fuse diagram CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 571 of 1938

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicle are solid state. When checking

voltages in these circuits use a meter with a 10-me-

gohm or greater impedance rating.

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: - Most of the electrical components used

in today's vehicle are Solid State. When checking

resistance in these circuits use a meter with a 10-

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle

electrical system can cause damage to the equip-

ment and provide false readings.

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 6). Select the proper

size tool from Special Tool Package 6807, and insert

it into the terminal being tested. Use the other end

of the tool to insert the meter probe.

INTERMITTENT AND POOR CONNECTIONS

Most intermittent electrical problems are caused

by faulty electrical connections or wiring. It is also

possible for a sticking component or relay to cause a

problem. Before condemning a component or wiring

assembly check the following items.

²Connectors are fully seated

²Spread terminals, or terminal push out

²Terminals in the wiring assembly are fully

seated into the connector/component and locked in

position

²Dirt or corrosion on the terminals. Any amount

of corrosion or dirt could cause an intermittent prob-

lem

²Damaged connector/component casing exposing

the item to dirt and moisture²Wire insulation that has rubbed through causing

a short to ground

²Some or all of the wiring strands broken inside

of the insulation covering.

²Wiring broken inside of the insulation

TROUBLESHOOTING TESTS

Before beginning any tests on a vehicles electrical

system use the Wiring Diagrams and study the cir-

cuit. Also refer to the Troubleshooting Wiring Prob-

lems in this section.

TESTING FOR VOLTAGE POTENTIAL

(1) Connect the ground lead of a voltmeter to a

known good ground (Fig. 7).

(2) Connect the other lead of the voltmeter to the

selected test point. The vehicle ignition may need to

be turned ON to check voltage. Refer to the appropri-

ate test procedure.

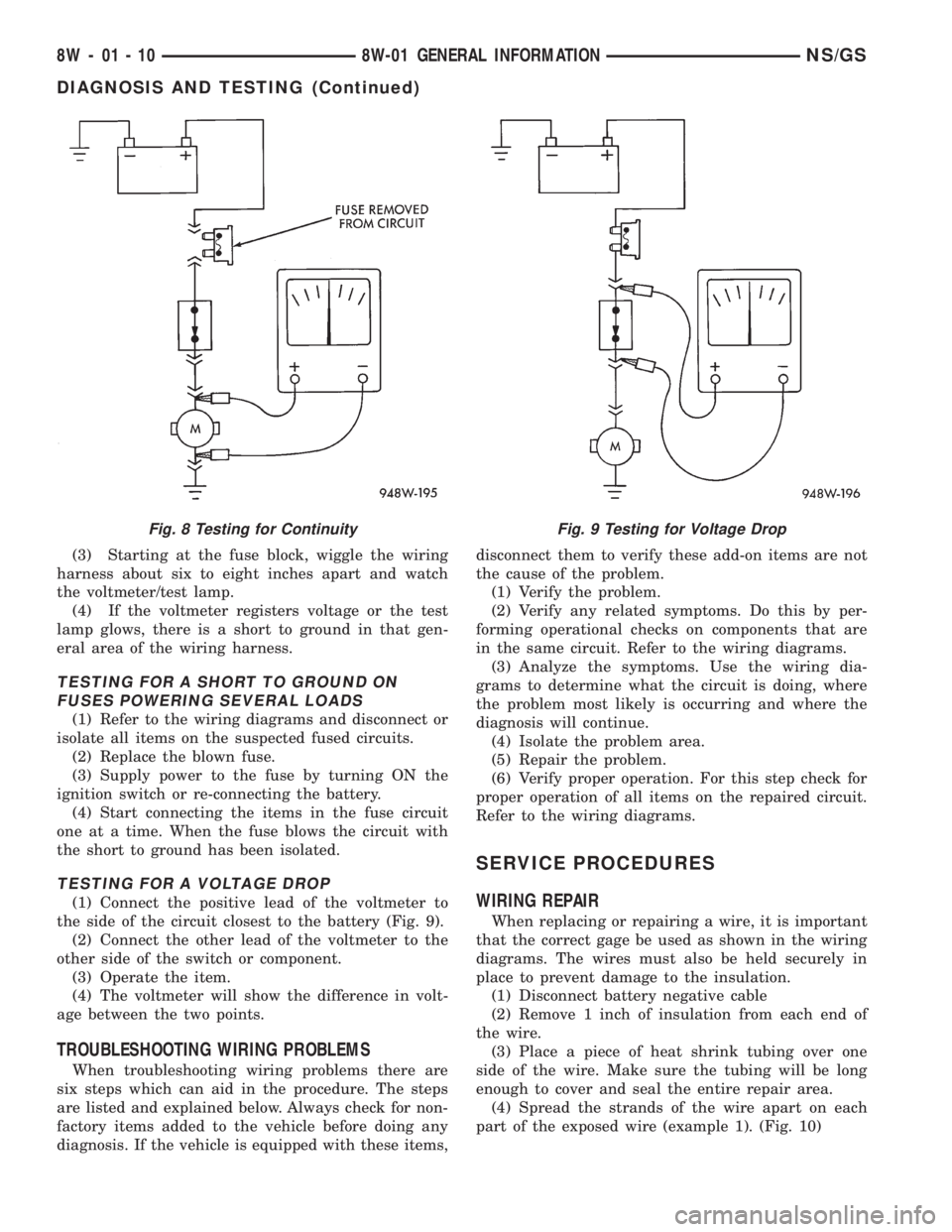

TESTING FOR CONTINUITY

(1) Remove the fuse for the circuit being checked

or, disconnect the battery.

(2) Connect one lead of the ohmmeter to one side

of the circuit being tested (Fig. 8).

(3) Connect the other lead to the other end of the

circuit being tested. Low or no resistance means good

continuity.

TESTING FOR A SHORT TO GROUND

(1) Remove the fuse and disconnect all items

involved with the fuse.

(2) Connect a test light or a voltmeter across the

terminals of the fuse.

Fig. 6 Probing Tool

Fig. 7 Testing for Voltage Potential

NS/GS8W-01 GENERAL INFORMATION 8W - 01 - 9

DIAGNOSIS AND TESTING (Continued)

Page 572 of 1938

(3) Starting at the fuse block, wiggle the wiring

harness about six to eight inches apart and watch

the voltmeter/test lamp.

(4) If the voltmeter registers voltage or the test

lamp glows, there is a short to ground in that gen-

eral area of the wiring harness.

TESTING FOR A SHORT TO GROUND ON

FUSES POWERING SEVERAL LOADS

(1) Refer to the wiring diagrams and disconnect or

isolate all items on the suspected fused circuits.

(2) Replace the blown fuse.

(3) Supply power to the fuse by turning ON the

ignition switch or re-connecting the battery.

(4) Start connecting the items in the fuse circuit

one at a time. When the fuse blows the circuit with

the short to ground has been isolated.

TESTING FOR A VOLTAGE DROP

(1) Connect the positive lead of the voltmeter to

the side of the circuit closest to the battery (Fig. 9).

(2) Connect the other lead of the voltmeter to the

other side of the switch or component.

(3) Operate the item.

(4) The voltmeter will show the difference in volt-

age between the two points.

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. Always check for non-

factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem.

(6) Verify proper operation. For this step check for

proper operation of all items on the repaired circuit.

Refer to the wiring diagrams.

SERVICE PROCEDURES

WIRING REPAIR

When replacing or repairing a wire, it is important

that the correct gage be used as shown in the wiring

diagrams. The wires must also be held securely in

place to prevent damage to the insulation.

(1) Disconnect battery negative cable

(2) Remove 1 inch of insulation from each end of

the wire.

(3) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(4) Spread the strands of the wire apart on each

part of the exposed wire (example 1). (Fig. 10)

Fig. 8 Testing for ContinuityFig. 9 Testing for Voltage Drop

8W - 01 - 10 8W-01 GENERAL INFORMATIONNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1336 of 1938

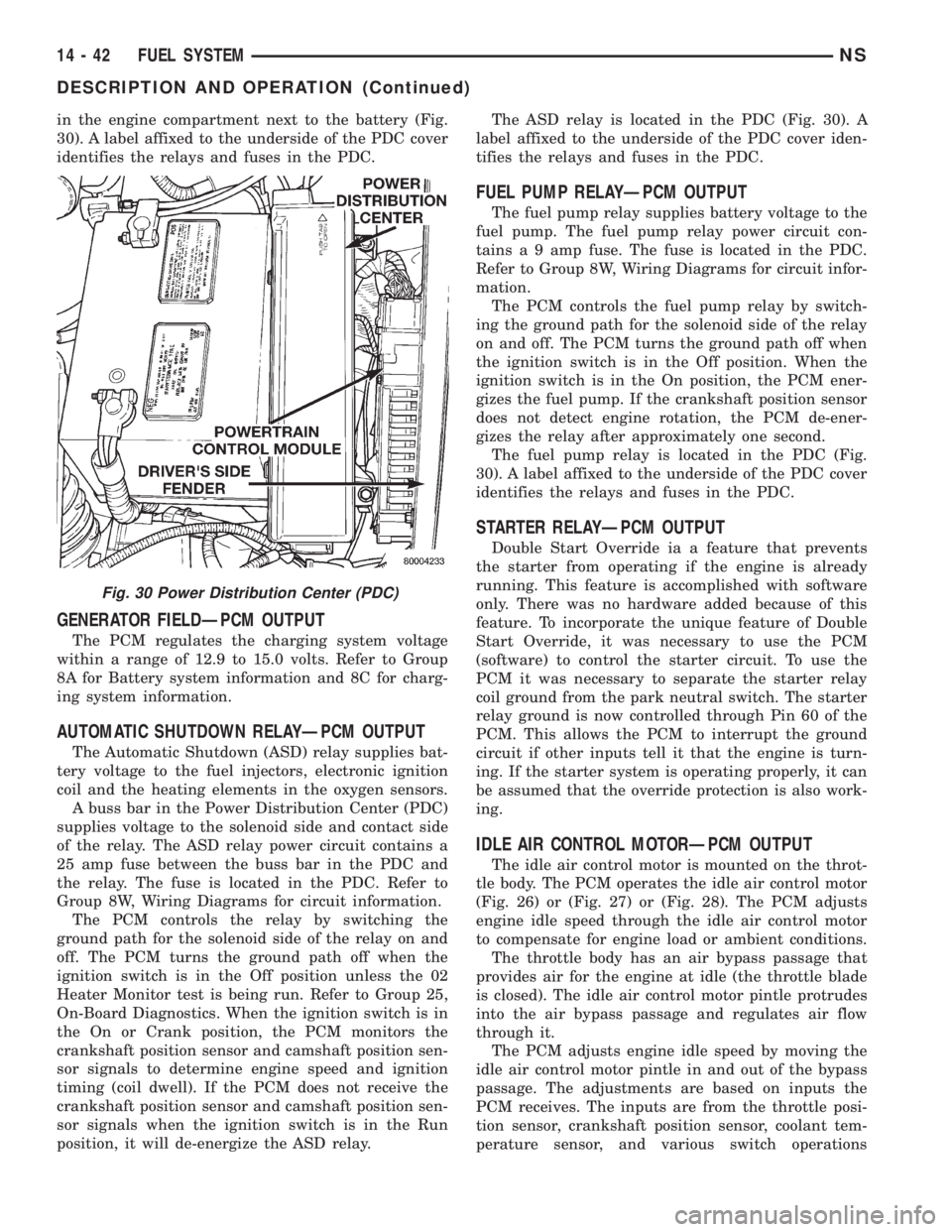

in the engine compartment next to the battery (Fig.

30). A label affixed to the underside of the PDC cover

identifies the relays and fuses in the PDC.

GENERATOR FIELDÐPCM OUTPUT

The PCM regulates the charging system voltage

within a range of 12.9 to 15.0 volts. Refer to Group

8A for Battery system information and 8C for charg-

ing system information.

AUTOMATIC SHUTDOWN RELAYÐPCM OUTPUT

The Automatic Shutdown (ASD) relay supplies bat-

tery voltage to the fuel injectors, electronic ignition

coil and the heating elements in the oxygen sensors.

A buss bar in the Power Distribution Center (PDC)

supplies voltage to the solenoid side and contact side

of the relay. The ASD relay power circuit contains a

25 amp fuse between the buss bar in the PDC and

the relay. The fuse is located in the PDC. Refer to

Group 8W, Wiring Diagrams for circuit information.

The PCM controls the relay by switching the

ground path for the solenoid side of the relay on and

off. The PCM turns the ground path off when the

ignition switch is in the Off position unless the 02

Heater Monitor test is being run. Refer to Group 25,

On-Board Diagnostics. When the ignition switch is in

the On or Crank position, the PCM monitors the

crankshaft position sensor and camshaft position sen-

sor signals to determine engine speed and ignition

timing (coil dwell). If the PCM does not receive the

crankshaft position sensor and camshaft position sen-

sor signals when the ignition switch is in the Run

position, it will de-energize the ASD relay.The ASD relay is located in the PDC (Fig. 30). A

label affixed to the underside of the PDC cover iden-

tifies the relays and fuses in the PDC.

FUEL PUMP RELAYÐPCM OUTPUT

The fuel pump relay supplies battery voltage to the

fuel pump. The fuel pump relay power circuit con-

tains a 9 amp fuse. The fuse is located in the PDC.

Refer to Group 8W, Wiring Diagrams for circuit infor-

mation.

The PCM controls the fuel pump relay by switch-

ing the ground path for the solenoid side of the relay

on and off. The PCM turns the ground path off when

the ignition switch is in the Off position. When the

ignition switch is in the On position, the PCM ener-

gizes the fuel pump. If the crankshaft position sensor

does not detect engine rotation, the PCM de-ener-

gizes the relay after approximately one second.

The fuel pump relay is located in the PDC (Fig.

30). A label affixed to the underside of the PDC cover

identifies the relays and fuses in the PDC.

STARTER RELAYÐPCM OUTPUT

Double Start Override ia a feature that prevents

the starter from operating if the engine is already

running. This feature is accomplished with software

only. There was no hardware added because of this

feature. To incorporate the unique feature of Double

Start Override, it was necessary to use the PCM

(software) to control the starter circuit. To use the

PCM it was necessary to separate the starter relay

coil ground from the park neutral switch. The starter

relay ground is now controlled through Pin 60 of the

PCM. This allows the PCM to interrupt the ground

circuit if other inputs tell it that the engine is turn-

ing. If the starter system is operating properly, it can

be assumed that the override protection is also work-

ing.

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The idle air control motor is mounted on the throt-

tle body. The PCM operates the idle air control motor

(Fig. 26) or (Fig. 27) or (Fig. 28). The PCM adjusts

engine idle speed through the idle air control motor

to compensate for engine load or ambient conditions.

The throttle body has an air bypass passage that

provides air for the engine at idle (the throttle blade

is closed). The idle air control motor pintle protrudes

into the air bypass passage and regulates air flow

through it.

The PCM adjusts engine idle speed by moving the

idle air control motor pintle in and out of the bypass

passage. The adjustments are based on inputs the

PCM receives. The inputs are from the throttle posi-

tion sensor, crankshaft position sensor, coolant tem-

perature sensor, and various switch operations

Fig. 30 Power Distribution Center (PDC)

14 - 42 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1829 of 1938

BLOWER MOTOR AND WHEEL ASSEMBLY

VIBRATION AND/OR NOISE DIAGNOSIS

The blower speed switch, in conjunction with the

resistor block, supplies the blower motor with varied

voltage.

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater A/C

housing.

Refer to the Blower Motor Vibration/Noise chart in

this section for diagnosis.

COMPRESSOR NOISE DIAGNOSIS

Excessive noise while the A/C is being used, can be

caused by loose mounts, loose clutch, or high operat-

ing pressure. Verify compressor drive belt condition,

proper refrigerant charge and head pressure before

compressor repair is performed.

If the A/C drive belt slips at initial start-up, it does

not necessarily mean the compressor has failed.

With the close tolerances of a compressor it is pos-

sible to experience a temporary lockup. The longer

the A/C system is inactive, the more likely the condi-

tion to occur.

This condition is the result of normal refrigerant

movement within the A/C system caused by temper-

ature changes. The refrigerant movement may wash

the oil out of the compressor.

COMPRESSOR CLUTCH/COIL

The air conditioning compressor clutch electrical

circuit is controlled by the Powertrain Control Mod-

ule. It is located in the engine compartment outboard

of the battery.If the compressor clutch does not engage verify

refrigerant charge.

If the compressor clutch still does not engage check

for battery voltage at the pressure transducer located

on the liquid line. If voltage is not detected, refer to:

²Group 8W, Wiring diagrams.

²Powertrain Diagnostic Procedures manual for

diagnostic information.

If voltage is detected at the pressure transducer,

connect pressure transducer and check for battery

voltage between the compressor clutch connector ter-

minals.

If voltage is detected, perform A/C Clutch Coil

Tests.

TESTS

(1) Verify battery state of charge. (Test indicator in

battery should be green).

(2) Connect an ampmeter (0-10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0-20 volt scale) with clip leads measuring voltage

across the battery and A/C clutch.

(3) With A/C control in A/C mode and blower at

low speed, start the engine and run at normal idle.

(4) The A/C clutch should engage immediately and

the clutch voltage should be within two volts of the

battery voltage. If the A/C clutch does not engage,

test the fuse.

(5) The A/C clutch coil is acceptable if the current

draw is 2.0 to 3.7 amperes at 11.5-12.5 volts at clutch

coil. This is with the work area temperature at 21ÉC

(70ÉF). If voltage is more than 12.5 volts, add electri-

cal loads by turning on electrical accessories until

voltage reads below 12.5 volts.

(6) If coil current reads zero, the coil is open and

should be replaced. If the ammeter reading is 4

amperes or more, the coil is shorted and should be

replaced. If the coil voltage is not within two volts of

the battery voltage, test clutch coil feed circuit for

excessive voltage drop.

EXPANSION VALVE

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

TESTS

NOTE: Expansion valve tests should be performed

after compressor tests.

Review Safety Precautions and Warnings in this

group. The work area and vehicle temperature must

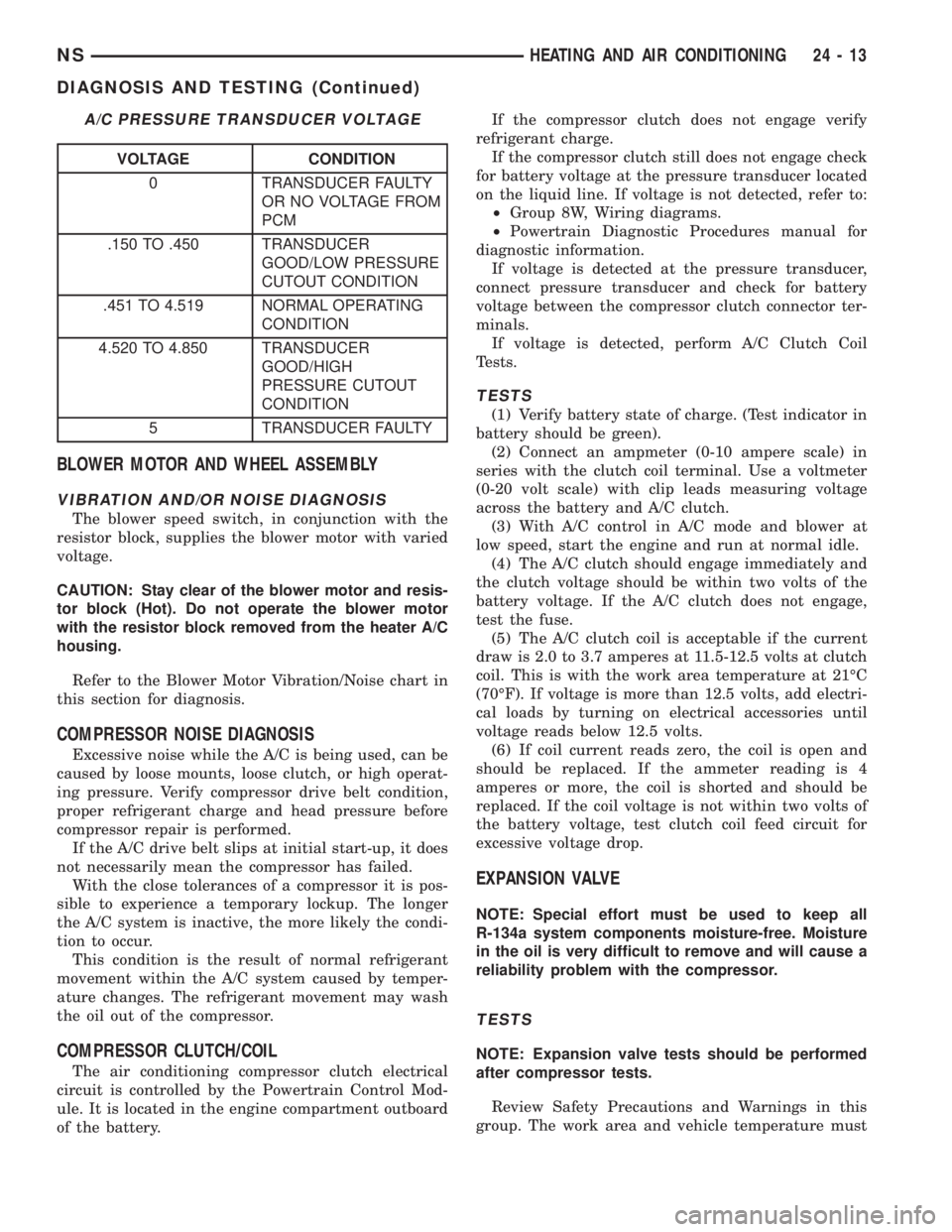

A/C PRESSURE TRANSDUCER VOLTAGE

VOLTAGE CONDITION

0 TRANSDUCER FAULTY

OR NO VOLTAGE FROM

PCM

.150 TO .450 TRANSDUCER

GOOD/LOW PRESSURE

CUTOUT CONDITION

.451 TO 4.519 NORMAL OPERATING

CONDITION

4.520 TO 4.850 TRANSDUCER

GOOD/HIGH

PRESSURE CUTOUT

CONDITION

5 TRANSDUCER FAULTY

NSHEATING AND AIR CONDITIONING 24 - 13

DIAGNOSIS AND TESTING (Continued)

Page 1878 of 1938

BLOWER MOTOR AND WHEEL ASSEMBLY

VIBRATION AND/OR NOISE DIAGNOSIS

The blower speed switch, in conjunction with the

resistor block, supplies the blower motor with varied

voltage.

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater A/C

housing.

Refer to the Blower Motor Vibration/Noise chart in

this section for diagnosis.

COMPRESSOR NOISE DIAGNOSIS

Excessive noise while the A/C is being used, can be

caused by loose mounts, clutch, or high operating

pressure. Verify compressor drive belt condition,

proper refrigerant charge and head pressure before

compressor repair is performed.

COMPRESSOR CLUTCH/COIL

The air conditioning compressor clutch electrical

circuit is controlled by the Powertrain Control Mod-ule. It is located in the engine compartment outboard

of the battery.

If the compressor clutch does not engage verify

refrigerant charge.

If the compressor clutch still does not engage check

for battery voltage at the pressure transducer located

on the liquid line. If voltage is not detected, refer to:

²Group 8W, Wiring diagrams.

²Powertrain Diagnostic Procedures manual for

diagnostic information.

If voltage is detected at the pressure transducer,

connect pressure transducer and check for battery

voltage between the compressor clutch connector ter-

minals.

If voltage is detected, perform A/C Clutch Coil

Tests.

TESTS

(1) Verify battery state of charge. (Test indicator in

battery should be green).

(2) Connect an ampmeter (0-10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0-20 volt scale) with clip leads measuring voltage

across the battery and A/C clutch.

(3) With A/C control in A/C mode and blower at

low speed, start the engine and run at normal idle.

(4) The A/C clutch should engage immediately and

the clutch voltage should be within two volts of the

battery voltage. If the A/C clutch does not engage,

test the fuse.

(5) The A/C clutch coil is acceptable if the current

draw is 2.0 to 3.7 amperes at 11.5-12.5 volts at clutch

coil. This is with the work area temperature at 21ÉC

(70ÉF). If voltage is more than 12.5 volts, add electri-

cal loads by turning on electrical accessories until

voltage reads below 12.5 volts.

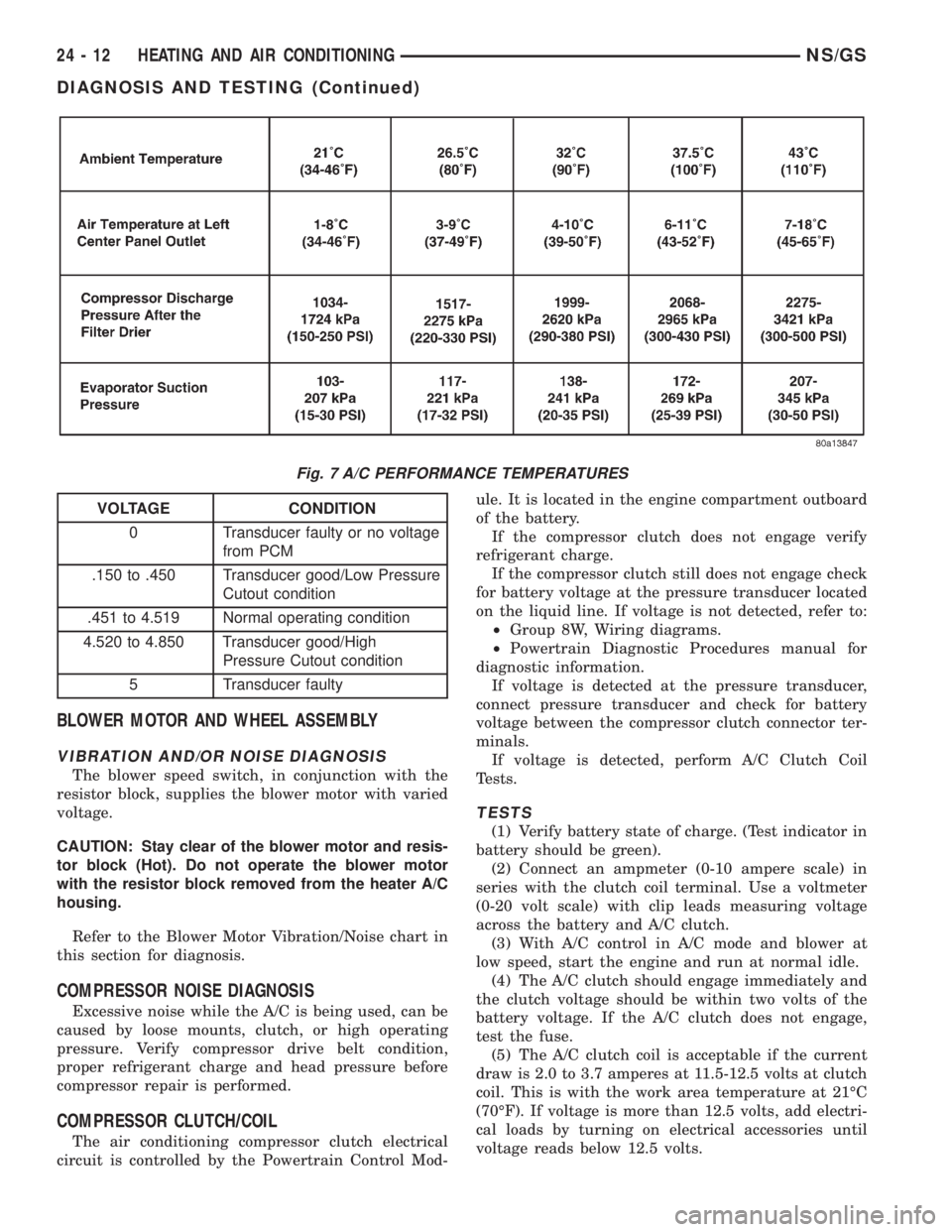

Fig. 7 A/C PERFORMANCE TEMPERATURES

VOLTAGE CONDITION

0 Transducer faulty or no voltage

from PCM

.150 to .450 Transducer good/Low Pressure

Cutout condition

.451 to 4.519 Normal operating condition

4.520 to 4.850 Transducer good/High

Pressure Cutout condition

5 Transducer faulty

24 - 12 HEATING AND AIR CONDITIONINGNS/GS

DIAGNOSIS AND TESTING (Continued)