tow CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1231 of 1938

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect the battery.

(2) Remove the air cleaner assembly and inlet

hose.

(3) Remove both hoses at intercooler and engine.

(4) Disconnect EGR vacuum hose.

(5) Disconnect brake booster vacuum hose.

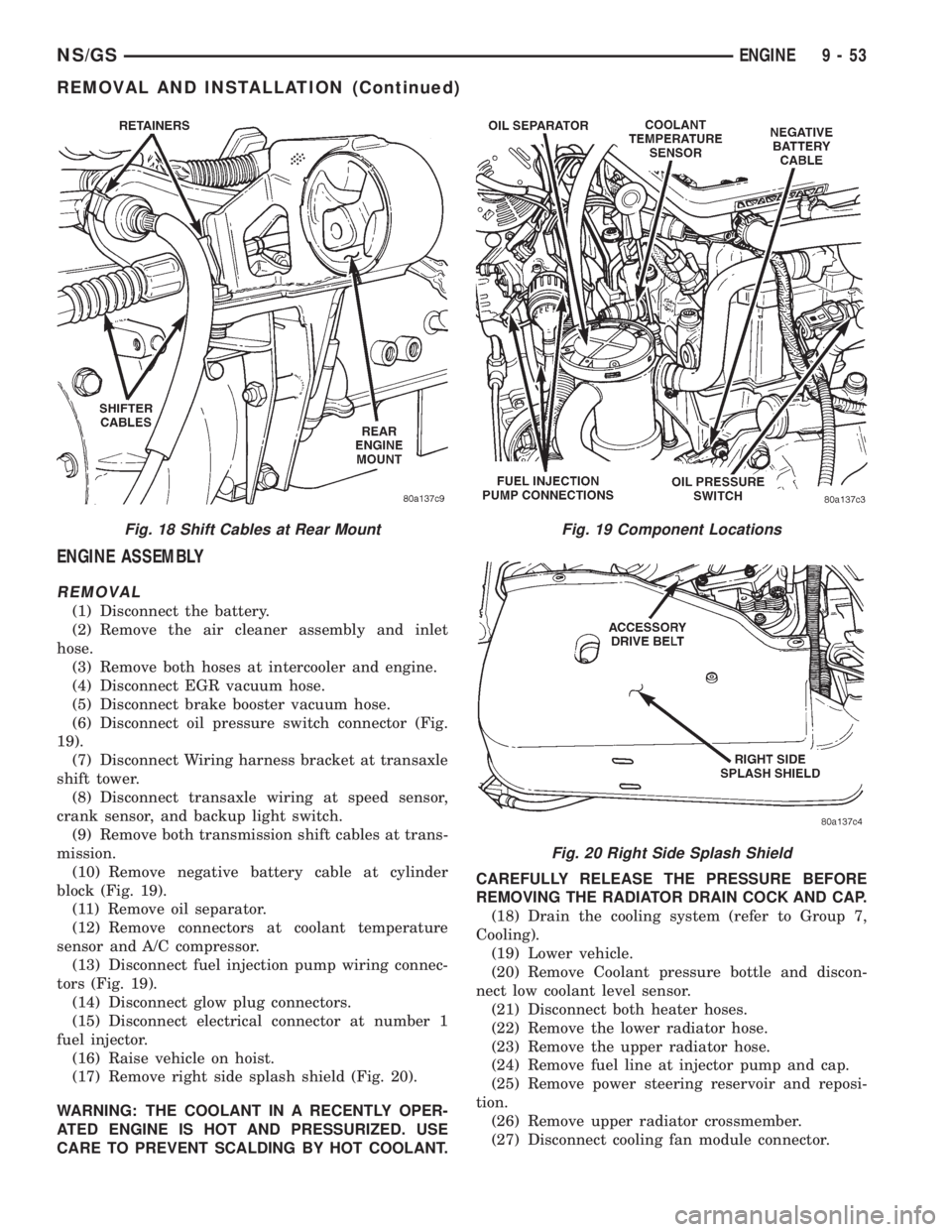

(6) Disconnect oil pressure switch connector (Fig.

19).

(7) Disconnect Wiring harness bracket at transaxle

shift tower.

(8) Disconnect transaxle wiring at speed sensor,

crank sensor, and backup light switch.

(9) Remove both transmission shift cables at trans-

mission.

(10) Remove negative battery cable at cylinder

block (Fig. 19).

(11) Remove oil separator.

(12) Remove connectors at coolant temperature

sensor and A/C compressor.

(13) Disconnect fuel injection pump wiring connec-

tors (Fig. 19).

(14) Disconnect glow plug connectors.

(15) Disconnect electrical connector at number 1

fuel injector.

(16) Raise vehicle on hoist.

(17) Remove right side splash shield (Fig. 20).

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. USE

CARE TO PREVENT SCALDING BY HOT COOLANT.CAREFULLY RELEASE THE PRESSURE BEFORE

REMOVING THE RADIATOR DRAIN COCK AND CAP.

(18) Drain the cooling system (refer to Group 7,

Cooling).

(19) Lower vehicle.

(20) Remove Coolant pressure bottle and discon-

nect low coolant level sensor.

(21) Disconnect both heater hoses.

(22) Remove the lower radiator hose.

(23) Remove the upper radiator hose.

(24) Remove fuel line at injector pump and cap.

(25) Remove power steering reservoir and reposi-

tion.

(26) Remove upper radiator crossmember.

(27) Disconnect cooling fan module connector.

Fig. 18 Shift Cables at Rear MountFig. 19 Component Locations

Fig. 20 Right Side Splash Shield

NS/GSENGINE 9 - 53

REMOVAL AND INSTALLATION (Continued)

Page 1235 of 1938

(22) Remove the injector sensor wire at the con-

nector, and glow plug Connectors.

NOTE: The attachment point for the injector sensor

wire at the injector is not a connector. The connec-

tor is located in the wire 4 to 6 inches away from

the injector.

(23) Remove injector fuel lines from injectors to

pump.

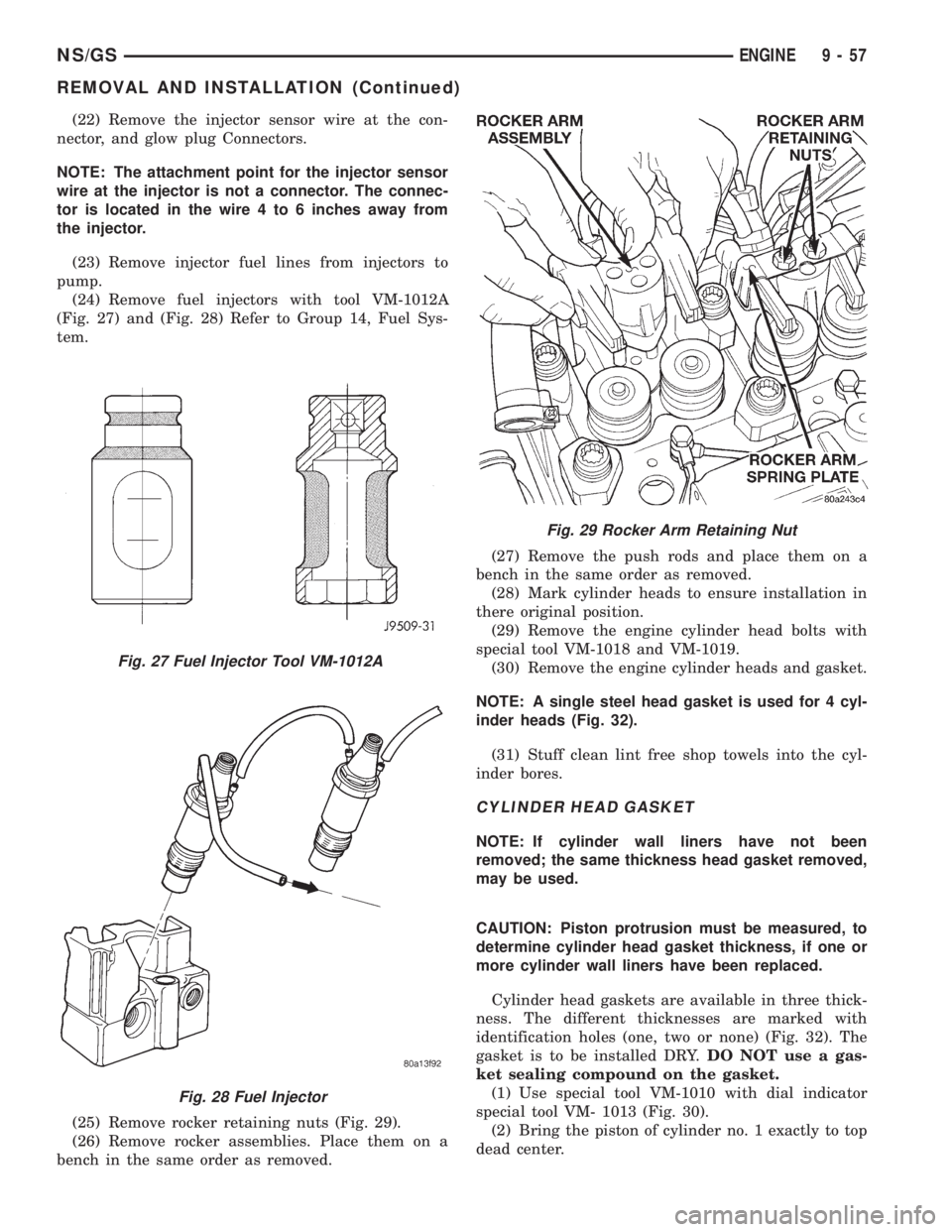

(24) Remove fuel injectors with tool VM-1012A

(Fig. 27) and (Fig. 28) Refer to Group 14, Fuel Sys-

tem.

(25) Remove rocker retaining nuts (Fig. 29).

(26) Remove rocker assemblies. Place them on a

bench in the same order as removed.(27) Remove the push rods and place them on a

bench in the same order as removed.

(28) Mark cylinder heads to ensure installation in

there original position.

(29) Remove the engine cylinder head bolts with

special tool VM-1018 and VM-1019.

(30) Remove the engine cylinder heads and gasket.

NOTE: A single steel head gasket is used for 4 cyl-

inder heads (Fig. 32).

(31) Stuff clean lint free shop towels into the cyl-

inder bores.

CYLINDER HEAD GASKET

NOTE: If cylinder wall liners have not been

removed; the same thickness head gasket removed,

may be used.

CAUTION: Piston protrusion must be measured, to

determine cylinder head gasket thickness, if one or

more cylinder wall liners have been replaced.

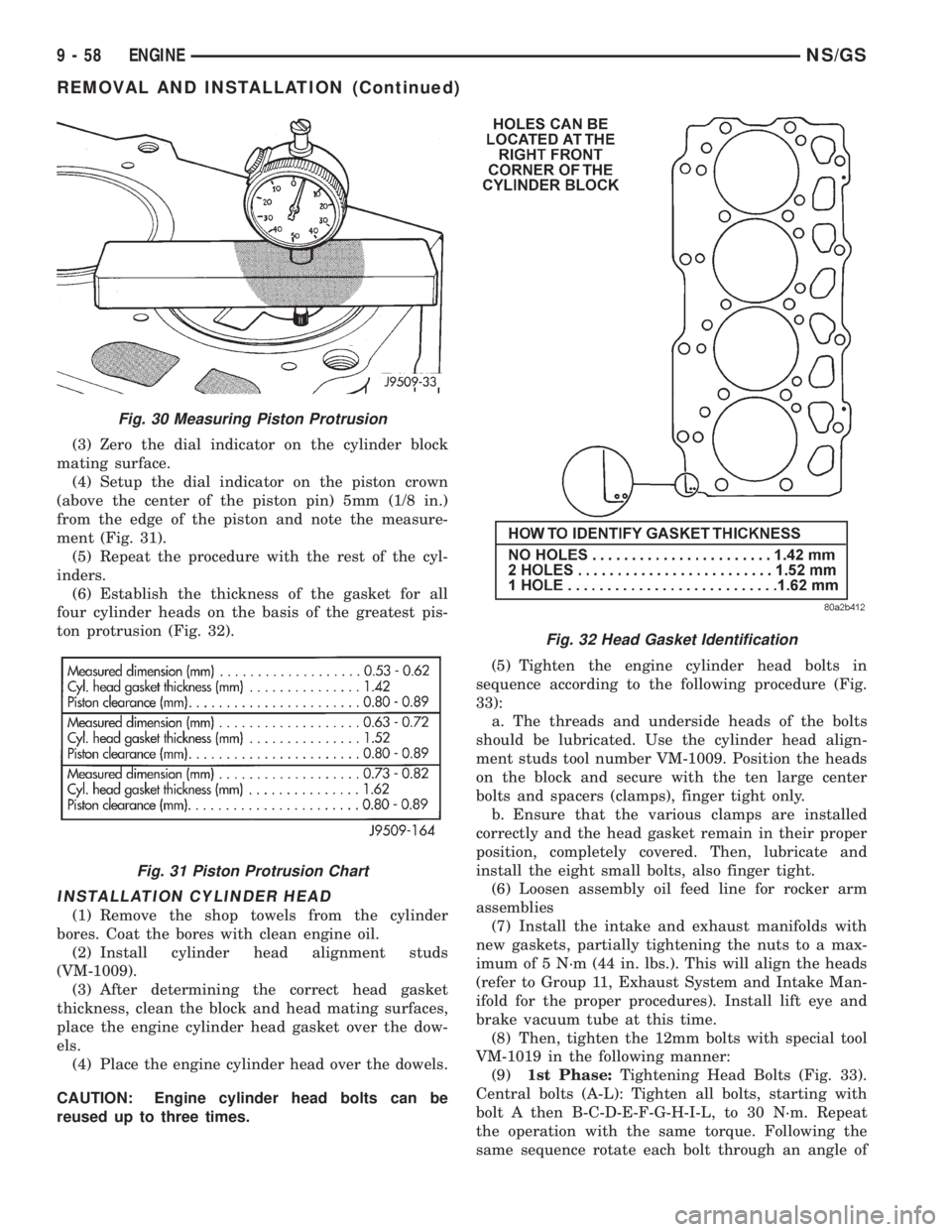

Cylinder head gaskets are available in three thick-

ness. The different thicknesses are marked with

identification holes (one, two or none) (Fig. 32). The

gasket is to be installed DRY.DO NOT use a gas-

ket sealing compound on the gasket.

(1) Use special tool VM-1010 with dial indicator

special tool VM- 1013 (Fig. 30).

(2) Bring the piston of cylinder no. 1 exactly to top

dead center.

Fig. 27 Fuel Injector Tool VM-1012A

Fig. 28 Fuel Injector

Fig. 29 Rocker Arm Retaining Nut

NS/GSENGINE 9 - 57

REMOVAL AND INSTALLATION (Continued)

Page 1236 of 1938

(3) Zero the dial indicator on the cylinder block

mating surface.

(4) Setup the dial indicator on the piston crown

(above the center of the piston pin) 5mm (1/8 in.)

from the edge of the piston and note the measure-

ment (Fig. 31).

(5) Repeat the procedure with the rest of the cyl-

inders.

(6) Establish the thickness of the gasket for all

four cylinder heads on the basis of the greatest pis-

ton protrusion (Fig. 32).

INSTALLATION CYLINDER HEAD

(1) Remove the shop towels from the cylinder

bores. Coat the bores with clean engine oil.

(2) Install cylinder head alignment studs

(VM-1009).

(3) After determining the correct head gasket

thickness, clean the block and head mating surfaces,

place the engine cylinder head gasket over the dow-

els.

(4) Place the engine cylinder head over the dowels.

CAUTION: Engine cylinder head bolts can be

reused up to three times.(5) Tighten the engine cylinder head bolts in

sequence according to the following procedure (Fig.

33):

a. The threads and underside heads of the bolts

should be lubricated. Use the cylinder head align-

ment studs tool number VM-1009. Position the heads

on the block and secure with the ten large center

bolts and spacers (clamps), finger tight only.

b. Ensure that the various clamps are installed

correctly and the head gasket remain in their proper

position, completely covered. Then, lubricate and

install the eight small bolts, also finger tight.

(6) Loosen assembly oil feed line for rocker arm

assemblies

(7) Install the intake and exhaust manifolds with

new gaskets, partially tightening the nuts to a max-

imum of 5 N´m (44 in. lbs.). This will align the heads

(refer to Group 11, Exhaust System and Intake Man-

ifold for the proper procedures). Install lift eye and

brake vacuum tube at this time.

(8) Then, tighten the 12mm bolts with special tool

VM-1019 in the following manner:

(9)1st Phase:Tightening Head Bolts (Fig. 33).

Central bolts (A-L): Tighten all bolts, starting with

bolt A then B-C-D-E-F-G-H-I-L, to 30 N´m. Repeat

the operation with the same torque. Following the

same sequence rotate each bolt through an angle of

Fig. 30 Measuring Piston Protrusion

Fig. 31 Piston Protrusion Chart

Fig. 32 Head Gasket Identification

9 - 58 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1242 of 1938

(13) Remove pistons and connecting rods from

block.

(14) Remove vibration damper. Refer to procedure

in this section.

(15) Remove front cover. Refer to procedure in this

section.

(16) Remove oil pump drive gear.

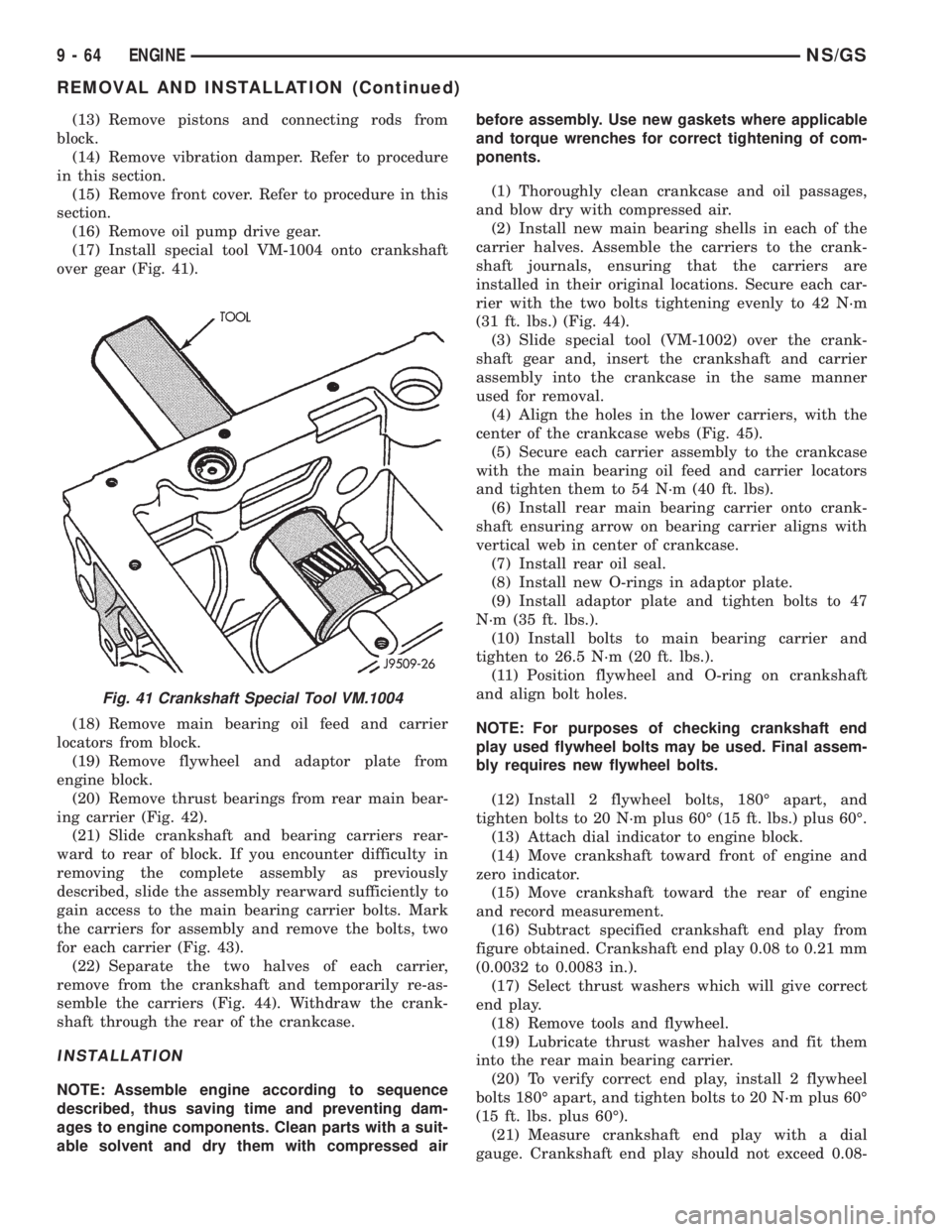

(17) Install special tool VM-1004 onto crankshaft

over gear (Fig. 41).

(18) Remove main bearing oil feed and carrier

locators from block.

(19) Remove flywheel and adaptor plate from

engine block.

(20) Remove thrust bearings from rear main bear-

ing carrier (Fig. 42).

(21) Slide crankshaft and bearing carriers rear-

ward to rear of block. If you encounter difficulty in

removing the complete assembly as previously

described, slide the assembly rearward sufficiently to

gain access to the main bearing carrier bolts. Mark

the carriers for assembly and remove the bolts, two

for each carrier (Fig. 43).

(22) Separate the two halves of each carrier,

remove from the crankshaft and temporarily re-as-

semble the carriers (Fig. 44). Withdraw the crank-

shaft through the rear of the crankcase.

INSTALLATION

NOTE: Assemble engine according to sequence

described, thus saving time and preventing dam-

ages to engine components. Clean parts with a suit-

able solvent and dry them with compressed airbefore assembly. Use new gaskets where applicable

and torque wrenches for correct tightening of com-

ponents.

(1) Thoroughly clean crankcase and oil passages,

and blow dry with compressed air.

(2) Install new main bearing shells in each of the

carrier halves. Assemble the carriers to the crank-

shaft journals, ensuring that the carriers are

installed in their original locations. Secure each car-

rier with the two bolts tightening evenly to 42 N´m

(31 ft. lbs.) (Fig. 44).

(3) Slide special tool (VM-1002) over the crank-

shaft gear and, insert the crankshaft and carrier

assembly into the crankcase in the same manner

used for removal.

(4) Align the holes in the lower carriers, with the

center of the crankcase webs (Fig. 45).

(5) Secure each carrier assembly to the crankcase

with the main bearing oil feed and carrier locators

and tighten them to 54 N´m (40 ft. lbs).

(6) Install rear main bearing carrier onto crank-

shaft ensuring arrow on bearing carrier aligns with

vertical web in center of crankcase.

(7) Install rear oil seal.

(8) Install new O-rings in adaptor plate.

(9) Install adaptor plate and tighten bolts to 47

N´m (35 ft. lbs.).

(10) Install bolts to main bearing carrier and

tighten to 26.5 N´m (20 ft. lbs.).

(11) Position flywheel and O-ring on crankshaft

and align bolt holes.

NOTE: For purposes of checking crankshaft end

play used flywheel bolts may be used. Final assem-

bly requires new flywheel bolts.

(12) Install 2 flywheel bolts, 180É apart, and

tighten bolts to 20 N´m plus 60É (15 ft. lbs.) plus 60É.

(13) Attach dial indicator to engine block.

(14) Move crankshaft toward front of engine and

zero indicator.

(15) Move crankshaft toward the rear of engine

and record measurement.

(16) Subtract specified crankshaft end play from

figure obtained. Crankshaft end play 0.08 to 0.21 mm

(0.0032 to 0.0083 in.).

(17) Select thrust washers which will give correct

end play.

(18) Remove tools and flywheel.

(19) Lubricate thrust washer halves and fit them

into the rear main bearing carrier.

(20) To verify correct end play, install 2 flywheel

bolts 180É apart, and tighten bolts to 20 N´m plus 60É

(15 ft. lbs. plus 60É).

(21) Measure crankshaft end play with a dial

gauge. Crankshaft end play should not exceed 0.08-

Fig. 41 Crankshaft Special Tool VM.1004

9 - 64 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1248 of 1938

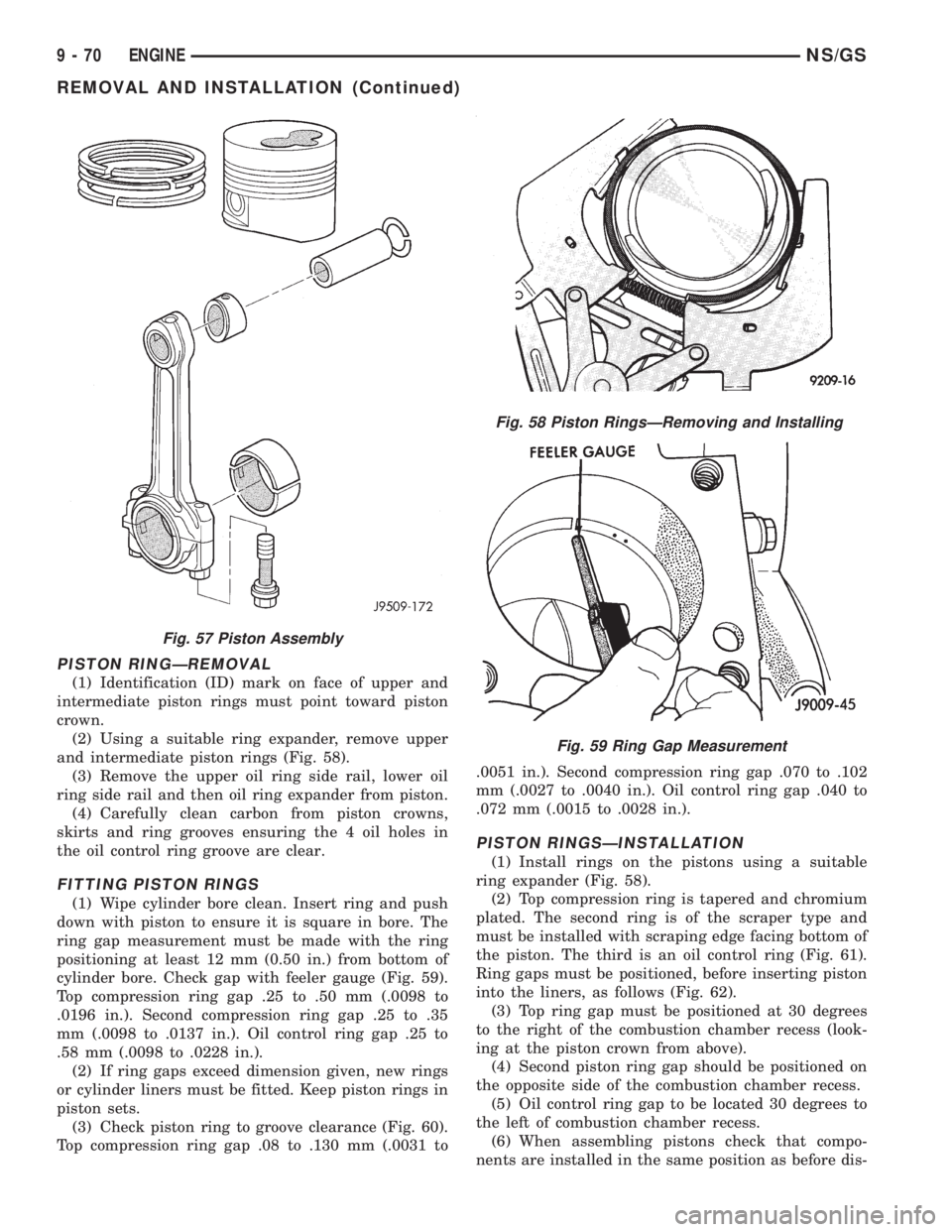

PISTON RINGÐREMOVAL

(1) Identification (ID) mark on face of upper and

intermediate piston rings must point toward piston

crown.

(2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 58).

(3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston.

(4) Carefully clean carbon from piston crowns,

skirts and ring grooves ensuring the 4 oil holes in

the oil control ring groove are clear.

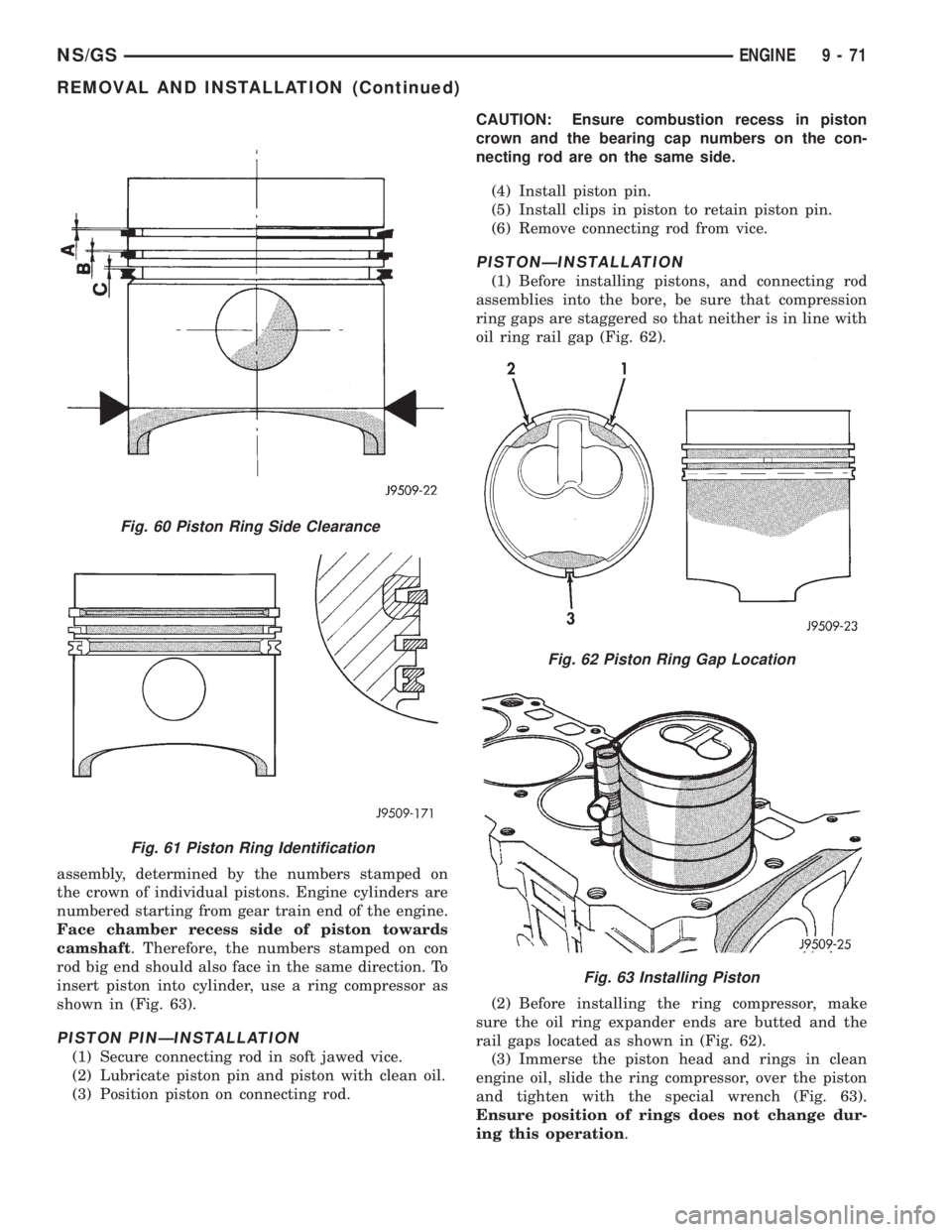

FITTING PISTON RINGS

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 12 mm (0.50 in.) from bottom of

cylinder bore. Check gap with feeler gauge (Fig. 59).

Top compression ring gap .25 to .50 mm (.0098 to

.0196 in.). Second compression ring gap .25 to .35

mm (.0098 to .0137 in.). Oil control ring gap .25 to

.58 mm (.0098 to .0228 in.).

(2) If ring gaps exceed dimension given, new rings

or cylinder liners must be fitted. Keep piston rings in

piston sets.

(3) Check piston ring to groove clearance (Fig. 60).

Top compression ring gap .08 to .130 mm (.0031 to.0051 in.). Second compression ring gap .070 to .102

mm (.0027 to .0040 in.). Oil control ring gap .040 to

.072 mm (.0015 to .0028 in.).

PISTON RINGSÐINSTALLATION

(1) Install rings on the pistons using a suitable

ring expander (Fig. 58).

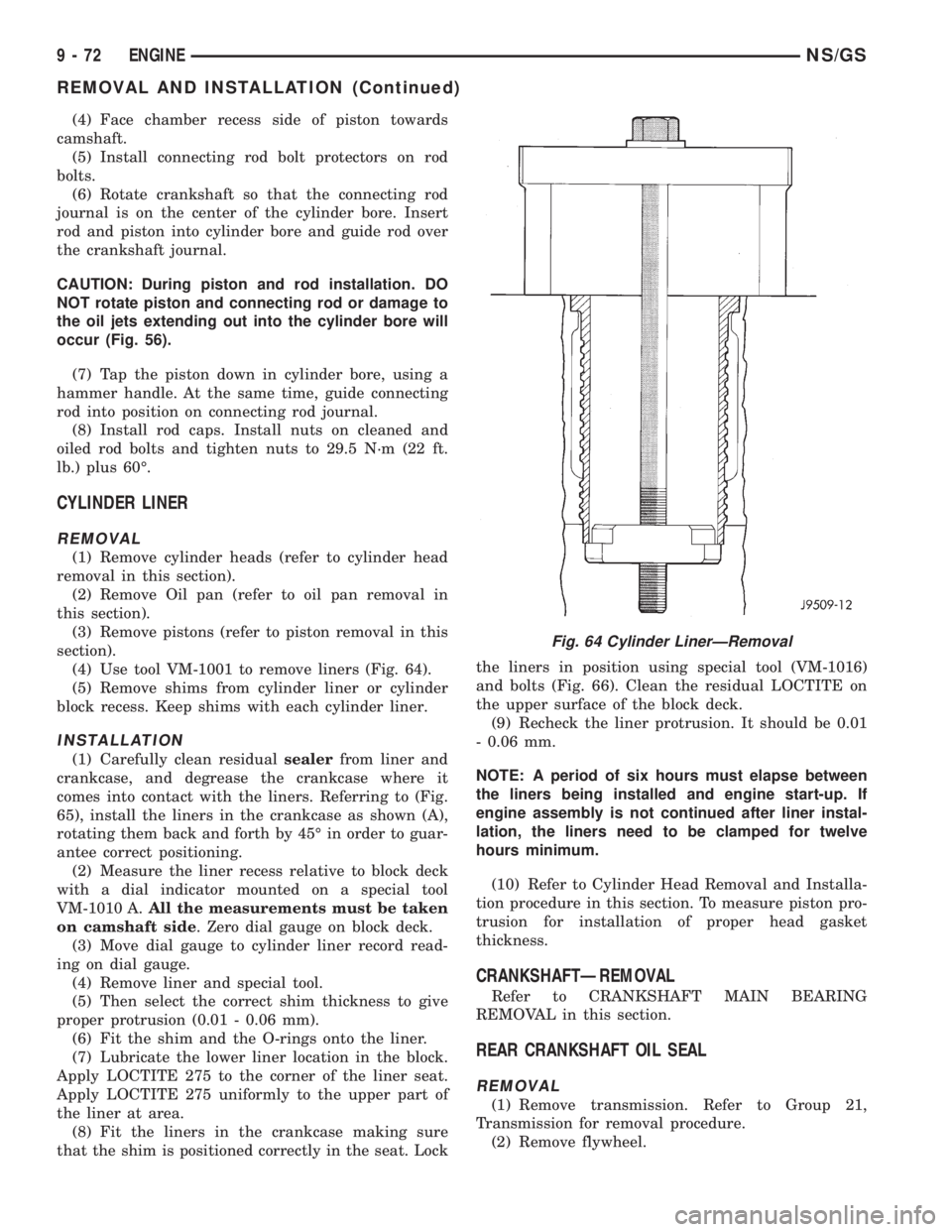

(2) Top compression ring is tapered and chromium

plated. The second ring is of the scraper type and

must be installed with scraping edge facing bottom of

the piston. The third is an oil control ring (Fig. 61).

Ring gaps must be positioned, before inserting piston

into the liners, as follows (Fig. 62).

(3) Top ring gap must be positioned at 30 degrees

to the right of the combustion chamber recess (look-

ing at the piston crown from above).

(4) Second piston ring gap should be positioned on

the opposite side of the combustion chamber recess.

(5) Oil control ring gap to be located 30 degrees to

the left of combustion chamber recess.

(6) When assembling pistons check that compo-

nents are installed in the same position as before dis-

Fig. 57 Piston Assembly

Fig. 58 Piston RingsÐRemoving and Installing

Fig. 59 Ring Gap Measurement

9 - 70 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1249 of 1938

assembly, determined by the numbers stamped on

the crown of individual pistons. Engine cylinders are

numbered starting from gear train end of the engine.

Face chamber recess side of piston towards

camshaft. Therefore, the numbers stamped on con

rod big end should also face in the same direction. To

insert piston into cylinder, use a ring compressor as

shown in (Fig. 63).

PISTON PINÐINSTALLATION

(1) Secure connecting rod in soft jawed vice.

(2) Lubricate piston pin and piston with clean oil.

(3) Position piston on connecting rod.CAUTION: Ensure combustion recess in piston

crown and the bearing cap numbers on the con-

necting rod are on the same side.

(4) Install piston pin.

(5) Install clips in piston to retain piston pin.

(6) Remove connecting rod from vice.

PISTONÐINSTALLATION

(1) Before installing pistons, and connecting rod

assemblies into the bore, be sure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap (Fig. 62).

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 62).

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston

and tighten with the special wrench (Fig. 63).

Ensure position of rings does not change dur-

ing this operation.

Fig. 60 Piston Ring Side Clearance

Fig. 61 Piston Ring Identification

Fig. 62 Piston Ring Gap Location

Fig. 63 Installing Piston

NS/GSENGINE 9 - 71

REMOVAL AND INSTALLATION (Continued)

Page 1250 of 1938

(4) Face chamber recess side of piston towards

camshaft.

(5) Install connecting rod bolt protectors on rod

bolts.

(6) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insert

rod and piston into cylinder bore and guide rod over

the crankshaft journal.

CAUTION: During piston and rod installation. DO

NOT rotate piston and connecting rod or damage to

the oil jets extending out into the cylinder bore will

occur (Fig. 56).

(7) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(8) Install rod caps. Install nuts on cleaned and

oiled rod bolts and tighten nuts to 29.5 N´m (22 ft.

lb.) plus 60É.

CYLINDER LINER

REMOVAL

(1) Remove cylinder heads (refer to cylinder head

removal in this section).

(2) Remove Oil pan (refer to oil pan removal in

this section).

(3) Remove pistons (refer to piston removal in this

section).

(4) Use tool VM-1001 to remove liners (Fig. 64).

(5) Remove shims from cylinder liner or cylinder

block recess. Keep shims with each cylinder liner.

INSTALLATION

(1) Carefully clean residualsealerfrom liner and

crankcase, and degrease the crankcase where it

comes into contact with the liners. Referring to (Fig.

65), install the liners in the crankcase as shown (A),

rotating them back and forth by 45É in order to guar-

antee correct positioning.

(2) Measure the liner recess relative to block deck

with a dial indicator mounted on a special tool

VM-1010 A.All the measurements must be taken

on camshaft side. Zero dial gauge on block deck.

(3) Move dial gauge to cylinder liner record read-

ing on dial gauge.

(4) Remove liner and special tool.

(5) Then select the correct shim thickness to give

proper protrusion (0.01 - 0.06 mm).

(6) Fit the shim and the O-rings onto the liner.

(7) Lubricate the lower liner location in the block.

Apply LOCTITE 275 to the corner of the liner seat.

Apply LOCTITE 275 uniformly to the upper part of

the liner at area.

(8) Fit the liners in the crankcase making sure

that the shim is positioned correctly in the seat. Lockthe liners in position using special tool (VM-1016)

and bolts (Fig. 66). Clean the residual LOCTITE on

the upper surface of the block deck.

(9) Recheck the liner protrusion. It should be 0.01

- 0.06 mm.

NOTE: A period of six hours must elapse between

the liners being installed and engine start-up. If

engine assembly is not continued after liner instal-

lation, the liners need to be clamped for twelve

hours minimum.

(10) Refer to Cylinder Head Removal and Installa-

tion procedure in this section. To measure piston pro-

trusion for installation of proper head gasket

thickness.

CRANKSHAFTÐREMOVAL

Refer to CRANKSHAFT MAIN BEARING

REMOVAL in this section.

REAR CRANKSHAFT OIL SEAL

REMOVAL

(1) Remove transmission. Refer to Group 21,

Transmission for removal procedure.

(2) Remove flywheel.

Fig. 64 Cylinder LinerÐRemoval

9 - 72 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1268 of 1938

INSTALLATION

(1) Install new upper intake manifold gasket.

NOTE: Center outboard fastener is a double stud.

(2) Tighten upper intake manifold fasteners start-

ing at center and progressing outward in both direc-

tions. Tighten bolts to 28 N´m (250 in. lbs.). Repeat

this procedures until all fasteners are at specified

torque.

(3) Install dipstick tube. Seal tube to cylinder

block using MopartStud N' Bearing Mount Adhe-

sive. Tighten dipstick tube fastener to 12 N´m (105

in. lbs.)

(4) Install dipstick.

(5) Install upper bolt in intake manifold to front

support bracket (Fig. 11). Torque to 28 N´m (250 in.

lbs.).

(6) Install two top bolts at intake manifold to rear

support bracket making sure bracket to manifold

spacer is in place (Fig. 10). Tighten bolts to 28 N´m

(250 in. lbs.)

(7) Install throttle cables in bracket.

(8) Install throttle cable and speed control cable (if

equipped) to throttle lever.

(9) Install vacuum lines for power brake booster

and speed control vacuum reservoir at upper intake

manifold fittings.

(10) Install vacuum lines for purge solenoid and

PCV valve.

(11) Install electrical connectors for MAP sensor,

throttle position sensor, and idle air control motor.(12) Install air intake tube and resonator box to

throttle body.

(13) Connect negative cable to battery.

INTAKE MANIFOLD LOWERÐ2.4L ENGINE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE

To release fuel pressure, refer to the Fuel Delivery

System Pressure Release section of Group 14 Fuel

System for procedure.

REMOVAL

(1) Perform fuel system pressure release proce-

durebefore attempting any repairs.

(2) Remove upper intake manifold. Refer to proce-

dure in this section.

CAUTION: Cover intake manifold to prevent foreign

material from entering engine.

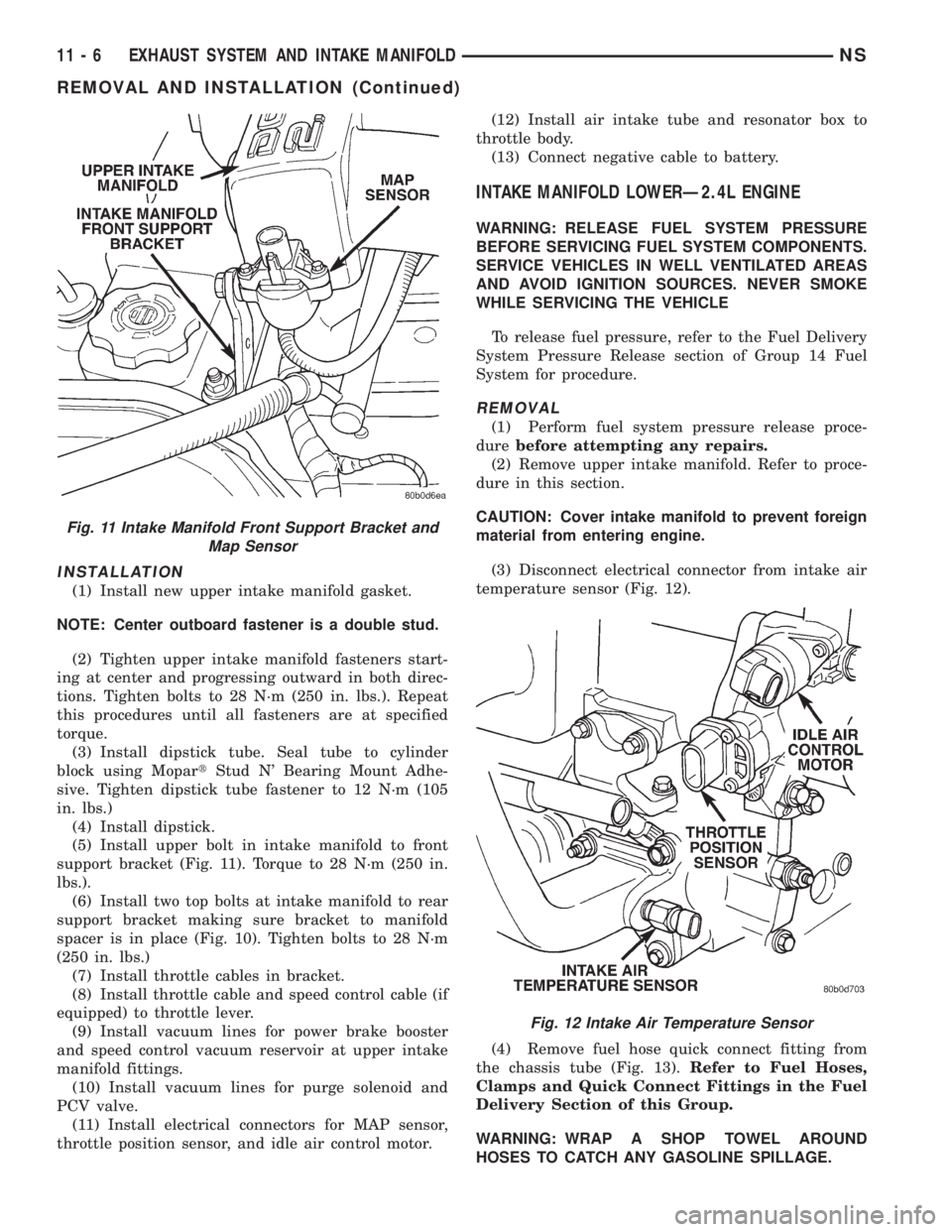

(3) Disconnect electrical connector from intake air

temperature sensor (Fig. 12).

(4) Remove fuel hose quick connect fitting from

the chassis tube (Fig. 13).Refer to Fuel Hoses,

Clamps and Quick Connect Fittings in the Fuel

Delivery Section of this Group.

WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE.

Fig. 11 Intake Manifold Front Support Bracket and

Map Sensor

Fig. 12 Intake Air Temperature Sensor

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLDNS

REMOVAL AND INSTALLATION (Continued)

Page 1270 of 1938

(2) Tighten intake manifold fasteners in the fol-

lowing sequence (Fig. 16). Torque to 23 N´m (200 in.

lbs.). Repeat this procedure until all bolts are at

specified torque.

(3) Install intake manifold center support bracket

bolts (Y bracket):

²Fastener to block 54 N´m (40 ft. lbs.)

²Fastener to intake 28 N´m (250 in. lbs.)

(4) Install fuel hose quick connector fitting to

chassis tubes.Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in Group 14, Fuel Deliv-

ery.Push the fitting onto the chassis tube until it

clicks into place. Pull on the fitting to ensure com-

plete insertion.

(5) Reverse removal procedures 2 through 12 for

installation.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(6) With the ignition key in ON position, access

the DRB scan tool ASD Fuel System Test to pressur-

ize the fuel system. Check for leaks.

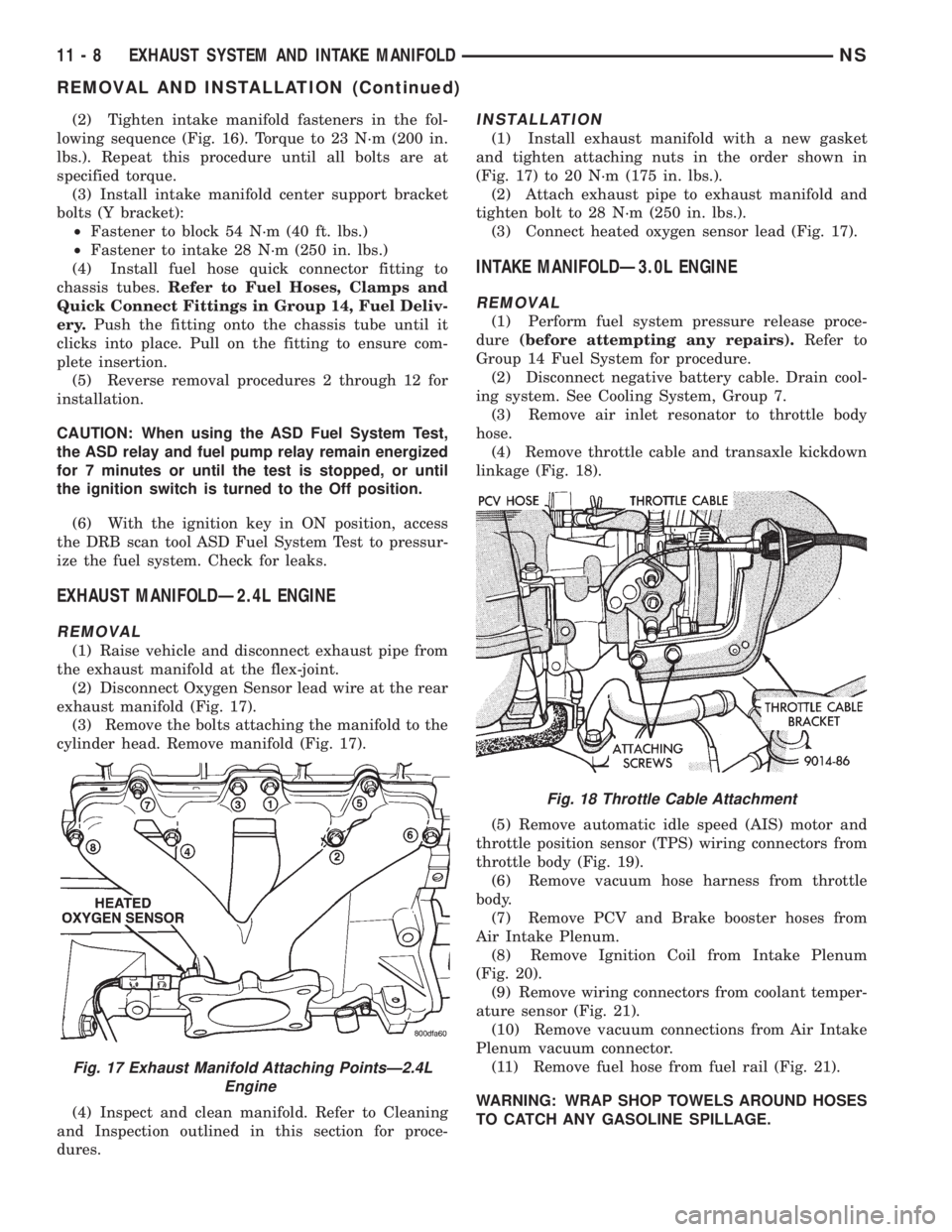

EXHAUST MANIFOLDÐ2.4L ENGINE

REMOVAL

(1) Raise vehicle and disconnect exhaust pipe from

the exhaust manifold at the flex-joint.

(2) Disconnect Oxygen Sensor lead wire at the rear

exhaust manifold (Fig. 17).

(3) Remove the bolts attaching the manifold to the

cylinder head. Remove manifold (Fig. 17).

(4) Inspect and clean manifold. Refer to Cleaning

and Inspection outlined in this section for proce-

dures.

INSTALLATION

(1) Install exhaust manifold with a new gasket

and tighten attaching nuts in the order shown in

(Fig. 17) to 20 N´m (175 in. lbs.).

(2) Attach exhaust pipe to exhaust manifold and

tighten bolt to 28 N´m (250 in. lbs.).

(3) Connect heated oxygen sensor lead (Fig. 17).

INTAKE MANIFOLDÐ3.0L ENGINE

REMOVAL

(1) Perform fuel system pressure release proce-

dure(before attempting any repairs).Refer to

Group 14 Fuel System for procedure.

(2) Disconnect negative battery cable. Drain cool-

ing system. See Cooling System, Group 7.

(3) Remove air inlet resonator to throttle body

hose.

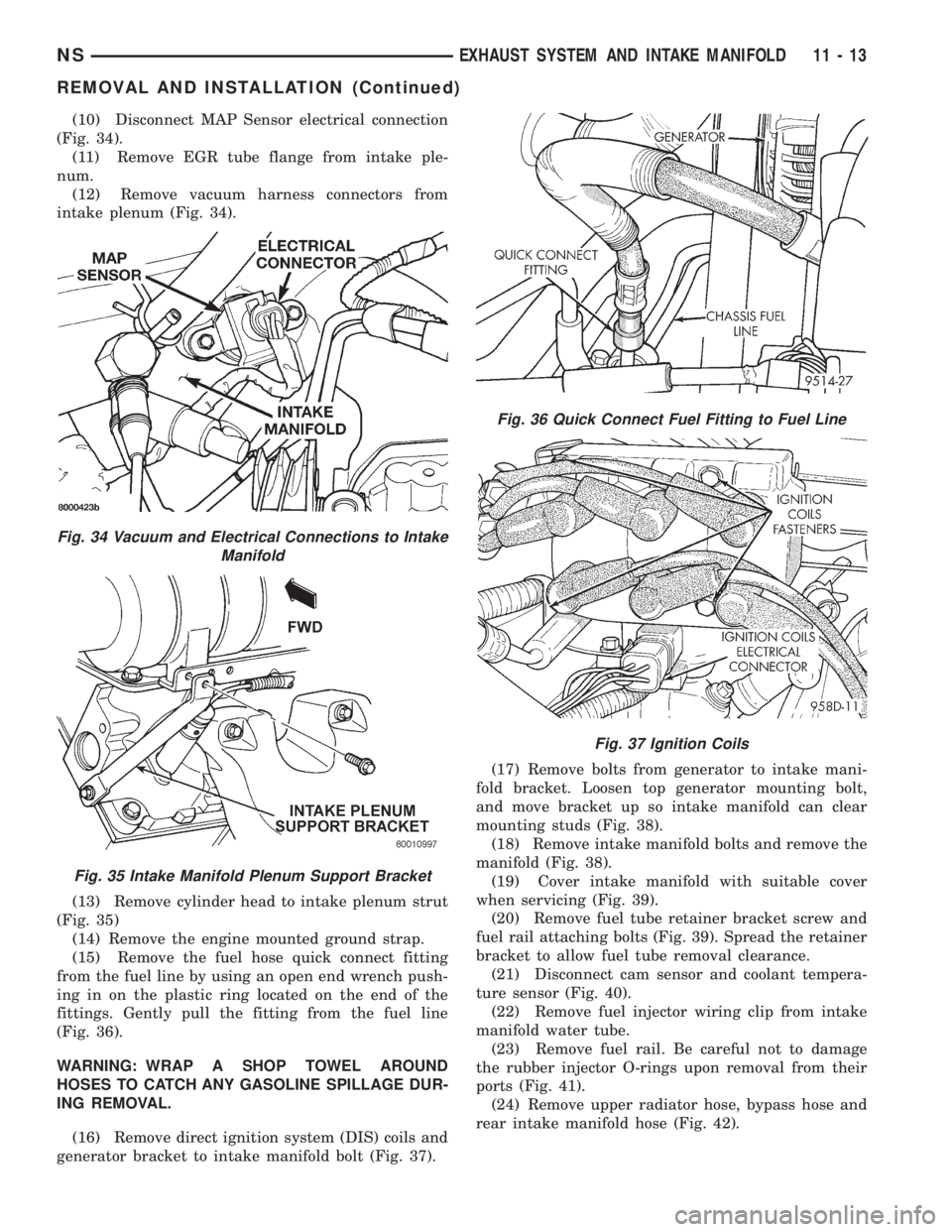

(4) Remove throttle cable and transaxle kickdown

linkage (Fig. 18).

(5) Remove automatic idle speed (AIS) motor and

throttle position sensor (TPS) wiring connectors from

throttle body (Fig. 19).

(6) Remove vacuum hose harness from throttle

body.

(7) Remove PCV and Brake booster hoses from

Air Intake Plenum.

(8) Remove Ignition Coil from Intake Plenum

(Fig. 20).

(9) Remove wiring connectors from coolant temper-

ature sensor (Fig. 21).

(10) Remove vacuum connections from Air Intake

Plenum vacuum connector.

(11) Remove fuel hose from fuel rail (Fig. 21).

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY GASOLINE SPILLAGE.

Fig. 17 Exhaust Manifold Attaching PointsÐ2.4L

Engine

Fig. 18 Throttle Cable Attachment

11 - 8 EXHAUST SYSTEM AND INTAKE MANIFOLDNS

REMOVAL AND INSTALLATION (Continued)

Page 1275 of 1938

(10) Disconnect MAP Sensor electrical connection

(Fig. 34).

(11) Remove EGR tube flange from intake ple-

num.

(12) Remove vacuum harness connectors from

intake plenum (Fig. 34).

(13) Remove cylinder head to intake plenum strut

(Fig. 35)

(14) Remove the engine mounted ground strap.

(15) Remove the fuel hose quick connect fitting

from the fuel line by using an open end wrench push-

ing in on the plastic ring located on the end of the

fittings. Gently pull the fitting from the fuel line

(Fig. 36).

WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE DUR-

ING REMOVAL.

(16) Remove direct ignition system (DIS) coils and

generator bracket to intake manifold bolt (Fig. 37).(17) Remove bolts from generator to intake mani-

fold bracket. Loosen top generator mounting bolt,

and move bracket up so intake manifold can clear

mounting studs (Fig. 38).

(18) Remove intake manifold bolts and remove the

manifold (Fig. 38).

(19) Cover intake manifold with suitable cover

when servicing (Fig. 39).

(20) Remove fuel tube retainer bracket screw and

fuel rail attaching bolts (Fig. 39). Spread the retainer

bracket to allow fuel tube removal clearance.

(21) Disconnect cam sensor and coolant tempera-

ture sensor (Fig. 40).

(22) Remove fuel injector wiring clip from intake

manifold water tube.

(23) Remove fuel rail. Be careful not to damage

the rubber injector O-rings upon removal from their

ports (Fig. 41).

(24) Remove upper radiator hose, bypass hose and

rear intake manifold hose (Fig. 42).

Fig. 34 Vacuum and Electrical Connections to Intake

Manifold

Fig. 35 Intake Manifold Plenum Support Bracket

Fig. 36 Quick Connect Fuel Fitting to Fuel Line

Fig. 37 Ignition Coils

NSEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 13

REMOVAL AND INSTALLATION (Continued)