boot CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 64 of 1938

²Inspect jounce bumper for cracks and signs of

deterioration.

(13) Replace any components of the strut assembly

found to be worn or defective during the inspection,

before re-assembling the strut.

ASSEMBLY

(1) Clamp strut in vise, with strut in vertical posi-

tion.Do not clamp strut in vise by body of strut,

only by the clevis bracket (Fig. 68).

(2) Install the spring isolator on the strut lower

spring seat (Fig. 74). When installing the spring iso-

lator, be sure the 2 retaining tabs on the spring iso-

lator (Fig. 74) are installed in the 2 holes in the

spring seat. When properly installed, the oversize

holes in the spring seat should line up with the holes

in the spring isolator.

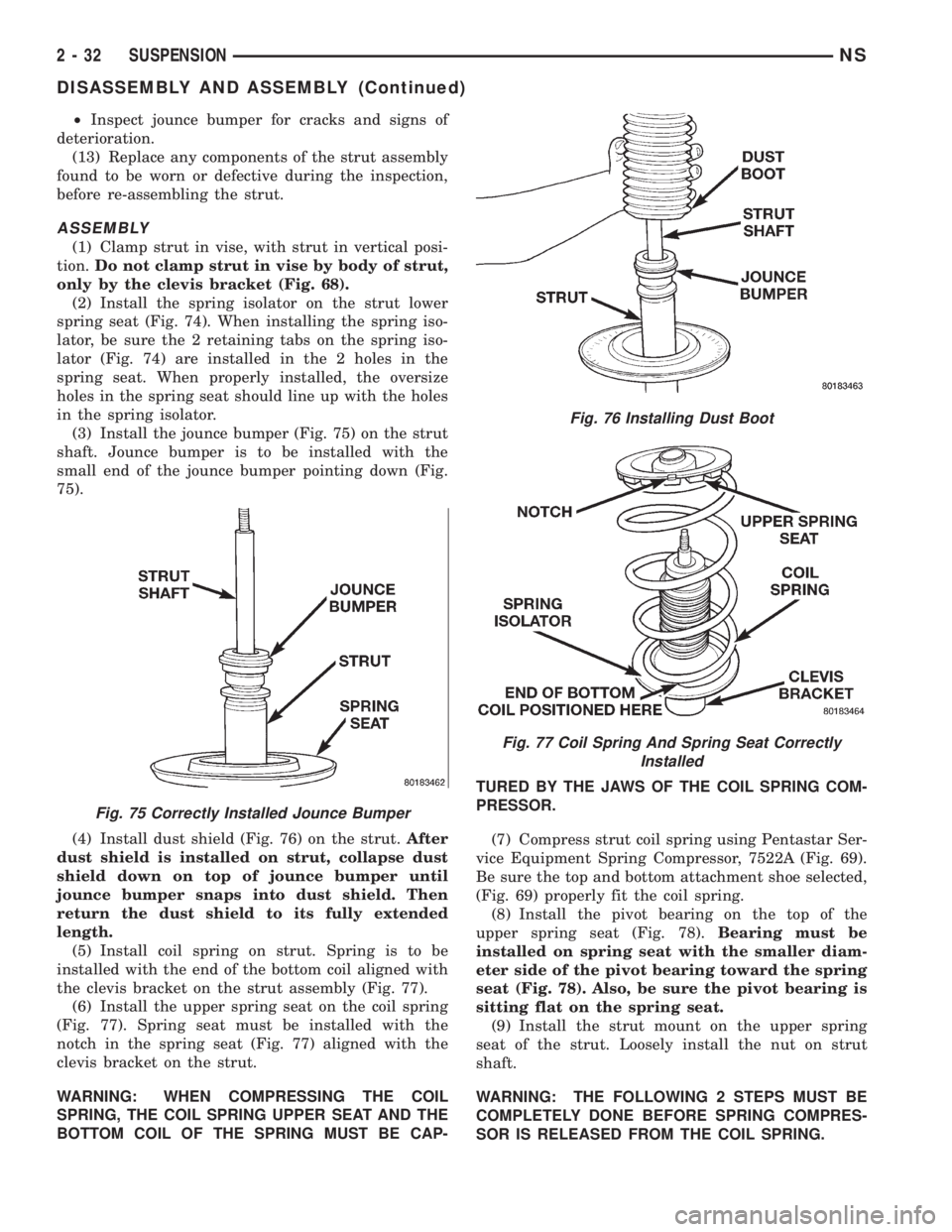

(3) Install the jounce bumper (Fig. 75) on the strut

shaft. Jounce bumper is to be installed with the

small end of the jounce bumper pointing down (Fig.

75).

(4) Install dust shield (Fig. 76) on the strut.After

dust shield is installed on strut, collapse dust

shield down on top of jounce bumper until

jounce bumper snaps into dust shield. Then

return the dust shield to its fully extended

length.

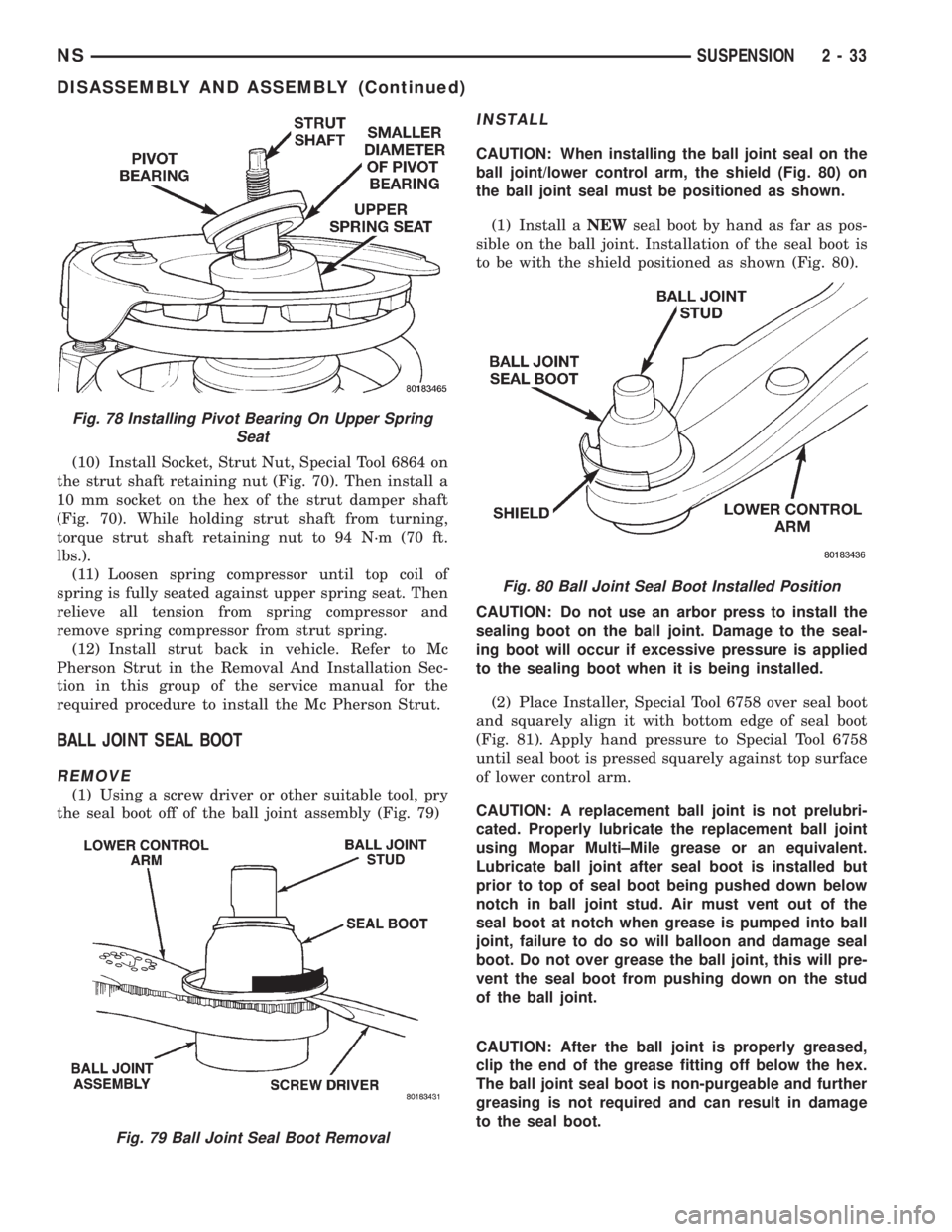

(5) Install coil spring on strut. Spring is to be

installed with the end of the bottom coil aligned with

the clevis bracket on the strut assembly (Fig. 77).

(6) Install the upper spring seat on the coil spring

(Fig. 77). Spring seat must be installed with the

notch in the spring seat (Fig. 77) aligned with the

clevis bracket on the strut.

WARNING: WHEN COMPRESSING THE COIL

SPRING, THE COIL SPRING UPPER SEAT AND THE

BOTTOM COIL OF THE SPRING MUST BE CAP-TURED BY THE JAWS OF THE COIL SPRING COM-

PRESSOR.

(7) Compress strut coil spring using Pentastar Ser-

vice Equipment Spring Compressor, 7522A (Fig. 69).

Be sure the top and bottom attachment shoe selected,

(Fig. 69) properly fit the coil spring.

(8) Install the pivot bearing on the top of the

upper spring seat (Fig. 78).Bearing must be

installed on spring seat with the smaller diam-

eter side of the pivot bearing toward the spring

seat (Fig. 78). Also, be sure the pivot bearing is

sitting flat on the spring seat.

(9) Install the strut mount on the upper spring

seat of the strut. Loosely install the nut on strut

shaft.

WARNING: THE FOLLOWING 2 STEPS MUST BE

COMPLETELY DONE BEFORE SPRING COMPRES-

SOR IS RELEASED FROM THE COIL SPRING.

Fig. 75 Correctly Installed Jounce Bumper

Fig. 76 Installing Dust Boot

Fig. 77 Coil Spring And Spring Seat Correctly

Installed

2 - 32 SUSPENSIONNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 65 of 1938

(10) Install Socket, Strut Nut, Special Tool 6864 on

the strut shaft retaining nut (Fig. 70). Then install a

10 mm socket on the hex of the strut damper shaft

(Fig. 70). While holding strut shaft from turning,

torque strut shaft retaining nut to 94 N´m (70 ft.

lbs.).

(11) Loosen spring compressor until top coil of

spring is fully seated against upper spring seat. Then

relieve all tension from spring compressor and

remove spring compressor from strut spring.

(12) Install strut back in vehicle. Refer to Mc

Pherson Strut in the Removal And Installation Sec-

tion in this group of the service manual for the

required procedure to install the Mc Pherson Strut.

BALL JOINT SEAL BOOT

REMOVE

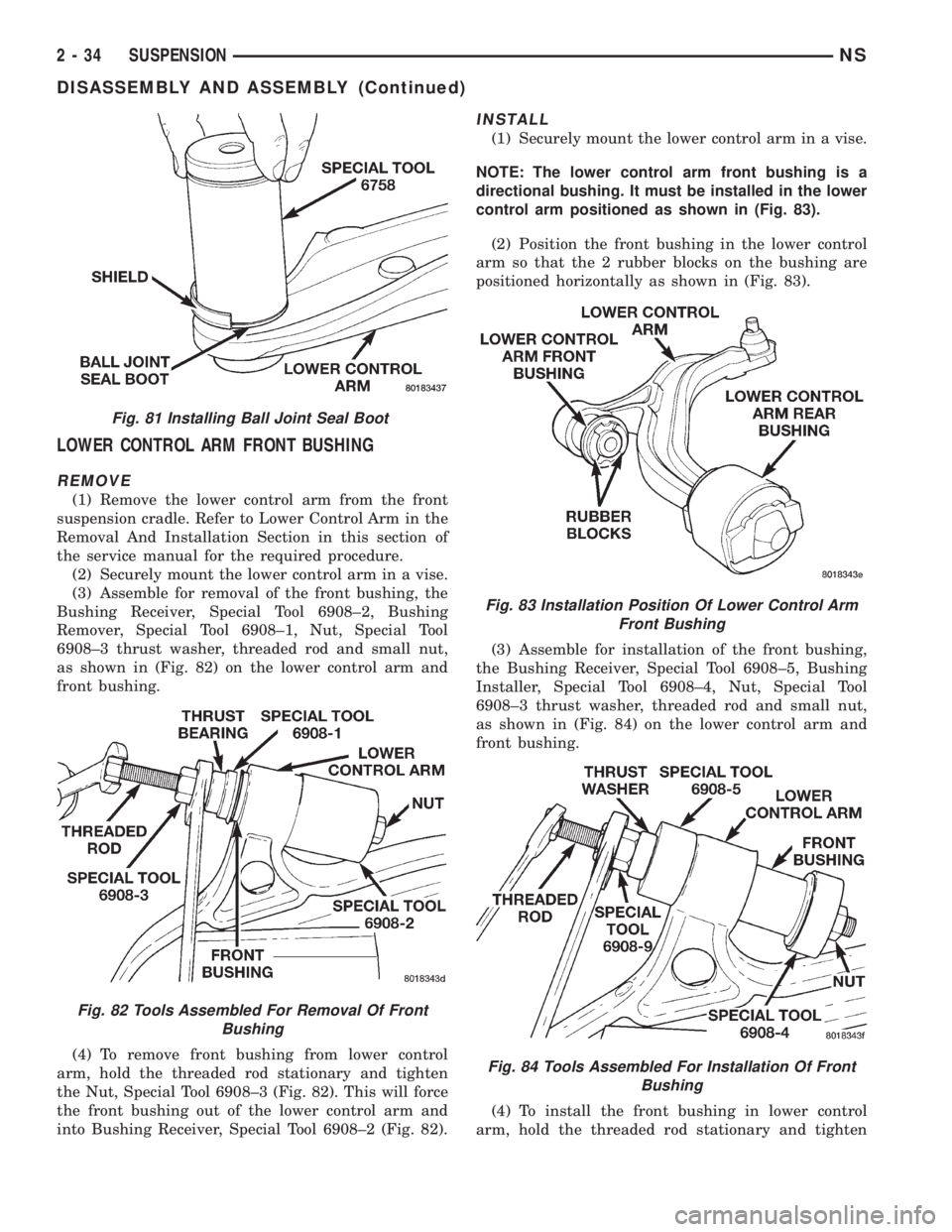

(1) Using a screw driver or other suitable tool, pry

the seal boot off of the ball joint assembly (Fig. 79)

INSTALL

CAUTION: When installing the ball joint seal on the

ball joint/lower control arm, the shield (Fig. 80) on

the ball joint seal must be positioned as shown.

(1) Install aNEWseal boot by hand as far as pos-

sible on the ball joint. Installation of the seal boot is

to be with the shield positioned as shown (Fig. 80).

CAUTION: Do not use an arbor press to install the

sealing boot on the ball joint. Damage to the seal-

ing boot will occur if excessive pressure is applied

to the sealing boot when it is being installed.

(2) Place Installer, Special Tool 6758 over seal boot

and squarely align it with bottom edge of seal boot

(Fig. 81). Apply hand pressure to Special Tool 6758

until seal boot is pressed squarely against top surface

of lower control arm.

CAUTION: A replacement ball joint is not prelubri-

cated. Properly lubricate the replacement ball joint

using Mopar Multi±Mile grease or an equivalent.

Lubricate ball joint after seal boot is installed but

prior to top of seal boot being pushed down below

notch in ball joint stud. Air must vent out of the

seal boot at notch when grease is pumped into ball

joint, failure to do so will balloon and damage seal

boot. Do not over grease the ball joint, this will pre-

vent the seal boot from pushing down on the stud

of the ball joint.

CAUTION: After the ball joint is properly greased,

clip the end of the grease fitting off below the hex.

The ball joint seal boot is non-purgeable and further

greasing is not required and can result in damage

to the seal boot.

Fig. 78 Installing Pivot Bearing On Upper Spring

Seat

Fig. 79 Ball Joint Seal Boot Removal

Fig. 80 Ball Joint Seal Boot Installed Position

NSSUSPENSION 2 - 33

DISASSEMBLY AND ASSEMBLY (Continued)

Page 66 of 1938

LOWER CONTROL ARM FRONT BUSHING

REMOVE

(1) Remove the lower control arm from the front

suspension cradle. Refer to Lower Control Arm in the

Removal And Installation Section in this section of

the service manual for the required procedure.

(2) Securely mount the lower control arm in a vise.

(3) Assemble for removal of the front bushing, the

Bushing Receiver, Special Tool 6908±2, Bushing

Remover, Special Tool 6908±1, Nut, Special Tool

6908±3 thrust washer, threaded rod and small nut,

as shown in (Fig. 82) on the lower control arm and

front bushing.

(4) To remove front bushing from lower control

arm, hold the threaded rod stationary and tighten

the Nut, Special Tool 6908±3 (Fig. 82). This will force

the front bushing out of the lower control arm and

into Bushing Receiver, Special Tool 6908±2 (Fig. 82).

INSTALL

(1) Securely mount the lower control arm in a vise.

NOTE: The lower control arm front bushing is a

directional bushing. It must be installed in the lower

control arm positioned as shown in (Fig. 83).

(2) Position the front bushing in the lower control

arm so that the 2 rubber blocks on the bushing are

positioned horizontally as shown in (Fig. 83).

(3) Assemble for installation of the front bushing,

the Bushing Receiver, Special Tool 6908±5, Bushing

Installer, Special Tool 6908±4, Nut, Special Tool

6908±3 thrust washer, threaded rod and small nut,

as shown in (Fig. 84) on the lower control arm and

front bushing.

(4) To install the front bushing in lower control

arm, hold the threaded rod stationary and tighten

Fig. 81 Installing Ball Joint Seal Boot

Fig. 82 Tools Assembled For Removal Of Front

Bushing

Fig. 83 Installation Position Of Lower Control Arm

Front Bushing

Fig. 84 Tools Assembled For Installation Of Front

Bushing

2 - 34 SUSPENSIONNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 87 of 1938

The caliper is a one piece casting with the inboard

side containing a single piston cylinder bore.

The phenolic piston is 60 mm (2.36 inch) in diam-

eter.

A square cut rubber piston seal is located in a

machined groove in the cylinder bore. It provides a

hydraulic seal between the piston and the cylinder

wall (Fig. 4).

The molded rubber dust boot mounts in a counter

bore of the cylinder bore opening and in a groove

which is machined in the outer surface of the piston

(Fig. 4). This prevents contamination of the piston

and the bore area.

As lining wears, reservoir level will go down. If

fluid has been added, reservoir overflow may occur

when the piston is pushed back into the new lining

position. Overflowing can be avoided by removing a

small amount of fluid from the master cylinder res-

ervoir.

REAR DRUM BRAKES

The rear wheel drum brakes are a two shoe, inter-

nal expanding type with an automatic adjuster screw.

The automatic adjuster screw is actuated each time

the brakes are applied. The automatic adjuster screw

is located directly below the wheel cylinder.

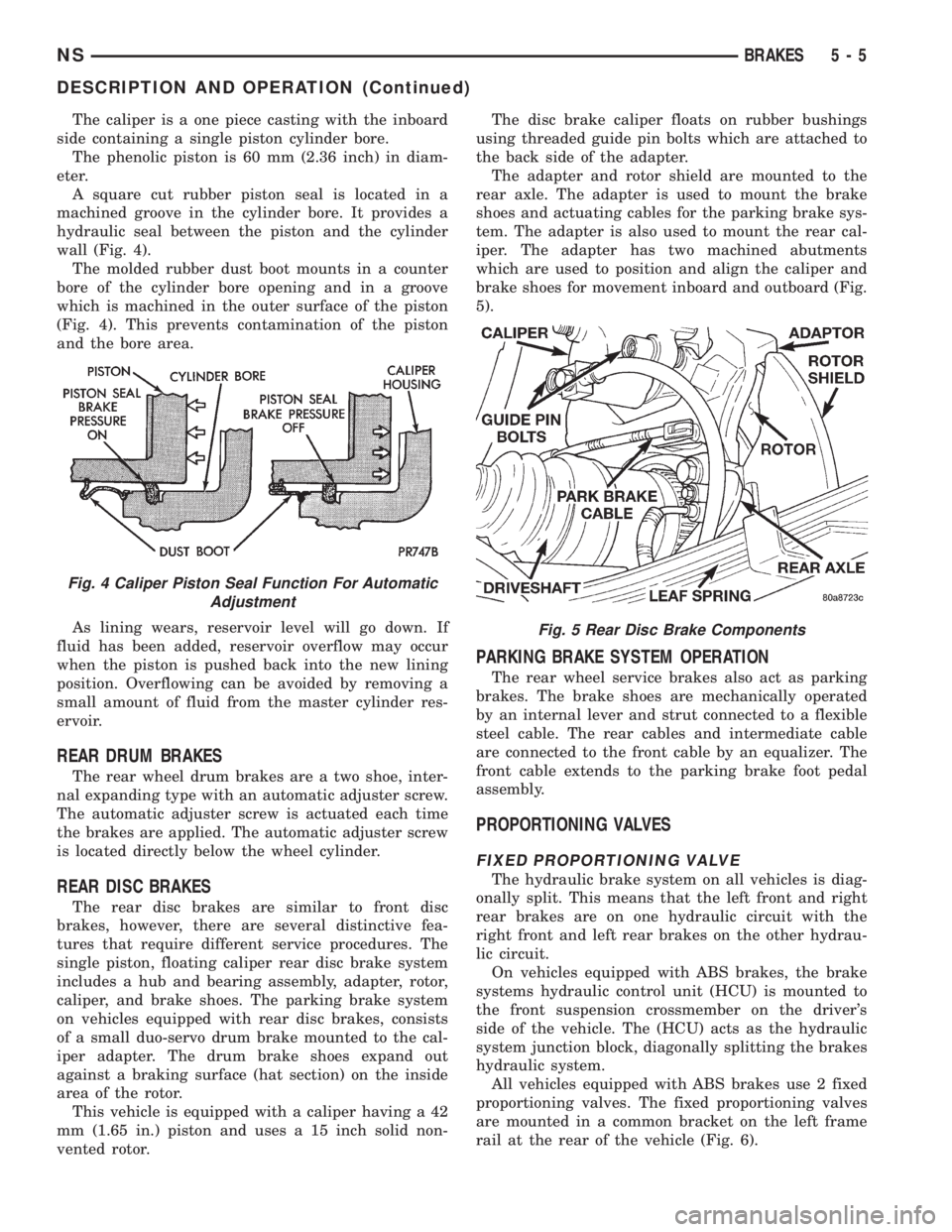

REAR DISC BRAKES

The rear disc brakes are similar to front disc

brakes, however, there are several distinctive fea-

tures that require different service procedures. The

single piston, floating caliper rear disc brake system

includes a hub and bearing assembly, adapter, rotor,

caliper, and brake shoes. The parking brake system

on vehicles equipped with rear disc brakes, consists

of a small duo-servo drum brake mounted to the cal-

iper adapter. The drum brake shoes expand out

against a braking surface (hat section) on the inside

area of the rotor.

This vehicle is equipped with a caliper having a 42

mm (1.65 in.) piston and uses a 15 inch solid non-

vented rotor.The disc brake caliper floats on rubber bushings

using threaded guide pin bolts which are attached to

the back side of the adapter.

The adapter and rotor shield are mounted to the

rear axle. The adapter is used to mount the brake

shoes and actuating cables for the parking brake sys-

tem. The adapter is also used to mount the rear cal-

iper. The adapter has two machined abutments

which are used to position and align the caliper and

brake shoes for movement inboard and outboard (Fig.

5).

PARKING BRAKE SYSTEM OPERATION

The rear wheel service brakes also act as parking

brakes. The brake shoes are mechanically operated

by an internal lever and strut connected to a flexible

steel cable. The rear cables and intermediate cable

are connected to the front cable by an equalizer. The

front cable extends to the parking brake foot pedal

assembly.

PROPORTIONING VALVES

FIXED PROPORTIONING VALVE

The hydraulic brake system on all vehicles is diag-

onally split. This means that the left front and right

rear brakes are on one hydraulic circuit with the

right front and left rear brakes on the other hydrau-

lic circuit.

On vehicles equipped with ABS brakes, the brake

systems hydraulic control unit (HCU) is mounted to

the front suspension crossmember on the driver's

side of the vehicle. The (HCU) acts as the hydraulic

system junction block, diagonally splitting the brakes

hydraulic system.

All vehicles equipped with ABS brakes use 2 fixed

proportioning valves. The fixed proportioning valves

are mounted in a common bracket on the left frame

rail at the rear of the vehicle (Fig. 6).

Fig. 4 Caliper Piston Seal Function For Automatic

Adjustment

Fig. 5 Rear Disc Brake Components

NSBRAKES 5 - 5

DESCRIPTION AND OPERATION (Continued)

Page 104 of 1938

MASTER CYLINDER BLEEDING PROCEDURE

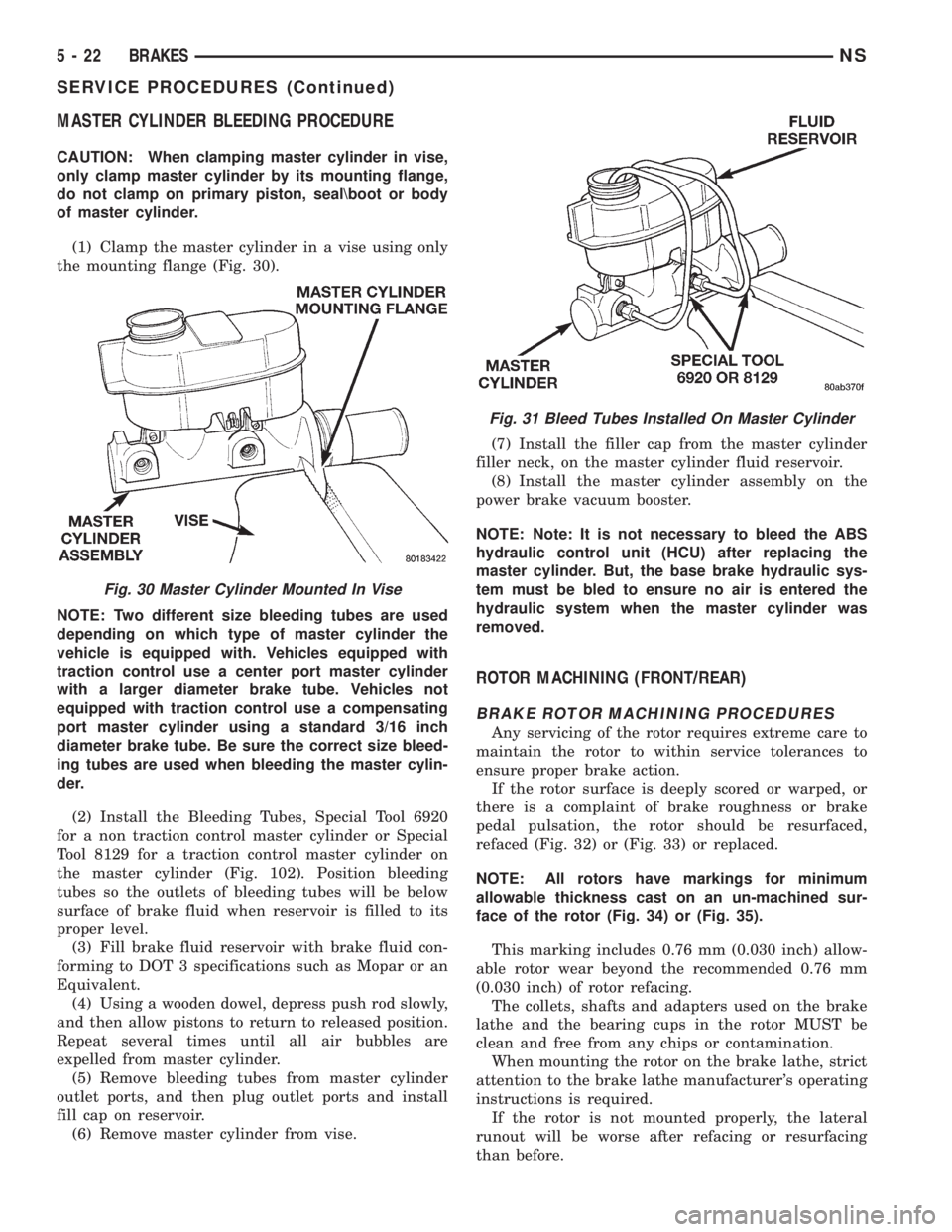

CAUTION: When clamping master cylinder in vise,

only clamp master cylinder by its mounting flange,

do not clamp on primary piston, seal\boot or body

of master cylinder.

(1) Clamp the master cylinder in a vise using only

the mounting flange (Fig. 30).

NOTE: Two different size bleeding tubes are used

depending on which type of master cylinder the

vehicle is equipped with. Vehicles equipped with

traction control use a center port master cylinder

with a larger diameter brake tube. Vehicles not

equipped with traction control use a compensating

port master cylinder using a standard 3/16 inch

diameter brake tube. Be sure the correct size bleed-

ing tubes are used when bleeding the master cylin-

der.

(2) Install the Bleeding Tubes, Special Tool 6920

for a non traction control master cylinder or Special

Tool 8129 for a traction control master cylinder on

the master cylinder (Fig. 102). Position bleeding

tubes so the outlets of bleeding tubes will be below

surface of brake fluid when reservoir is filled to its

proper level.

(3) Fill brake fluid reservoir with brake fluid con-

forming to DOT 3 specifications such as Mopar or an

Equivalent.

(4) Using a wooden dowel, depress push rod slowly,

and then allow pistons to return to released position.

Repeat several times until all air bubbles are

expelled from master cylinder.

(5) Remove bleeding tubes from master cylinder

outlet ports, and then plug outlet ports and install

fill cap on reservoir.

(6) Remove master cylinder from vise.(7) Install the filler cap from the master cylinder

filler neck, on the master cylinder fluid reservoir.

(8) Install the master cylinder assembly on the

power brake vacuum booster.

NOTE: Note: It is not necessary to bleed the ABS

hydraulic control unit (HCU) after replacing the

master cylinder. But, the base brake hydraulic sys-

tem must be bled to ensure no air is entered the

hydraulic system when the master cylinder was

removed.

ROTOR MACHINING (FRONT/REAR)

BRAKE ROTOR MACHINING PROCEDURES

Any servicing of the rotor requires extreme care to

maintain the rotor to within service tolerances to

ensure proper brake action.

If the rotor surface is deeply scored or warped, or

there is a complaint of brake roughness or brake

pedal pulsation, the rotor should be resurfaced,

refaced (Fig. 32) or (Fig. 33) or replaced.

NOTE: All rotors have markings for minimum

allowable thickness cast on an un-machined sur-

face of the rotor (Fig. 34) or (Fig. 35).

This marking includes 0.76 mm (0.030 inch) allow-

able rotor wear beyond the recommended 0.76 mm

(0.030 inch) of rotor refacing.

The collets, shafts and adapters used on the brake

lathe and the bearing cups in the rotor MUST be

clean and free from any chips or contamination.

When mounting the rotor on the brake lathe, strict

attention to the brake lathe manufacturer's operating

instructions is required.

If the rotor is not mounted properly, the lateral

runout will be worse after refacing or resurfacing

than before.

Fig. 30 Master Cylinder Mounted In Vise

Fig. 31 Bleed Tubes Installed On Master Cylinder

5 - 22 BRAKESNS

SERVICE PROCEDURES (Continued)

Page 114 of 1938

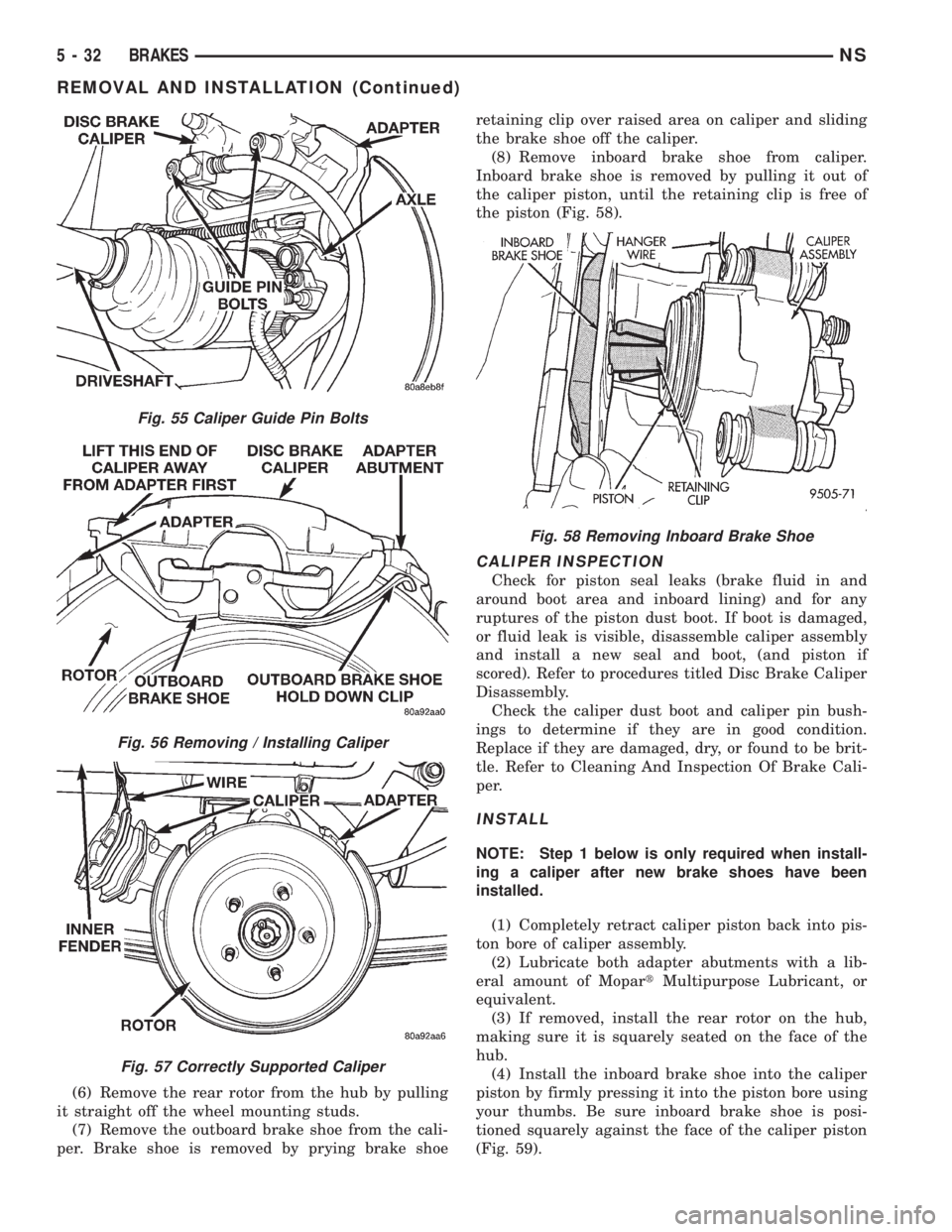

(6) Remove the rear rotor from the hub by pulling

it straight off the wheel mounting studs.

(7) Remove the outboard brake shoe from the cali-

per. Brake shoe is removed by prying brake shoeretaining clip over raised area on caliper and sliding

the brake shoe off the caliper.

(8) Remove inboard brake shoe from caliper.

Inboard brake shoe is removed by pulling it out of

the caliper piston, until the retaining clip is free of

the piston (Fig. 58).

CALIPER INSPECTION

Check for piston seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of the piston dust boot. If boot is damaged,

or fluid leak is visible, disassemble caliper assembly

and install a new seal and boot, (and piston if

scored). Refer to procedures titled Disc Brake Caliper

Disassembly.

Check the caliper dust boot and caliper pin bush-

ings to determine if they are in good condition.

Replace if they are damaged, dry, or found to be brit-

tle. Refer to Cleaning And Inspection Of Brake Cali-

per.

INSTALL

NOTE: Step 1 below is only required when install-

ing a caliper after new brake shoes have been

installed.

(1) Completely retract caliper piston back into pis-

ton bore of caliper assembly.

(2) Lubricate both adapter abutments with a lib-

eral amount of MopartMultipurpose Lubricant, or

equivalent.

(3) If removed, install the rear rotor on the hub,

making sure it is squarely seated on the face of the

hub.

(4) Install the inboard brake shoe into the caliper

piston by firmly pressing it into the piston bore using

your thumbs. Be sure inboard brake shoe is posi-

tioned squarely against the face of the caliper piston

(Fig. 59).

Fig. 55 Caliper Guide Pin Bolts

Fig. 56 Removing / Installing Caliper

Fig. 57 Correctly Supported Caliper

Fig. 58 Removing Inboard Brake Shoe

5 - 32 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 127 of 1938

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughlycleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(6) Clean the area where the master cylinder

assembly attaches to the power brake booster. Use

only a solvent such as Mopar Brake Parts Cleaner or

an equivalent.

(7) Remove the 2 nuts attaching the master cylin-

der assembly to the brake vacuum booster (Fig. 100).

(8) Slide master cylinder assembly straight out of

the power brake vacuum booster.

CAUTION: The master cylinder is used to create

the seal for holding vacuum in the power brake vac-

uum booster. The vacuum seal/boot on the master

cylinder MUST be replaced whenever the master

cylinder is removed from the power brake vacuum

booster.

(9) Remove the vacuum seal located on the mount-

ing flange of the master cylinder. The vacuum seal is

removed from the master cylinder bycarefullypull-

ing it away from the master cylinder.Do not

attempt to pry the seal off the master cylinder

by inserting a sharp tool between seal and mas-

ter cylinder casting.

BLEEDING MASTER CYLINDER

CAUTION: When clamping master cylinder in vise,

only clamp master cylinder by its mounting flange,

do not clamp on primary piston, seal or body of

master cylinder.

(1) Clamp the master cylinder in a vise using only

the mounting flange (Fig. 101).

Fig. 97 Master Cylinder Filler Tube Removal

Fig. 98 Electrical Connector At Fluid Level Sensor

Fig. 99 Primary/Secondary Brake Tubes At Master

Cylinder

Fig. 100 Master Cylinder Mounting To Vacuum

Booster

NSBRAKES 5 - 45

REMOVAL AND INSTALLATION (Continued)

Page 153 of 1938

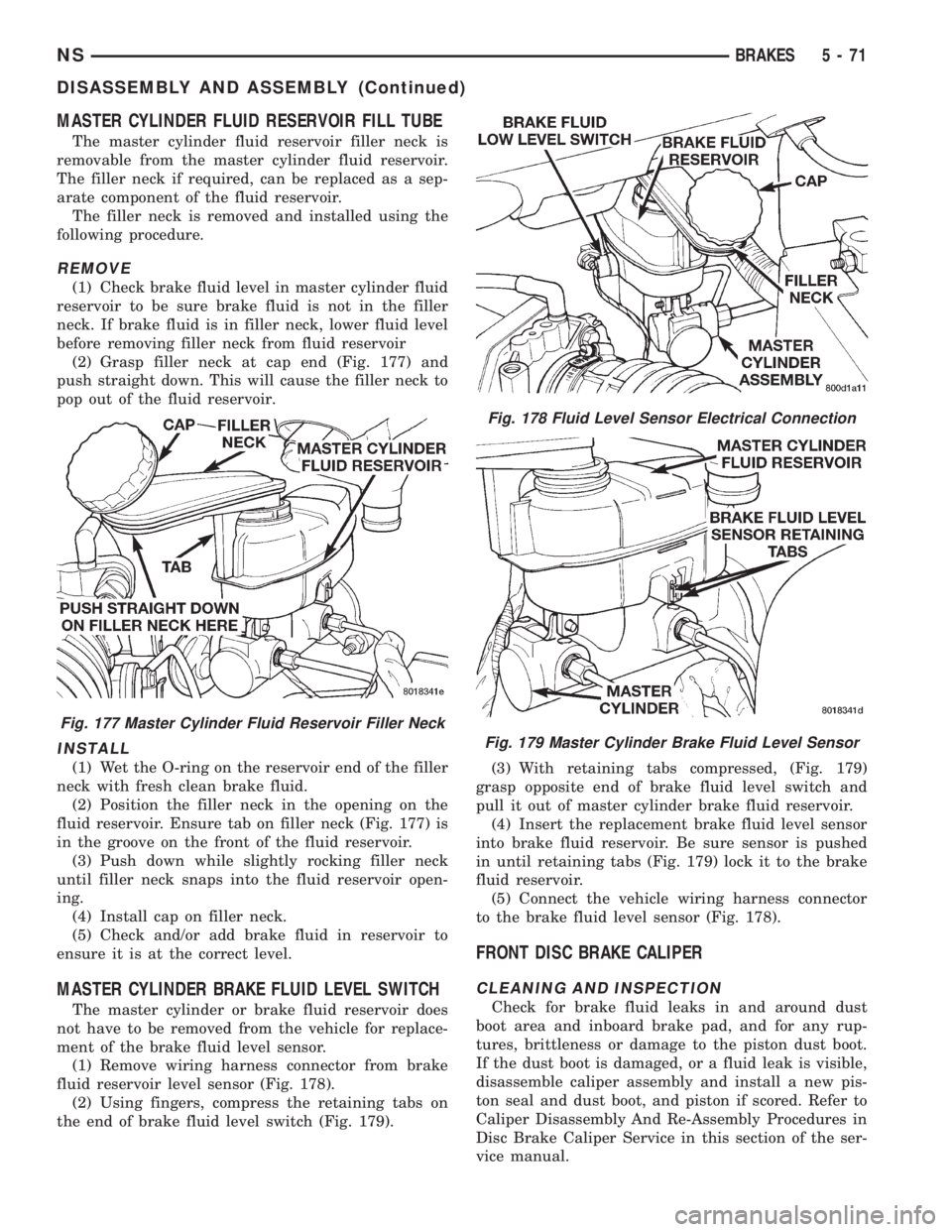

MASTER CYLINDER FLUID RESERVOIR FILL TUBE

The master cylinder fluid reservoir filler neck is

removable from the master cylinder fluid reservoir.

The filler neck if required, can be replaced as a sep-

arate component of the fluid reservoir.

The filler neck is removed and installed using the

following procedure.

REMOVE

(1) Check brake fluid level in master cylinder fluid

reservoir to be sure brake fluid is not in the filler

neck. If brake fluid is in filler neck, lower fluid level

before removing filler neck from fluid reservoir

(2) Grasp filler neck at cap end (Fig. 177) and

push straight down. This will cause the filler neck to

pop out of the fluid reservoir.

INSTALL

(1) Wet the O-ring on the reservoir end of the filler

neck with fresh clean brake fluid.

(2) Position the filler neck in the opening on the

fluid reservoir. Ensure tab on filler neck (Fig. 177) is

in the groove on the front of the fluid reservoir.

(3) Push down while slightly rocking filler neck

until filler neck snaps into the fluid reservoir open-

ing.

(4) Install cap on filler neck.

(5) Check and/or add brake fluid in reservoir to

ensure it is at the correct level.

MASTER CYLINDER BRAKE FLUID LEVEL SWITCH

The master cylinder or brake fluid reservoir does

not have to be removed from the vehicle for replace-

ment of the brake fluid level sensor.

(1) Remove wiring harness connector from brake

fluid reservoir level sensor (Fig. 178).

(2) Using fingers, compress the retaining tabs on

the end of brake fluid level switch (Fig. 179).(3) With retaining tabs compressed, (Fig. 179)

grasp opposite end of brake fluid level switch and

pull it out of master cylinder brake fluid reservoir.

(4) Insert the replacement brake fluid level sensor

into brake fluid reservoir. Be sure sensor is pushed

in until retaining tabs (Fig. 179) lock it to the brake

fluid reservoir.

(5) Connect the vehicle wiring harness connector

to the brake fluid level sensor (Fig. 178).

FRONT DISC BRAKE CALIPER

CLEANING AND INSPECTION

Check for brake fluid leaks in and around dust

boot area and inboard brake pad, and for any rup-

tures, brittleness or damage to the piston dust boot.

If the dust boot is damaged, or a fluid leak is visible,

disassemble caliper assembly and install a new pis-

ton seal and dust boot, and piston if scored. Refer to

Caliper Disassembly And Re-Assembly Procedures in

Disc Brake Caliper Service in this section of the ser-

vice manual.

Fig. 177 Master Cylinder Fluid Reservoir Filler Neck

Fig. 178 Fluid Level Sensor Electrical Connection

Fig. 179 Master Cylinder Brake Fluid Level Sensor

NSBRAKES 5 - 71

DISASSEMBLY AND ASSEMBLY (Continued)

Page 154 of 1938

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to Guide Pin Bush-

ing Service in Disc Brake Caliper Service in this sec-

tion of the service manual.

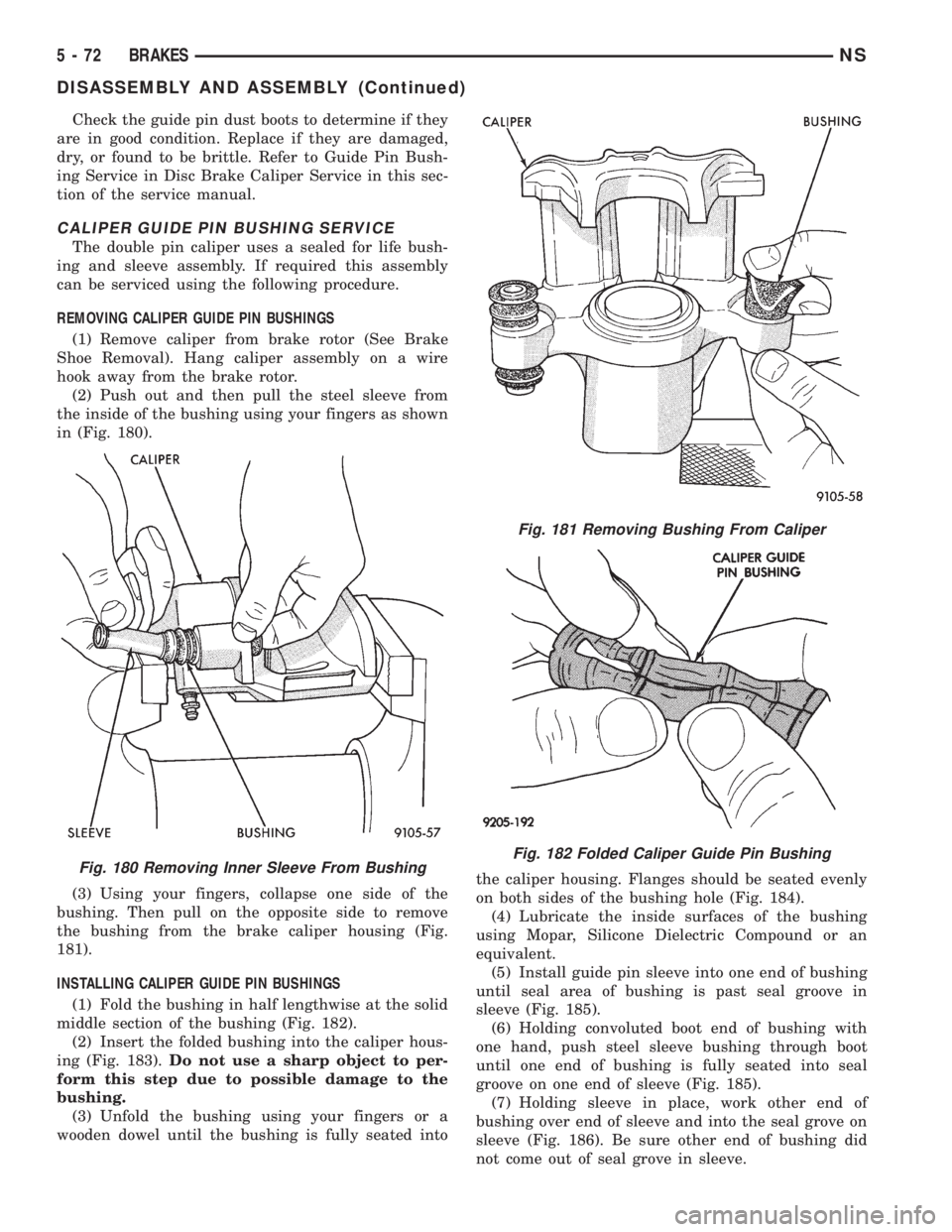

CALIPER GUIDE PIN BUSHING SERVICE

The double pin caliper uses a sealed for life bush-

ing and sleeve assembly. If required this assembly

can be serviced using the following procedure.

REMOVING CALIPER GUIDE PIN BUSHINGS

(1) Remove caliper from brake rotor (See Brake

Shoe Removal). Hang caliper assembly on a wire

hook away from the brake rotor.

(2) Push out and then pull the steel sleeve from

the inside of the bushing using your fingers as shown

in (Fig. 180).

(3) Using your fingers, collapse one side of the

bushing. Then pull on the opposite side to remove

the bushing from the brake caliper housing (Fig.

181).

INSTALLING CALIPER GUIDE PIN BUSHINGS

(1) Fold the bushing in half lengthwise at the solid

middle section of the bushing (Fig. 182).

(2) Insert the folded bushing into the caliper hous-

ing (Fig. 183).Do not use a sharp object to per-

form this step due to possible damage to the

bushing.

(3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated intothe caliper housing. Flanges should be seated evenly

on both sides of the bushing hole (Fig. 184).

(4) Lubricate the inside surfaces of the bushing

using Mopar, Silicone Dielectric Compound or an

equivalent.

(5) Install guide pin sleeve into one end of bushing

until seal area of bushing is past seal groove in

sleeve (Fig. 185).

(6) Holding convoluted boot end of bushing with

one hand, push steel sleeve bushing through boot

until one end of bushing is fully seated into seal

groove on one end of sleeve (Fig. 185).

(7) Holding sleeve in place, work other end of

bushing over end of sleeve and into the seal grove on

sleeve (Fig. 186). Be sure other end of bushing did

not come out of seal grove in sleeve.

Fig. 180 Removing Inner Sleeve From Bushing

Fig. 181 Removing Bushing From Caliper

Fig. 182 Folded Caliper Guide Pin Bushing

5 - 72 BRAKESNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 156 of 1938

from rotor, so hydraulic fluid cannot get on rotor.

Place a small piece of wood between the piston and

caliper fingers.

(2)Carefullydepress brake pedal to hydraulically

push piston out of bore. Then apply and hold down

the brake pedal to any position beyond the first inch

of pedal travel. This will prevent loss of brake fluid

from the master cylinder.

(3) If both front caliper pistons are to be removed,

disconnect brake tube at flexible brake hose at frame

rail. Plug brake tube and remove piston from oppo-

site caliper using the same process as above for the

first piston removal.

(4) Disconnect the brake fluid flex hose from the

caliper assembly.

CAUTION: Do not use excessive force when clamp-

ing caliper in vise. Excessive vise pressure will

cause bore distortion and binding of piston.

(5) To disassemble caliper, mount in a vise

equipped with protective jaws.

(6) Remove guide pin sleeves and guide pin bush-

ings. See Removing Guide Pin Bushings in the cali-

per disassembly section of this manual.

(7) Remove the piston dust boot from the caliper

and discard (Fig. 187).

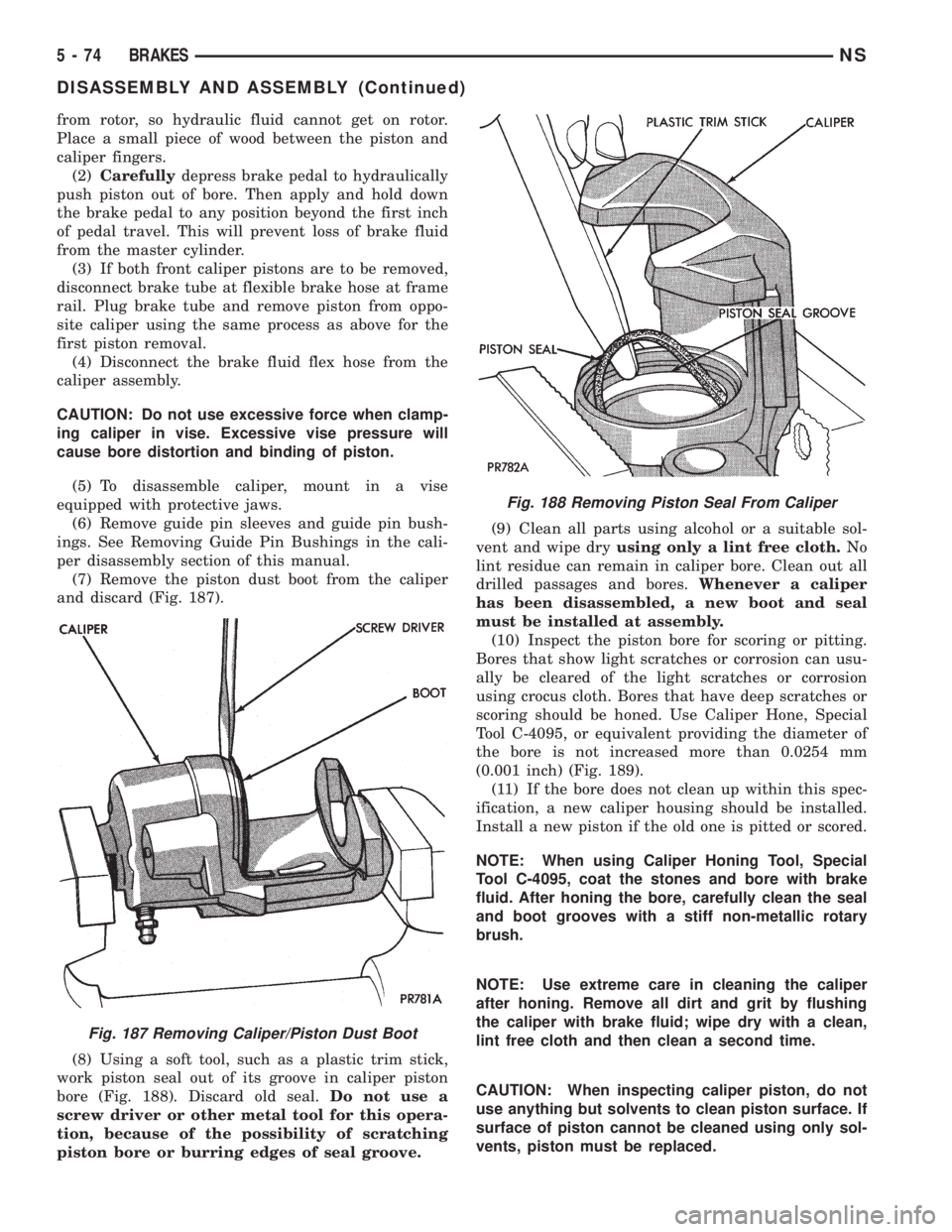

(8) Using a soft tool, such as a plastic trim stick,

work piston seal out of its groove in caliper piston

bore (Fig. 188). Discard old seal.Do not use a

screw driver or other metal tool for this opera-

tion, because of the possibility of scratching

piston bore or burring edges of seal groove.(9) Clean all parts using alcohol or a suitable sol-

vent and wipe dryusing only a lint free cloth.No

lint residue can remain in caliper bore. Clean out all

drilled passages and bores.Whenever a caliper

has been disassembled, a new boot and seal

must be installed at assembly.

(10) Inspect the piston bore for scoring or pitting.

Bores that show light scratches or corrosion can usu-

ally be cleared of the light scratches or corrosion

using crocus cloth. Bores that have deep scratches or

scoring should be honed. Use Caliper Hone, Special

Tool C-4095, or equivalent providing the diameter of

the bore is not increased more than 0.0254 mm

(0.001 inch) (Fig. 189).

(11) If the bore does not clean up within this spec-

ification, a new caliper housing should be installed.

Install a new piston if the old one is pitted or scored.

NOTE: When using Caliper Honing Tool, Special

Tool C-4095, coat the stones and bore with brake

fluid. After honing the bore, carefully clean the seal

and boot grooves with a stiff non-metallic rotary

brush.

NOTE: Use extreme care in cleaning the caliper

after honing. Remove all dirt and grit by flushing

the caliper with brake fluid; wipe dry with a clean,

lint free cloth and then clean a second time.

CAUTION: When inspecting caliper piston, do not

use anything but solvents to clean piston surface. If

surface of piston cannot be cleaned using only sol-

vents, piston must be replaced.

Fig. 187 Removing Caliper/Piston Dust Boot

Fig. 188 Removing Piston Seal From Caliper

5 - 74 BRAKESNS

DISASSEMBLY AND ASSEMBLY (Continued)