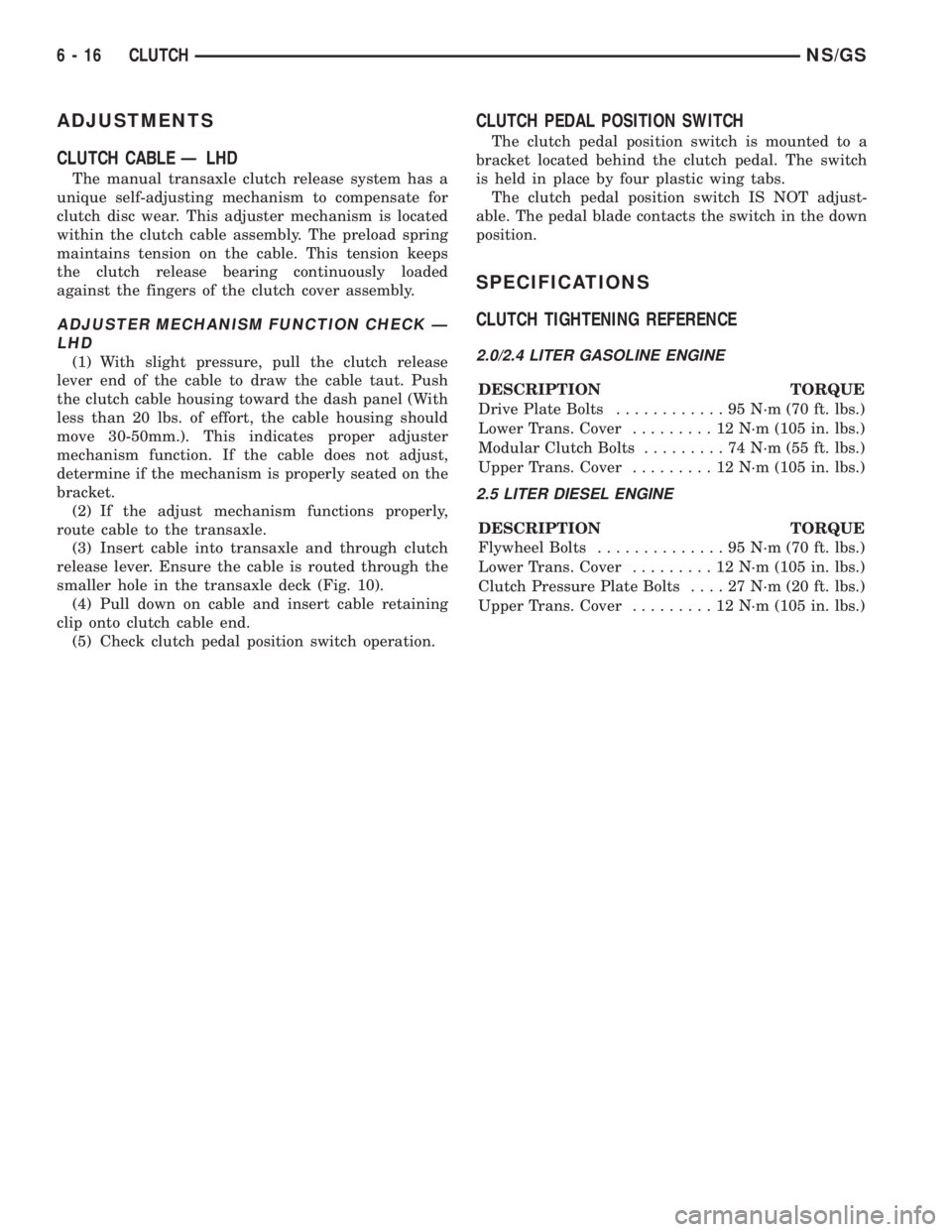

CLUTCH RELEASE BEARING AND FORK

Remove the transaxle from the vehicle. See Group

21, for removal and installation procedures.

REMOVAL

(1) Remove clutch release shaft E-clip (Fig. 20).

(2) Remove the clutch release shaft and then slide

the fork and bearing assembly off the bearing pilot

(Fig. 21).

Fig. 19 2.5 Diesel Clutch Assembly

Fig. 20 E-clip at Clutch Release Lever Shaft

Fig. 21 Clutch Release Shaft

6 - 14 CLUTCHNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 213 of 1938

(3) Remove the fork from the bearing thrust plate

(Fig. 22).

(4) Examine the condition of the bearing. It is pre-

lubricated and sealed and should not be immersed in

oil or solvent.

(5) The bearing should turn smoothly when held in

the hand under a light thrust load. A light drag

caused by the lubricant fill is normal. If the bearing

is noisy, rough, or dry, replace the complete bearing

assembly with a new bearing.

(6) The bearing has a plastic sleeve pre-lubricated

at assembly. Wipe out the old grease. Refill the sleeve

cavities and coat the inner surface with multipurpose

grease. If the liner is cracked or worn, replace the

bearing assembly.

(7) Check the condition of the spring clips. If the

clips are broken or distorted, replace the bearing

assembly.

INSTALLATION

(1) Before assembling the fork, lubricate the

rounded thrust pads and the spring clip cavities with

multipurpose grease.

(2) Assemble the fork to the bearing by sliding the

thrust pads under the spring clips. Be careful to

avoid distorting the spring clips. These clips prevent

the bearing thrust plate from rotating with the bear-

ing.

(3) Slide the bearing and fork assembly onto the

input shaft bearing retainer.

(4) Position the release shaft bushings in the hous-

ing and install the release shaft. A small amount of

bearing grease between the release shaft bushing

and the shaft is beneficial but not required. Install

the retainer clip in the shaft groove near the large

bushing.

(5) Install the release lever and retaining clip on

the outer end of the release shaft.

CLEANING AND INSPECTION

CLUTCH CONTAMINATION

Fluid contamination is a frequent cause of clutch

malfunctions. Oil, grease, water, or other fluids on

the clutch contact surfaces will cause faulty opera-

tion.

During inspection, note if any components are con-

taminated. Look for evidence of oil, grease, or water/

road splash on clutch components.

OIL CONTAMINATION

Oil contamination indicates a leak at the rear main

seal and/or transaxle input shaft. Oil leaks produce a

residue of oil on the transaxle housing interior, clutch

cover and flywheel. Heat buildup caused by slippage

can bake the oil residue onto the components. This

glaze-like residue ranges in color from amber to

black.

GREASE CONTAMINATION

Grease contamination is usually a product of over-

lubrication. During clutch service, apply only a small

amount of grease to the input shaft splines. Excess

grease may be thrown off during operation, contami-

nating the disc.

ROAD SPLASH/WATER CONTAMINATION

Road splash contamination is usually caused by

driving the vehicle through deep water puddles.

Water can be forced into the clutch housing, causing

clutch components to become contaminated. Facing of

disc will absorb moisture and bond to the flywheel

and/or, pressure plate, if vehicle is allowed to stand

for some time before use. If this condition occurs,

replacement of clutch assembly may be required.

Drive the vehicle until normal clutch operating tem-

perature has been obtained. This will dry off disc

assembly, pressure plate, and flywheel.

CLEANING PRECAUTIONS

Condensation from steam vapors tend to accumu-

late on the internal clutch mechanism when the vehi-

cle is steam cleaned. Facing of disc will absorb

moisture and will bond to flywheel and/or pressure

plate, if vehicle is allowed to stand for some time

before use. If this condition occurs, it may require

replacement of clutch assembly. After cleaning, drive

the vehicle to its normal clutch operating tempera-

ture. This will dry off disc assembly, pressure plate,

and flywheel.

Fig. 22 Clutch Release Fork

NS/GSCLUTCH 6 - 15

REMOVAL AND INSTALLATION (Continued)

Page 214 of 1938

ADJUSTMENTS

CLUTCH CABLE Ð LHD

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch cable assembly. The preload spring

maintains tension on the cable. This tension keeps

the clutch release bearing continuously loaded

against the fingers of the clutch cover assembly.

ADJUSTER MECHANISM FUNCTION CHECK Ð

LHD

(1) With slight pressure, pull the clutch release

lever end of the cable to draw the cable taut. Push

the clutch cable housing toward the dash panel (With

less than 20 lbs. of effort, the cable housing should

move 30-50mm.). This indicates proper adjuster

mechanism function. If the cable does not adjust,

determine if the mechanism is properly seated on the

bracket.

(2) If the adjust mechanism functions properly,

route cable to the transaxle.

(3) Insert cable into transaxle and through clutch

release lever. Ensure the cable is routed through the

smaller hole in the transaxle deck (Fig. 10).

(4) Pull down on cable and insert cable retaining

clip onto clutch cable end.

(5) Check clutch pedal position switch operation.

CLUTCH PEDAL POSITION SWITCH

The clutch pedal position switch is mounted to a

bracket located behind the clutch pedal. The switch

is held in place by four plastic wing tabs.

The clutch pedal position switch IS NOT adjust-

able. The pedal blade contacts the switch in the down

position.

SPECIFICATIONS

CLUTCH TIGHTENING REFERENCE

2.0/2.4 LITER GASOLINE ENGINE

DESCRIPTION TORQUE

Drive Plate Bolts............95N´m(70ft.lbs.)

Lower Trans. Cover.........12N´m(105 in. lbs.)

Modular Clutch Bolts.........74N´m(55ft.lbs.)

Upper Trans. Cover.........12N´m(105 in. lbs.)

2.5 LITER DIESEL ENGINE

DESCRIPTION TORQUE

Flywheel Bolts..............95N´m(70ft.lbs.)

Lower Trans. Cover.........12N´m(105 in. lbs.)

Clutch Pressure Plate Bolts....27N´m(20ft.lbs.)

Upper Trans. Cover.........12N´m(105 in. lbs.)

6 - 16 CLUTCHNS/GS

Page 278 of 1938

INSTALLATION

(1) Place starter in position on vehicle.

(2) Install bolts to hold starter to transaxle bell-

housing.

(3) Place solenoid and B+ wires in position on

starter terminals.

(4) Install nut to hold B+ wire to terminal.

(5) Connect solenoid wire connector onto terminal.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

STARTERÐ3.0L ENGINE

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable (Fig. 8).

(3) Hoist and support vehicle on safety stands.

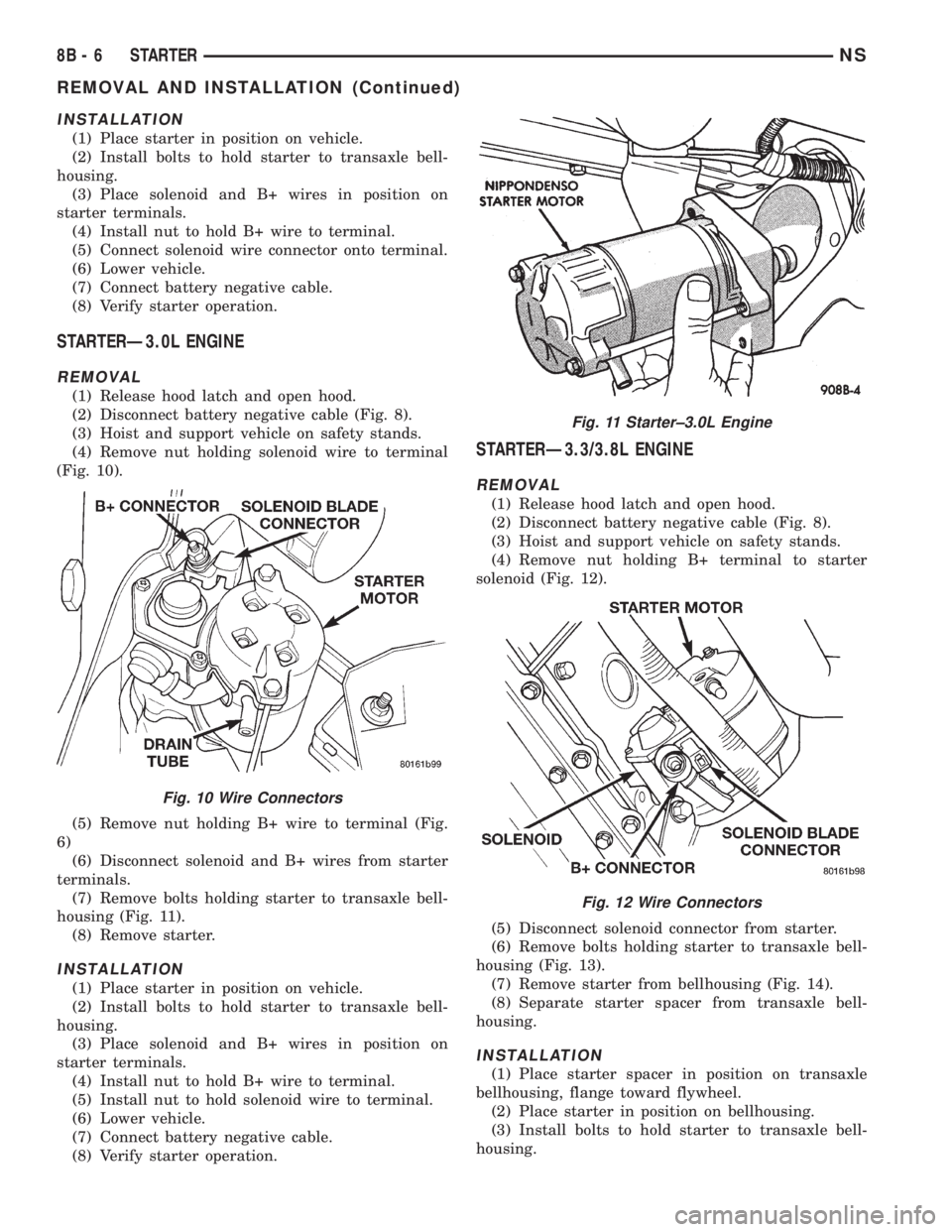

(4) Remove nut holding solenoid wire to terminal

(Fig. 10).

(5) Remove nut holding B+ wire to terminal (Fig.

6)

(6) Disconnect solenoid and B+ wires from starter

terminals.

(7) Remove bolts holding starter to transaxle bell-

housing (Fig. 11).

(8) Remove starter.

INSTALLATION

(1) Place starter in position on vehicle.

(2) Install bolts to hold starter to transaxle bell-

housing.

(3) Place solenoid and B+ wires in position on

starter terminals.

(4) Install nut to hold B+ wire to terminal.

(5) Install nut to hold solenoid wire to terminal.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

STARTERÐ3.3/3.8L ENGINE

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable (Fig. 8).

(3) Hoist and support vehicle on safety stands.

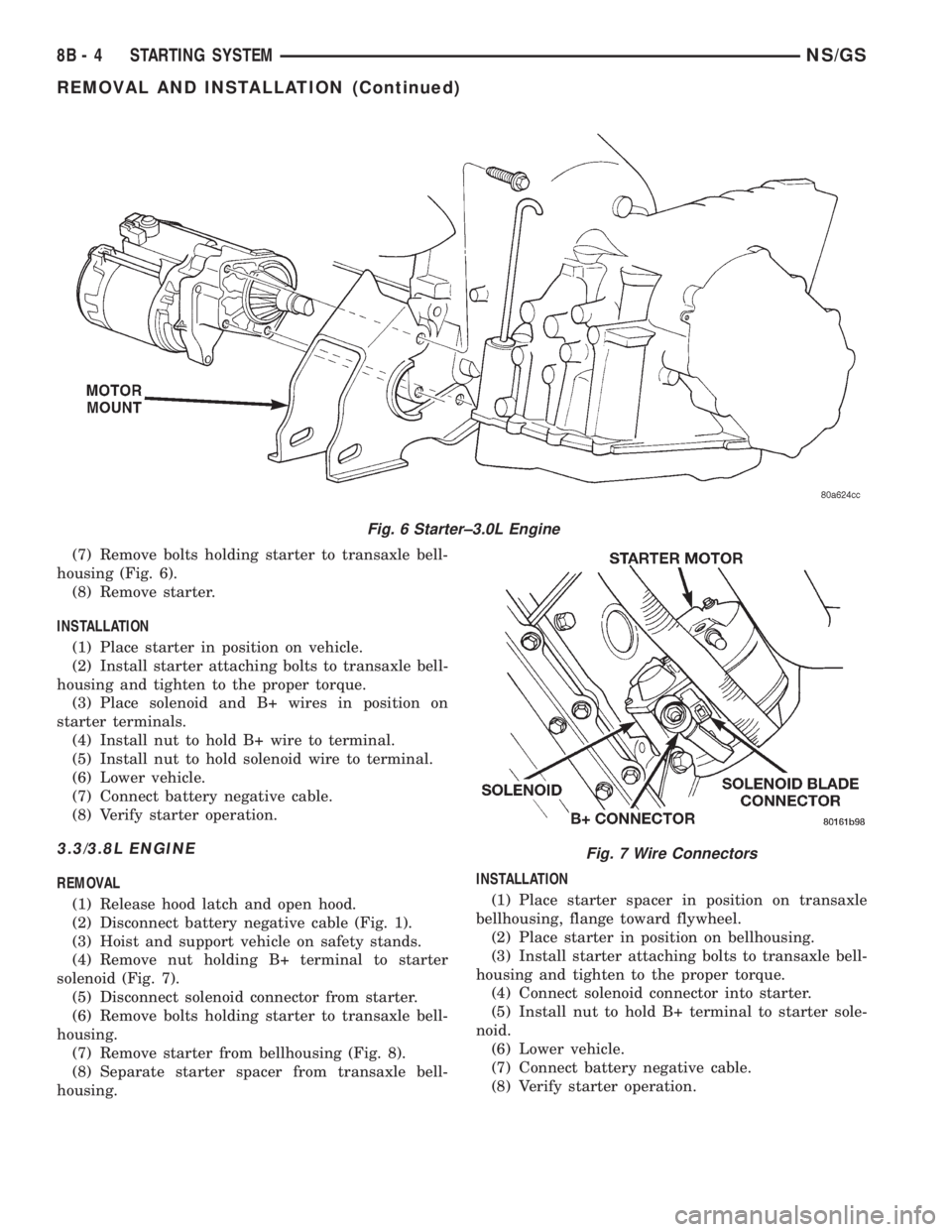

(4) Remove nut holding B+ terminal to starter

solenoid (Fig. 12).

(5) Disconnect solenoid connector from starter.

(6) Remove bolts holding starter to transaxle bell-

housing (Fig. 13).

(7) Remove starter from bellhousing (Fig. 14).

(8) Separate starter spacer from transaxle bell-

housing.

INSTALLATION

(1) Place starter spacer in position on transaxle

bellhousing, flange toward flywheel.

(2) Place starter in position on bellhousing.

(3) Install bolts to hold starter to transaxle bell-

housing.

Fig. 10 Wire Connectors

Fig. 11 Starter±3.0L Engine

Fig. 12 Wire Connectors

8B - 6 STARTERNS

REMOVAL AND INSTALLATION (Continued)

Page 284 of 1938

(7) Remove bolts holding starter to transaxle bell-

housing (Fig. 6).

(8) Remove starter.

INSTALLATION

(1) Place starter in position on vehicle.

(2) Install starter attaching bolts to transaxle bell-

housing and tighten to the proper torque.

(3) Place solenoid and B+ wires in position on

starter terminals.

(4) Install nut to hold B+ wire to terminal.

(5) Install nut to hold solenoid wire to terminal.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

3.3/3.8L ENGINE

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable (Fig. 1).

(3) Hoist and support vehicle on safety stands.

(4) Remove nut holding B+ terminal to starter

solenoid (Fig. 7).

(5) Disconnect solenoid connector from starter.

(6) Remove bolts holding starter to transaxle bell-

housing.

(7) Remove starter from bellhousing (Fig. 8).

(8) Separate starter spacer from transaxle bell-

housing.INSTALLATION

(1) Place starter spacer in position on transaxle

bellhousing, flange toward flywheel.

(2) Place starter in position on bellhousing.

(3) Install starter attaching bolts to transaxle bell-

housing and tighten to the proper torque.

(4) Connect solenoid connector into starter.

(5) Install nut to hold B+ terminal to starter sole-

noid.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

Fig. 6 Starter±3.0L Engine

Fig. 7 Wire Connectors

8B - 4 STARTING SYSTEMNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 306 of 1938

NOTE: Over or under tightening effects knock sen-

sor performance, possibly causing improper spark

control.

DIAGNOSIS AND TESTING

TESTING FOR SPARK AT COILÐ2.4/3.3/3.8L

ENGINES

WARNING: THE DIRECT IGNITION SYSTEMS GEN-

ERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

The coil pack contains independent coils. Each coil

must be checked individually.

CAUTION: Spark plug wire damage may occur if

the spark plug is moved more than 1/4 inch away

from the engine ground.

CAUTION: Do not leave any one spark plug cable

disconnected any longer than 30 seconds or possi-

ble heat damage to catalytic converter will occur.

CAUTION: Test must be performed at idle and in

park only with the parking brake on.

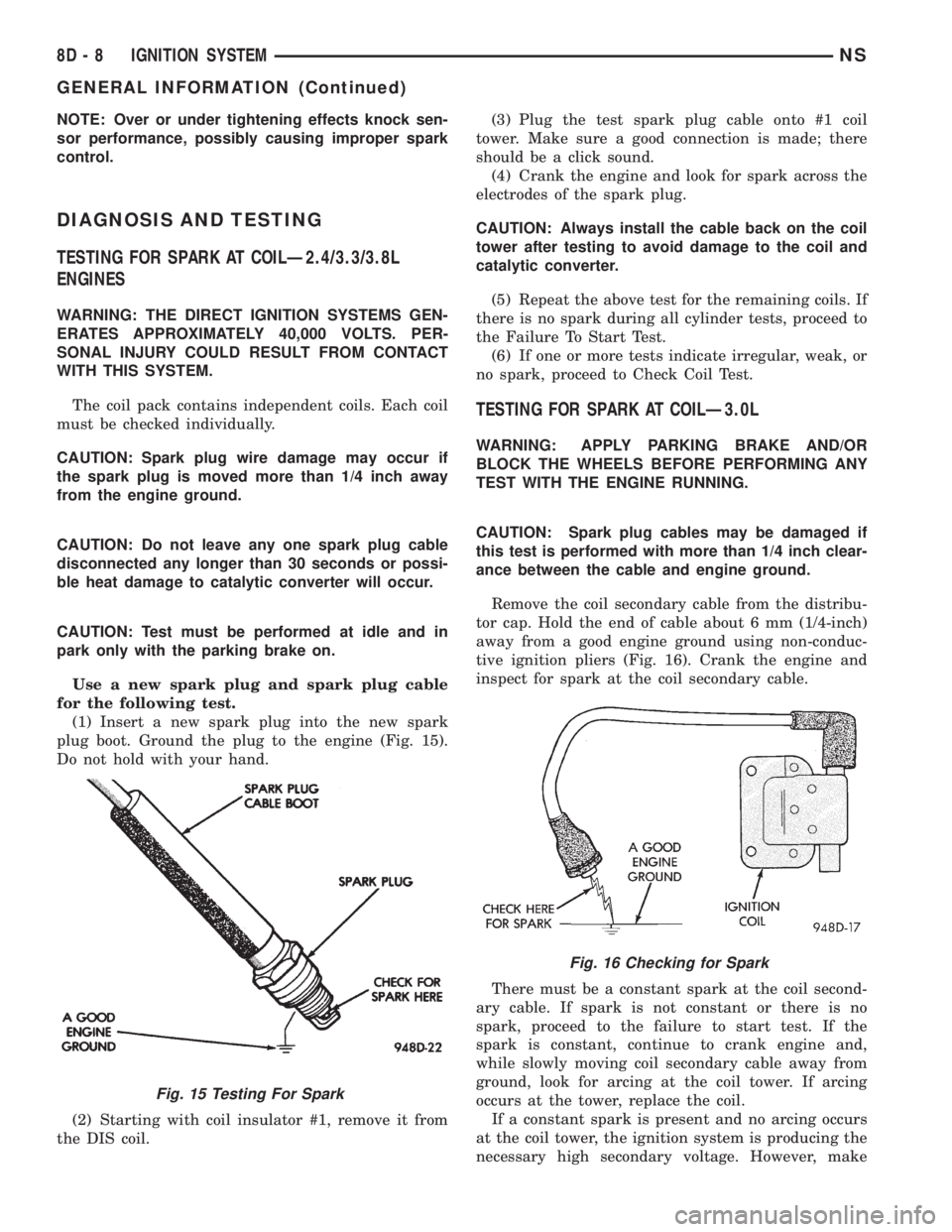

Use a new spark plug and spark plug cable

for the following test.

(1) Insert a new spark plug into the new spark

plug boot. Ground the plug to the engine (Fig. 15).

Do not hold with your hand.

(2) Starting with coil insulator #1, remove it from

the DIS coil.(3) Plug the test spark plug cable onto #1 coil

tower. Make sure a good connection is made; there

should be a click sound.

(4) Crank the engine and look for spark across the

electrodes of the spark plug.

CAUTION: Always install the cable back on the coil

tower after testing to avoid damage to the coil and

catalytic converter.

(5) Repeat the above test for the remaining coils. If

there is no spark during all cylinder tests, proceed to

the Failure To Start Test.

(6) If one or more tests indicate irregular, weak, or

no spark, proceed to Check Coil Test.

TESTING FOR SPARK AT COILÐ3.0L

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK THE WHEELS BEFORE PERFORMING ANY

TEST WITH THE ENGINE RUNNING.

CAUTION: Spark plug cables may be damaged if

this test is performed with more than 1/4 inch clear-

ance between the cable and engine ground.

Remove the coil secondary cable from the distribu-

tor cap. Hold the end of cable about 6 mm (1/4-inch)

away from a good engine ground using non-conduc-

tive ignition pliers (Fig. 16). Crank the engine and

inspect for spark at the coil secondary cable.

There must be a constant spark at the coil second-

ary cable. If spark is not constant or there is no

spark, proceed to the failure to start test. If the

spark is constant, continue to crank engine and,

while slowly moving coil secondary cable away from

ground, look for arcing at the coil tower. If arcing

occurs at the tower, replace the coil.

If a constant spark is present and no arcing occurs

at the coil tower, the ignition system is producing the

necessary high secondary voltage. However, make

Fig. 15 Testing For Spark

Fig. 16 Checking for Spark

8D - 8 IGNITION SYSTEMNS

GENERAL INFORMATION (Continued)

Page 353 of 1938

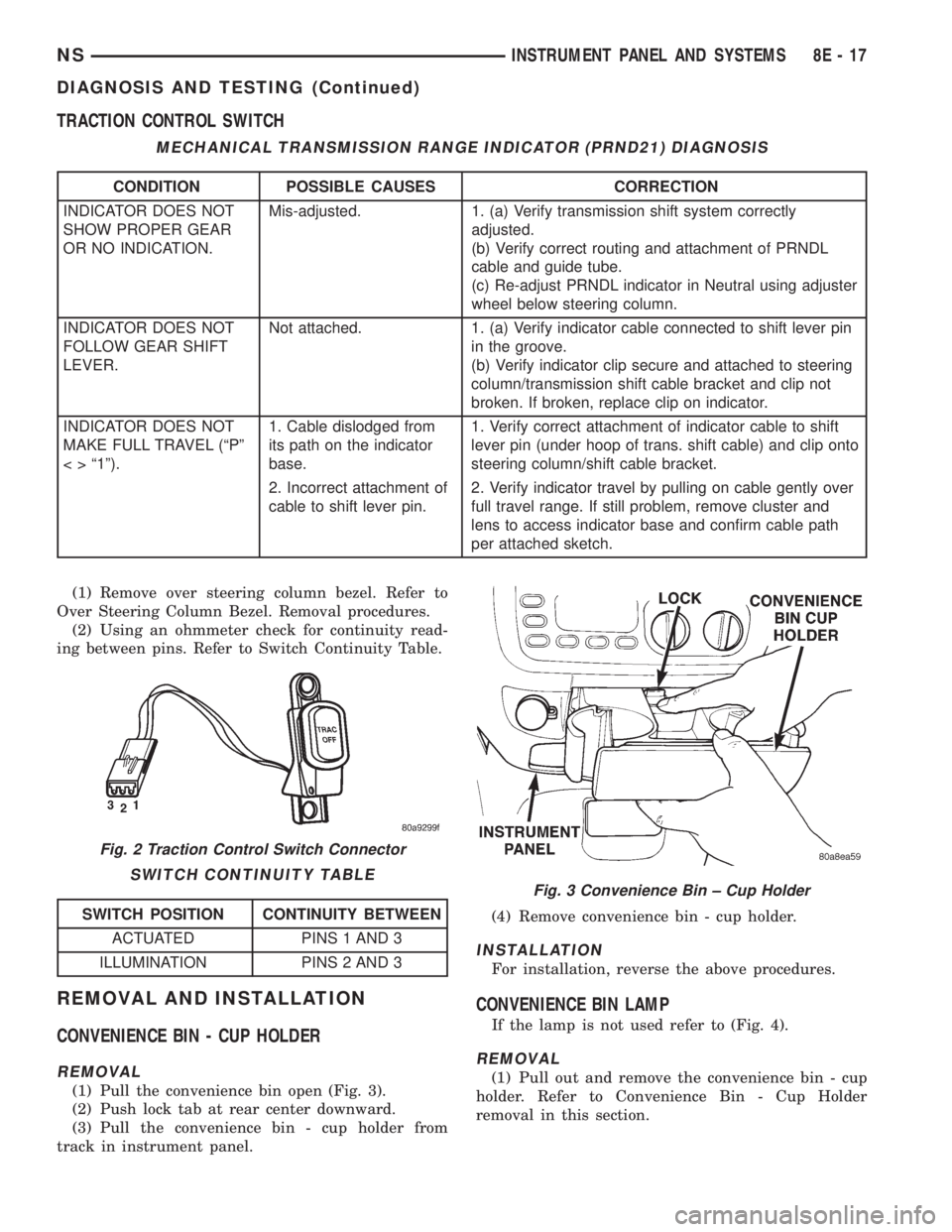

TRACTION CONTROL SWITCH

(1) Remove over steering column bezel. Refer to

Over Steering Column Bezel. Removal procedures.

(2) Using an ohmmeter check for continuity read-

ing between pins. Refer to Switch Continuity Table.

REMOVAL AND INSTALLATION

CONVENIENCE BIN - CUP HOLDER

REMOVAL

(1) Pull the convenience bin open (Fig. 3).

(2) Push lock tab at rear center downward.

(3) Pull the convenience bin - cup holder from

track in instrument panel.(4) Remove convenience bin - cup holder.

INSTALLATION

For installation, reverse the above procedures.

CONVENIENCE BIN LAMP

If the lamp is not used refer to (Fig. 4).

REMOVAL

(1) Pull out and remove the convenience bin - cup

holder. Refer to Convenience Bin - Cup Holder

removal in this section.

MECHANICAL TRANSMISSION RANGE INDICATOR (PRND21) DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

INDICATOR DOES NOT

SHOW PROPER GEAR

OR NO INDICATION.Mis-adjusted. 1. (a) Verify transmission shift system correctly

adjusted.

(b) Verify correct routing and attachment of PRNDL

cable and guide tube.

(c) Re-adjust PRNDL indicator in Neutral using adjuster

wheel below steering column.

INDICATOR DOES NOT

FOLLOW GEAR SHIFT

LEVER.Not attached. 1. (a) Verify indicator cable connected to shift lever pin

in the groove.

(b) Verify indicator clip secure and attached to steering

column/transmission shift cable bracket and clip not

broken. If broken, replace clip on indicator.

INDICATOR DOES NOT

MAKE FULL TRAVEL (ªPº

< > ª1º).1. Cable dislodged from

its path on the indicator

base.1. Verify correct attachment of indicator cable to shift

lever pin (under hoop of trans. shift cable) and clip onto

steering column/shift cable bracket.

2. Incorrect attachment of

cable to shift lever pin.2. Verify indicator travel by pulling on cable gently over

full travel range. If still problem, remove cluster and

lens to access indicator base and confirm cable path

per attached sketch.

Fig. 2 Traction Control Switch Connector

SWITCH CONTINUITY TABLE

SWITCH POSITION CONTINUITY BETWEEN

ACTUATED PINS 1 AND 3

ILLUMINATION PINS 2 AND 3

Fig. 3 Convenience Bin ± Cup Holder

NSINSTRUMENT PANEL AND SYSTEMS 8E - 17

DIAGNOSIS AND TESTING (Continued)

Page 361 of 1938

(8) Using the indicator adjuster thumbwheel on

the indicator clip below the steering column. Rotate

the indicator thumbwheel to position the indicator

calibration arrow to the center of the N slot on the

instrument cluster mask.

(9) After the indicator has been properly adjusted,

move the shift lever through each gear position to

verify the appropriate gear position has been selected

and the slot is fully covered by the indicator. The left

edge of the indicator will just peek at the left edge of

the P slot in Park.

(10) If the indicator is not covering each of the

selected gear positions when selected, place the shift

lever back into neutral N and readjust the indicator.

Repeat the process until each gear is covered when

selected.

(11) Install the metal knee blocker panel.

(12) Install the lower steering column cover.

INSTRUMENT PANEL

The instrument panel is removed as a unit. The

steering column and wiring harnesses are assembled

into the panel before installation. Service procedures

for interior trim not related to the instrument panel

can be found in Group 23, Body.

REMOVAL

(1) Disconnect the battery, negative cable first.

(2) Remove the lower console.

(3) Remove the screw holding the lower heat duct

to the instrument panel support (Fig. 26).

(4) Disconnect the heat duct from the vehicle.

(5) Remove the bolts holding the lower supports to

the instrument panel frame (Fig. 27).(6) Remove the bolts holding the lower supports to

the floor pan.

(7) Remove the right and left end covers.

(8) Disconnect the wire connectors from the Pas-

senger Airbag Module.

(9) Remove the front door sill trim covers.

(10) Remove the A-pillar trim covers.

(11) Remove the glove box.

(12) Disconnect the antenna lead connector from

behind the glove box.

(13) Remove the lower steering column cover.

(14) Remove the knee blocker panel.

(15) Disconnect the lower two, forty pin wire har-

ness connectors, from the main Junction Block near

left cowl side panel (Fig. 28).

(16) Disconnect the instrument panel wire harness

connector from the bottom of Body Control Module.

(17) Disconnect the two forty pin connectors from

the right of the steering column (Fig. 29).

(18) Remove the clinch bolt holding upper the

steering shaft to the lower steering shaft (Fig. 29).

Fig. 25 Range Indicator Cable

Fig. 26 Heat Duct

Fig. 27 Lower Supports

NSINSTRUMENT PANEL AND SYSTEMS 8E - 25

REMOVAL AND INSTALLATION (Continued)

Page 405 of 1938

bracket behind the junction block/body control mod-

ule (Fig. 5).

REMOTE RADIO SWITCHES

A remote radio control switch option is available on

LXI models sold in North America with the AM/FM/

cassette/5-band graphic equalizer with CD changer

control feature (RBN sales code), or the AM/FM/CD/

cassette/3-band graphic equalizer (RAZ sales code)

radio receivers. Two rocker-type switches are

mounted on the back (instrument panel side) of the

steering wheel spokes. The switch on the left spoke is

the seek switch and has seek up, seek down, and pre-

set station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions (Fig. 6).

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the propermessages on the Chrysler Collision Detection (CCD)

data bus network to the radio receiver. For diagnosis

of the BCM or the CCD data bus, the use of a DRB

scan tool and the proper Diagnostic Procedures man-

ual are recommended. For more information on the

operation of the remote radio switch controls, refer to

the owner's manual in the vehicle glove box.

NAME BRAND SPEAKER RELAY

Relay is located in the junction block. To test relay

refer to the Audio Diagnostic Test Procedures or use

a known good relay.

DIAGNOSIS AND TESTING

ANTENNA

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The following four tests are used to diagnose the

antenna with an ohmmeter:

²Test 1- Mast to ground test

²Test 2- Tip-of-mast to tip-of-conductor test

²Test 3- Body ground to battery ground test

²Test 4- Body ground to coaxial shield test.

The ohmmeter test lead connections for each test

are shown in Antenna Tests (Fig. 7).

NOTE: This model has a two-piece antenna coaxial

cable. Tests 2 and 4 must be conducted in two

steps to isolate a coaxial cable problem; from the

coaxial cable connection under the right end of the

instrument panel near the right cowl side panel to

the antenna base, and then from the coaxial cable

connection to the radio chassis connection.

TEST 1

Test 1 determines if the antenna mast is insulated

from the base. Proceed as follows:

(1) Unplug the antenna coaxial cable connector

from the radio chassis and isolate.

(2) Connect one ohmmeter test lead to the tip of

the antenna mast. Connect the other test lead to the

antenna base. Check for continuity.

(3) There should be no continuity. If continuity is

found, replace the faulty or damaged antenna base

and cable assembly.

Fig. 5 Choke Location

Fig. 6 Remote Radio Switch Operational View

NSAUDIO SYSTEMS 8F - 3

DESCRIPTION AND OPERATION (Continued)