shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1351 of 1938

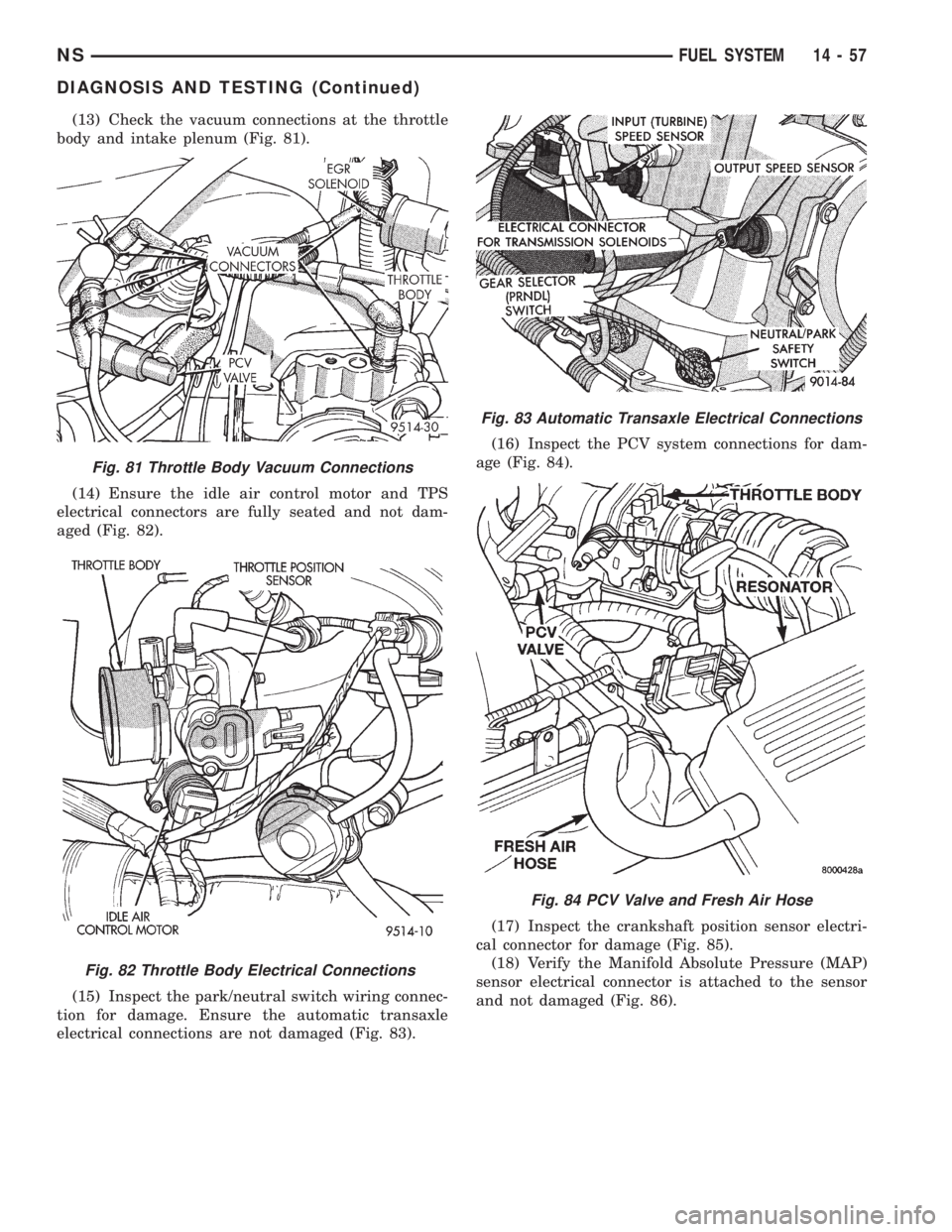

(13) Check the vacuum connections at the throttle

body and intake plenum (Fig. 81).

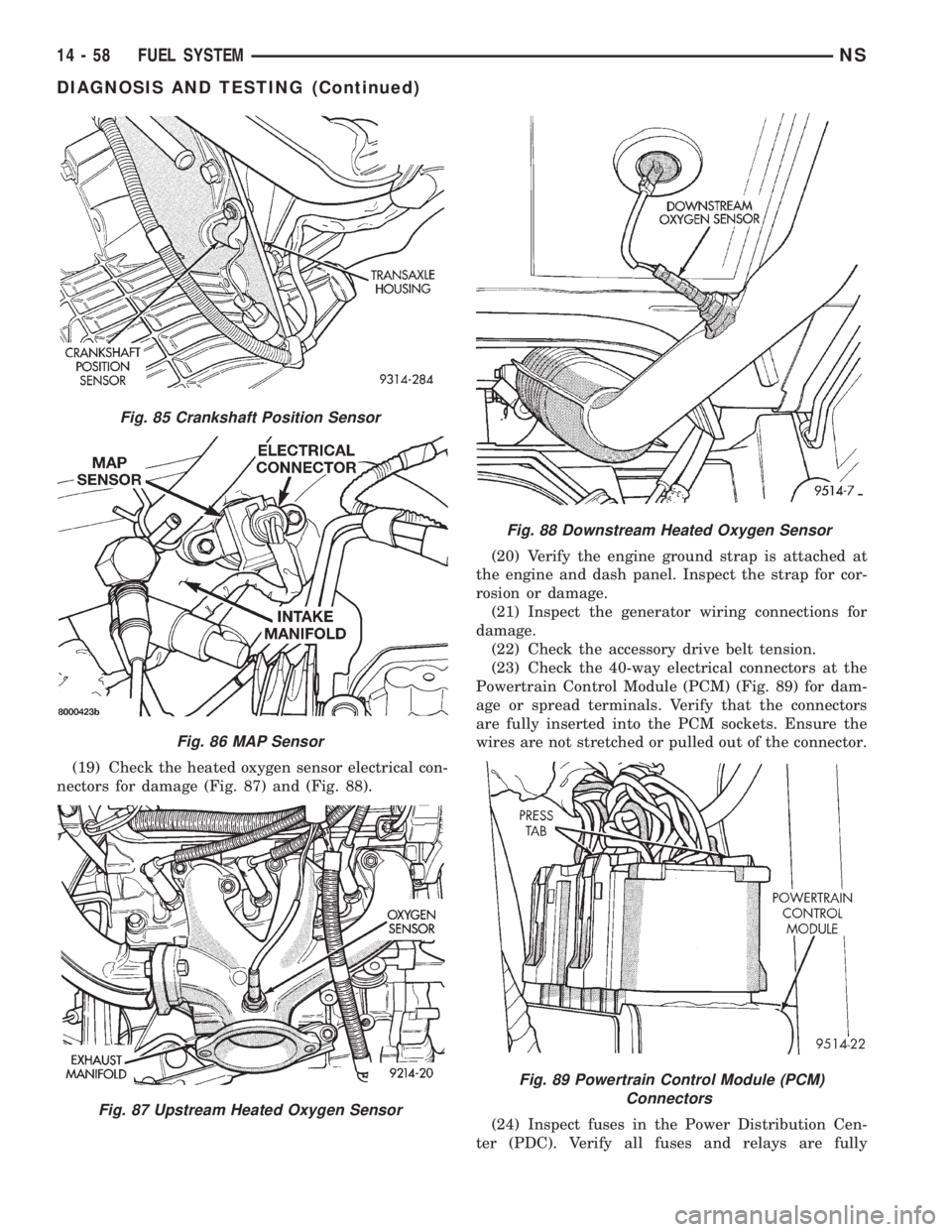

(14) Ensure the idle air control motor and TPS

electrical connectors are fully seated and not dam-

aged (Fig. 82).

(15) Inspect the park/neutral switch wiring connec-

tion for damage. Ensure the automatic transaxle

electrical connections are not damaged (Fig. 83).(16) Inspect the PCV system connections for dam-

age (Fig. 84).

(17) Inspect the crankshaft position sensor electri-

cal connector for damage (Fig. 85).

(18) Verify the Manifold Absolute Pressure (MAP)

sensor electrical connector is attached to the sensor

and not damaged (Fig. 86).

Fig. 81 Throttle Body Vacuum Connections

Fig. 82 Throttle Body Electrical Connections

Fig. 83 Automatic Transaxle Electrical Connections

Fig. 84 PCV Valve and Fresh Air Hose

NSFUEL SYSTEM 14 - 57

DIAGNOSIS AND TESTING (Continued)

Page 1352 of 1938

(19) Check the heated oxygen sensor electrical con-

nectors for damage (Fig. 87) and (Fig. 88).(20) Verify the engine ground strap is attached at

the engine and dash panel. Inspect the strap for cor-

rosion or damage.

(21) Inspect the generator wiring connections for

damage.

(22) Check the accessory drive belt tension.

(23) Check the 40-way electrical connectors at the

Powertrain Control Module (PCM) (Fig. 89) for dam-

age or spread terminals. Verify that the connectors

are fully inserted into the PCM sockets. Ensure the

wires are not stretched or pulled out of the connector.

(24) Inspect fuses in the Power Distribution Cen-

ter (PDC). Verify all fuses and relays are fully

Fig. 85 Crankshaft Position Sensor

Fig. 86 MAP Sensor

Fig. 87 Upstream Heated Oxygen Sensor

Fig. 88 Downstream Heated Oxygen Sensor

Fig. 89 Powertrain Control Module (PCM)

Connectors

14 - 58 FUEL SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 1355 of 1938

PCM. If OK, replace MAP sensor. If not OK, repair or

replace the wire harness as required.

HEATED OXYGEN SENSOR

Use an ohmmeter to test the heating element of

the oxygen sensors. Disconnect the electrical connec-

tor from each oxygen sensor. The white wires in the

sensor connector are the power and ground circuits

for the heater. Connect the ohmmeter test leads to

terminals of the white wires in the heated oxygen

sensor connector. Replace the heated oxygen sensor if

the resistance is not between 4 and 7 ohms.

KNOCK SENSOR

The engine knock sensor is affected by a number of

factors. A few of these are: ignition timing, cylinder

pressure, fuel octane, etc. The knock sensor gener-

ates an AC voltage whose amplitude increases with

the increase of engine knock. The knock sensor can

be tested with a digital voltmeter. The RMS voltage

starts at about 20mVac (at about 700 rpm) and

increases to approximately 600 mVac (5000 rpm). If

the output falls outside of this range a DTC will be

set.

CAMSHAFT AND CRANKSHAFT POSITION SENSOR

Refer to Group 8D, Ignition for Diagnosis and Test-

ing of Camshaft and Crankshaft Sensors.

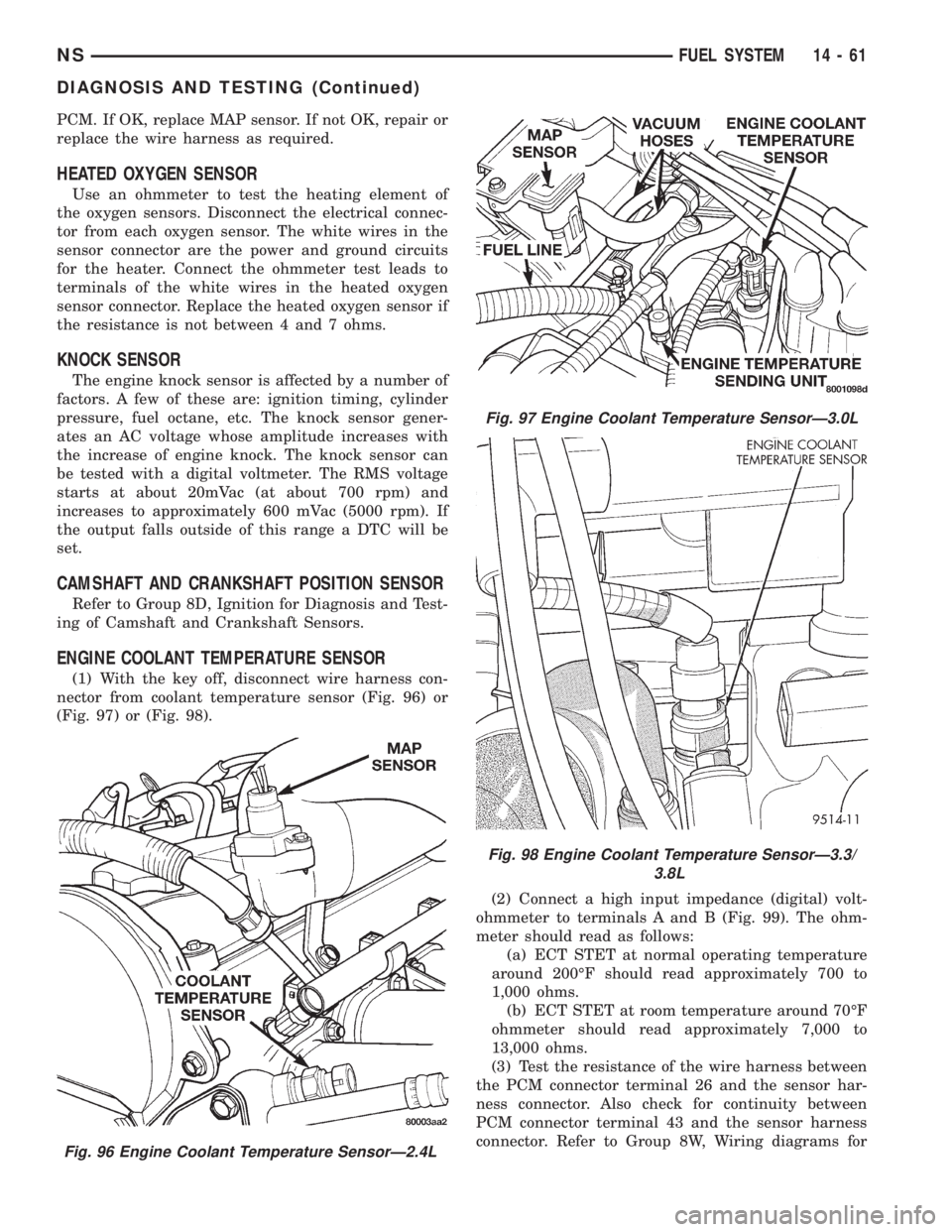

ENGINE COOLANT TEMPERATURE SENSOR

(1) With the key off, disconnect wire harness con-

nector from coolant temperature sensor (Fig. 96) or

(Fig. 97) or (Fig. 98).

(2) Connect a high input impedance (digital) volt-

ohmmeter to terminals A and B (Fig. 99). The ohm-

meter should read as follows:

(a) ECT STET at normal operating temperature

around 200ÉF should read approximately 700 to

1,000 ohms.

(b) ECT STET at room temperature around 70ÉF

ohmmeter should read approximately 7,000 to

13,000 ohms.

(3) Test the resistance of the wire harness between

the PCM connector terminal 26 and the sensor har-

ness connector. Also check for continuity between

PCM connector terminal 43 and the sensor harness

connector. Refer to Group 8W, Wiring diagrams for

Fig. 96 Engine Coolant Temperature SensorÐ2.4L

Fig. 97 Engine Coolant Temperature SensorÐ3.0L

Fig. 98 Engine Coolant Temperature SensorÐ3.3/

3.8L

NSFUEL SYSTEM 14 - 61

DIAGNOSIS AND TESTING (Continued)

Page 1359 of 1938

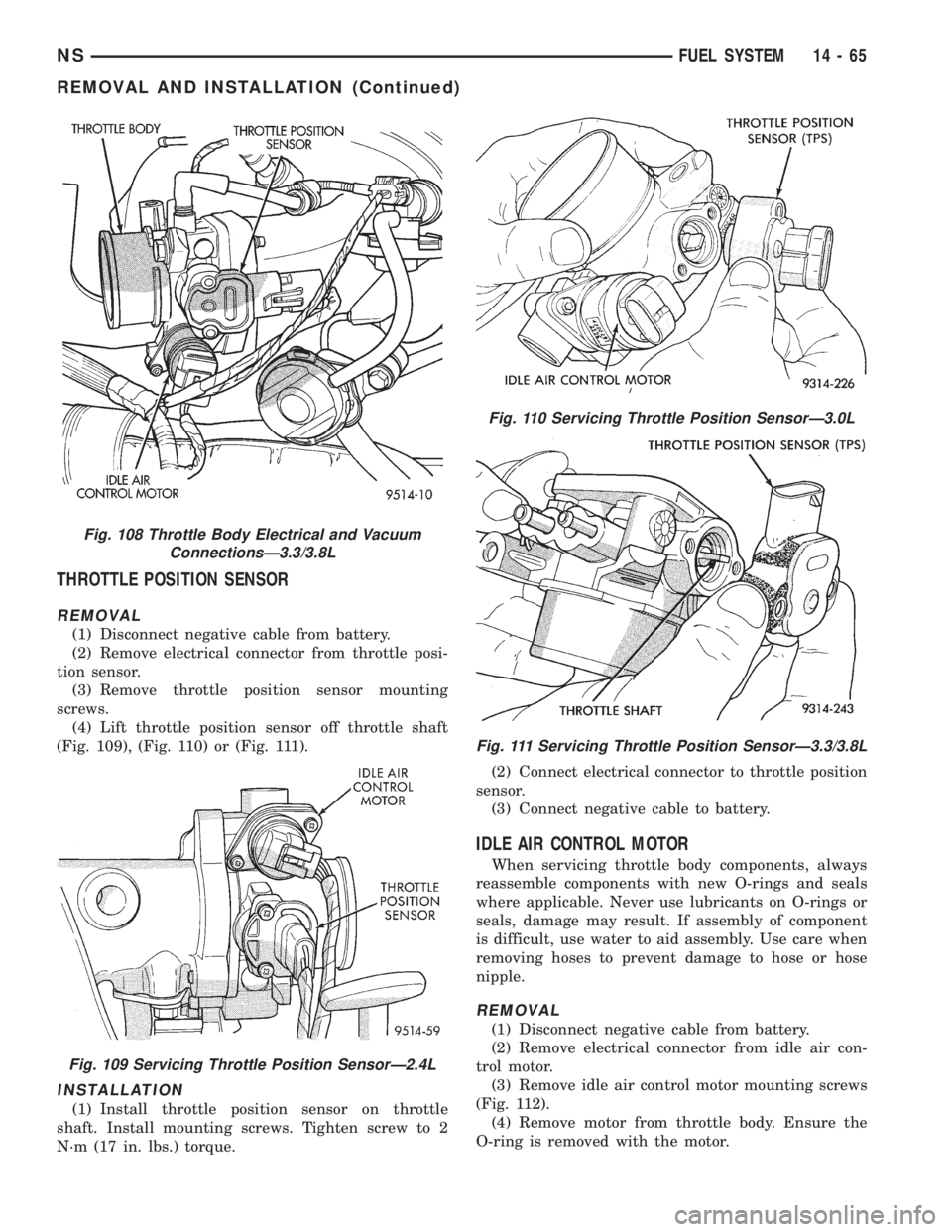

THROTTLE POSITION SENSOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from throttle posi-

tion sensor.

(3) Remove throttle position sensor mounting

screws.

(4) Lift throttle position sensor off throttle shaft

(Fig. 109), (Fig. 110) or (Fig. 111).

INSTALLATION

(1) Install throttle position sensor on throttle

shaft. Install mounting screws. Tighten screw to 2

N´m (17 in. lbs.) torque.(2) Connect electrical connector to throttle position

sensor.

(3) Connect negative cable to battery.

IDLE AIR CONTROL MOTOR

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. Never use lubricants on O-rings or

seals, damage may result. If assembly of component

is difficult, use water to aid assembly. Use care when

removing hoses to prevent damage to hose or hose

nipple.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from idle air con-

trol motor.

(3) Remove idle air control motor mounting screws

(Fig. 112).

(4) Remove motor from throttle body. Ensure the

O-ring is removed with the motor.

Fig. 108 Throttle Body Electrical and Vacuum

ConnectionsÐ3.3/3.8L

Fig. 109 Servicing Throttle Position SensorÐ2.4L

Fig. 110 Servicing Throttle Position SensorÐ3.0L

Fig. 111 Servicing Throttle Position SensorÐ3.3/3.8L

NSFUEL SYSTEM 14 - 65

REMOVAL AND INSTALLATION (Continued)

Page 1362 of 1938

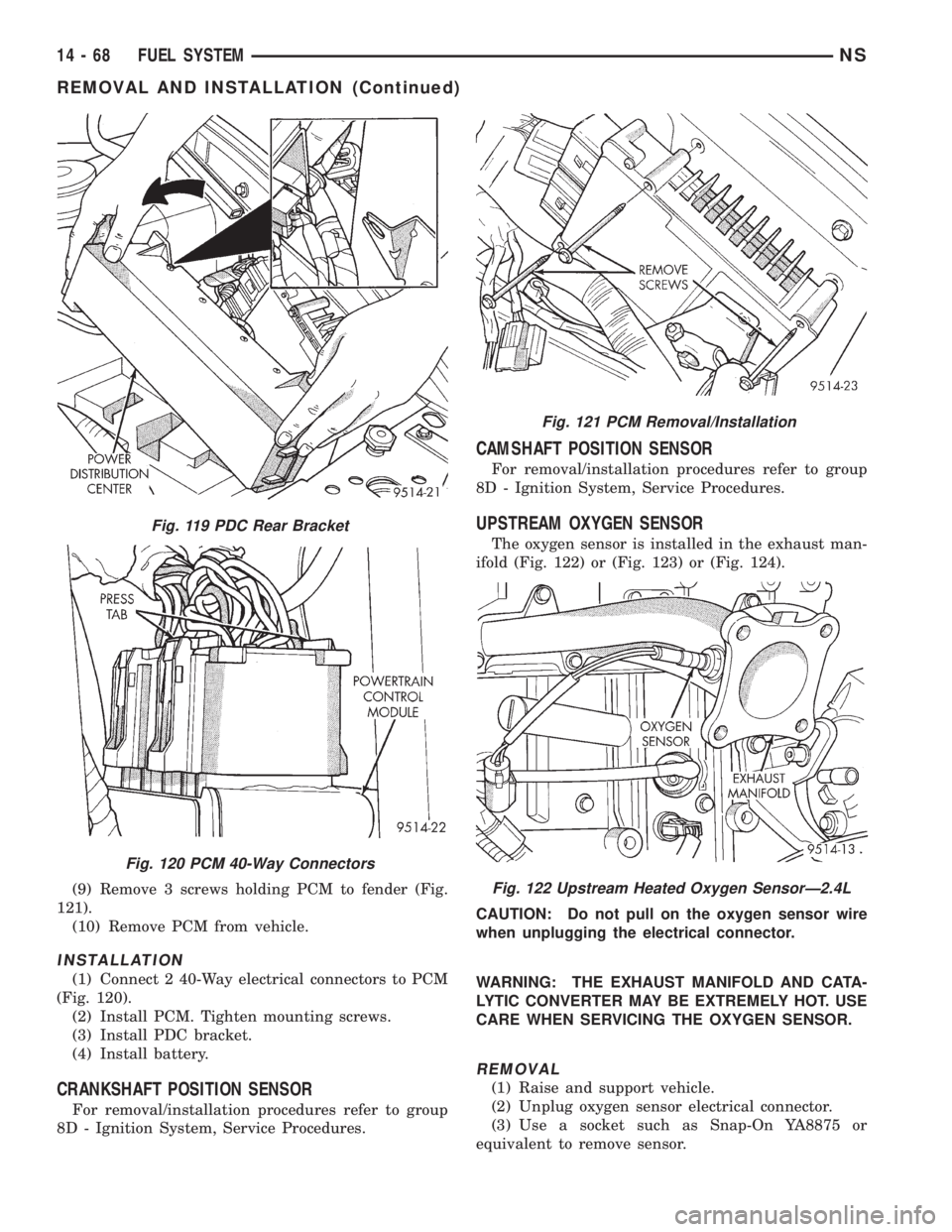

(9) Remove 3 screws holding PCM to fender (Fig.

121).

(10) Remove PCM from vehicle.

INSTALLATION

(1) Connect 2 40-Way electrical connectors to PCM

(Fig. 120).

(2) Install PCM. Tighten mounting screws.

(3) Install PDC bracket.

(4) Install battery.

CRANKSHAFT POSITION SENSOR

For removal/installation procedures refer to group

8D - Ignition System, Service Procedures.

CAMSHAFT POSITION SENSOR

For removal/installation procedures refer to group

8D - Ignition System, Service Procedures.

UPSTREAM OXYGEN SENSOR

The oxygen sensor is installed in the exhaust man-

ifold (Fig. 122) or (Fig. 123) or (Fig. 124).

CAUTION: Do not pull on the oxygen sensor wire

when unplugging the electrical connector.

WARNING: THE EXHAUST MANIFOLD AND CATA-

LYTIC CONVERTER MAY BE EXTREMELY HOT. USE

CARE WHEN SERVICING THE OXYGEN SENSOR.

REMOVAL

(1) Raise and support vehicle.

(2) Unplug oxygen sensor electrical connector.

(3) Use a socket such as Snap-On YA8875 or

equivalent to remove sensor.

Fig. 119 PDC Rear Bracket

Fig. 120 PCM 40-Way Connectors

Fig. 121 PCM Removal/Installation

Fig. 122 Upstream Heated Oxygen SensorÐ2.4L

14 - 68 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1373 of 1938

For periodic draining of water from the bowl, refer

to Fuel Filter/Water Separator Removal/Installation

in this group.

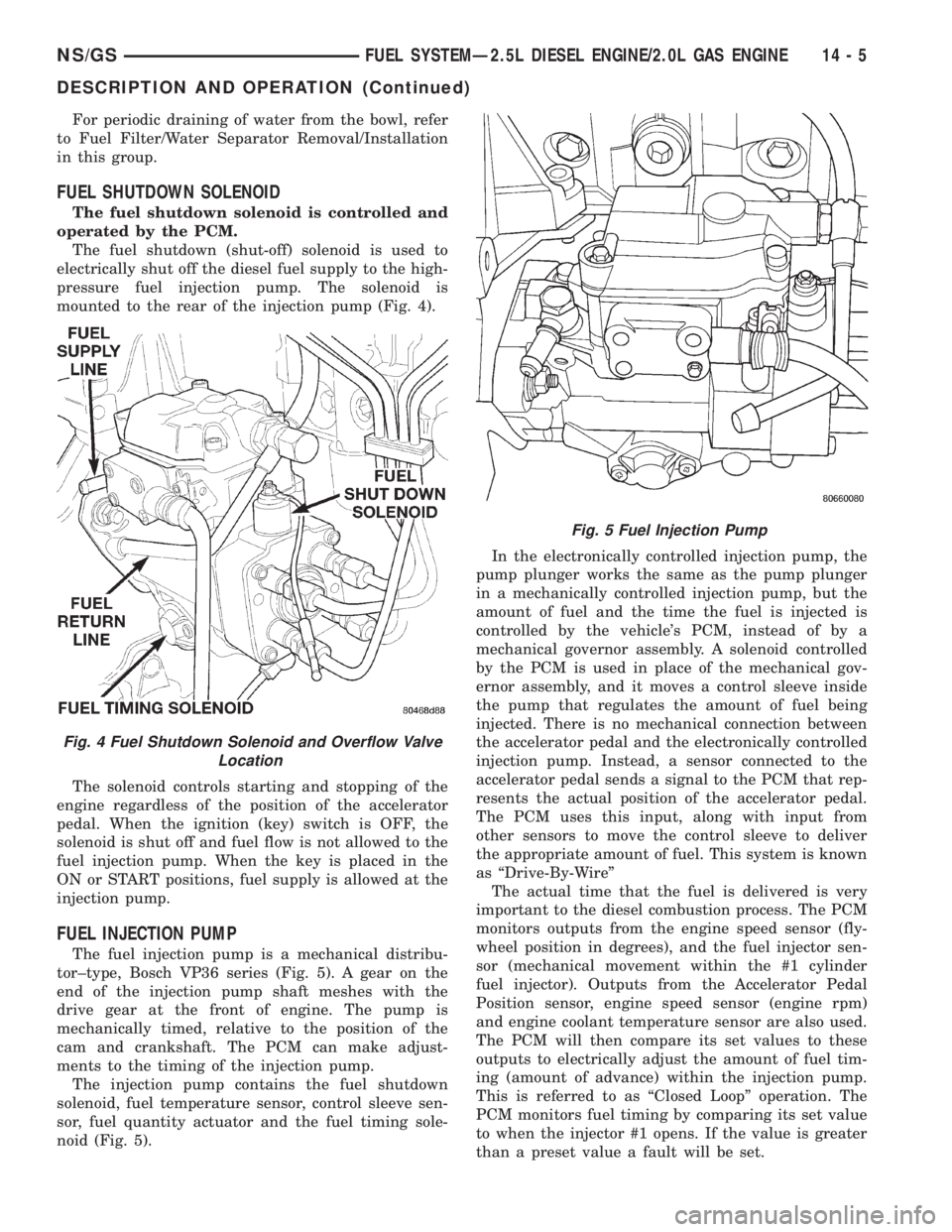

FUEL SHUTDOWN SOLENOID

The fuel shutdown solenoid is controlled and

operated by the PCM.

The fuel shutdown (shut-off) solenoid is used to

electrically shut off the diesel fuel supply to the high-

pressure fuel injection pump. The solenoid is

mounted to the rear of the injection pump (Fig. 4).

The solenoid controls starting and stopping of the

engine regardless of the position of the accelerator

pedal. When the ignition (key) switch is OFF, the

solenoid is shut off and fuel flow is not allowed to the

fuel injection pump. When the key is placed in the

ON or START positions, fuel supply is allowed at the

injection pump.

FUEL INJECTION PUMP

The fuel injection pump is a mechanical distribu-

tor±type, Bosch VP36 series (Fig. 5). A gear on the

end of the injection pump shaft meshes with the

drive gear at the front of engine. The pump is

mechanically timed, relative to the position of the

cam and crankshaft. The PCM can make adjust-

ments to the timing of the injection pump.

The injection pump contains the fuel shutdown

solenoid, fuel temperature sensor, control sleeve sen-

sor, fuel quantity actuator and the fuel timing sole-

noid (Fig. 5).In the electronically controlled injection pump, the

pump plunger works the same as the pump plunger

in a mechanically controlled injection pump, but the

amount of fuel and the time the fuel is injected is

controlled by the vehicle's PCM, instead of by a

mechanical governor assembly. A solenoid controlled

by the PCM is used in place of the mechanical gov-

ernor assembly, and it moves a control sleeve inside

the pump that regulates the amount of fuel being

injected. There is no mechanical connection between

the accelerator pedal and the electronically controlled

injection pump. Instead, a sensor connected to the

accelerator pedal sends a signal to the PCM that rep-

resents the actual position of the accelerator pedal.

The PCM uses this input, along with input from

other sensors to move the control sleeve to deliver

the appropriate amount of fuel. This system is known

as ªDrive-By-Wireº

The actual time that the fuel is delivered is very

important to the diesel combustion process. The PCM

monitors outputs from the engine speed sensor (fly-

wheel position in degrees), and the fuel injector sen-

sor (mechanical movement within the #1 cylinder

fuel injector). Outputs from the Accelerator Pedal

Position sensor, engine speed sensor (engine rpm)

and engine coolant temperature sensor are also used.

The PCM will then compare its set values to these

outputs to electrically adjust the amount of fuel tim-

ing (amount of advance) within the injection pump.

This is referred to as ªClosed Loopº operation. The

PCM monitors fuel timing by comparing its set value

to when the injector #1 opens. If the value is greater

than a preset value a fault will be set.

Fig. 4 Fuel Shutdown Solenoid and Overflow Valve

Location

Fig. 5 Fuel Injection Pump

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1379 of 1938

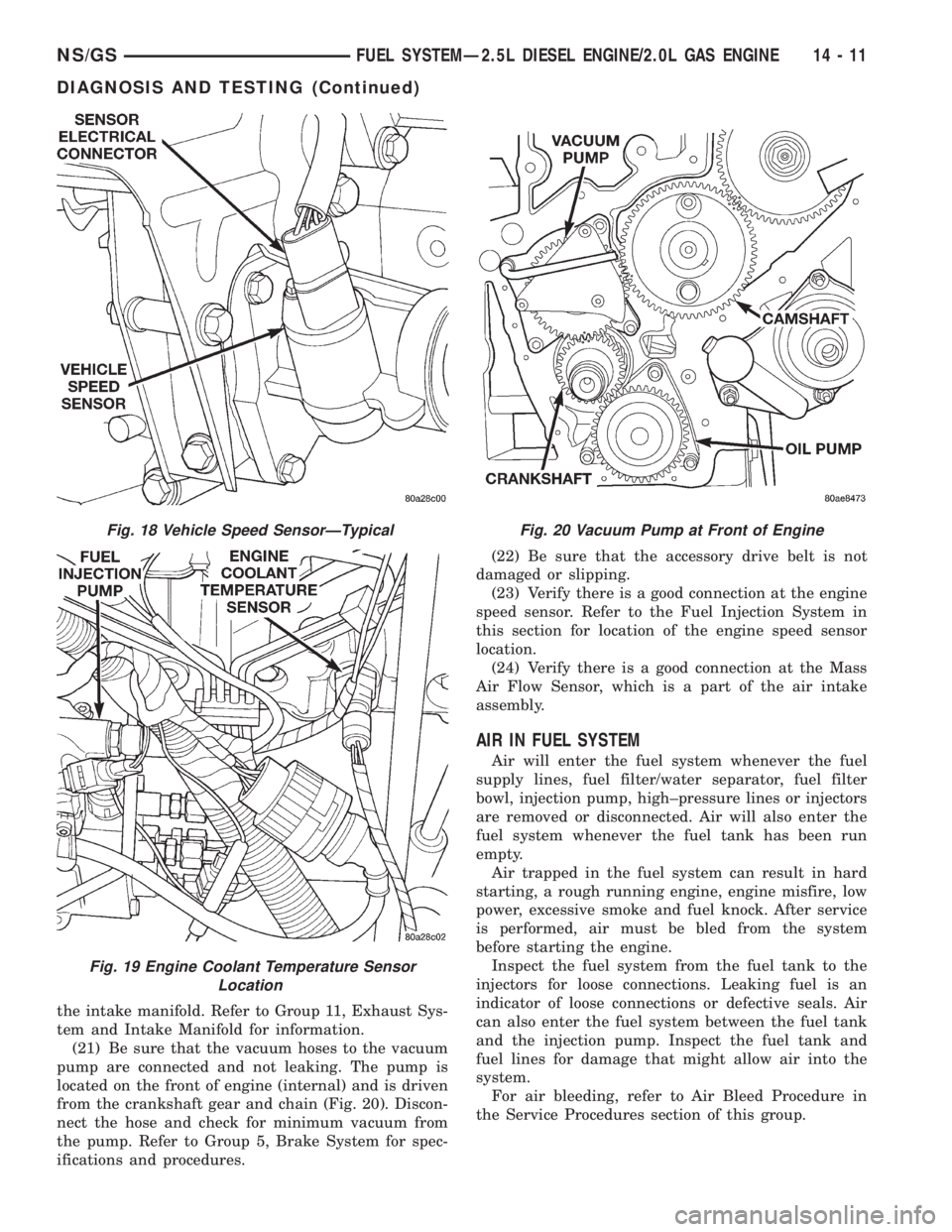

the intake manifold. Refer to Group 11, Exhaust Sys-

tem and Intake Manifold for information.

(21) Be sure that the vacuum hoses to the vacuum

pump are connected and not leaking. The pump is

located on the front of engine (internal) and is driven

from the crankshaft gear and chain (Fig. 20). Discon-

nect the hose and check for minimum vacuum from

the pump. Refer to Group 5, Brake System for spec-

ifications and procedures.(22) Be sure that the accessory drive belt is not

damaged or slipping.

(23) Verify there is a good connection at the engine

speed sensor. Refer to the Fuel Injection System in

this section for location of the engine speed sensor

location.

(24) Verify there is a good connection at the Mass

Air Flow Sensor, which is a part of the air intake

assembly.

AIR IN FUEL SYSTEM

Air will enter the fuel system whenever the fuel

supply lines, fuel filter/water separator, fuel filter

bowl, injection pump, high±pressure lines or injectors

are removed or disconnected. Air will also enter the

fuel system whenever the fuel tank has been run

empty.

Air trapped in the fuel system can result in hard

starting, a rough running engine, engine misfire, low

power, excessive smoke and fuel knock. After service

is performed, air must be bled from the system

before starting the engine.

Inspect the fuel system from the fuel tank to the

injectors for loose connections. Leaking fuel is an

indicator of loose connections or defective seals. Air

can also enter the fuel system between the fuel tank

and the injection pump. Inspect the fuel tank and

fuel lines for damage that might allow air into the

system.

For air bleeding, refer to Air Bleed Procedure in

the Service Procedures section of this group.

Fig. 18 Vehicle Speed SensorÐTypical

Fig. 19 Engine Coolant Temperature Sensor

Location

Fig. 20 Vacuum Pump at Front of Engine

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 11

DIAGNOSIS AND TESTING (Continued)

Page 1388 of 1938

(8) Disconnect the main engine wiring harness

from the glow plugs.

(9) Disconnect the four high±pressure fuel lines

from the fuel injection pump. Also disconnect fuel

lines at the fuel injectors. For procedures, refer to

High±Pressure Fuel Lines in this group. Place a rag

beneath the fittings to catch excess fuel.

(10) Remove plug from timing gear cover.

(11) The ªTop Dead Centerº (TDC) compression fir-

ing stroke must be determined as follows:

(a) Remove the valve cover, refer to Group 9,

Valve Cover Removal/Installation.

(b) Remove the right front tire and splash

shield. Using a socket attached to the end of crank-

shaft, rotate the engine (counterÐclockwise as

viewed from front).

(c) Rotate the engine until cylinder #4 rockers

are in between movement.

(d) Remove rocker arm assembly.

(e) Remove valve spring and keepers.CAU-

TION: When the piston is at TDC there is only

2 mm (.080 thousand) clearance between the

valve and piston.

(f) Let the valve set on top of piston. Install a

dial indicator to the top of the valve stem.

(g) Rotate engine back and forth to find the TDC

position with the indicator on the valve stem. Mark

the damper and timing cover for TDC.

NOTE: On later model 1997 engines, a hole in the

bottom of the clutch housing can be lined up with a

hole in the flywheel, allowing the engine to be held

at TDC with a special alignment tool, part # VM1035.(12) Remove injection pump drive gear nut (Fig.

41) and washer.CAUTION: Be very careful not to

drop the washer into the timing gear cover.

(13) A special 3±piece gear removal tool set

VM.1003 (Fig. 42) must be used to remove the injec-

tion pump drive gear from the pump shaft.

(a) Thread the adapter (Fig. 43) into the timing

cover.

(b) Thread the gear puller into the injection

pump drive gear (Fig. 43). This tool is also used to

hold the gear in synchronization during pump

removal.

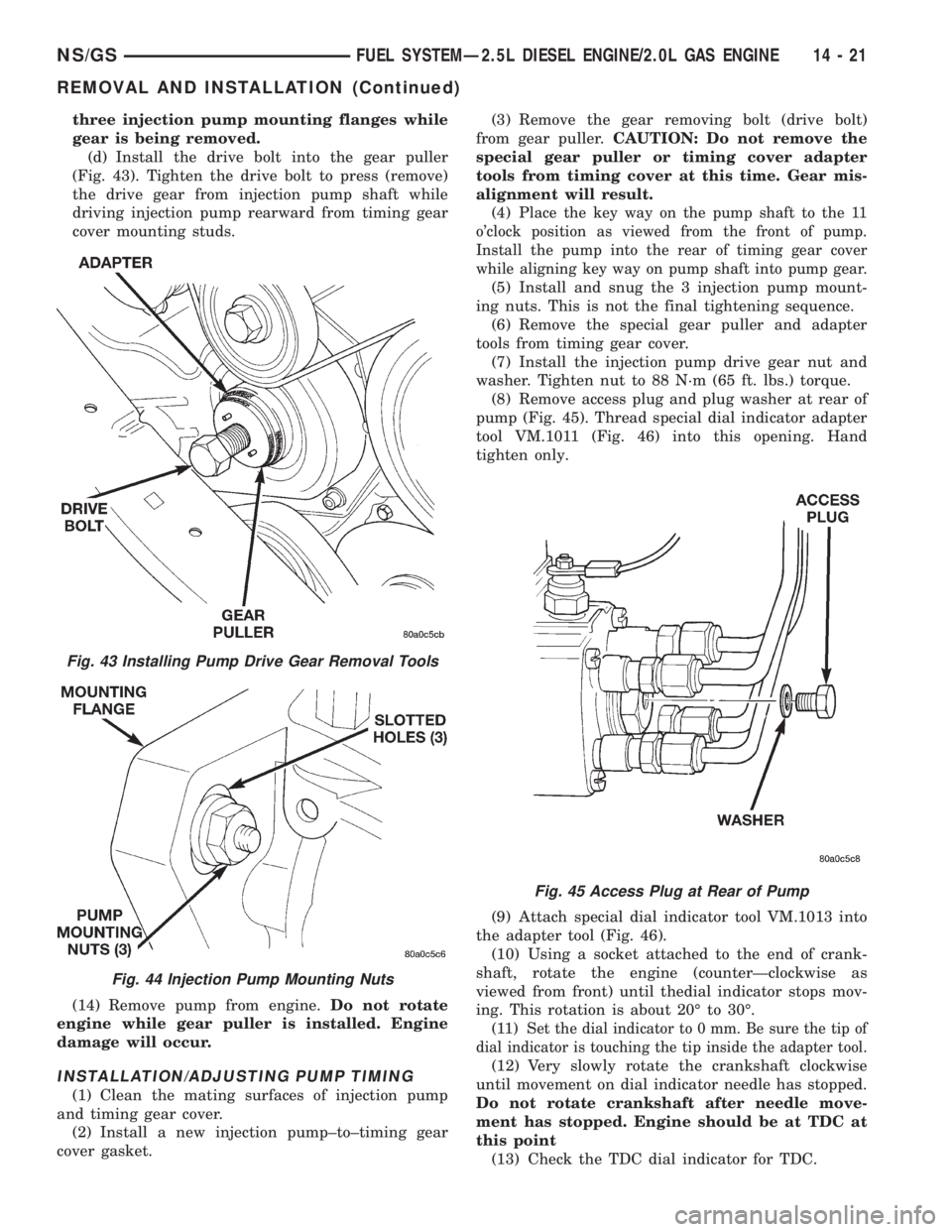

(c) Remove the three injection pump±to±gear

cover mounting nuts (Fig. 44).CAUTION: This

step must be done to prevent breakage of the

Fig. 40 Engine Coolant Temperature Sensor

Fig. 41 Removing Pump Drive Gear Nut

Fig. 42 Pump Gear Tools

14 - 20 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1389 of 1938

three injection pump mounting flanges while

gear is being removed.

(d) Install the drive bolt into the gear puller

(Fig. 43). Tighten the drive bolt to press (remove)

the drive gear from injection pump shaft while

driving injection pump rearward from timing gear

cover mounting studs.

(14) Remove pump from engine.Do not rotate

engine while gear puller is installed. Engine

damage will occur.

INSTALLATION/ADJUSTING PUMP TIMING

(1) Clean the mating surfaces of injection pump

and timing gear cover.

(2) Install a new injection pump±to±timing gear

cover gasket.(3) Remove the gear removing bolt (drive bolt)

from gear puller.CAUTION: Do not remove the

special gear puller or timing cover adapter

tools from timing cover at this time. Gear mis-

alignment will result.

(4) P

lace the key way on the pump shaft to the 11

o'clock position as viewed from the front of pump.

Install the pump into the rear of timing gear cover

while aligning key way on pump shaft into pump gear.

(5) Install and snug the 3 injection pump mount-

ing nuts. This is not the final tightening sequence.

(6) Remove the special gear puller and adapter

tools from timing gear cover.

(7) Install the injection pump drive gear nut and

washer. Tighten nut to 88 N´m (65 ft. lbs.) torque.

(8) Remove access plug and plug washer at rear of

pump (Fig. 45). Thread special dial indicator adapter

tool VM.1011 (Fig. 46) into this opening. Hand

tighten only.

(9) Attach special dial indicator tool VM.1013 into

the adapter tool (Fig. 46).

(10) Using a socket attached to the end of crank-

shaft, rotate the engine (counterÐclockwise as

viewed from front) until thedial indicator stops mov-

ing. This rotation is about 20É to 30É.

(11) S

et the dial indicator to 0 mm. Be sure the tip of

dial indicator is touching the tip inside the adapter tool.

(12) Very slowly rotate the crankshaft clockwise

until movement on dial indicator needle has stopped.

Do not rotate crankshaft after needle move-

ment has stopped. Engine should be at TDC at

this point

(13) Check the TDC dial indicator for TDC.

Fig. 43 Installing Pump Drive Gear Removal Tools

Fig. 44 Injection Pump Mounting Nuts

Fig. 45 Access Plug at Rear of Pump

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 21

REMOVAL AND INSTALLATION (Continued)

Page 1400 of 1938

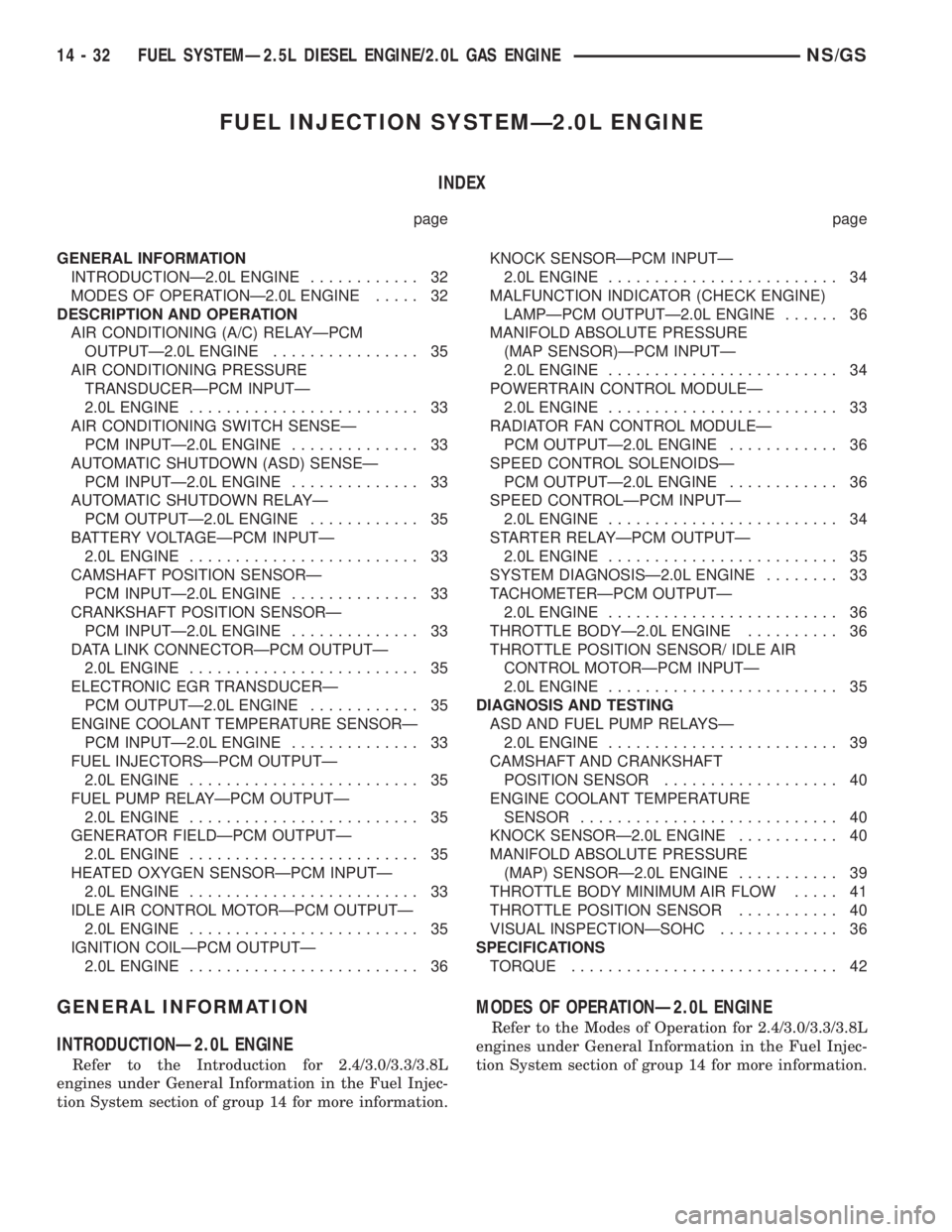

FUEL INJECTION SYSTEMÐ2.0L ENGINE

INDEX

page page

GENERAL INFORMATION

INTRODUCTIONÐ2.0L ENGINE............ 32

MODES OF OPERATIONÐ2.0L ENGINE..... 32

DESCRIPTION AND OPERATION

AIR CONDITIONING (A/C) RELAYÐPCM

OUTPUTÐ2.0L ENGINE................ 35

AIR CONDITIONING PRESSURE

TRANSDUCERÐPCM INPUTÐ

2.0L ENGINE......................... 33

AIR CONDITIONING SWITCH SENSEÐ

PCM INPUTÐ2.0L ENGINE.............. 33

AUTOMATIC SHUTDOWN (ASD) SENSEÐ

PCM INPUTÐ2.0L ENGINE.............. 33

AUTOMATIC SHUTDOWN RELAYÐ

PCM OUTPUTÐ2.0L ENGINE............ 35

BATTERY VOLTAGEÐPCM INPUTÐ

2.0L ENGINE......................... 33

CAMSHAFT POSITION SENSORÐ

PCM INPUTÐ2.0L ENGINE.............. 33

CRANKSHAFT POSITION SENSORÐ

PCM INPUTÐ2.0L ENGINE.............. 33

DATA LINK CONNECTORÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

ELECTRONIC EGR TRANSDUCERÐ

PCM OUTPUTÐ2.0L ENGINE............ 35

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUTÐ2.0L ENGINE.............. 33

FUEL INJECTORSÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

FUEL PUMP RELAYÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

GENERATOR FIELDÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

HEATED OXYGEN SENSORÐPCM INPUTÐ

2.0L ENGINE......................... 33

IDLE AIR CONTROL MOTORÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

IGNITION COILÐPCM OUTPUTÐ

2.0L ENGINE......................... 36KNOCK SENSORÐPCM INPUTÐ

2.0L ENGINE......................... 34

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUTÐ2.0L ENGINE...... 36

MANIFOLD ABSOLUTE PRESSURE

(MAP SENSOR)ÐPCM INPUTÐ

2.0L ENGINE......................... 34

POWERTRAIN CONTROL MODULEÐ

2.0L ENGINE......................... 33

RADIATOR FAN CONTROL MODULEÐ

PCM OUTPUTÐ2.0L ENGINE............ 36

SPEED CONTROL SOLENOIDSÐ

PCM OUTPUTÐ2.0L ENGINE............ 36

SPEED CONTROLÐPCM INPUTÐ

2.0L ENGINE......................... 34

STARTER RELAYÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

SYSTEM DIAGNOSISÐ2.0L ENGINE........ 33

TACHOMETERÐPCM OUTPUTÐ

2.0L ENGINE......................... 36

THROTTLE BODYÐ2.0L ENGINE.......... 36

THROTTLE POSITION SENSOR/ IDLE AIR

CONTROL MOTORÐPCM INPUTÐ

2.0L ENGINE......................... 35

DIAGNOSIS AND TESTING

ASD AND FUEL PUMP RELAYSÐ

2.0L ENGINE......................... 39

CAMSHAFT AND CRANKSHAFT

POSITION SENSOR................... 40

ENGINE COOLANT TEMPERATURE

SENSOR............................ 40

KNOCK SENSORÐ2.0L ENGINE........... 40

MANIFOLD ABSOLUTE PRESSURE

(MAP) SENSORÐ2.0L ENGINE........... 39

THROTTLE BODY MINIMUM AIR FLOW..... 41

THROTTLE POSITION SENSOR........... 40

VISUAL INSPECTIONÐSOHC............. 36

SPECIFICATIONS

TORQUE............................. 42

GENERAL INFORMATION

INTRODUCTIONÐ2.0L ENGINE

Refer to the Introduction for 2.4/3.0/3.3/3.8L

engines under General Information in the Fuel Injec-

tion System section of group 14 for more information.

MODES OF OPERATIONÐ2.0L ENGINE

Refer to the Modes of Operation for 2.4/3.0/3.3/3.8L

engines under General Information in the Fuel Injec-

tion System section of group 14 for more information.

14 - 32 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS