tire size CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1548 of 1938

TORQUE MANAGEMENT

Most 41TE transaxles utilize torque management.

Torque management is a unique function of the Pow-

ertrain Control Module (PCM). The PCM receives

output signals from the Transmission Control Module

(TCM) and many various engine sensors. The PCM

evaluates these signals and decides if it is necessary

to decrease the output of the engine's torque. This

reduction in torque does not interfere with the nor-

mal operation of the vehicle. This reduction in torque

will prolong the life of the drivetrain components.

Torque reduction is not noticeable in normal driving

functions. The torque reduction function shuts off

above 16 MPH.

ON-BOARD DIAGNOSTICS

This vehicle utilizes a diagnostic system called

OBDII. The powertrain control module communicates

with the Transmission Control Module. Whenever

the transaxle sets a fault in the Transmission Con-

trol Module (dependent on which fault is set), the

powertrain control module will turn on a MIL (Mal-

function Indicator Lamp) on the instrument cluster.

By reading the code in the powertrain control module

it will tell you where the fault occurred. If the fault

occurred in the transaxle, the controller will read a

CODE 45.For further information regarding OBDII,

refer to Group 25, Emission Systems.

These controls provide comprehensive, on-board

transaxle diagnostics. The information available can

aid in transaxle diagnosis. For example, apply ele-

ment buildup rate indicates solenoid performance.

Also included are self diagnostic functions. Self diag-

nostics allow the technician to test the condition of

the electronic controls. The Transmission Control

Module continuously monitors its critical functions. It

also records any malfunctions, and the number of

engine starts since the last malfunction. This allows

the technician to use the information in the event of

a customer complaint.

TRANSMISSION CONTROL MODULE

Do not interchange Transmission Control Modules

with previous year transmission control modules. If a

same year TCM is being used from a different vehi-

cle, the following procedures must be performed:

²Quick Learn Procedure

²Electronic Pinion Factor Procedure

The Transmission Control Module is located on the

right inner fender panel, in the engine compartment.

It is held in place by four mounting screws.NOTE: If the Transmission Control Module has

been replaced, the following procedures must be

performed:

²Quick Learn Procedure: This procedure will

allow the transmission control module to learn the

characteristics of the vehicle.

²Electronic Pinion Factor Procedure: This proce-

dure will reprogram the TCM to compensate for dif-

ferent tire sizes and final drive ratios.

GEARSHIFT AND PARKING LOCK CONTROLS

The transaxle is controlled by a lever type gear-

shift incorporated within the steering column. The

control has six selector lever positions: P (park), R

(reverse), N (neutral), and D (drive), 2 (second), and

1 (first). The parking lock is applied by moving the

selector lever past a gate to the P position.Do not

apply the parking lock until the vehicle has

stopped; otherwise, a severe ratchet noise will

occur.

TRANSMISSION RANGE SENSOR

The 41TE transaxle is equipped with a transmis-

sion range sensor that is located on top of the valve

body. This sensor will allow for accurate transmission

gear position measurement.

To service the transmission range sensor (TRS),

you must remove the valve body. For repair proce-

dures, refer to the Removal and Installation section

within this group.

Also located within the TRS is a transmission tem-

perature sensor. This sensor is used to measure the

transmission fluid sump temperature. The transmis-

sion temperature sensor is serviced with the TRS as

a unit.

SHIFT POSITION INDICATOR

The shifter position indicator is located in the

instrument cluster. The shifter position indicator out-

lines with a box the gear position the transaxle man-

ual valve lever is in.

The transmission range sensor (located on the

valvebody) sends a signal to the TCM on the position

of the transaxle manual valve lever. The TCM

receives the switch signal and processes the data.

The TCM sends the Shift Lever Position (SLP) infor-

mation to the BCM via the CCD bus. The BCM then

outlines with a box the appropriate shifter position

indicator in the instrument cluster.

To replace the shifter position indicator, refer to

Group 8E, Instrument Panel And Gauges.

21 - 74 TRANSAXLE AND POWER TRANSFER UNITNS

DESCRIPTION AND OPERATION (Continued)

Page 1561 of 1938

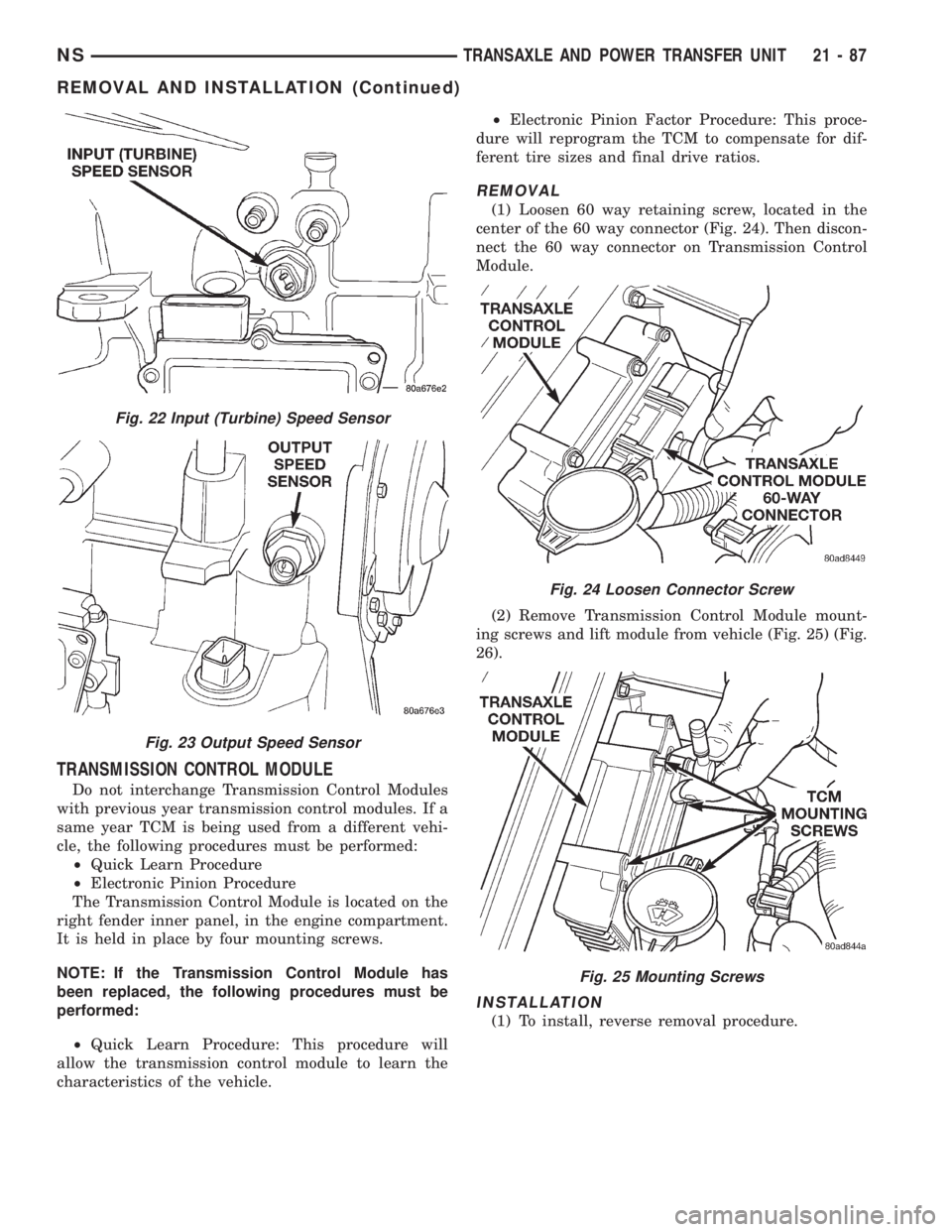

TRANSMISSION CONTROL MODULE

Do not interchange Transmission Control Modules

with previous year transmission control modules. If a

same year TCM is being used from a different vehi-

cle, the following procedures must be performed:

²Quick Learn Procedure

²Electronic Pinion Procedure

The Transmission Control Module is located on the

right fender inner panel, in the engine compartment.

It is held in place by four mounting screws.

NOTE: If the Transmission Control Module has

been replaced, the following procedures must be

performed:

²Quick Learn Procedure: This procedure will

allow the transmission control module to learn the

characteristics of the vehicle.²Electronic Pinion Factor Procedure: This proce-

dure will reprogram the TCM to compensate for dif-

ferent tire sizes and final drive ratios.

REMOVAL

(1) Loosen 60 way retaining screw, located in the

center of the 60 way connector (Fig. 24). Then discon-

nect the 60 way connector on Transmission Control

Module.

(2) Remove Transmission Control Module mount-

ing screws and lift module from vehicle (Fig. 25) (Fig.

26).

INSTALLATION

(1) To install, reverse removal procedure.

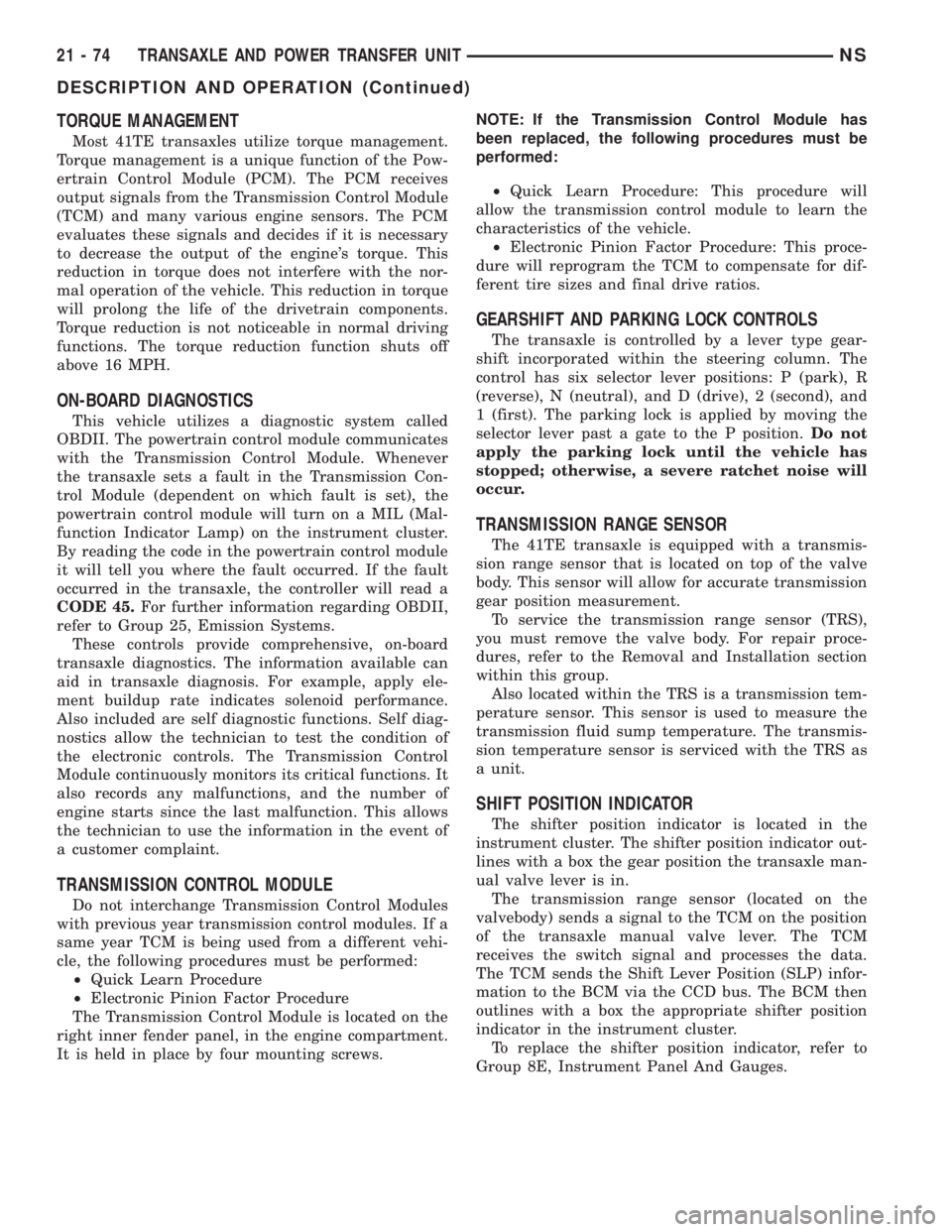

Fig. 22 Input (Turbine) Speed Sensor

Fig. 23 Output Speed Sensor

Fig. 24 Loosen Connector Screw

Fig. 25 Mounting Screws

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 87

REMOVAL AND INSTALLATION (Continued)

Page 1618 of 1938

(11) Install the oil baffle. Install the proper shim

combination under the bearing cup.

(12) Install the differential bearing retainer. Seal

the retainer to the housing with MopartSilicone

Rubber Adhesive Sealant. Torque bolts to 28 N´m

(250 in. lbs.).

(13) Using Miller Special Tool L-4436-A and an

inch-pound torque wrench, check the turning torque

of the differential (Fig. 299). The turning torque

should be between 5-18 inch-pounds.

NOTE: If turning torque is too high install a .05mm

(.002 inch) thicker shim. If the turning torque is too

low, install a .05mm (.002 inch) thinner shim. Repeat

until 5-18 inch-pounds of turning torque is

obtained.

CLEANING AND INSPECTION

CLEANING VALVE BODY

Prior to removing any transaxle parts, plug all

openings and clean unit, preferably by steam. Clean-

liness through entire disassembly and assembly can-

not be overemphasized. When disassembling, each

part should be washed in a suitable solvent, then

dried by compressed air.Do not wipe parts with

shop towels.All mating surfaces in the transaxles

are accurately machined; therefore, careful handling

of all parts must be exercised to avoid nicks or burrs.

NOTE: Tag all springs, as they are removed, for

reassembly identification.

ADJUSTMENTS

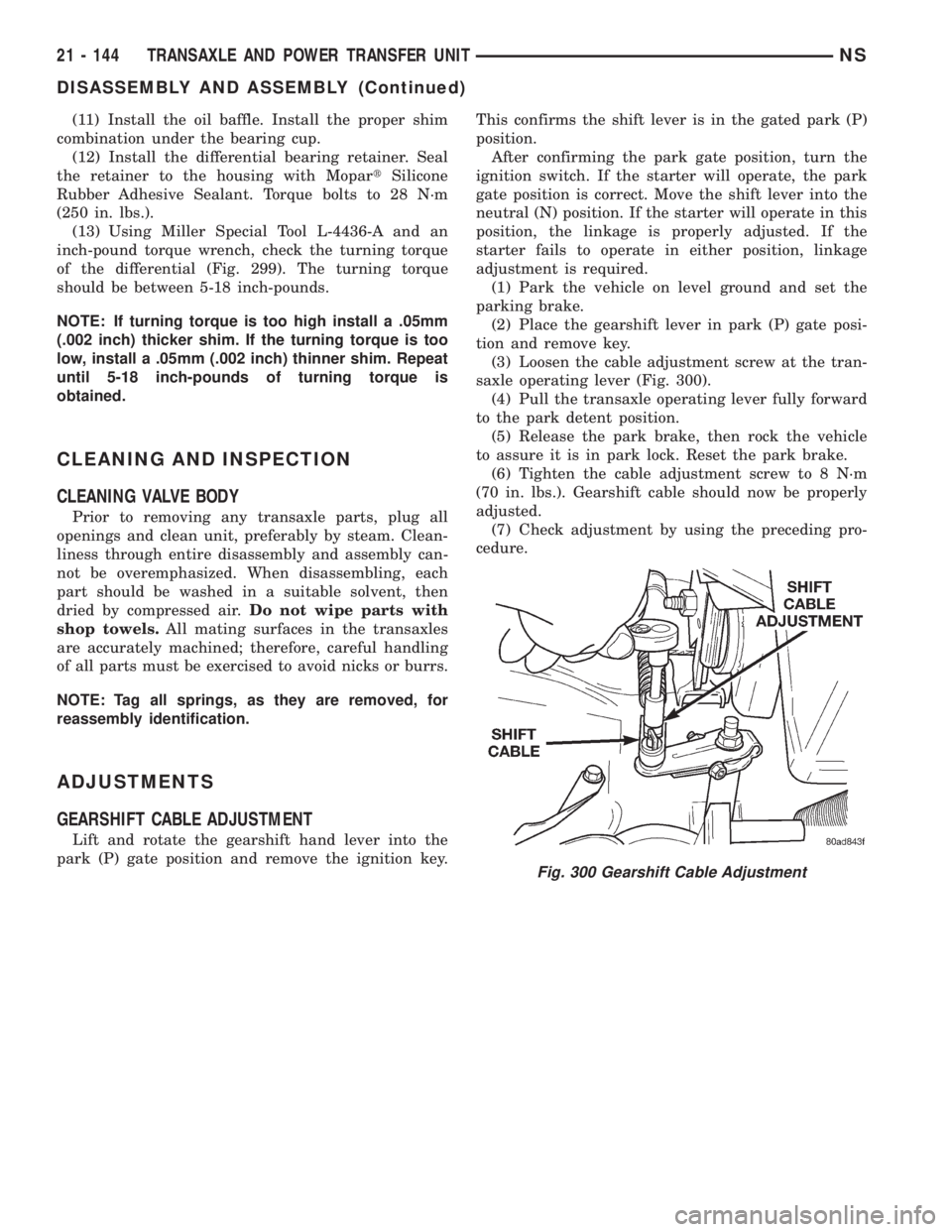

GEARSHIFT CABLE ADJUSTMENT

Lift and rotate the gearshift hand lever into the

park (P) gate position and remove the ignition key.This confirms the shift lever is in the gated park (P)

position.

After confirming the park gate position, turn the

ignition switch. If the starter will operate, the park

gate position is correct. Move the shift lever into the

neutral (N) position. If the starter will operate in this

position, the linkage is properly adjusted. If the

starter fails to operate in either position, linkage

adjustment is required.

(1) Park the vehicle on level ground and set the

parking brake.

(2) Place the gearshift lever in park (P) gate posi-

tion and remove key.

(3) Loosen the cable adjustment screw at the tran-

saxle operating lever (Fig. 300).

(4) Pull the transaxle operating lever fully forward

to the park detent position.

(5) Release the park brake, then rock the vehicle

to assure it is in park lock. Reset the park brake.

(6) Tighten the cable adjustment screw to 8 N´m

(70 in. lbs.). Gearshift cable should now be properly

adjusted.

(7) Check adjustment by using the preceding pro-

cedure.

Fig. 300 Gearshift Cable Adjustment

21 - 144 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1719 of 1938

TIRES AND WHEELS

CONTENTS

page page

TIRES.................................. 1WHEELS................................ 9

TIRES

INDEX

page page

DESCRIPTION AND OPERATION

RADIAL-PLY TIRES....................... 2

REPLACEMENT TIRES.................... 3

SPARE TIRE (TEMPORARY)................ 2

TIRE INFLATION PRESSURES.............. 2

TIRE INFORMATION...................... 1

TIRE PRESSURE FOR HIGH-SPEED DRIVING . . 3

DIAGNOSIS AND TESTING

LEAD CORRECTION CHART................ 4

PRESSURE GAUGES..................... 3

TIRE NOISE OR VIBRATION................ 4TIRE WEAR PATTERNS.................... 4

TREAD WEAR INDICATORS................ 3

SERVICE PROCEDURES

REPAIRING TIRE LEAKS................... 6

TIRE AND WHEEL MATCH MOUNTING........ 6

TIRE AND WHEEL ROTATION (NON-

DIRECTIONAL THREAD PATTERN).......... 6

CLEANING AND INSPECTION

CLEANING TIRES........................ 7

SPECIFICATIONS

TIRE SPECIFICATIONS.................... 8

DESCRIPTION AND OPERATION

TIRE INFORMATION

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain, in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe application of brakes

²High-speed driving

²Taking turns at excessive speeds

²Striking curbs and other obstacles

Radial ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation. This will

help to achieve a greater tread-life potential.

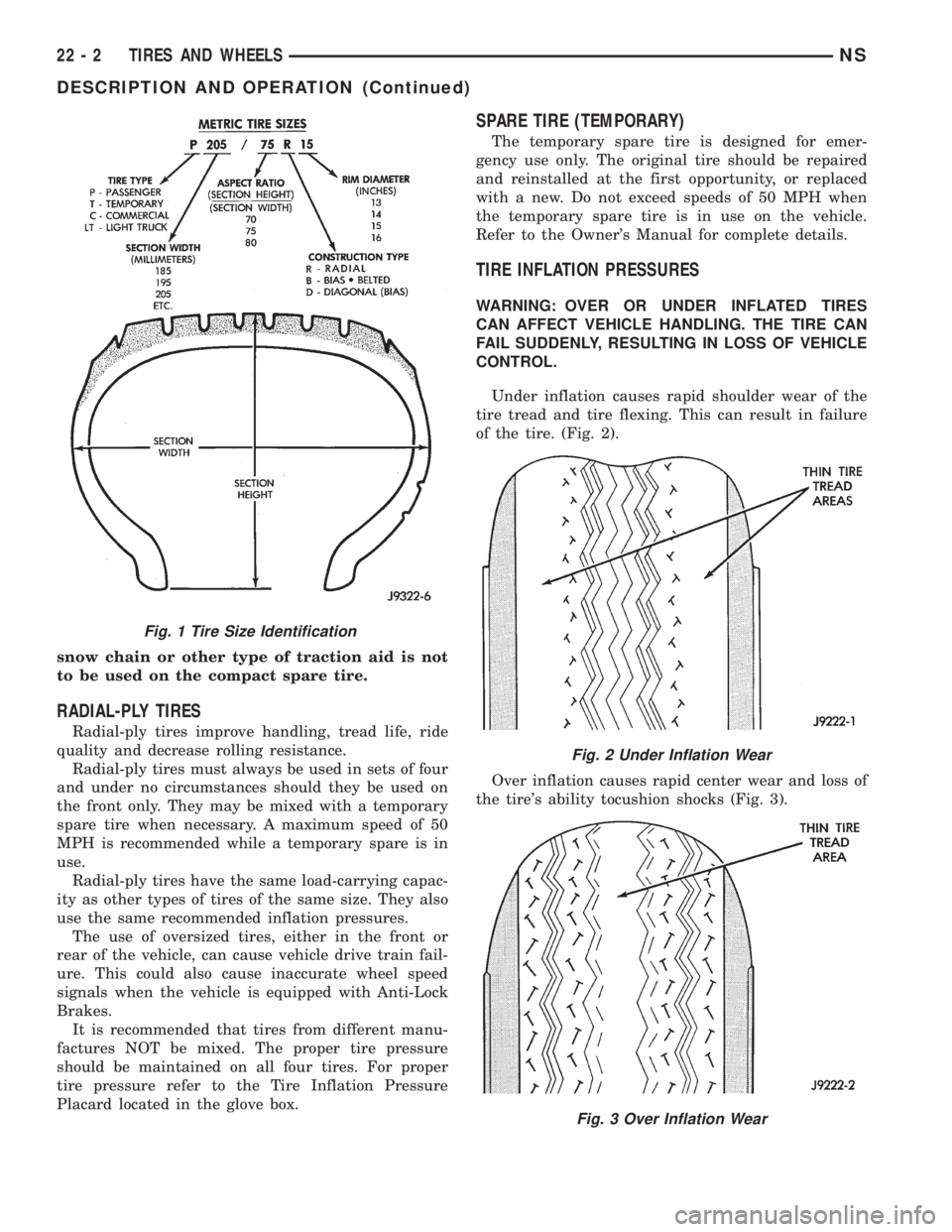

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 1).

Performance tires will have a speed rating letter

after the aspect ratio number. The speed rating is not

always printed on the tire sidewall. The letterSindi-

cates that the tire is speed rated up to 112 mph.

²Qup to 100 mph

²Tup to 118 mph

²Uup to 124 mph

²Hup to 130 mph

²Vup to 149 mph

²Zmore than 149 mph (consult the tire manu-

facturer for the specific speed rating)

An All Season type tire will have eitherM+S,M

&SorM±S(indicating mud and snow traction)

imprinted on the side wall.

TIRE CHAINS

This vehicle was designed to allow the use of a

specified type of snow chain on the tires. Only com-

pact snow chains or other traction aidsmeeting SAE

type ªClass Sº specifications may be used.Any style

NSTIRES AND WHEELS 22 - 1

Page 1720 of 1938

snow chain or other type of traction aid is not

to be used on the compact spare tire.

RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life, ride

quality and decrease rolling resistance.

Radial-ply tires must always be used in sets of four

and under no circumstances should they be used on

the front only. They may be mixed with a temporary

spare tire when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train fail-

ure. This could also cause inaccurate wheel speed

signals when the vehicle is equipped with Anti-Lock

Brakes.

It is recommended that tires from different manu-

factures NOT be mixed. The proper tire pressure

should be maintained on all four tires. For proper

tire pressure refer to the Tire Inflation Pressure

Placard located in the glove box.

SPARE TIRE (TEMPORARY)

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

and reinstalled at the first opportunity, or replaced

with a new. Do not exceed speeds of 50 MPH when

the temporary spare tire is in use on the vehicle.

Refer to the Owner's Manual for complete details.

TIRE INFLATION PRESSURES

WARNING: OVER OR UNDER INFLATED TIRES

CAN AFFECT VEHICLE HANDLING. THE TIRE CAN

FAIL SUDDENLY, RESULTING IN LOSS OF VEHICLE

CONTROL.

Under inflation causes rapid shoulder wear of the

tire tread and tire flexing. This can result in failure

of the tire. (Fig. 2).

Over inflation causes rapid center wear and loss of

the tire's ability tocushion shocks (Fig. 3).

Fig. 1 Tire Size Identification

Fig. 2 Under Inflation Wear

Fig. 3 Over Inflation Wear

22 - 2 TIRES AND WHEELSNS

DESCRIPTION AND OPERATION (Continued)

Page 1721 of 1938

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²The vehicle to drift.

Proper tire air inflation pressure specifications can

be found on the Vehicle Tire Placard provided with

the vehicle. See owner's manual.

Tire pressures have been chosen to provide safe

operation, vehicle stability, and a smooth ride. Tire

pressure should be checked cold once per month.

Check tire pressure more frequently when the

weather temperature varies widely. Tire pressure will

decrease when the outdoor temperature drops.

Tire inflation pressures specified on the placard

are always cold inflation pressure. Cold inflation

pressure is obtained after the vehicle has not been

operated for at least 3 hours, or the vehicle is driven

less than one mile after being inoperative for 3

hours. Tire inflation pressures may increase from 2

to 6 pounds per square inch (psi) during operation.

Do not reduce this normal pressure build-up.

TIRE PRESSURE FOR HIGH-SPEED DRIVING

Chrysler Corporation advocates driving at safe

speeds within posted speed limits. Where speed lim-

its allow the vehicle to be driven at high speeds, cor-

rect tire inflation pressure is very important. For

speeds up to and including 75 mph (120 km/h), tires

must be inflated to the pressures shown on the tire

placard.

Vehicles loaded to the maximum capacity should

not be driven at speeds above 75 mph (120 km/h).

For emergency vehicles that are driven at speeds

over 90 mph (144 km/h), special high-speed tires

must be used. Consult tire manufacturer for correct

inflation pressure recommendations.

REPLACEMENT TIRES

The original equipment tires provide a proper bal-

ance of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

It is recommend that tires equivalent to the origi-

nal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehicle.

The use of oversize tires not listed in the specifica-

tion charts may cause interference with vehicle com-

ponents. Under extremes of suspension and steering

travel, interference with vehicle components may

cause tire damage.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

DIAGNOSIS AND TESTING

PRESSURE GAUGES

A quality air pressure gauge is recommended to

check tire pressure. After checking the air pressure,

replace valve cap finger tight.

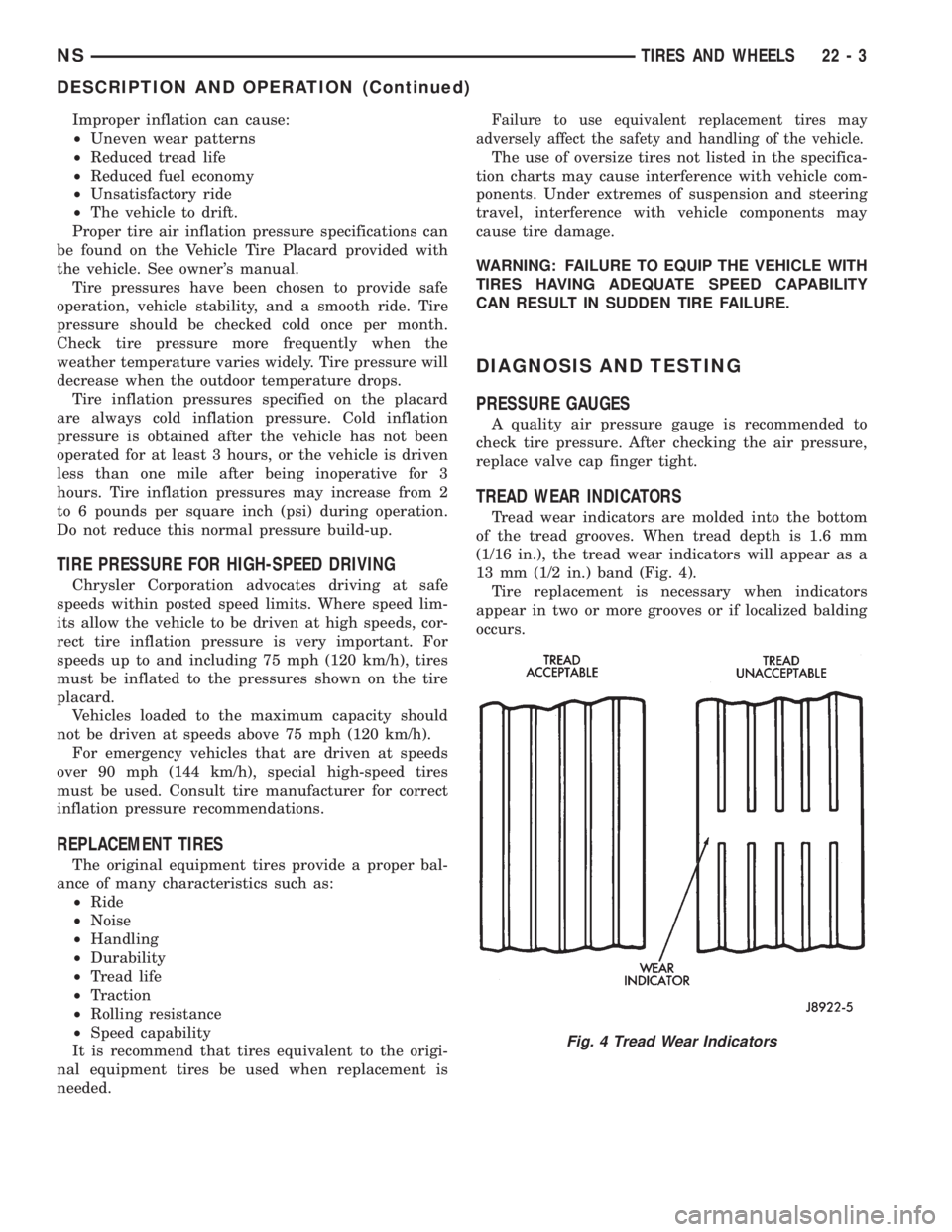

TREAD WEAR INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 4).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

Fig. 4 Tread Wear Indicators

NSTIRES AND WHEELS 22 - 3

DESCRIPTION AND OPERATION (Continued)

Page 1730 of 1938

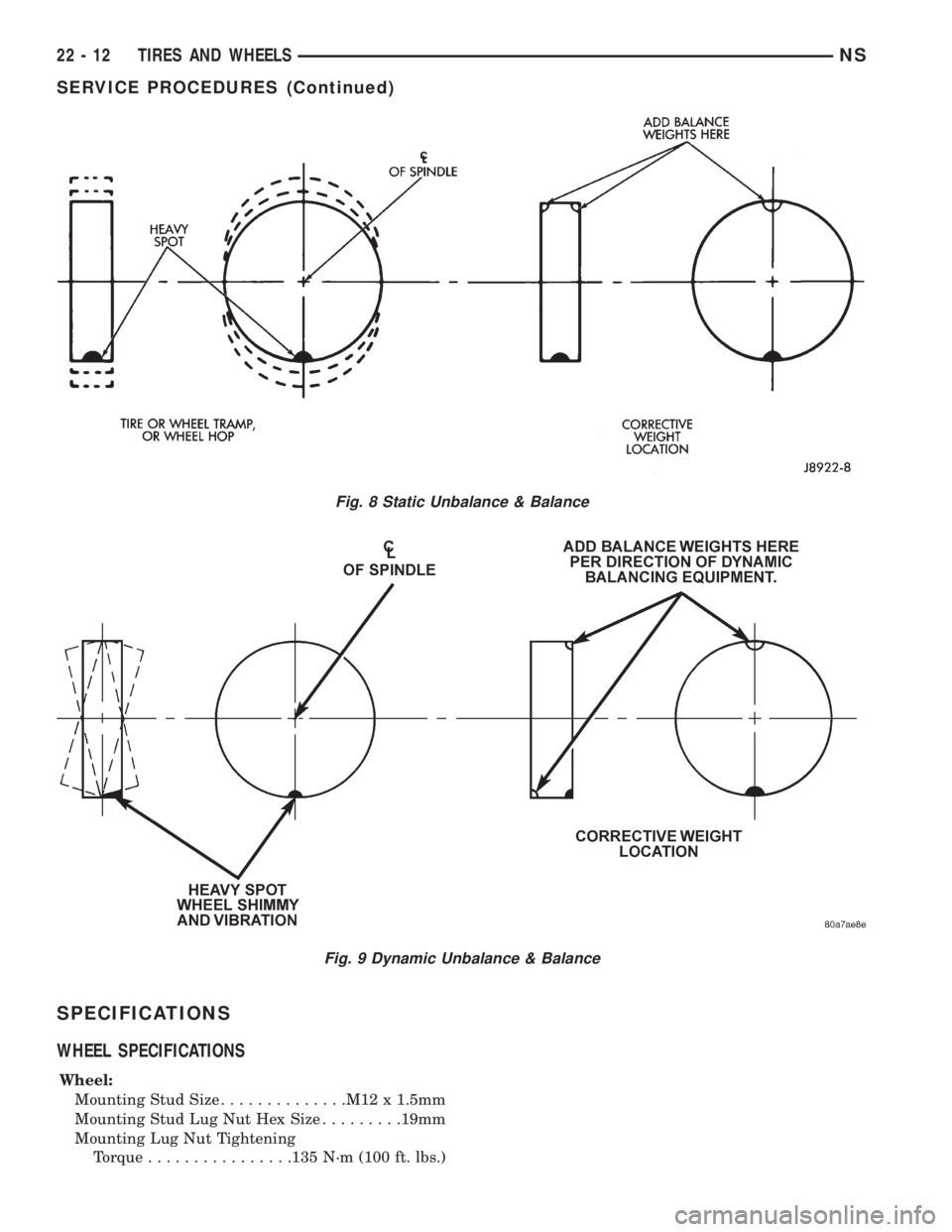

SPECIFICATIONS

WHEEL SPECIFICATIONS

Wheel:

Mounting Stud Size..............M12 x 1.5mm

Mounting Stud Lug Nut Hex Size.........19mm

Mounting Lug Nut Tightening

Torque................135 N´m (100 ft. lbs.)

Fig. 8 Static Unbalance & Balance

Fig. 9 Dynamic Unbalance & Balance

22 - 12 TIRES AND WHEELSNS

SERVICE PROCEDURES (Continued)