tow CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1525 of 1938

Inspect all valve springs for distortion and col-

lapsed coils. Inspect all valves and plugs for burrs,

nicks, and scores. Small nicks and scores may be

removed with crocus cloth, providing extreme care is

taken not to round off sharp edges. The sharpness of

these edges is vitally important. It prevents foreign

matter from lodging between valve and valve body.

This reduces the possibility of sticking. Inspect all

valves and plugs for freedom of operation in valve

body bores.

When bores, valves, and plugs are clean and dry,

the valves and plugs should fall freely in the bores.

The valve body bores do not change its dimensions

with use. Therefore, a valve body that was function-

ing properly when vehicle was new, will operate cor-

rectly if it is properly and thoroughly cleaned. There

is no need to replace valve body unless it is damaged

in handling.

ADJUSTMENTS

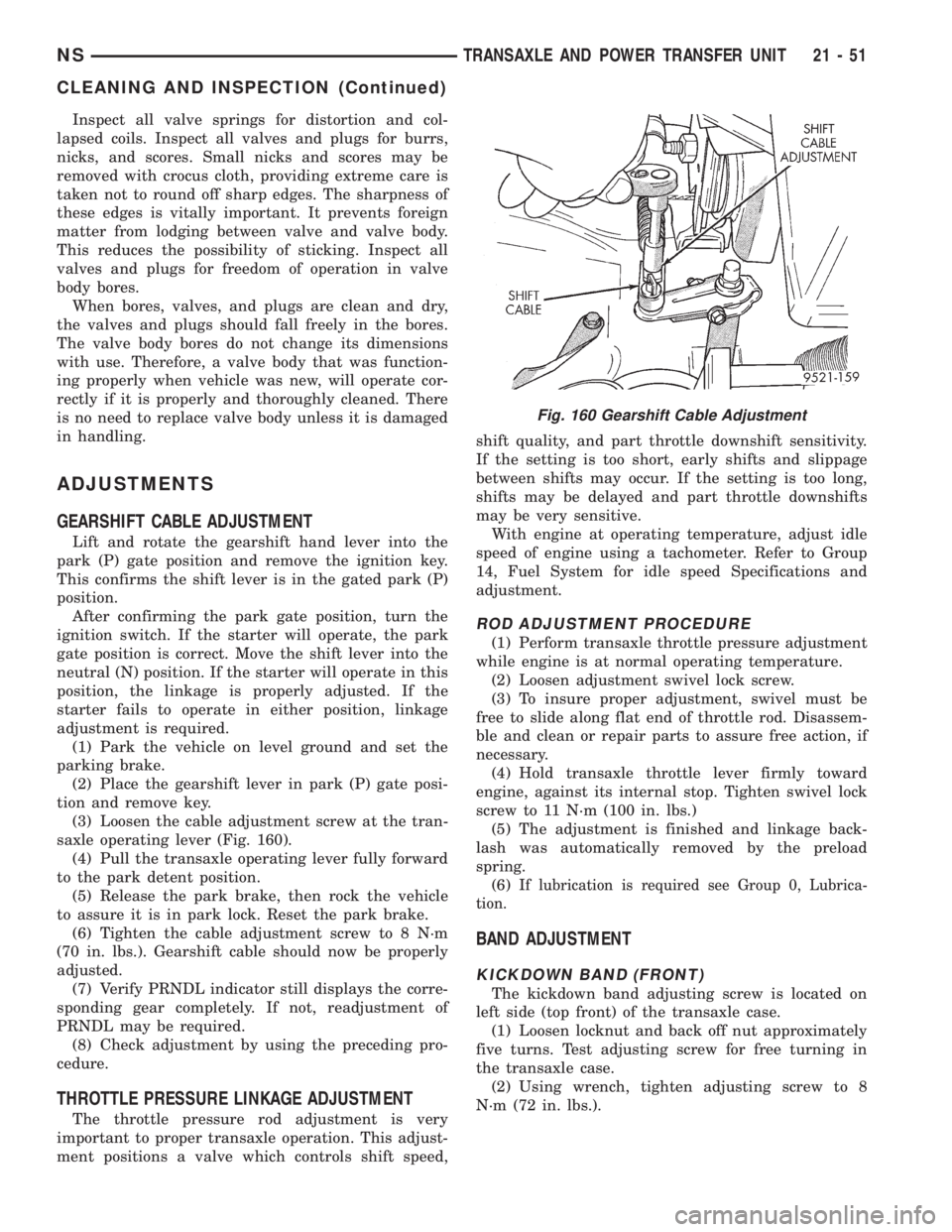

GEARSHIFT CABLE ADJUSTMENT

Lift and rotate the gearshift hand lever into the

park (P) gate position and remove the ignition key.

This confirms the shift lever is in the gated park (P)

position.

After confirming the park gate position, turn the

ignition switch. If the starter will operate, the park

gate position is correct. Move the shift lever into the

neutral (N) position. If the starter will operate in this

position, the linkage is properly adjusted. If the

starter fails to operate in either position, linkage

adjustment is required.

(1) Park the vehicle on level ground and set the

parking brake.

(2) Place the gearshift lever in park (P) gate posi-

tion and remove key.

(3) Loosen the cable adjustment screw at the tran-

saxle operating lever (Fig. 160).

(4) Pull the transaxle operating lever fully forward

to the park detent position.

(5) Release the park brake, then rock the vehicle

to assure it is in park lock. Reset the park brake.

(6) Tighten the cable adjustment screw to 8 N´m

(70 in. lbs.). Gearshift cable should now be properly

adjusted.

(7) Verify PRNDL indicator still displays the corre-

sponding gear completely. If not, readjustment of

PRNDL may be required.

(8) Check adjustment by using the preceding pro-

cedure.

THROTTLE PRESSURE LINKAGE ADJUSTMENT

The throttle pressure rod adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,shift quality, and part throttle downshift sensitivity.

If the setting is too short, early shifts and slippage

between shifts may occur. If the setting is too long,

shifts may be delayed and part throttle downshifts

may be very sensitive.

With engine at operating temperature, adjust idle

speed of engine using a tachometer. Refer to Group

14, Fuel System for idle speed Specifications and

adjustment.

ROD ADJUSTMENT PROCEDURE

(1) Perform transaxle throttle pressure adjustment

while engine is at normal operating temperature.

(2) Loosen adjustment swivel lock screw.

(3) To insure proper adjustment, swivel must be

free to slide along flat end of throttle rod. Disassem-

ble and clean or repair parts to assure free action, if

necessary.

(4) Hold transaxle throttle lever firmly toward

engine, against its internal stop. Tighten swivel lock

screw to 11 N´m (100 in. lbs.)

(5) The adjustment is finished and linkage back-

lash was automatically removed by the preload

spring.

(6) I

f lubrication is required see Group 0, Lubrica-

tion.

BAND ADJUSTMENT

KICKDOWN BAND (FRONT)

The kickdown band adjusting screw is located on

left side (top front) of the transaxle case.

(1) Loosen locknut and back off nut approximately

five turns. Test adjusting screw for free turning in

the transaxle case.

(2) Using wrench, tighten adjusting screw to 8

N´m (72 in. lbs.).

Fig. 160 Gearshift Cable Adjustment

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 51

CLEANING AND INSPECTION (Continued)

Page 1574 of 1938

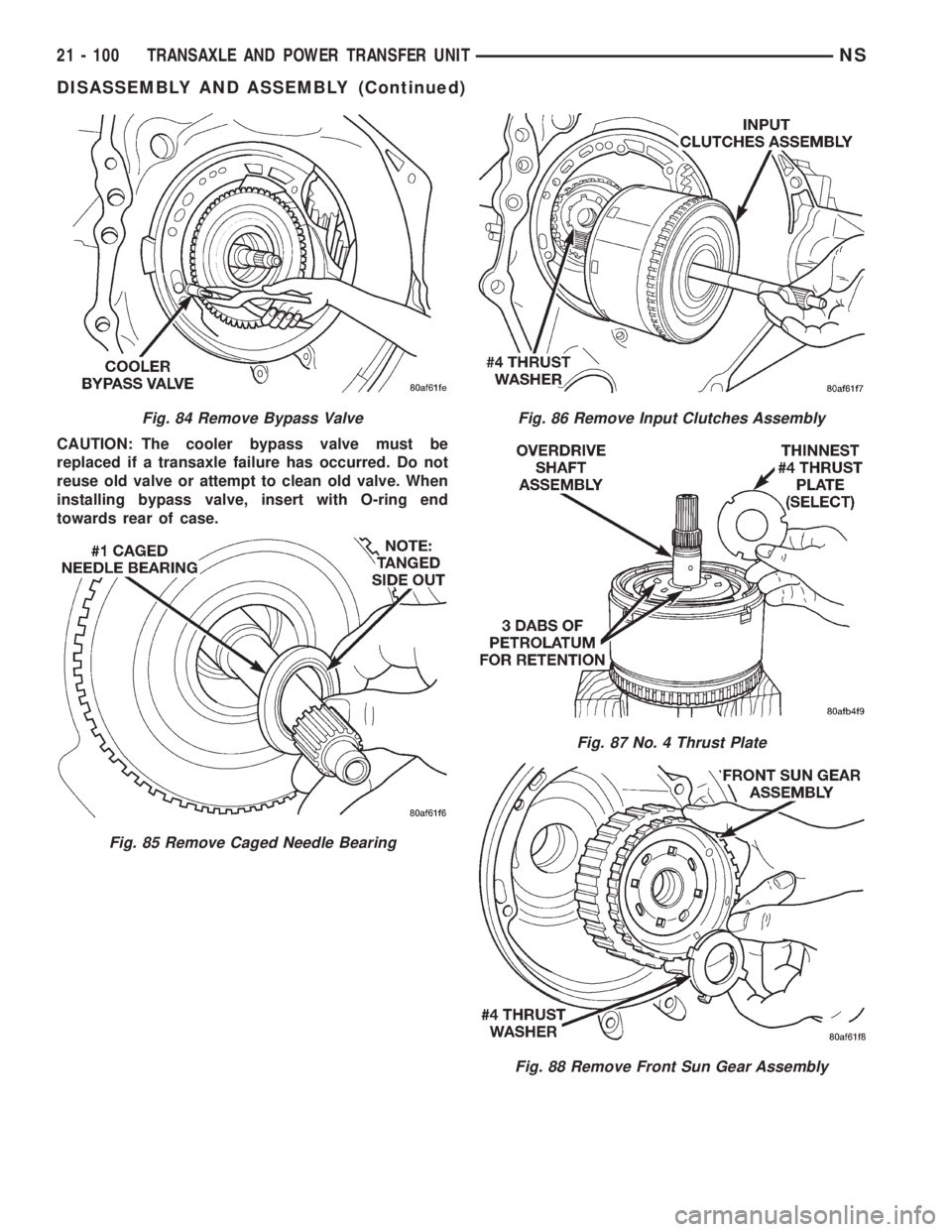

CAUTION: The cooler bypass valve must be

replaced if a transaxle failure has occurred. Do not

reuse old valve or attempt to clean old valve. When

installing bypass valve, insert with O-ring end

towards rear of case.

Fig. 84 Remove Bypass Valve

Fig. 85 Remove Caged Needle Bearing

Fig. 86 Remove Input Clutches Assembly

Fig. 87 No. 4 Thrust Plate

Fig. 88 Remove Front Sun Gear Assembly

21 - 100 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1610 of 1938

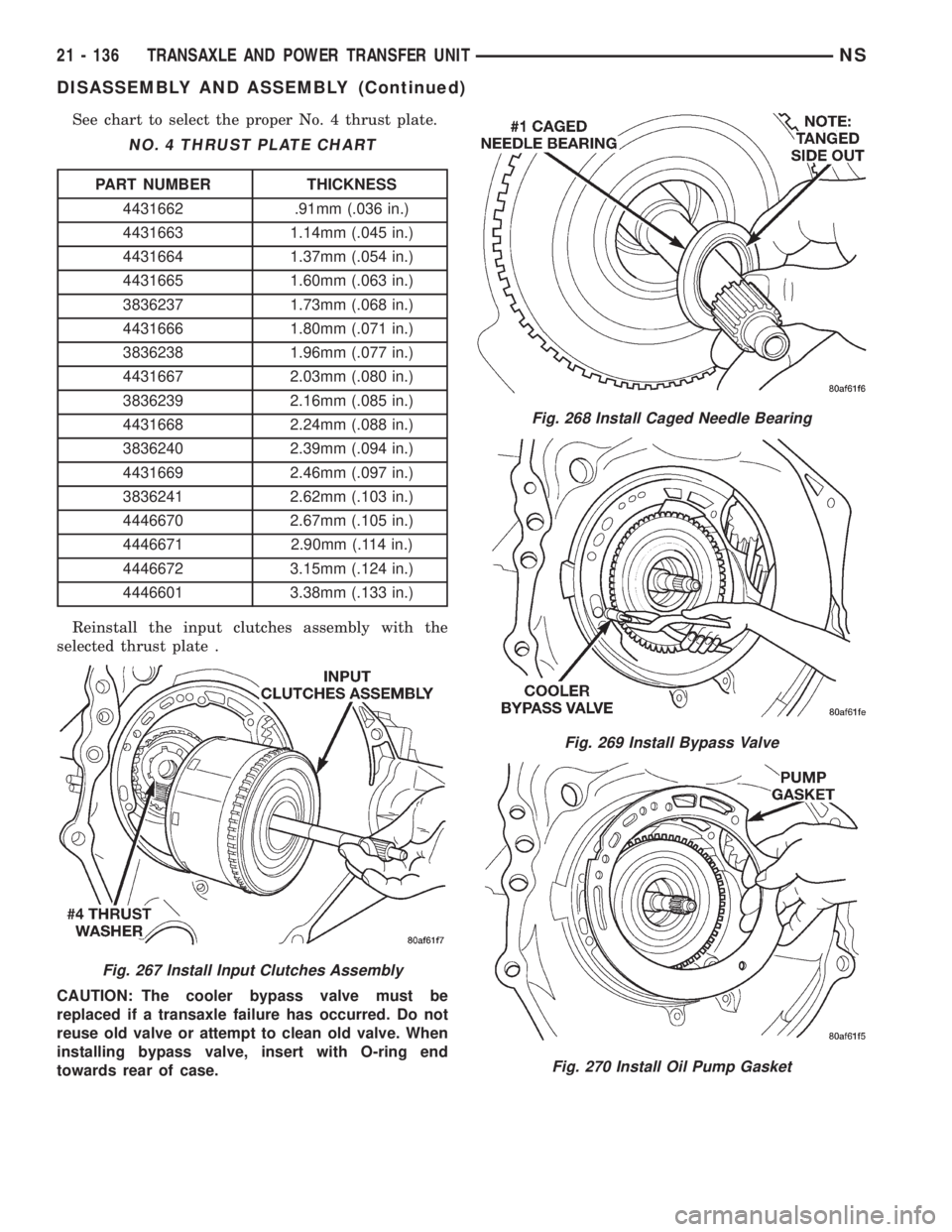

See chart to select the proper No. 4 thrust plate.

Reinstall the input clutches assembly with the

selected thrust plate .

CAUTION: The cooler bypass valve must be

replaced if a transaxle failure has occurred. Do not

reuse old valve or attempt to clean old valve. When

installing bypass valve, insert with O-ring end

towards rear of case.

NO. 4 THRUST PLATE CHART

PART NUMBER THICKNESS

4431662 .91mm (.036 in.)

4431663 1.14mm (.045 in.)

4431664 1.37mm (.054 in.)

4431665 1.60mm (.063 in.)

3836237 1.73mm (.068 in.)

4431666 1.80mm (.071 in.)

3836238 1.96mm (.077 in.)

4431667 2.03mm (.080 in.)

3836239 2.16mm (.085 in.)

4431668 2.24mm (.088 in.)

3836240 2.39mm (.094 in.)

4431669 2.46mm (.097 in.)

3836241 2.62mm (.103 in.)

4446670 2.67mm (.105 in.)

4446671 2.90mm (.114 in.)

4446672 3.15mm (.124 in.)

4446601 3.38mm (.133 in.)

Fig. 267 Install Input Clutches Assembly

Fig. 268 Install Caged Needle Bearing

Fig. 269 Install Bypass Valve

Fig. 270 Install Oil Pump Gasket

21 - 136 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1618 of 1938

(11) Install the oil baffle. Install the proper shim

combination under the bearing cup.

(12) Install the differential bearing retainer. Seal

the retainer to the housing with MopartSilicone

Rubber Adhesive Sealant. Torque bolts to 28 N´m

(250 in. lbs.).

(13) Using Miller Special Tool L-4436-A and an

inch-pound torque wrench, check the turning torque

of the differential (Fig. 299). The turning torque

should be between 5-18 inch-pounds.

NOTE: If turning torque is too high install a .05mm

(.002 inch) thicker shim. If the turning torque is too

low, install a .05mm (.002 inch) thinner shim. Repeat

until 5-18 inch-pounds of turning torque is

obtained.

CLEANING AND INSPECTION

CLEANING VALVE BODY

Prior to removing any transaxle parts, plug all

openings and clean unit, preferably by steam. Clean-

liness through entire disassembly and assembly can-

not be overemphasized. When disassembling, each

part should be washed in a suitable solvent, then

dried by compressed air.Do not wipe parts with

shop towels.All mating surfaces in the transaxles

are accurately machined; therefore, careful handling

of all parts must be exercised to avoid nicks or burrs.

NOTE: Tag all springs, as they are removed, for

reassembly identification.

ADJUSTMENTS

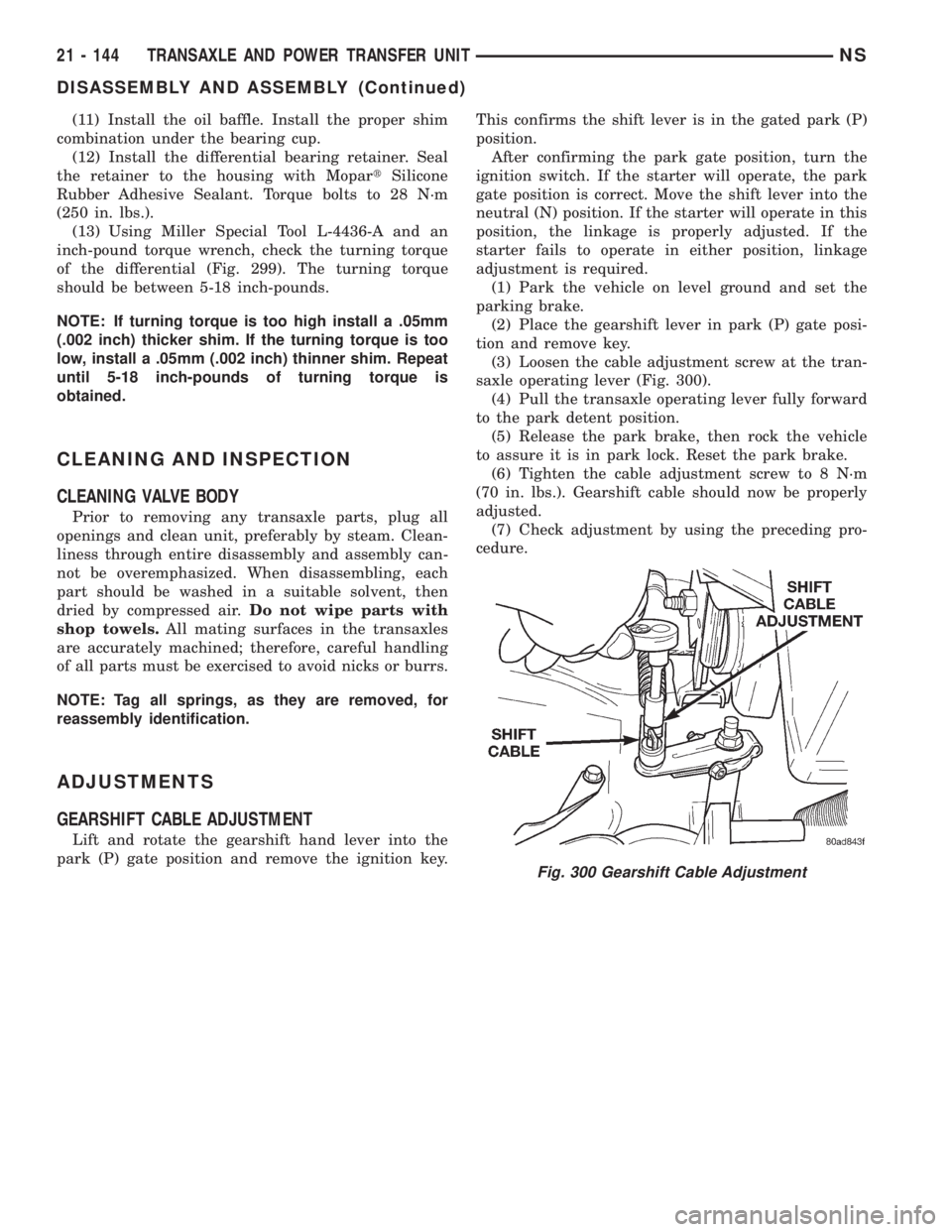

GEARSHIFT CABLE ADJUSTMENT

Lift and rotate the gearshift hand lever into the

park (P) gate position and remove the ignition key.This confirms the shift lever is in the gated park (P)

position.

After confirming the park gate position, turn the

ignition switch. If the starter will operate, the park

gate position is correct. Move the shift lever into the

neutral (N) position. If the starter will operate in this

position, the linkage is properly adjusted. If the

starter fails to operate in either position, linkage

adjustment is required.

(1) Park the vehicle on level ground and set the

parking brake.

(2) Place the gearshift lever in park (P) gate posi-

tion and remove key.

(3) Loosen the cable adjustment screw at the tran-

saxle operating lever (Fig. 300).

(4) Pull the transaxle operating lever fully forward

to the park detent position.

(5) Release the park brake, then rock the vehicle

to assure it is in park lock. Reset the park brake.

(6) Tighten the cable adjustment screw to 8 N´m

(70 in. lbs.). Gearshift cable should now be properly

adjusted.

(7) Check adjustment by using the preceding pro-

cedure.

Fig. 300 Gearshift Cable Adjustment

21 - 144 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1644 of 1938

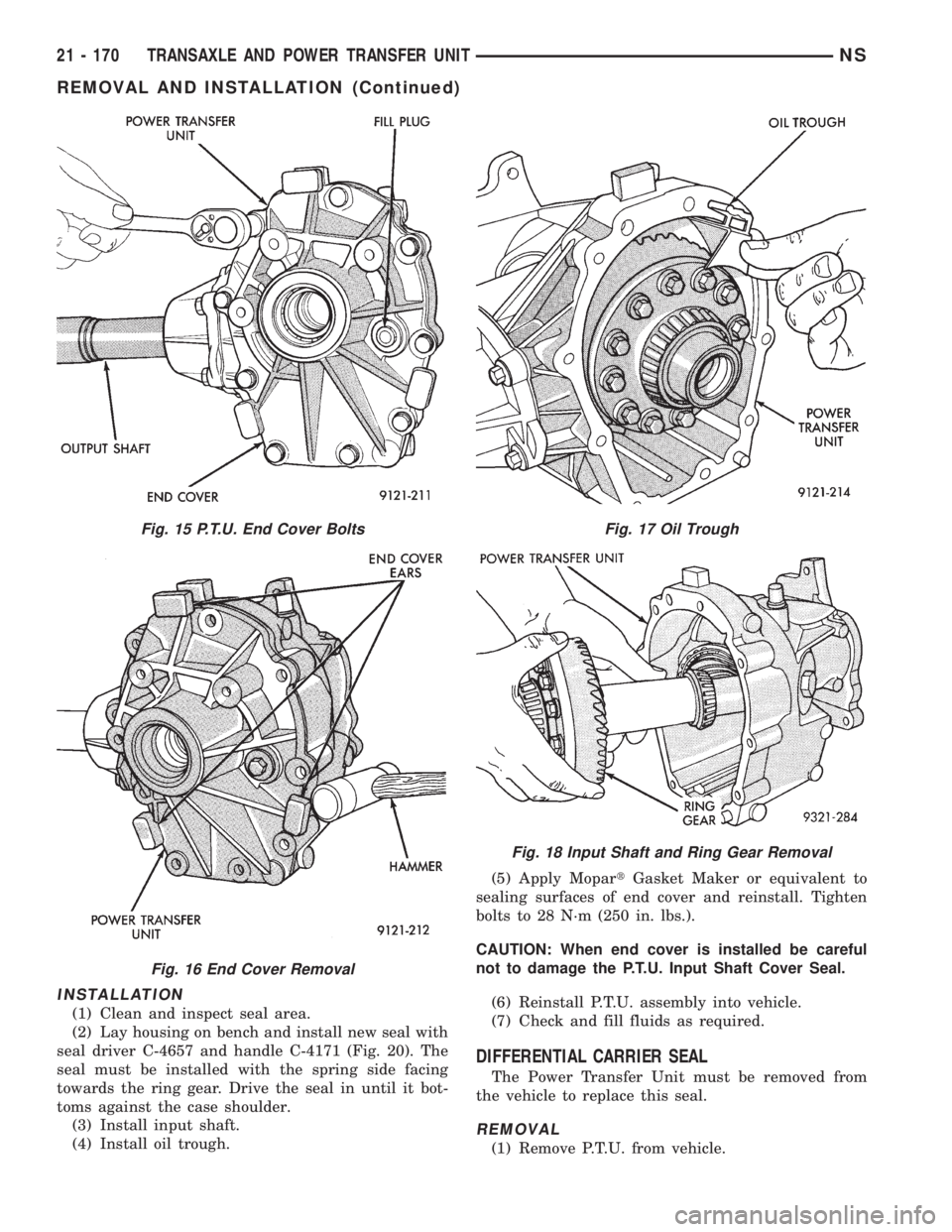

INSTALLATION

(1) Clean and inspect seal area.

(2) Lay housing on bench and install new seal with

seal driver C-4657 and handle C-4171 (Fig. 20). The

seal must be installed with the spring side facing

towards the ring gear. Drive the seal in until it bot-

toms against the case shoulder.

(3) Install input shaft.

(4) Install oil trough.(5) Apply MopartGasket Maker or equivalent to

sealing surfaces of end cover and reinstall. Tighten

bolts to 28 N´m (250 in. lbs.).

CAUTION: When end cover is installed be careful

not to damage the P.T.U. Input Shaft Cover Seal.

(6) Reinstall P.T.U. assembly into vehicle.

(7) Check and fill fluids as required.

DIFFERENTIAL CARRIER SEAL

The Power Transfer Unit must be removed from

the vehicle to replace this seal.

REMOVAL

(1) Remove P.T.U. from vehicle.

Fig. 15 P.T.U. End Cover Bolts

Fig. 16 End Cover Removal

Fig. 17 Oil Trough

Fig. 18 Input Shaft and Ring Gear Removal

21 - 170 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1648 of 1938

(4) Install rear cover. Use care not to cut rear

cover O-Ring when installing rear cover into P.T.U.

housing.

(5) Install rear cover retaining bolts and tighten to

28 N´m (250 in. lbs.).

(6) Install propeller shaft.

(7) Check and fill fluids as required.

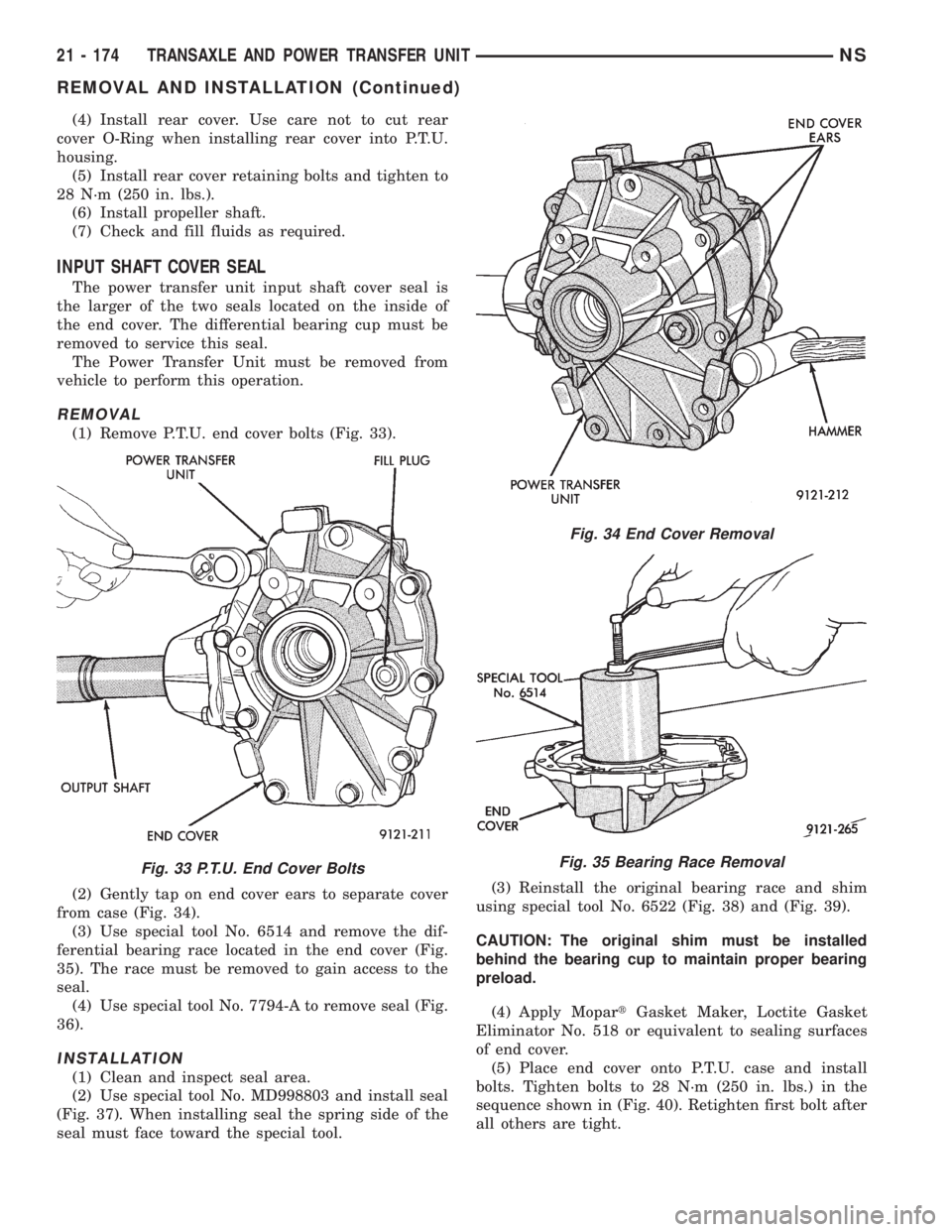

INPUT SHAFT COVER SEAL

The power transfer unit input shaft cover seal is

the larger of the two seals located on the inside of

the end cover. The differential bearing cup must be

removed to service this seal.

The Power Transfer Unit must be removed from

vehicle to perform this operation.

REMOVAL

(1) Remove P.T.U. end cover bolts (Fig. 33).

(2) Gently tap on end cover ears to separate cover

from case (Fig. 34).

(3) Use special tool No. 6514 and remove the dif-

ferential bearing race located in the end cover (Fig.

35). The race must be removed to gain access to the

seal.

(4) Use special tool No. 7794-A to remove seal (Fig.

36).

INSTALLATION

(1) Clean and inspect seal area.

(2) Use special tool No. MD998803 and install seal

(Fig. 37). When installing seal the spring side of the

seal must face toward the special tool.(3) Reinstall the original bearing race and shim

using special tool No. 6522 (Fig. 38) and (Fig. 39).

CAUTION: The original shim must be installed

behind the bearing cup to maintain proper bearing

preload.

(4) Apply MopartGasket Maker, Loctite Gasket

Eliminator No. 518 or equivalent to sealing surfaces

of end cover.

(5) Place end cover onto P.T.U. case and install

bolts. Tighten bolts to 28 N´m (250 in. lbs.) in the

sequence shown in (Fig. 40). Retighten first bolt after

all others are tight.

Fig. 33 P.T.U. End Cover Bolts

Fig. 34 End Cover Removal

Fig. 35 Bearing Race Removal

21 - 174 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1708 of 1938

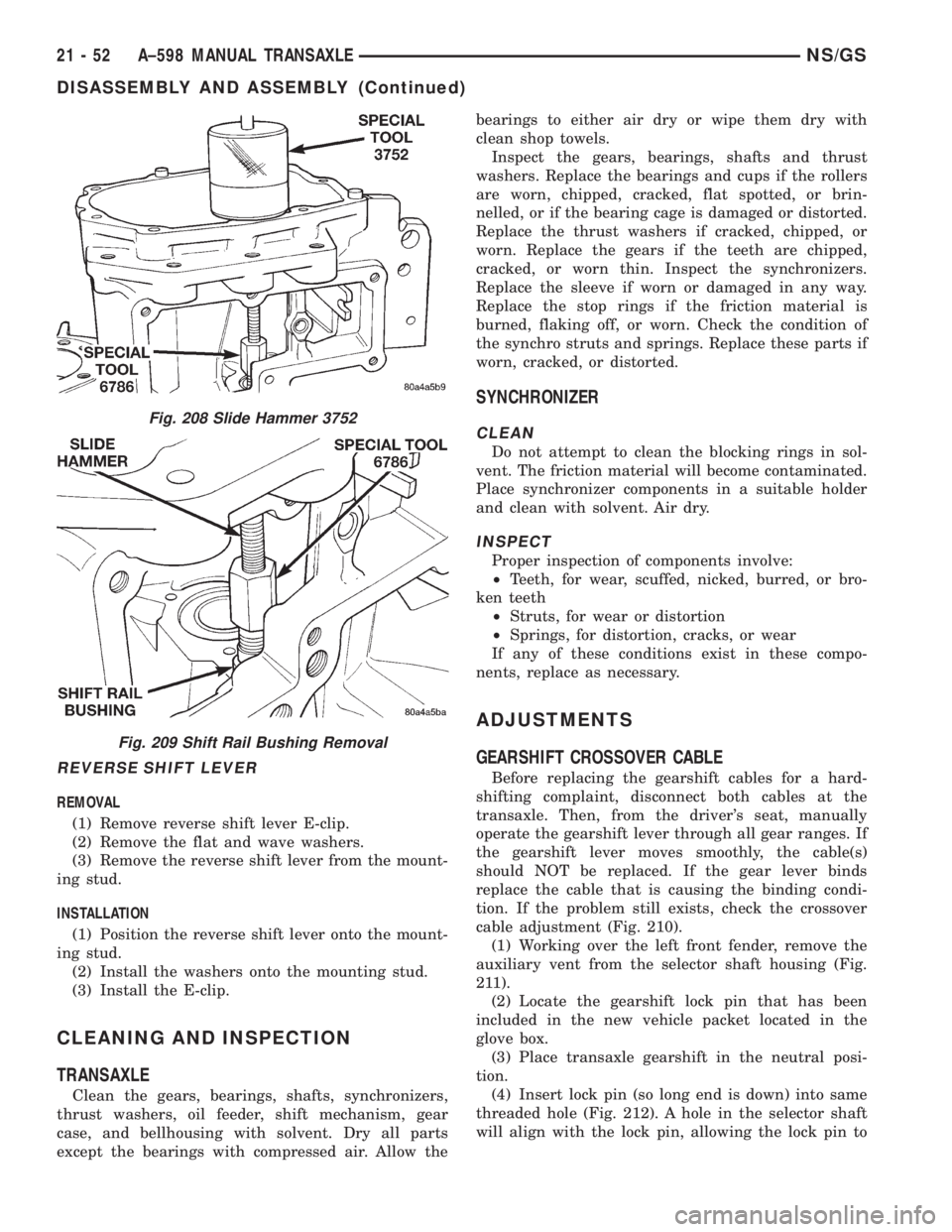

REVERSE SHIFT LEVER

REMOVAL

(1) Remove reverse shift lever E-clip.

(2) Remove the flat and wave washers.

(3) Remove the reverse shift lever from the mount-

ing stud.

INSTALLATION

(1) Position the reverse shift lever onto the mount-

ing stud.

(2) Install the washers onto the mounting stud.

(3) Install the E-clip.

CLEANING AND INSPECTION

TRANSAXLE

Clean the gears, bearings, shafts, synchronizers,

thrust washers, oil feeder, shift mechanism, gear

case, and bellhousing with solvent. Dry all parts

except the bearings with compressed air. Allow thebearings to either air dry or wipe them dry with

clean shop towels.

Inspect the gears, bearings, shafts and thrust

washers. Replace the bearings and cups if the rollers

are worn, chipped, cracked, flat spotted, or brin-

nelled, or if the bearing cage is damaged or distorted.

Replace the thrust washers if cracked, chipped, or

worn. Replace the gears if the teeth are chipped,

cracked, or worn thin. Inspect the synchronizers.

Replace the sleeve if worn or damaged in any way.

Replace the stop rings if the friction material is

burned, flaking off, or worn. Check the condition of

the synchro struts and springs. Replace these parts if

worn, cracked, or distorted.

SYNCHRONIZER

CLEAN

Do not attempt to clean the blocking rings in sol-

vent. The friction material will become contaminated.

Place synchronizer components in a suitable holder

and clean with solvent. Air dry.

INSPECT

Proper inspection of components involve:

²Teeth, for wear, scuffed, nicked, burred, or bro-

ken teeth

²Struts, for wear or distortion

²Springs, for distortion, cracks, or wear

If any of these conditions exist in these compo-

nents, replace as necessary.

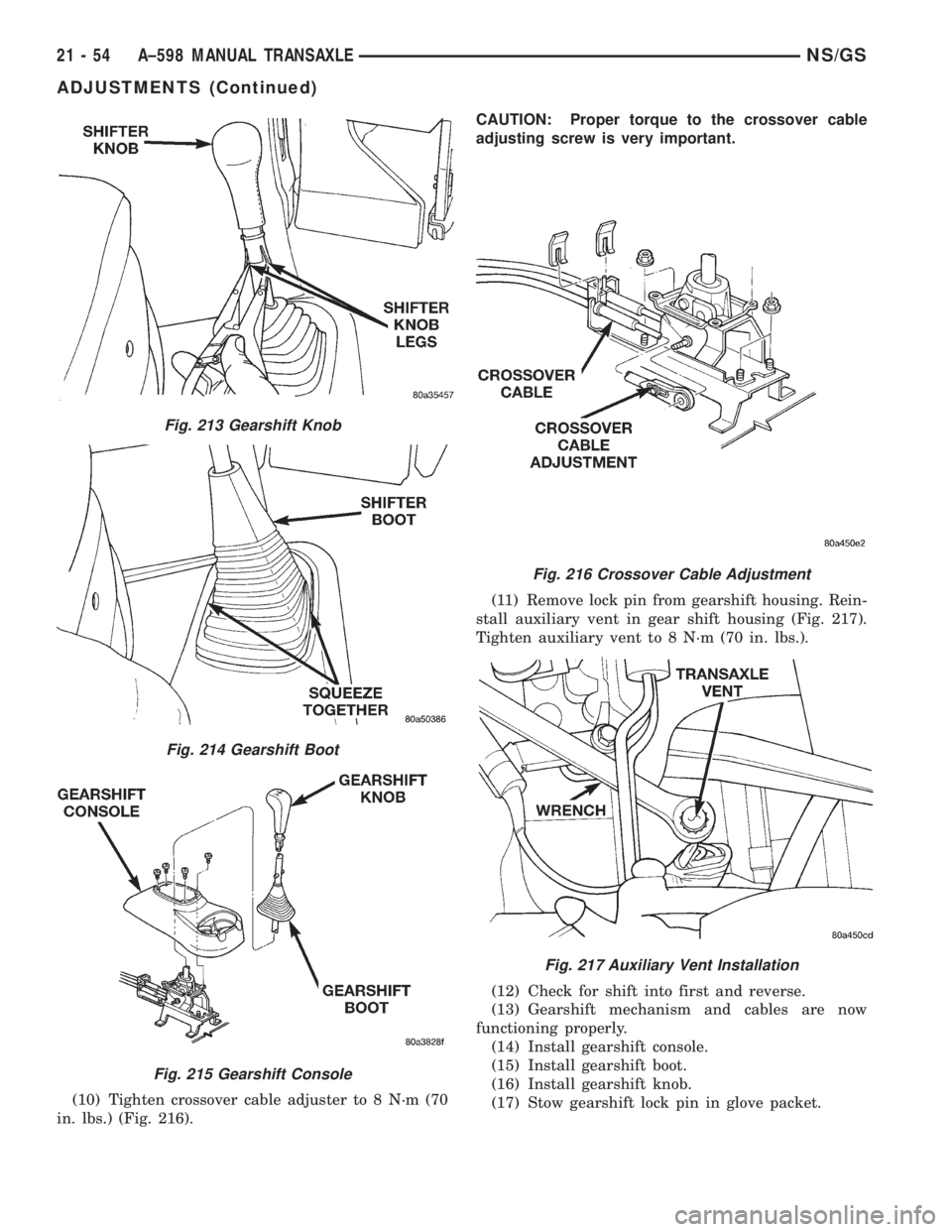

ADJUSTMENTS

GEARSHIFT CROSSOVER CABLE

Before replacing the gearshift cables for a hard-

shifting complaint, disconnect both cables at the

transaxle. Then, from the driver's seat, manually

operate the gearshift lever through all gear ranges. If

the gearshift lever moves smoothly, the cable(s)

should NOT be replaced. If the gear lever binds

replace the cable that is causing the binding condi-

tion. If the problem still exists, check the crossover

cable adjustment (Fig. 210).

(1) Working over the left front fender, remove the

auxiliary vent from the selector shaft housing (Fig.

211).

(2) Locate the gearshift lock pin that has been

included in the new vehicle packet located in the

glove box.

(3) Place transaxle gearshift in the neutral posi-

tion.

(4) Insert lock pin (so long end is down) into same

threaded hole (Fig. 212). A hole in the selector shaft

will align with the lock pin, allowing the lock pin to

Fig. 208 Slide Hammer 3752

Fig. 209 Shift Rail Bushing Removal

21 - 52 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1710 of 1938

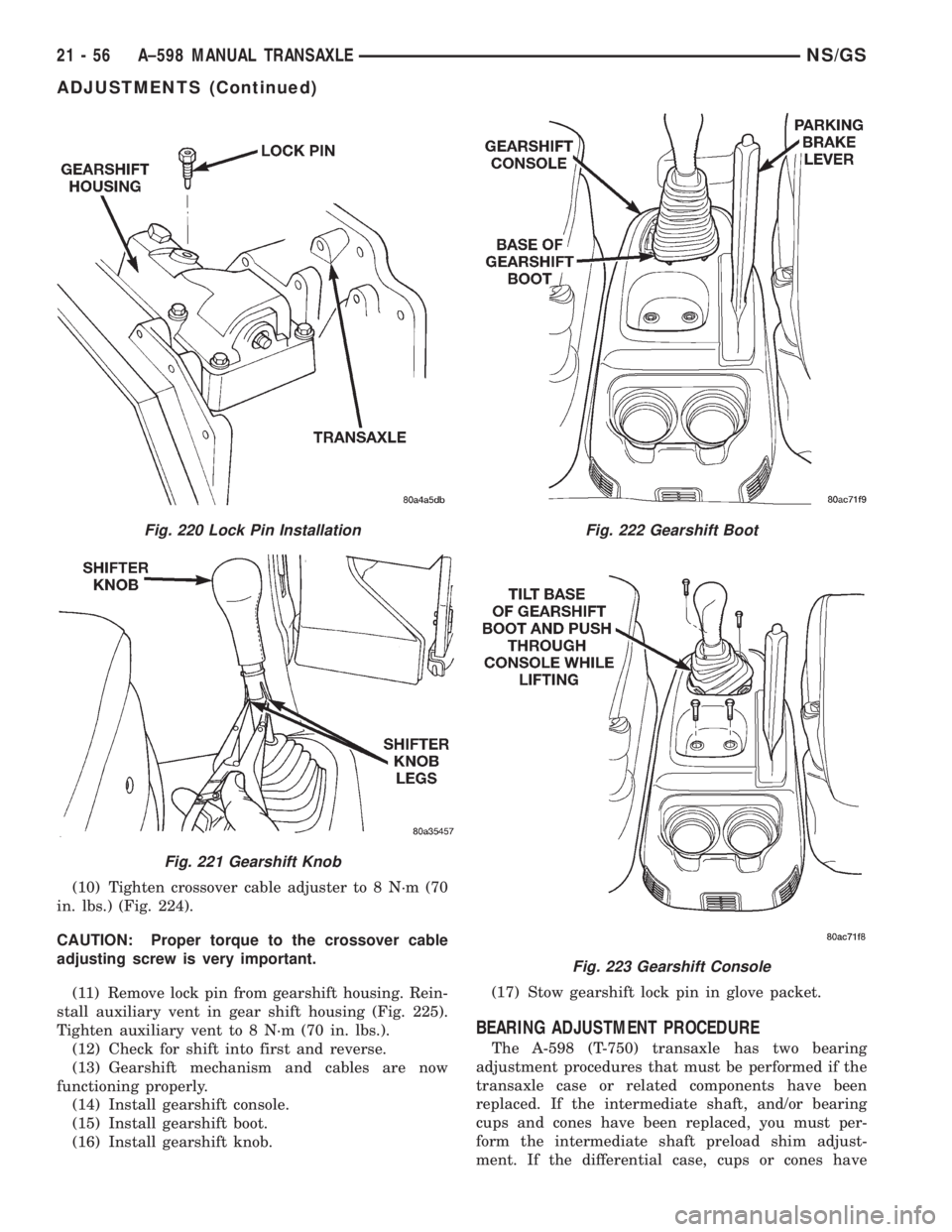

(10) Tighten crossover cable adjuster to 8 N´m (70

in. lbs.) (Fig. 216).CAUTION: Proper torque to the crossover cable

adjusting screw is very important.

(11) Remove lock pin from gearshift housing. Rein-

stall auxiliary vent in gear shift housing (Fig. 217).

Tighten auxiliary vent to 8 N´m (70 in. lbs.).

(12) Check for shift into first and reverse.

(13) Gearshift mechanism and cables are now

functioning properly.

(14) Install gearshift console.

(15) Install gearshift boot.

(16) Install gearshift knob.

(17) Stow gearshift lock pin in glove packet.

Fig. 213 Gearshift Knob

Fig. 214 Gearshift Boot

Fig. 215 Gearshift Console

Fig. 216 Crossover Cable Adjustment

Fig. 217 Auxiliary Vent Installation

21 - 54 A±598 MANUAL TRANSAXLENS/GS

ADJUSTMENTS (Continued)

Page 1712 of 1938

(10) Tighten crossover cable adjuster to 8 N´m (70

in. lbs.) (Fig. 224).

CAUTION: Proper torque to the crossover cable

adjusting screw is very important.

(11) Remove lock pin from gearshift housing. Rein-

stall auxiliary vent in gear shift housing (Fig. 225).

Tighten auxiliary vent to 8 N´m (70 in. lbs.).

(12) Check for shift into first and reverse.

(13) Gearshift mechanism and cables are now

functioning properly.

(14) Install gearshift console.

(15) Install gearshift boot.

(16) Install gearshift knob.(17) Stow gearshift lock pin in glove packet.

BEARING ADJUSTMENT PROCEDURE

The A-598 (T-750) transaxle has two bearing

adjustment procedures that must be performed if the

transaxle case or related components have been

replaced. If the intermediate shaft, and/or bearing

cups and cones have been replaced, you must per-

form the intermediate shaft preload shim adjust-

ment. If the differential case, cups or cones have

Fig. 220 Lock Pin Installation

Fig. 221 Gearshift Knob

Fig. 222 Gearshift Boot

Fig. 223 Gearshift Console

21 - 56 A±598 MANUAL TRANSAXLENS/GS

ADJUSTMENTS (Continued)

Page 1742 of 1938

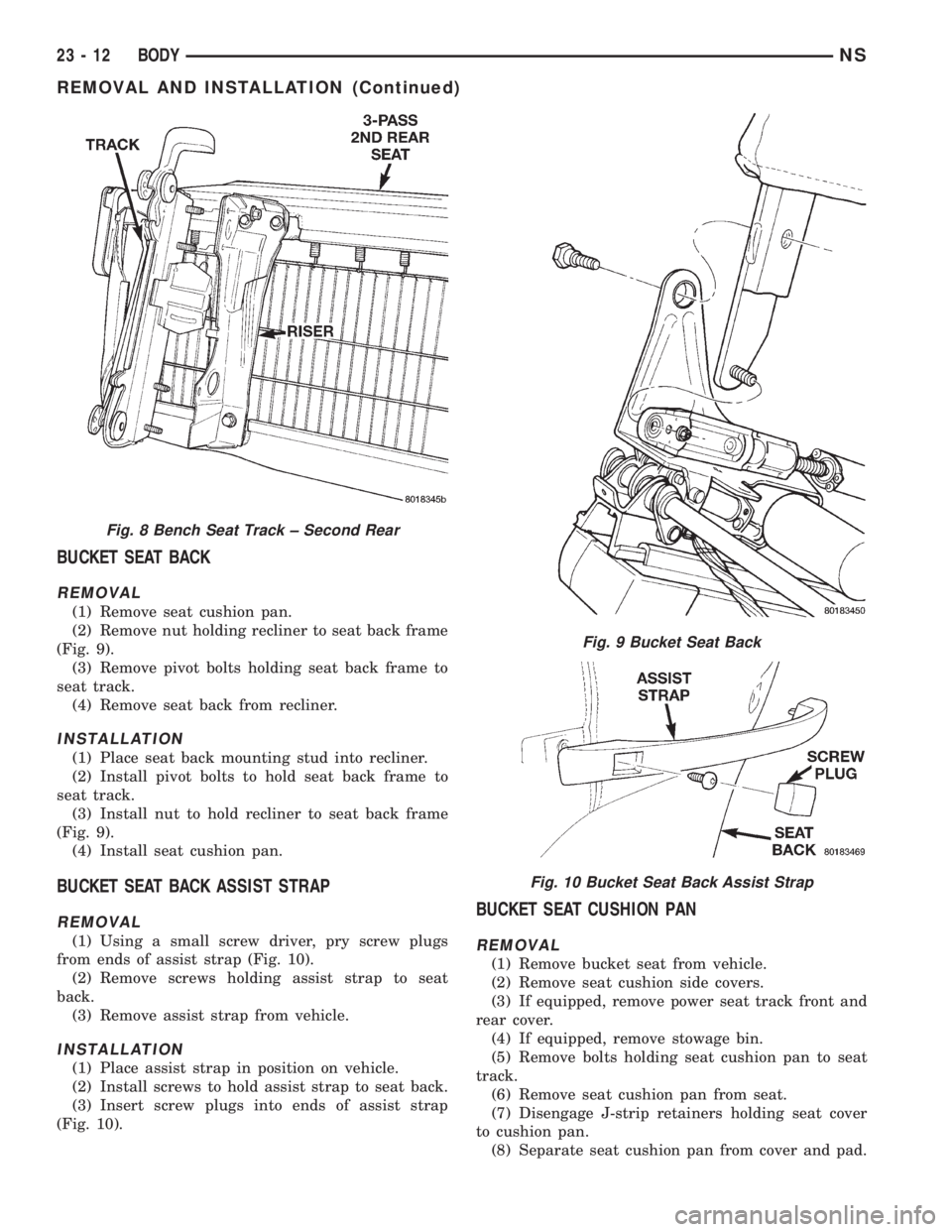

BUCKET SEAT BACK

REMOVAL

(1) Remove seat cushion pan.

(2) Remove nut holding recliner to seat back frame

(Fig. 9).

(3) Remove pivot bolts holding seat back frame to

seat track.

(4) Remove seat back from recliner.

INSTALLATION

(1) Place seat back mounting stud into recliner.

(2) Install pivot bolts to hold seat back frame to

seat track.

(3) Install nut to hold recliner to seat back frame

(Fig. 9).

(4) Install seat cushion pan.

BUCKET SEAT BACK ASSIST STRAP

REMOVAL

(1) Using a small screw driver, pry screw plugs

from ends of assist strap (Fig. 10).

(2) Remove screws holding assist strap to seat

back.

(3) Remove assist strap from vehicle.

INSTALLATION

(1) Place assist strap in position on vehicle.

(2) Install screws to hold assist strap to seat back.

(3) Insert screw plugs into ends of assist strap

(Fig. 10).

BUCKET SEAT CUSHION PAN

REMOVAL

(1) Remove bucket seat from vehicle.

(2) Remove seat cushion side covers.

(3) If equipped, remove power seat track front and

rear cover.

(4) If equipped, remove stowage bin.

(5) Remove bolts holding seat cushion pan to seat

track.

(6) Remove seat cushion pan from seat.

(7) Disengage J-strip retainers holding seat cover

to cushion pan.

(8) Separate seat cushion pan from cover and pad.

Fig. 8 Bench Seat Track ± Second Rear

Fig. 9 Bucket Seat Back

Fig. 10 Bucket Seat Back Assist Strap

23 - 12 BODYNS

REMOVAL AND INSTALLATION (Continued)