wheel CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1146 of 1938

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger which will

necessitate replacing the tappet, or by the plunger

partially sticking in the tappet body cylinder. A heavy

click is caused either by a tappet check valve not

seating, or by foreign particles becoming wedged

between the plunger and the tappet body causing the

plunger to stick in the down position. This heavy

click will be accompanied by excessive clearance

between the valve stem and rocker arm as valve

closes. In either case, tappet assembly should be

removed for inspection and cleaning.

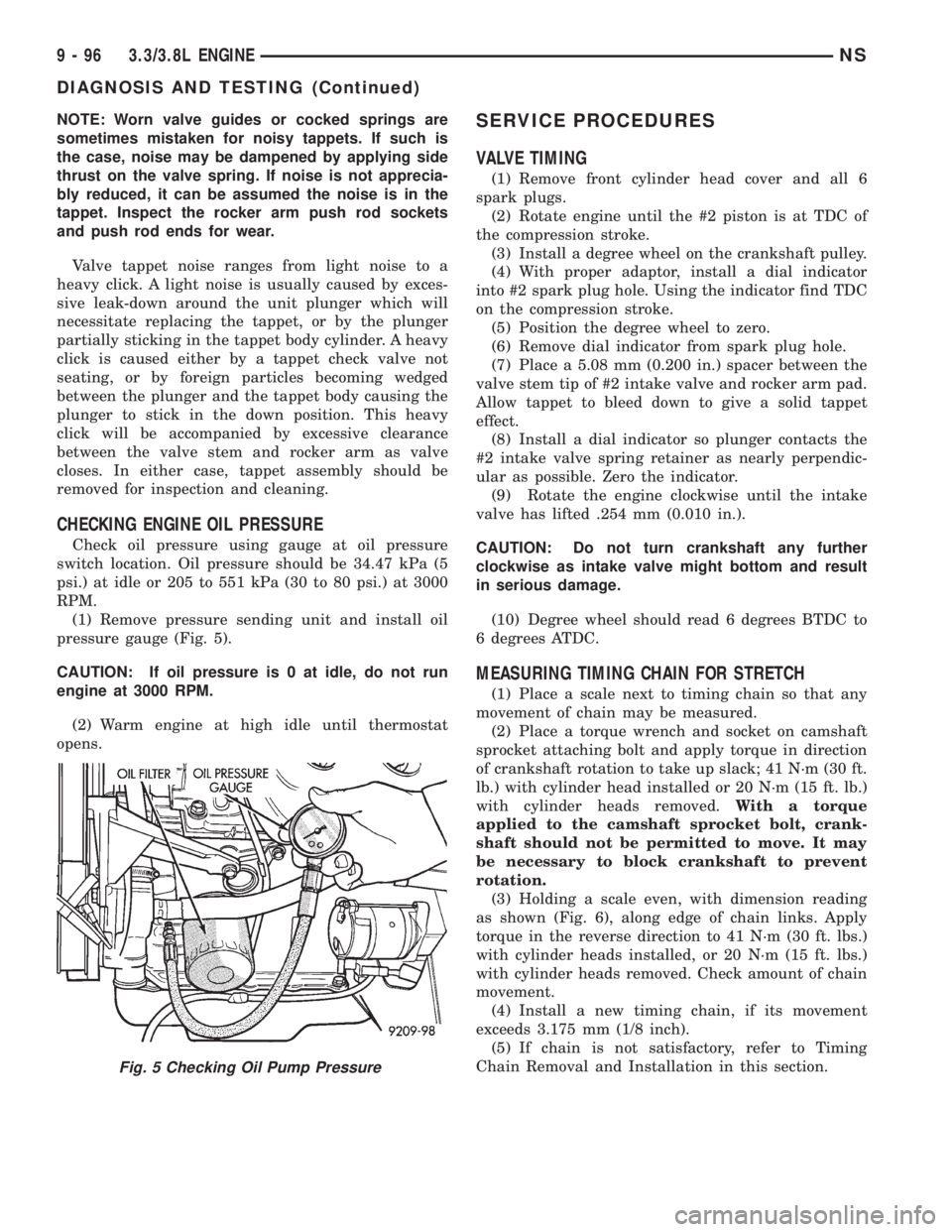

CHECKING ENGINE OIL PRESSURE

Check oil pressure using gauge at oil pressure

switch location. Oil pressure should be 34.47 kPa (5

psi.) at idle or 205 to 551 kPa (30 to 80 psi.) at 3000

RPM.

(1) Remove pressure sending unit and install oil

pressure gauge (Fig. 5).

CAUTION: If oil pressure is 0 at idle, do not run

engine at 3000 RPM.

(2) Warm engine at high idle until thermostat

opens.

SERVICE PROCEDURES

VALVE TIMING

(1) Remove front cylinder head cover and all 6

spark plugs.

(2) Rotate engine until the #2 piston is at TDC of

the compression stroke.

(3) Install a degree wheel on the crankshaft pulley.

(4) With proper adaptor, install a dial indicator

into #2 spark plug hole. Using the indicator find TDC

on the compression stroke.

(5) Position the degree wheel to zero.

(6) Remove dial indicator from spark plug hole.

(7) Place a 5.08 mm (0.200 in.) spacer between the

valve stem tip of #2 intake valve and rocker arm pad.

Allow tappet to bleed down to give a solid tappet

effect.

(8) Install a dial indicator so plunger contacts the

#2 intake valve spring retainer as nearly perpendic-

ular as possible. Zero the indicator.

(9) Rotate the engine clockwise until the intake

valve has lifted .254 mm (0.010 in.).

CAUTION: Do not turn crankshaft any further

clockwise as intake valve might bottom and result

in serious damage.

(10) Degree wheel should read 6 degrees BTDC to

6 degrees ATDC.

MEASURING TIMING CHAIN FOR STRETCH

(1) Place a scale next to timing chain so that any

movement of chain may be measured.

(2) Place a torque wrench and socket on camshaft

sprocket attaching bolt and apply torque in direction

of crankshaft rotation to take up slack; 41 N´m (30 ft.

lb.) with cylinder head installed or 20 N´m (15 ft. lb.)

with cylinder heads removed.With a torque

applied to the camshaft sprocket bolt, crank-

shaft should not be permitted to move. It may

be necessary to block crankshaft to prevent

rotation.

(3) Holding a scale even, with dimension reading

as shown (Fig. 6), along edge of chain links. Apply

torque in the reverse direction to 41 N´m (30 ft. lbs.)

with cylinder heads installed, or 20 N´m (15 ft. lbs.)

with cylinder heads removed. Check amount of chain

movement.

(4) Install a new timing chain, if its movement

exceeds 3.175 mm (1/8 inch).

(5) If chain is not satisfactory, refer to Timing

Chain Removal and Installation in this section.

Fig. 5 Checking Oil Pump Pressure

9 - 96 3.3/3.8L ENGINENS

DIAGNOSIS AND TESTING (Continued)

Page 1153 of 1938

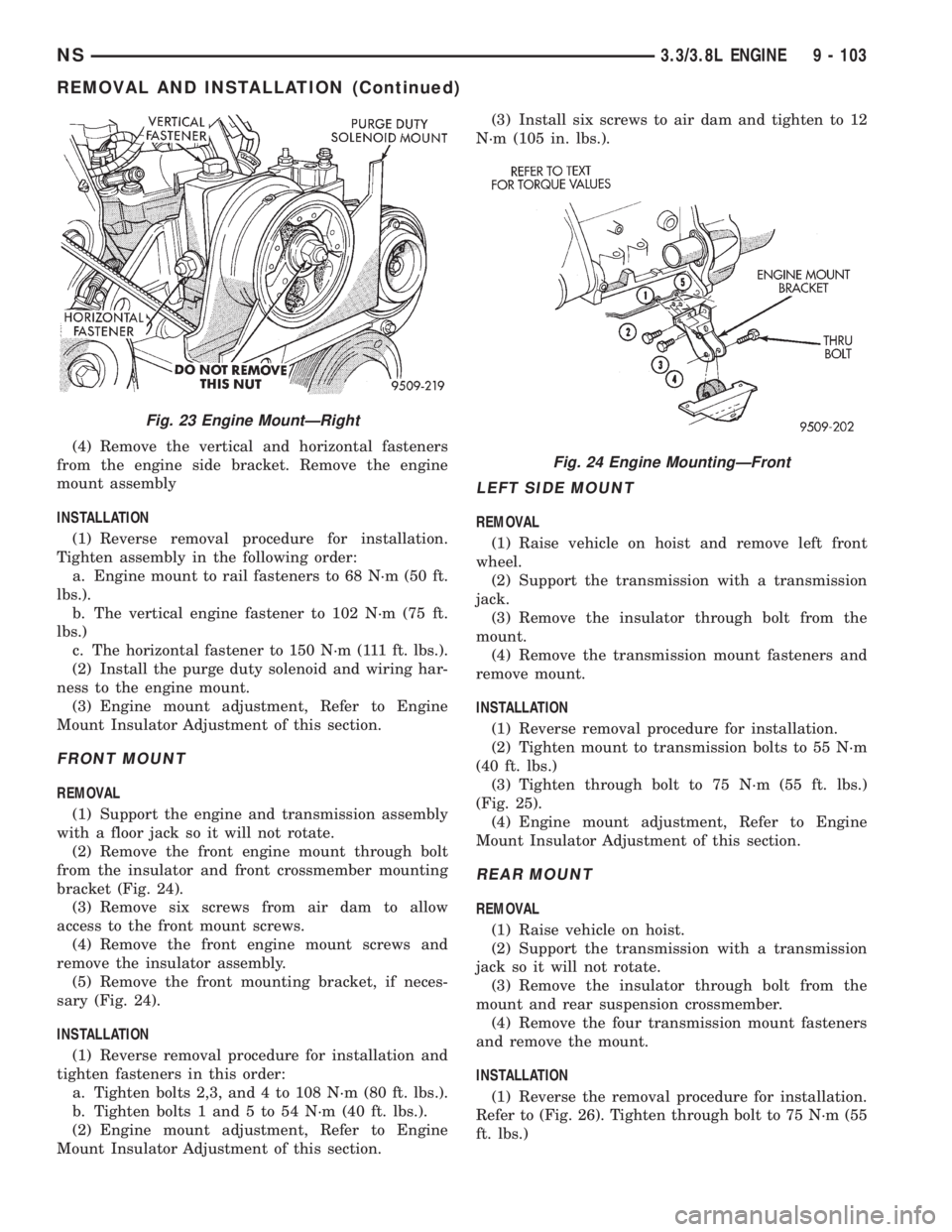

(4) Remove the vertical and horizontal fasteners

from the engine side bracket. Remove the engine

mount assembly

INSTALLATION

(1) Reverse removal procedure for installation.

Tighten assembly in the following order:

a. Engine mount to rail fasteners to 68 N´m (50 ft.

lbs.).

b. The vertical engine fastener to 102 N´m (75 ft.

lbs.)

c. The horizontal fastener to 150 N´m (111 ft. lbs.).

(2) Install the purge duty solenoid and wiring har-

ness to the engine mount.

(3) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

FRONT MOUNT

REMOVAL

(1) Support the engine and transmission assembly

with a floor jack so it will not rotate.

(2) Remove the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 24).

(3) Remove six screws from air dam to allow

access to the front mount screws.

(4) Remove the front engine mount screws and

remove the insulator assembly.

(5) Remove the front mounting bracket, if neces-

sary (Fig. 24).

INSTALLATION

(1) Reverse removal procedure for installation and

tighten fasteners in this order:

a. Tighten bolts 2,3, and 4 to 108 N´m (80 ft. lbs.).

b. Tighten bolts 1 and 5 to 54 N´m (40 ft. lbs.).

(2) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.(3) Install six screws to air dam and tighten to 12

N´m (105 in. lbs.).

LEFT SIDE MOUNT

REMOVAL

(1) Raise vehicle on hoist and remove left front

wheel.

(2) Support the transmission with a transmission

jack.

(3) Remove the insulator through bolt from the

mount.

(4) Remove the transmission mount fasteners and

remove mount.

INSTALLATION

(1) Reverse removal procedure for installation.

(2) Tighten mount to transmission bolts to 55 N´m

(40 ft. lbs.)

(3) Tighten through bolt to 75 N´m (55 ft. lbs.)

(Fig. 25).

(4) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

REAR MOUNT

REMOVAL

(1) Raise vehicle on hoist.

(2) Support the transmission with a transmission

jack so it will not rotate.

(3) Remove the insulator through bolt from the

mount and rear suspension crossmember.

(4) Remove the four transmission mount fasteners

and remove the mount.

INSTALLATION

(1) Reverse the removal procedure for installation.

Refer to (Fig. 26). Tighten through bolt to 75 N´m (55

ft. lbs.)

Fig. 23 Engine MountÐRight

Fig. 24 Engine MountingÐFront

NS3.3/3.8L ENGINE 9 - 103

REMOVAL AND INSTALLATION (Continued)

Page 1156 of 1938

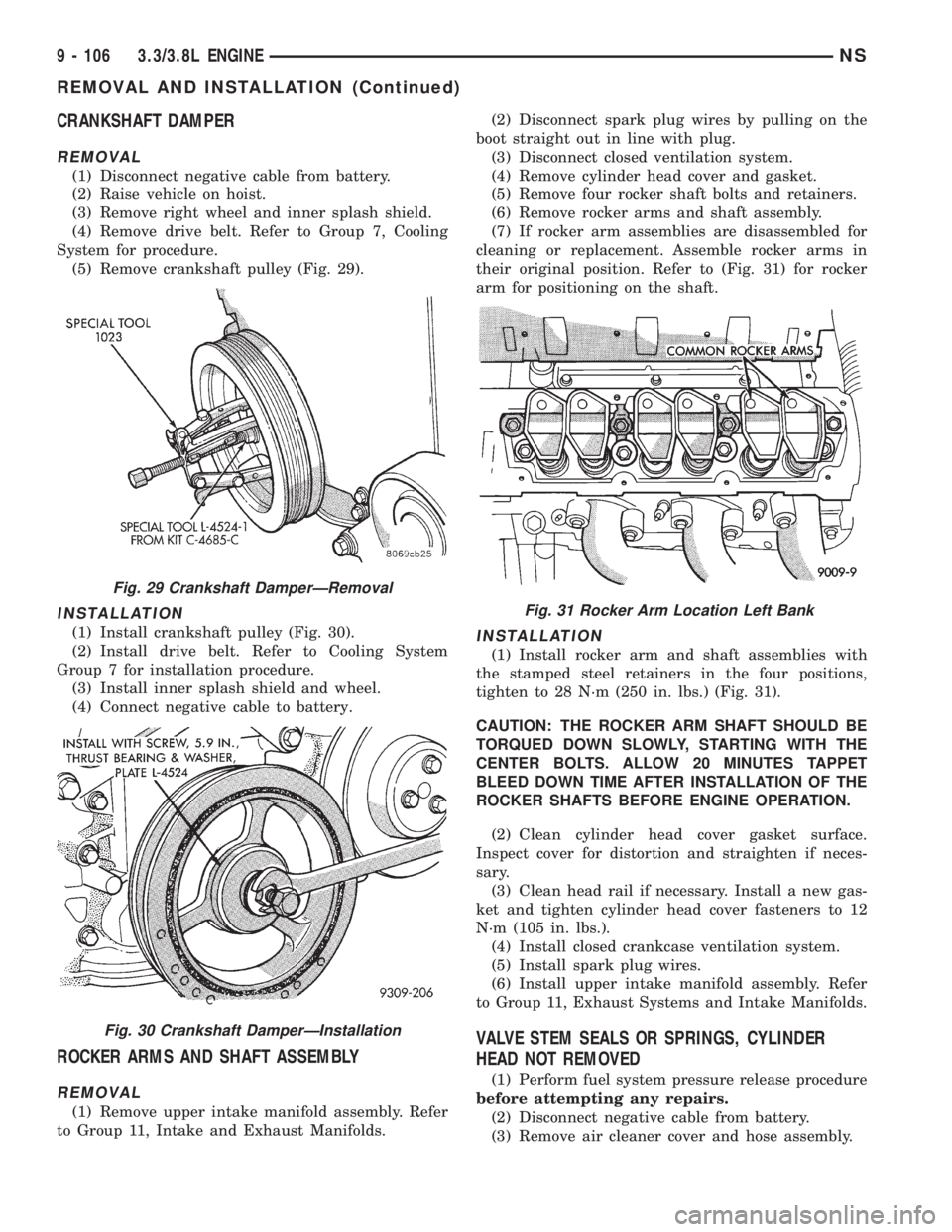

CRANKSHAFT DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Remove right wheel and inner splash shield.

(4) Remove drive belt. Refer to Group 7, Cooling

System for procedure.

(5) Remove crankshaft pulley (Fig. 29).

INSTALLATION

(1) Install crankshaft pulley (Fig. 30).

(2) Install drive belt. Refer to Cooling System

Group 7 for installation procedure.

(3) Install inner splash shield and wheel.

(4) Connect negative cable to battery.

ROCKER ARMS AND SHAFT ASSEMBLY

REMOVAL

(1) Remove upper intake manifold assembly. Refer

to Group 11, Intake and Exhaust Manifolds.(2) Disconnect spark plug wires by pulling on the

boot straight out in line with plug.

(3) Disconnect closed ventilation system.

(4) Remove cylinder head cover and gasket.

(5) Remove four rocker shaft bolts and retainers.

(6) Remove rocker arms and shaft assembly.

(7) If rocker arm assemblies are disassembled for

cleaning or replacement. Assemble rocker arms in

their original position. Refer to (Fig. 31) for rocker

arm for positioning on the shaft.

INSTALLATION

(1) Install rocker arm and shaft assemblies with

the stamped steel retainers in the four positions,

tighten to 28 N´m (250 in. lbs.) (Fig. 31).

CAUTION: THE ROCKER ARM SHAFT SHOULD BE

TORQUED DOWN SLOWLY, STARTING WITH THE

CENTER BOLTS. ALLOW 20 MINUTES TAPPET

BLEED DOWN TIME AFTER INSTALLATION OF THE

ROCKER SHAFTS BEFORE ENGINE OPERATION.

(2) Clean cylinder head cover gasket surface.

Inspect cover for distortion and straighten if neces-

sary.

(3) Clean head rail if necessary. Install a new gas-

ket and tighten cylinder head cover fasteners to 12

N´m (105 in. lbs.).

(4) Install closed crankcase ventilation system.

(5) Install spark plug wires.

(6) Install upper intake manifold assembly. Refer

to Group 11, Exhaust Systems and Intake Manifolds.

VALVE STEM SEALS OR SPRINGS, CYLINDER

HEAD NOT REMOVED

(1) Perform fuel system pressure release procedure

before attempting any repairs.

(2) Disconnect negative cable from battery.

(3) Remove air cleaner cover and hose assembly.

Fig. 29 Crankshaft DamperÐRemoval

Fig. 30 Crankshaft DamperÐInstallation

Fig. 31 Rocker Arm Location Left Bank

9 - 106 3.3/3.8L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1161 of 1938

(6) Start and operate engine. Warm up to normal

operating temperature.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

TIMING CHAIN COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system. Refer to Cooling System

Group 7 for procedure.

(3) Support engine and remove right engine

mount.

(4) Raise vehicle on hoist. Drain engine oil.

(5) Remove oil pan and oil pump pick-up. It may

necessary to remove transaxle inspection cover.

(6) Remove right wheel and inner splash shield.

(7) Remove drive belt. Refer to Cooling System

Group 7 for procedure.

(8) Remove A/C compressor and set aside.

(9) Remove A/C compressor mounting bracket.

(10) Remove crankshaft damper (Fig. 44).

(11) Remove idler pulley from engine bracket.

(12) Remove engine bracket (Fig. 45).

(13) Remove cam sensor from chain case cover

(Fig. 46).

(14) Remove chain case cover (Fig. 46).

INSTALLATION

(1) Be sure mating surfaces of chain case cover

and cylinder block are clean and free from burrs.

Crankshaft oil seal must be removed to insure cor-

rect oil pump engagement.

NOTE: DO NOT USE SEALER ON COVER GASKET

(2) Use a new cover gasket, and O-rings (Fig. 47).

Adhere new gasket to chain case cover, making surethat the lower edge of the gasket is flush to 0.5 mm

(0.020 in.) passed the lower edge of the cover. Refer

to Oil Pan sealing outlined in this section.

Fig. 43 Roller Tappets Aligning Yoke and Retainer

Fig. 44 Crankshaft DamperÐRemoval

Fig. 45 Engine Bracket

Fig. 46 Timing Chain Case Cover

NS3.3/3.8L ENGINE 9 - 111

REMOVAL AND INSTALLATION (Continued)

Page 1162 of 1938

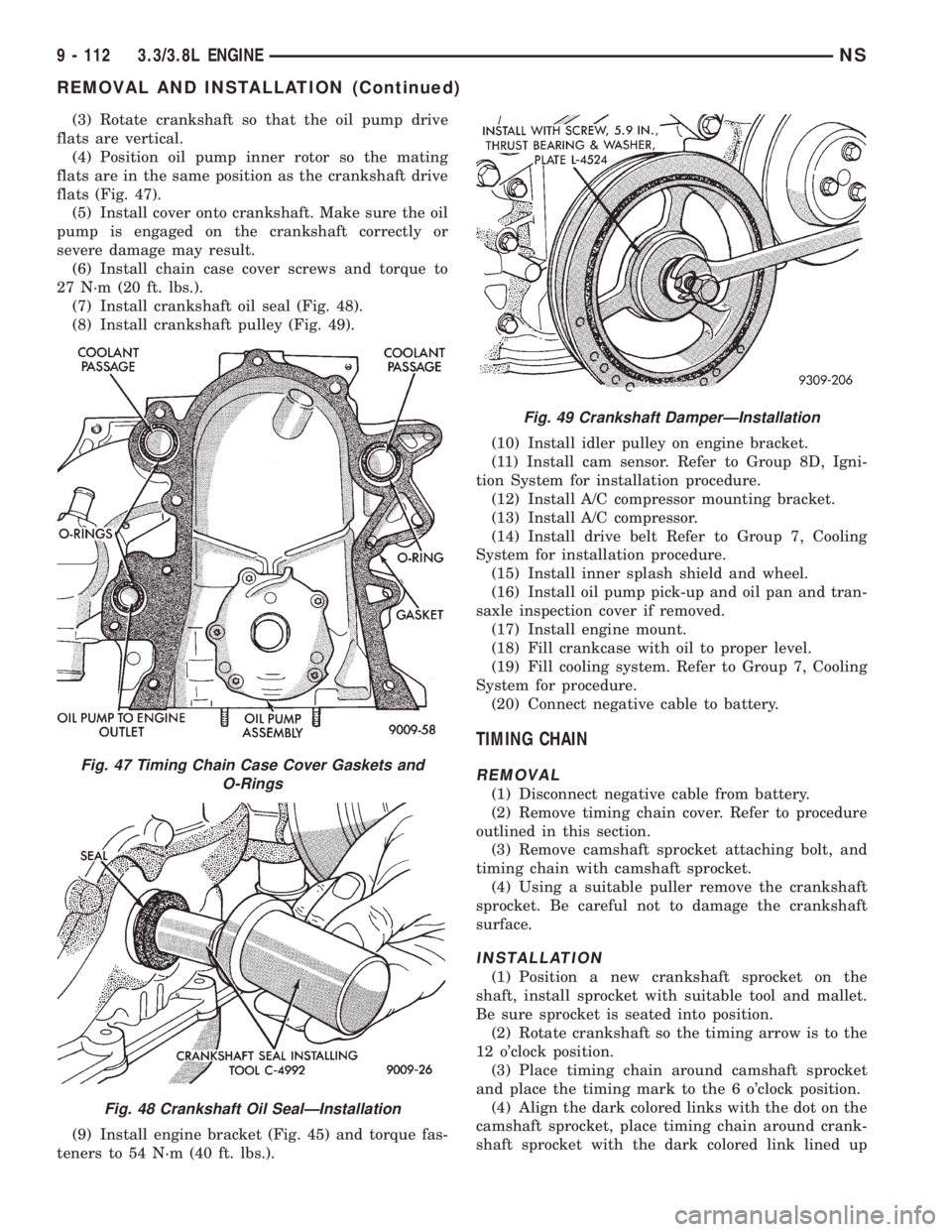

(3) Rotate crankshaft so that the oil pump drive

flats are vertical.

(4) Position oil pump inner rotor so the mating

flats are in the same position as the crankshaft drive

flats (Fig. 47).

(5) Install cover onto crankshaft. Make sure the oil

pump is engaged on the crankshaft correctly or

severe damage may result.

(6) Install chain case cover screws and torque to

27 N´m (20 ft. lbs.).

(7) Install crankshaft oil seal (Fig. 48).

(8) Install crankshaft pulley (Fig. 49).

(9) Install engine bracket (Fig. 45) and torque fas-

teners to 54 N´m (40 ft. lbs.).(10) Install idler pulley on engine bracket.

(11) Install cam sensor. Refer to Group 8D, Igni-

tion System for installation procedure.

(12) Install A/C compressor mounting bracket.

(13) Install A/C compressor.

(14) Install drive belt Refer to Group 7, Cooling

System for installation procedure.

(15) Install inner splash shield and wheel.

(16) Install oil pump pick-up and oil pan and tran-

saxle inspection cover if removed.

(17) Install engine mount.

(18) Fill crankcase with oil to proper level.

(19) Fill cooling system. Refer to Group 7, Cooling

System for procedure.

(20) Connect negative cable to battery.

TIMING CHAIN

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove timing chain cover. Refer to procedure

outlined in this section.

(3) Remove camshaft sprocket attaching bolt, and

timing chain with camshaft sprocket.

(4) Using a suitable puller remove the crankshaft

sprocket. Be careful not to damage the crankshaft

surface.

INSTALLATION

(1) Position a new crankshaft sprocket on the

shaft, install sprocket with suitable tool and mallet.

Be sure sprocket is seated into position.

(2) Rotate crankshaft so the timing arrow is to the

12 o'clock position.

(3) Place timing chain around camshaft sprocket

and place the timing mark to the 6 o'clock position.

(4) Align the dark colored links with the dot on the

camshaft sprocket, place timing chain around crank-

shaft sprocket with the dark colored link lined up

Fig. 47 Timing Chain Case Cover Gaskets and

O-Rings

Fig. 48 Crankshaft Oil SealÐInstallation

Fig. 49 Crankshaft DamperÐInstallation

9 - 112 3.3/3.8L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1167 of 1938

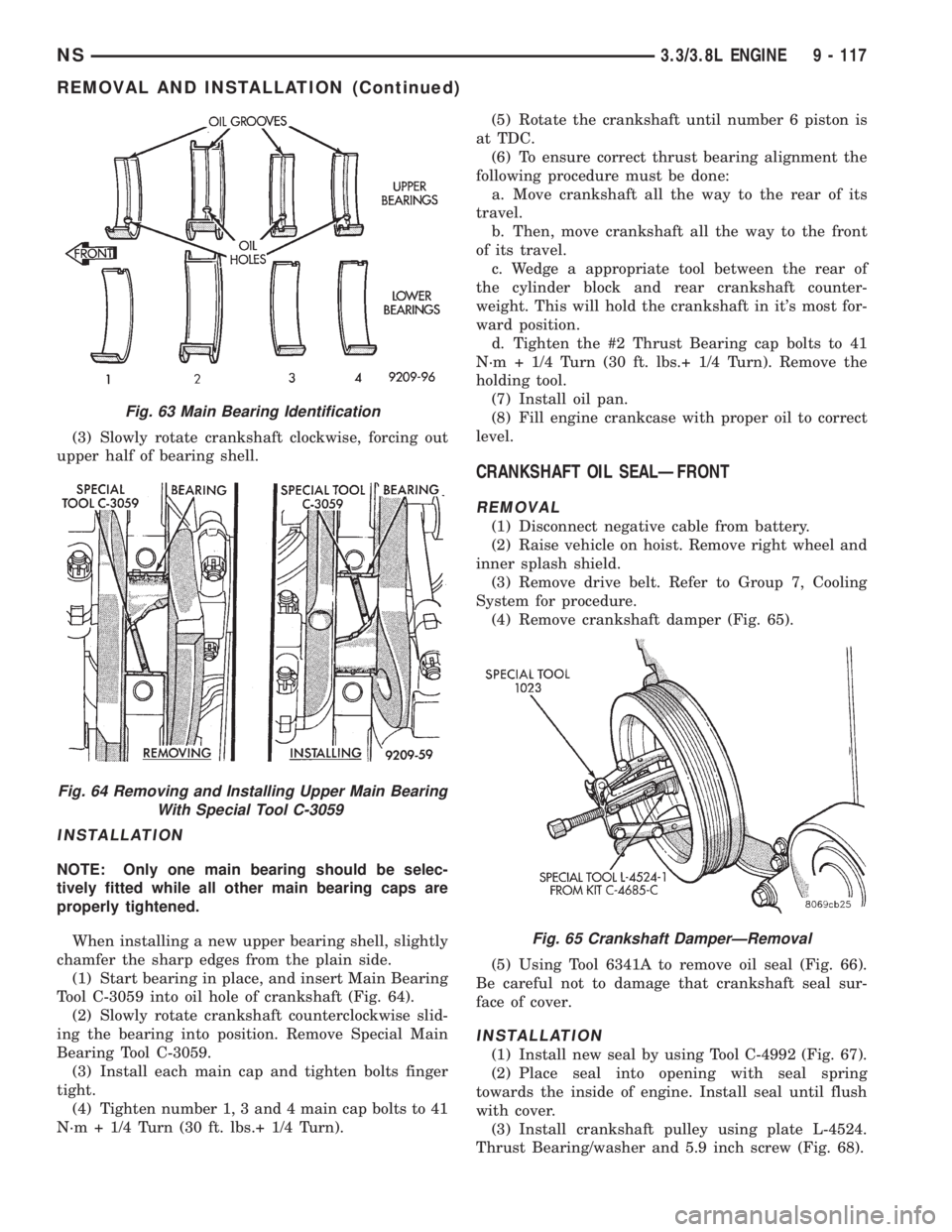

(3) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION

NOTE: Only one main bearing should be selec-

tively fitted while all other main bearing caps are

properly tightened.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

(1) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 64).

(2) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

(3) Install each main cap and tighten bolts finger

tight.

(4) Tighten number 1, 3 and 4 main cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn).(5) Rotate the crankshaft until number 6 piston is

at TDC.

(6) To ensure correct thrust bearing alignment the

following procedure must be done:

a. Move crankshaft all the way to the rear of its

travel.

b. Then, move crankshaft all the way to the front

of its travel.

c. Wedge a appropriate tool between the rear of

the cylinder block and rear crankshaft counter-

weight. This will hold the crankshaft in it's most for-

ward position.

d. Tighten the #2 Thrust Bearing cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn). Remove the

holding tool.

(7) Install oil pan.

(8) Fill engine crankcase with proper oil to correct

level.

CRANKSHAFT OIL SEALÐFRONT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist. Remove right wheel and

inner splash shield.

(3) Remove drive belt. Refer to Group 7, Cooling

System for procedure.

(4) Remove crankshaft damper (Fig. 65).

(5) Using Tool 6341A to remove oil seal (Fig. 66).

Be careful not to damage that crankshaft seal sur-

face of cover.

INSTALLATION

(1) Install new seal by using Tool C-4992 (Fig. 67).

(2) Place seal into opening with seal spring

towards the inside of engine. Install seal until flush

with cover.

(3) Install crankshaft pulley using plate L-4524.

Thrust Bearing/washer and 5.9 inch screw (Fig. 68).

Fig. 63 Main Bearing Identification

Fig. 64 Removing and Installing Upper Main Bearing

With Special Tool C-3059

Fig. 65 Crankshaft DamperÐRemoval

NS3.3/3.8L ENGINE 9 - 117

REMOVAL AND INSTALLATION (Continued)

Page 1168 of 1938

(4) Install drive belt Refer to Group 7, Cooling

System for installation procedure.

(5) Install inner splash shield and wheel.

(6) Lower vehicle and connect negative cable to

battery.

CRANKSHAFT OIL SEALÐREAR

REMOVAL

(1) Insert a 3/16 flat bladed pry tool between the

dust lip and the metal case of the crankshaft seal.

Angle the pry tool (Fig. 69) through the dust lip

against metal case of the seal. Pry out seal.

CAUTION: Do not permit the pry tool blade to con-

tact crankshaft seal surface. Contact of the pry toolblade against crankshaft edge (chamfer) is permit-

ted.

INSTALLATION

CAUTION: If burr or scratch is present on the

crankshaft edge (chamfer), cleanup with 400 grit

sand paper to prevent seal damage during installa-

tion of new seal.

(1) Place Special Tool 6926-1 magnetic pilot tool on

crankshaft (Fig. 70).

(2) Lightly coat seal O.D. with MopartStud N'

Bearing Mount Adhesive or equivalent.

(3) Place seal over Special Tool 6926-1 Pilot. Using

Special Tool 6926-2 Installer with C-4171 Handle,

drive seal into the retainer housing (Fig. 70).

REAR CRANKSHAFT SEAL RETAINER

When retainer removal is required, remove

retainer and clean engine block and retainer of old

gasket. Make sure surfaces are clean and free of oil.

Fig. 66 Front Crankshaft Oil SealÐRemoval

Fig. 67 Crankshaft Oil SealÐInstallation

Fig. 68 Crankshaft DamperÐInstallation

Fig. 69 Rear Crankshaft Oil SealÐRemoval

9 - 118 3.3/3.8L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1181 of 1938

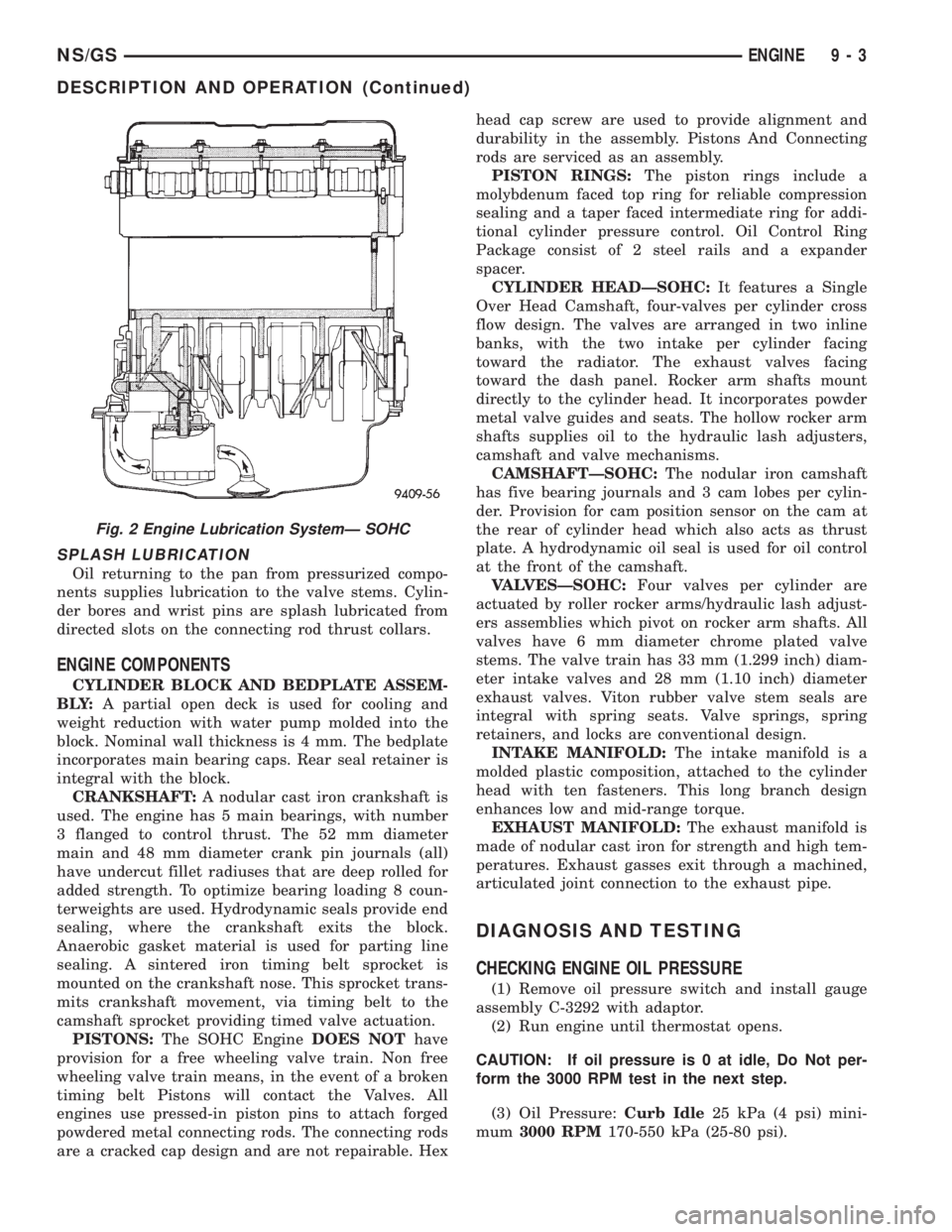

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylin-

der bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

ENGINE COMPONENTS

CYLINDER BLOCK AND BEDPLATE ASSEM-

B LY:A partial open deck is used for cooling and

weight reduction with water pump molded into the

block. Nominal wall thickness is 4 mm. The bedplate

incorporates main bearing caps. Rear seal retainer is

integral with the block.

CRANKSHAFT:A nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 52 mm diameter

main and 48 mm diameter crank pin journals (all)

have undercut fillet radiuses that are deep rolled for

added strength. To optimize bearing loading 8 coun-

terweights are used. Hydrodynamic seals provide end

sealing, where the crankshaft exits the block.

Anaerobic gasket material is used for parting line

sealing. A sintered iron timing belt sprocket is

mounted on the crankshaft nose. This sprocket trans-

mits crankshaft movement, via timing belt to the

camshaft sprocket providing timed valve actuation.

PISTONS:The SOHC EngineDOES NOThave

provision for a free wheeling valve train. Non free

wheeling valve train means, in the event of a broken

timing belt Pistons will contact the Valves. All

engines use pressed-in piston pins to attach forged

powdered metal connecting rods. The connecting rods

are a cracked cap design and are not repairable. Hexhead cap screw are used to provide alignment and

durability in the assembly. Pistons And Connecting

rods are serviced as an assembly.

PISTON RINGS:The piston rings include a

molybdenum faced top ring for reliable compression

sealing and a taper faced intermediate ring for addi-

tional cylinder pressure control. Oil Control Ring

Package consist of 2 steel rails and a expander

spacer.

CYLINDER HEADÐSOHC:It features a Single

Over Head Camshaft, four-valves per cylinder cross

flow design. The valves are arranged in two inline

banks, with the two intake per cylinder facing

toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFTÐSOHC:The nodular iron camshaft

has five bearing journals and 3 cam lobes per cylin-

der. Provision for cam position sensor on the cam at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVESÐSOHC:Four valves per cylinder are

actuated by roller rocker arms/hydraulic lash adjust-

ers assemblies which pivot on rocker arm shafts. All

valves have 6 mm diameter chrome plated valve

stems. The valve train has 33 mm (1.299 inch) diam-

eter intake valves and 28 mm (1.10 inch) diameter

exhaust valves. Viton rubber valve stem seals are

integral with spring seats. Valve springs, spring

retainers, and locks are conventional design.

INTAKE MANIFOLD:The intake manifold is a

molded plastic composition, attached to the cylinder

head with ten fasteners. This long branch design

enhances low and mid-range torque.

EXHAUST MANIFOLD:The exhaust manifold is

made of nodular cast iron for strength and high tem-

peratures. Exhaust gasses exit through a machined,

articulated joint connection to the exhaust pipe.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

Fig. 2 Engine Lubrication SystemÐ SOHC

NS/GSENGINE 9 - 3

DESCRIPTION AND OPERATION (Continued)

Page 1221 of 1938

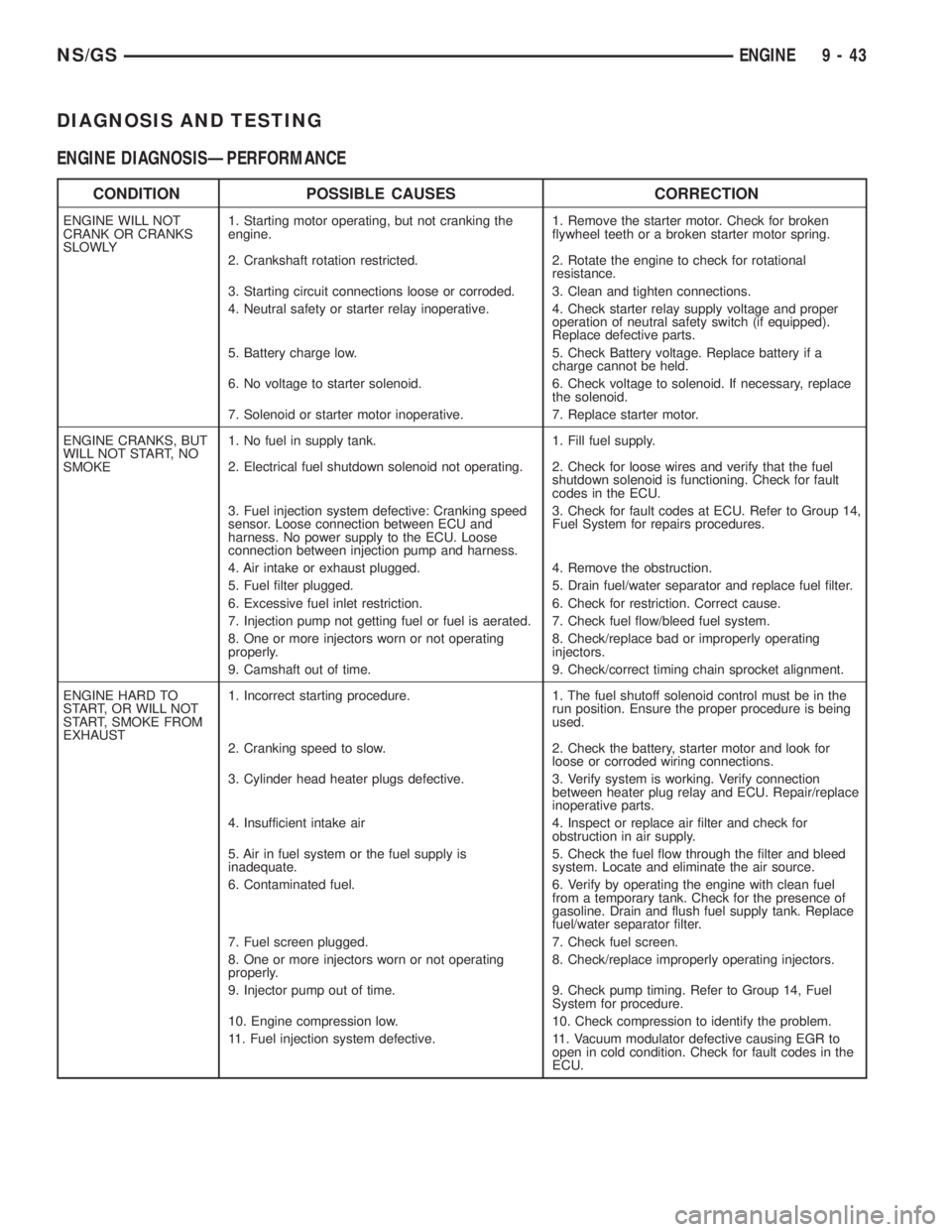

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐPERFORMANCE

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT

CRANK OR CRANKS

SLOWLY1. Starting motor operating, but not cranking the

engine.1. Remove the starter motor. Check for broken

flywheel teeth or a broken starter motor spring.

2. Crankshaft rotation restricted. 2. Rotate the engine to check for rotational

resistance.

3. Starting circuit connections loose or corroded. 3. Clean and tighten connections.

4. Neutral safety or starter relay inoperative. 4. Check starter relay supply voltage and proper

operation of neutral safety switch (if equipped).

Replace defective parts.

5. Battery charge low. 5. Check Battery voltage. Replace battery if a

charge cannot be held.

6. No voltage to starter solenoid. 6. Check voltage to solenoid. If necessary, replace

the solenoid.

7. Solenoid or starter motor inoperative. 7. Replace starter motor.

ENGINE CRANKS, BUT

WILL NOT START, NO

SMOKE1. No fuel in supply tank. 1. Fill fuel supply.

2. Electrical fuel shutdown solenoid not operating. 2. Check for loose wires and verify that the fuel

shutdown solenoid is functioning. Check for fault

codes in the ECU.

3. Fuel injection system defective: Cranking speed

sensor. Loose connection between ECU and

harness. No power supply to the ECU. Loose

connection between injection pump and harness.3. Check for fault codes at ECU. Refer to Group 14,

Fuel System for repairs procedures.

4. Air intake or exhaust plugged. 4. Remove the obstruction.

5. Fuel filter plugged. 5. Drain fuel/water separator and replace fuel filter.

6. Excessive fuel inlet restriction. 6. Check for restriction. Correct cause.

7. Injection pump not getting fuel or fuel is aerated. 7. Check fuel flow/bleed fuel system.

8. One or more injectors worn or not operating

properly.8. Check/replace bad or improperly operating

injectors.

9. Camshaft out of time. 9. Check/correct timing chain sprocket alignment.

ENGINE HARD TO

START, OR WILL NOT

START, SMOKE FROM

EXHAUST1. Incorrect starting procedure. 1. The fuel shutoff solenoid control must be in the

run position. Ensure the proper procedure is being

used.

2. Cranking speed to slow. 2. Check the battery, starter motor and look for

loose or corroded wiring connections.

3. Cylinder head heater plugs defective. 3. Verify system is working. Verify connection

between heater plug relay and ECU. Repair/replace

inoperative parts.

4. Insufficient intake air 4. Inspect or replace air filter and check for

obstruction in air supply.

5. Air in fuel system or the fuel supply is

inadequate.5. Check the fuel flow through the filter and bleed

system. Locate and eliminate the air source.

6. Contaminated fuel. 6. Verify by operating the engine with clean fuel

from a temporary tank. Check for the presence of

gasoline. Drain and flush fuel supply tank. Replace

fuel/water separator filter.

7. Fuel screen plugged. 7. Check fuel screen.

8. One or more injectors worn or not operating

properly.8. Check/replace improperly operating injectors.

9. Injector pump out of time. 9. Check pump timing. Refer to Group 14, Fuel

System for procedure.

10. Engine compression low. 10. Check compression to identify the problem.

11. Fuel injection system defective. 11. Vacuum modulator defective causing EGR to

open in cold condition. Check for fault codes in the

ECU.

NS/GSENGINE 9 - 43

Page 1223 of 1938

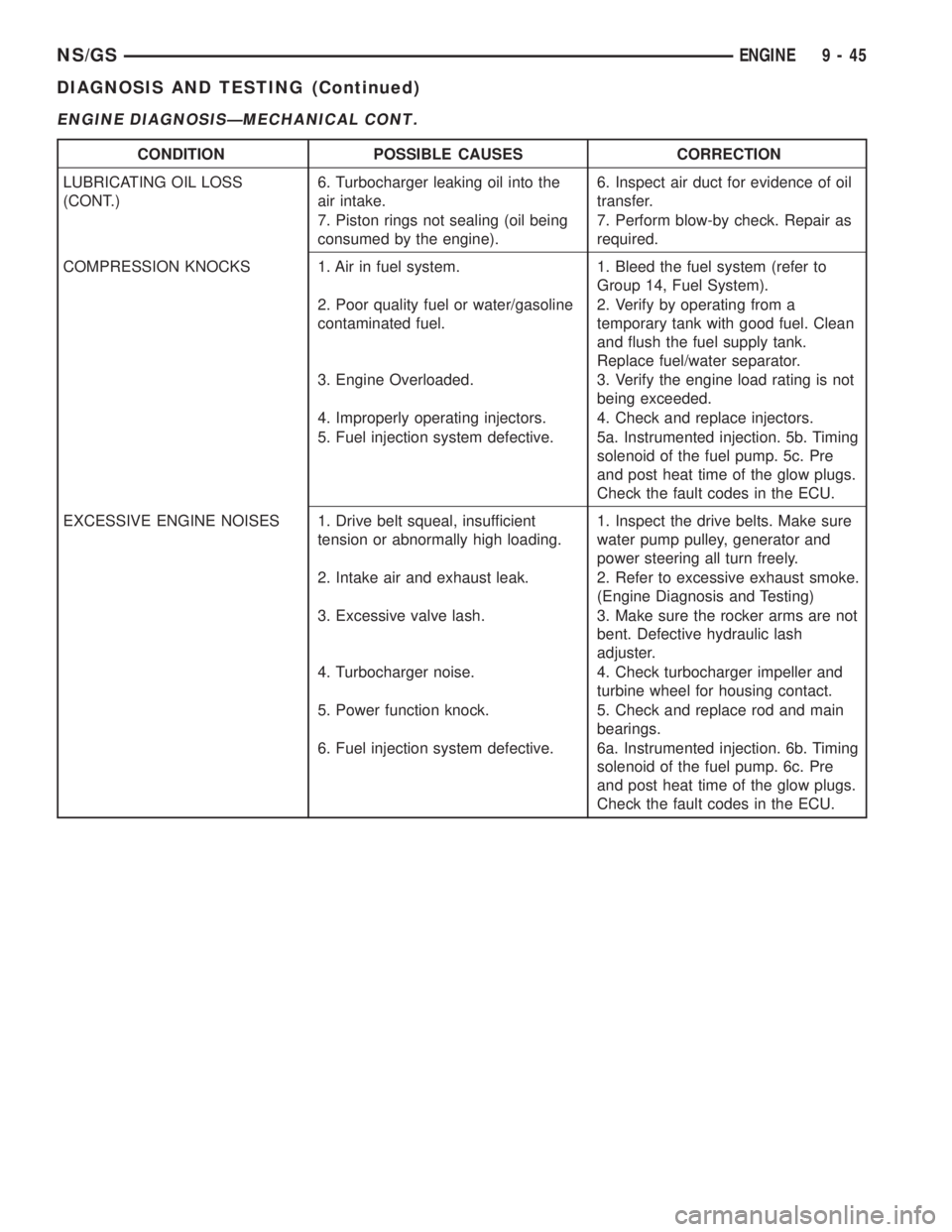

ENGINE DIAGNOSISÐMECHANICAL CONT.

CONDITION POSSIBLE CAUSES CORRECTION

LUBRICATING OIL LOSS

(CONT.)6. Turbocharger leaking oil into the

air intake.6. Inspect air duct for evidence of oil

transfer.

7. Piston rings not sealing (oil being

consumed by the engine).7. Perform blow-by check. Repair as

required.

COMPRESSION KNOCKS 1. Air in fuel system. 1. Bleed the fuel system (refer to

Group 14, Fuel System).

2. Poor quality fuel or water/gasoline

contaminated fuel.2. Verify by operating from a

temporary tank with good fuel. Clean

and flush the fuel supply tank.

Replace fuel/water separator.

3. Engine Overloaded. 3. Verify the engine load rating is not

being exceeded.

4. Improperly operating injectors. 4. Check and replace injectors.

5. Fuel injection system defective. 5a. Instrumented injection. 5b. Timing

solenoid of the fuel pump. 5c. Pre

and post heat time of the glow plugs.

Check the fault codes in the ECU.

EXCESSIVE ENGINE NOISES 1. Drive belt squeal, insufficient

tension or abnormally high loading.1. Inspect the drive belts. Make sure

water pump pulley, generator and

power steering all turn freely.

2. Intake air and exhaust leak. 2. Refer to excessive exhaust smoke.

(Engine Diagnosis and Testing)

3. Excessive valve lash. 3. Make sure the rocker arms are not

bent. Defective hydraulic lash

adjuster.

4. Turbocharger noise. 4. Check turbocharger impeller and

turbine wheel for housing contact.

5. Power function knock. 5. Check and replace rod and main

bearings.

6. Fuel injection system defective. 6a. Instrumented injection. 6b. Timing

solenoid of the fuel pump. 6c. Pre

and post heat time of the glow plugs.

Check the fault codes in the ECU.

NS/GSENGINE 9 - 45

DIAGNOSIS AND TESTING (Continued)