key battery CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1420 of 1938

In this chart, Pre±Heat and Post±Heat times are

mentioned. Pre±heat is the amount of time the glow

plug relay circuit is activated when the ignition (key)

switch is ON, but the engine has yet to be started.

Post±heat is the amount of time the glow plug relay

circuit is activated after the engine is operating. The

Glow Plug lamp will not be illuminated during the

post±heat cycle.

TESTING:

Disconnect and isolate the electrical connectors

(Fig. 16) at all four glow plugs. With the engine cool

or cold, and the key in the ON position, check for

10±12 volts + at each electrical connector. 10±12 volts

+ should be at each connector whenever the PCM is

operating in the pre±heat or post±heat cycles (refer

to the following Glow Plug Control chart).Be very

careful not to allow any of the four discon-

nected glow plug electrical connectors to con-

tact a metal surface. When the key is turned to

the ON position, approximately 100 amps at 12

volts is supplied to these connectors.If 10±12

volts + is not available at each connector, check con-

tinuity of wiring harness directly to the relay. If con-

tinuity is good directly to the relay, the fault is either

with the relay or the relay input from the PCM. To

test the relay only, refer to RelaysÐOperation/Test-

ing in this section of the group. If the relay test is

good, refer to the DRB scan tool.

Diagnostic Trouble Codes:Refer to On-Board

Diagnostics in Group 25, Emission Control System

for a list of Diagnostic Trouble Codes (DTC's) for cer-

tain fuel system components.

RELAYSÐOPERATION/TESTING

The following description of operation and

tests apply only to the Diesel PCM and other

relays. The terminals on the bottom of each relay

are numbered (Fig. 17).

OPERATION

²Terminal number 30 is connected to battery volt-

age. For both the Diesel and other relays, terminal

30 is connected to battery voltage at all times.

²The PCM grounds the coil side of the relay

through terminal number 85.

²Terminal number 86 supplies voltage to the coil

side of the relay.

²When the PCM de-energizes the Diesel PCM

and other relays, terminal number 87A connects to

terminal 30. This is the Off position. In the off posi-

tion, voltage is not supplied to the rest of the circuit.

Terminal 87A is the center terminal on the relay.

Fig. 15 Glow Plug Relay Location

Fig. 16 Wiring Connection at Glow Plug

GLOW PLUG CONTROL

14 - 52 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1464 of 1938

DIAGNOSIS AND TESTING

STEERING COLUMN

For diagnosis of conditions relating to the steering

column, refer to the steering system diagnosis charts,

in the diagnosis and testing section at the beginning

of this group.

SERVICE PROCEDURES

STEERING COLUMN SERVICE PROCEDURE

WARNINGS

WARNING: BEFORE BEGINNING ANY SERVICE

PROCEDURES THAT INVOLVES REMOVING THE

AIR BAG. REMOVE AND ISOLATE THE NEGATIVE

(-) BATTERY CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. FAILURE TO DO SO

COULD RESULT IN ACCIDENTAL DEPLOYMENT OF

THE AIR BAG AND POSSIBLE PERSONAL INJURY.

THE FASTENERS, SCREWS, AND BOLTS, ORIGI-

NALLY USED FOR THE AIR BAG COMPONENTS,

HAVE SPECIAL COATINGS AND ARE SPECIFI-

CALLY DESIGNED FOR THE AIR BAG SYSTEM.

THEY MUST NEVER BE REPLACED WITH ANY SUB-

STITUTES. ANYTIME A NEW FASTENER IS

NEEDED, REPLACE WITH THE CORRECT FASTEN-

ERS PROVIDED IN THE SERVICE PACKAGE OR

FASTENERS LISTED IN THE PARTS BOOKS.

BEFORE SERVICING A STEERING COLUMN

EQUIPPED WITH AN AIR BAG, REFER TO GROUP

8M, ELECTRICAL FOR PROPER AND SAFE SER-

VICE PROCEDURES.

NOTE: Safety goggles should be worn at all times

when working on steering columns.

CAUTION: Disconnect negative (ground) cable

from the battery, before servicing any column com-

ponent.CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

REMOVAL AND INSTALLATION

STEERING COLUMN ASSEMBLY

To service the steering wheel and its components

or the air bag, refer to Group 8M, Restraint Systems.

Follow all WARNINGS.

To service the switches, refer to the appropriate

section of Group 8, Electrical.

To replace the steering column assembly, refer to

the steering column removal procedure.

REMOVE

(1) Make sure the front wheels of the vehicle are

in thestraight aheadposition before beginning the

column removal procedure.

(2) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

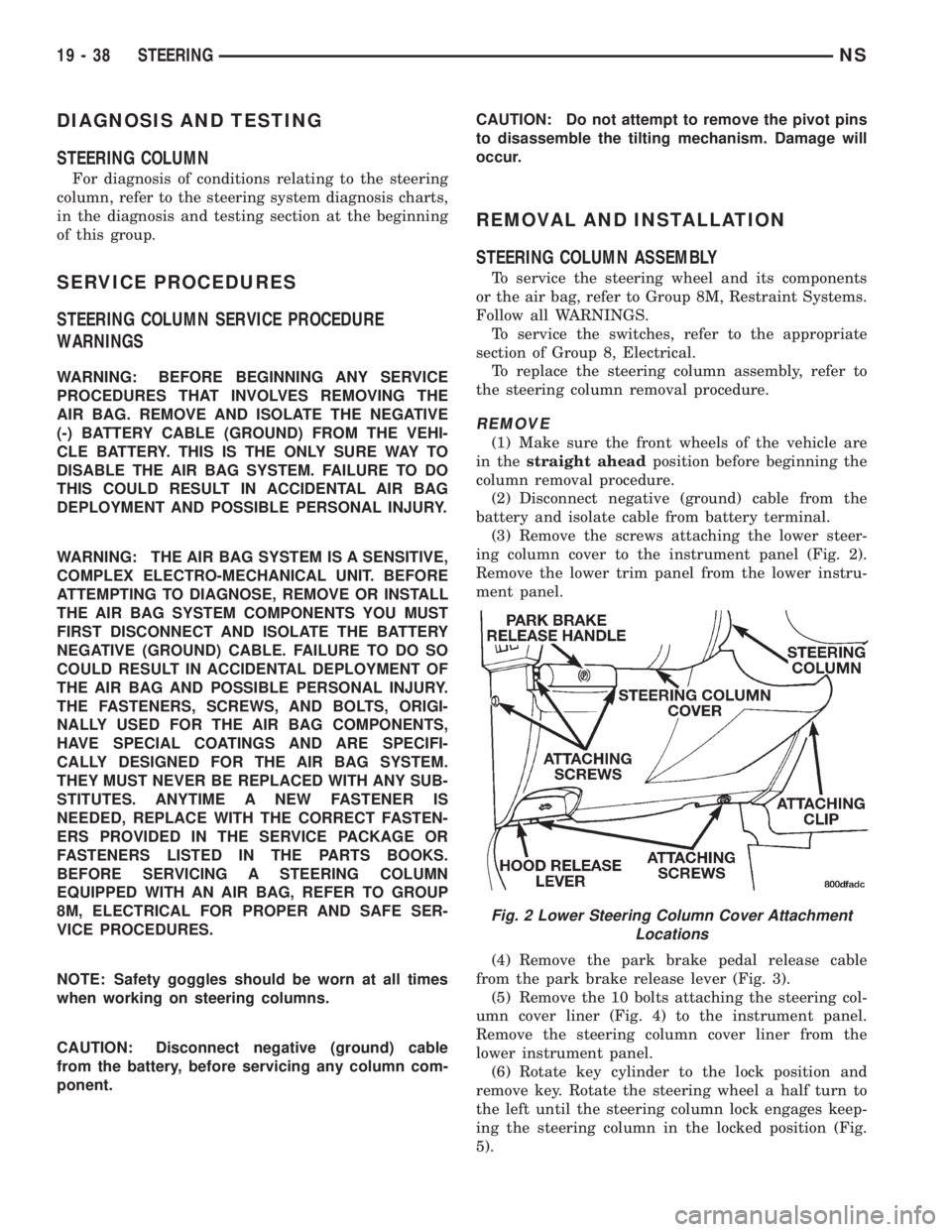

(3) Remove the screws attaching the lower steer-

ing column cover to the instrument panel (Fig. 2).

Remove the lower trim panel from the lower instru-

ment panel.

(4) Remove the park brake pedal release cable

from the park brake release lever (Fig. 3).

(5) Remove the 10 bolts attaching the steering col-

umn cover liner (Fig. 4) to the instrument panel.

Remove the steering column cover liner from the

lower instrument panel.

(6) Rotate key cylinder to the lock position and

remove key. Rotate the steering wheel a half turn to

the left until the steering column lock engages keep-

ing the steering column in the locked position (Fig.

5).

Fig. 2 Lower Steering Column Cover Attachment

Locations

19 - 38 STEERINGNS