tow CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1293 of 1938

FRAME AND BUMPERS

CONTENTS

page

FRAME................................ 1

FRAME

INDEX

page page

REMOVAL AND INSTALLATION

FRONT TOW HOOK BRACKET............. 1REAR TOW HOOK BRACKET.............. 1

REMOVAL AND INSTALLATION

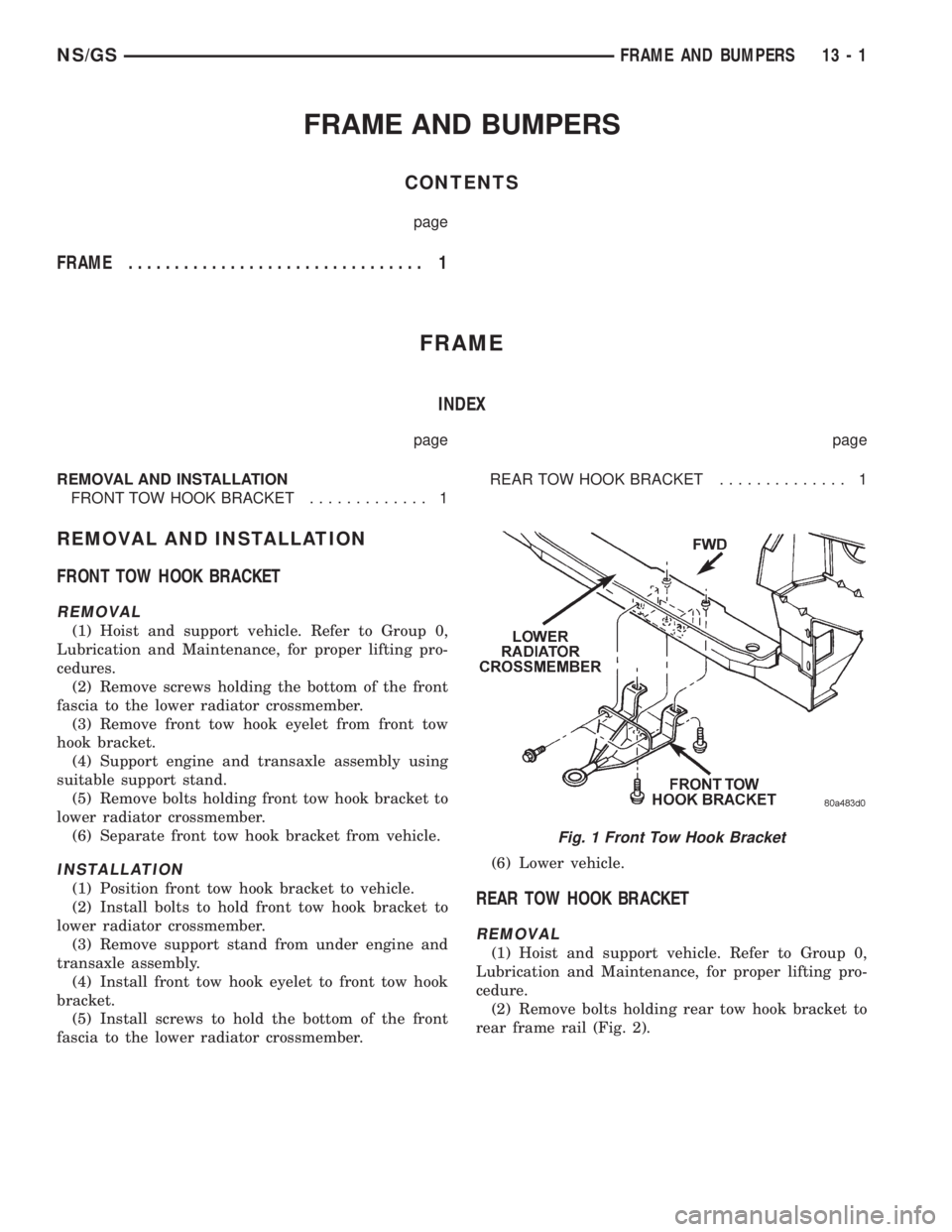

FRONT TOW HOOK BRACKET

REMOVAL

(1) Hoist and support vehicle. Refer to Group 0,

Lubrication and Maintenance, for proper lifting pro-

cedures.

(2) Remove screws holding the bottom of the front

fascia to the lower radiator crossmember.

(3) Remove front tow hook eyelet from front tow

hook bracket.

(4) Support engine and transaxle assembly using

suitable support stand.

(5) Remove bolts holding front tow hook bracket to

lower radiator crossmember.

(6) Separate front tow hook bracket from vehicle.

INSTALLATION

(1) Position front tow hook bracket to vehicle.

(2) Install bolts to hold front tow hook bracket to

lower radiator crossmember.

(3) Remove support stand from under engine and

transaxle assembly.

(4) Install front tow hook eyelet to front tow hook

bracket.

(5) Install screws to hold the bottom of the front

fascia to the lower radiator crossmember.(6) Lower vehicle.REAR TOW HOOK BRACKET

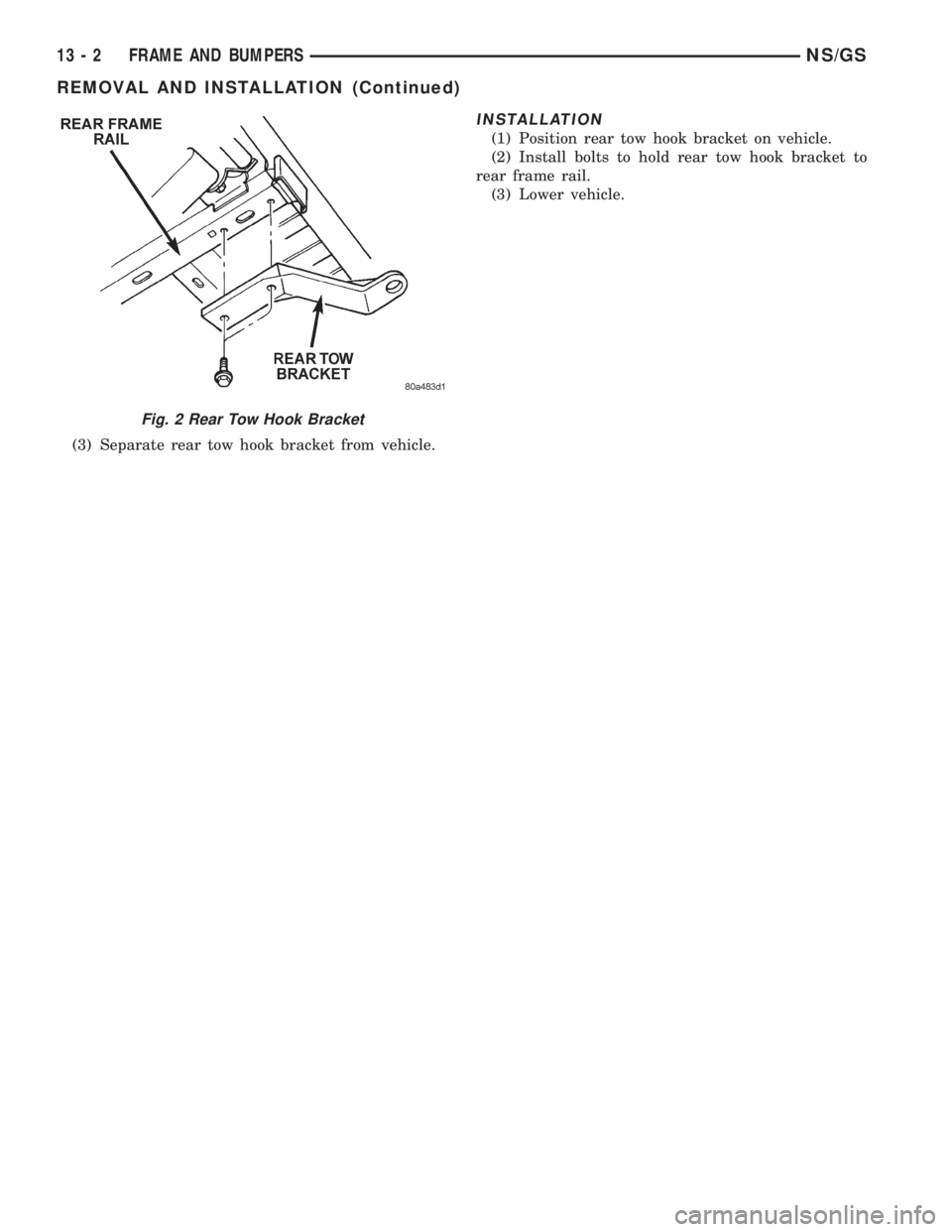

REMOVAL

(1) Hoist and support vehicle. Refer to Group 0,

Lubrication and Maintenance, for proper lifting pro-

cedure.

(2) Remove bolts holding rear tow hook bracket to

rear frame rail (Fig. 2).

Fig. 1 Front Tow Hook Bracket

NS/GSFRAME AND BUMPERS 13 - 1

Page 1294 of 1938

(3) Separate rear tow hook bracket from vehicle.

INSTALLATION

(1) Position rear tow hook bracket on vehicle.

(2) Install bolts to hold rear tow hook bracket to

rear frame rail.

(3) Lower vehicle.

Fig. 2 Rear Tow Hook Bracket

13 - 2 FRAME AND BUMPERSNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1306 of 1938

(9) Momentarily touch the other end of this

jumper wire to the negative terminal of the battery

for no more than 4 seconds.

(10) Place a rag or towel below the fuel line at the

quick connect to the rail.

(11) Disconnect the quick connect fitting to the

rail. Refer to Quick-Connect Fittings in this section.

(12) Return the fuel pump relay to the PDC.

(13) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in the PCM memory due to the

fuel pump relay removal. The DRB scan tool must be

used to erase a DTC. Refer to group 25, On-Board

Diagnostics.

HOSES AND CLAMPS

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that cause

abrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

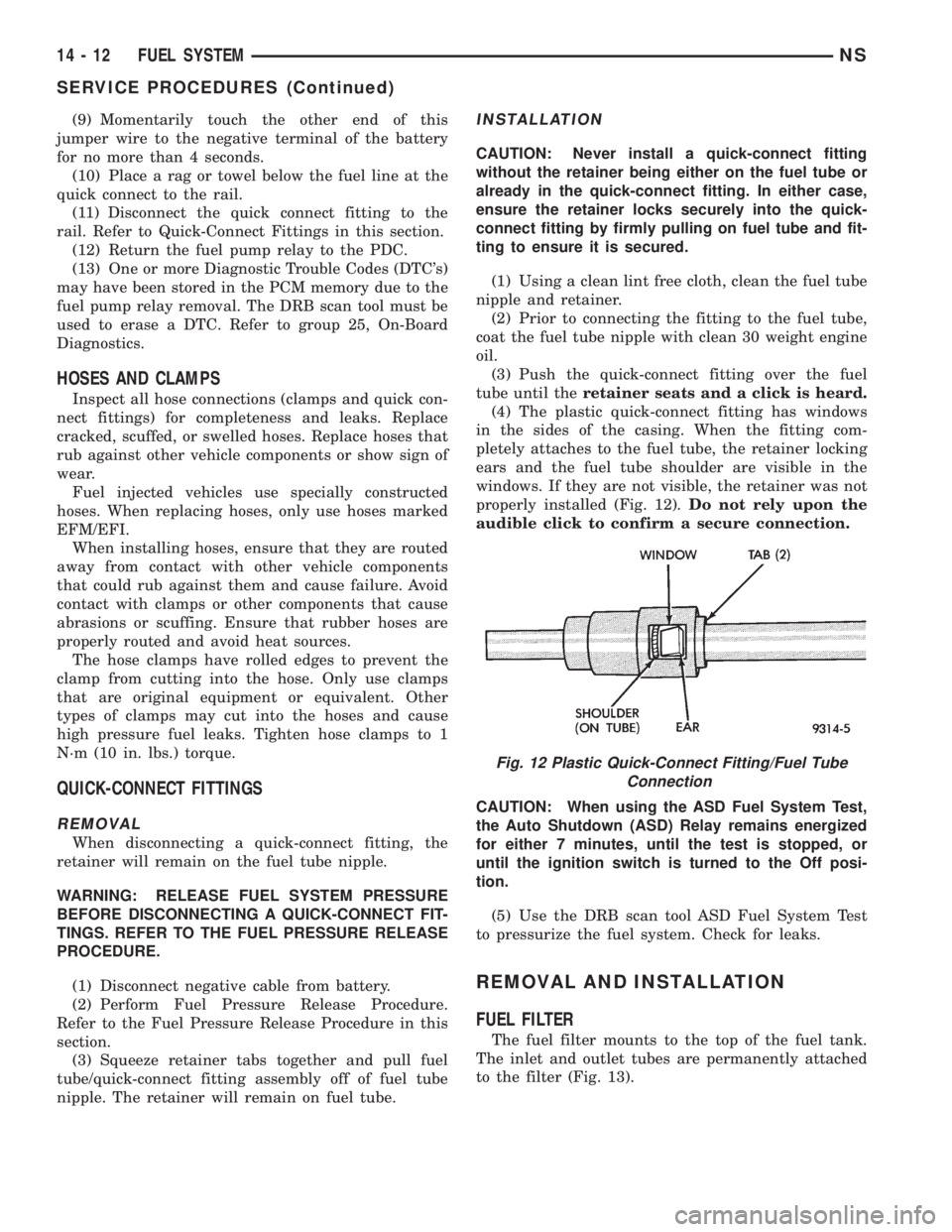

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 12).Do not rely upon the

audible click to confirm a secure connection.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(5) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

REMOVAL AND INSTALLATION

FUEL FILTER

The fuel filter mounts to the top of the fuel tank.

The inlet and outlet tubes are permanently attached

to the filter (Fig. 13).

Fig. 12 Plastic Quick-Connect Fitting/Fuel Tube

Connection

14 - 12 FUEL SYSTEMNS

SERVICE PROCEDURES (Continued)

Page 1312 of 1938

INSTALLATION

(1) Position fuel tank on transmission jack. Con-

nect pressure relief/rollover valve hose. Connect fuel

filler tube vent hose and replace clamp.

(2) Raise tank into position and carefully work

filler tube into tank. A light coating of clean engine

oil on the tube end may be used to aid assembly.

(3) Feed filler vent line thru frame rail. Careful

not to cross lines.

(4) Tighten strap bolts to 54 N´m (40 ft. lbs.)

torque. Remove transmission jack.

(5) Tighten filler hose clamp to 3.3 N´m (30 in.

lbs.).

CAUTION: Ensure straps are not twisted or bent

before or after tightening strap nuts.

(6) Connect fuel pump/module electrical connector.

Place retainer in locked position.

(7) Lubricate the fuel supply line with clean 30

weight engine oil, install the quick connect fuel fit-

ting. Refer to Tube/Fitting Assembly in the Fuel

Delivery section of this Group.

(8) Attach filler line to filler tube. Pull on connec-

tor to make sure of connection.

(9) Fill fuel tank, replace cap, and connect battery

negative cable.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(10) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

FUEL INJECTOR RAILÐ2.4L

REMOVAL

(1) Perform fuel system pressure release procedure

before servicing or starting repairs.Refer to

Fuel System Pressure Release Procedure in this sec-

tion.

(2) Disconnect negative cable from battery.

(3) Remove air cleaner inlet hose from throttle

body.

(4) Remove throttle cable and speed control cable

(if equipped) from throttle lever.

(5) Remove throttle cables from bracket by com-

pressing retaining tabs.

(6) Remove connector from throttle position sensor.

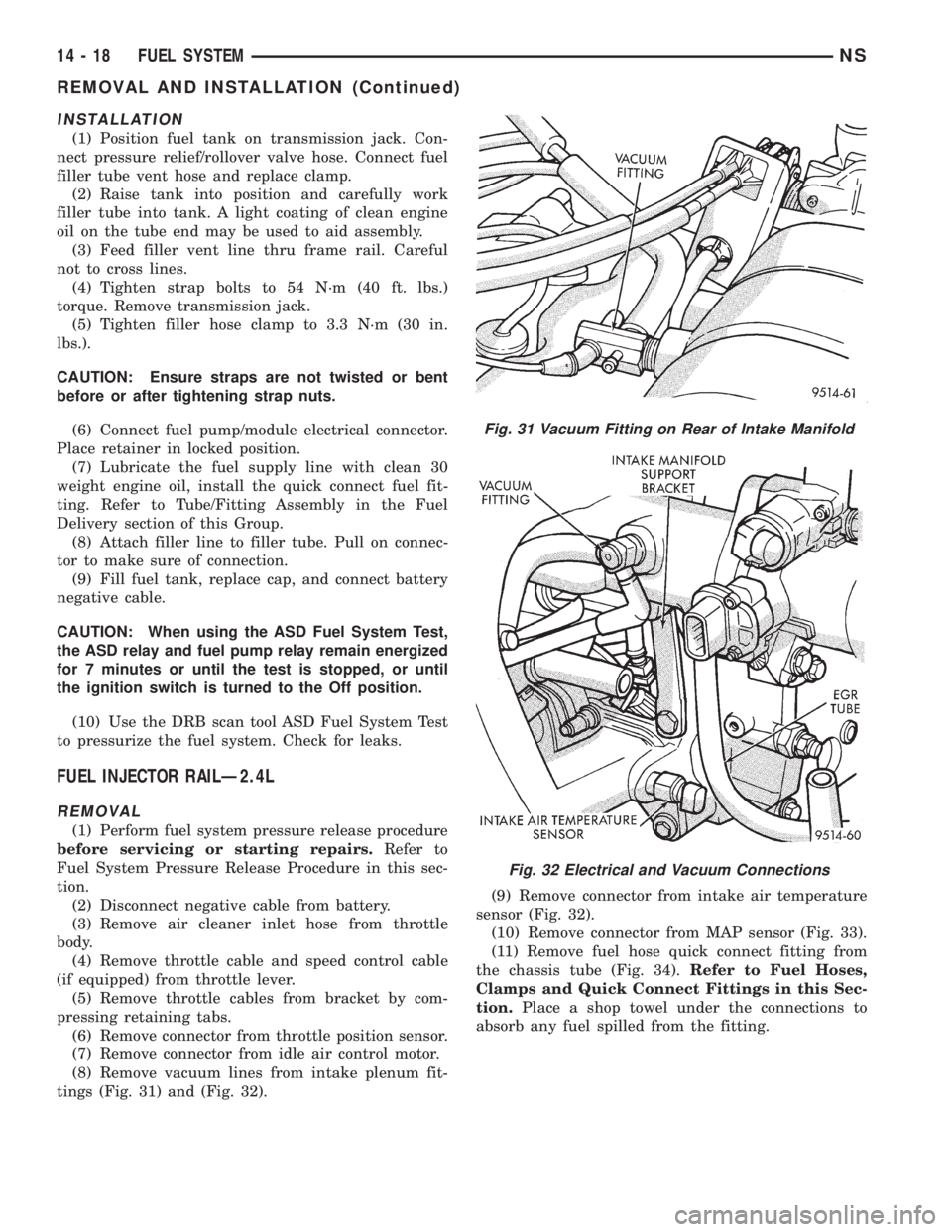

(7) Remove connector from idle air control motor.

(8) Remove vacuum lines from intake plenum fit-

tings (Fig. 31) and (Fig. 32).(9) Remove connector from intake air temperature

sensor (Fig. 32).

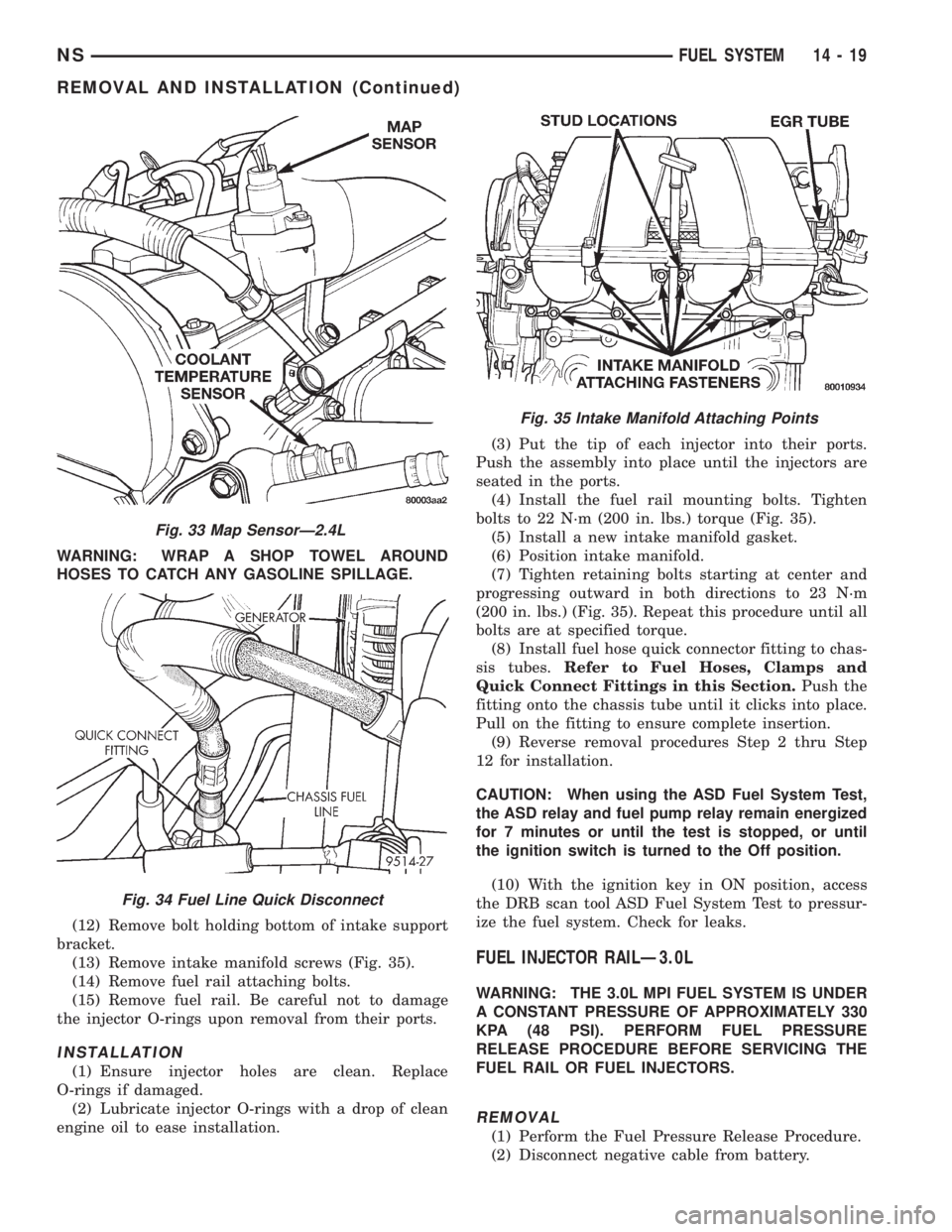

(10) Remove connector from MAP sensor (Fig. 33).

(11) Remove fuel hose quick connect fitting from

the chassis tube (Fig. 34).Refer to Fuel Hoses,

Clamps and Quick Connect Fittings in this Sec-

tion.Place a shop towel under the connections to

absorb any fuel spilled from the fitting.

Fig. 31 Vacuum Fitting on Rear of Intake Manifold

Fig. 32 Electrical and Vacuum Connections

14 - 18 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1313 of 1938

WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE.

(12) Remove bolt holding bottom of intake support

bracket.

(13) Remove intake manifold screws (Fig. 35).

(14) Remove fuel rail attaching bolts.

(15) Remove fuel rail. Be careful not to damage

the injector O-rings upon removal from their ports.

INSTALLATION

(1) Ensure injector holes are clean. Replace

O-rings if damaged.

(2) Lubricate injector O-rings with a drop of clean

engine oil to ease installation.(3) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports.

(4) Install the fuel rail mounting bolts. Tighten

bolts to 22 N´m (200 in. lbs.) torque (Fig. 35).

(5) Install a new intake manifold gasket.

(6) Position intake manifold.

(7) Tighten retaining bolts starting at center and

progressing outward in both directions to 23 N´m

(200 in. lbs.) (Fig. 35). Repeat this procedure until all

bolts are at specified torque.

(8) Install fuel hose quick connector fitting to chas-

sis tubes.Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in this Section.Push the

fitting onto the chassis tube until it clicks into place.

Pull on the fitting to ensure complete insertion.

(9) Reverse removal procedures Step 2 thru Step

12 for installation.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(10) With the ignition key in ON position, access

the DRB scan tool ASD Fuel System Test to pressur-

ize the fuel system. Check for leaks.

FUEL INJECTOR RAILÐ3.0L

WARNING: THE 3.0L MPI FUEL SYSTEM IS UNDER

A CONSTANT PRESSURE OF APPROXIMATELY 330

KPA (48 PSI). PERFORM FUEL PRESSURE

RELEASE PROCEDURE BEFORE SERVICING THE

FUEL RAIL OR FUEL INJECTORS.

REMOVAL

(1) Perform the Fuel Pressure Release Procedure.

(2) Disconnect negative cable from battery.

Fig. 33 Map SensorÐ2.4L

Fig. 34 Fuel Line Quick Disconnect

Fig. 35 Intake Manifold Attaching Points

NSFUEL SYSTEM 14 - 19

REMOVAL AND INSTALLATION (Continued)

Page 1314 of 1938

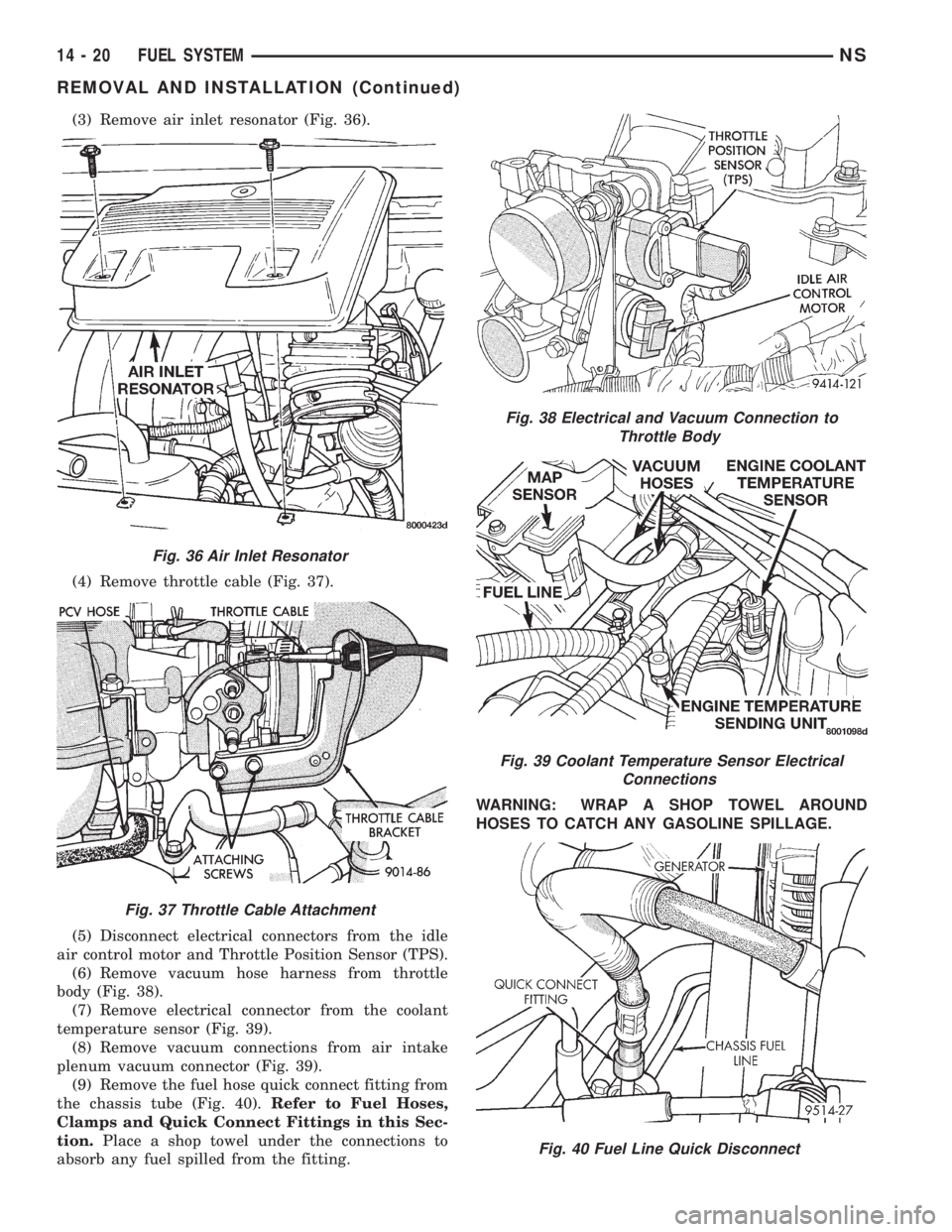

(3) Remove air inlet resonator (Fig. 36).

(4) Remove throttle cable (Fig. 37).

(5) Disconnect electrical connectors from the idle

air control motor and Throttle Position Sensor (TPS).

(6) Remove vacuum hose harness from throttle

body (Fig. 38).

(7) Remove electrical connector from the coolant

temperature sensor (Fig. 39).

(8) Remove vacuum connections from air intake

plenum vacuum connector (Fig. 39).

(9) Remove the fuel hose quick connect fitting from

the chassis tube (Fig. 40).Refer to Fuel Hoses,

Clamps and Quick Connect Fittings in this Sec-

tion.Place a shop towel under the connections to

absorb any fuel spilled from the fitting.WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE.

Fig. 36 Air Inlet Resonator

Fig. 37 Throttle Cable Attachment

Fig. 38 Electrical and Vacuum Connection to

Throttle Body

Fig. 39 Coolant Temperature Sensor Electrical

Connections

Fig. 40 Fuel Line Quick Disconnect

14 - 20 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1316 of 1938

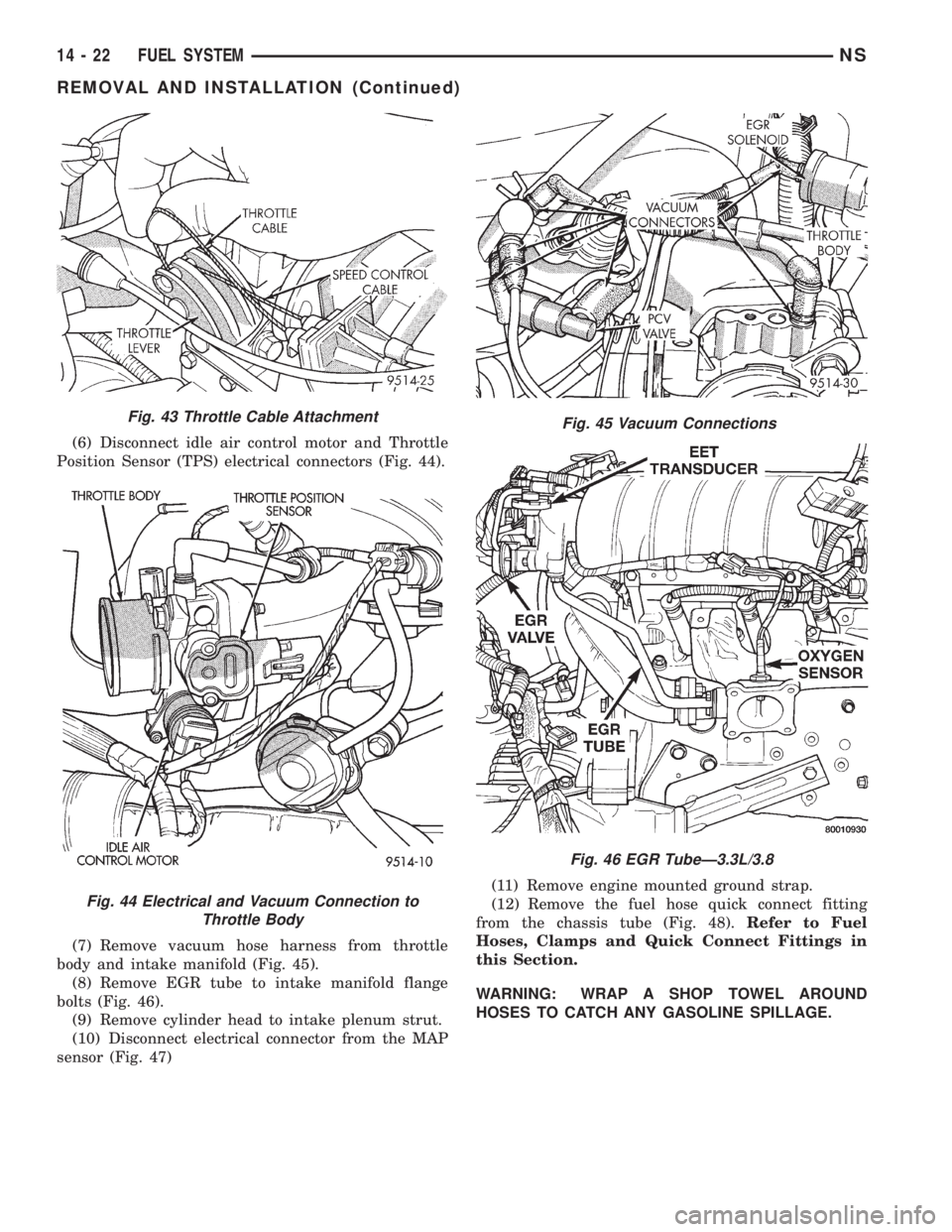

(6) Disconnect idle air control motor and Throttle

Position Sensor (TPS) electrical connectors (Fig. 44).

(7) Remove vacuum hose harness from throttle

body and intake manifold (Fig. 45).

(8) Remove EGR tube to intake manifold flange

bolts (Fig. 46).

(9) Remove cylinder head to intake plenum strut.

(10) Disconnect electrical connector from the MAP

sensor (Fig. 47)(11) Remove engine mounted ground strap.

(12) Remove the fuel hose quick connect fitting

from the chassis tube (Fig. 48).Refer to Fuel

Hoses, Clamps and Quick Connect Fittings in

this Section.

WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE.

Fig. 43 Throttle Cable Attachment

Fig. 44 Electrical and Vacuum Connection to

Throttle Body

Fig. 45 Vacuum Connections

Fig. 46 EGR TubeÐ3.3L/3.8

14 - 22 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1361 of 1938

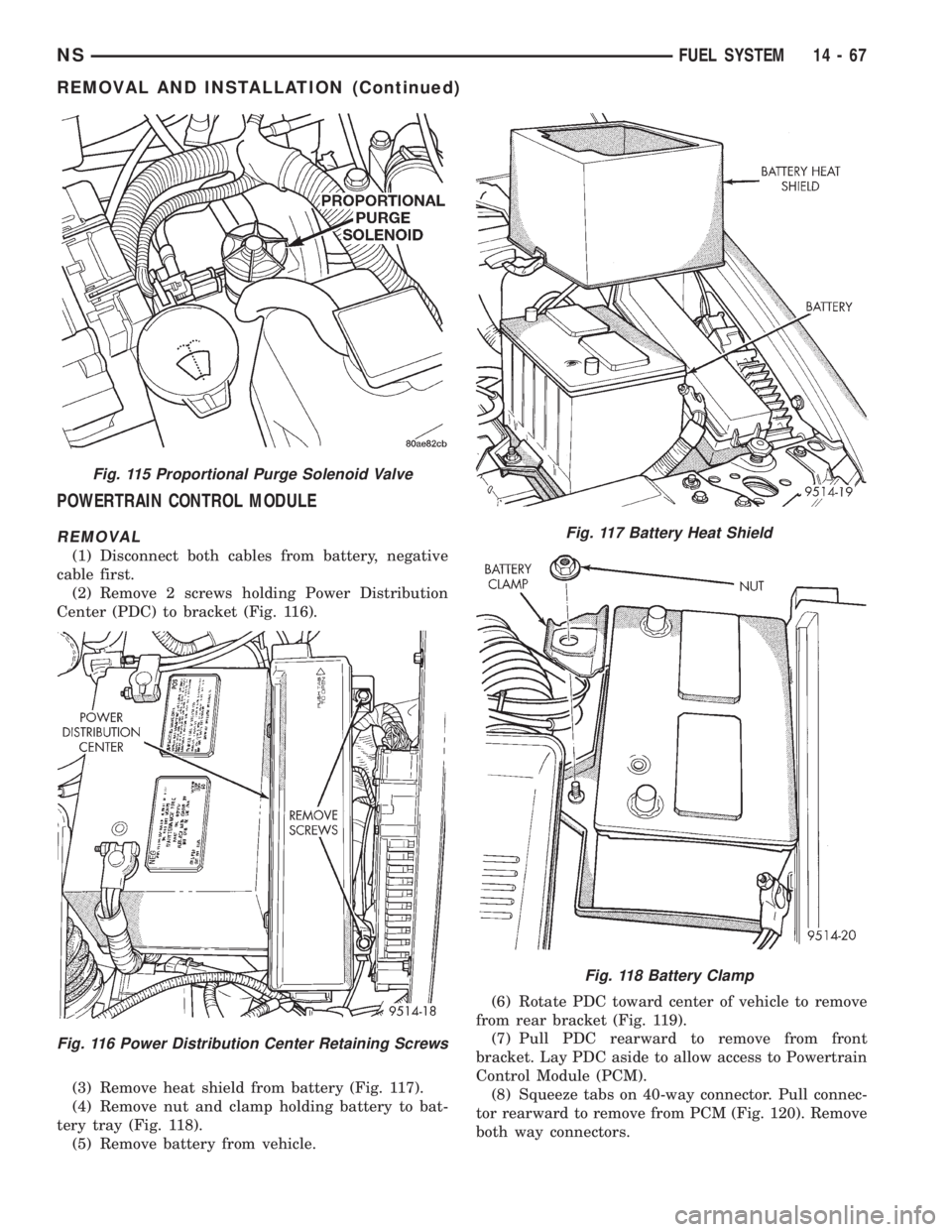

POWERTRAIN CONTROL MODULE

REMOVAL

(1) Disconnect both cables from battery, negative

cable first.

(2) Remove 2 screws holding Power Distribution

Center (PDC) to bracket (Fig. 116).

(3) Remove heat shield from battery (Fig. 117).

(4) Remove nut and clamp holding battery to bat-

tery tray (Fig. 118).

(5) Remove battery from vehicle.(6) Rotate PDC toward center of vehicle to remove

from rear bracket (Fig. 119).

(7) Pull PDC rearward to remove from front

bracket. Lay PDC aside to allow access to Powertrain

Control Module (PCM).

(8) Squeeze tabs on 40-way connector. Pull connec-

tor rearward to remove from PCM (Fig. 120). Remove

both way connectors.

Fig. 115 Proportional Purge Solenoid Valve

Fig. 116 Power Distribution Center Retaining Screws

Fig. 117 Battery Heat Shield

Fig. 118 Battery Clamp

NSFUEL SYSTEM 14 - 67

REMOVAL AND INSTALLATION (Continued)

Page 1372 of 1938

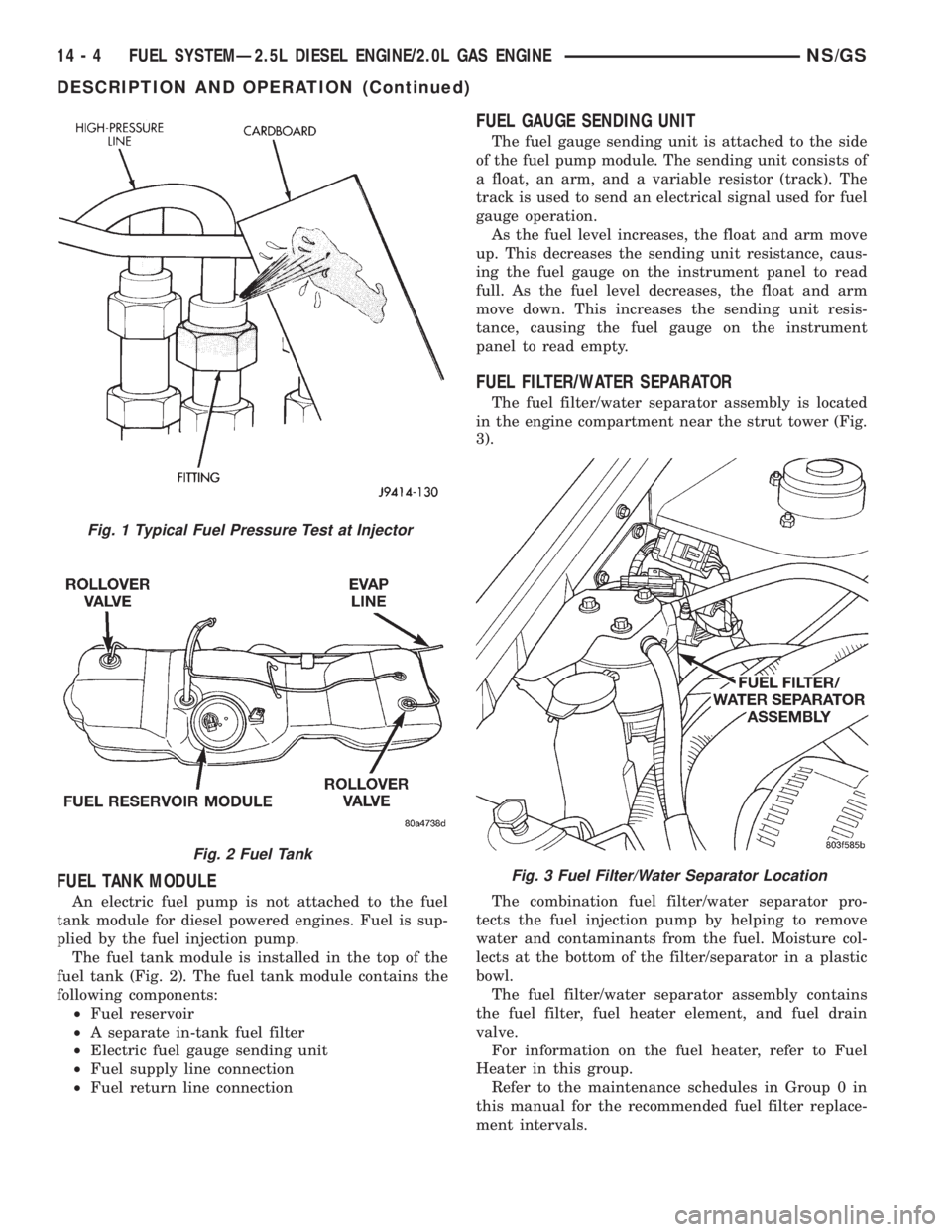

FUEL TANK MODULE

An electric fuel pump is not attached to the fuel

tank module for diesel powered engines. Fuel is sup-

plied by the fuel injection pump.

The fuel tank module is installed in the top of the

fuel tank (Fig. 2). The fuel tank module contains the

following components:

²Fuel reservoir

²A separate in-tank fuel filter

²Electric fuel gauge sending unit

²Fuel supply line connection

²Fuel return line connection

FUEL GAUGE SENDING UNIT

The fuel gauge sending unit is attached to the side

of the fuel pump module. The sending unit consists of

a float, an arm, and a variable resistor (track). The

track is used to send an electrical signal used for fuel

gauge operation.

As the fuel level increases, the float and arm move

up. This decreases the sending unit resistance, caus-

ing the fuel gauge on the instrument panel to read

full. As the fuel level decreases, the float and arm

move down. This increases the sending unit resis-

tance, causing the fuel gauge on the instrument

panel to read empty.

FUEL FILTER/WATER SEPARATOR

The fuel filter/water separator assembly is located

in the engine compartment near the strut tower (Fig.

3).

The combination fuel filter/water separator pro-

tects the fuel injection pump by helping to remove

water and contaminants from the fuel. Moisture col-

lects at the bottom of the filter/separator in a plastic

bowl.

The fuel filter/water separator assembly contains

the fuel filter, fuel heater element, and fuel drain

valve.

For information on the fuel heater, refer to Fuel

Heater in this group.

Refer to the maintenance schedules in Group 0 in

this manual for the recommended fuel filter replace-

ment intervals.

Fig. 1 Typical Fuel Pressure Test at Injector

Fig. 2 Fuel Tank

Fig. 3 Fuel Filter/Water Separator Location

14 - 4 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1383 of 1938

²High±pressure fuel line connections are loosened

or lines replaced

²Initial engine start±up or start±up after an

extended period of no engine operation

²Running fuel tank empty

FUEL INJECTION PUMP BLEEDING

(1) If the fuel injection pump has been replaced,

air should be bled at the overflow valve before

attempting to start engine.

(a) Loosen the overflow valve (Fig. 25) at the

rear of the injection pump.

(b) Place a towel below the valve.

WARNING: WHEN CRANKING THE ENGINE TO

BLEED AIR FROM THE INJECTION PUMP, THE

ENGINE MAY START. PLACE THE TRANSMISSION

IN NEUTRAL OR PARK AND SET PARKING BRAKE

BEFORE ENGAGING THE STARTER MOTOR.

CAUTION: Do not engage the starter motor for

more than 30 seconds at a time. Allow 2 minutes

between cranking intervals.

(2) Crank the engine for 30 seconds at a time to

allow air trapped in the injection pump to vent out

the fuel injector drain tubes. Continue this procedure

until the engine starts. Observe the previous WARN-

ING and CAUTION.

(3) Tighten overflow valve.

HIGH±PRESSURE FUEL LINE BLEEDING

WARNING: THE INJECTION PUMP SUPPLIES HIGH-

±PRESSURE FUEL OF APPROXIMATELY 59,000 KPA

(8,557 PSI) TO EACH INDIVIDUAL INJECTOR

THROUGH THE HIGH±PRESSURE LINES. FUEL

UNDER THIS AMOUNT OF PRESSURE CAN PENE-

TRATE THE SKIN AND CAUSE PERSONAL INJURY.

WEAR SAFETY GOGGLES AND ADEQUATE PRO-

TECTIVE CLOTHING AND AVOID CONTACT WITH

FUEL SPRAY WHEN BLEEDING HIGH±PRESSURE

FUEL LINES.

WARNING: DO NOT BLEED AIR FROM THE FUEL

SYSTEM OF A HOT ENGINE. DO NOT ALLOW FUEL

TO SPRAY ONTO THE EXHAUST MANIFOLD WHEN

BLEEDING AIR FROM THE FUEL SYSTEM.

Bleed air from one injector at time.

(1) Loosen the high±pressure fuel line fitting at

the injector (Fig. 26).

(2) Crank the engine until all air has been bled

from the line.Do not operate the starter motor

for longer than 30 seconds. Wait 2 minutes

between cranking intervals.

(3) Start the engine and bleed one injector at a

time until the engine runs smoothly.

FUEL INJECTION PUMP TIMING

Refer to Removal/Installation and Adjusting Fuel

Pump Timing in this Group.

Fig. 25 Overflow Valve

Fig. 26 Bleeding High±Pressure Fuel LineÐTypical

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 15

SERVICE PROCEDURES (Continued)