key battery CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 514 of 1938

SERVICE PROCEDURES

HORN CHIRP DISABLE OR ENABLE

The horn chirp can be DISABLED or ENABLED

using the following procedure.

To DISABLE (cancelling) the horn chirp feature,

press and hold the transmitter LOCK button for a

minimum four seconds. While pressing LOCK button

in, press the UNLOCK button. The horn chirp fea-

ture will not function until the above procedure is

repeated. To ENABLE (reinstate) the horn chirp fea-

ture, use any one of the four key fob transmitters

and reverse the above procedures. It will ENABLE

the horn chirp feature for all transmitters.

REMOVAL AND INSTALLATION

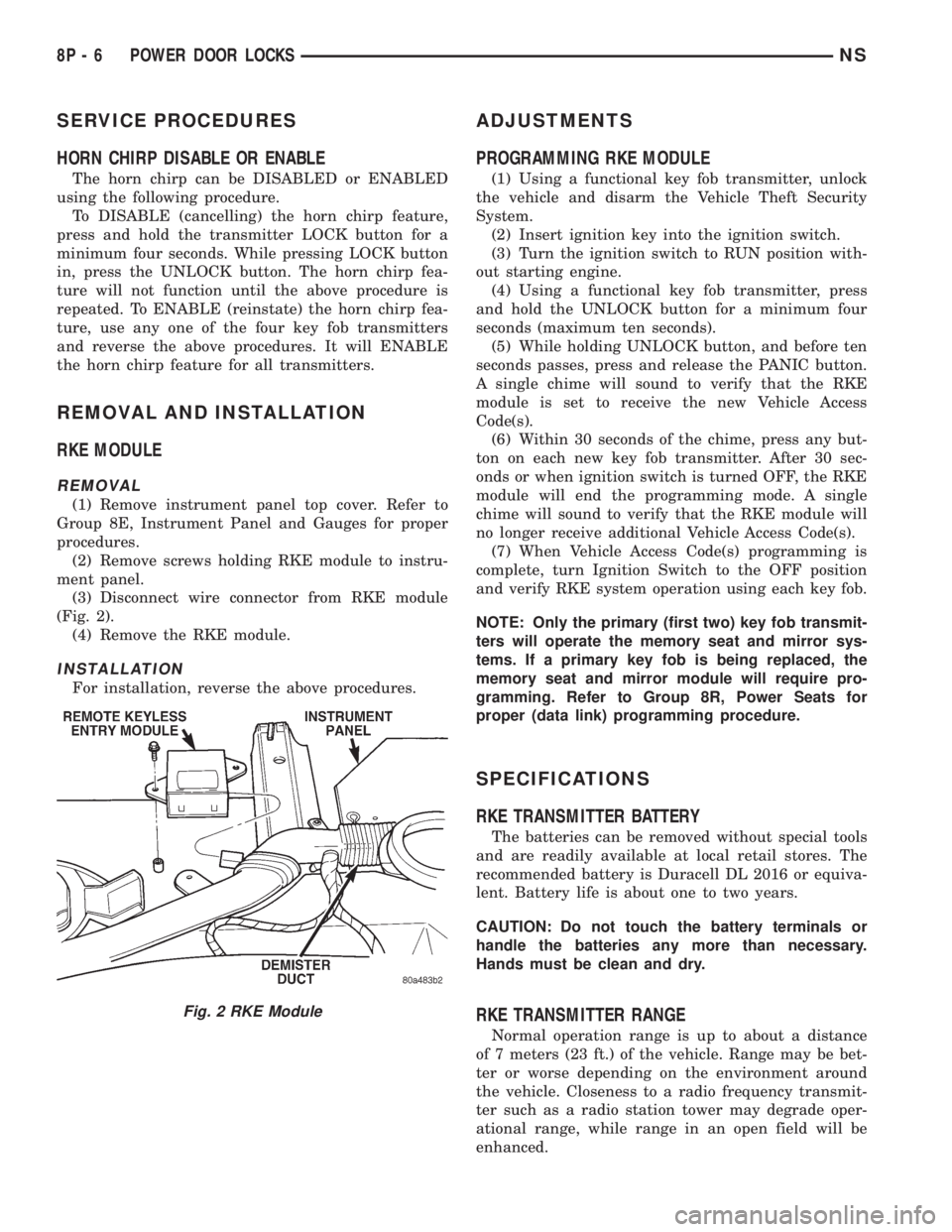

RKE MODULE

REMOVAL

(1) Remove instrument panel top cover. Refer to

Group 8E, Instrument Panel and Gauges for proper

procedures.

(2) Remove screws holding RKE module to instru-

ment panel.

(3) Disconnect wire connector from RKE module

(Fig. 2).

(4) Remove the RKE module.

INSTALLATION

For installation, reverse the above procedures.

ADJUSTMENTS

PROGRAMMING RKE MODULE

(1) Using a functional key fob transmitter, unlock

the vehicle and disarm the Vehicle Theft Security

System.

(2) Insert ignition key into the ignition switch.

(3) Turn the ignition switch to RUN position with-

out starting engine.

(4) Using a functional key fob transmitter, press

and hold the UNLOCK button for a minimum four

seconds (maximum ten seconds).

(5) While holding UNLOCK button, and before ten

seconds passes, press and release the PANIC button.

A single chime will sound to verify that the RKE

module is set to receive the new Vehicle Access

Code(s).

(6) Within 30 seconds of the chime, press any but-

ton on each new key fob transmitter. After 30 sec-

onds or when ignition switch is turned OFF, the RKE

module will end the programming mode. A single

chime will sound to verify that the RKE module will

no longer receive additional Vehicle Access Code(s).

(7) When Vehicle Access Code(s) programming is

complete, turn Ignition Switch to the OFF position

and verify RKE system operation using each key fob.

NOTE: Only the primary (first two) key fob transmit-

ters will operate the memory seat and mirror sys-

tems. If a primary key fob is being replaced, the

memory seat and mirror module will require pro-

gramming. Refer to Group 8R, Power Seats for

proper (data link) programming procedure.

SPECIFICATIONS

RKE TRANSMITTER BATTERY

The batteries can be removed without special tools

and are readily available at local retail stores. The

recommended battery is Duracell DL 2016 or equiva-

lent. Battery life is about one to two years.

CAUTION: Do not touch the battery terminals or

handle the batteries any more than necessary.

Hands must be clean and dry.

RKE TRANSMITTER RANGE

Normal operation range is up to about a distance

of 7 meters (23 ft.) of the vehicle. Range may be bet-

ter or worse depending on the environment around

the vehicle. Closeness to a radio frequency transmit-

ter such as a radio station tower may degrade oper-

ational range, while range in an open field will be

enhanced.

Fig. 2 RKE Module

8P - 6 POWER DOOR LOCKSNS

Page 515 of 1938

VEHICLE THEFT SECURITY SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

ARMING PROCEDURE.................... 1

TIME-OUT PERIOD....................... 2

TRIGGERING THE VTSS................... 2

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES................ 2

REMOVAL AND INSTALLATION

BODY CONTROL MODULE................. 2DOOR LOCK CYLINDER SWITCH............ 2

FRONT DOOR AJAR (VTSS TRIGGER)

SWITCH.............................. 2

HOOD AJAR (VTSS TRIGGER) SWITCH...... 3

LIFTGATE AJAR (VTSS TRIGGER) SWITCH.... 3

LIFTGATE LOCK CYLINDER SWITCH......... 3

SLIDING DOOR AJAR (VTSS TRIGGER)

SWITCH.............................. 4

GENERAL INFORMATION

INTRODUCTION

Vehicles equipped with the Vehicle Theft Security

System (VTSS) system, the doors, liftgate, hood and

ignition circuit are monitored by the Body Control

Module (BCM) when the system is armed. The VTSS

will prevent the engine from starting until the BCM

receives a disarm signal. If the VTSS is triggered,

the horn will pulse, headlamps/marker lamps will

flash, and the VTSS warning lamp will flash. If BCM

determines the threat to be false and the VTSS is not

triggered again, the system will shut down and

rearm itself after three minutes. The VTSS monitor-

ing portion of the system is split into two sections.

The engine compartment section and the passenger

compartment section. If a malfunction occurs in the

engine compartment section, the passenger compart-

ment section would still arm and function normally.

If an electrical malfunction occurs in either section of

the system a Diagnostic Trouble Code (DTC) would

be stored the BCM memory to aid system repair.

DTCs can be retrieved using scan tool (DRB)

attached to the diagnostic connector above the accel-

erator pedal.

ENABLING

To initialize the VTSS feature the operator must,

with the engine compartment hood open, cycle the

key in the liftgate key cylinder to the unlock position

giving the BCM a disarm signal. At this time the

visual alarm outputs the headlamps and marker

lamps will function. However the audio alarm output

the horn and engine disable portion of the VTSS will

not function until there has been twenty consecutiveengine run cycles. When this has occurred the total

VTSS will function.

If during alarm being set the BCM receives a

request from the RKE module to enter PANIC mode

the BCM will cancel the alarm, return VTSS armed

state and then perform the RKE PANIC feature.

DESCRIPTION AND OPERATION

ARMING PROCEDURE

METHOD-A

(1) With the key removed from the ignition lock

and any door open, actuate one of the following:

²Power door lock button to LOCK,

²Key fob LOCK button

²Door lock key cylinder to locked position.

(2) Close all opened doors.

(3) After the last door is closed, an arming time-

out period of sixteen seconds will start, then the

VTSS will become armed.

METHOD-B

Actuating the key fob transmitter LOCK button,

key locking the front doors or liftgate with the doors

closed and the ignition locked will begin the arming

time-out period. If method-A, 16 second time-out

sequence was in process when method-B was actu-

ated, the 16 second time-out will restart from the

time of the second actuation.

If the security lamp does not illuminate at all upon

final door closure, it indicates that the system is not

arming.

The current VTSS status armed or disarmed shall

be maintained in memory to prevent battery discon-

nects from disarming the system.

NSVEHICLE THEFT SECURITY SYSTEM 8Q - 1

Page 516 of 1938

TIME-OUT PERIOD

The VTSS requires 16 consecutive seconds to time-

out and arm the alarm. If a door is key unlocked, key

fob unlocked. or the ignition is switched ON, the

VTSS will cancel out. To reset the VTSS, perform

methods A or B.

TRIGGERING THE VTSS

After the VTSS is armed, following actions will

trigger the alarm:

²Opening any door.

²Opening the hood

²Turning the ignition to the ON or unlock posi-

tion.

²The ignition switch can be turned to the acces-

sory position without triggering alarm system.

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES

Refer to Group 8W, Wiring Diagrams for circuit

information and component locations. Using a scan

tool (DRB). Refer to the proper Body Diagnostic Pro-

cedures manual for test procedures.

REMOVAL AND INSTALLATION

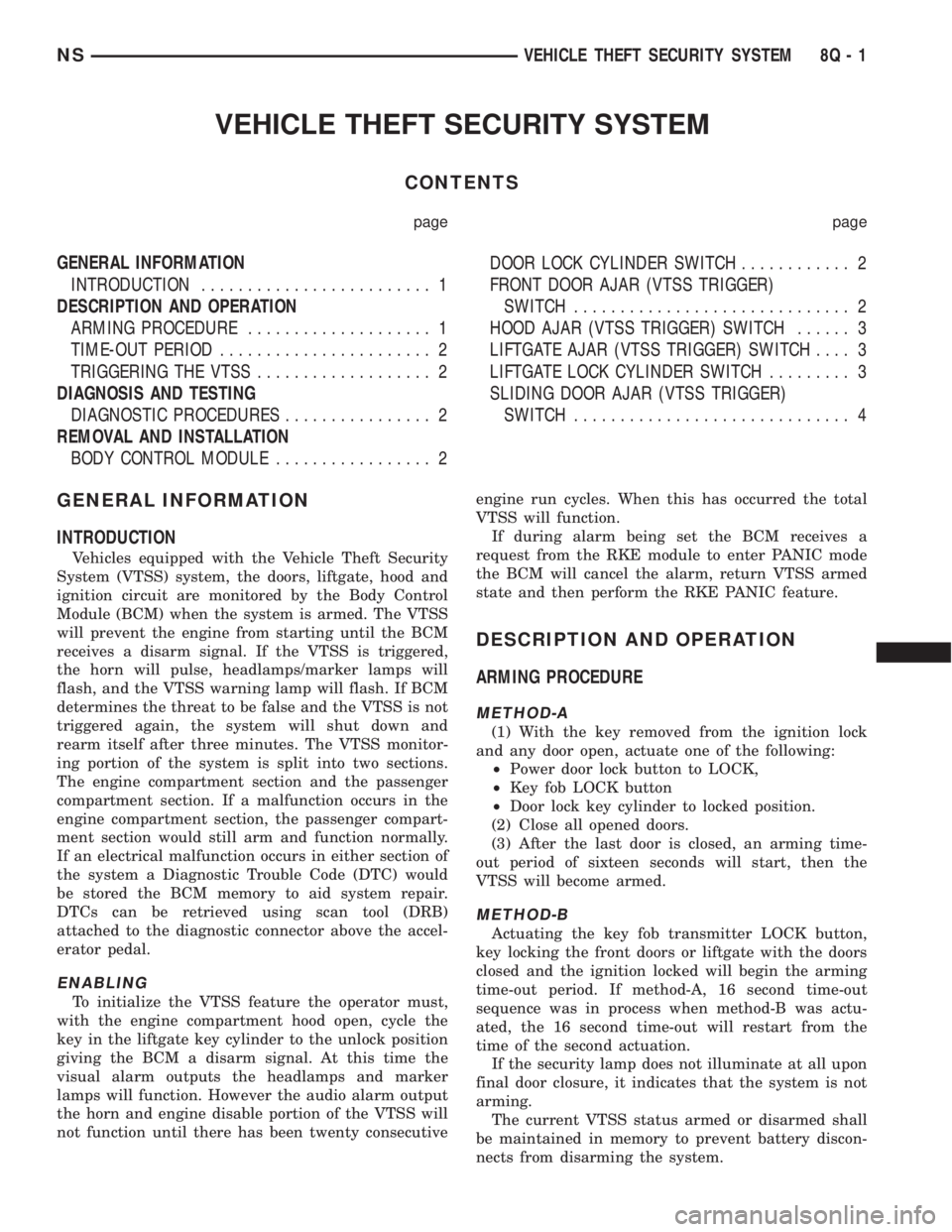

BODY CONTROL MODULE

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the lower steering column cover and

the knee blocker reinforcement.

(3) Disconnect the two wire connectors from the

bottom of the Body Control Module (BCM) (Fig. 1).

(4) Remove the bolts holding the Junction Block to

the dash panel mounting bracket.

(5) Remove the Junction Block from the mounting

bracket.

(6) Remove the screws holding BCM to Junction

Block.

(7) Slide the BCM downward to disengage guide

studs on Junction Block from the channels on the

BCM mounting bracket.

(8) Remove the BCM from Junction Block.

INSTALLATION

For installation, reverse the above procedure.

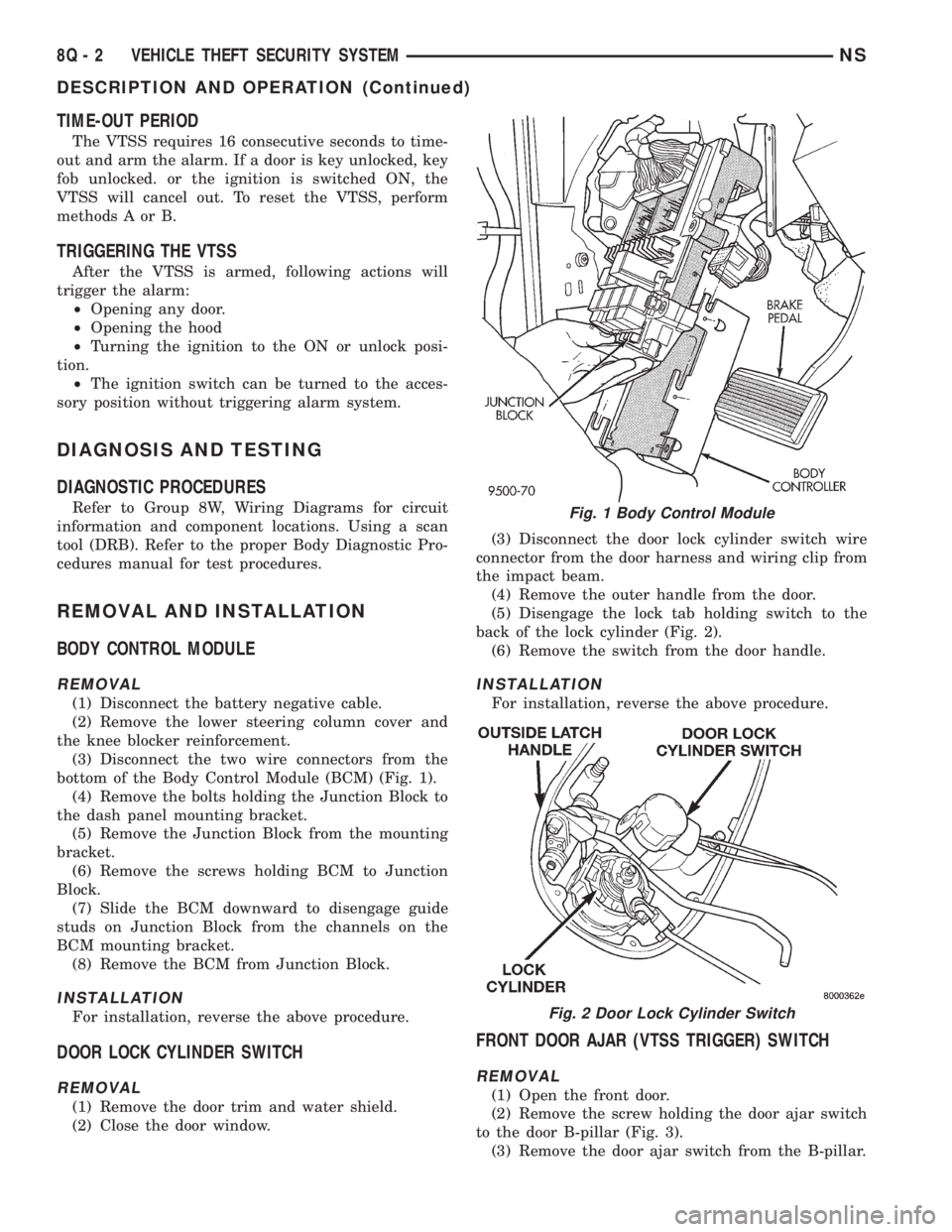

DOOR LOCK CYLINDER SWITCH

REMOVAL

(1) Remove the door trim and water shield.

(2) Close the door window.(3) Disconnect the door lock cylinder switch wire

connector from the door harness and wiring clip from

the impact beam.

(4) Remove the outer handle from the door.

(5) Disengage the lock tab holding switch to the

back of the lock cylinder (Fig. 2).

(6) Remove the switch from the door handle.

INSTALLATION

For installation, reverse the above procedure.

FRONT DOOR AJAR (VTSS TRIGGER) SWITCH

REMOVAL

(1) Open the front door.

(2) Remove the screw holding the door ajar switch

to the door B-pillar (Fig. 3).

(3) Remove the door ajar switch from the B-pillar.

Fig. 1 Body Control Module

Fig. 2 Door Lock Cylinder Switch

8Q - 2 VEHICLE THEFT SECURITY SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 521 of 1938

determine whether a valid key is in the ignition lock

cylinder.

The Smart Key transponder cannot be repaired

and, if faulty or damaged, it must be replaced.

SMART KEY IMMOBILIZER SYSTEM INDICATOR

LAMP

The Smart Key Immobilizer System (SKIS) indica-

tor lamp gives an indication when the SKIS is faulty

or when the vehicle has been immobilized due to the

use of an invalid ignition key. The lamp is controlled

by the instrument cluster circuitry based upon mes-

sages received from the Smart Key Immobilizer Mod-

ule (SKIM) on the Chrysler Collision Detection (CCD)

data bus.

The SKIM sends messages to the instrument clus-

ter to turn the lamp on for about three seconds when

the ignition switch is turned to the On position as a

bulb test. After completion of the bulb test, the SKIM

sends bus messages to keep the lamp off for a dura-

tion of about one second. Then the SKIM sends mes-

sages to the instrument cluster circuitry to turn the

lamp on or off based upon the results of the SKIS

self-tests. If the SKIS indicator lamp comes on and

stays on after the bulb test, it indicates that the

SKIM has detected a system malfunction and/or that

the SKIS has become inoperative. If the SKIM

detects an invalid key when the ignition switch is

turned to the On position, it sends messages to the

instrument cluster to flash the SKIS indicator lamp.

The SKIM can also send messages to the instru-

ment cluster to flash the lamp and to generate a sin-

gle audible chime tone. These functions serve as an

indication to the customer that the SKIS has been

placed in its ªCustomer Learnº programming mode.

See Smart Key Immobilizer System Transponder Pro-

gramming in this group for more information on the

ªCustomer Learnº programming mode.

The SKIS indicator lamp uses a replaceable incan-

descent bulb and bulb holder on the instrument clus-

ter electronic circuit board. Refer to Group 8E -

Instrument Panel Systems for diagnosis and service

of a faulty SKIS indicator lamp. If the SKIS indicator

lamp comes on and stays on after the bulb test func-

tion, diagnosis of the SKIS should be performed with

a DRB scan tool and the proper Diagnostic Proce-

dures manual.

DIAGNOSIS AND TESTING

SMART KEY IMMOBILIZER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Smart Key Immobilizer System involves the use of a

DRB scan tool. Refer to the proper Diagnostic Pro-

cedures manual for the procedures.

The Smart Key Immobilizer System (SKIS) and the

Chrysler Collision Detection (CCD) data bus network

should be diagnosed using a DRB scan tool. The DRB

will allow confirmation that the CCD data bus is

functional, that the Smart Key Immobilizer Module

(SKIM) is placing the proper messages on the CCD

data bus, and that the Powertrain Control Module

(PCM) and the instrument cluster are receiving the

CCD data bus messages. Refer to the proper Diag-

nostic Procedures manual for the procedures. Refer

to 8W-30 - Fuel/Ignition System in Group 8W - Wir-

ing Diagrams for complete circuit descriptions and

diagrams.

(1) Check the fuses in the fuseblock module. If OK,

go to Step 2. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(2) Disconnect and isolate the battery negative

cable. Unplug the wire harness connector at the

SKIM. Check for continuity between the ground cir-

cuit cavity of the SKIM wire harness connector and a

good ground. There should be continuity. If OK, go to

Step 3. If not OK, repair the open circuit to ground

as required.

(3) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

SKIM wire harness connector. If OK, go to Step 4. If

not OK, repair the open circuit to the fuse in the

fuseblock module as required.

NS/GSVEHICLE THEFT/SECURITY SYSTEMS 8Q - 3

DESCRIPTION AND OPERATION (Continued)

Page 522 of 1938

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the SKIM wire

harness connector. If OK, use a DRB scan tool and

the proper Diagnostic Procedures manual to complete

the diagnosis of the SKIS. If not OK, repair the open

circuit to the fuse in the fuseblock module as

required.

SERVICE PROCEDURES

SMART KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING

Two programmed Smart Key transponders are

included with the Smart Key Immobilizer System

(SKIS) when it is shipped from the factory. The

Smart Key Immobilizer Module (SKIM) can be pro-

grammed to recognize up to six additional transpon-

ders, for a total of eight Smart Keys. The following

ªCustomer Learnº programming procedure for the

programming of additional transponders requires

access to at least two of the valid Smart Keys. If two

valid Smart Keys are not available, Smart Key pro-

gramming will require the use of a DRB scan tool

and the proper Diagnostic Procedures manual.

PROGRAMMING THE SKIM MODULE WITH

THE DRBIII

(1) Turn the ignition on. Transmission must be in

park or neutral. Alarm set lamp will flash.

(2) Use the DRBIII and select ªSKIMº under the

ªMISCELLANEOUSº menu.

(3) Select ªPROGRAM PINº and enter the cus-

tomer 4±digit PIN number.

(4) Select ªUPDATE VINº. The SKIM module will

learn the VIN from the PCM in gasoline engine vehi-

cles, and from the BCM in diesel engine vehicles.

(5) Select ªCOUNTRY CODEº and enter the cor-

rect country.

(6) Select ªPROGRAM NEW EMSº. The SKIM

module will send the ªsecret keyº data to the PCM.

(7) Program ignition keys to the SKIM module.

PROGRAMMING IGNITION KEYS WITH THE

DRBIII

(1) Turn ignition on. Transmission must be in park

or neutral. Alarm set lamp will flash.

(2) Use the DRBIII and select ªSKIMº under the

ªMISCELLANEOUSº menu.

(3) Select ªLEARN NEW KEYº. Alarm Set lamp

will begin flashing.

NOTE: The PIN must be re-entered each time an

additional key is learned.(4) Insert key into ignition switch. Once the key

has been learned, the Alarm Set lamp will turn off.

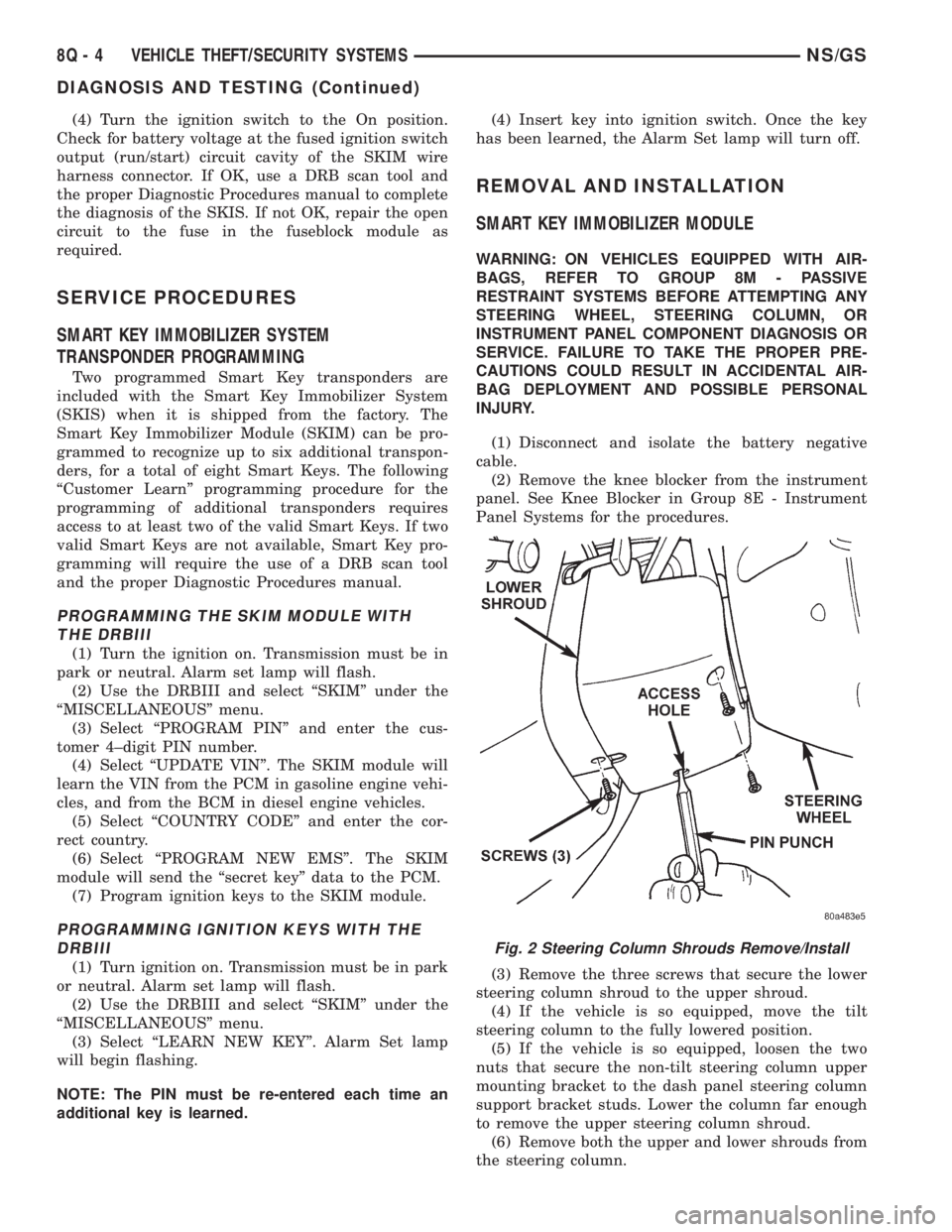

REMOVAL AND INSTALLATION

SMART KEY IMMOBILIZER MODULE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the knee blocker from the instrument

panel. See Knee Blocker in Group 8E - Instrument

Panel Systems for the procedures.

(3) Remove the three screws that secure the lower

steering column shroud to the upper shroud.

(4) If the vehicle is so equipped, move the tilt

steering column to the fully lowered position.

(5) If the vehicle is so equipped, loosen the two

nuts that secure the non-tilt steering column upper

mounting bracket to the dash panel steering column

support bracket studs. Lower the column far enough

to remove the upper steering column shroud.

(6) Remove both the upper and lower shrouds from

the steering column.

Fig. 2 Steering Column Shrouds Remove/Install

8Q - 4 VEHICLE THEFT/SECURITY SYSTEMSNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 537 of 1938

coming from the module, replace the Memory Seat/

Mirror Module.

²If P9 low current battery is present at (cavity 5)

referenced to ground Z1 (cavity 1) of the seat switch,

verify the presence of the P9 voltage at the switch

outputs. If there is no output voltage from the

switch, replace the switch.

²If P9 voltage is present at the output of the

switch, but there is no reaction from the memory

seat/mirror module, verify that the P9 voltage is

present at the appropriate 21-way connector pins

into the module. If the P9 voltage is not present at

the 21-way connector, repair or replace the seat wir-

ing harness. If the verification check of the seat wir-

ing harness is correct, replace the control module.

(2) If the control module does not respond with a

relay click to a specific seat switch when actuated,

verify the continuity of the particular circuit between

the seat switch and the Memory Seat/Mirror Module.

If the P9 voltage is present at the correct input of the

21-way connector of the module when the switch is

actuated, but there is no response by the module,

replace the Memory Seat/Mirror Module.

(3) If the Memory Seat/Mirror Module responds

with a relay click when a seat switch is actuated for

a given direction, but there is no reaction from a seat

or recliner motor relating to that switch input, dis-

connect the 10-way connector from the control mod-

ule. Jumper the battery and ground from cavities 8

and 7 of the seat harness 10-way connector to the

proper cavities for the seat or recliner motor in ques-

tion and direction of travel desired. If the motor oper-

ates, replace the control module. If the motor does

not operate, verify continuity of the wiring into the

motor 2-way connector. Repair or replace the wiring

as necessary. If the wiring has continuity, and the

motor will not operate when fed directly, replace the

track assembly, since the motor/transmission combi-

nations are not designed to be serviced on an individ-

ual basis.

SEAT AND RECLINER POSITION SENSING

Seat and recliner position sense ground reference

circuit P28 BR/RD feed is from the memory seat/mir-

ror module (cavity 10) 21-way connector to each of

the position sense connectors.

Seat and recliner position sense +5 volt feed circuit

P29 BR/WT feed is from the memory seat/mirror

module (cavity 20) 21-way connector to each of the

position sense connectors.

To test for the presence of a sense voltage, a volt

meter must be used as follows:

²Connect the negative probe to the P28 circuit

(cavity 10) of the 21-way connector.

²Connect the positive probe to the P29 circuit

(cavity 20) of the 21-way connector and verify a volt-age reading between 3.5 and 5 volts when a seat or

recliner switch is activated.An internal timer in

the Memory Seat/Mirror Module (MSM Module)

regulates the length of time this voltage stays

active i.e., 3 seconds from the time that the

switch was activated, unless the switch is held

or while the transmission is out of PARK.If the

voltage is less than 3.5, there is a fault in the system

that is drawing it down. To troubleshoot this circuit,

disconnect the 25-way connector from the MSM Mod-

ule (this removes all of the vehicle mirror circuitry).

If the voltage is still less than 3.5, disconnect each of

the position sense connectors from each of the

motors. If the voltage remains less than 3.5, replace

the MSM Module. If the voltage increases when a

motor is disconnected from the system, determine if

the fault is in the wiring or the motor assembly.

Repair or replace the wire harness assembly as

needed. If the fault is in the motor position sensing

potentiometer, replace the track assembly.

²The potentiometers built onto the motor end-bell

provide voltages to the MSM Module through the

21-way connector, which change as follows, corre-

sponding to the given seat actuations. Refer to Seat

Actuations Table.

SERVICE PROCEDURES

REMOTE KEYLESS ENTRY (RKE) DATA LINK

The memory seat/mirror module interfaces with

the RKE via a serial data link (single wire). The pro-

gramming sequence to relate an RKE transmitter to

the chosen seat, recliner and side view mirror posi-

tions consists of the following steps:

(1) Adjust the seat, recliner and side view mirrors

to the desired position.

(2) Press momentarily and release memory switch

S.

(3) Press momentarily and release memory switch

1or2.

(4) Press momentarily and release a LOCK button

on an RKE transmitter.

(5) To program the second driver's position, follow

the previous sequence with a second transmitter.

(6) To recall either of the programmed positions

with an RKE transmitter, press momentarily and

release an UNLOCK button on one of the pro-

grammed RKE transmitters.An unprogrammed

RKE transmitter will have no effect on the sys-

tem.

(7) The RKE receiver uses the serial data link to

notify the module of a request from a programmed

transmitter, that an UNLOCK button has been

pressed. This UNLOCK request (from a transmitter

associated with either switch 1 or 2) will activate the

NSPOWER SEATS 8R - 9

DIAGNOSIS AND TESTING (Continued)

Page 543 of 1938

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

CHIME SYSTEM DIAGNOSIS............... 1

DOME LAMP ON CHIME.................. 2

ENGINE TEMPERATURE CRITICAL CHIME.... 2

EXTERIOR LAMPS ON CHIME.............. 2KEY-IN IGNITION CHIME.................. 2

LOW OIL PRESSURE CHIME OPERATION..... 2

SEAT BELT CHIME....................... 2

SEAT BELT LAMP........................ 2

TURN SIGNAL ON CHIME................. 3

WARNING LAMP ANNOUNCEMENT CHIME . . . 3

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AN

AIRBAG, REFER TO GROUP 8M, RESTRAINT SYS-

TEMS FOR SAFETY PRECAUTIONS AND WARN-

INGS TO OBSERVE WHEN SERVICING AIRBAG

RELATED COMPONENTS.

The chime system provides the driver with warn-

ing chimes for:

²Seat Belt

²Exterior Lamps ON

²Key-In Ignition

²Engine Temperature Critical

²Turn Signals ON

²Dome Lamp ON

²Low Oil Pressure

²High Speed Warning

²Warning Lamp Announcement

The Chime Warning/Reminder System is diagnosed

using a scan tool (DRB). Refer to the proper Body

Diagnostic Procedures manual for testing procedures

and scan tool usage instructions.

DIAGNOSIS AND TESTING

CHIME SYSTEM DIAGNOSIS

NO TONE WHEN IGNITION SWITCH IS

TURNED ON AND DRIVER'S SEAT BELT IS

NOT BUCKLED.

(1) Using a scan tool (DRB), check for tone in any

other function.

(2) Using a voltmeter, check for voltage:

(a) Pin 9 of the internal 32 way connector of the

BCM for battery feed.(b) Pin 8 of the internal 32 way connector of the

BCM for ignition feed.

(c) If voltage OK, go to step Step 3

(d) If NO voltage repair as necessary. Refer to

Group 8W, Wiring Diagrams for component loca-

tions and circuit information.

(3) Check driver's seat belt buckle switch input for

a closed circuit when not buckled. If input not seen,

look for open in wiring or switch. The switch is

grounded when belt is not buckled.

(4) Repair as necessary.

NO FASTEN SEAT BELT LAMP WHEN

IGNITION SWITCH IS TURNED ON.

(1) Check for burned out lamp.

(2) Using a voltmeter check for voltage:

(a) Pin 2 of the mechanical instrument cluster

for battery feed.

(b) Pin 11 of the mechanical instrument cluster

for ignition voltage.

(3) Repair as necessary.

FASTEN SEAT BELT LAMP OR TONE

CONTINUES FOR MORE THAN 10 SECONDS

AFTER SEAT BELTS ARE FASTENED AND

DRIVER'S DOOR IS CLOSED.

(1) Check left door ajar switch for no ground when

switch is depressed.

(a) If continuity replace door ajar switch.

(b) If NO continuity replace BCM for tone condi-

tion, or replace mechanical instrument panel for

lamp condition.

(c) Replace BCM for tone condition.

(d) Replace mechanical instrument cluster for

lamp condition.

NO TONE WHEN PARK OR HEADLAMPS ARE

ON AND DRIVER'S DOOR IS OPEN.

(1) Check left door ajar switch for good ground

when driver's door is open. Repair as necessary.

NSCHIME WARNING/REMINDER SYSTEM 8U - 1

Page 544 of 1938

(2) Inspect BCM connectors and wires for proper

connection. If OK, replace BCM for tone condition.

DOME LAMP ON CHIME

The dome lamp on chime will warn the driver that

the dome lamps have been left on.

With the ignition is OFF:

²Driver's door OPEN (door ajar switch is closed to

ground)

²Dome lamps are ON (dome lamp switch is closed

to ground),

The chime will sound continuously until driver's

door is closed, dome lamps tuned OFF or until the

battery protection time out of 15 minutes has

expired. Refer Group 8L, Lamps proper procedures.

Chime rate: 168 to 192 chimes per minute.

ENGINE TEMPERATURE CRITICAL CHIME

The engine temperature critical chime will warn

the driver that the vehicle's engine is overheating.

While monitoring the coolant temperature, the Pow-

ertrain Control Module (PCM) will send on the CCD

bus as engine temperature every 1.376 seconds to the

Body Control Module (BCM). The BCM calculates

engine temperature and determines if a warning

should occur. This feature is functional only with the

Ignition Switch in the Run/Start position.

When the engine temperature reaches 122ÉC

(252ÉF) the BCM will chime one tone and the engine

temperature lamp comes ON. The BCM turns OFF

the lamp when the engine temperature reaches

117ÉC (242ÉF). The BCM will chime continuously

when the engine temperature reaches 125ÉC (257ÉF).

The chime will turn OFF after four minutes or when

the temperature reaches 117ÉC (242ÉF), which ever

occurs first.

EXTERIOR LAMPS ON CHIME

The exterior lamp on chime will warn the driver

that the exterior lights have been left on.

With the ignition switch OFF:

²Driver's door is open (door ajar switch is closed

to ground)

²Parking lamps or headlamps ON (parking lamp

switch is closed to ground)

The chime will sound until lights are turned OFF,

driver's door closed or until the battery protection

time out of 3 minutes has expired.

Refer to Group 8L, Lamps, for proper service pro-

cedures. Chime rate: 168 to 192 chimes per minute.

To test the exterior lamps left on function:

²Turn ignition off

²Remove ignition key

²Turn exterior lamps on with driver's door open.

Chime should sound until lamps are turned off or

driver's door is closed.

KEY-IN IGNITION CHIME

The key-in ignition chime will act as a warning to

the driver that the ignition key has been left in the

ignition switch.

With the ignition switch is in OFF position ONLY:

²Driver's door is open/ajar (door ajar switch is

closed to ground)

²Key is in the ignition switch (key-in ignition

switch is closed to ground)

The chime will sound until one of the above condi-

tions is removed. Chime rate: 168 to 192 chimes per

minute.

To test the key-in ignition function, insert key into

the ignition and open driver's door. Do not turn igni-

tion ON. Chime should sound until key is removed

from ignition or driver's door is closed.

LOW OIL PRESSURE CHIME OPERATION

The low oil pressure chime will warn the driver

that the engine oil pressure is low. The oil pressure

switch, will close to ground during a low oil pressure

condition. The oil pressure lamp will illuminate in

the message center. The body control module will

monitor the oil pressure switch and signal a low oil

pressure condition. A continuous four minute warn-

ing chime will sound and the oil pressure lamp will

come ON when the following conditions are met:

²Ignition on and engine not cranking

²Engine running at 420 to 480 rpm for 10 sec-

onds

²Oil pressure switch closed to ground for (1 sec-

ond minimum, 2 seconds maximum)

Chime rate: 168 to 192 chimes per minute.

SEAT BELT CHIME

The seat belt chime will sound for 4 to 8 seconds,

when the ignition is turned on and the driver's seat

belt is not buckled (seat belt switch is closed to

ground). This is a reminder to the driver to buckle

the seat belt. The seat belt lamp is controlled by the

mechanical instrument cluster. The cluster will also

illuminate the seat belt warning lamp for 6 seconds.

Buckling the driver's seat belt before the time out

has expired will cause the chime to stop immediately.

Chime rate: 38 to 62 chimes per minute.

To test the seat belt warning system, the ignition

switch must be in the OFF position for 1 minute

before starting the test. Turn the ignition switch to

the on position with the driver's seat belt not buck-

led. The seat belt warning lamp should light and the

chime should sound 4 to 8 seconds.

SEAT BELT LAMP

The seat belt lamp in the instrument cluster sig-

nals the vehicle passengers to fasten their seat belts.

The seat belt lamp is illuminated directly by the

8U - 2 CHIME WARNING/REMINDER SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 547 of 1938

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION........................ 1

DIAGNOSIS AND TESTING

CATALYST OVERHEAT WARNING CHIME.... 1

CHIME SYSTEM DIAGNOSIS.............. 1

DOME LAMP ON CHIME................. 2

ENGINE TEMPERATURE CRITICAL CHIME . . . 2EXTERIOR LAMPS ON CHIME............. 2

KEY-IN IGNITION CHIME................. 2

LOW OIL PRESSURE CHIME OPERATION . . . 2

SEAT BELT CHIME...................... 3

SEAT BELT LAMP...................... 3

TURN SIGNAL ON CHIME................ 3

WARNING LAMP ANNOUNCEMENT CHIME . . 3

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AN

AIRBAG, REFER TO GROUP 8M, RESTRAINT SYS-

TEMS FOR SAFETY PRECAUTIONS AND WARN-

INGS TO OBSERVE WHEN SERVICING AIRBAG

RELATED COMPONENTS.

The chime system provides the driver with warn-

ing chimes for:

²Seat Belt

²Exterior Lamps ON

²Key-In Ignition

²Engine Temperature Critical

²Turn Signals ON

²Dome Lamp ON

²Low Oil Pressure

²High Speed Warning

²Warning Lamp Announcement

²Catalyst Overheating

The Chime Warning/Reminder System is diagnosed

using a scan tool (DRB). Refer to the proper Body

Diagnostic Procedures manual for testing procedures

and scan tool usage instructions.

DIAGNOSIS AND TESTING

CATALYST OVERHEAT WARNING CHIME

The Catalyst Overheat Warning Chime will act as

a warning to the driver that the vehicle's catalyst

has entered an overheat condition. The Powertrain

Control Module (PCM) will enable or disable this fea-

ture for the appropriate vehicles. Right hand drive

gas vehicles only. The Body Control Module (BCM)

will monitor the CCD bus for status and signal a cat-

alyst overheat condition with continuous warning

chime when the following conditions are met:²Ignition switch in the ON position

²Engine running at 420 to 480 rpm for 10 sec-

onds

²CCD status and with a chime rate of one chime

per second.

CHIME SYSTEM DIAGNOSIS

NO TONE WHEN IGNITION SWITCH IS

TURNED ON AND DRIVER'S SEAT BELT IS

NOT BUCKLED.

(1) Using a scan tool (DRB), check for tone in any

other function.

(2) Using a voltmeter, check for voltage:

(a) Pin 9 of the internal 32 way connector of the

BCM for battery feed.

(b) Pin 8 of the internal 32 way connector of the

BCM for ignition feed.

(c) If voltage OK, go to step Step 3

(d) If NO voltage repair as necessary. Refer to

Group 8W, Wiring Diagrams for component loca-

tions and circuit information.

(3) Check driver's seat belt buckle switch input for

a closed circuit when not buckled. If input not seen,

look for open in wiring or switch. The switch is

grounded when belt is not buckled.

(4) Repair as necessary.

NO FASTEN SEAT BELT LAMP WHEN

IGNITION SWITCH IS TURNED ON.

(1) Check for burned out lamp.

(2) Using a voltmeter check for voltage:

(a) Pin 2 of the mechanical instrument cluster

for battery feed.

(b) Pin 11 of the mechanical instrument cluster

for ignition voltage.

(3) Repair as necessary.

NS/GSCHIME WARNING/REMINDER SYSTEM 8U - 1

Page 548 of 1938

FASTEN SEAT BELT LAMP OR TONE

CONTINUES FOR MORE THAN 10 SECONDS

AFTER SEAT BELTS ARE FASTENED AND

DRIVER'S DOOR IS CLOSED.

(1) Check left door ajar switch for no ground when

switch is depressed.

(a) If continuity replace door ajar switch.

(b) If NO continuity replace BCM for tone condi-

tion, or replace mechanical instrument panel for

lamp condition.

(c) Replace BCM for tone condition.

(d) Replace mechanical instrument cluster for

lamp condition.

NO TONE WHEN PARK OR HEADLAMPS ARE

ON AND DRIVER'S DOOR IS OPEN.

(1) Check left door ajar switch for good ground

when driver's door is open. Repair as necessary.

(2) Inspect BCM connectors and wires for proper

connection. If OK, replace BCM for tone condition.

DOME LAMP ON CHIME

The dome lamp on chime will warn the driver that

the dome lamps have been left on.

With the ignition is OFF:

²Driver's door OPEN (door ajar switch is closed to

ground)

²Dome lamps are ON (dome lamp switch is closed

to ground),

The chime will sound continuously until driver's

door is closed, dome lamps tuned OFF or until the

battery protection time out of 15 minutes has

expired. Refer Group 8L, Lamps proper procedures.

Chime rate: 168 to 192 chimes per minute.

ENGINE TEMPERATURE CRITICAL CHIME

The engine temperature critical chime will warn

the driver that the vehicle's engine is overheating.

While monitoring the coolant temperature, the Pow-

ertrain Control Module (PCM) will send on the CCD

bus as engine temperature every 1.376 seconds to the

Body Control Module (BCM). The BCM calculates

engine temperature and determines if a warning

should occur. This feature is functional only with the

Ignition Switch in the Run/Start position. On the

Diesel vehicles, the coolant temperature sensor is

read directly by the BCM.

When the engine temperature reaches 122ÉC

(252ÉF) or the diesel engine 112ÉC (234ÉF), the BCM

will chime one tone and the engine temperature lamp

comes ON. The BCM turns OFF the lamp when the

engine temperature reaches 117ÉC (242ÉF) or the die-

sel engine 108ÉC (226ÉF). The BCM will chime con-

tinuously when the engine temperature reaches

125ÉC (257ÉF) or diesel engine 116ÉC (241ÉF). The

chime will turn OFF after four minutes or when thetemperature reaches 117ÉC (242ÉF) or diesel engine

108ÉC (226ÉF), which ever occurs first.

EXTERIOR LAMPS ON CHIME

The exterior lamp on chime will warn the driver

that the exterior lights have been left on.

With the ignition switch OFF:

²Driver's door is open (door ajar switch is closed

to ground)

²Parking lamps or headlamps ON (parking lamp

switch is closed to ground)

The chime will sound until lights are turned OFF,

driver's door closed or until the battery protection

time out of 3 minutes has expired.

Refer to Group 8L, Lamps, for proper service pro-

cedures. Chime rate: 168 to 192 chimes per minute.

To test the exterior lamps left on function:

²Turn ignition off

²Remove ignition key

²Turn exterior lamps on with driver's door open.

Chime should sound until lamps are turned off or

driver's door is closed.

KEY-IN IGNITION CHIME

The key-in ignition chime will act as a warning to

the driver that the ignition key has been left in the

ignition switch.

With the ignition switch is in OFF position ONLY:

²Driver's door is open/ajar (door ajar switch is

closed to ground)

²Key is in the ignition switch (key-in ignition

switch is closed to ground)

The chime will sound until one of the above condi-

tions is removed. Chime rate: 168 to 192 chimes per

minute.

To test the key-in ignition function, insert key into

the ignition and open driver's door. Do not turn igni-

tion ON. Chime should sound until key is removed

from ignition or driver's door is closed.

LOW OIL PRESSURE CHIME OPERATION

The low oil pressure chime will warn the driver

that the engine oil pressure is low. The oil pressure

switch, will close to ground during a low oil pressure

condition. The oil pressure lamp will illuminate in

the message center. The body control module will

monitor the oil pressure switch and signal a low oil

pressure condition. A continuous four minute warn-

ing chime will sound and the oil pressure lamp will

come ON when the following conditions are met:

²Ignition on and engine not cranking

²Engine running at 420 to 480 rpm for 10 sec-

onds

²Oil pressure switch closed to ground for (1 sec-

ond minimum, 2 seconds maximum)

Chime rate: 168 to 192 chimes per minute.

8U - 2 CHIME WARNING/REMINDER SYSTEMNS/GS

DIAGNOSIS AND TESTING (Continued)