shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1328 of 1938

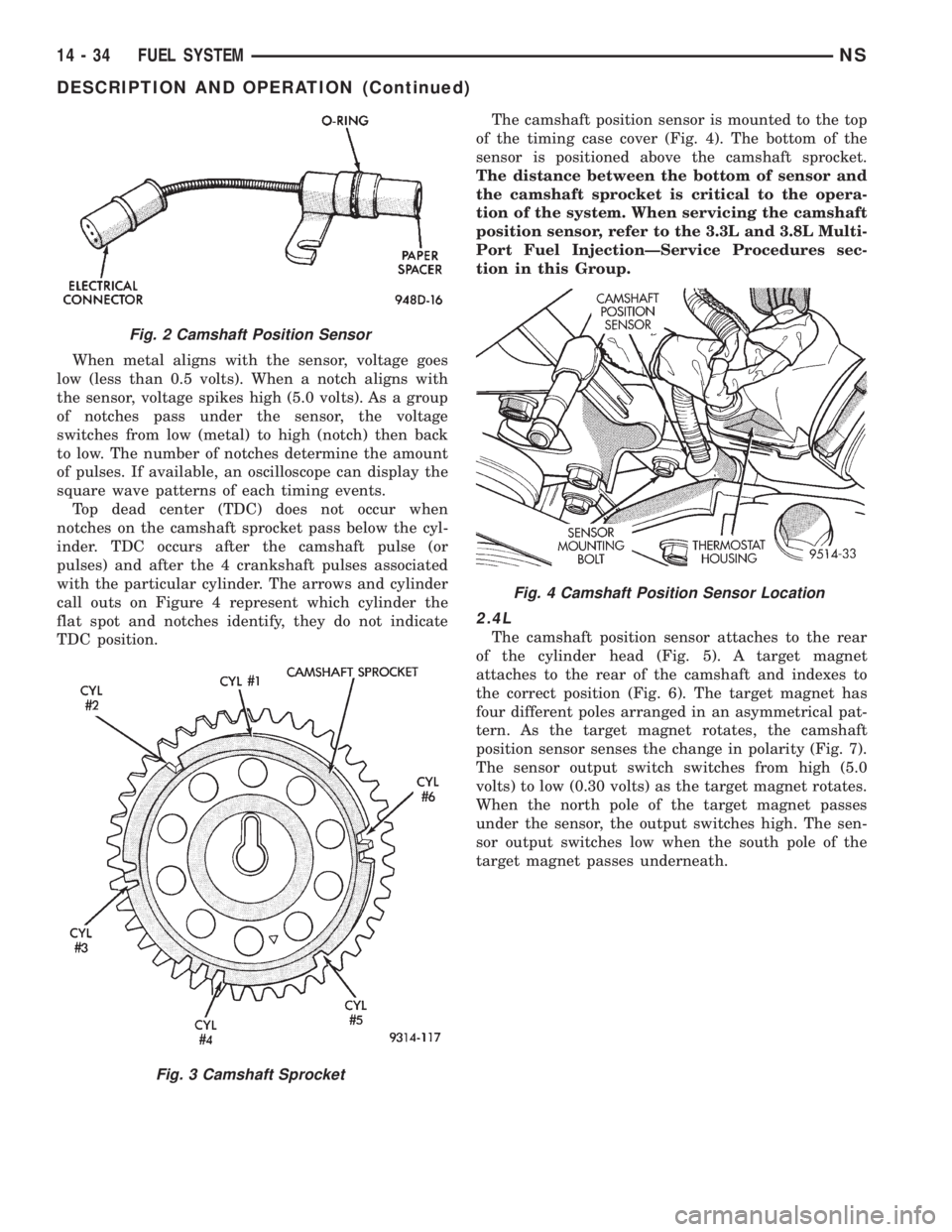

When metal aligns with the sensor, voltage goes

low (less than 0.5 volts). When a notch aligns with

the sensor, voltage spikes high (5.0 volts). As a group

of notches pass under the sensor, the voltage

switches from low (metal) to high (notch) then back

to low. The number of notches determine the amount

of pulses. If available, an oscilloscope can display the

square wave patterns of each timing events.

Top dead center (TDC) does not occur when

notches on the camshaft sprocket pass below the cyl-

inder. TDC occurs after the camshaft pulse (or

pulses) and after the 4 crankshaft pulses associated

with the particular cylinder. The arrows and cylinder

call outs on Figure 4 represent which cylinder the

flat spot and notches identify, they do not indicate

TDC position.The camshaft position sensor is mounted to the top

of the timing case cover (Fig. 4). The bottom of the

sensor is positioned above the camshaft sprocket.

The distance between the bottom of sensor and

the camshaft sprocket is critical to the opera-

tion of the system. When servicing the camshaft

position sensor, refer to the 3.3L and 3.8L Multi-

Port Fuel InjectionÐService Procedures sec-

tion in this Group.

2.4L

The camshaft position sensor attaches to the rear

of the cylinder head (Fig. 5). A target magnet

attaches to the rear of the camshaft and indexes to

the correct position (Fig. 6). The target magnet has

four different poles arranged in an asymmetrical pat-

tern. As the target magnet rotates, the camshaft

position sensor senses the change in polarity (Fig. 7).

The sensor output switch switches from high (5.0

volts) to low (0.30 volts) as the target magnet rotates.

When the north pole of the target magnet passes

under the sensor, the output switches high. The sen-

sor output switches low when the south pole of the

target magnet passes underneath.

Fig. 2 Camshaft Position Sensor

Fig. 3 Camshaft Sprocket

Fig. 4 Camshaft Position Sensor Location

14 - 34 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1329 of 1938

CRANKSHAFT POSITION SENSORÐPCM INPUT

3.0/3.3/3.8L

The crankshaft position sensor (Fig. 8) senses slots

cut into the transaxle driveplate extension. There are

3 sets of slots. Each set contains 4 slots, for a total of

12 slots (Fig. 9). Basic timing is set by the position of

the last slot in each group. Once the PCM senses the

last slot, it determines crankshaft position (which

piston will next be at TDC) from the camshaft posi-

tion sensor input. It may take the PCM one engine

revolution to determine crankshaft position.

The PCM uses the crankshaft position sensor sig-

nal to determine injector sequence, ignition timing

and presence of misfire. Once crankshaft position has

been determined, the PCM begins energizing the

injectors in sequence.

Fig. 5 Camshaft Position Sensor

Fig. 6 Target Magnet

Fig. 7 Target Magnet Polarity

Fig. 8 Crankshaft Position Sensor

Fig. 9 Timing Slots

NSFUEL SYSTEM 14 - 35

DESCRIPTION AND OPERATION (Continued)

Page 1330 of 1938

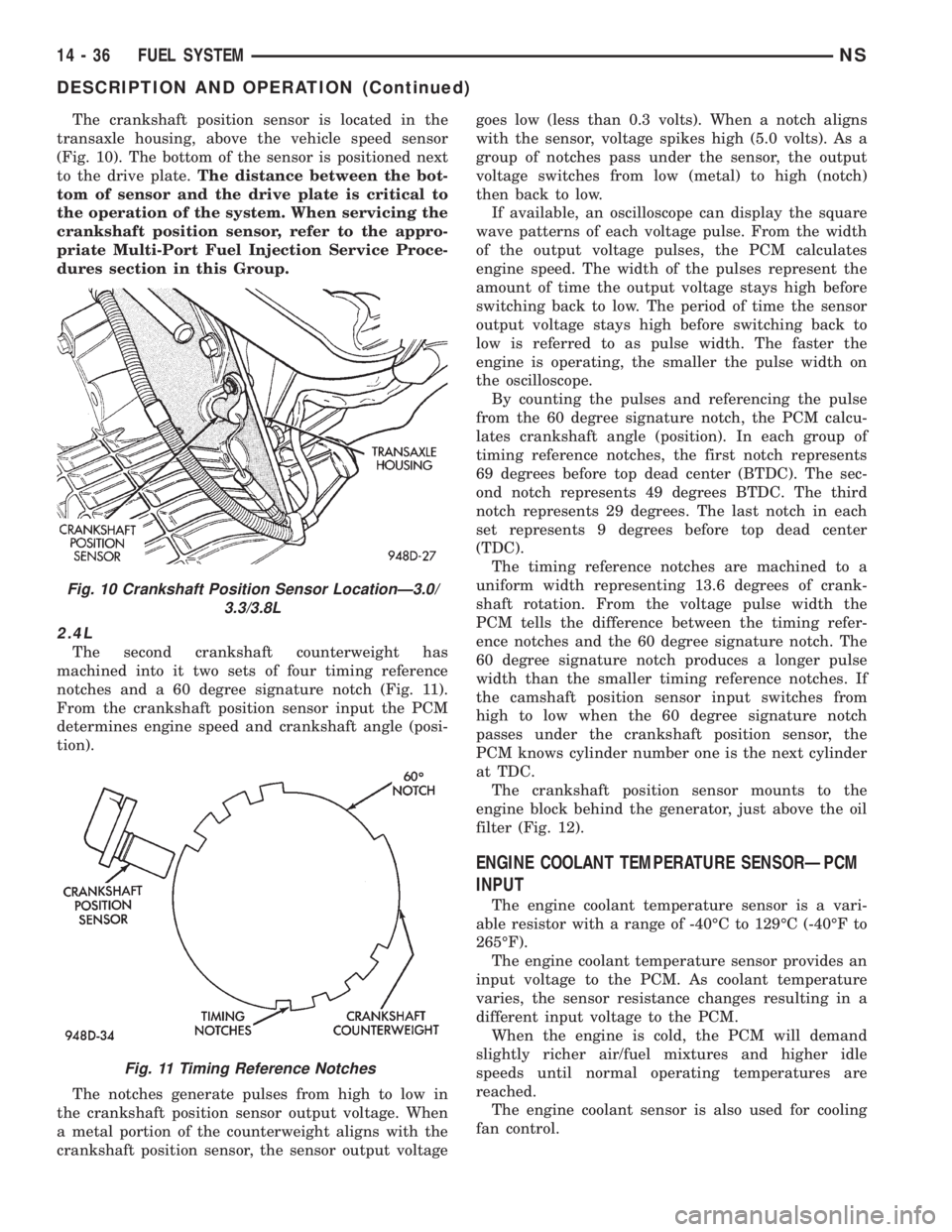

The crankshaft position sensor is located in the

transaxle housing, above the vehicle speed sensor

(Fig. 10). The bottom of the sensor is positioned next

to the drive plate.The distance between the bot-

tom of sensor and the drive plate is critical to

the operation of the system. When servicing the

crankshaft position sensor, refer to the appro-

priate Multi-Port Fuel Injection Service Proce-

dures section in this Group.

2.4L

The second crankshaft counterweight has

machined into it two sets of four timing reference

notches and a 60 degree signature notch (Fig. 11).

From the crankshaft position sensor input the PCM

determines engine speed and crankshaft angle (posi-

tion).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltagegoes low (less than 0.3 volts). When a notch aligns

with the sensor, voltage spikes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.

If available, an oscilloscope can display the square

wave patterns of each voltage pulse. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined to a

uniform width representing 13.6 degrees of crank-

shaft rotation. From the voltage pulse width the

PCM tells the difference between the timing refer-

ence notches and the 60 degree signature notch. The

60 degree signature notch produces a longer pulse

width than the smaller timing reference notches. If

the camshaft position sensor input switches from

high to low when the 60 degree signature notch

passes under the crankshaft position sensor, the

PCM knows cylinder number one is the next cylinder

at TDC.

The crankshaft position sensor mounts to the

engine block behind the generator, just above the oil

filter (Fig. 12).

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The engine coolant temperature sensor is a vari-

able resistor with a range of -40ÉC to 129ÉC (-40ÉF to

265ÉF).

The engine coolant temperature sensor provides an

input voltage to the PCM. As coolant temperature

varies, the sensor resistance changes resulting in a

different input voltage to the PCM.

When the engine is cold, the PCM will demand

slightly richer air/fuel mixtures and higher idle

speeds until normal operating temperatures are

reached.

The engine coolant sensor is also used for cooling

fan control.

Fig. 10 Crankshaft Position Sensor LocationÐ3.0/

3.3/3.8L

Fig. 11 Timing Reference Notches

14 - 36 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1331 of 1938

3.0/3.3/3.8L

The sensor is installed next to the thermostat

housing (Fig. 13) and (Fig. 14).

2.4L

The coolant sensor threads into the top of the ther-

mostat housing (Fig. 15). New sensors have sealant

applied to the threads.

HEATED OXYGEN SENSOR (O2S SENSOR)ÐPCM

INPUT

The O2S produce voltages from 0 to 1 volt, depend-

ing upon the oxygen content of the exhaust gas in

the exhaust manifold. When a large amount of oxy-

gen is present (caused by a lean air/fuel mixture), the

sensors produces a low voltage. When there is a

lesser amount present (rich air/fuel mixture) it pro-

duces a higher voltage. By monitoring the oxygen

content and converting it to electrical voltage, the

sensors act as a rich- lean switch.

The oxygen sensors are equipped with a heating

element that keeps the sensors at proper operating

temperature during all operating modes. Maintaining

correct sensor temperature at all times allows the

Fig. 12 Crankshaft Position SensorÐ2.4L

Fig. 13 Engine Coolant Temperature SensorÐ3.3/

3.8L

Fig. 14 Engine Coolant Temperature SensorÐ3.0L

Fig. 15 Engine Coolant Temperature SensorÐ2.4L

NSFUEL SYSTEM 14 - 37

DESCRIPTION AND OPERATION (Continued)

Page 1334 of 1938

a fixed vehicle speed has been selected. The speed

control RESUME voltage indicates the previous fixed

speed is requested. The speed control CANCEL volt-

age tells the PCM to deactivate but retain set speed

in memory (same as depressing the brake pedal). The

speed control OFF voltage tells the PCM that the

speed control system has deactivated. Refer to Group

8H for more speed control information.

TRANSAXLE PARK/NEUTRAL SWITCHÐPCM

INPUT

The park/neutral switch is located on the transaxle

housing (Fig. 25). It provides an input to the PCM

indicating whether the automatic transaxle is in

Park or Neutral. This input is used to determine idlespeed (varying with gear selection) and ignition tim-

ing advance. The park neutral switch is sometimes

referred to as the neutral safety switch.

THROTTLE POSITION SENSOR (TPS)ÐPCM INPUT

The TPS is mounted on the throttle body and con-

nected to the throttle blade shaft (Fig. 26) or (Fig.

27) or (Fig. 28). The TPS is a variable resistor that

provides the (PCM) with an input signal (voltage)

representing throttle blade position. As the position

of the throttle blade changes, the resistance of the

TPS changes.

Fig. 23 MAP SensorÐ3.0L

Fig. 24 MAP SensorÐ2.4L

Fig. 25 Park Neutral SwitchÐ4-Speed Electronic

Automatic TransaxleÐTypical

Fig. 26 Throttle Position SensorÐ3.3/3.8L

14 - 40 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1336 of 1938

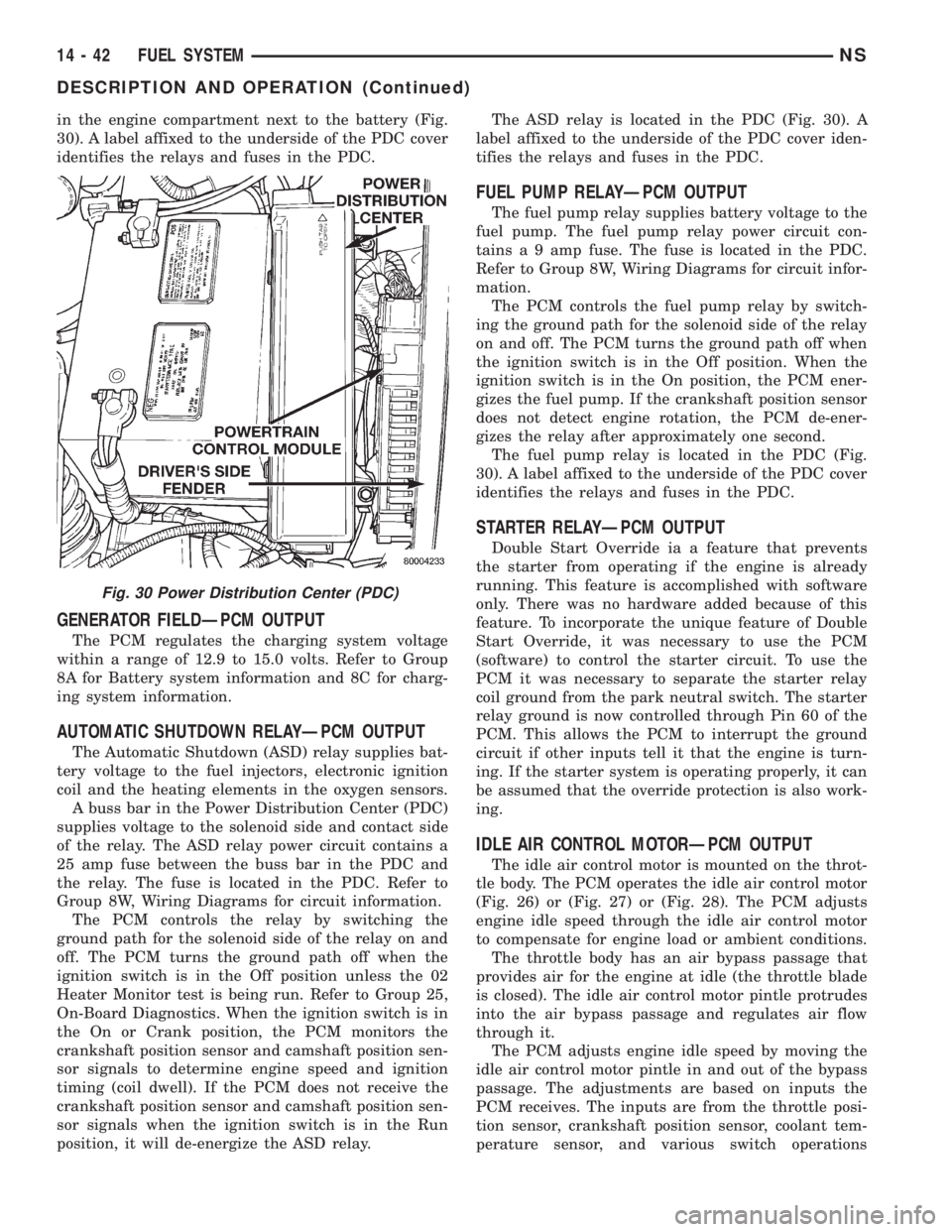

in the engine compartment next to the battery (Fig.

30). A label affixed to the underside of the PDC cover

identifies the relays and fuses in the PDC.

GENERATOR FIELDÐPCM OUTPUT

The PCM regulates the charging system voltage

within a range of 12.9 to 15.0 volts. Refer to Group

8A for Battery system information and 8C for charg-

ing system information.

AUTOMATIC SHUTDOWN RELAYÐPCM OUTPUT

The Automatic Shutdown (ASD) relay supplies bat-

tery voltage to the fuel injectors, electronic ignition

coil and the heating elements in the oxygen sensors.

A buss bar in the Power Distribution Center (PDC)

supplies voltage to the solenoid side and contact side

of the relay. The ASD relay power circuit contains a

25 amp fuse between the buss bar in the PDC and

the relay. The fuse is located in the PDC. Refer to

Group 8W, Wiring Diagrams for circuit information.

The PCM controls the relay by switching the

ground path for the solenoid side of the relay on and

off. The PCM turns the ground path off when the

ignition switch is in the Off position unless the 02

Heater Monitor test is being run. Refer to Group 25,

On-Board Diagnostics. When the ignition switch is in

the On or Crank position, the PCM monitors the

crankshaft position sensor and camshaft position sen-

sor signals to determine engine speed and ignition

timing (coil dwell). If the PCM does not receive the

crankshaft position sensor and camshaft position sen-

sor signals when the ignition switch is in the Run

position, it will de-energize the ASD relay.The ASD relay is located in the PDC (Fig. 30). A

label affixed to the underside of the PDC cover iden-

tifies the relays and fuses in the PDC.

FUEL PUMP RELAYÐPCM OUTPUT

The fuel pump relay supplies battery voltage to the

fuel pump. The fuel pump relay power circuit con-

tains a 9 amp fuse. The fuse is located in the PDC.

Refer to Group 8W, Wiring Diagrams for circuit infor-

mation.

The PCM controls the fuel pump relay by switch-

ing the ground path for the solenoid side of the relay

on and off. The PCM turns the ground path off when

the ignition switch is in the Off position. When the

ignition switch is in the On position, the PCM ener-

gizes the fuel pump. If the crankshaft position sensor

does not detect engine rotation, the PCM de-ener-

gizes the relay after approximately one second.

The fuel pump relay is located in the PDC (Fig.

30). A label affixed to the underside of the PDC cover

identifies the relays and fuses in the PDC.

STARTER RELAYÐPCM OUTPUT

Double Start Override ia a feature that prevents

the starter from operating if the engine is already

running. This feature is accomplished with software

only. There was no hardware added because of this

feature. To incorporate the unique feature of Double

Start Override, it was necessary to use the PCM

(software) to control the starter circuit. To use the

PCM it was necessary to separate the starter relay

coil ground from the park neutral switch. The starter

relay ground is now controlled through Pin 60 of the

PCM. This allows the PCM to interrupt the ground

circuit if other inputs tell it that the engine is turn-

ing. If the starter system is operating properly, it can

be assumed that the override protection is also work-

ing.

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The idle air control motor is mounted on the throt-

tle body. The PCM operates the idle air control motor

(Fig. 26) or (Fig. 27) or (Fig. 28). The PCM adjusts

engine idle speed through the idle air control motor

to compensate for engine load or ambient conditions.

The throttle body has an air bypass passage that

provides air for the engine at idle (the throttle blade

is closed). The idle air control motor pintle protrudes

into the air bypass passage and regulates air flow

through it.

The PCM adjusts engine idle speed by moving the

idle air control motor pintle in and out of the bypass

passage. The adjustments are based on inputs the

PCM receives. The inputs are from the throttle posi-

tion sensor, crankshaft position sensor, coolant tem-

perature sensor, and various switch operations

Fig. 30 Power Distribution Center (PDC)

14 - 42 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1339 of 1938

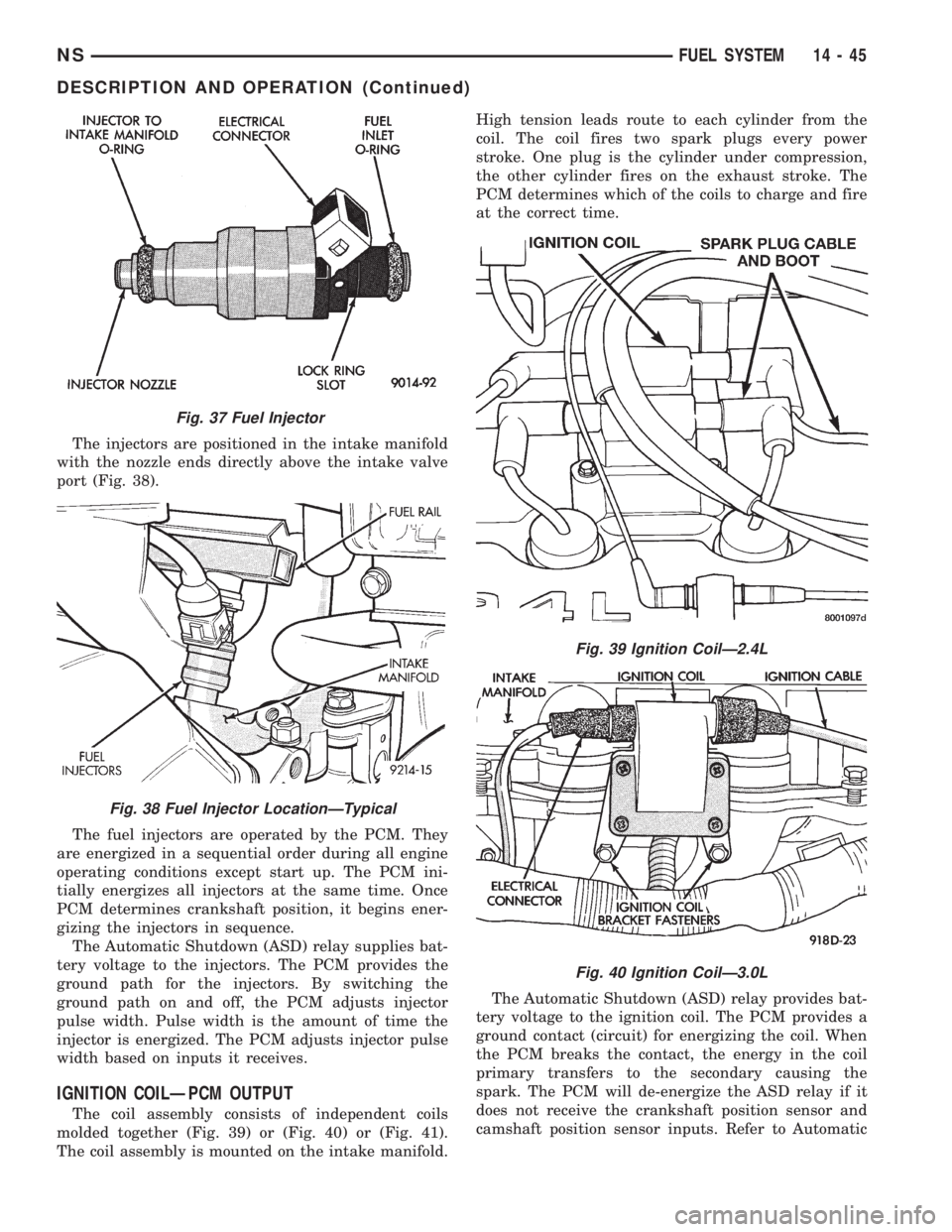

The injectors are positioned in the intake manifold

with the nozzle ends directly above the intake valve

port (Fig. 38).

The fuel injectors are operated by the PCM. They

are energized in a sequential order during all engine

operating conditions except start up. The PCM ini-

tially energizes all injectors at the same time. Once

PCM determines crankshaft position, it begins ener-

gizing the injectors in sequence.

The Automatic Shutdown (ASD) relay supplies bat-

tery voltage to the injectors. The PCM provides the

ground path for the injectors. By switching the

ground path on and off, the PCM adjusts injector

pulse width. Pulse width is the amount of time the

injector is energized. The PCM adjusts injector pulse

width based on inputs it receives.

IGNITION COILÐPCM OUTPUT

The coil assembly consists of independent coils

molded together (Fig. 39) or (Fig. 40) or (Fig. 41).

The coil assembly is mounted on the intake manifold.High tension leads route to each cylinder from the

coil. The coil fires two spark plugs every power

stroke. One plug is the cylinder under compression,

the other cylinder fires on the exhaust stroke. The

PCM determines which of the coils to charge and fire

at the correct time.

The Automatic Shutdown (ASD) relay provides bat-

tery voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Automatic

Fig. 37 Fuel Injector

Fig. 38 Fuel Injector LocationÐTypical

Fig. 39 Ignition CoilÐ2.4L

Fig. 40 Ignition CoilÐ3.0L

NSFUEL SYSTEM 14 - 45

DESCRIPTION AND OPERATION (Continued)

Page 1342 of 1938

(3) Verify the camshaft position sensor electrical

connector is connected to the harness and not dam-

aged (Fig. 47).(4) Ensure the engine temperature sensor electri-

cal connector is connected to the sensor and not dam-

aged (Fig. 48).

(5) Verify the quick connect fuel fitting is fully

inserted on the fuel supply tube.

(6) Check the oil pressure sending unit electrical

connection.

(7) Verify the electrical connector at the knock sen-

sor is fully seated and not damaged (Fig. 49).

Fig. 45 Throttle BodyÐ3.3/3.8L

Fig. 46 Ignition Coil Pack Electrical Connection

Fig. 47 Camshaft Position Sensor

14 - 48 FUEL SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 1344 of 1938

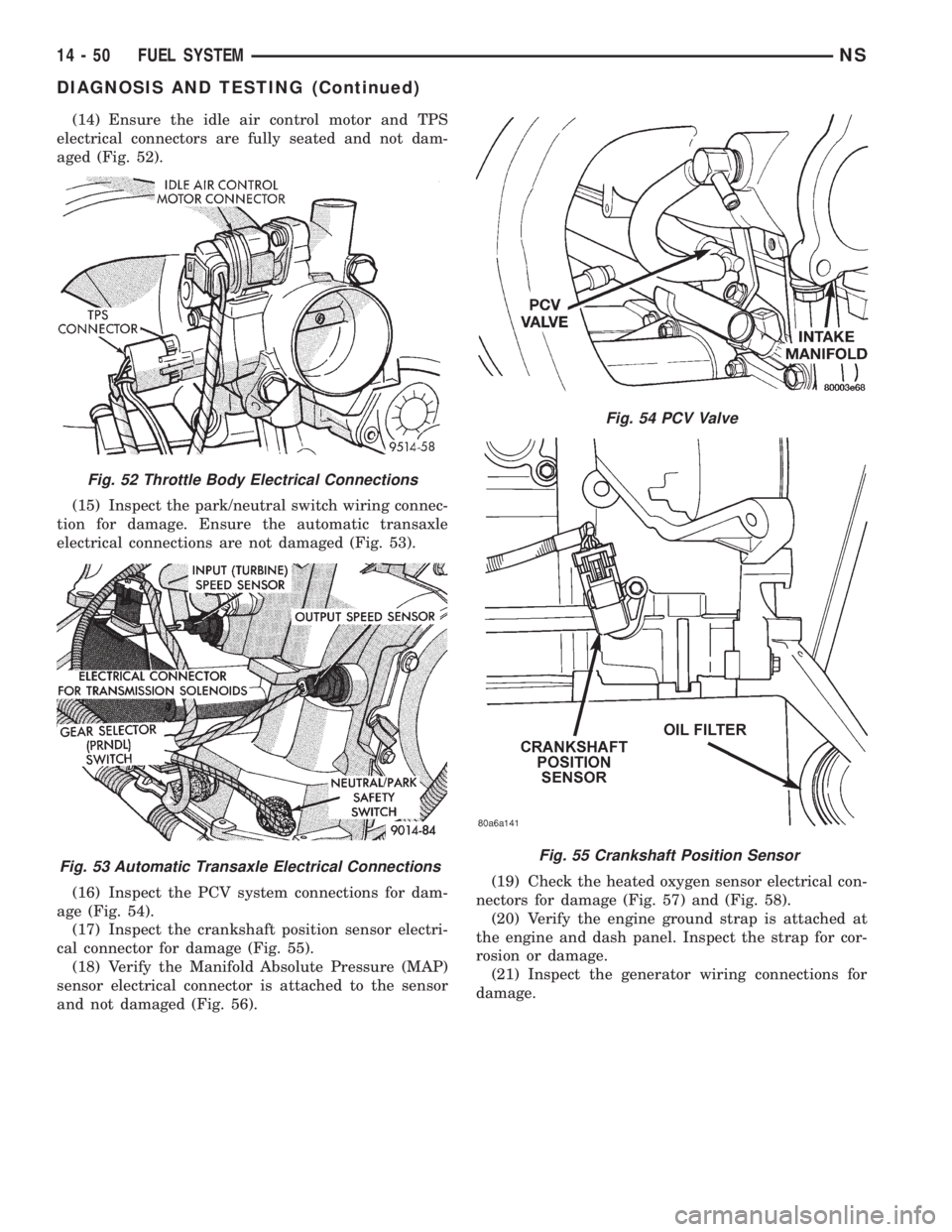

(14) Ensure the idle air control motor and TPS

electrical connectors are fully seated and not dam-

aged (Fig. 52).

(15) Inspect the park/neutral switch wiring connec-

tion for damage. Ensure the automatic transaxle

electrical connections are not damaged (Fig. 53).

(16) Inspect the PCV system connections for dam-

age (Fig. 54).

(17) Inspect the crankshaft position sensor electri-

cal connector for damage (Fig. 55).

(18) Verify the Manifold Absolute Pressure (MAP)

sensor electrical connector is attached to the sensor

and not damaged (Fig. 56).(19) Check the heated oxygen sensor electrical con-

nectors for damage (Fig. 57) and (Fig. 58).

(20) Verify the engine ground strap is attached at

the engine and dash panel. Inspect the strap for cor-

rosion or damage.

(21) Inspect the generator wiring connections for

damage.

Fig. 52 Throttle Body Electrical Connections

Fig. 53 Automatic Transaxle Electrical Connections

Fig. 54 PCV Valve

Fig. 55 Crankshaft Position Sensor

14 - 50 FUEL SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 1349 of 1938

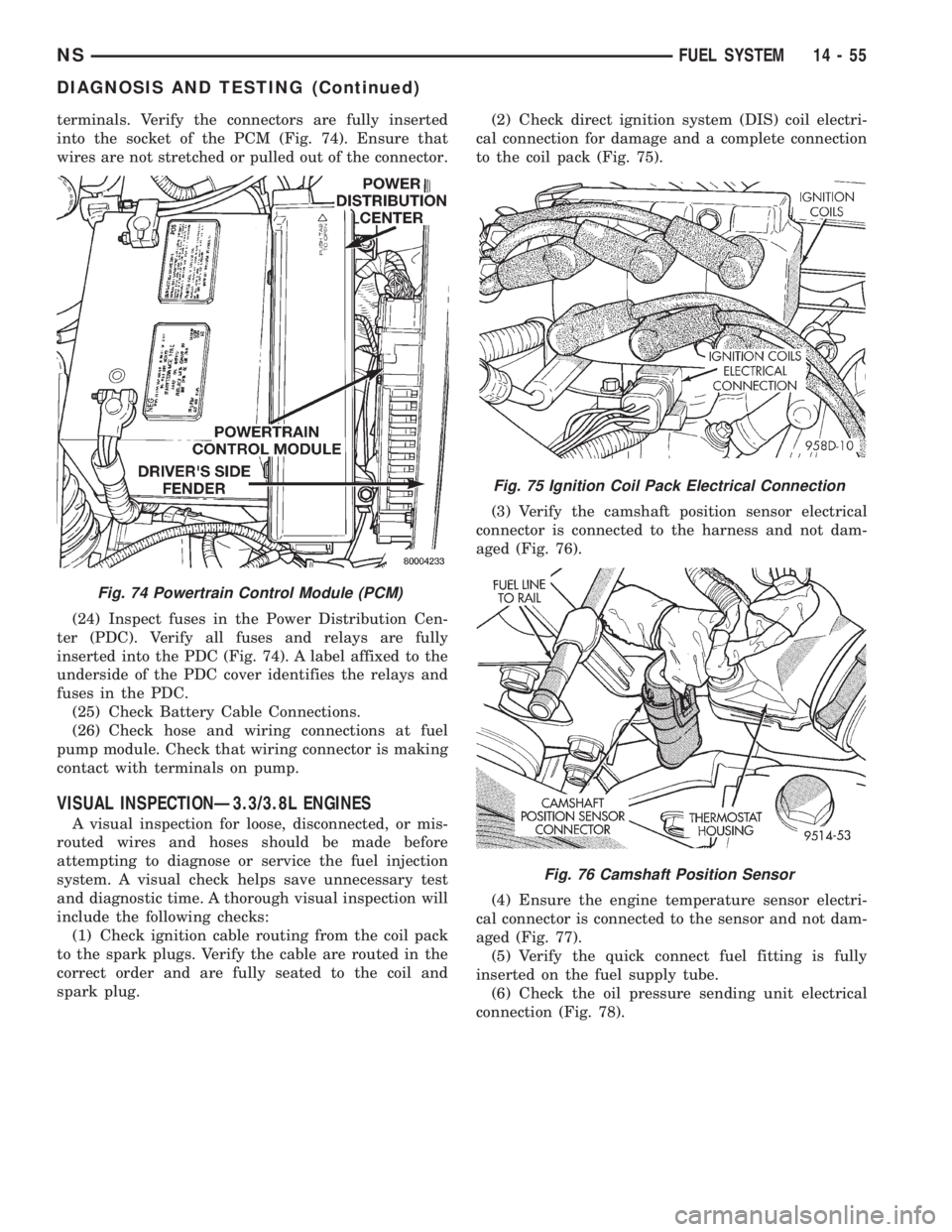

terminals. Verify the connectors are fully inserted

into the socket of the PCM (Fig. 74). Ensure that

wires are not stretched or pulled out of the connector.

(24) Inspect fuses in the Power Distribution Cen-

ter (PDC). Verify all fuses and relays are fully

inserted into the PDC (Fig. 74). A label affixed to the

underside of the PDC cover identifies the relays and

fuses in the PDC.

(25) Check Battery Cable Connections.

(26) Check hose and wiring connections at fuel

pump module. Check that wiring connector is making

contact with terminals on pump.

VISUAL INSPECTIONÐ3.3/3.8L ENGINES

A visual inspection for loose, disconnected, or mis-

routed wires and hoses should be made before

attempting to diagnose or service the fuel injection

system. A visual check helps save unnecessary test

and diagnostic time. A thorough visual inspection will

include the following checks:

(1) Check ignition cable routing from the coil pack

to the spark plugs. Verify the cable are routed in the

correct order and are fully seated to the coil and

spark plug.(2) Check direct ignition system (DIS) coil electri-

cal connection for damage and a complete connection

to the coil pack (Fig. 75).

(3) Verify the camshaft position sensor electrical

connector is connected to the harness and not dam-

aged (Fig. 76).

(4) Ensure the engine temperature sensor electri-

cal connector is connected to the sensor and not dam-

aged (Fig. 77).

(5) Verify the quick connect fuel fitting is fully

inserted on the fuel supply tube.

(6) Check the oil pressure sending unit electrical

connection (Fig. 78).

Fig. 74 Powertrain Control Module (PCM)

Fig. 75 Ignition Coil Pack Electrical Connection

Fig. 76 Camshaft Position Sensor

NSFUEL SYSTEM 14 - 55

DIAGNOSIS AND TESTING (Continued)