shaft CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 142 of 1938

(23) Install the negative (ground) cable on the bat-

tery.

(24) Cycle the park brake pedal one time. This will

seat the park brake cables and will allow the auto-

matic self adjuster to properly tension the park brake

cables.

PARK BRAKE SHOES (WITH REAR DISC BRAKES)

On this vehicle, the park brake shoes are removed

from the disc brake adapter with the disc brake

adapter removed from the vehicle.

REMOVE

(1) Set the parking brake.The parking brake is

set to keep the hub/bearing and axle shaft from

rotating when loosening the hub nut.

(2) Raise vehicle. Vehicle is to be raised and sup-

ported on jackstands or on a frame contact type

hoist. See Hoisting in the Lubrication And Mainte-

nance section of this service manual.

(3) Remove the wheel/tire.

(4) Remove the cotter pin and nut retainer (Fig.

139) from the stub shaft of the outer C/V joint.

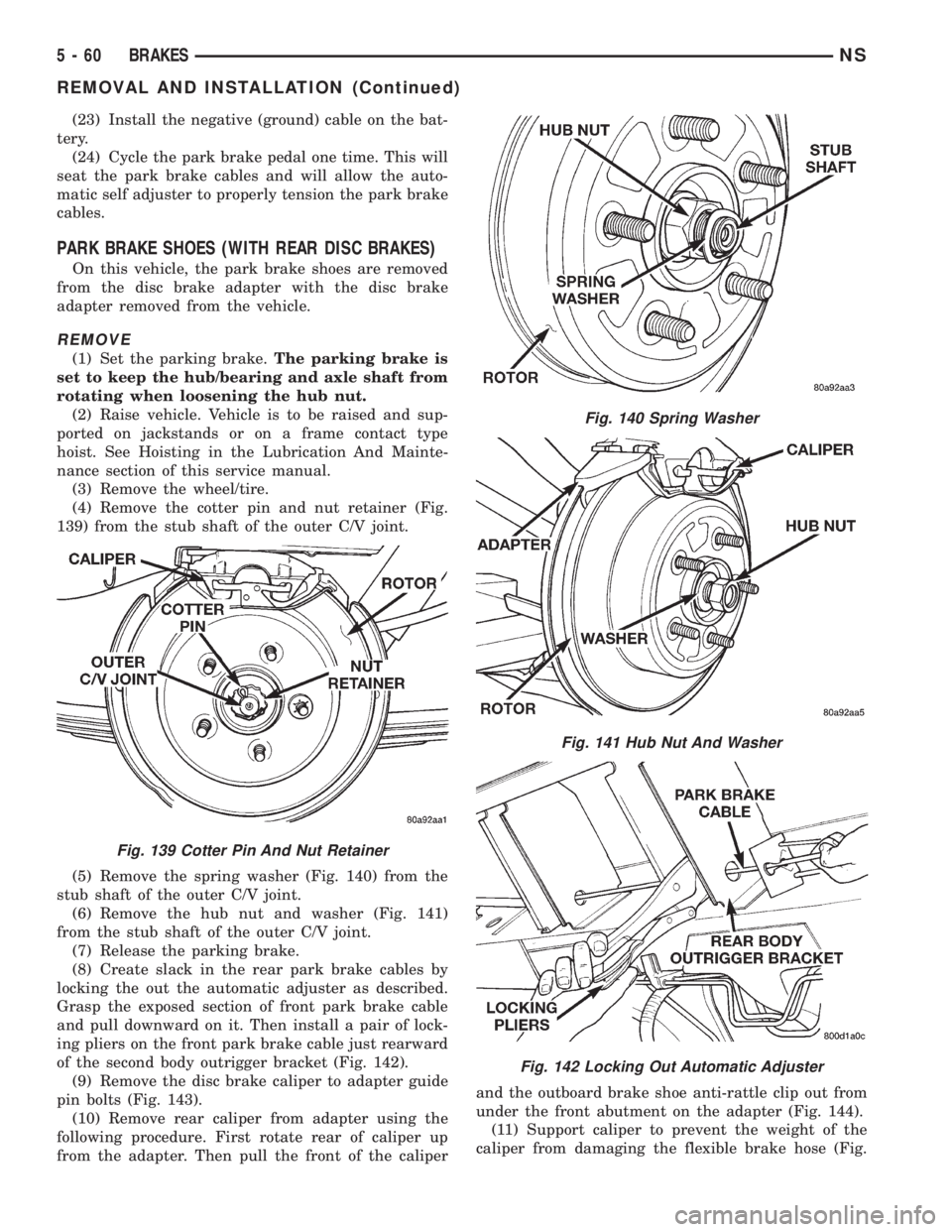

(5) Remove the spring washer (Fig. 140) from the

stub shaft of the outer C/V joint.

(6) Remove the hub nut and washer (Fig. 141)

from the stub shaft of the outer C/V joint.

(7) Release the parking brake.

(8) Create slack in the rear park brake cables by

locking the out the automatic adjuster as described.

Grasp the exposed section of front park brake cable

and pull downward on it. Then install a pair of lock-

ing pliers on the front park brake cable just rearward

of the second body outrigger bracket (Fig. 142).

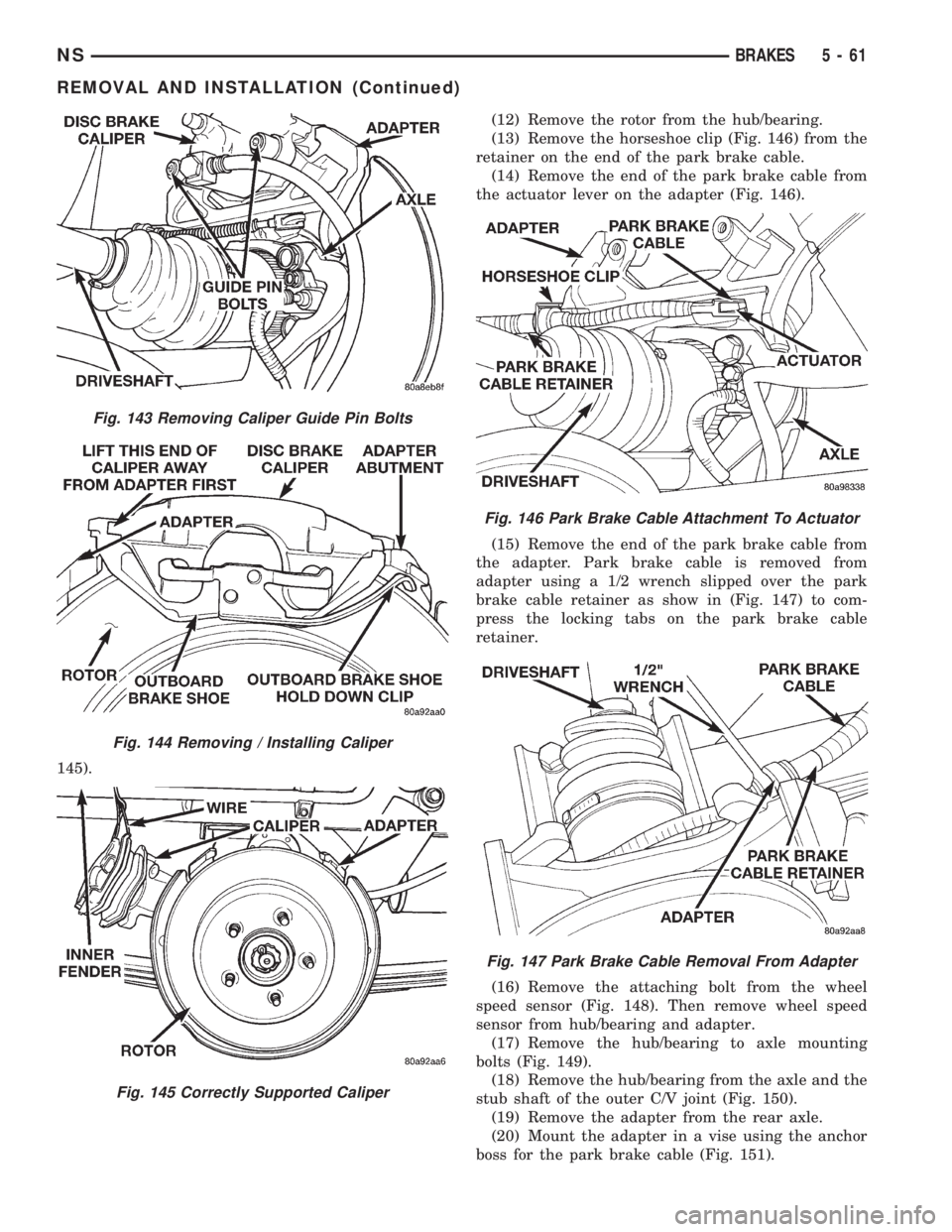

(9) Remove the disc brake caliper to adapter guide

pin bolts (Fig. 143).

(10) Remove rear caliper from adapter using the

following procedure. First rotate rear of caliper up

from the adapter. Then pull the front of the caliperand the outboard brake shoe anti-rattle clip out from

under the front abutment on the adapter (Fig. 144).

(11) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

Fig. 139 Cotter Pin And Nut Retainer

Fig. 140 Spring Washer

Fig. 141 Hub Nut And Washer

Fig. 142 Locking Out Automatic Adjuster

5 - 60 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 143 of 1938

145).(12) Remove the rotor from the hub/bearing.

(13) Remove the horseshoe clip (Fig. 146) from the

retainer on the end of the park brake cable.

(14) Remove the end of the park brake cable from

the actuator lever on the adapter (Fig. 146).

(15) Remove the end of the park brake cable from

the adapter. Park brake cable is removed from

adapter using a 1/2 wrench slipped over the park

brake cable retainer as show in (Fig. 147) to com-

press the locking tabs on the park brake cable

retainer.

(16) Remove the attaching bolt from the wheel

speed sensor (Fig. 148). Then remove wheel speed

sensor from hub/bearing and adapter.

(17) Remove the hub/bearing to axle mounting

bolts (Fig. 149).

(18) Remove the hub/bearing from the axle and the

stub shaft of the outer C/V joint (Fig. 150).

(19) Remove the adapter from the rear axle.

(20) Mount the adapter in a vise using the anchor

boss for the park brake cable (Fig. 151).

Fig. 143 Removing Caliper Guide Pin Bolts

Fig. 144 Removing / Installing Caliper

Fig. 145 Correctly Supported Caliper

Fig. 146 Park Brake Cable Attachment To Actuator

Fig. 147 Park Brake Cable Removal From Adapter

NSBRAKES 5 - 61

REMOVAL AND INSTALLATION (Continued)

Page 146 of 1938

NOTE: When the hold down pin is installed, the

long part of the hold down pin is to be positioned

strait up and down. This will ensure that the hold

down pin is correctly engaged with the adapter.

(6) Install the hold down spring and pin (Fig. 153)

on the leading park brake shoe.

(7) Install the lower return spring (Fig. 152) on

the leading and trailing park brake shoes.When

installing the hold down spring it is to be

installed behind the park brake shoes (Fig.

152).

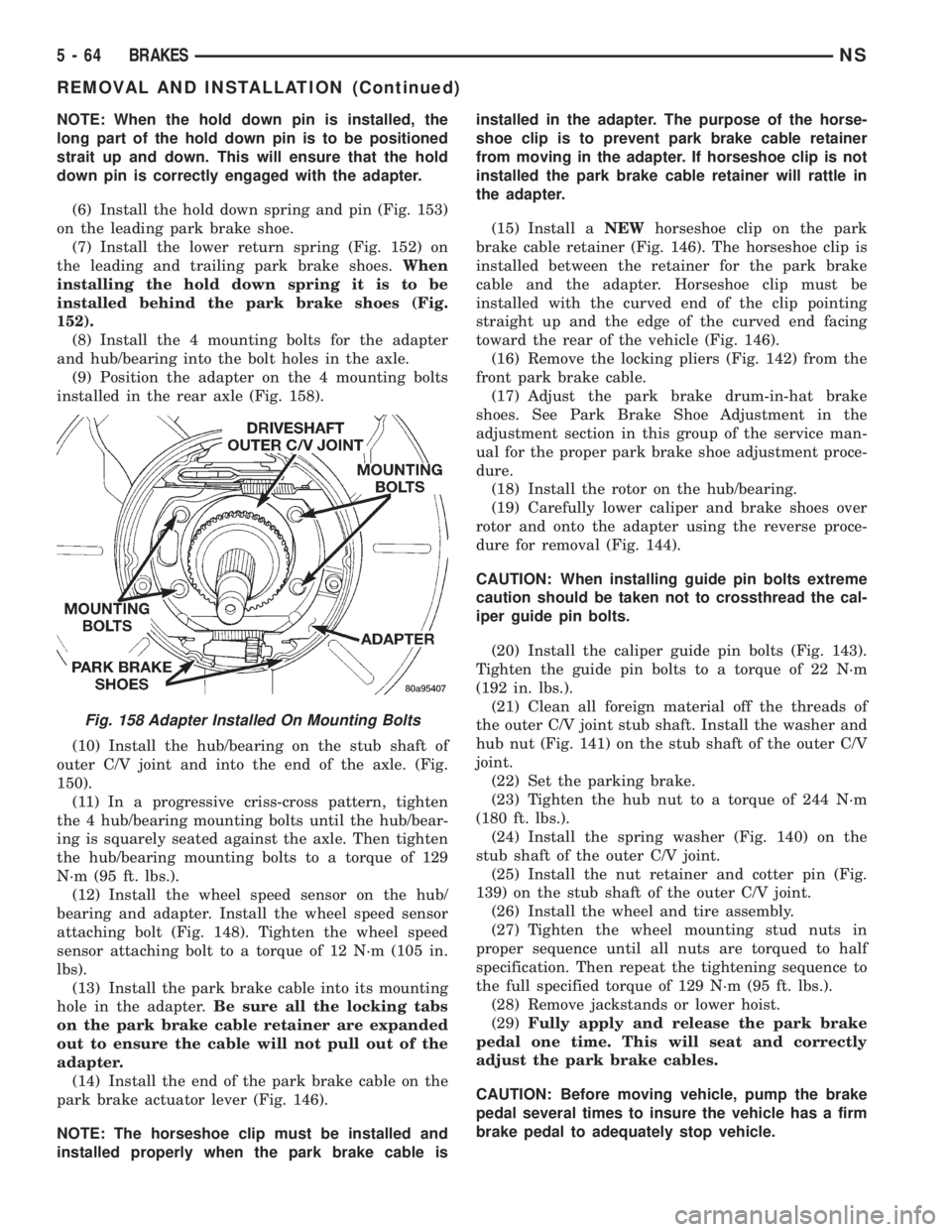

(8) Install the 4 mounting bolts for the adapter

and hub/bearing into the bolt holes in the axle.

(9) Position the adapter on the 4 mounting bolts

installed in the rear axle (Fig. 158).

(10) Install the hub/bearing on the stub shaft of

outer C/V joint and into the end of the axle. (Fig.

150).

(11) In a progressive criss-cross pattern, tighten

the 4 hub/bearing mounting bolts until the hub/bear-

ing is squarely seated against the axle. Then tighten

the hub/bearing mounting bolts to a torque of 129

N´m (95 ft. lbs.).

(12) Install the wheel speed sensor on the hub/

bearing and adapter. Install the wheel speed sensor

attaching bolt (Fig. 148). Tighten the wheel speed

sensor attaching bolt to a torque of 12 N´m (105 in.

lbs).

(13) Install the park brake cable into its mounting

hole in the adapter.Be sure all the locking tabs

on the park brake cable retainer are expanded

out to ensure the cable will not pull out of the

adapter.

(14) Install the end of the park brake cable on the

park brake actuator lever (Fig. 146).

NOTE: The horseshoe clip must be installed and

installed properly when the park brake cable isinstalled in the adapter. The purpose of the horse-

shoe clip is to prevent park brake cable retainer

from moving in the adapter. If horseshoe clip is not

installed the park brake cable retainer will rattle in

the adapter.

(15) Install aNEWhorseshoe clip on the park

brake cable retainer (Fig. 146). The horseshoe clip is

installed between the retainer for the park brake

cable and the adapter. Horseshoe clip must be

installed with the curved end of the clip pointing

straight up and the edge of the curved end facing

toward the rear of the vehicle (Fig. 146).

(16) Remove the locking pliers (Fig. 142) from the

front park brake cable.

(17) Adjust the park brake drum-in-hat brake

shoes. See Park Brake Shoe Adjustment in the

adjustment section in this group of the service man-

ual for the proper park brake shoe adjustment proce-

dure.

(18) Install the rotor on the hub/bearing.

(19) Carefully lower caliper and brake shoes over

rotor and onto the adapter using the reverse proce-

dure for removal (Fig. 144).

CAUTION: When installing guide pin bolts extreme

caution should be taken not to crossthread the cal-

iper guide pin bolts.

(20) Install the caliper guide pin bolts (Fig. 143).

Tighten the guide pin bolts to a torque of 22 N´m

(192 in. lbs.).

(21) Clean all foreign material off the threads of

the outer C/V joint stub shaft. Install the washer and

hub nut (Fig. 141) on the stub shaft of the outer C/V

joint.

(22) Set the parking brake.

(23) Tighten the hub nut to a torque of 244 N´m

(180 ft. lbs.).

(24) Install the spring washer (Fig. 140) on the

stub shaft of the outer C/V joint.

(25) Install the nut retainer and cotter pin (Fig.

139) on the stub shaft of the outer C/V joint.

(26) Install the wheel and tire assembly.

(27) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 129 N´m (95 ft. lbs.).

(28) Remove jackstands or lower hoist.

(29)Fully apply and release the park brake

pedal one time. This will seat and correctly

adjust the park brake cables.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop vehicle.

Fig. 158 Adapter Installed On Mounting Bolts

5 - 64 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 172 of 1938

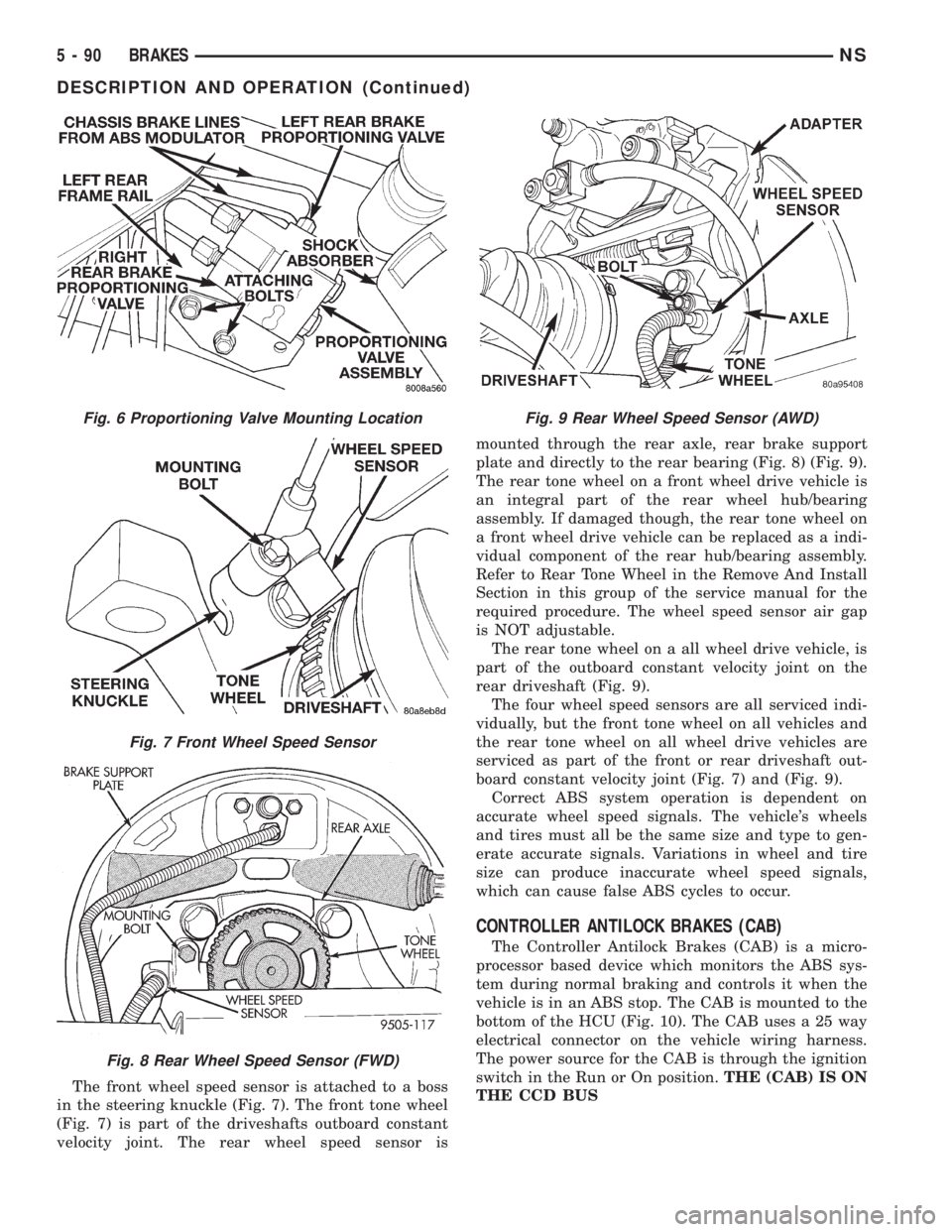

The front wheel speed sensor is attached to a boss

in the steering knuckle (Fig. 7). The front tone wheel

(Fig. 7) is part of the driveshafts outboard constant

velocity joint. The rear wheel speed sensor ismounted through the rear axle, rear brake support

plate and directly to the rear bearing (Fig. 8) (Fig. 9).

The rear tone wheel on a front wheel drive vehicle is

an integral part of the rear wheel hub/bearing

assembly. If damaged though, the rear tone wheel on

a front wheel drive vehicle can be replaced as a indi-

vidual component of the rear hub/bearing assembly.

Refer to Rear Tone Wheel in the Remove And Install

Section in this group of the service manual for the

required procedure. The wheel speed sensor air gap

is NOT adjustable.

The rear tone wheel on a all wheel drive vehicle, is

part of the outboard constant velocity joint on the

rear driveshaft (Fig. 9).

The four wheel speed sensors are all serviced indi-

vidually, but the front tone wheel on all vehicles and

the rear tone wheel on all wheel drive vehicles are

serviced as part of the front or rear driveshaft out-

board constant velocity joint (Fig. 7) and (Fig. 9).

Correct ABS system operation is dependent on

accurate wheel speed signals. The vehicle's wheels

and tires must all be the same size and type to gen-

erate accurate signals. Variations in wheel and tire

size can produce inaccurate wheel speed signals,

which can cause false ABS cycles to occur.

CONTROLLER ANTILOCK BRAKES (CAB)

The Controller Antilock Brakes (CAB) is a micro-

processor based device which monitors the ABS sys-

tem during normal braking and controls it when the

vehicle is in an ABS stop. The CAB is mounted to the

bottom of the HCU (Fig. 10). The CAB uses a 25 way

electrical connector on the vehicle wiring harness.

The power source for the CAB is through the ignition

switch in the Run or On position.THE (CAB) IS ON

THE CCD BUS

Fig. 6 Proportioning Valve Mounting Location

Fig. 7 Front Wheel Speed Sensor

Fig. 8 Rear Wheel Speed Sensor (FWD)

Fig. 9 Rear Wheel Speed Sensor (AWD)

5 - 90 BRAKESNS

DESCRIPTION AND OPERATION (Continued)

Page 180 of 1938

these inputs to the CAB should be investigated if a

complaint of intermittent warning system operation

is encountered.

(12) Low system voltage. If Low System Voltage is

detected by the CAB, the CAB will turn on the ABS

Warning Lamp until normal system voltage is

achieved. Once normal voltage is seen at the CAB,

normal operation resumes.

(13) High system voltage. If high system voltage is

detected by the CAB, the CAB will turn on the

Amber ABS Warning Lamp until normal system volt-

age is achieved. Once normal voltage is again

detected by the CAB, normal ABS operation will be

resumed at the next key on cycle.

(14) Additionally, any condition which results in

interruption of electrical current to the CAB or mod-

ulator assembly may cause the ABS Warning Lamp

to turn on intermittently.

(15) The body controller can turn on the (yellow)

ABS warning lamp if CCD communication between

the body controller and the CAB is interupted.

TONEWHEEL INSPECTION

CAUTION: The tone wheels used on this vehicle

equipped with the Teves Mark 20 Antilock Brake

System are different then those used on past mod-

els of this vehicle equipped with antilock brakes.

Reduced braking performance will result if this part

is used on earlier model vehicles and an accident

could result. Do not use on pre-1998 model year

vehicles.

Carefully inspect tonewheel at the suspected faulty

wheel speed sensor for missing, chipped or broken

teeth, this can cause erratic speed sensor signals.

Tonewheels should show no evidence of contact

with the wheel speed sensors. If contact was made,

determine cause and correct before replacing the

wheel speed sensor.

Excessive runout of the tonewheel can cause

erratic wheel speed sensor signals. Refer to Tone-

wheel Runout in the Specification Section in this sec-

tion of the service manual for the tonewheel runout

specification. Replace drive shaft assembly or rear

hub/bearing assembly if tonewheel runout exceeds

the specification.

Inspect tonewheels for looseness on their mounting

surfaces. Tonewheels are pressed onto their mounting

surfaces and should not rotate independently from

the mounting surface.

Check the wheel speed sensor head alignment to

the tone wheel. Also check the gap between the speed

sensor head and the tone wheel to ensure it is at

specification. Refer to Wheel Speed Sensor Clearance

in the Specification Section in this section of the ser-

vice manual.

PROPORTIONING VALVE

CAUTION: Proportioning valves (Fig. 18) should

never be disassembled.

If premature rear wheel skid occurs on hard brake

application, it could be an indication that a malfunc-

tion has occurred with one of the proportioning

valves.

If a malfunctioning proportioning valve is sus-

pected on a vehicle, refer to Proportioning Valve Test

in the Proportioning Valves Section in this group of

the service manual for the required test procedure.

BRAKE FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brakes hydraulic unit and all hydraulic

fluid hoses.

TEST DRIVING ABS COMPLAINT VEHICLE

Most ABS complaints will require a test drive as a

part of the diagnostic procedure. The purpose of the

test drive is to duplicate the condition.

NOTE: Remember conditions that result in the

turning on of the Red BRAKE Warning Lamp may

indicate reduced braking ability. The following pro-

cedure should be used to test drive an ABS com-

plaint vehicle.

Fig. 18 Brake Proportioning Valve Identification

5 - 98 BRAKESNS

DIAGNOSIS AND TESTING (Continued)

Page 193 of 1938

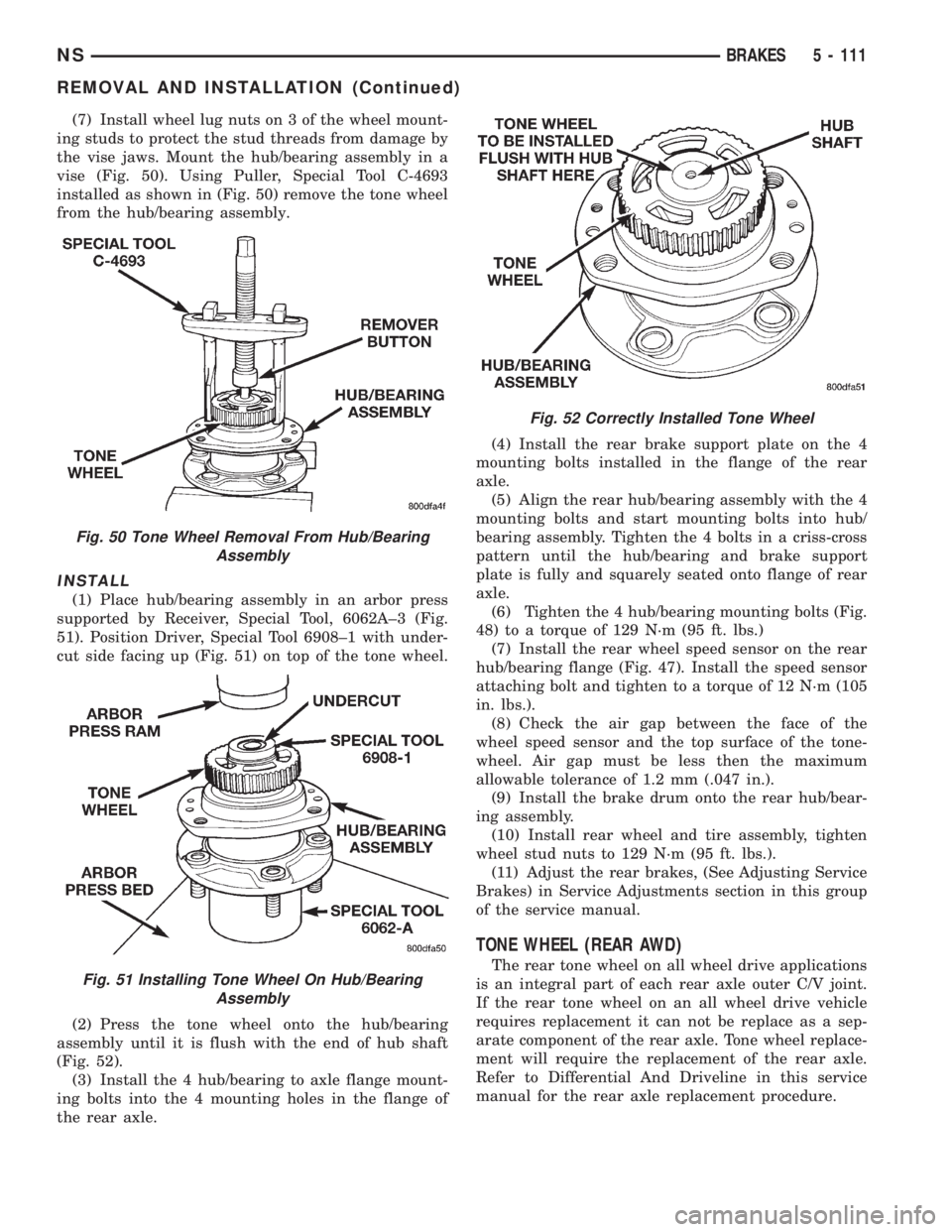

(7) Install wheel lug nuts on 3 of the wheel mount-

ing studs to protect the stud threads from damage by

the vise jaws. Mount the hub/bearing assembly in a

vise (Fig. 50). Using Puller, Special Tool C-4693

installed as shown in (Fig. 50) remove the tone wheel

from the hub/bearing assembly.

INSTALL

(1) Place hub/bearing assembly in an arbor press

supported by Receiver, Special Tool, 6062A±3 (Fig.

51). Position Driver, Special Tool 6908±1 with under-

cut side facing up (Fig. 51) on top of the tone wheel.

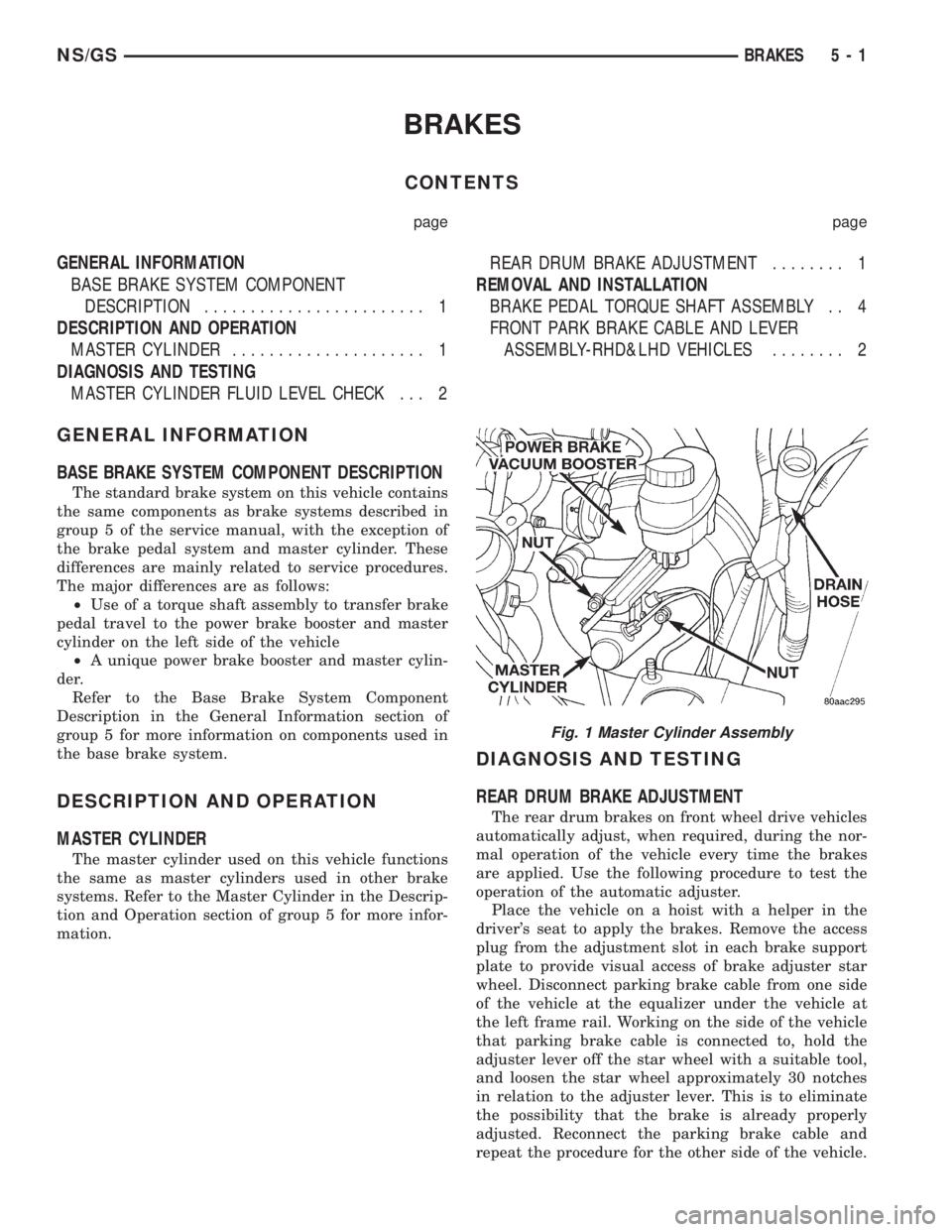

(2) Press the tone wheel onto the hub/bearing

assembly until it is flush with the end of hub shaft

(Fig. 52).

(3) Install the 4 hub/bearing to axle flange mount-

ing bolts into the 4 mounting holes in the flange of

the rear axle.(4) Install the rear brake support plate on the 4

mounting bolts installed in the flange of the rear

axle.

(5) Align the rear hub/bearing assembly with the 4

mounting bolts and start mounting bolts into hub/

bearing assembly. Tighten the 4 bolts in a criss-cross

pattern until the hub/bearing and brake support

plate is fully and squarely seated onto flange of rear

axle.

(6) Tighten the 4 hub/bearing mounting bolts (Fig.

48) to a torque of 129 N´m (95 ft. lbs.)

(7) Install the rear wheel speed sensor on the rear

hub/bearing flange (Fig. 47). Install the speed sensor

attaching bolt and tighten to a torque of 12 N´m (105

in. lbs.).

(8) Check the air gap between the face of the

wheel speed sensor and the top surface of the tone-

wheel. Air gap must be less then the maximum

allowable tolerance of 1.2 mm (.047 in.).

(9) Install the brake drum onto the rear hub/bear-

ing assembly.

(10) Install rear wheel and tire assembly, tighten

wheel stud nuts to 129 N´m (95 ft. lbs.).

(11) Adjust the rear brakes, (See Adjusting Service

Brakes) in Service Adjustments section in this group

of the service manual.

TONE WHEEL (REAR AWD)

The rear tone wheel on all wheel drive applications

is an integral part of each rear axle outer C/V joint.

If the rear tone wheel on an all wheel drive vehicle

requires replacement it can not be replace as a sep-

arate component of the rear axle. Tone wheel replace-

ment will require the replacement of the rear axle.

Refer to Differential And Driveline in this service

manual for the rear axle replacement procedure.

Fig. 50 Tone Wheel Removal From Hub/Bearing

Assembly

Fig. 51 Installing Tone Wheel On Hub/Bearing

Assembly

Fig. 52 Correctly Installed Tone Wheel

NSBRAKES 5 - 111

REMOVAL AND INSTALLATION (Continued)

Page 195 of 1938

BRAKES

CONTENTS

page page

GENERAL INFORMATION

BASE BRAKE SYSTEM COMPONENT

DESCRIPTION........................ 1

DESCRIPTION AND OPERATION

MASTER CYLINDER..................... 1

DIAGNOSIS AND TESTING

MASTER CYLINDER FLUID LEVEL CHECK . . . 2REAR DRUM BRAKE ADJUSTMENT........ 1

REMOVAL AND INSTALLATION

BRAKE PEDAL TORQUE SHAFT ASSEMBLY . . 4

FRONT PARK BRAKE CABLE AND LEVER

ASSEMBLY-RHD&LHD VEHICLES........ 2

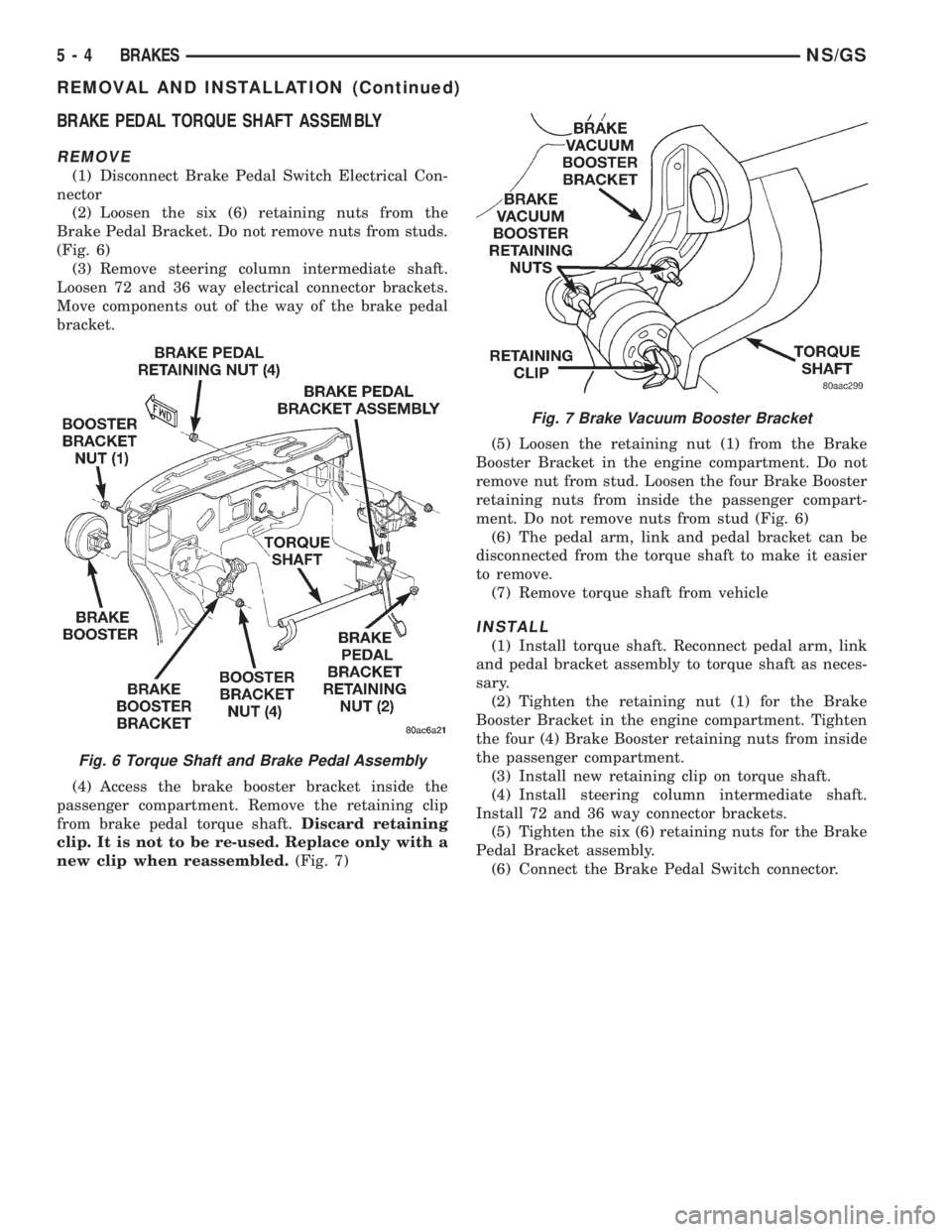

GENERAL INFORMATION

BASE BRAKE SYSTEM COMPONENT DESCRIPTION

The standard brake system on this vehicle contains

the same components as brake systems described in

group 5 of the service manual, with the exception of

the brake pedal system and master cylinder. These

differences are mainly related to service procedures.

The major differences are as follows:

²Use of a torque shaft assembly to transfer brake

pedal travel to the power brake booster and master

cylinder on the left side of the vehicle

²A unique power brake booster and master cylin-

der.

Refer to the Base Brake System Component

Description in the General Information section of

group 5 for more information on components used in

the base brake system.

DESCRIPTION AND OPERATION

MASTER CYLINDER

The master cylinder used on this vehicle functions

the same as master cylinders used in other brake

systems. Refer to the Master Cylinder in the Descrip-

tion and Operation section of group 5 for more infor-

mation.

DIAGNOSIS AND TESTING

REAR DRUM BRAKE ADJUSTMENT

The rear drum brakes on front wheel drive vehicles

automatically adjust, when required, during the nor-

mal operation of the vehicle every time the brakes

are applied. Use the following procedure to test the

operation of the automatic adjuster.

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the adjustment slot in each brake support

plate to provide visual access of brake adjuster star

wheel. Disconnect parking brake cable from one side

of the vehicle at the equalizer under the vehicle at

the left frame rail. Working on the side of the vehicle

that parking brake cable is connected to, hold the

adjuster lever off the star wheel with a suitable tool,

and loosen the star wheel approximately 30 notches

in relation to the adjuster lever. This is to eliminate

the possibility that the brake is already properly

adjusted. Reconnect the parking brake cable and

repeat the procedure for the other side of the vehicle.

Fig. 1 Master Cylinder Assembly

NS/GSBRAKES 5 - 1

Page 198 of 1938

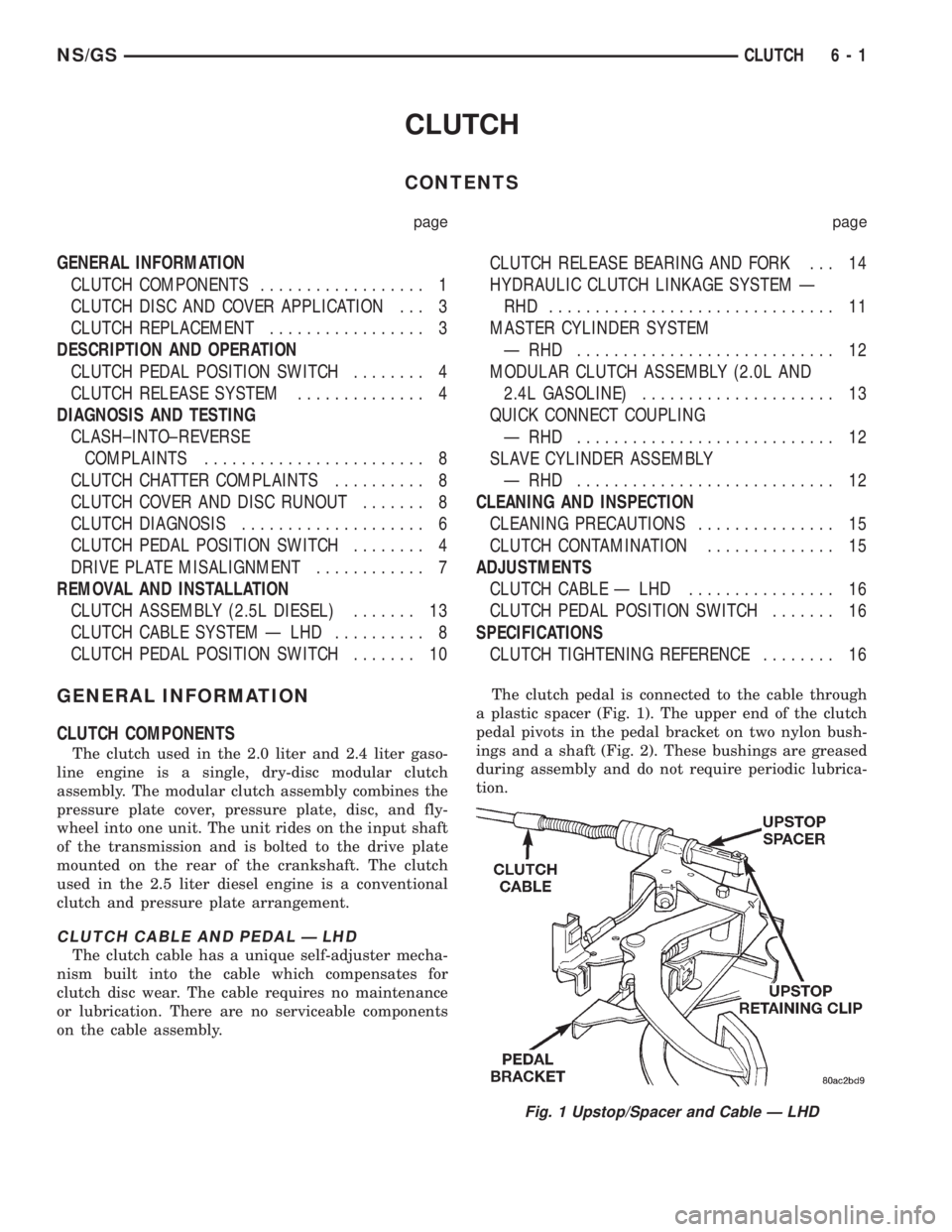

BRAKE PEDAL TORQUE SHAFT ASSEMBLY

REMOVE

(1) Disconnect Brake Pedal Switch Electrical Con-

nector

(2) Loosen the six (6) retaining nuts from the

Brake Pedal Bracket. Do not remove nuts from studs.

(Fig. 6)

(3) Remove steering column intermediate shaft.

Loosen 72 and 36 way electrical connector brackets.

Move components out of the way of the brake pedal

bracket.

(4) Access the brake booster bracket inside the

passenger compartment. Remove the retaining clip

from brake pedal torque shaft.Discard retaining

clip. It is not to be re-used. Replace only with a

new clip when reassembled.(Fig. 7)(5) Loosen the retaining nut (1) from the Brake

Booster Bracket in the engine compartment. Do not

remove nut from stud. Loosen the four Brake Booster

retaining nuts from inside the passenger compart-

ment. Do not remove nuts from stud (Fig. 6)

(6) The pedal arm, link and pedal bracket can be

disconnected from the torque shaft to make it easier

to remove.

(7) Remove torque shaft from vehicle

INSTALL

(1) Install torque shaft. Reconnect pedal arm, link

and pedal bracket assembly to torque shaft as neces-

sary.

(2) Tighten the retaining nut (1) for the Brake

Booster Bracket in the engine compartment. Tighten

the four (4) Brake Booster retaining nuts from inside

the passenger compartment.

(3) Install new retaining clip on torque shaft.

(4) Install steering column intermediate shaft.

Install 72 and 36 way connector brackets.

(5) Tighten the six (6) retaining nuts for the Brake

Pedal Bracket assembly.

(6) Connect the Brake Pedal Switch connector.

Fig. 6 Torque Shaft and Brake Pedal Assembly

Fig. 7 Brake Vacuum Booster Bracket

5 - 4 BRAKESNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 199 of 1938

CLUTCH

CONTENTS

page page

GENERAL INFORMATION

CLUTCH COMPONENTS.................. 1

CLUTCH DISC AND COVER APPLICATION . . . 3

CLUTCH REPLACEMENT................. 3

DESCRIPTION AND OPERATION

CLUTCH PEDAL POSITION SWITCH........ 4

CLUTCH RELEASE SYSTEM.............. 4

DIAGNOSIS AND TESTING

CLASH±INTO±REVERSE

COMPLAINTS........................ 8

CLUTCH CHATTER COMPLAINTS.......... 8

CLUTCH COVER AND DISC RUNOUT....... 8

CLUTCH DIAGNOSIS.................... 6

CLUTCH PEDAL POSITION SWITCH........ 4

DRIVE PLATE MISALIGNMENT............ 7

REMOVAL AND INSTALLATION

CLUTCH ASSEMBLY (2.5L DIESEL)....... 13

CLUTCH CABLE SYSTEM Ð LHD.......... 8

CLUTCH PEDAL POSITION SWITCH....... 10CLUTCH RELEASE BEARING AND FORK . . . 14

HYDRAULIC CLUTCH LINKAGE SYSTEM Ð

RHD ............................... 11

MASTER CYLINDER SYSTEM

Ð RHD ............................ 12

MODULAR CLUTCH ASSEMBLY (2.0L AND

2.4L GASOLINE)..................... 13

QUICK CONNECT COUPLING

Ð RHD ............................ 12

SLAVE CYLINDER ASSEMBLY

Ð RHD ............................ 12

CLEANING AND INSPECTION

CLEANING PRECAUTIONS............... 15

CLUTCH CONTAMINATION.............. 15

ADJUSTMENTS

CLUTCH CABLE Ð LHD................ 16

CLUTCH PEDAL POSITION SWITCH....... 16

SPECIFICATIONS

CLUTCH TIGHTENING REFERENCE........ 16

GENERAL INFORMATION

CLUTCH COMPONENTS

The clutch used in the 2.0 liter and 2.4 liter gaso-

line engine is a single, dry-disc modular clutch

assembly. The modular clutch assembly combines the

pressure plate cover, pressure plate, disc, and fly-

wheel into one unit. The unit rides on the input shaft

of the transmission and is bolted to the drive plate

mounted on the rear of the crankshaft. The clutch

used in the 2.5 liter diesel engine is a conventional

clutch and pressure plate arrangement.

CLUTCH CABLE AND PEDAL Ð LHD

The clutch cable has a unique self-adjuster mecha-

nism built into the cable which compensates for

clutch disc wear. The cable requires no maintenance

or lubrication. There are no serviceable components

on the cable assembly.The clutch pedal is connected to the cable through

a plastic spacer (Fig. 1). The upper end of the clutch

pedal pivots in the pedal bracket on two nylon bush-

ings and a shaft (Fig. 2). These bushings are greased

during assembly and do not require periodic lubrica-

tion.

Fig. 1 Upstop/Spacer and Cable Ð LHD

NS/GSCLUTCH 6 - 1

Page 204 of 1938

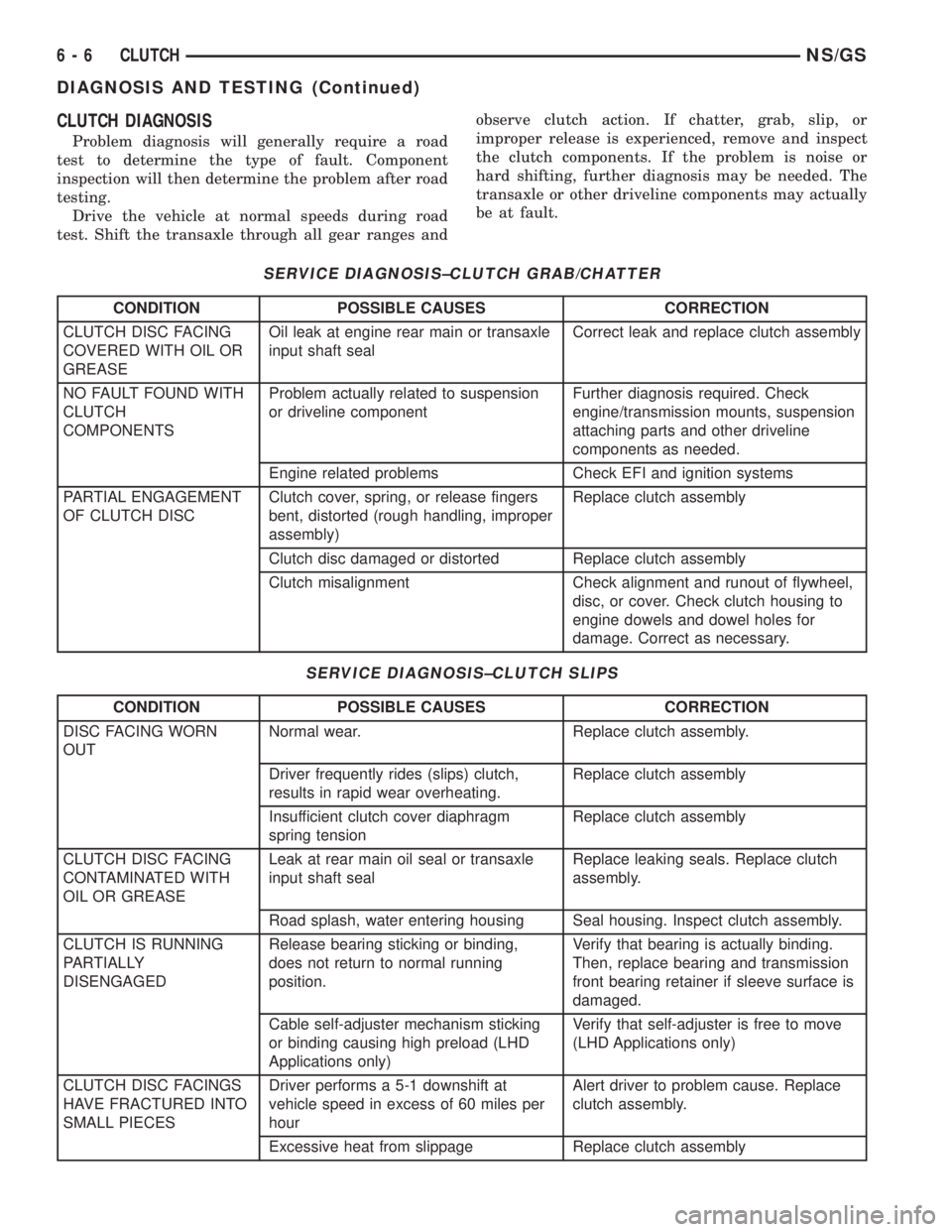

CLUTCH DIAGNOSIS

Problem diagnosis will generally require a road

test to determine the type of fault. Component

inspection will then determine the problem after road

testing.

Drive the vehicle at normal speeds during road

test. Shift the transaxle through all gear ranges andobserve clutch action. If chatter, grab, slip, or

improper release is experienced, remove and inspect

the clutch components. If the problem is noise or

hard shifting, further diagnosis may be needed. The

transaxle or other driveline components may actually

be at fault.

SERVICE DIAGNOSIS±CLUTCH GRAB/CHATTER

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC FACING

COVERED WITH OIL OR

GREASEOil leak at engine rear main or transaxle

input shaft sealCorrect leak and replace clutch assembly

NO FAULT FOUND WITH

CLUTCH

COMPONENTSProblem actually related to suspension

or driveline componentFurther diagnosis required. Check

engine/transmission mounts, suspension

attaching parts and other driveline

components as needed.

Engine related problems Check EFI and ignition systems

PARTIAL ENGAGEMENT

OF CLUTCH DISCClutch cover, spring, or release fingers

bent, distorted (rough handling, improper

assembly)Replace clutch assembly

Clutch disc damaged or distorted Replace clutch assembly

Clutch misalignment Check alignment and runout of flywheel,

disc, or cover. Check clutch housing to

engine dowels and dowel holes for

damage. Correct as necessary.

SERVICE DIAGNOSIS±CLUTCH SLIPS

CONDITION POSSIBLE CAUSES CORRECTION

DISC FACING WORN

OUTNormal wear. Replace clutch assembly.

Driver frequently rides (slips) clutch,

results in rapid wear overheating.Replace clutch assembly

Insufficient clutch cover diaphragm

spring tensionReplace clutch assembly

CLUTCH DISC FACING

CONTAMINATED WITH

OIL OR GREASELeak at rear main oil seal or transaxle

input shaft sealReplace leaking seals. Replace clutch

assembly.

Road splash, water entering housing Seal housing. Inspect clutch assembly.

CLUTCH IS RUNNING

PARTIALLY

DISENGAGEDRelease bearing sticking or binding,

does not return to normal running

position.Verify that bearing is actually binding.

Then, replace bearing and transmission

front bearing retainer if sleeve surface is

damaged.

Cable self-adjuster mechanism sticking

or binding causing high preload (LHD

Applications only)Verify that self-adjuster is free to move

(LHD Applications only)

CLUTCH DISC FACINGS

HAVE FRACTURED INTO

SMALL PIECESDriver performs a 5-1 downshift at

vehicle speed in excess of 60 miles per

hourAlert driver to problem cause. Replace

clutch assembly.

Excessive heat from slippage Replace clutch assembly

6 - 6 CLUTCHNS/GS

DIAGNOSIS AND TESTING (Continued)