service CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1099 of 1938

PISTON AND CONNECTING ROD

REMOVAL

NOTE: Cylinder Head must be removed before Pis-

tons and Rods. Refer to Cylinder Head Removal in

this section.

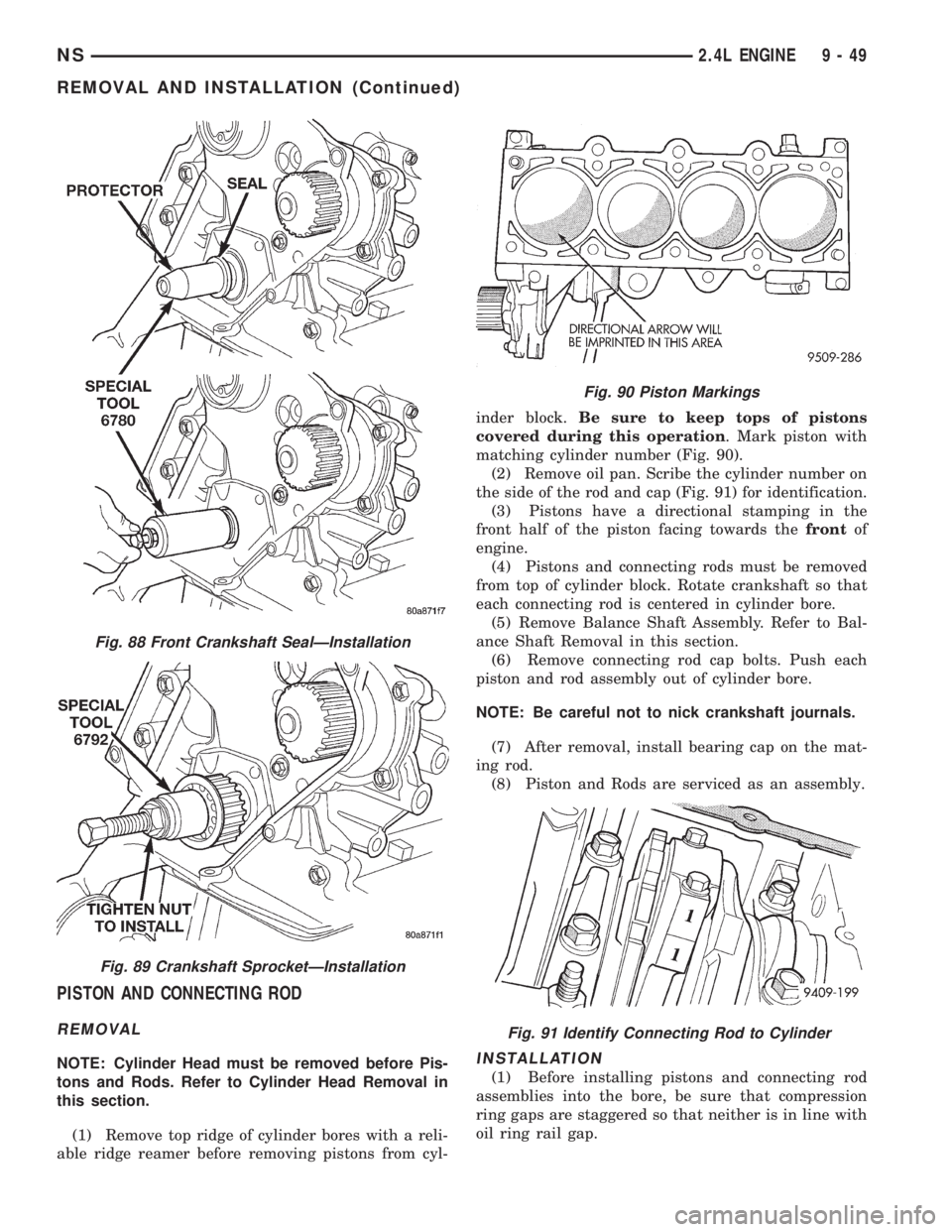

(1) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 90).

(2) Remove oil pan. Scribe the cylinder number on

the side of the rod and cap (Fig. 91) for identification.

(3) Pistons have a directional stamping in the

front half of the piston facing towards thefrontof

engine.

(4) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(5) Remove Balance Shaft Assembly. Refer to Bal-

ance Shaft Removal in this section.

(6) Remove connecting rod cap bolts. Push each

piston and rod assembly out of cylinder bore.

NOTE: Be careful not to nick crankshaft journals.

(7) After removal, install bearing cap on the mat-

ing rod.

(8) Piston and Rods are serviced as an assembly.INSTALLATION

(1) Before installing pistons and connecting rod

assemblies into the bore, be sure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap.

Fig. 88 Front Crankshaft SealÐInstallation

Fig. 89 Crankshaft SprocketÐInstallation

Fig. 90 Piston Markings

Fig. 91 Identify Connecting Rod to Cylinder

NS2.4L ENGINE 9 - 49

REMOVAL AND INSTALLATION (Continued)

Page 1101 of 1938

(4) Wash all parts in a suitable solvent and

inspect carefully for damage or wear.

ASSEMBLY

(1) Assemble pump, using new parts as required.

Install the inner rotor with chamfer facing the

cast iron oil pump cover.

(2) Prime oil pump before installation by filling

rotor cavity with engine oil.

(3) Install cover and tighten screws to 12 N´m

(105 in. lbs.).

CAUTION: Oil pump pressure relief valve must be

installed as shown in (Fig. 95) or serious damage

may occur.

(4) Install relief valve, spring, gasket and cap as

shown in (Fig. 95). Tighten cap to 41 N´m (30 ft. lbs.)

CLEANING AND INSPECTION

CYLINDER HEAD

CLEANING

Remove all gasket material from cylinder head and

block. Be careful not to gouge or scratch the alumi-

num head sealing surface.

INSPECTION

(1) Cylinder head must be flat within 0.1 mm

(0.004 inch) (Fig. 96).

(2) Inspect camshaft bearing journals for scoring.

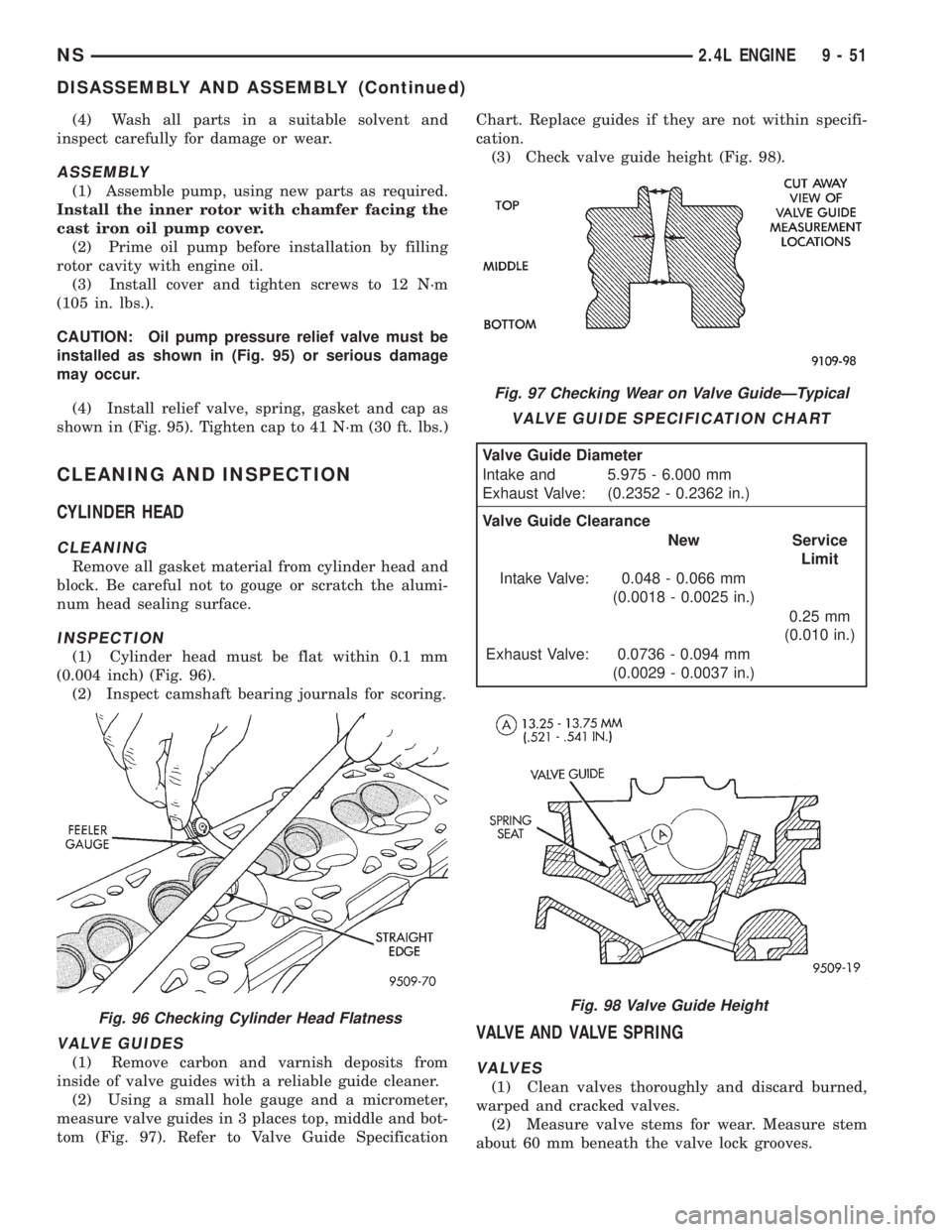

VALVE GUIDES

(1) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(2) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 97). Refer to Valve Guide SpecificationChart. Replace guides if they are not within specifi-

cation.

(3) Check valve guide height (Fig. 98).

VALVE AND VALVE SPRING

VALVES

(1) Clean valves thoroughly and discard burned,

warped and cracked valves.

(2) Measure valve stems for wear. Measure stem

about 60 mm beneath the valve lock grooves.

Fig. 96 Checking Cylinder Head Flatness

Fig. 97 Checking Wear on Valve GuideÐTypical

VALVE GUIDE SPECIFICATION CHART

Valve Guide Diameter

Intake and

Exhaust Valve:5.975 - 6.000 mm

(0.2352 - 0.2362 in.)

Valve Guide Clearance

New Service

Limit

Intake Valve: 0.048 - 0.066 mm

(0.0018 - 0.0025 in.)

0.25 mm

(0.010 in.)

Exhaust Valve: 0.0736 - 0.094 mm

(0.0029 - 0.0037 in.)

Fig. 98 Valve Guide Height

NS2.4L ENGINE 9 - 51

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1111 of 1938

3.0L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

ENGINE COMPONENTS.................. 61

ENGINE IDENTIFICATION NUMBER......... 61

ENGINE LUBRICATION................... 61

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE......... 62

SERVICE PROCEDURES

AUTO LASH ADJUSTER................... 62

CHECKING CRANKSHAFT END PLAY........ 65

FITTING CONNECTING ROD BEARINGS...... 63

FITTING MAIN BEARING.................. 63

VALVE SERVICE RECONDITION............ 66

REMOVAL AND INSTALLATION

CAMSHAFT SEAL....................... 72

CAMSHAFT............................ 71

CRANKSHAFT.......................... 81

CYLINDER HEAD COVER................. 70

CYLINDER HEAD........................ 73

ENGINE ASSEMBLY...................... 69

ENGINE MOUNTS....................... 68

FRONT CRANKSHAFT OIL SEAL............ 83OIL FILTER AND ADAPTOR................ 84

OILPAN ............................... 77

OIL PUMP............................. 84

PISTON AND CONNECTING ROD........... 78

REAR CRANKSHAFT SEAL................ 83

ROCKER ARMS......................... 72

TIMING BELT........................... 75

DISASSEMBLY AND ASSEMBLY

ROCKER ARMS AND SHAFTS.............. 85

CLEANING AND INSPECTION

CYLINDER BORE........................ 87

CYLINDER HEAD........................ 86

OIL PUMP............................. 87

TIMING BELT........................... 86

ADJUSTMENTS

ENGINE MOUNTS....................... 88

SPECIFICATIONS

3.0L ENGINE........................... 89

TORQUE CHART 3.0L.................... 90

SPECIAL TOOLS

3.0L ENGINE........................... 91

DESCRIPTION AND OPERATION

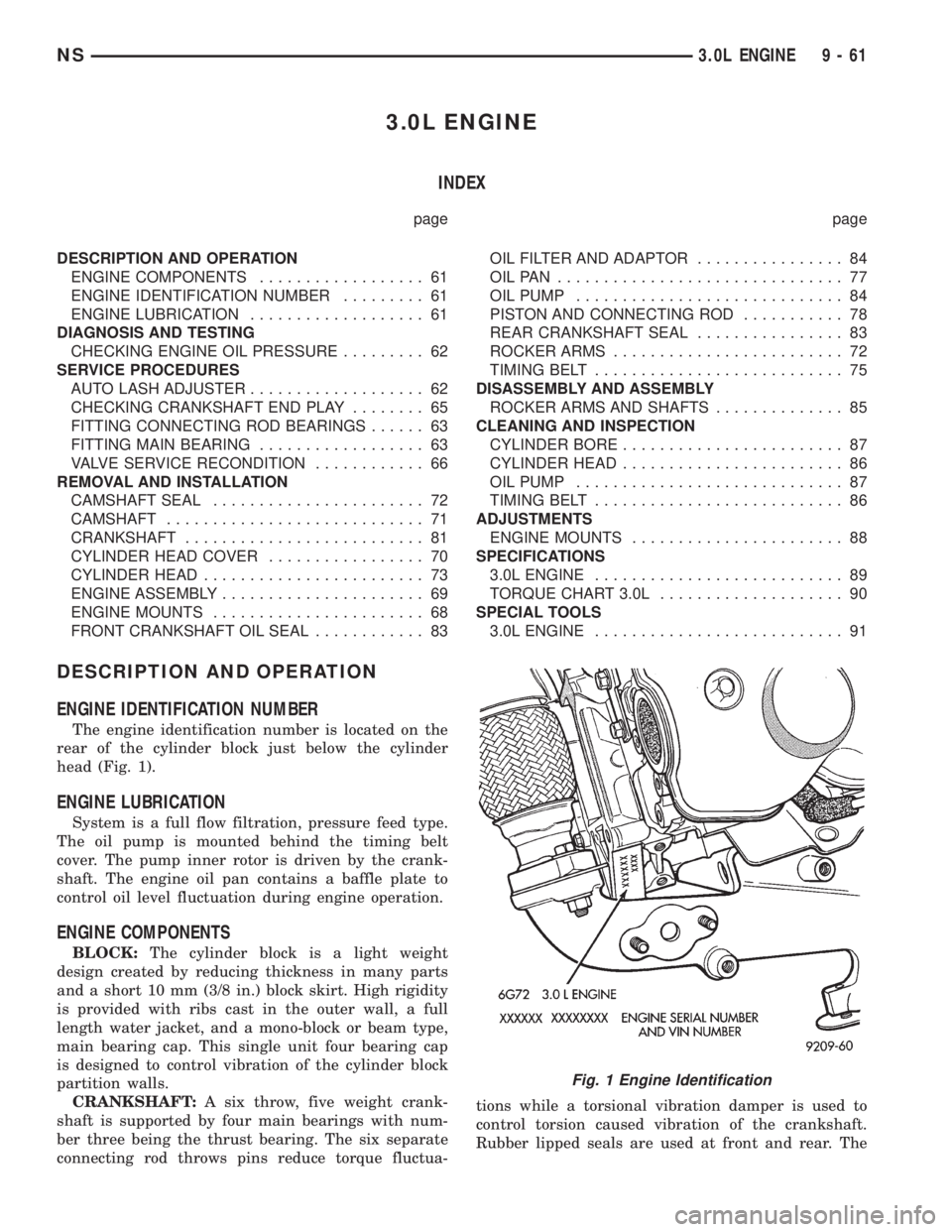

ENGINE IDENTIFICATION NUMBER

The engine identification number is located on the

rear of the cylinder block just below the cylinder

head (Fig. 1).

ENGINE LUBRICATION

System is a full flow filtration, pressure feed type.

The oil pump is mounted behind the timing belt

cover. The pump inner rotor is driven by the crank-

shaft. The engine oil pan contains a baffle plate to

control oil level fluctuation during engine operation.

ENGINE COMPONENTS

BLOCK:The cylinder block is a light weight

design created by reducing thickness in many parts

and a short 10 mm (3/8 in.) block skirt. High rigidity

is provided with ribs cast in the outer wall, a full

length water jacket, and a mono-block or beam type,

main bearing cap. This single unit four bearing cap

is designed to control vibration of the cylinder block

partition walls.

CRANKSHAFT:A six throw, five weight crank-

shaft is supported by four main bearings with num-

ber three being the thrust bearing. The six separate

connecting rod throws pins reduce torque fluctua-tions while a torsional vibration damper is used to

control torsion caused vibration of the crankshaft.

Rubber lipped seals are used at front and rear. The

Fig. 1 Engine Identification

NS3.0L ENGINE 9 - 61

Page 1112 of 1938

front seal is retained in the oil pump case and the

rear is retained in a block-mounted housing.

PISTONS:Are aluminum alloy with a steel strut,

short height, and thin wall so as to be autothermic

and light weight. The piston head with valve

recesses, in combination with the cylinder head,

forms a compact spherical head with clearance for

total valve lift with pistons at top dead center. The

piston skirt, top and second ring lands are finished to

a tapered roughness for oil retention and high resis-

tance to scuffing. Piston pins, pressed into place, join

the pistons to the connecting rods.

CYLINDER HEAD:The alloy cylinder heads fea-

ture cross-flow type intake and exhaust ports. Valve

guides and inserts are hardened cast iron. Valves of

heat resistance steel are arranged in a V with each

camshaft on center. To improve combustion speed the

chambers are a compact spherical design with a

squish area of approximately 30 percent of the piston

top area. The cylinder heads are common to either

cylinder bank by reversing the direction of installa-

tion.

CAMSHAFTS:Two overhead camshafts provide

valve actuation, one front (radiator side of cylinder

bank) and one rear. The front camshaft is provided

with a distributor drive and is longer. Both cam-

shafts are supported by four bearing journals, thrust

for the front camshaft is taken at journal two and

the rear at journal three. Front and rear camshaft

driving sprockets are interchangeable. The sprockets

and the engine water pump are driven by a single

notched timing belt.

ROCKER ARM SHAFTS:The shafts are retained

by the camshaft bearing journal caps. Four shafts are

used, one for each intake and exhaust rocker arm

assembly on each cylinder head. The hollow shafts

provide a duct for lubricating oil flow from the cylin-

der head to the valve mechanisms.

ROCKER ARMS:Are of light weight die-cast with

roller type follower operating against the cam shaft.

The valve actuating end of the rocker arms are

machined to retain hydraulic lash adjusters, elimi-

nating valve lash adjustment.

VALVES:Are made of heat resistant steel, valve

springs are especially designed to be short. The valve

spring wire cross-section is oval shaped and provides

the same spring tension as longer springs. Valve

spring retainers, locks and seals are conventional.

INTAKE MANIFOLD:The aluminum alloy mani-

fold is a cross type with long runners to improve

inertia. The runners, attaching below at the cylinder

head, also attach above and support an air plenum.

The air plenum chamber absorbs air pulsations cre-

ated during the suction phase of each cylinder.

EXHAUST MANIFOLDS:Both manifolds are a

log style made of ductile cast iron. Exhaust gasses,collected from the front cylinder bank, leave the front

manifold through an end outlet and are fed through

an upper crossover tube to the rear manifold. The

collected exhaust from both manifolds are combined,

and exit to the exhaust pipe through an articulated

joint.

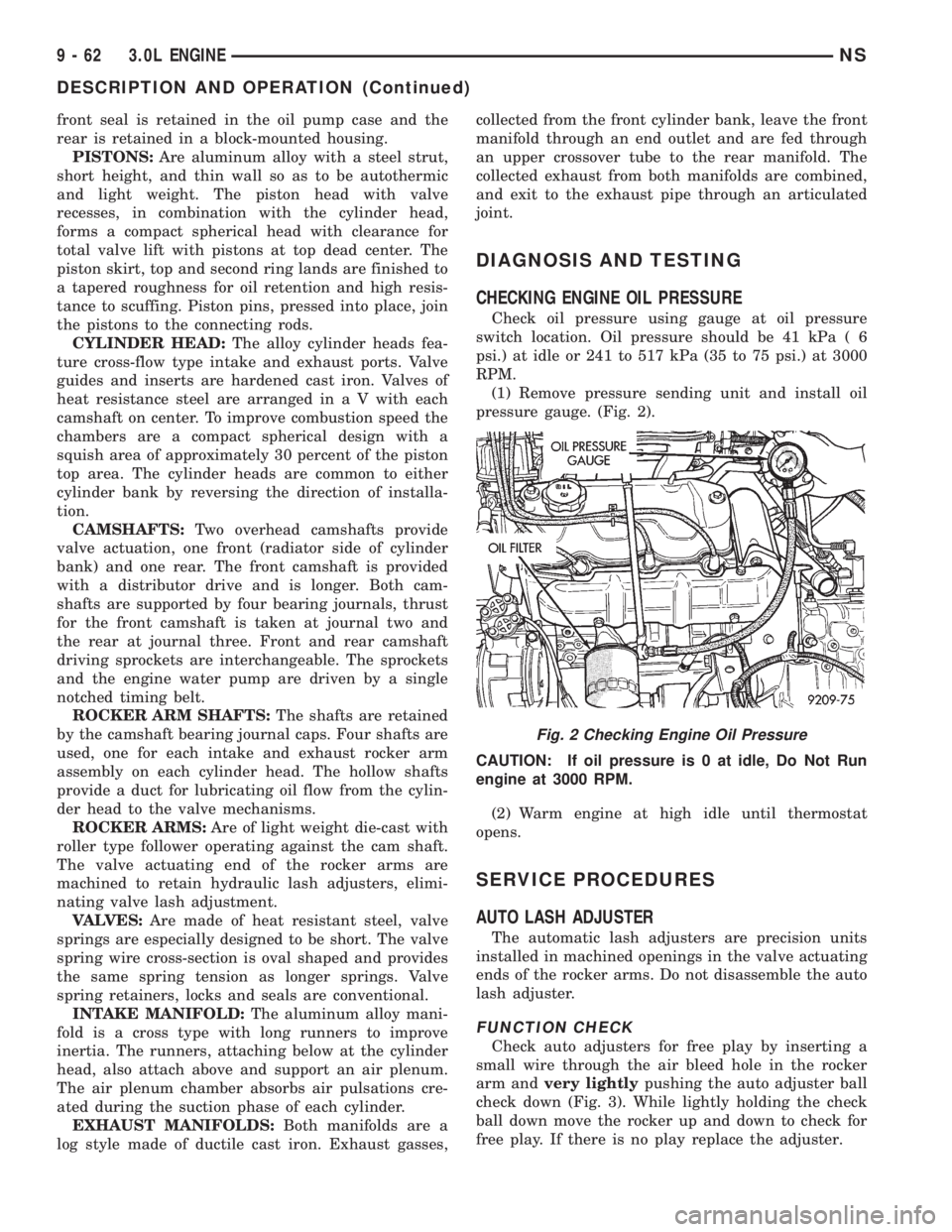

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

Check oil pressure using gauge at oil pressure

switch location. Oil pressure should be 41 kPa ( 6

psi.) at idle or 241 to 517 kPa (35 to 75 psi.) at 3000

RPM.

(1) Remove pressure sending unit and install oil

pressure gauge. (Fig. 2).

CAUTION: If oil pressure is 0 at idle, Do Not Run

engine at 3000 RPM.

(2) Warm engine at high idle until thermostat

opens.

SERVICE PROCEDURES

AUTO LASH ADJUSTER

The automatic lash adjusters are precision units

installed in machined openings in the valve actuating

ends of the rocker arms. Do not disassemble the auto

lash adjuster.

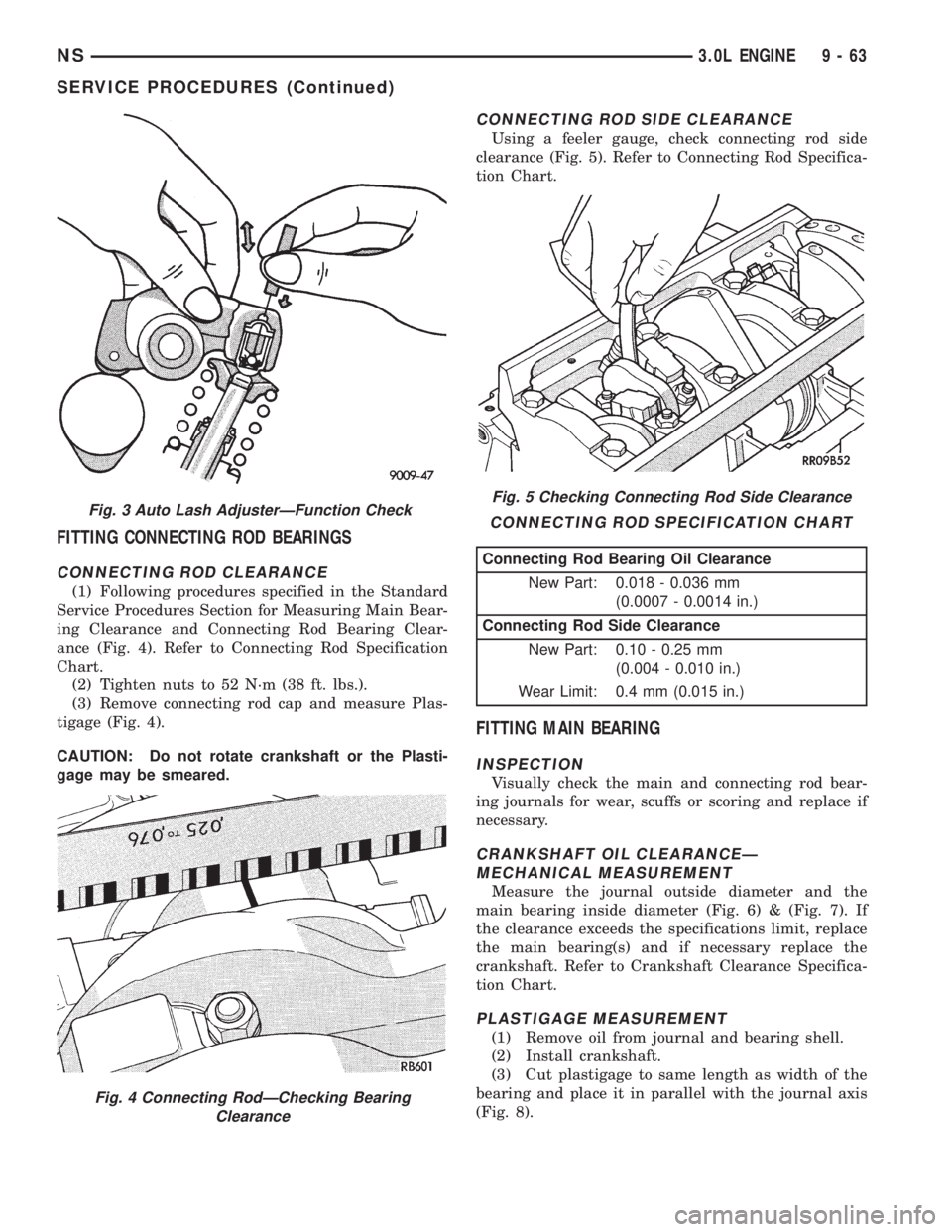

FUNCTION CHECK

Check auto adjusters for free play by inserting a

small wire through the air bleed hole in the rocker

arm andvery lightlypushing the auto adjuster ball

check down (Fig. 3). While lightly holding the check

ball down move the rocker up and down to check for

free play. If there is no play replace the adjuster.

Fig. 2 Checking Engine Oil Pressure

9 - 62 3.0L ENGINENS

DESCRIPTION AND OPERATION (Continued)

Page 1113 of 1938

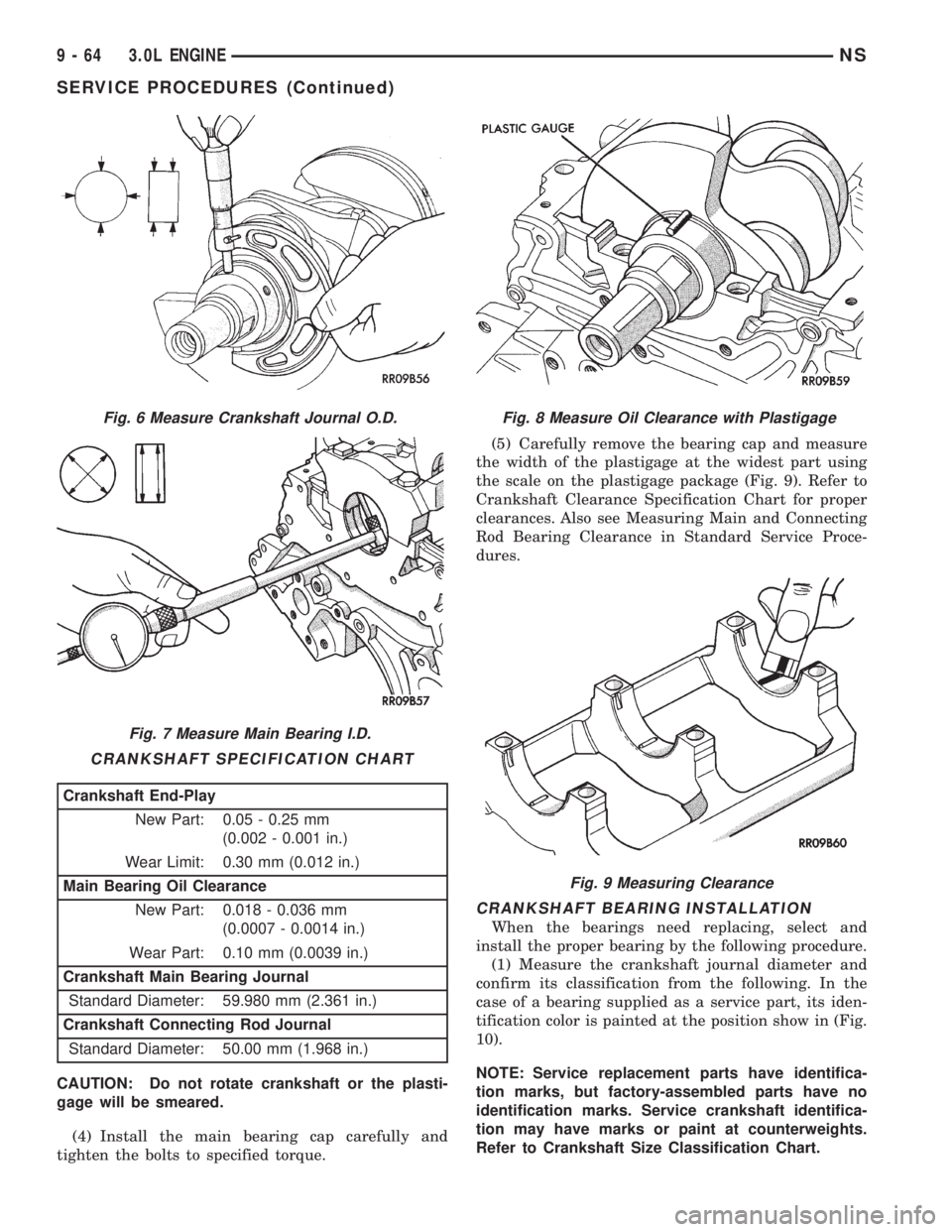

FITTING CONNECTING ROD BEARINGS

CONNECTING ROD CLEARANCE

(1) Following procedures specified in the Standard

Service Procedures Section for Measuring Main Bear-

ing Clearance and Connecting Rod Bearing Clear-

ance (Fig. 4). Refer to Connecting Rod Specification

Chart.

(2) Tighten nuts to 52 N´m (38 ft. lbs.).

(3) Remove connecting rod cap and measure Plas-

tigage (Fig. 4).

CAUTION: Do not rotate crankshaft or the Plasti-

gage may be smeared.

CONNECTING ROD SIDE CLEARANCE

Using a feeler gauge, check connecting rod side

clearance (Fig. 5). Refer to Connecting Rod Specifica-

tion Chart.

FITTING MAIN BEARING

INSPECTION

Visually check the main and connecting rod bear-

ing journals for wear, scuffs or scoring and replace if

necessary.

CRANKSHAFT OIL CLEARANCEÐ

MECHANICAL MEASUREMENT

Measure the journal outside diameter and the

main bearing inside diameter (Fig. 6) & (Fig. 7). If

the clearance exceeds the specifications limit, replace

the main bearing(s) and if necessary replace the

crankshaft. Refer to Crankshaft Clearance Specifica-

tion Chart.

PLASTIGAGE MEASUREMENT

(1) Remove oil from journal and bearing shell.

(2) Install crankshaft.

(3) Cut plastigage to same length as width of the

bearing and place it in parallel with the journal axis

(Fig. 8).

Fig. 3 Auto Lash AdjusterÐFunction Check

Fig. 4 Connecting RodÐChecking Bearing

Clearance

Fig. 5 Checking Connecting Rod Side Clearance

CONNECTING ROD SPECIFICATION CHART

Connecting Rod Bearing Oil Clearance

New Part: 0.018 - 0.036 mm

(0.0007 - 0.0014 in.)

Connecting Rod Side Clearance

New Part: 0.10 - 0.25 mm

(0.004 - 0.010 in.)

Wear Limit: 0.4 mm (0.015 in.)

NS3.0L ENGINE 9 - 63

SERVICE PROCEDURES (Continued)

Page 1114 of 1938

CAUTION: Do not rotate crankshaft or the plasti-

gage will be smeared.

(4) Install the main bearing cap carefully and

tighten the bolts to specified torque.(5) Carefully remove the bearing cap and measure

the width of the plastigage at the widest part using

the scale on the plastigage package (Fig. 9). Refer to

Crankshaft Clearance Specification Chart for proper

clearances. Also see Measuring Main and Connecting

Rod Bearing Clearance in Standard Service Proce-

dures.

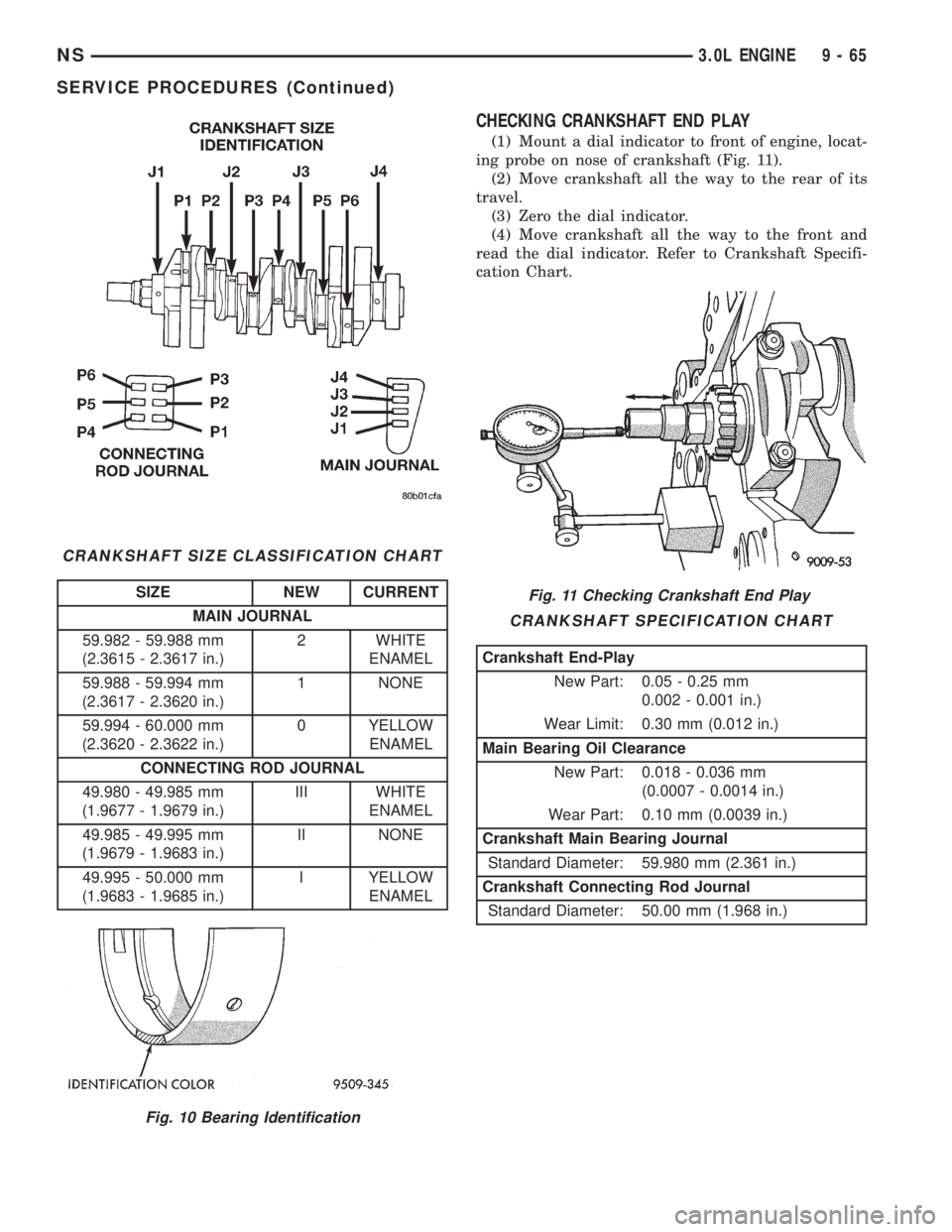

CRANKSHAFT BEARING INSTALLATION

When the bearings need replacing, select and

install the proper bearing by the following procedure.

(1) Measure the crankshaft journal diameter and

confirm its classification from the following. In the

case of a bearing supplied as a service part, its iden-

tification color is painted at the position show in (Fig.

10).

NOTE: Service replacement parts have identifica-

tion marks, but factory-assembled parts have no

identification marks. Service crankshaft identifica-

tion may have marks or paint at counterweights.

Refer to Crankshaft Size Classification Chart.

Fig. 6 Measure Crankshaft Journal O.D.

Fig. 7 Measure Main Bearing I.D.

CRANKSHAFT SPECIFICATION CHART

Crankshaft End-Play

New Part: 0.05 - 0.25 mm

(0.002 - 0.001 in.)

Wear Limit: 0.30 mm (0.012 in.)

Main Bearing Oil Clearance

New Part: 0.018 - 0.036 mm

(0.0007 - 0.0014 in.)

Wear Part: 0.10 mm (0.0039 in.)

Crankshaft Main Bearing Journal

Standard Diameter: 59.980 mm (2.361 in.)

Crankshaft Connecting Rod Journal

Standard Diameter: 50.00 mm (1.968 in.)

Fig. 8 Measure Oil Clearance with Plastigage

Fig. 9 Measuring Clearance

9 - 64 3.0L ENGINENS

SERVICE PROCEDURES (Continued)

Page 1115 of 1938

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 11).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Crankshaft Specifi-

cation Chart.

CRANKSHAFT SIZE CLASSIFICATION CHART

SIZE NEW CURRENT

MAIN JOURNAL

59.982 - 59.988 mm

(2.3615 - 2.3617 in.)2 WHITE

ENAMEL

59.988 - 59.994 mm

(2.3617 - 2.3620 in.)1 NONE

59.994 - 60.000 mm

(2.3620 - 2.3622 in.)0 YELLOW

ENAMEL

CONNECTING ROD JOURNAL

49.980 - 49.985 mm

(1.9677 - 1.9679 in.)III WHITE

ENAMEL

49.985 - 49.995 mm

(1.9679 - 1.9683 in.)II NONE

49.995 - 50.000 mm

(1.9683 - 1.9685 in.)I YELLOW

ENAMEL

Fig. 10 Bearing Identification

Fig. 11 Checking Crankshaft End Play

CRANKSHAFT SPECIFICATION CHART

Crankshaft End-Play

New Part: 0.05 - 0.25 mm

0.002 - 0.001 in.)

Wear Limit: 0.30 mm (0.012 in.)

Main Bearing Oil Clearance

New Part: 0.018 - 0.036 mm

(0.0007 - 0.0014 in.)

Wear Part: 0.10 mm (0.0039 in.)

Crankshaft Main Bearing Journal

Standard Diameter: 59.980 mm (2.361 in.)

Crankshaft Connecting Rod Journal

Standard Diameter: 50.00 mm (1.968 in.)

NS3.0L ENGINE 9 - 65

SERVICE PROCEDURES (Continued)

Page 1116 of 1938

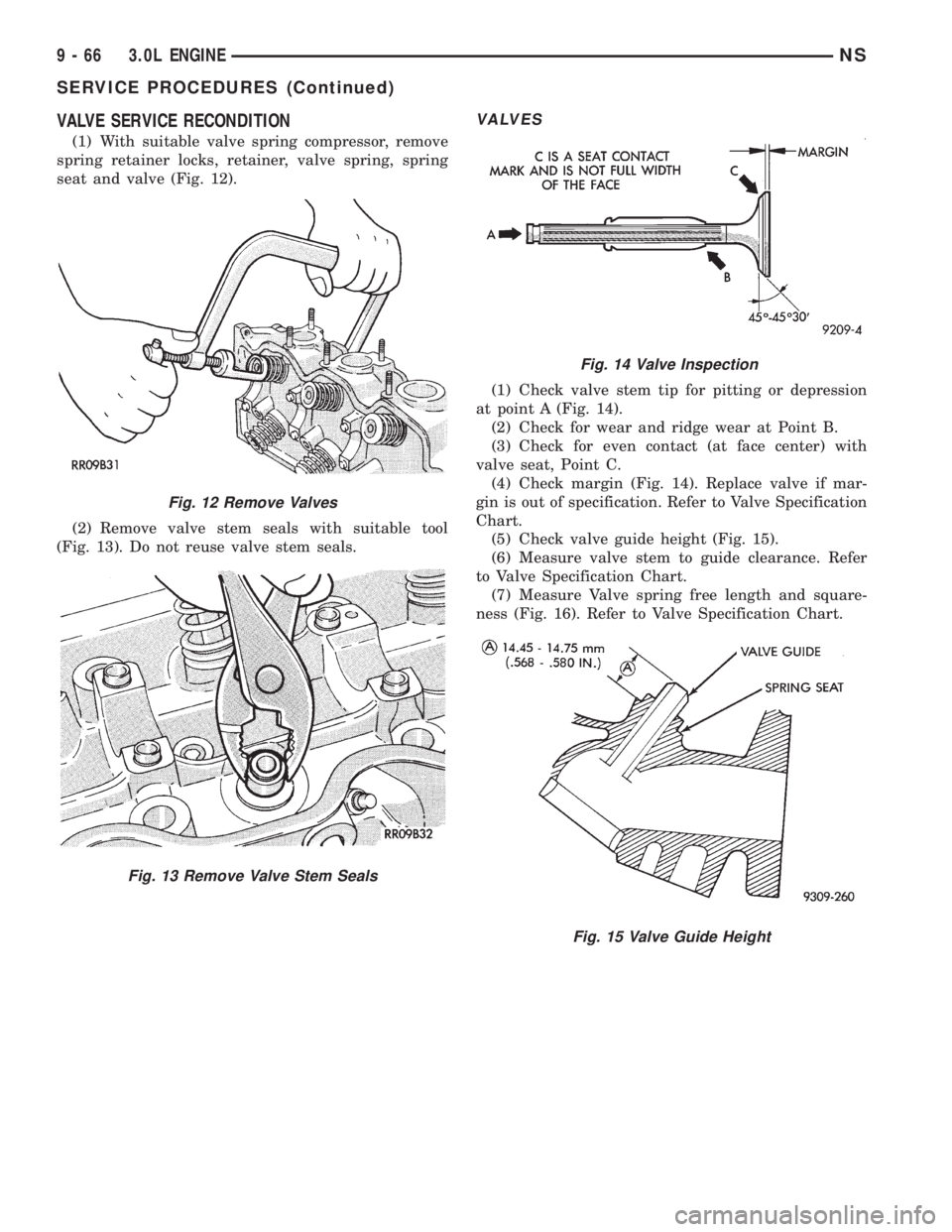

VALVE SERVICE RECONDITION

(1) With suitable valve spring compressor, remove

spring retainer locks, retainer, valve spring, spring

seat and valve (Fig. 12).

(2) Remove valve stem seals with suitable tool

(Fig. 13). Do not reuse valve stem seals.

VALVES

(1) Check valve stem tip for pitting or depression

at point A (Fig. 14).

(2) Check for wear and ridge wear at Point B.

(3) Check for even contact (at face center) with

valve seat, Point C.

(4) Check margin (Fig. 14). Replace valve if mar-

gin is out of specification. Refer to Valve Specification

Chart.

(5) Check valve guide height (Fig. 15).

(6) Measure valve stem to guide clearance. Refer

to Valve Specification Chart.

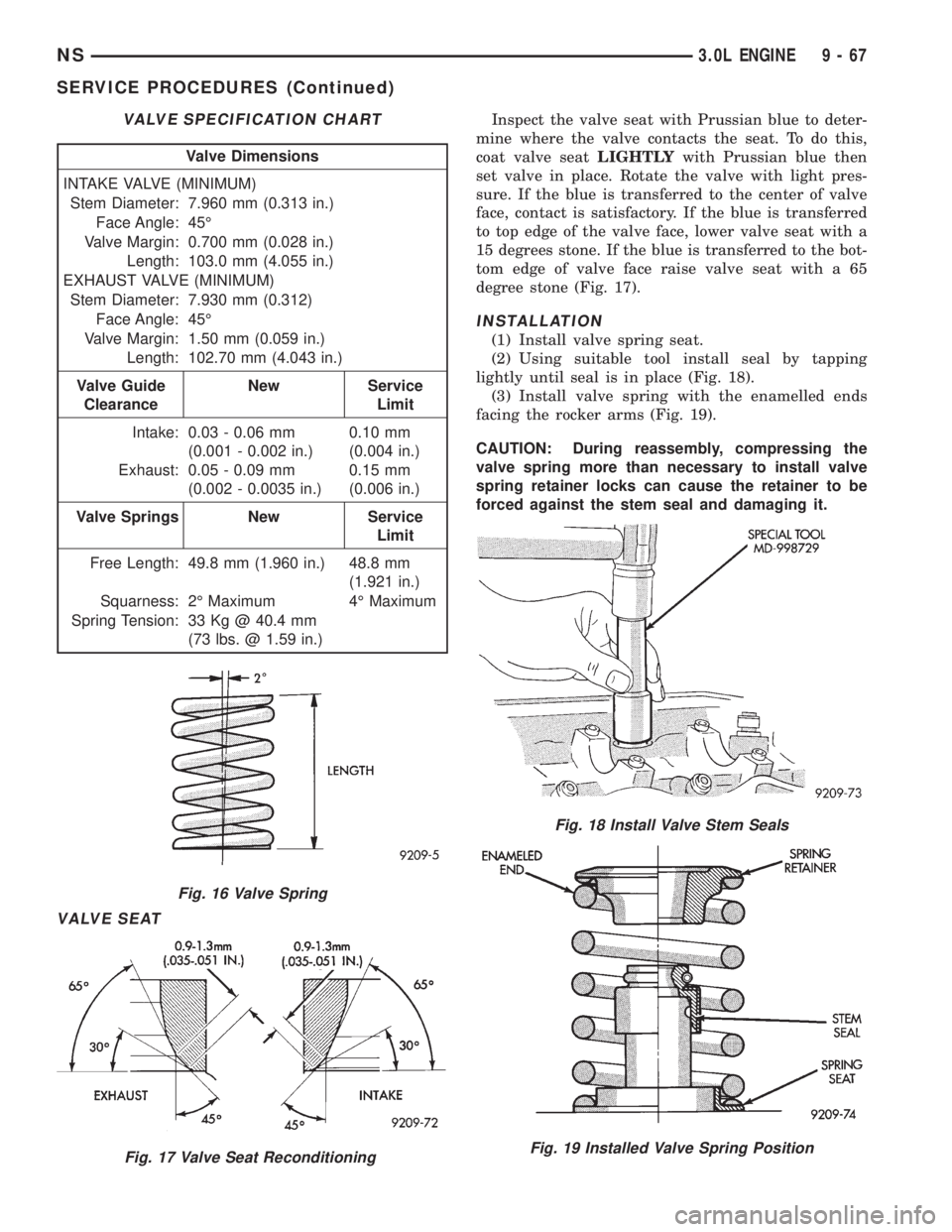

(7) Measure Valve spring free length and square-

ness (Fig. 16). Refer to Valve Specification Chart.

Fig. 12 Remove Valves

Fig. 13 Remove Valve Stem Seals

Fig. 14 Valve Inspection

Fig. 15 Valve Guide Height

9 - 66 3.0L ENGINENS

SERVICE PROCEDURES (Continued)

Page 1117 of 1938

VALVE SEAT

Inspect the valve seat with Prussian blue to deter-

mine where the valve contacts the seat. To do this,

coat valve seatLIGHTLYwith Prussian blue then

set valve in place. Rotate the valve with light pres-

sure. If the blue is transferred to the center of valve

face, contact is satisfactory. If the blue is transferred

to top edge of the valve face, lower valve seat with a

15 degrees stone. If the blue is transferred to the bot-

tom edge of valve face raise valve seat with a 65

degree stone (Fig. 17).

INSTALLATION

(1) Install valve spring seat.

(2) Using suitable tool install seal by tapping

lightly until seal is in place (Fig. 18).

(3) Install valve spring with the enamelled ends

facing the rocker arms (Fig. 19).

CAUTION: During reassembly, compressing the

valve spring more than necessary to install valve

spring retainer locks can cause the retainer to be

forced against the stem seal and damaging it.

VALVE SPECIFICATION CHART

Valve Dimensions

INTAKE VALVE (MINIMUM)

Stem Diameter: 7.960 mm (0.313 in.)

Face Angle: 45É

Valve Margin: 0.700 mm (0.028 in.)

Length: 103.0 mm (4.055 in.)

EXHAUST VALVE (MINIMUM)

Stem Diameter: 7.930 mm (0.312)

Face Angle: 45É

Valve Margin: 1.50 mm (0.059 in.)

Length: 102.70 mm (4.043 in.)

Valve Guide

ClearanceNew Service

Limit

Intake: 0.03 - 0.06 mm

(0.001 - 0.002 in.)0.10 mm

(0.004 in.)

Exhaust: 0.05 - 0.09 mm

(0.002 - 0.0035 in.)0.15 mm

(0.006 in.)

Valve Springs New Service

Limit

Free Length: 49.8 mm (1.960 in.) 48.8 mm

(1.921 in.)

Squarness: 2É Maximum 4É Maximum

Spring Tension: 33 Kg @ 40.4 mm

(73 lbs. @ 1.59 in.)

Fig. 16 Valve Spring

Fig. 17 Valve Seat Reconditioning

Fig. 18 Install Valve Stem Seals

Fig. 19 Installed Valve Spring Position

NS3.0L ENGINE 9 - 67

SERVICE PROCEDURES (Continued)

Page 1118 of 1938

REMOVAL AND INSTALLATION

ENGINE MOUNTS

RIGHT SIDE MOUNT

REMOVAL

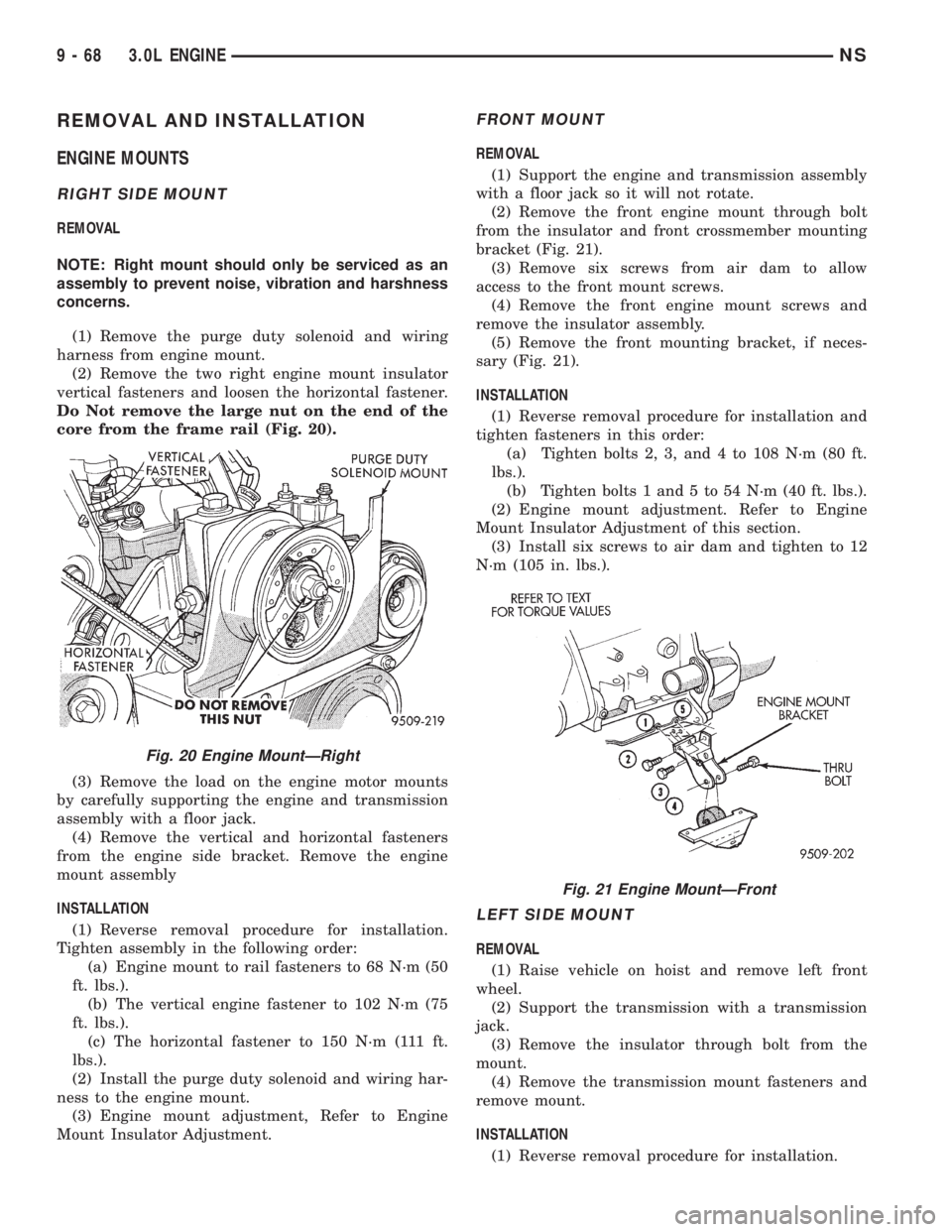

NOTE: Right mount should only be serviced as an

assembly to prevent noise, vibration and harshness

concerns.

(1) Remove the purge duty solenoid and wiring

harness from engine mount.

(2) Remove the two right engine mount insulator

vertical fasteners and loosen the horizontal fastener.

Do Not remove the large nut on the end of the

core from the frame rail (Fig. 20).

(3) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

(4) Remove the vertical and horizontal fasteners

from the engine side bracket. Remove the engine

mount assembly

INSTALLATION

(1) Reverse removal procedure for installation.

Tighten assembly in the following order:

(a) Engine mount to rail fasteners to 68 N´m (50

ft. lbs.).

(b) The vertical engine fastener to 102 N´m (75

ft. lbs.).

(c) The horizontal fastener to 150 N´m (111 ft.

lbs.).

(2) Install the purge duty solenoid and wiring har-

ness to the engine mount.

(3) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment.

FRONT MOUNT

REMOVAL

(1) Support the engine and transmission assembly

with a floor jack so it will not rotate.

(2) Remove the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 21).

(3) Remove six screws from air dam to allow

access to the front mount screws.

(4) Remove the front engine mount screws and

remove the insulator assembly.

(5) Remove the front mounting bracket, if neces-

sary (Fig. 21).

INSTALLATION

(1) Reverse removal procedure for installation and

tighten fasteners in this order:

(a) Tighten bolts 2, 3, and 4 to 108 N´m (80 ft.

lbs.).

(b) Tighten bolts 1 and 5 to 54 N´m (40 ft. lbs.).

(2) Engine mount adjustment. Refer to Engine

Mount Insulator Adjustment of this section.

(3) Install six screws to air dam and tighten to 12

N´m (105 in. lbs.).

LEFT SIDE MOUNT

REMOVAL

(1) Raise vehicle on hoist and remove left front

wheel.

(2) Support the transmission with a transmission

jack.

(3) Remove the insulator through bolt from the

mount.

(4) Remove the transmission mount fasteners and

remove mount.

INSTALLATION

(1) Reverse removal procedure for installation.

Fig. 20 Engine MountÐRight

Fig. 21 Engine MountÐFront

9 - 68 3.0L ENGINENS