wheel CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1283 of 1938

FRAME

INDEX

page page

REMOVAL AND INSTALLATION

FRONT CROSSMEMBER MOUNT BUSHINGS . . . 5

FRONT CROSSMEMBER................... 3SPECIFICATIONS

FRAME AND BODY OPENING DIMENSIONS.... 5

REMOVAL AND INSTALLATION

FRONT CROSSMEMBER

The front suspension crossmember must be

installed in the design location to achieve proper

front end suspension alignment. If the crossmember

is removed without applying reference marks on the

frame rails, align the crossmember according to the

dimensions provided in this group.

NOTE: If the caged nuts in the frame rails become

damaged and cannot be reused, a replacement nut

can be obtained through a MoparTParts supplier.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove steering column lower cover from

instrument panel. Refer to Group 8E, Instrument

Panel and Systems.

(3) Remove knee blocker reinforcement. Refer to

Group 8E, Instrument Panel and Systems.

(4) Position steering so front wheels are straight

ahead.

CAUTION: Do not rotate steering wheel after disen-

gaging lower coupling from steering gear, damage

to airbag clock spring can result.

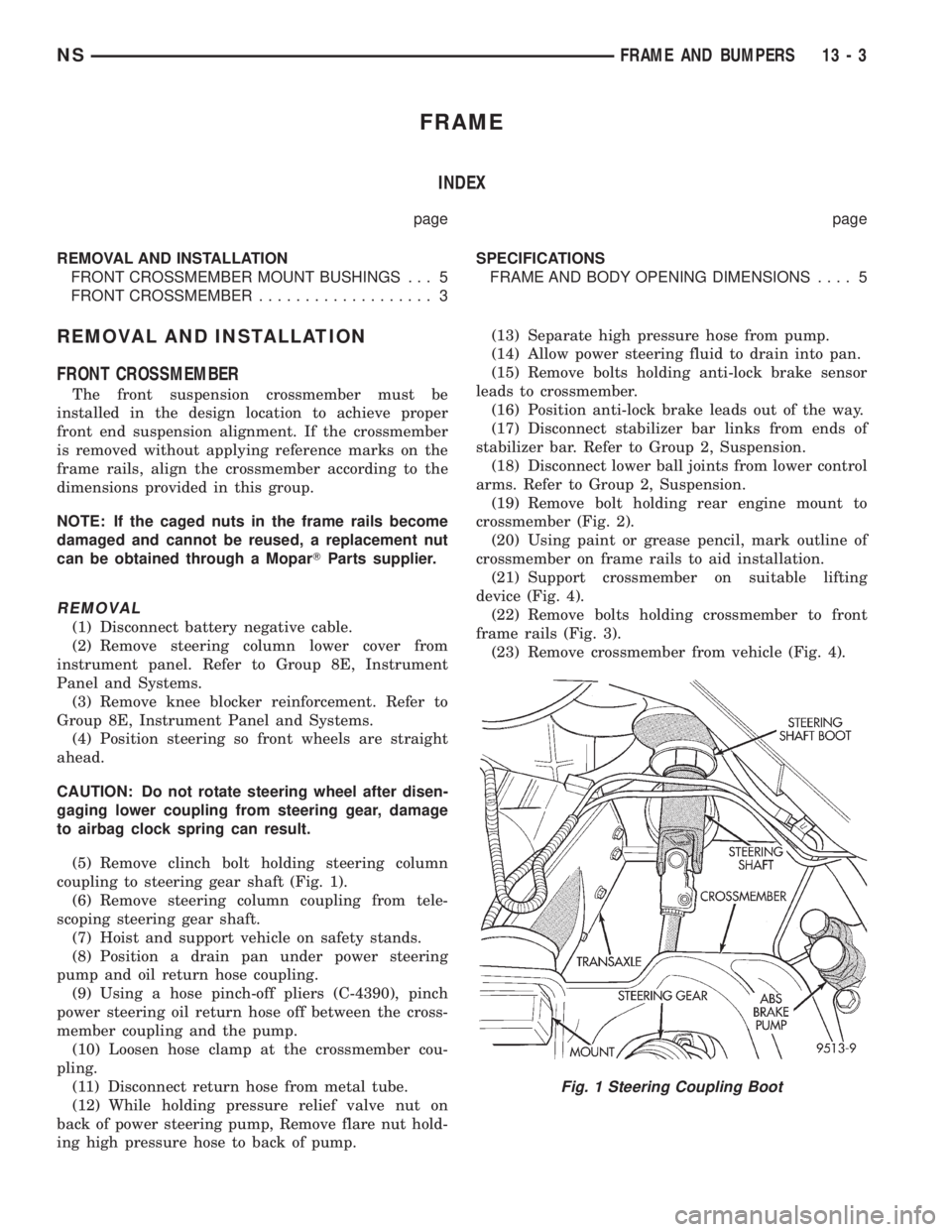

(5) Remove clinch bolt holding steering column

coupling to steering gear shaft (Fig. 1).

(6) Remove steering column coupling from tele-

scoping steering gear shaft.

(7) Hoist and support vehicle on safety stands.

(8) Position a drain pan under power steering

pump and oil return hose coupling.

(9) Using a hose pinch-off pliers (C-4390), pinch

power steering oil return hose off between the cross-

member coupling and the pump.

(10) Loosen hose clamp at the crossmember cou-

pling.

(11) Disconnect return hose from metal tube.

(12) While holding pressure relief valve nut on

back of power steering pump, Remove flare nut hold-

ing high pressure hose to back of pump.(13) Separate high pressure hose from pump.

(14) Allow power steering fluid to drain into pan.

(15) Remove bolts holding anti-lock brake sensor

leads to crossmember.

(16) Position anti-lock brake leads out of the way.

(17) Disconnect stabilizer bar links from ends of

stabilizer bar. Refer to Group 2, Suspension.

(18) Disconnect lower ball joints from lower control

arms. Refer to Group 2, Suspension.

(19) Remove bolt holding rear engine mount to

crossmember (Fig. 2).

(20) Using paint or grease pencil, mark outline of

crossmember on frame rails to aid installation.

(21) Support crossmember on suitable lifting

device (Fig. 4).

(22) Remove bolts holding crossmember to front

frame rails (Fig. 3).

(23) Remove crossmember from vehicle (Fig. 4).

Fig. 1 Steering Coupling Boot

NSFRAME AND BUMPERS 13 - 3

Page 1285 of 1938

(7) Connect lower ball joints to lower control arms.

Refer to Group 2, Suspension.

(8) Connect stabilizer bar links to ends of stabi-

lizer bar. Refer to Group 2, Suspension.

(9) Install bolts to hold anti-lock brake sensor

leads to crossmember.

(10) Install high pressure hose to pump.

(11) Connect return hose to metal tube.

(12) Tighten hose clamp at the crossmember cou-

pling.

(13) Remove pinch-off pliers.

(14) Position steering so front wheels are straight

ahead.

(15) Install steering column coupling to telescoping

steering gear shaft.

(16) Install clinch bolt to hold steering column cou-

pling to steering gear shaft.

(17) Install knee blocker reinforcement. Refer to

Group 8E, Instrument Panel and Systems.

(18) Install steering column lower cover from

instrument panel. Refer to Group 8E, Instrument

Panel and Systems.

(19) Connect battery negative cable.

FRONT CROSSMEMBER MOUNT BUSHINGS

REMOVAL

(1) Using paint or grease pencil, mark outline of

crossmember on frame rails.

(2) Loosen bolts holding crossmember to frame

rails.

(3) Remove bolt on bushing that requires replace-

ment.

(4) Allow crossmember to drop down enough to

gain clearance for bushing removal.

(5) Remove bushing from vehicle.

INSTALLATION

(1) Apply rubber lube or soap to replacement bush-

ing.(2) Insert lower half of bushing into square hole in

crossmember.

(3) Place upper half of bushing on top of cross-

member aligned to receive square tube protruding

upward from lower bushing half.

(4) Squeeze bushing halves together to ensure they

are properly mated.

(5) Lift crossmember upward to close gap between

the bushing and frame.

(6) Verify that lower bushing is fully seated into

crossmember and upper bushing.

(7) Install bolt to hold bushing and crossmember

to frame rail hand tight.

(8) Align crossmember to reference marks on

frame rails.

(9) Tighten crossmember to frame rails attaching

bolts to 163 N´m (120 ft. lbs.) torque.

SPECIFICATIONS

FRAME AND BODY OPENING DIMENSIONS

Frame dimensions are listed in metric scale. All

dimensions are from center to center of Principal

Locating Point (PLP), or from center to center of PLP

and fastener location.

VEHICLE PREPARATION

Position the vehicle on a frame alignment rack,

refer to instructions provided with equipment being

used. Adjust the vehicle PLP heights to the specified

dimension above the work surface (datum line). Ver-

tical dimensions can be taken from the datum line to

the locations indicated were applicable. Refer to (Fig.

5), (Fig. 6), (Fig. 7), (Fig. 8), (Fig. 9), (Fig. 10) and

(Fig. 11) for proper dimensions.

NSFRAME AND BUMPERS 13 - 5

REMOVAL AND INSTALLATION (Continued)

Page 1298 of 1938

FUEL DELIVERY SYSTEM

INDEX

page page

DESCRIPTION AND OPERATION

FUEL DELIVERY SYSTEM.................. 4

FUEL INJECTORS........................ 5

FUEL LEVEL SENSOR..................... 5

FUEL PRESSURE REGULATOR.............. 5

FUEL PUMP MODULE..................... 4

FUEL TANK............................. 5

PRESSURE-VACUUM FILLER CAP........... 6

QUICK-CONNECT FITTINGS................ 6

DIAGNOSIS AND TESTING

FUEL INJECTORS........................ 9

FUEL LEVEL SENSOR..................... 9

FUEL PUMP PRESSURE TEST 2.4/3.3/3.8L..... 6

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.4/3.3/3.8L............... 11

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ3.0L ENGINE............. 11

HOSES AND CLAMPS.................... 12QUICK-CONNECT FITTINGS............... 12

REMOVAL AND INSTALLATION

ACCELERATOR PEDAL................... 26

FUEL FILTER........................... 12

FUEL INJECTOR RAILÐ2.4L............... 18

FUEL INJECTOR RAILÐ3.0L............... 19

FUEL INJECTOR RAILÐ3.3/3.8L............ 21

FUEL INJECTORSÐ3.0L.................. 25

FUEL INJECTORÐ2.4L................... 24

FUEL INJECTORÐ3.3/3.8L................. 26

FUEL LEVEL SENSOR.................... 15

FUEL PRESSURE REGULATOR............. 14

FUEL PUMP INLET STRAINER............. 15

FUEL PUMP MODULE.................... 13

FUEL TANK............................ 17

THROTTLE CABLE...................... 27

SPECIFICATIONS

FUEL TANK CAPACITY................... 28

TORQUE.............................. 28

DESCRIPTION AND OPERATION

FUEL DELIVERY SYSTEM

The front wheel drive van uses a plastic fuel tank

located on the left side of the vehicle.

The Fuel Delivery System consists of: the electric

fuel pump module, fuel filter, tubes/lines/hoses, fuel

rail, and fuel injectors.

The in-tank fuel pump module contains the fuel

pump and pressure regulator. The pump is serviced

as part of the fuel pump module. Refer to Fuel Pump

Module.

The fuel filter is a replaceable in-line filter. The fil-

ter attaches to a bracket mounted on top of the fuel

tank. Refer to the Maintenance Schedules in the

Introduction section of this manual for recommended

fuel filter replacement intervals.

A returnless fuel system is used on all vehicles.

Fuel is returned through the fuel pump module and

back to the fuel tank. A separate fuel return line

from the tank to the engine is no longer used.

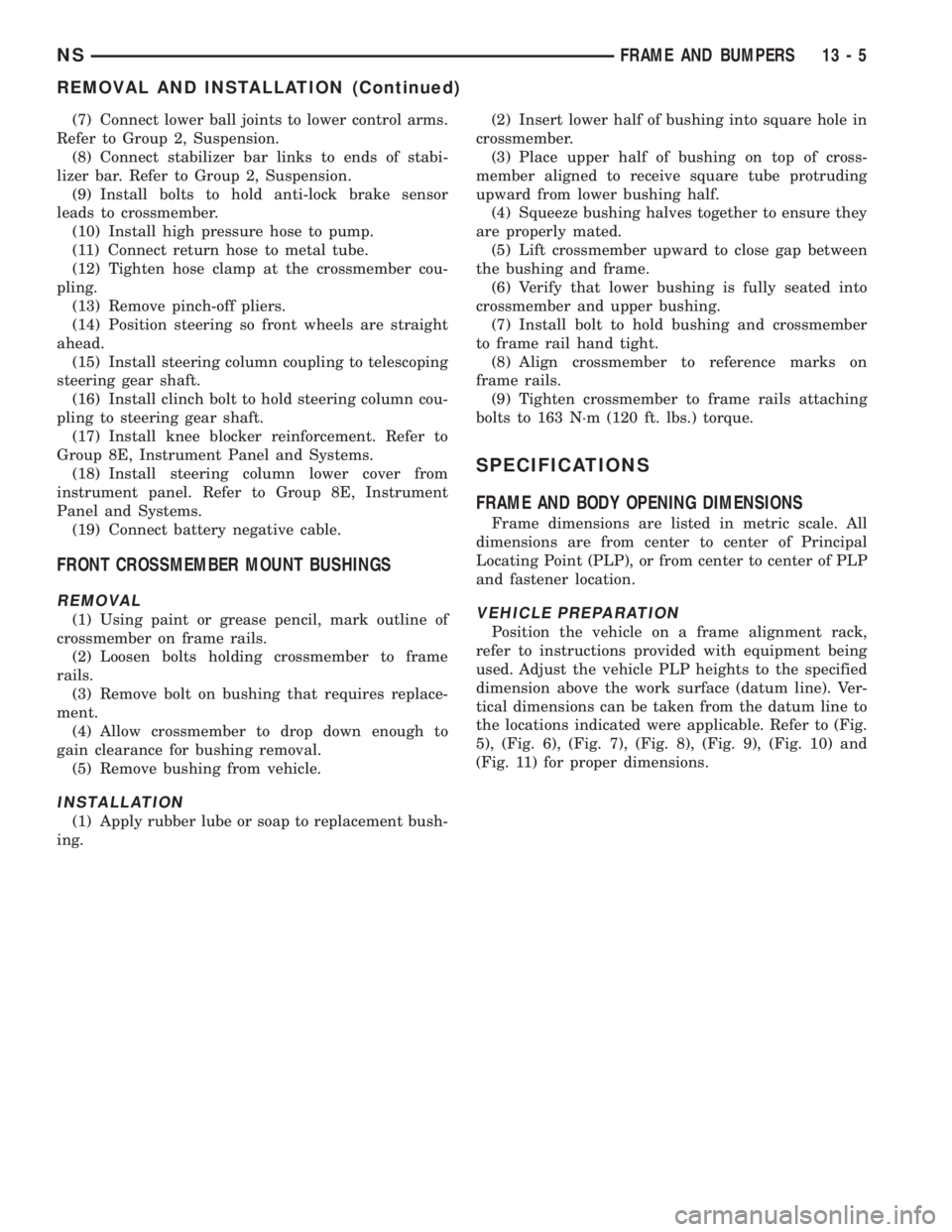

FUEL PUMP MODULE

The fuel pump module is installed in the top of the

fuel tank (Fig. 1). The fuel pump module contains the

following:

²Electric fuel pump

²Fuel pump reservoir

²Inlet strainer²Fuel pressure regulator

²Fuel gauge sending unit

²Fuel supply line connection

The inlet strainer, fuel pressure regulator

and fuel level sensor are the only serviceable

items. If the fuel pump or electrical wiring har-

ness requires service, replace the fuel pump

module.

ELECTRIC FUEL PUMP

The electric fuel pump is located in and is part of

the fuel pump module. It is a positive displacement,

gerotor type, immersible pump with a permanent

magnet electric motor. The pump draws fuel through

a strainer and pushes it through the motor to the

outlet. The pump contains one check valve. The

Fig. 1 Fuel Pump Module

14 - 4 FUEL SYSTEMNS

Page 1299 of 1938

check valve, in the pump outlet, maintains pump

pressure during engine off conditions. The fuel pump

relay provides voltage to the fuel pump.

The fuel pump has a maximum deadheaded pres-

sure output of approximately 635 kPa (95 psi). The

regulator adjusts fuel system pressure to approxi-

mately 338 kPa (49 psi).

FUEL PUMP ELECTRICAL CONTROL

Voltage to operate the electric pump is supplied

through the fuel pump relay. For an electrical opera-

tional description of the fuel pump refer to fuel Pump

RelayÐPCM Output.

ELECTRICAL PUMP REPLACEMENT

The electric fuel pump is not serviceable. If the

fuel pump or electrical wiring harness needs replace-

ment, the complete fuel pump module must be

replaced. Perform the Fuel System Pressure Release

procedure before servicing the fuel pump.

FUEL LEVEL SENSOR

The level sensor is attached to the side of the fuel

pump module. The level sensor consists of a float, an

arm, and a variable resistor. As the fuel level

increases, the float and arm move up. This decreases

the sending unit resistance, causing the fuel gauge

on the instrument panel to read full.

FUEL PRESSURE REGULATOR

The fuel system uses a nonadjustable pressure reg-

ulator that maintains fuel system pressure at

approximately 338 kPa (49 psi), 3.3l uses approxi-

mately 379 kPa (55 psi). The fuel pressure regulator

contains a diaphragm, calibrated spring and a fuel

return valve. The spring pushes down on the dia-

phragm and closes off the fuel return port. System

fuel pressure reflects the amount of fuel pressure

required to open the return port.

The pressure regulator is a mechanical device that

is NOT controlled by the PCM or engine vacuum.

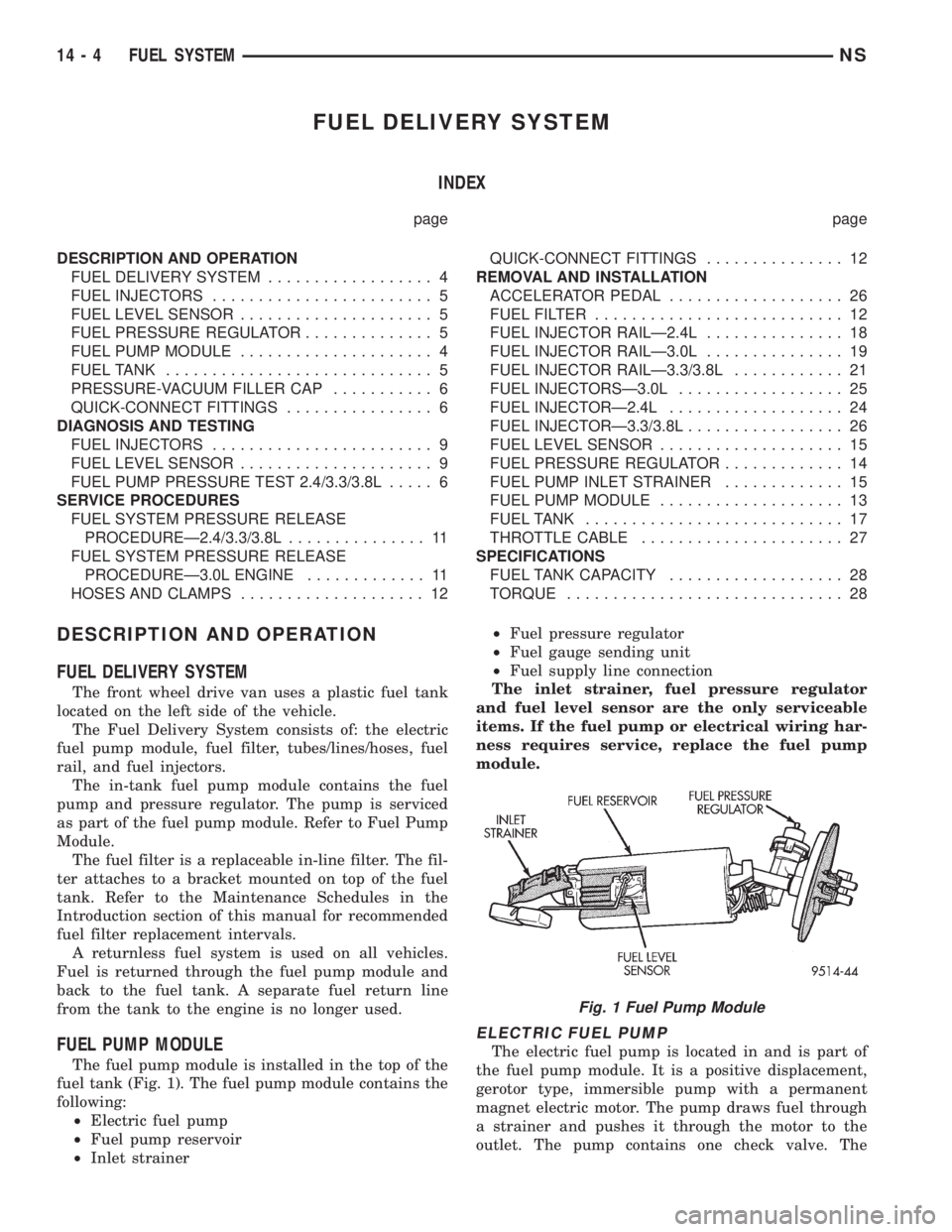

FUEL INJECTORS

The fuel injectors are 12 ohm electrical solenoids

(Fig. 2). The injector contains a pintle that closes off

an orifice at the nozzle end. When electric current is

supplied to the injector, the armature and needle

move a short distance against a spring, allowing fuel

to flow out the orifice. Because the fuel is under high

pressure, a fine spray is developed in the shape of a

hollow cone. The spraying action atomizes the fuel,

adding it to the air entering the combustion chamber.

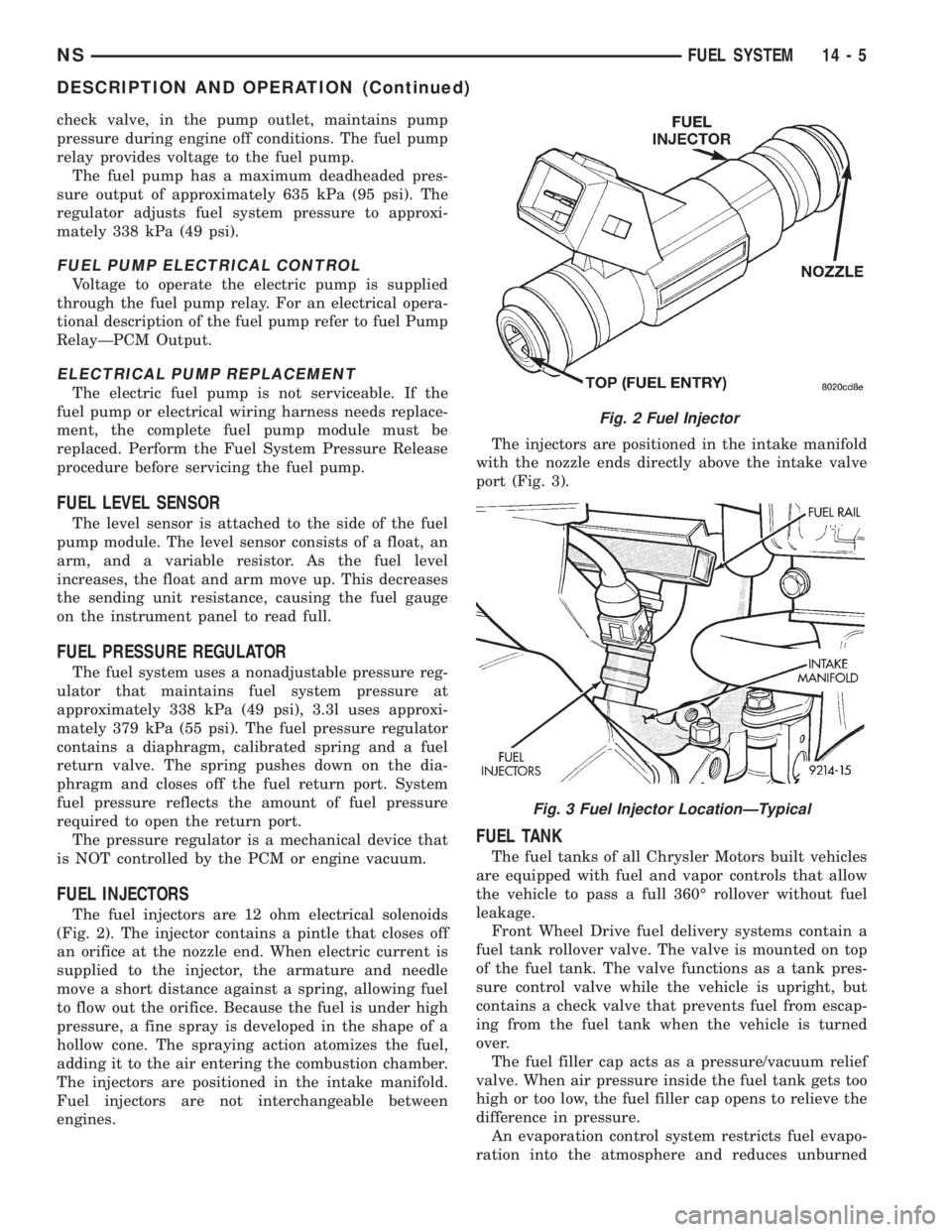

The injectors are positioned in the intake manifold.

Fuel injectors are not interchangeable between

engines.The injectors are positioned in the intake manifold

with the nozzle ends directly above the intake valve

port (Fig. 3).

FUEL TANK

The fuel tanks of all Chrysler Motors built vehicles

are equipped with fuel and vapor controls that allow

the vehicle to pass a full 360É rollover without fuel

leakage.

Front Wheel Drive fuel delivery systems contain a

fuel tank rollover valve. The valve is mounted on top

of the fuel tank. The valve functions as a tank pres-

sure control valve while the vehicle is upright, but

contains a check valve that prevents fuel from escap-

ing from the fuel tank when the vehicle is turned

over.

The fuel filler cap acts as a pressure/vacuum relief

valve. When air pressure inside the fuel tank gets too

high or too low, the fuel filler cap opens to relieve the

difference in pressure.

An evaporation control system restricts fuel evapo-

ration into the atmosphere and reduces unburned

Fig. 2 Fuel Injector

Fig. 3 Fuel Injector LocationÐTypical

NSFUEL SYSTEM 14 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1373 of 1938

For periodic draining of water from the bowl, refer

to Fuel Filter/Water Separator Removal/Installation

in this group.

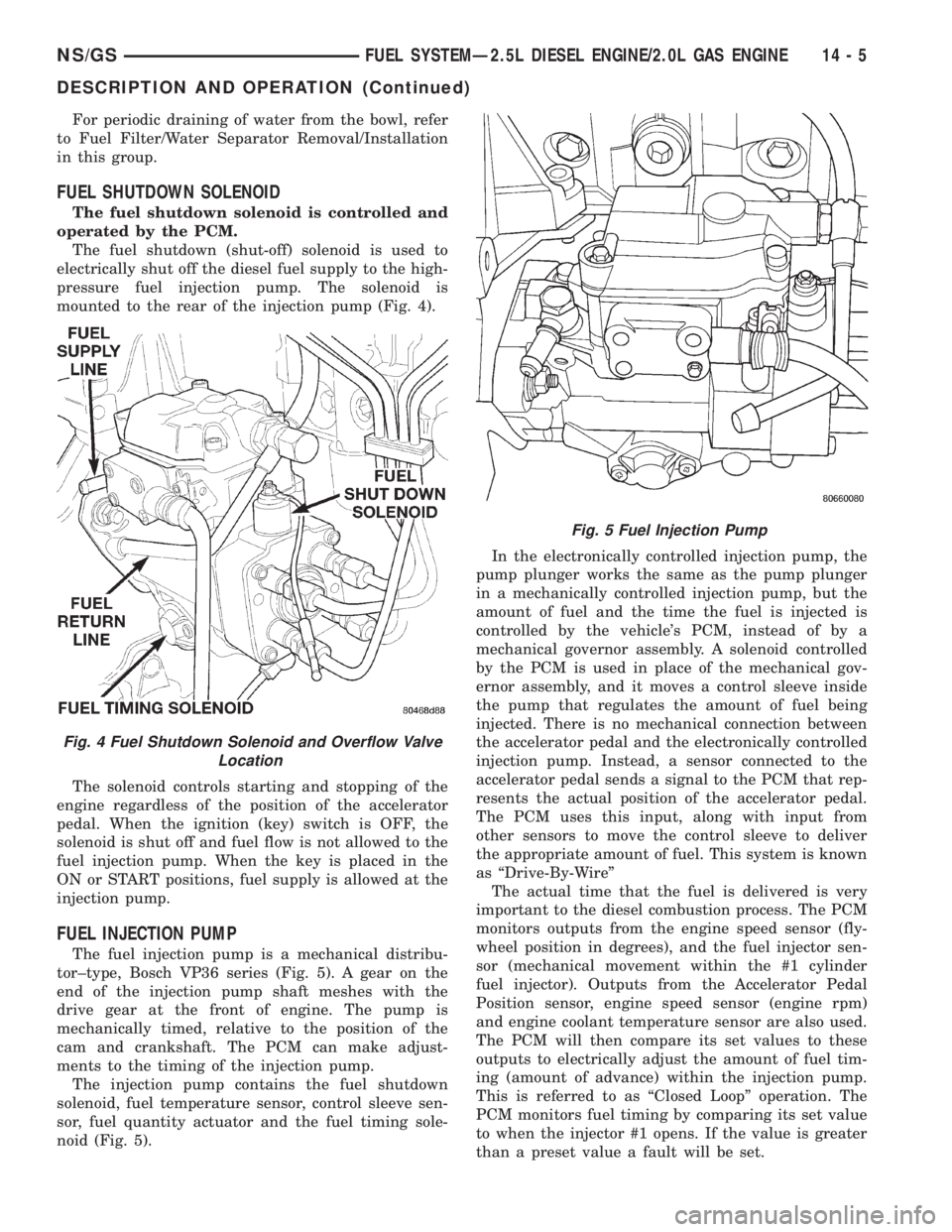

FUEL SHUTDOWN SOLENOID

The fuel shutdown solenoid is controlled and

operated by the PCM.

The fuel shutdown (shut-off) solenoid is used to

electrically shut off the diesel fuel supply to the high-

pressure fuel injection pump. The solenoid is

mounted to the rear of the injection pump (Fig. 4).

The solenoid controls starting and stopping of the

engine regardless of the position of the accelerator

pedal. When the ignition (key) switch is OFF, the

solenoid is shut off and fuel flow is not allowed to the

fuel injection pump. When the key is placed in the

ON or START positions, fuel supply is allowed at the

injection pump.

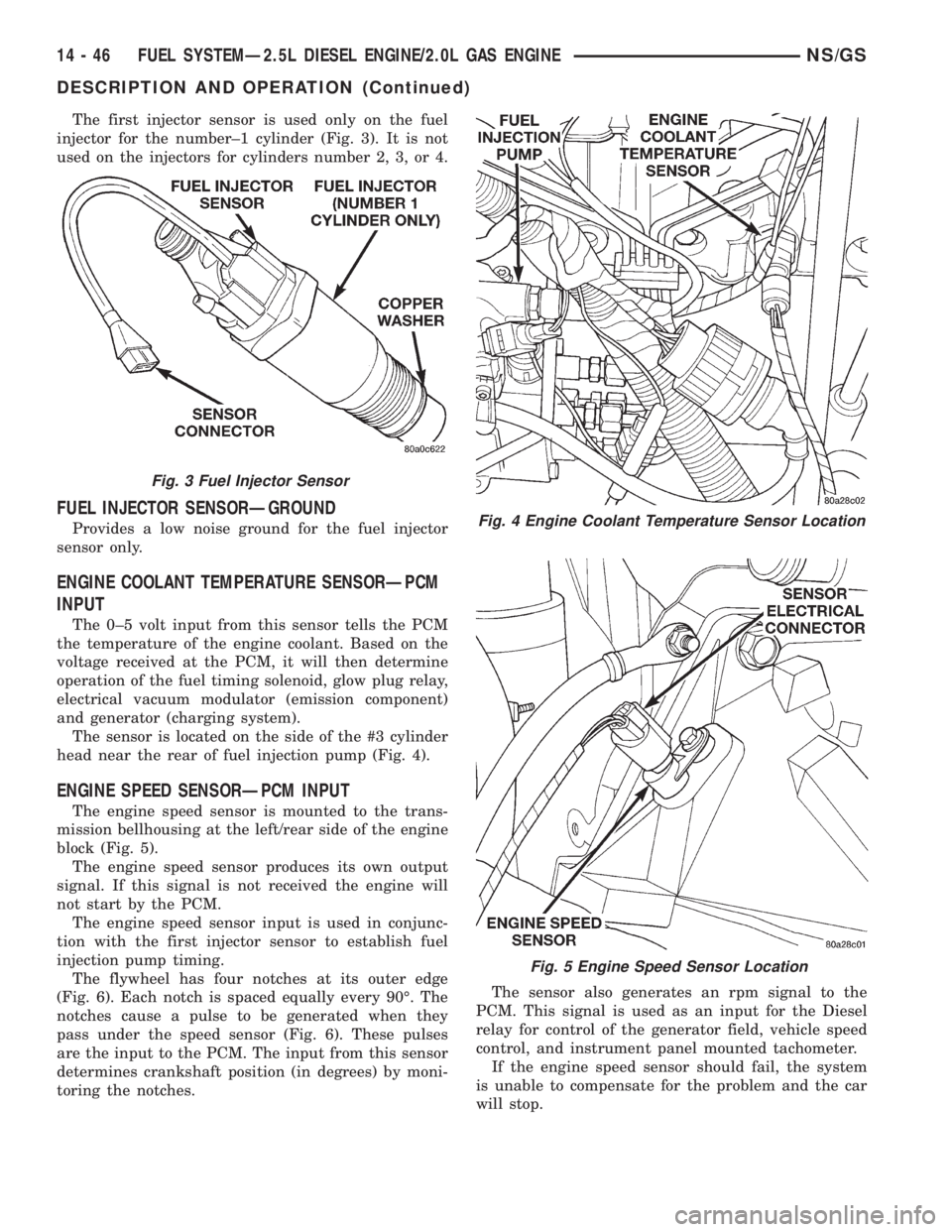

FUEL INJECTION PUMP

The fuel injection pump is a mechanical distribu-

tor±type, Bosch VP36 series (Fig. 5). A gear on the

end of the injection pump shaft meshes with the

drive gear at the front of engine. The pump is

mechanically timed, relative to the position of the

cam and crankshaft. The PCM can make adjust-

ments to the timing of the injection pump.

The injection pump contains the fuel shutdown

solenoid, fuel temperature sensor, control sleeve sen-

sor, fuel quantity actuator and the fuel timing sole-

noid (Fig. 5).In the electronically controlled injection pump, the

pump plunger works the same as the pump plunger

in a mechanically controlled injection pump, but the

amount of fuel and the time the fuel is injected is

controlled by the vehicle's PCM, instead of by a

mechanical governor assembly. A solenoid controlled

by the PCM is used in place of the mechanical gov-

ernor assembly, and it moves a control sleeve inside

the pump that regulates the amount of fuel being

injected. There is no mechanical connection between

the accelerator pedal and the electronically controlled

injection pump. Instead, a sensor connected to the

accelerator pedal sends a signal to the PCM that rep-

resents the actual position of the accelerator pedal.

The PCM uses this input, along with input from

other sensors to move the control sleeve to deliver

the appropriate amount of fuel. This system is known

as ªDrive-By-Wireº

The actual time that the fuel is delivered is very

important to the diesel combustion process. The PCM

monitors outputs from the engine speed sensor (fly-

wheel position in degrees), and the fuel injector sen-

sor (mechanical movement within the #1 cylinder

fuel injector). Outputs from the Accelerator Pedal

Position sensor, engine speed sensor (engine rpm)

and engine coolant temperature sensor are also used.

The PCM will then compare its set values to these

outputs to electrically adjust the amount of fuel tim-

ing (amount of advance) within the injection pump.

This is referred to as ªClosed Loopº operation. The

PCM monitors fuel timing by comparing its set value

to when the injector #1 opens. If the value is greater

than a preset value a fault will be set.

Fig. 4 Fuel Shutdown Solenoid and Overflow Valve

Location

Fig. 5 Fuel Injection Pump

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1388 of 1938

(8) Disconnect the main engine wiring harness

from the glow plugs.

(9) Disconnect the four high±pressure fuel lines

from the fuel injection pump. Also disconnect fuel

lines at the fuel injectors. For procedures, refer to

High±Pressure Fuel Lines in this group. Place a rag

beneath the fittings to catch excess fuel.

(10) Remove plug from timing gear cover.

(11) The ªTop Dead Centerº (TDC) compression fir-

ing stroke must be determined as follows:

(a) Remove the valve cover, refer to Group 9,

Valve Cover Removal/Installation.

(b) Remove the right front tire and splash

shield. Using a socket attached to the end of crank-

shaft, rotate the engine (counterÐclockwise as

viewed from front).

(c) Rotate the engine until cylinder #4 rockers

are in between movement.

(d) Remove rocker arm assembly.

(e) Remove valve spring and keepers.CAU-

TION: When the piston is at TDC there is only

2 mm (.080 thousand) clearance between the

valve and piston.

(f) Let the valve set on top of piston. Install a

dial indicator to the top of the valve stem.

(g) Rotate engine back and forth to find the TDC

position with the indicator on the valve stem. Mark

the damper and timing cover for TDC.

NOTE: On later model 1997 engines, a hole in the

bottom of the clutch housing can be lined up with a

hole in the flywheel, allowing the engine to be held

at TDC with a special alignment tool, part # VM1035.(12) Remove injection pump drive gear nut (Fig.

41) and washer.CAUTION: Be very careful not to

drop the washer into the timing gear cover.

(13) A special 3±piece gear removal tool set

VM.1003 (Fig. 42) must be used to remove the injec-

tion pump drive gear from the pump shaft.

(a) Thread the adapter (Fig. 43) into the timing

cover.

(b) Thread the gear puller into the injection

pump drive gear (Fig. 43). This tool is also used to

hold the gear in synchronization during pump

removal.

(c) Remove the three injection pump±to±gear

cover mounting nuts (Fig. 44).CAUTION: This

step must be done to prevent breakage of the

Fig. 40 Engine Coolant Temperature Sensor

Fig. 41 Removing Pump Drive Gear Nut

Fig. 42 Pump Gear Tools

14 - 20 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1414 of 1938

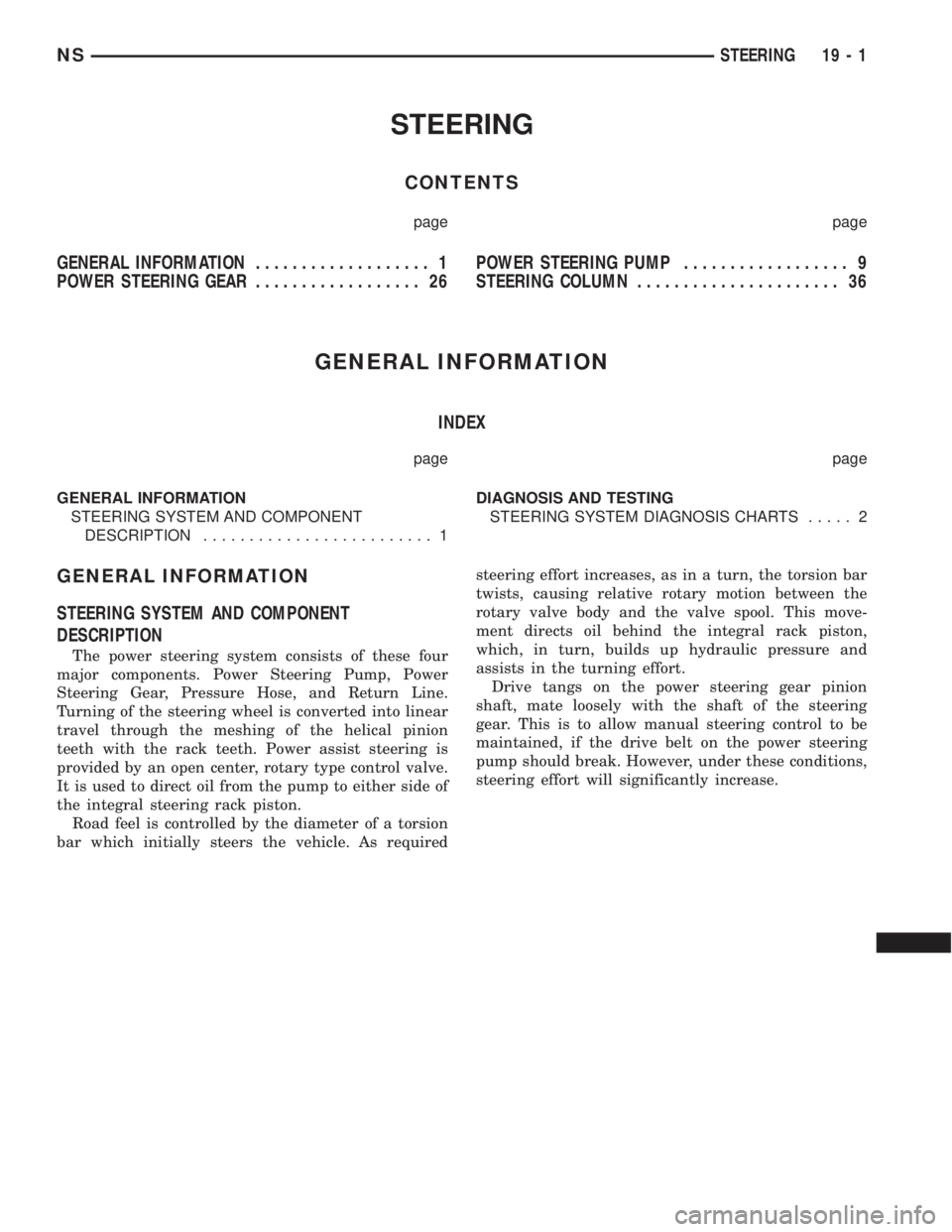

The first injector sensor is used only on the fuel

injector for the number±1 cylinder (Fig. 3). It is not

used on the injectors for cylinders number 2, 3, or 4.

FUEL INJECTOR SENSORÐGROUND

Provides a low noise ground for the fuel injector

sensor only.

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The 0±5 volt input from this sensor tells the PCM

the temperature of the engine coolant. Based on the

voltage received at the PCM, it will then determine

operation of the fuel timing solenoid, glow plug relay,

electrical vacuum modulator (emission component)

and generator (charging system).

The sensor is located on the side of the #3 cylinder

head near the rear of fuel injection pump (Fig. 4).

ENGINE SPEED SENSORÐPCM INPUT

The engine speed sensor is mounted to the trans-

mission bellhousing at the left/rear side of the engine

block (Fig. 5).

The engine speed sensor produces its own output

signal. If this signal is not received the engine will

not start by the PCM.

The engine speed sensor input is used in conjunc-

tion with the first injector sensor to establish fuel

injection pump timing.

The flywheel has four notches at its outer edge

(Fig. 6). Each notch is spaced equally every 90É. The

notches cause a pulse to be generated when they

pass under the speed sensor (Fig. 6). These pulses

are the input to the PCM. The input from this sensor

determines crankshaft position (in degrees) by moni-

toring the notches.The sensor also generates an rpm signal to the

PCM. This signal is used as an input for the Diesel

relay for control of the generator field, vehicle speed

control, and instrument panel mounted tachometer.

If the engine speed sensor should fail, the system

is unable to compensate for the problem and the car

will stop.

Fig. 3 Fuel Injector Sensor

Fig. 4 Engine Coolant Temperature Sensor Location

Fig. 5 Engine Speed Sensor Location

14 - 46 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1427 of 1938

STEERING

CONTENTS

page page

GENERAL INFORMATION................... 1

POWER STEERING GEAR.................. 26POWER STEERING PUMP.................. 9

STEERING COLUMN...................... 36

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

STEERING SYSTEM AND COMPONENT

DESCRIPTION......................... 1DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS..... 2

GENERAL INFORMATION

STEERING SYSTEM AND COMPONENT

DESCRIPTION

The power steering system consists of these four

major components. Power Steering Pump, Power

Steering Gear, Pressure Hose, and Return Line.

Turning of the steering wheel is converted into linear

travel through the meshing of the helical pinion

teeth with the rack teeth. Power assist steering is

provided by an open center, rotary type control valve.

It is used to direct oil from the pump to either side of

the integral steering rack piston.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As requiredsteering effort increases, as in a turn, the torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This move-

ment directs oil behind the integral rack piston,

which, in turn, builds up hydraulic pressure and

assists in the turning effort.

Drive tangs on the power steering gear pinion

shaft, mate loosely with the shaft of the steering

gear. This is to allow manual steering control to be

maintained, if the drive belt on the power steering

pump should break. However, under these conditions,

steering effort will significantly increase.

NSSTEERING 19 - 1

Page 1428 of 1938

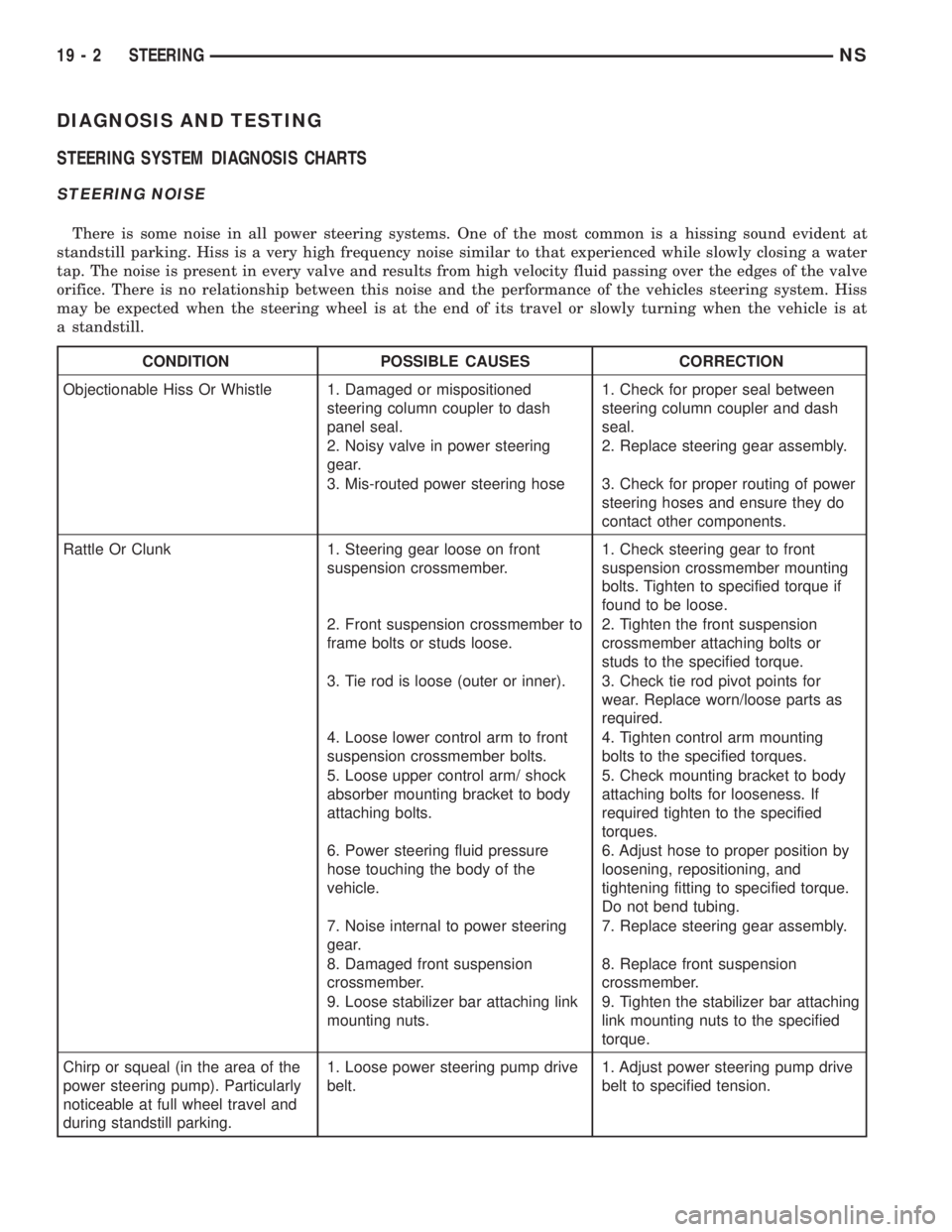

DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS

STEERING NOISE

There is some noise in all power steering systems. One of the most common is a hissing sound evident at

standstill parking. Hiss is a very high frequency noise similar to that experienced while slowly closing a water

tap. The noise is present in every valve and results from high velocity fluid passing over the edges of the valve

orifice. There is no relationship between this noise and the performance of the vehicles steering system. Hiss

may be expected when the steering wheel is at the end of its travel or slowly turning when the vehicle is at

a standstill.

CONDITION POSSIBLE CAUSES CORRECTION

Objectionable Hiss Or Whistle 1. Damaged or mispositioned

steering column coupler to dash

panel seal.1. Check for proper seal between

steering column coupler and dash

seal.

2. Noisy valve in power steering

gear.2. Replace steering gear assembly.

3. Mis-routed power steering hose 3. Check for proper routing of power

steering hoses and ensure they do

contact other components.

Rattle Or Clunk 1. Steering gear loose on front

suspension crossmember.1. Check steering gear to front

suspension crossmember mounting

bolts. Tighten to specified torque if

found to be loose.

2. Front suspension crossmember to

frame bolts or studs loose.2. Tighten the front suspension

crossmember attaching bolts or

studs to the specified torque.

3. Tie rod is loose (outer or inner). 3. Check tie rod pivot points for

wear. Replace worn/loose parts as

required.

4. Loose lower control arm to front

suspension crossmember bolts.4. Tighten control arm mounting

bolts to the specified torques.

5. Loose upper control arm/ shock

absorber mounting bracket to body

attaching bolts.5. Check mounting bracket to body

attaching bolts for looseness. If

required tighten to the specified

torques.

6. Power steering fluid pressure

hose touching the body of the

vehicle.6. Adjust hose to proper position by

loosening, repositioning, and

tightening fitting to specified torque.

Do not bend tubing.

7. Noise internal to power steering

gear.7. Replace steering gear assembly.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

9. Loose stabilizer bar attaching link

mounting nuts.9. Tighten the stabilizer bar attaching

link mounting nuts to the specified

torque.

Chirp or squeal (in the area of the

power steering pump). Particularly

noticeable at full wheel travel and

during standstill parking.1. Loose power steering pump drive

belt.1. Adjust power steering pump drive

belt to specified tension.

19 - 2 STEERINGNS

Page 1429 of 1938

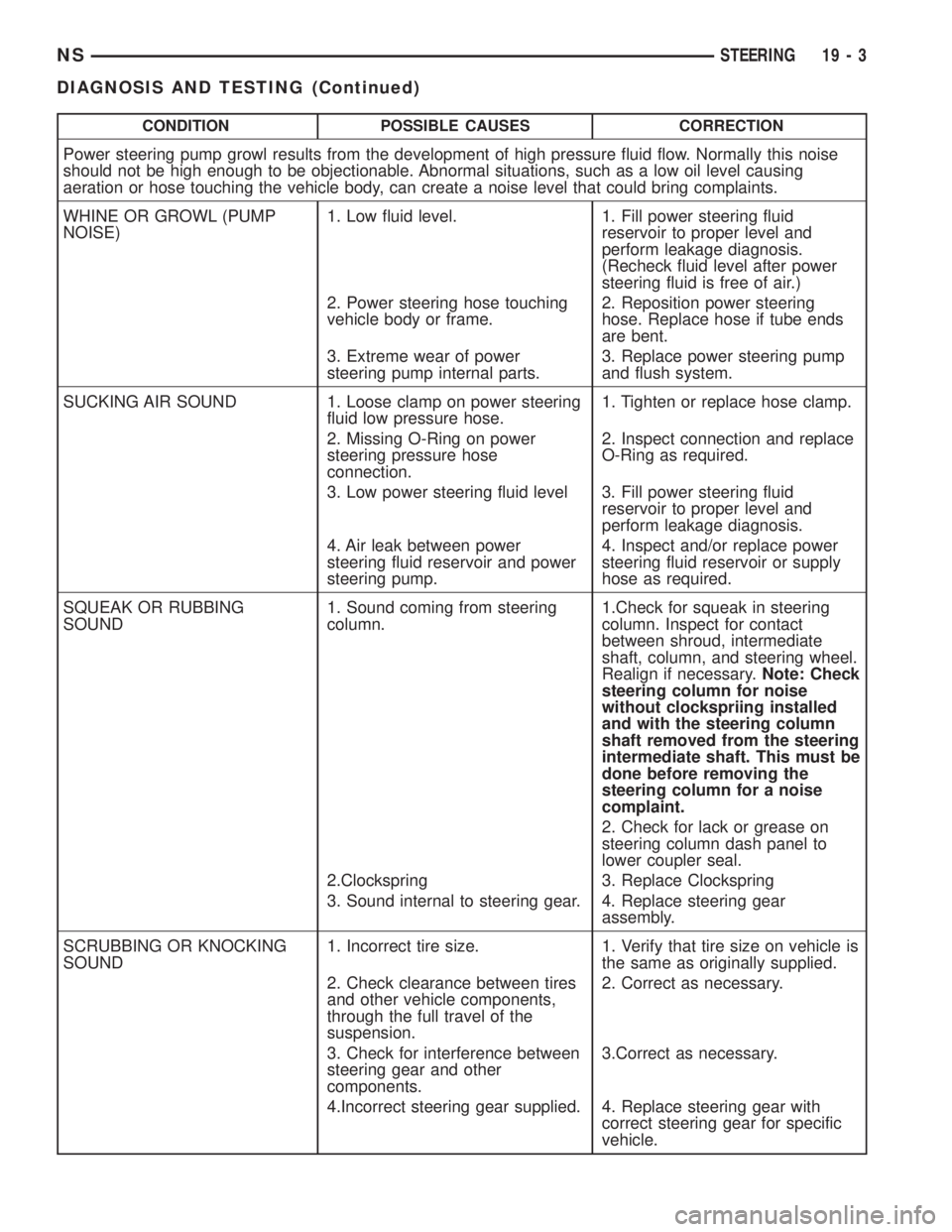

CONDITION POSSIBLE CAUSES CORRECTION

Power steering pump growl results from the development of high pressure fluid flow. Normally this noise

should not be high enough to be objectionable. Abnormal situations, such as a low oil level causing

aeration or hose touching the vehicle body, can create a noise level that could bring complaints.

WHINE OR GROWL (PUMP

NOISE)1. Low fluid level. 1. Fill power steering fluid

reservoir to proper level and

perform leakage diagnosis.

(Recheck fluid level after power

steering fluid is free of air.)

2. Power steering hose touching

vehicle body or frame.2. Reposition power steering

hose. Replace hose if tube ends

are bent.

3. Extreme wear of power

steering pump internal parts.3. Replace power steering pump

and flush system.

SUCKING AIR SOUND 1. Loose clamp on power steering

fluid low pressure hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power

steering pressure hose

connection.2. Inspect connection and replace

O-Ring as required.

3. Low power steering fluid level 3. Fill power steering fluid

reservoir to proper level and

perform leakage diagnosis.

4. Air leak between power

steering fluid reservoir and power

steering pump.4. Inspect and/or replace power

steering fluid reservoir or supply

hose as required.

SQUEAK OR RUBBING

SOUND1. Sound coming from steering

column.1.Check for squeak in steering

column. Inspect for contact

between shroud, intermediate

shaft, column, and steering wheel.

Realign if necessary.Note: Check

steering column for noise

without clockspriing installed

and with the steering column

shaft removed from the steering

intermediate shaft. This must be

done before removing the

steering column for a noise

complaint.

2. Check for lack or grease on

steering column dash panel to

lower coupler seal.

2.Clockspring 3. Replace Clockspring

3. Sound internal to steering gear. 4. Replace steering gear

assembly.

SCRUBBING OR KNOCKING

SOUND1. Incorrect tire size. 1. Verify that tire size on vehicle is

the same as originally supplied.

2. Check clearance between tires

and other vehicle components,

through the full travel of the

suspension.2. Correct as necessary.

3. Check for interference between

steering gear and other

components.3.Correct as necessary.

4.Incorrect steering gear supplied. 4. Replace steering gear with

correct steering gear for specific

vehicle.

NSSTEERING 19 - 3

DIAGNOSIS AND TESTING (Continued)