shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1502 of 1938

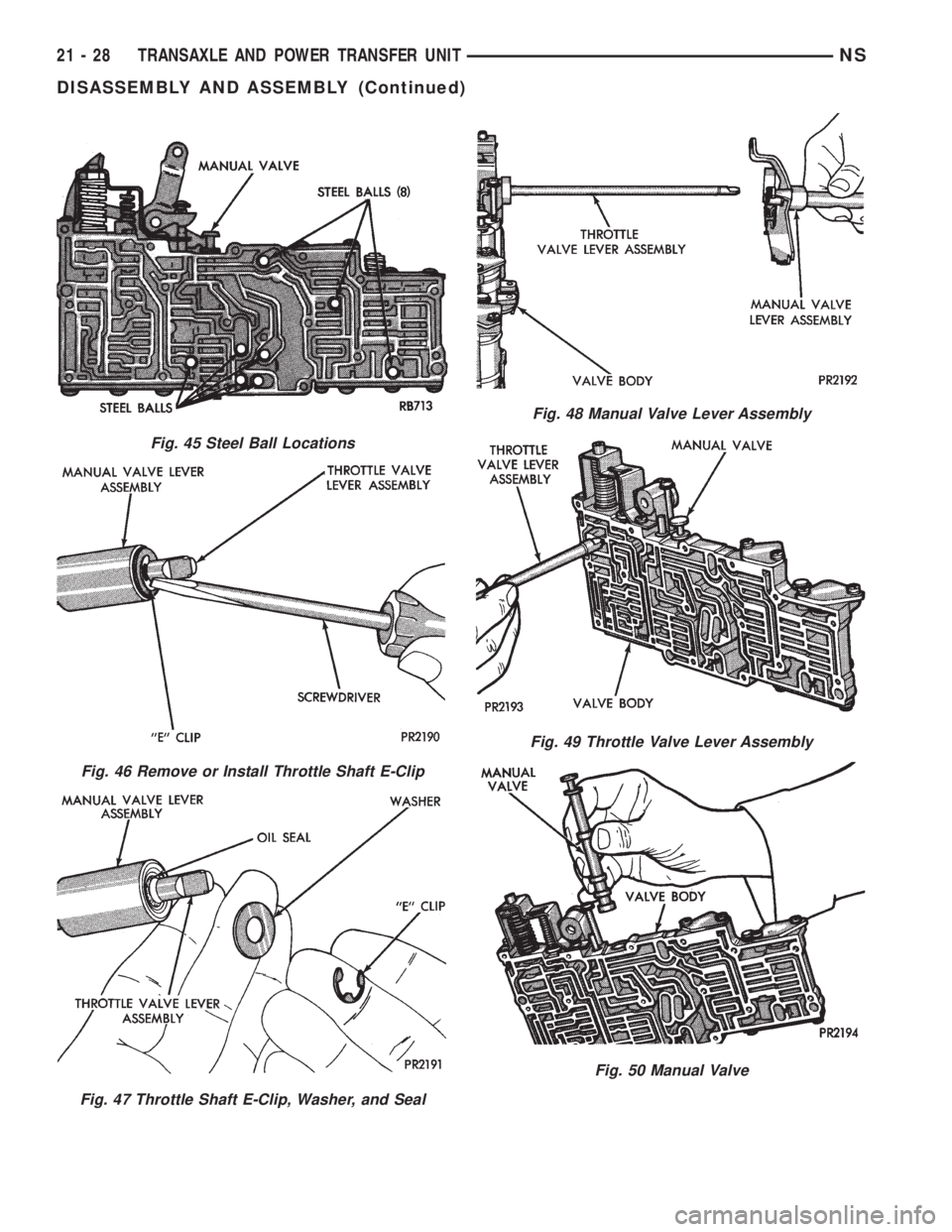

Fig. 45 Steel Ball Locations

Fig. 46 Remove or Install Throttle Shaft E-Clip

Fig. 47 Throttle Shaft E-Clip, Washer, and Seal

Fig. 48 Manual Valve Lever Assembly

Fig. 49 Throttle Valve Lever Assembly

Fig. 50 Manual Valve

21 - 28 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1505 of 1938

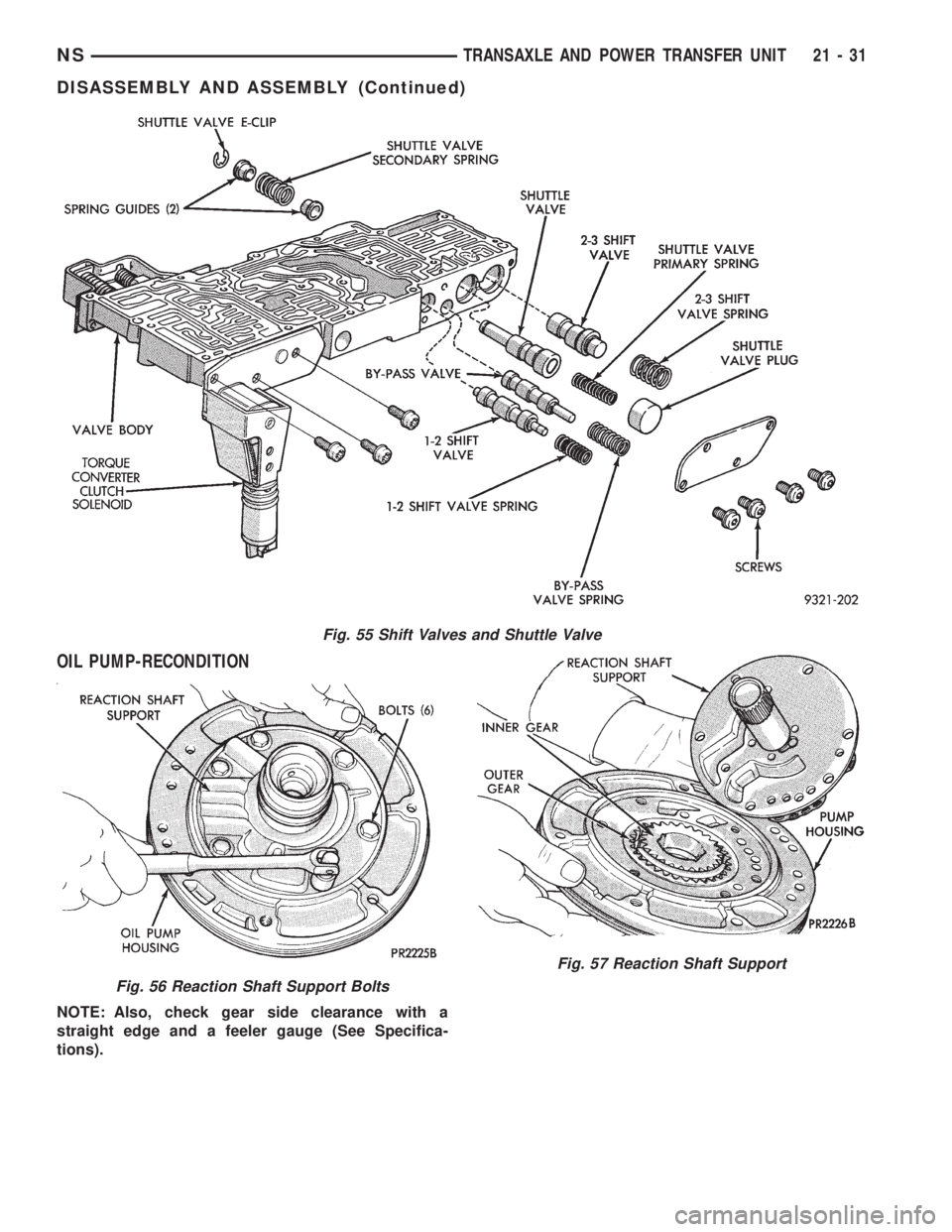

OIL PUMP-RECONDITION

NOTE: Also, check gear side clearance with a

straight edge and a feeler gauge (See Specifica-

tions).

Fig. 55 Shift Valves and Shuttle Valve

Fig. 56 Reaction Shaft Support Bolts

Fig. 57 Reaction Shaft Support

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 31

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1506 of 1938

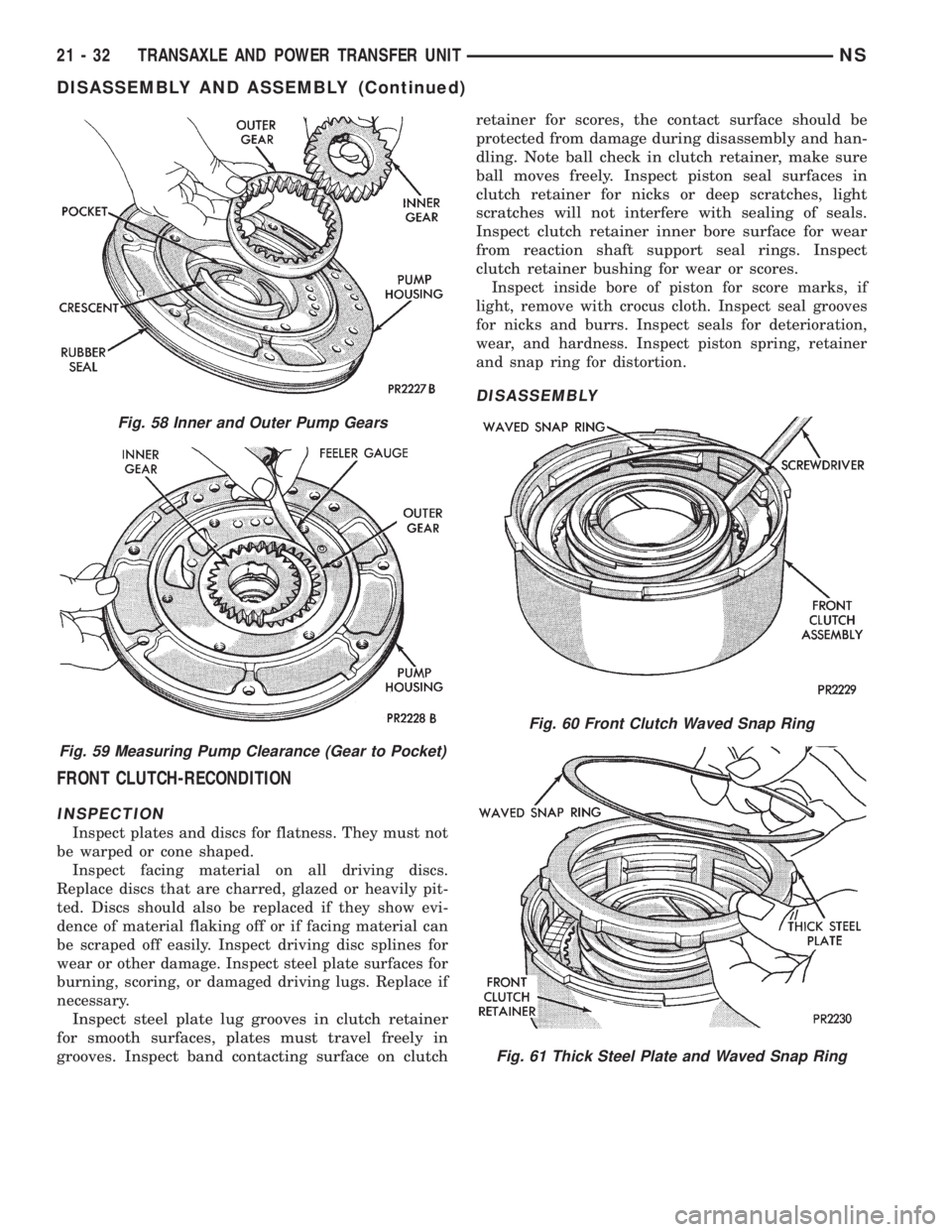

FRONT CLUTCH-RECONDITION

INSPECTION

Inspect plates and discs for flatness. They must not

be warped or cone shaped.

Inspect facing material on all driving discs.

Replace discs that are charred, glazed or heavily pit-

ted. Discs should also be replaced if they show evi-

dence of material flaking off or if facing material can

be scraped off easily. Inspect driving disc splines for

wear or other damage. Inspect steel plate surfaces for

burning, scoring, or damaged driving lugs. Replace if

necessary.

Inspect steel plate lug grooves in clutch retainer

for smooth surfaces, plates must travel freely in

grooves. Inspect band contacting surface on clutchretainer for scores, the contact surface should be

protected from damage during disassembly and han-

dling. Note ball check in clutch retainer, make sure

ball moves freely. Inspect piston seal surfaces in

clutch retainer for nicks or deep scratches, light

scratches will not interfere with sealing of seals.

Inspect clutch retainer inner bore surface for wear

from reaction shaft support seal rings. Inspect

clutch retainer bushing for wear or scores.

Inspect inside bore of piston for score marks, if

light, remove with crocus cloth. Inspect seal grooves

for nicks and burrs. Inspect seals for deterioration,

wear, and hardness. Inspect piston spring, retainer

and snap ring for distortion.

DISASSEMBLY

Fig. 58 Inner and Outer Pump Gears

Fig. 59 Measuring Pump Clearance (Gear to Pocket)

Fig. 60 Front Clutch Waved Snap Ring

Fig. 61 Thick Steel Plate and Waved Snap Ring

21 - 32 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1507 of 1938

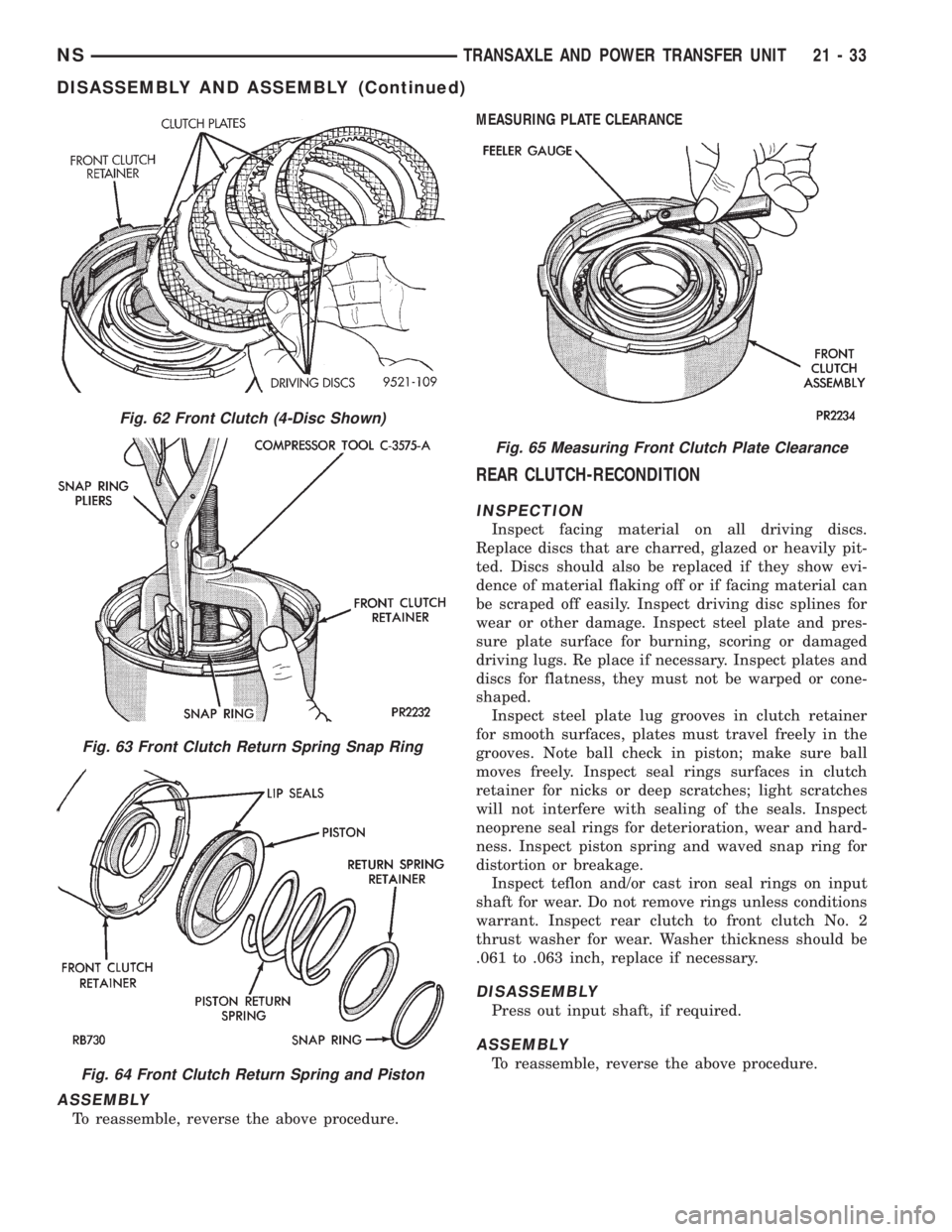

ASSEMBLY

To reassemble, reverse the above procedure.MEASURING PLATE CLEARANCE

REAR CLUTCH-RECONDITION

INSPECTION

Inspect facing material on all driving discs.

Replace discs that are charred, glazed or heavily pit-

ted. Discs should also be replaced if they show evi-

dence of material flaking off or if facing material can

be scraped off easily. Inspect driving disc splines for

wear or other damage. Inspect steel plate and pres-

sure plate surface for burning, scoring or damaged

driving lugs. Re place if necessary. Inspect plates and

discs for flatness, they must not be warped or cone-

shaped.

Inspect steel plate lug grooves in clutch retainer

for smooth surfaces, plates must travel freely in the

grooves. Note ball check in piston; make sure ball

moves freely. Inspect seal rings surfaces in clutch

retainer for nicks or deep scratches; light scratches

will not interfere with sealing of the seals. Inspect

neoprene seal rings for deterioration, wear and hard-

ness. Inspect piston spring and waved snap ring for

distortion or breakage.

Inspect teflon and/or cast iron seal rings on input

shaft for wear. Do not remove rings unless conditions

warrant. Inspect rear clutch to front clutch No. 2

thrust washer for wear. Washer thickness should be

.061 to .063 inch, replace if necessary.

DISASSEMBLY

Press out input shaft, if required.

ASSEMBLY

To reassemble, reverse the above procedure.

Fig. 62 Front Clutch (4-Disc Shown)

Fig. 63 Front Clutch Return Spring Snap Ring

Fig. 64 Front Clutch Return Spring and Piston

Fig. 65 Measuring Front Clutch Plate Clearance

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 33

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1508 of 1938

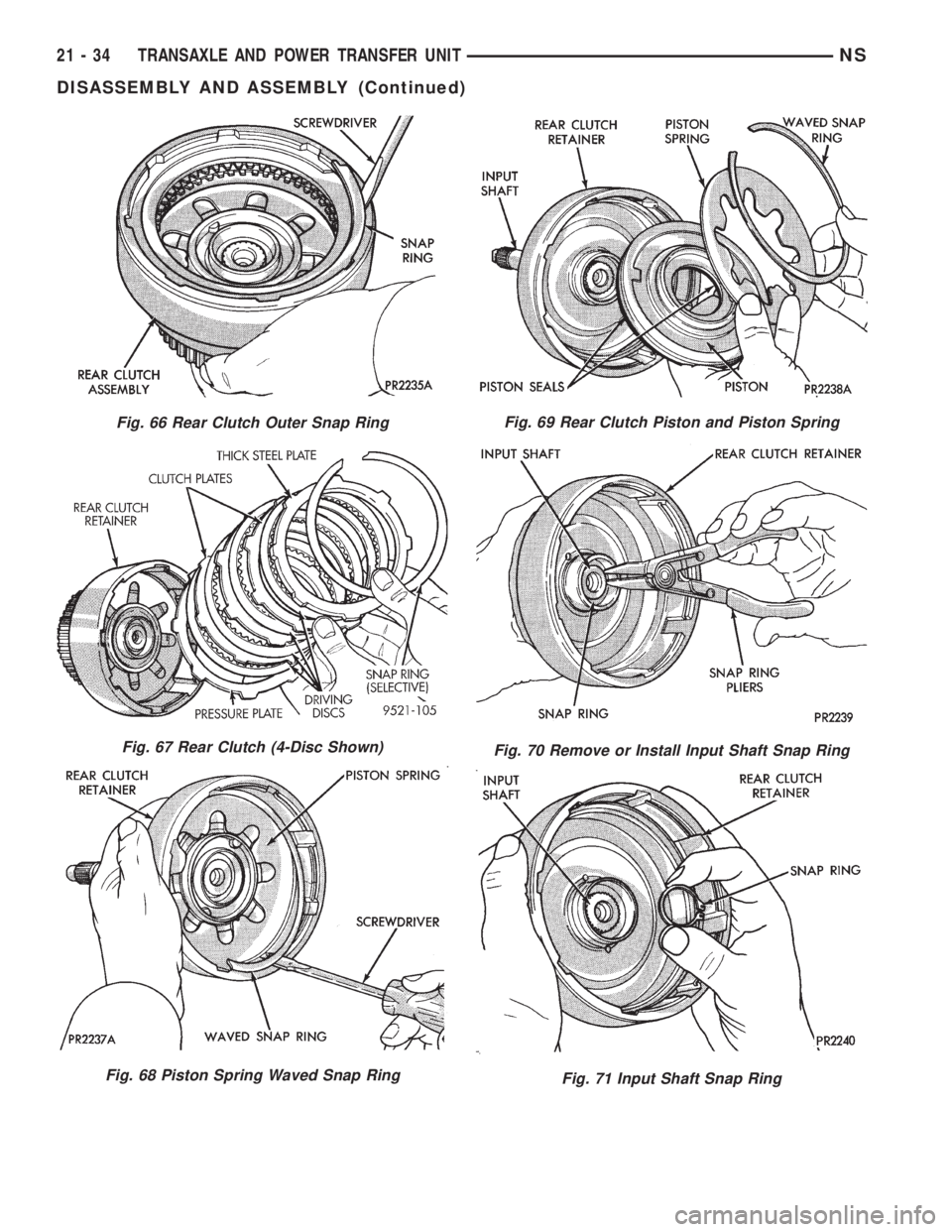

Fig. 66 Rear Clutch Outer Snap Ring

Fig. 67 Rear Clutch (4-Disc Shown)

Fig. 68 Piston Spring Waved Snap Ring

Fig. 69 Rear Clutch Piston and Piston Spring

Fig. 70 Remove or Install Input Shaft Snap Ring

Fig. 71 Input Shaft Snap Ring

21 - 34 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1512 of 1938

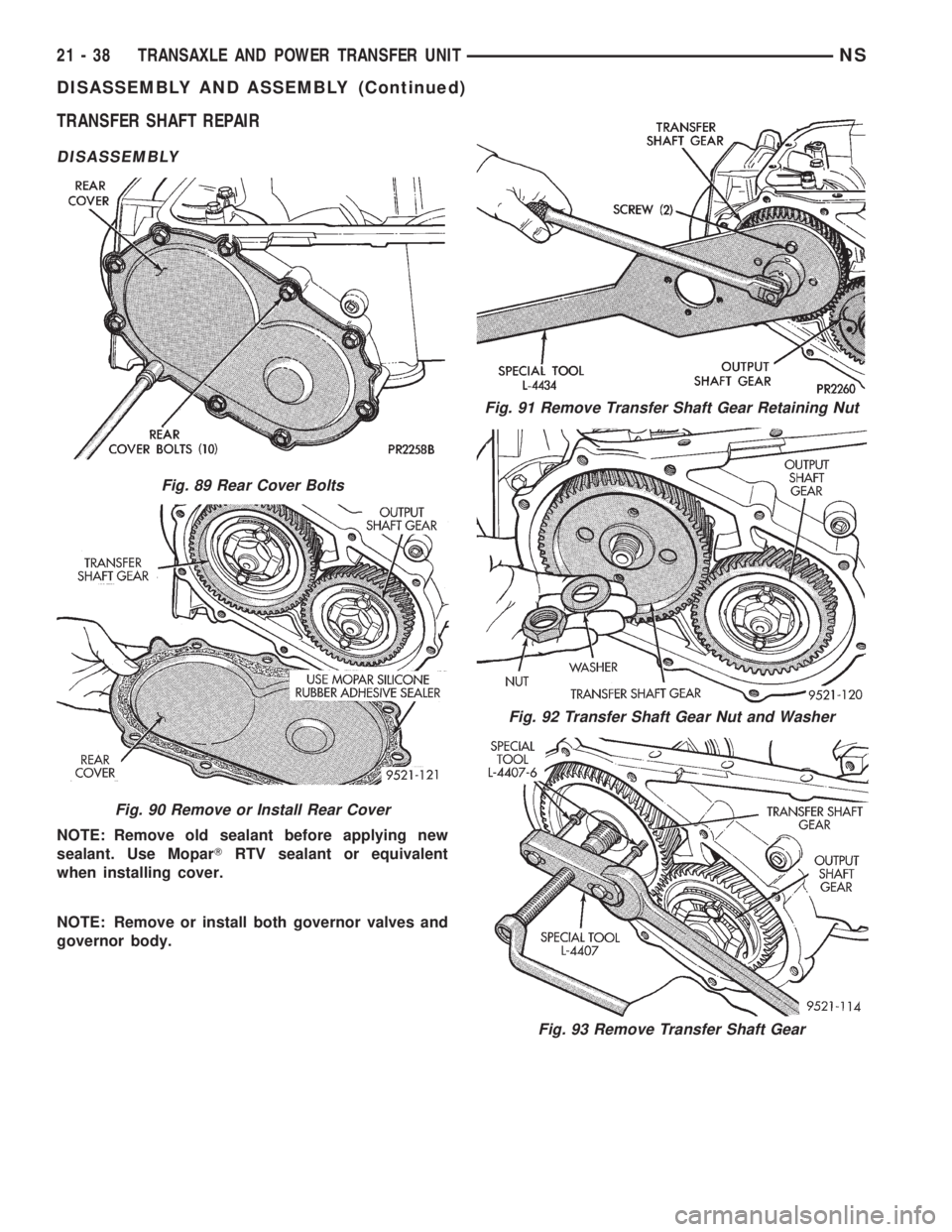

TRANSFER SHAFT REPAIR

DISASSEMBLY

NOTE: Remove old sealant before applying new

sealant. Use MoparTRTV sealant or equivalent

when installing cover.

NOTE: Remove or install both governor valves and

governor body.

Fig. 89 Rear Cover Bolts

Fig. 90 Remove or Install Rear Cover

Fig. 91 Remove Transfer Shaft Gear Retaining Nut

Fig. 92 Transfer Shaft Gear Nut and Washer

Fig. 93 Remove Transfer Shaft Gear

21 - 38 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1513 of 1938

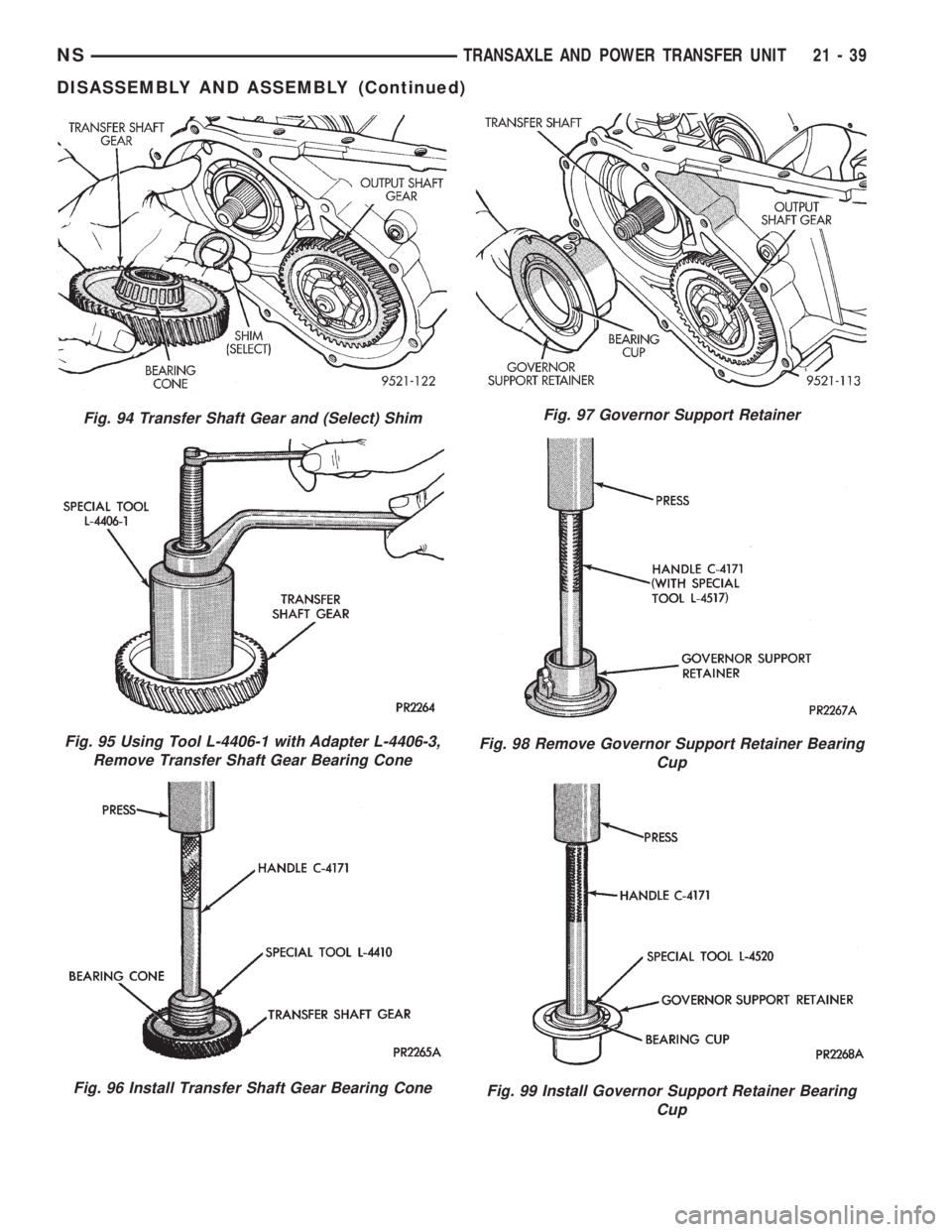

Fig. 94 Transfer Shaft Gear and (Select) Shim

Fig. 95 Using Tool L-4406-1 with Adapter L-4406-3,

Remove Transfer Shaft Gear Bearing Cone

Fig. 96 Install Transfer Shaft Gear Bearing Cone

Fig. 97 Governor Support Retainer

Fig. 98 Remove Governor Support Retainer Bearing

Cup

Fig. 99 Install Governor Support Retainer Bearing

Cup

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 39

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1514 of 1938

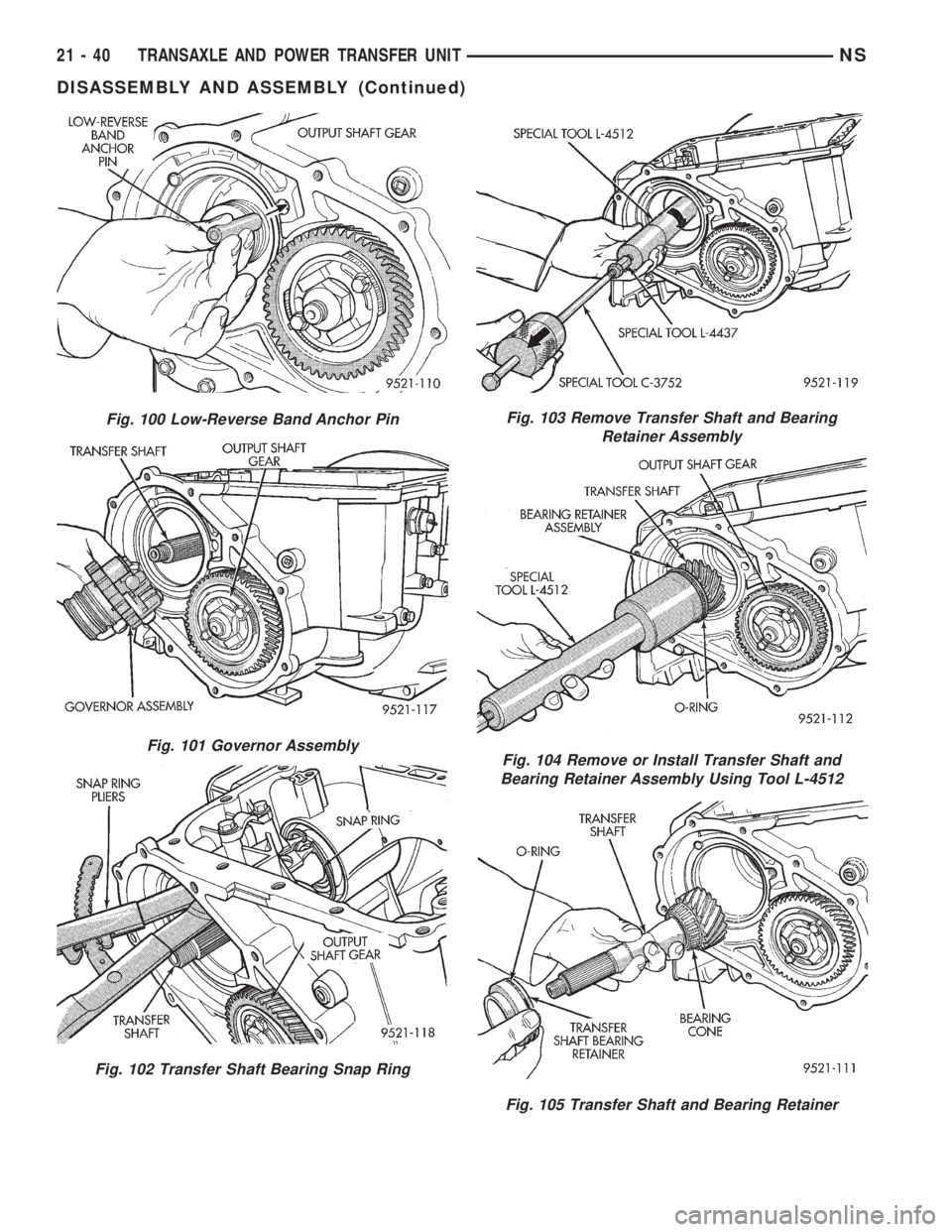

Fig. 100 Low-Reverse Band Anchor Pin

Fig. 101 Governor Assembly

Fig. 102 Transfer Shaft Bearing Snap Ring

Fig. 103 Remove Transfer Shaft and Bearing

Retainer Assembly

Fig. 104 Remove or Install Transfer Shaft and

Bearing Retainer Assembly Using Tool L-4512

Fig. 105 Transfer Shaft and Bearing Retainer

21 - 40 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1515 of 1938

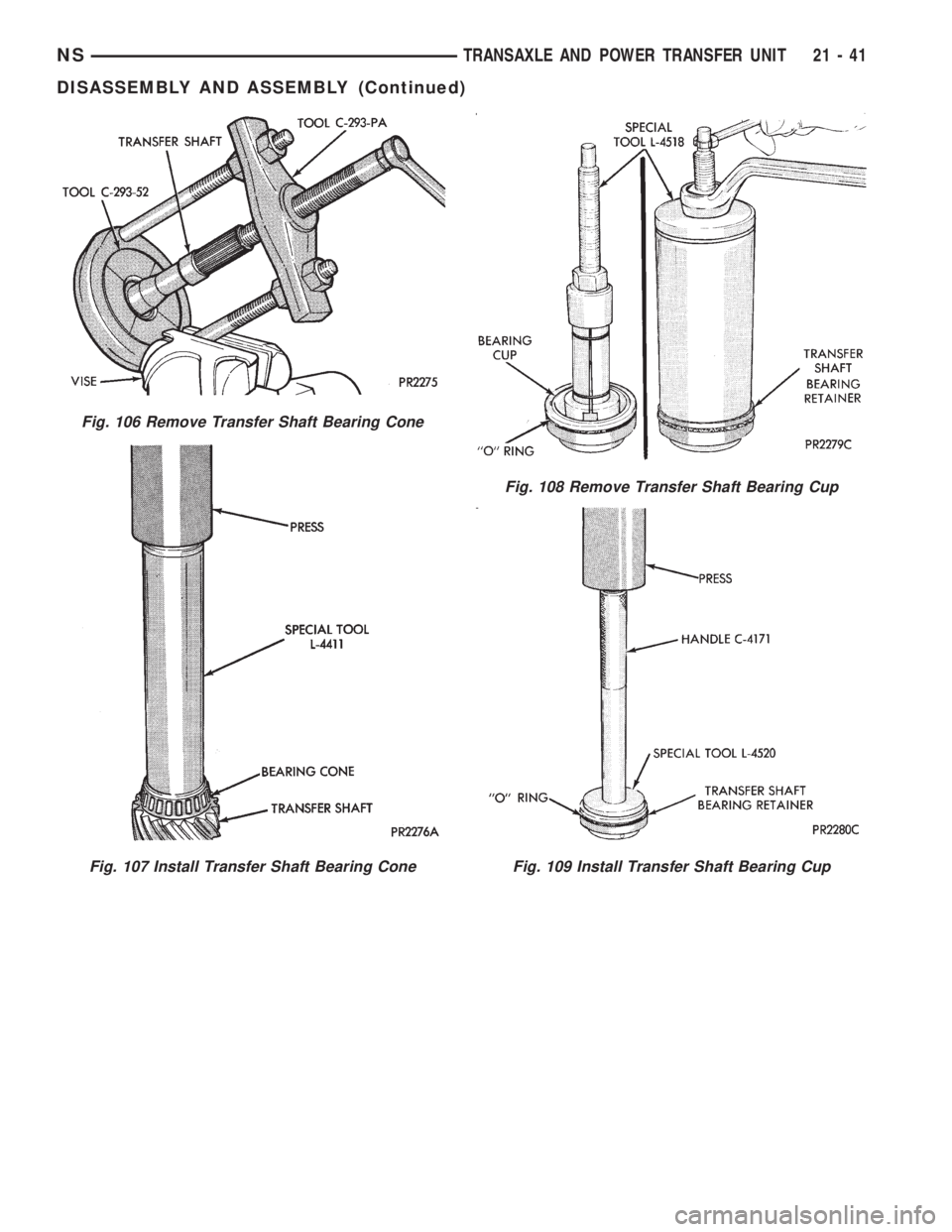

Fig. 106 Remove Transfer Shaft Bearing Cone

Fig. 107 Install Transfer Shaft Bearing Cone

Fig. 108 Remove Transfer Shaft Bearing Cup

Fig. 109 Install Transfer Shaft Bearing Cup

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 41

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1516 of 1938

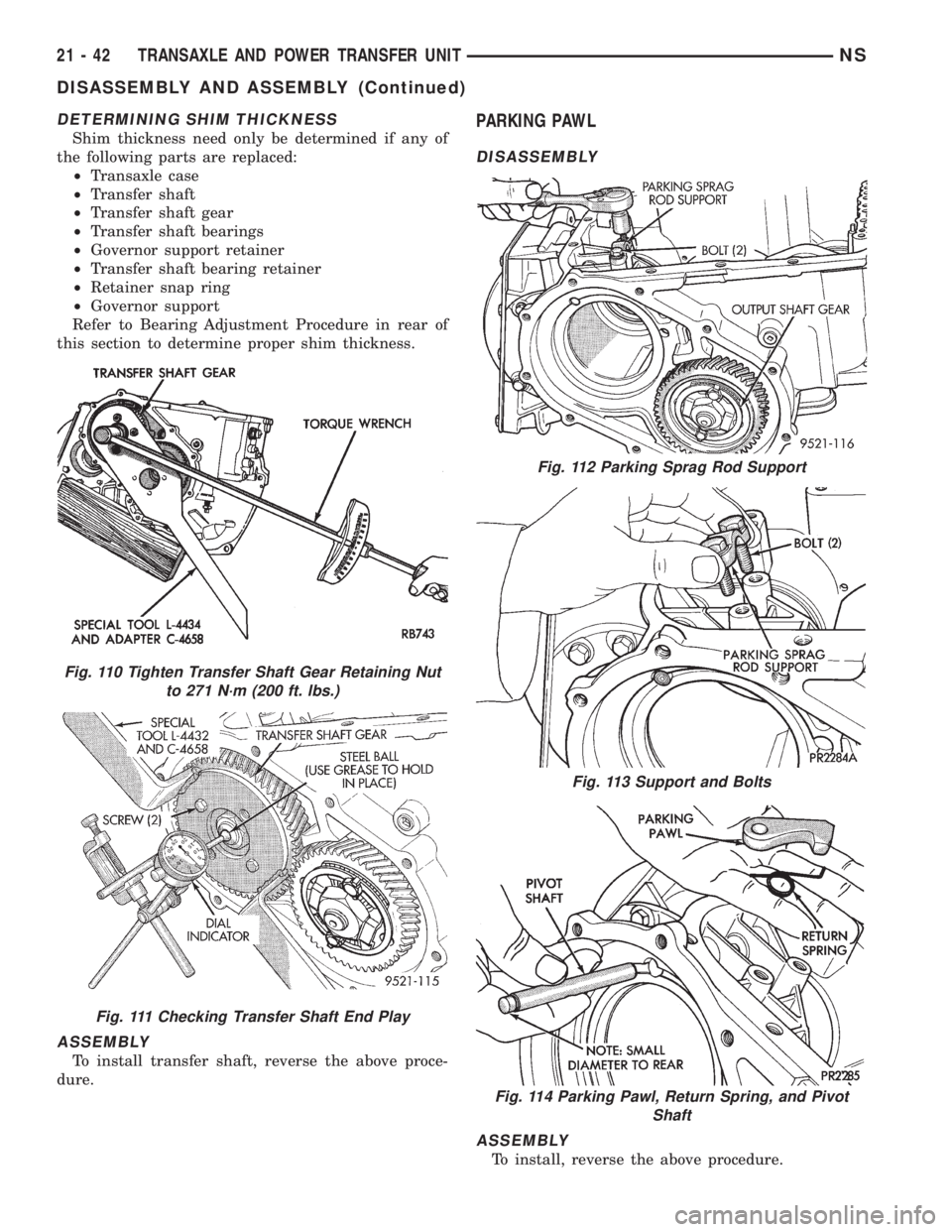

DETERMINING SHIM THICKNESS

Shim thickness need only be determined if any of

the following parts are replaced:

²Transaxle case

²Transfer shaft

²Transfer shaft gear

²Transfer shaft bearings

²Governor support retainer

²Transfer shaft bearing retainer

²Retainer snap ring

²Governor support

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness.

ASSEMBLY

To install transfer shaft, reverse the above proce-

dure.

PARKING PAWL

DISASSEMBLY

ASSEMBLY

To install, reverse the above procedure.

Fig. 110 Tighten Transfer Shaft Gear Retaining Nut

to 271 N´m (200 ft. lbs.)

Fig. 111 Checking Transfer Shaft End Play

Fig. 112 Parking Sprag Rod Support

Fig. 113 Support and Bolts

Fig. 114 Parking Pawl, Return Spring, and Pivot

Shaft

21 - 42 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)