tow CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 103 of 1938

NOTE: The following wheel sequence should be

used when bleeding the brake hydraulic system.

The use of this wheel sequence will ensure ade-

quate removal of all trapped air from the brake

hydraulic system.

²Left Rear Wheel

²Right Front Wheel

²Right Rear Wheel

²Left Front Wheel

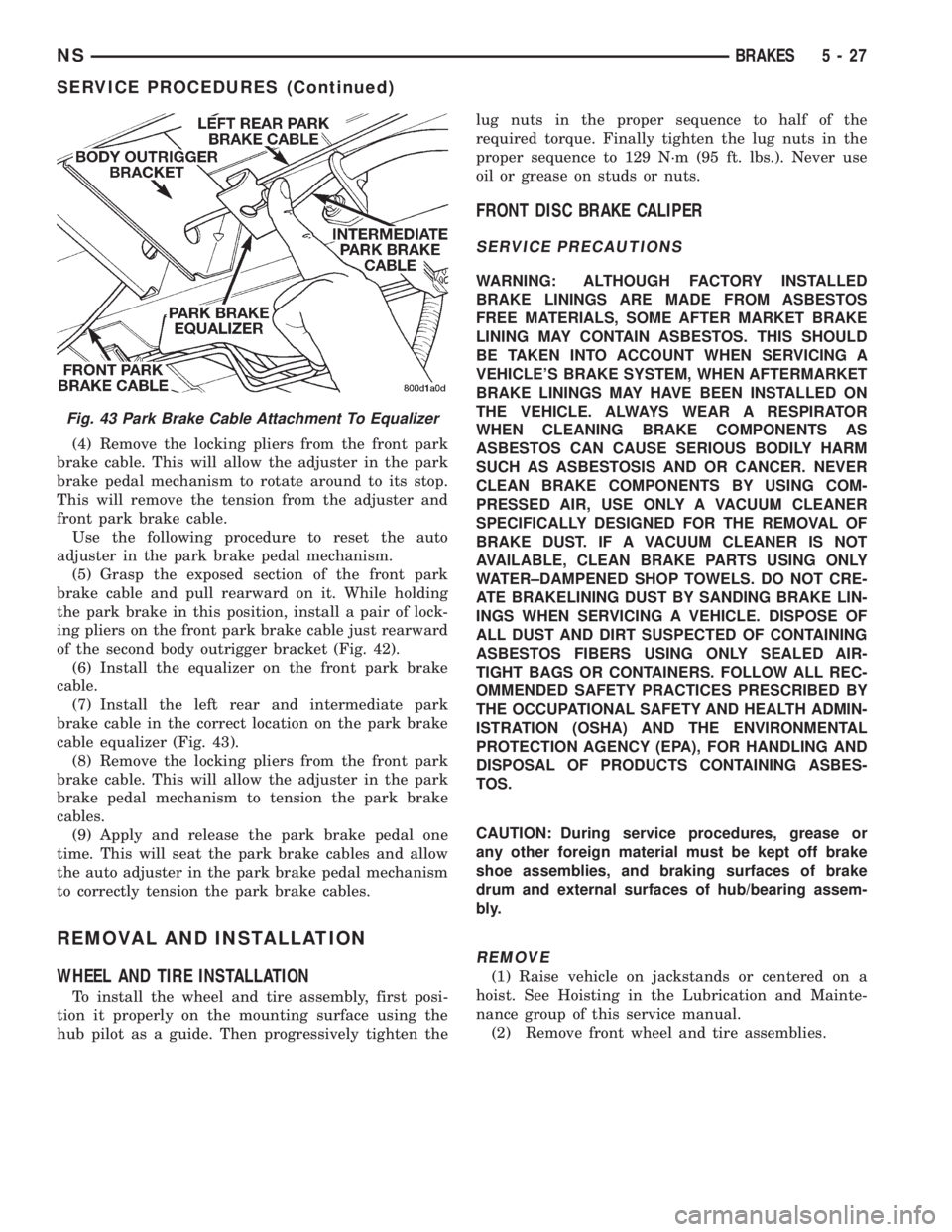

(4) Open the left rear wheel bleeder screw at least

one full turnor more to obtain an adequate flow of

brake fluid (Fig. 29).

CAUTION: Just cracking the bleeder screw often

restricts fluid flow, and a slow, weak fluid discharge

will NOT get all the air out.

(5) After 4 to 8 ounces of brake fluid has been bled

through the hydraulic system, and an air-free flow is

maintained in the hose and jar, this will indicate agood bleed of the hydraulic system has been

obtained.

(6) Repeat the procedure at all the other remain-

ing bleeder screws. Then check the pedal for travel.

If pedal travel is excessive or has not been improved,

enough fluid has not passed through the system to

expel all the trapped air. Be sure to monitor the fluid

level in the pressure bleeder, so it stays at a proper

level so air will not enter the brake system through

the master cylinder.

(7) Perform a final adjustment of the rear brake

shoes and then test drive vehicle to be sure brakes

are operating correctly and that pedal is solid.

BLEEDING WITHOUT A PRESSURE BLEEDER

NOTE: Correct manual bleeding of the brakes

hydraulic system will require the aid of a helper.

NOTE: To adequately bleed the brakes using the

manual bleeding procedure the rear brakes must be

correctly adjusted. Prior to the manual bleeding of

the brake hydraulic system, correctly adjust the

rear brakes.

NOTE: The following wheel sequence should be

used when bleeding the brake hydraulic system.

The use of this wheel sequence will ensure ade-

quate removal of all trapped air from the brake

hydraulic system.

²Left Rear Wheel

²Right Front Wheel

²Right Rear Wheel

²Left Front Wheel

(1) Pump the brake pedal three or four times and

hold it down before the bleeder screw is opened.

(2) Push the brake pedal toward the floor and hold

it down. Then open the left rear bleeder screw at

least 1 full turn. When the bleeder screw opens the

brake pedal will drop all the way to the floor.

(3) Release the brake pedal onlyafterthe bleeder

screw is closed.

(4) Repeat steps 1 through 3, four or five times, at

each bleeder screw in the required sequence. This

should pass a sufficient amount of fluid to expel all

the trapped air from the brake system. Be sure to

monitor the fluid level in the master cylinder, so it

stays at a proper level so air will not enter the brake

system through the master cylinder.

(5) Perform a final adjustment of the rear brake

shoes and then test drive vehicle to be sure brakes

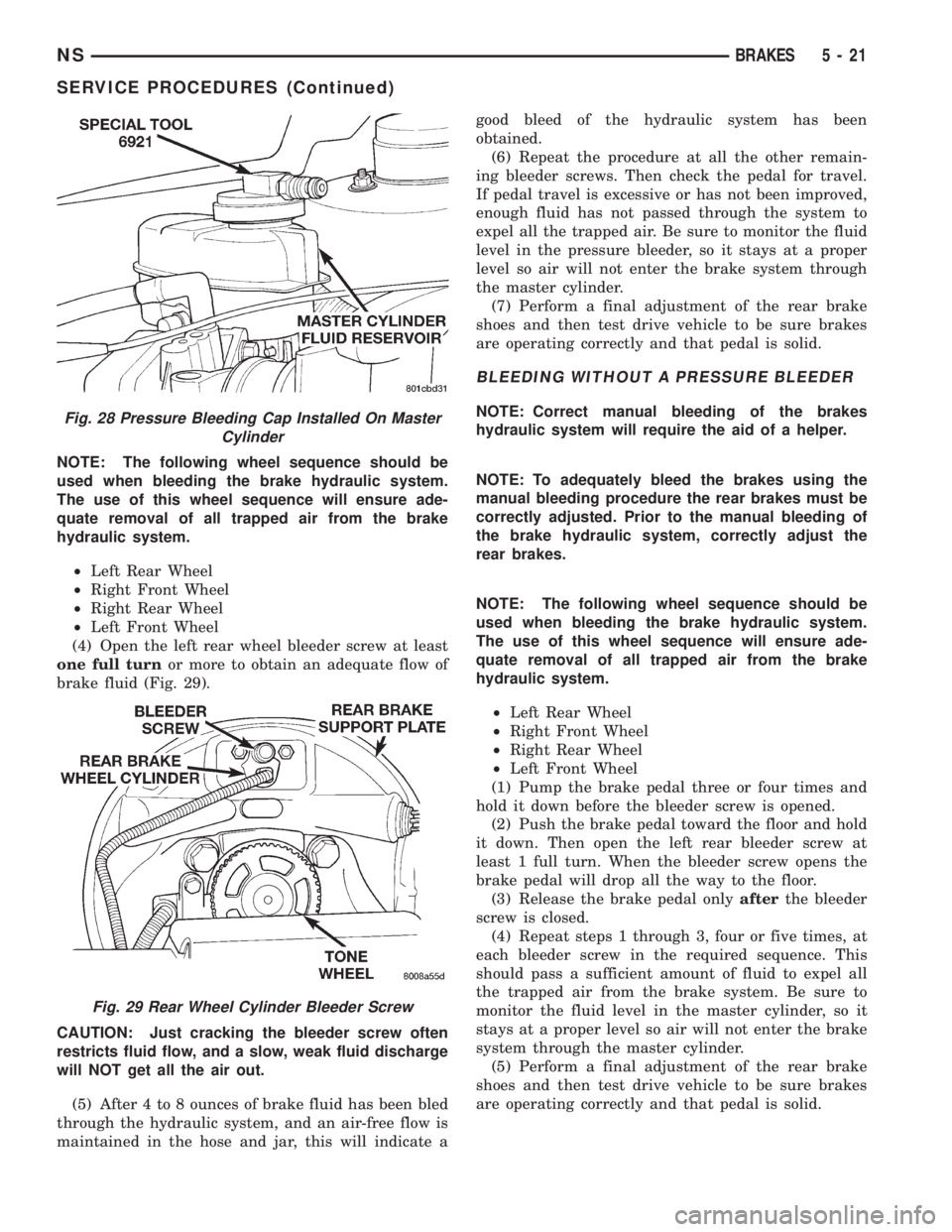

are operating correctly and that pedal is solid.Fig. 28 Pressure Bleeding Cap Installed On Master

Cylinder

Fig. 29 Rear Wheel Cylinder Bleeder Screw

NSBRAKES 5 - 21

SERVICE PROCEDURES (Continued)

Page 109 of 1938

(4) Remove the locking pliers from the front park

brake cable. This will allow the adjuster in the park

brake pedal mechanism to rotate around to its stop.

This will remove the tension from the adjuster and

front park brake cable.

Use the following procedure to reset the auto

adjuster in the park brake pedal mechanism.

(5) Grasp the exposed section of the front park

brake cable and pull rearward on it. While holding

the park brake in this position, install a pair of lock-

ing pliers on the front park brake cable just rearward

of the second body outrigger bracket (Fig. 42).

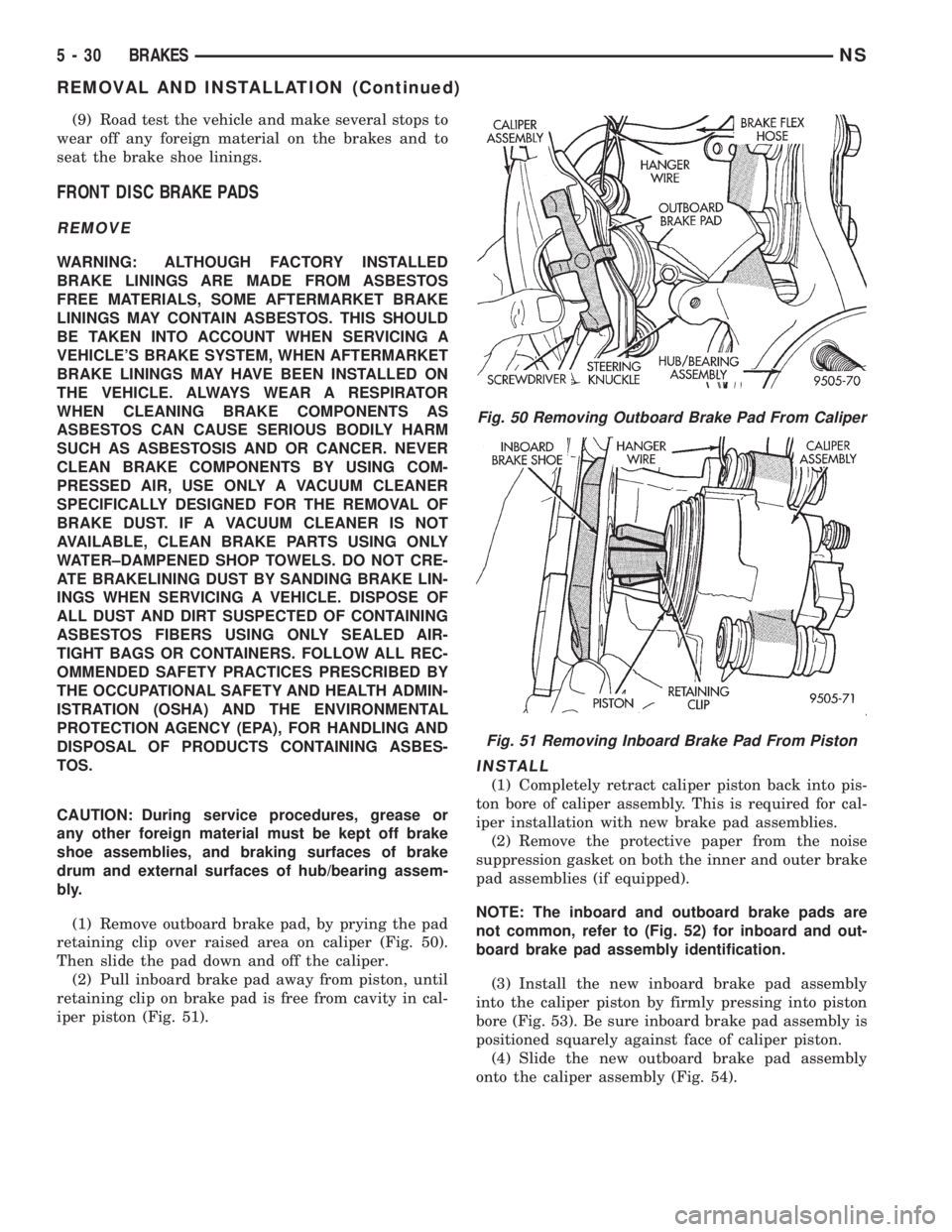

(6) Install the equalizer on the front park brake

cable.

(7) Install the left rear and intermediate park

brake cable in the correct location on the park brake

cable equalizer (Fig. 43).

(8) Remove the locking pliers from the front park

brake cable. This will allow the adjuster in the park

brake pedal mechanism to tension the park brake

cables.

(9) Apply and release the park brake pedal one

time. This will seat the park brake cables and allow

the auto adjuster in the park brake pedal mechanism

to correctly tension the park brake cables.

REMOVAL AND INSTALLATION

WHEEL AND TIRE INSTALLATION

To install the wheel and tire assembly, first posi-

tion it properly on the mounting surface using the

hub pilot as a guide. Then progressively tighten thelug nuts in the proper sequence to half of the

required torque. Finally tighten the lug nuts in the

proper sequence to 129 N´m (95 ft. lbs.). Never use

oil or grease on studs or nuts.

FRONT DISC BRAKE CALIPER

SERVICE PRECAUTIONS

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKE LININGS ARE MADE FROM ASBESTOS

FREE MATERIALS, SOME AFTER MARKET BRAKE

LINING MAY CONTAIN ASBESTOS. THIS SHOULD

BE TAKEN INTO ACCOUNT WHEN SERVICING A

VEHICLE'S BRAKE SYSTEM, WHEN AFTERMARKET

BRAKE LININGS MAY HAVE BEEN INSTALLED ON

THE VEHICLE. ALWAYS WEAR A RESPIRATOR

WHEN CLEANING BRAKE COMPONENTS AS

ASBESTOS CAN CAUSE SERIOUS BODILY HARM

SUCH AS ASBESTOSIS AND OR CANCER. NEVER

CLEAN BRAKE COMPONENTS BY USING COM-

PRESSED AIR, USE ONLY A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR THE REMOVAL OF

BRAKE DUST. IF A VACUUM CLEANER IS NOT

AVAILABLE, CLEAN BRAKE PARTS USING ONLY

WATER±DAMPENED SHOP TOWELS. DO NOT CRE-

ATE BRAKELINING DUST BY SANDING BRAKE LIN-

INGS WHEN SERVICING A VEHICLE. DISPOSE OF

ALL DUST AND DIRT SUSPECTED OF CONTAINING

ASBESTOS FIBERS USING ONLY SEALED AIR-

TIGHT BAGS OR CONTAINERS. FOLLOW ALL REC-

OMMENDED SAFETY PRACTICES PRESCRIBED BY

THE OCCUPATIONAL SAFETY AND HEALTH ADMIN-

ISTRATION (OSHA) AND THE ENVIRONMENTAL

PROTECTION AGENCY (EPA), FOR HANDLING AND

DISPOSAL OF PRODUCTS CONTAINING ASBES-

TOS.

CAUTION: During service procedures, grease or

any other foreign material must be kept off brake

shoe assemblies, and braking surfaces of brake

drum and external surfaces of hub/bearing assem-

bly.

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Remove front wheel and tire assemblies.

Fig. 43 Park Brake Cable Attachment To Equalizer

NSBRAKES 5 - 27

SERVICE PROCEDURES (Continued)

Page 112 of 1938

(9) Road test the vehicle and make several stops to

wear off any foreign material on the brakes and to

seat the brake shoe linings.

FRONT DISC BRAKE PADS

REMOVE

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKE LININGS ARE MADE FROM ASBESTOS

FREE MATERIALS, SOME AFTERMARKET BRAKE

LININGS MAY CONTAIN ASBESTOS. THIS SHOULD

BE TAKEN INTO ACCOUNT WHEN SERVICING A

VEHICLE'S BRAKE SYSTEM, WHEN AFTERMARKET

BRAKE LININGS MAY HAVE BEEN INSTALLED ON

THE VEHICLE. ALWAYS WEAR A RESPIRATOR

WHEN CLEANING BRAKE COMPONENTS AS

ASBESTOS CAN CAUSE SERIOUS BODILY HARM

SUCH AS ASBESTOSIS AND OR CANCER. NEVER

CLEAN BRAKE COMPONENTS BY USING COM-

PRESSED AIR, USE ONLY A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR THE REMOVAL OF

BRAKE DUST. IF A VACUUM CLEANER IS NOT

AVAILABLE, CLEAN BRAKE PARTS USING ONLY

WATER±DAMPENED SHOP TOWELS. DO NOT CRE-

ATE BRAKELINING DUST BY SANDING BRAKE LIN-

INGS WHEN SERVICING A VEHICLE. DISPOSE OF

ALL DUST AND DIRT SUSPECTED OF CONTAINING

ASBESTOS FIBERS USING ONLY SEALED AIR-

TIGHT BAGS OR CONTAINERS. FOLLOW ALL REC-

OMMENDED SAFETY PRACTICES PRESCRIBED BY

THE OCCUPATIONAL SAFETY AND HEALTH ADMIN-

ISTRATION (OSHA) AND THE ENVIRONMENTAL

PROTECTION AGENCY (EPA), FOR HANDLING AND

DISPOSAL OF PRODUCTS CONTAINING ASBES-

TOS.

CAUTION: During service procedures, grease or

any other foreign material must be kept off brake

shoe assemblies, and braking surfaces of brake

drum and external surfaces of hub/bearing assem-

bly.

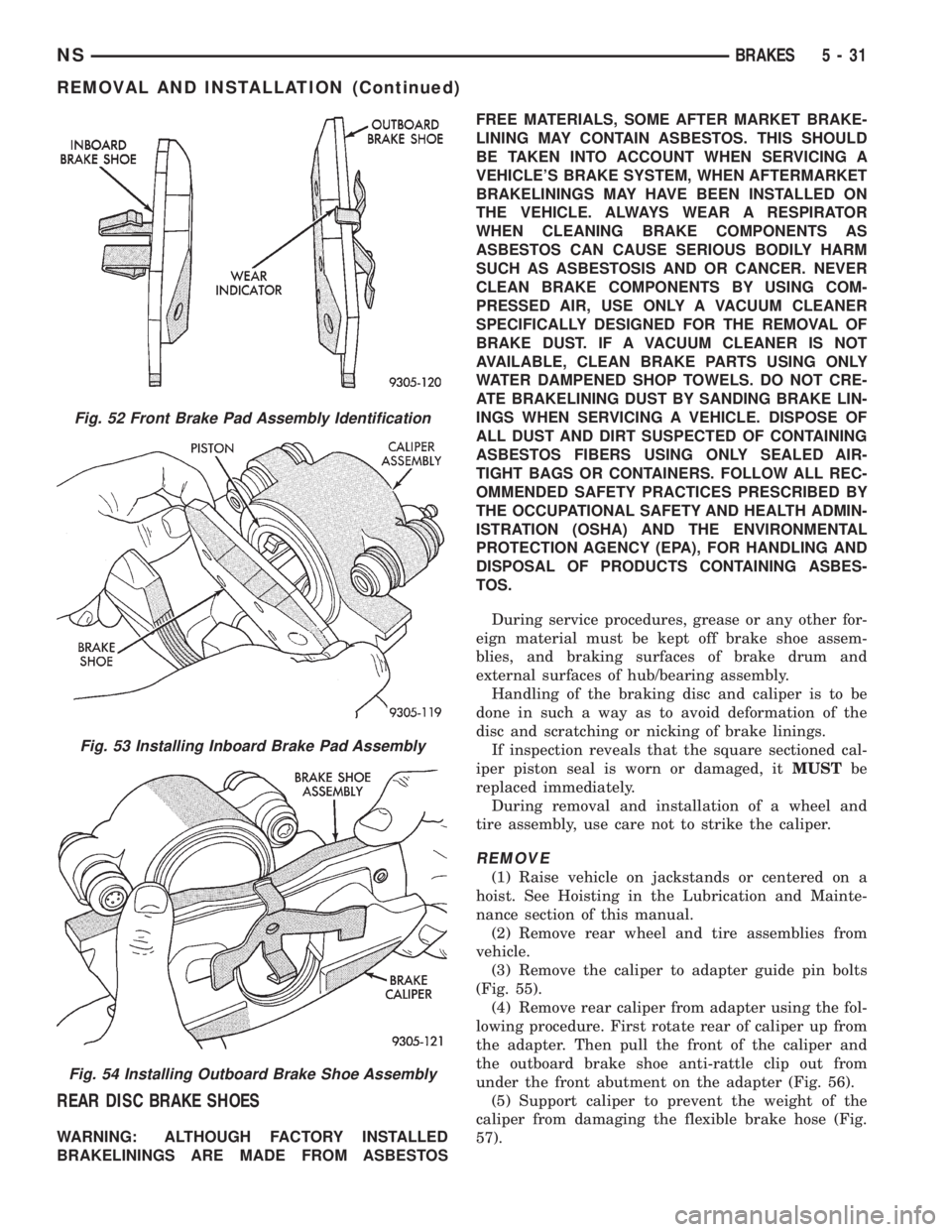

(1) Remove outboard brake pad, by prying the pad

retaining clip over raised area on caliper (Fig. 50).

Then slide the pad down and off the caliper.

(2) Pull inboard brake pad away from piston, until

retaining clip on brake pad is free from cavity in cal-

iper piston (Fig. 51).

INSTALL

(1) Completely retract caliper piston back into pis-

ton bore of caliper assembly. This is required for cal-

iper installation with new brake pad assemblies.

(2) Remove the protective paper from the noise

suppression gasket on both the inner and outer brake

pad assemblies (if equipped).

NOTE: The inboard and outboard brake pads are

not common, refer to (Fig. 52) for inboard and out-

board brake pad assembly identification.

(3) Install the new inboard brake pad assembly

into the caliper piston by firmly pressing into piston

bore (Fig. 53). Be sure inboard brake pad assembly is

positioned squarely against face of caliper piston.

(4) Slide the new outboard brake pad assembly

onto the caliper assembly (Fig. 54).

Fig. 50 Removing Outboard Brake Pad From Caliper

Fig. 51 Removing Inboard Brake Pad From Piston

5 - 30 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 113 of 1938

REAR DISC BRAKE SHOES

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKELININGS ARE MADE FROM ASBESTOSFREE MATERIALS, SOME AFTER MARKET BRAKE-

LINING MAY CONTAIN ASBESTOS. THIS SHOULD

BE TAKEN INTO ACCOUNT WHEN SERVICING A

VEHICLE'S BRAKE SYSTEM, WHEN AFTERMARKET

BRAKELININGS MAY HAVE BEEN INSTALLED ON

THE VEHICLE. ALWAYS WEAR A RESPIRATOR

WHEN CLEANING BRAKE COMPONENTS AS

ASBESTOS CAN CAUSE SERIOUS BODILY HARM

SUCH AS ASBESTOSIS AND OR CANCER. NEVER

CLEAN BRAKE COMPONENTS BY USING COM-

PRESSED AIR, USE ONLY A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR THE REMOVAL OF

BRAKE DUST. IF A VACUUM CLEANER IS NOT

AVAILABLE, CLEAN BRAKE PARTS USING ONLY

WATER DAMPENED SHOP TOWELS. DO NOT CRE-

ATE BRAKELINING DUST BY SANDING BRAKE LIN-

INGS WHEN SERVICING A VEHICLE. DISPOSE OF

ALL DUST AND DIRT SUSPECTED OF CONTAINING

ASBESTOS FIBERS USING ONLY SEALED AIR-

TIGHT BAGS OR CONTAINERS. FOLLOW ALL REC-

OMMENDED SAFETY PRACTICES PRESCRIBED BY

THE OCCUPATIONAL SAFETY AND HEALTH ADMIN-

ISTRATION (OSHA) AND THE ENVIRONMENTAL

PROTECTION AGENCY (EPA), FOR HANDLING AND

DISPOSAL OF PRODUCTS CONTAINING ASBES-

TOS.

During service procedures, grease or any other for-

eign material must be kept off brake shoe assem-

blies, and braking surfaces of brake drum and

external surfaces of hub/bearing assembly.

Handling of the braking disc and caliper is to be

done in such a way as to avoid deformation of the

disc and scratching or nicking of brake linings.

If inspection reveals that the square sectioned cal-

iper piston seal is worn or damaged, itMUSTbe

replaced immediately.

During removal and installation of a wheel and

tire assembly, use care not to strike the caliper.

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this manual.

(2) Remove rear wheel and tire assemblies from

vehicle.

(3) Remove the caliper to adapter guide pin bolts

(Fig. 55).

(4) Remove rear caliper from adapter using the fol-

lowing procedure. First rotate rear of caliper up from

the adapter. Then pull the front of the caliper and

the outboard brake shoe anti-rattle clip out from

under the front abutment on the adapter (Fig. 56).

(5) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

57).

Fig. 52 Front Brake Pad Assembly Identification

Fig. 53 Installing Inboard Brake Pad Assembly

Fig. 54 Installing Outboard Brake Shoe Assembly

NSBRAKES 5 - 31

REMOVAL AND INSTALLATION (Continued)

Page 116 of 1938

REAR DRUM BRAKE SHOES

REMOVE

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKE LININGS ARE MADE FROM ASBESTOS

FREE MATERIALS, SOME AFTERMARKET BRAK-

LINING MAY CONTAIN ASBESTOS. THIS SHOULD

BE TAKEN INTO ACCOUNT WHEN SERVICING A

VEHICLE'S BRAKE SYSTEM, WHEN AFTERMARKET

BRAKE LININGS MAY HAVE BEEN INSTALLED ON

THE VEHICLE. ALWAYS WEAR A RESPIRATOR

WHEN CLEANING BRAKE COMPONENTS AS

ASBESTOS CAN CAUSE SERIOUS BODILY HARM

SUCH AS ASBESTOSIS AND OR CANCER. NEVER

CLEAN BRAKE COMPONENTS BY USING COM-

PRESSED AIR, USE ONLY A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR THE REMOVAL OF

BRAKE DUST. IF A VACUUM CLEANER IS NOT

AVAILABLE, CLEAN BRAKE PARTS USING ONLY

WATER±DAMPENED SHOP TOWELS. DO NOT CRE-

ATE BRAKE LINING DUST BY SANDING BRAKE

LININGS WHEN SERVICING A VEHICLE. DISPOSE

OF ALL DUST AND DIRT SUSPECTED OF CONTAIN-

ING ASBESTOS FIBERS USING ONLY SEALED AIR-

TIGHT BAGS OR CONTAINERS. FOLLOW ALL

RECOMMENDED SAFETY PRACTICES PRE-

SCRIBED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION (OSHA) AND THE ENVI-

RONMENTAL PROTECTION AGENCY (EPA), FOR

HANDLING AND DISPOSAL OF PRODUCTS CON-

TAINING ASBESTOS.

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this manual.

(2) Remove the rear wheel and tire assemblies

from the vehicle.

(3) Remove rear brake drum to hub retaining nuts

(if equipped). Then remove rear brake drums from

hub and bearing assemblies.

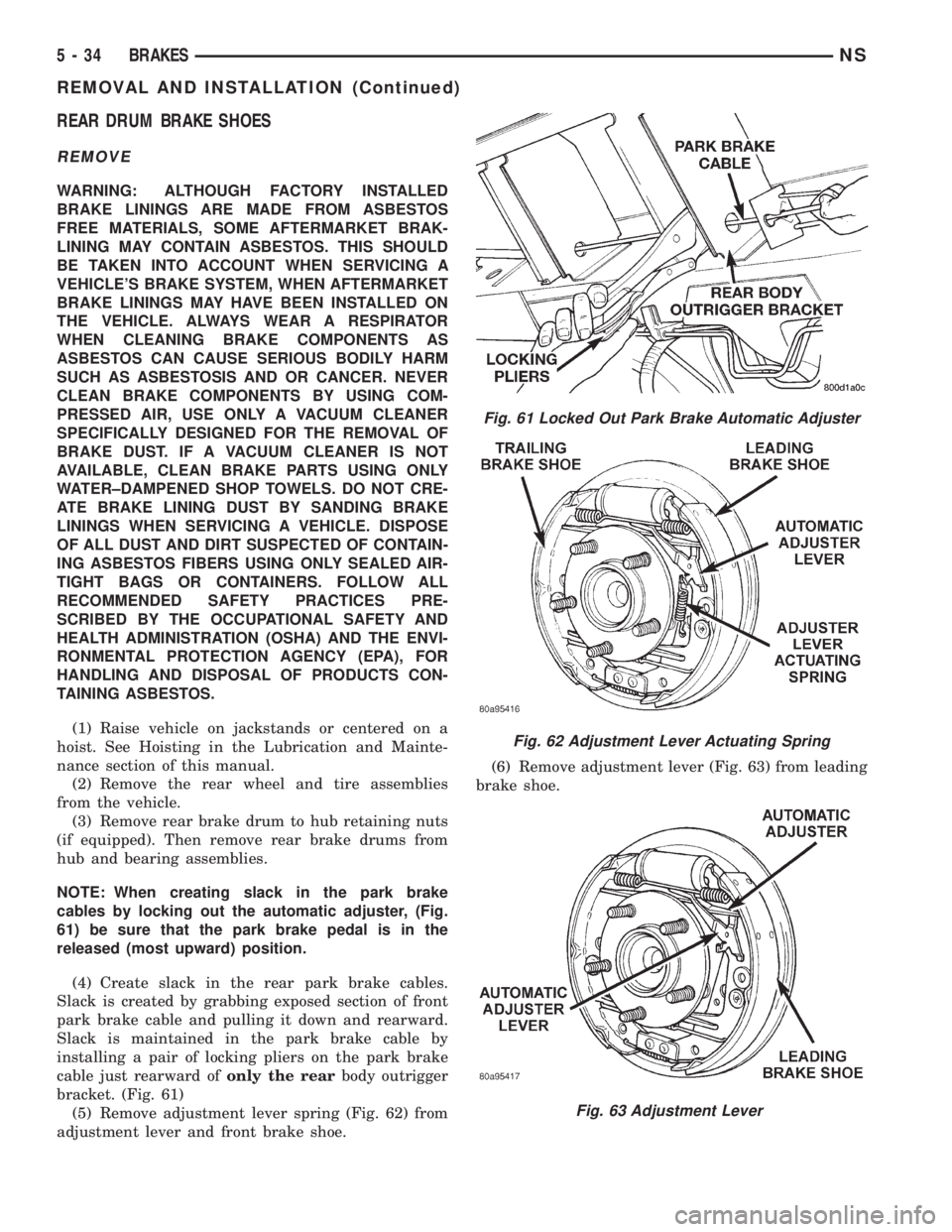

NOTE: When creating slack in the park brake

cables by locking out the automatic adjuster, (Fig.

61) be sure that the park brake pedal is in the

released (most upward) position.

(4) Create slack in the rear park brake cables.

Slack is created by grabbing exposed section of front

park brake cable and pulling it down and rearward.

Slack is maintained in the park brake cable by

installing a pair of locking pliers on the park brake

cable just rearward ofonly the rearbody outrigger

bracket. (Fig. 61)

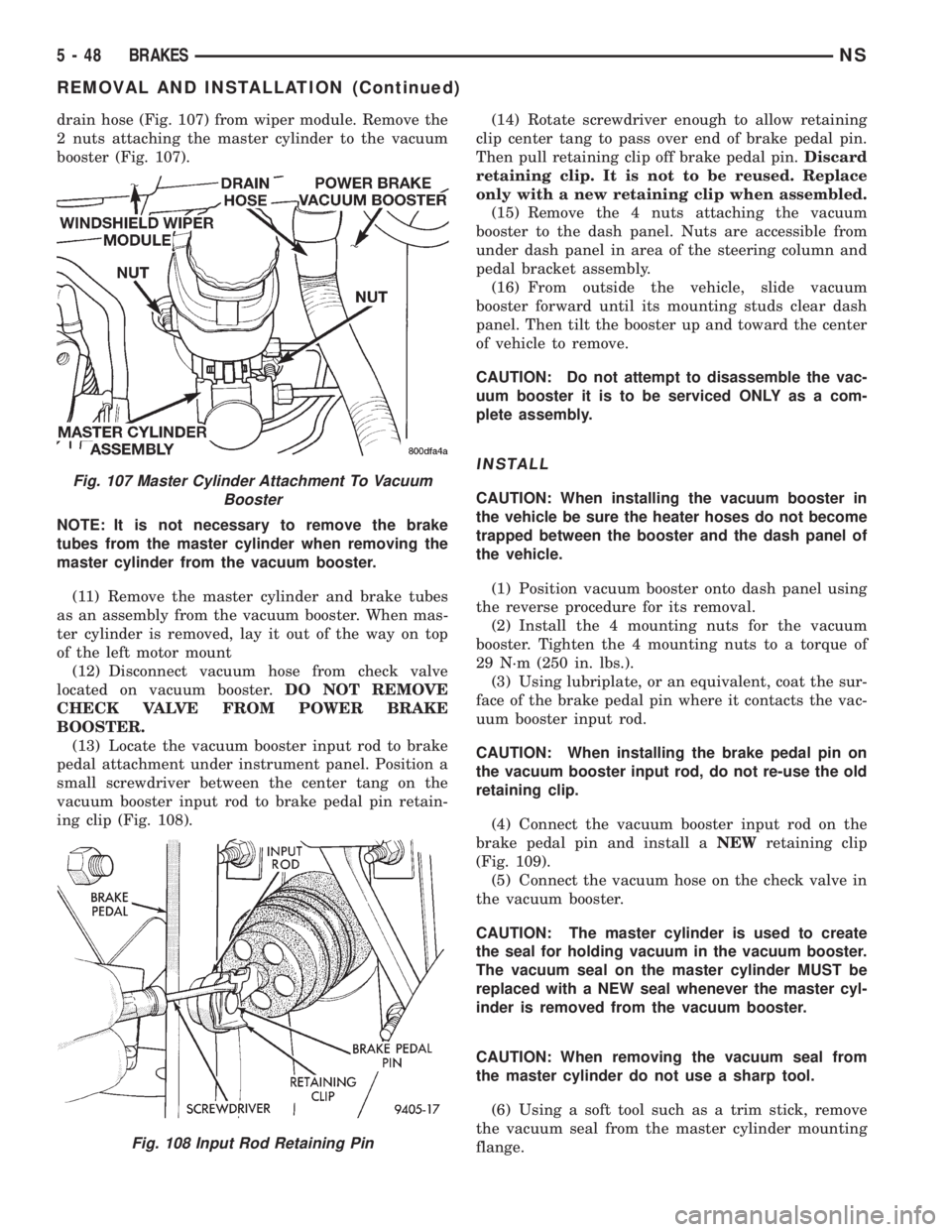

(5) Remove adjustment lever spring (Fig. 62) from

adjustment lever and front brake shoe.(6) Remove adjustment lever (Fig. 63) from leading

brake shoe.

Fig. 61 Locked Out Park Brake Automatic Adjuster

Fig. 62 Adjustment Lever Actuating Spring

Fig. 63 Adjustment Lever

5 - 34 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 130 of 1938

drain hose (Fig. 107) from wiper module. Remove the

2 nuts attaching the master cylinder to the vacuum

booster (Fig. 107).

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the vacuum booster.

(11) Remove the master cylinder and brake tubes

as an assembly from the vacuum booster. When mas-

ter cylinder is removed, lay it out of the way on top

of the left motor mount

(12) Disconnect vacuum hose from check valve

located on vacuum booster.DO NOT REMOVE

CHECK VALVE FROM POWER BRAKE

BOOSTER.

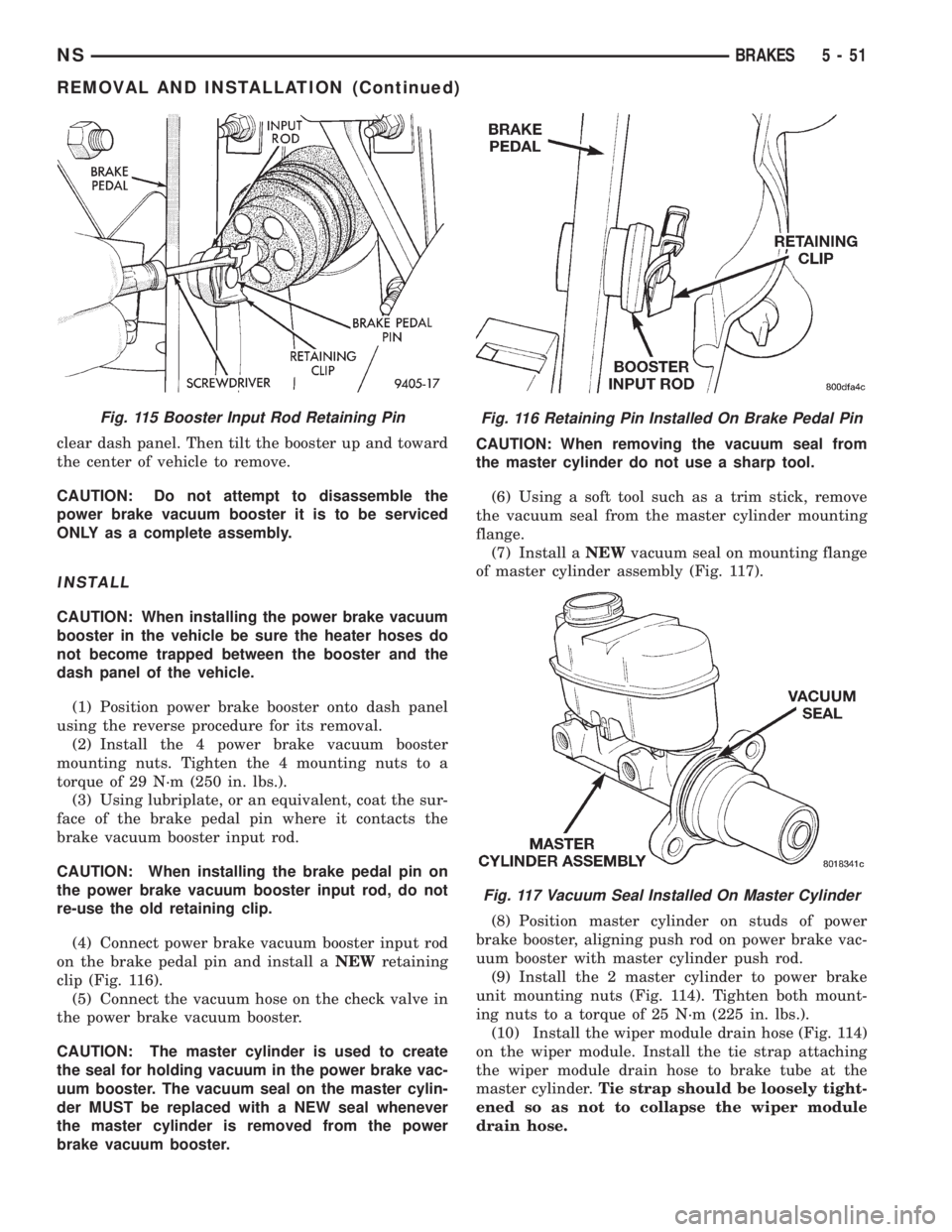

(13) Locate the vacuum booster input rod to brake

pedal attachment under instrument panel. Position a

small screwdriver between the center tang on the

vacuum booster input rod to brake pedal pin retain-

ing clip (Fig. 108).(14) Rotate screwdriver enough to allow retaining

clip center tang to pass over end of brake pedal pin.

Then pull retaining clip off brake pedal pin.Discard

retaining clip. It is not to be reused. Replace

only with a new retaining clip when assembled.

(15) Remove the 4 nuts attaching the vacuum

booster to the dash panel. Nuts are accessible from

under dash panel in area of the steering column and

pedal bracket assembly.

(16) From outside the vehicle, slide vacuum

booster forward until its mounting studs clear dash

panel. Then tilt the booster up and toward the center

of vehicle to remove.

CAUTION: Do not attempt to disassemble the vac-

uum booster it is to be serviced ONLY as a com-

plete assembly.

INSTALL

CAUTION: When installing the vacuum booster in

the vehicle be sure the heater hoses do not become

trapped between the booster and the dash panel of

the vehicle.

(1) Position vacuum booster onto dash panel using

the reverse procedure for its removal.

(2) Install the 4 mounting nuts for the vacuum

booster. Tighten the 4 mounting nuts to a torque of

29 N´m (250 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the vac-

uum booster input rod.

CAUTION: When installing the brake pedal pin on

the vacuum booster input rod, do not re-use the old

retaining clip.

(4) Connect the vacuum booster input rod on the

brake pedal pin and install aNEWretaining clip

(Fig. 109).

(5) Connect the vacuum hose on the check valve in

the vacuum booster.

CAUTION: The master cylinder is used to create

the seal for holding vacuum in the vacuum booster.

The vacuum seal on the master cylinder MUST be

replaced with a NEW seal whenever the master cyl-

inder is removed from the vacuum booster.

CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(6) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

Fig. 107 Master Cylinder Attachment To Vacuum

Booster

Fig. 108 Input Rod Retaining Pin

5 - 48 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 133 of 1938

clear dash panel. Then tilt the booster up and toward

the center of vehicle to remove.

CAUTION: Do not attempt to disassemble the

power brake vacuum booster it is to be serviced

ONLY as a complete assembly.

INSTALL

CAUTION: When installing the power brake vacuum

booster in the vehicle be sure the heater hoses do

not become trapped between the booster and the

dash panel of the vehicle.

(1) Position power brake booster onto dash panel

using the reverse procedure for its removal.

(2) Install the 4 power brake vacuum booster

mounting nuts. Tighten the 4 mounting nuts to a

torque of 29 N´m (250 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the

brake vacuum booster input rod.

CAUTION: When installing the brake pedal pin on

the power brake vacuum booster input rod, do not

re-use the old retaining clip.

(4) Connect power brake vacuum booster input rod

on the brake pedal pin and install aNEWretaining

clip (Fig. 116).

(5) Connect the vacuum hose on the check valve in

the power brake vacuum booster.

CAUTION: The master cylinder is used to create

the seal for holding vacuum in the power brake vac-

uum booster. The vacuum seal on the master cylin-

der MUST be replaced with a NEW seal whenever

the master cylinder is removed from the power

brake vacuum booster.CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(6) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(7) Install aNEWvacuum seal on mounting flange

of master cylinder assembly (Fig. 117).

(8) Position master cylinder on studs of power

brake booster, aligning push rod on power brake vac-

uum booster with master cylinder push rod.

(9) Install the 2 master cylinder to power brake

unit mounting nuts (Fig. 114). Tighten both mount-

ing nuts to a torque of 25 N´m (225 in. lbs.).

(10) Install the wiper module drain hose (Fig. 114)

on the wiper module. Install the tie strap attaching

the wiper module drain hose to brake tube at the

master cylinder.Tie strap should be loosely tight-

ened so as not to collapse the wiper module

drain hose.

Fig. 115 Booster Input Rod Retaining PinFig. 116 Retaining Pin Installed On Brake Pedal Pin

Fig. 117 Vacuum Seal Installed On Master Cylinder

NSBRAKES 5 - 51

REMOVAL AND INSTALLATION (Continued)

Page 136 of 1938

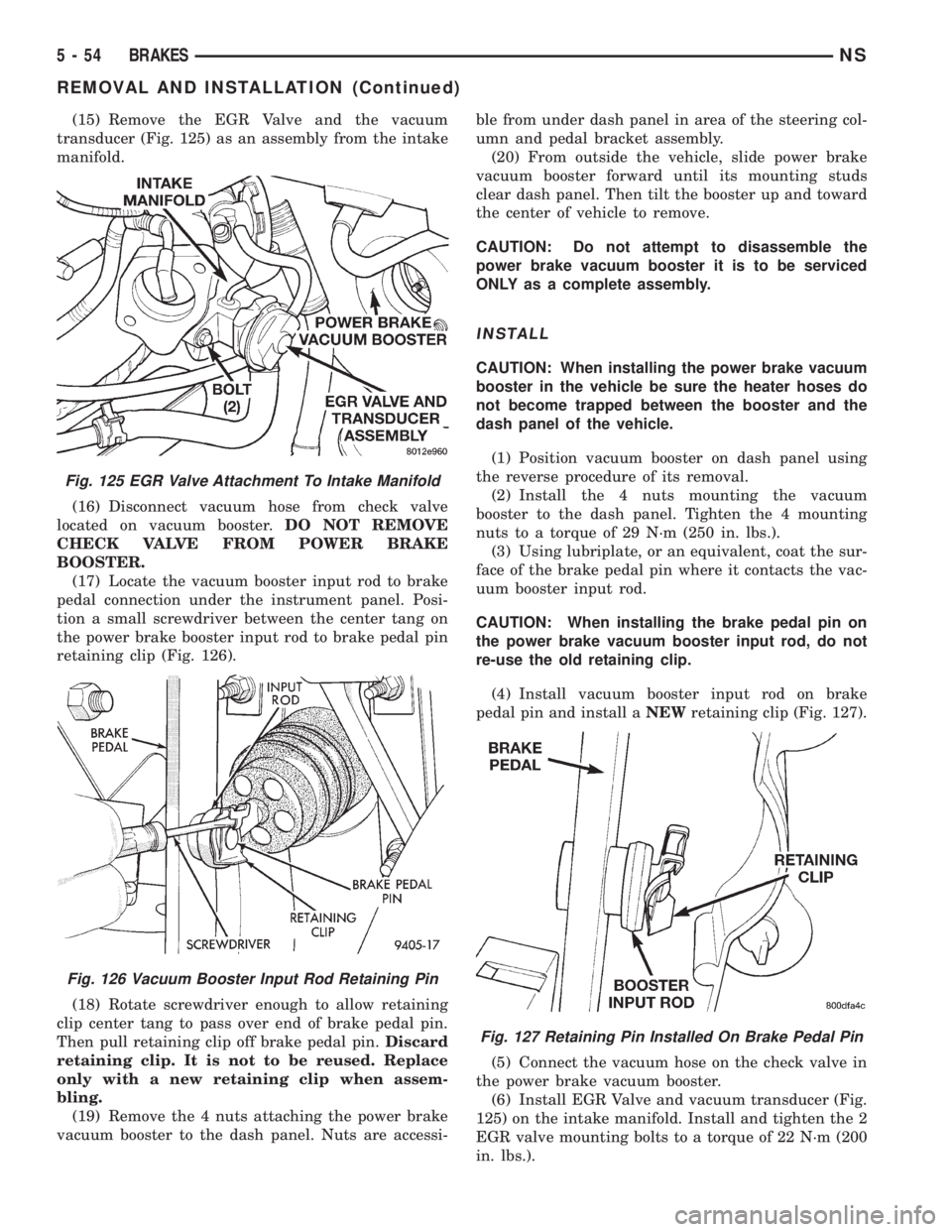

(15) Remove the EGR Valve and the vacuum

transducer (Fig. 125) as an assembly from the intake

manifold.

(16) Disconnect vacuum hose from check valve

located on vacuum booster.DO NOT REMOVE

CHECK VALVE FROM POWER BRAKE

BOOSTER.

(17) Locate the vacuum booster input rod to brake

pedal connection under the instrument panel. Posi-

tion a small screwdriver between the center tang on

the power brake booster input rod to brake pedal pin

retaining clip (Fig. 126).

(18) Rotate screwdriver enough to allow retaining

clip center tang to pass over end of brake pedal pin.

Then pull retaining clip off brake pedal pin.Discard

retaining clip. It is not to be reused. Replace

only with a new retaining clip when assem-

bling.

(19) Remove the 4 nuts attaching the power brake

vacuum booster to the dash panel. Nuts are accessi-ble from under dash panel in area of the steering col-

umn and pedal bracket assembly.

(20) From outside the vehicle, slide power brake

vacuum booster forward until its mounting studs

clear dash panel. Then tilt the booster up and toward

the center of vehicle to remove.

CAUTION: Do not attempt to disassemble the

power brake vacuum booster it is to be serviced

ONLY as a complete assembly.

INSTALL

CAUTION: When installing the power brake vacuum

booster in the vehicle be sure the heater hoses do

not become trapped between the booster and the

dash panel of the vehicle.

(1) Position vacuum booster on dash panel using

the reverse procedure of its removal.

(2) Install the 4 nuts mounting the vacuum

booster to the dash panel. Tighten the 4 mounting

nuts to a torque of 29 N´m (250 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the vac-

uum booster input rod.

CAUTION: When installing the brake pedal pin on

the power brake vacuum booster input rod, do not

re-use the old retaining clip.

(4) Install vacuum booster input rod on brake

pedal pin and install aNEWretaining clip (Fig. 127).

(5) Connect the vacuum hose on the check valve in

the power brake vacuum booster.

(6) Install EGR Valve and vacuum transducer (Fig.

125) on the intake manifold. Install and tighten the 2

EGR valve mounting bolts to a torque of 22 N´m (200

in. lbs.).

Fig. 125 EGR Valve Attachment To Intake Manifold

Fig. 126 Vacuum Booster Input Rod Retaining Pin

Fig. 127 Retaining Pin Installed On Brake Pedal Pin

5 - 54 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 146 of 1938

NOTE: When the hold down pin is installed, the

long part of the hold down pin is to be positioned

strait up and down. This will ensure that the hold

down pin is correctly engaged with the adapter.

(6) Install the hold down spring and pin (Fig. 153)

on the leading park brake shoe.

(7) Install the lower return spring (Fig. 152) on

the leading and trailing park brake shoes.When

installing the hold down spring it is to be

installed behind the park brake shoes (Fig.

152).

(8) Install the 4 mounting bolts for the adapter

and hub/bearing into the bolt holes in the axle.

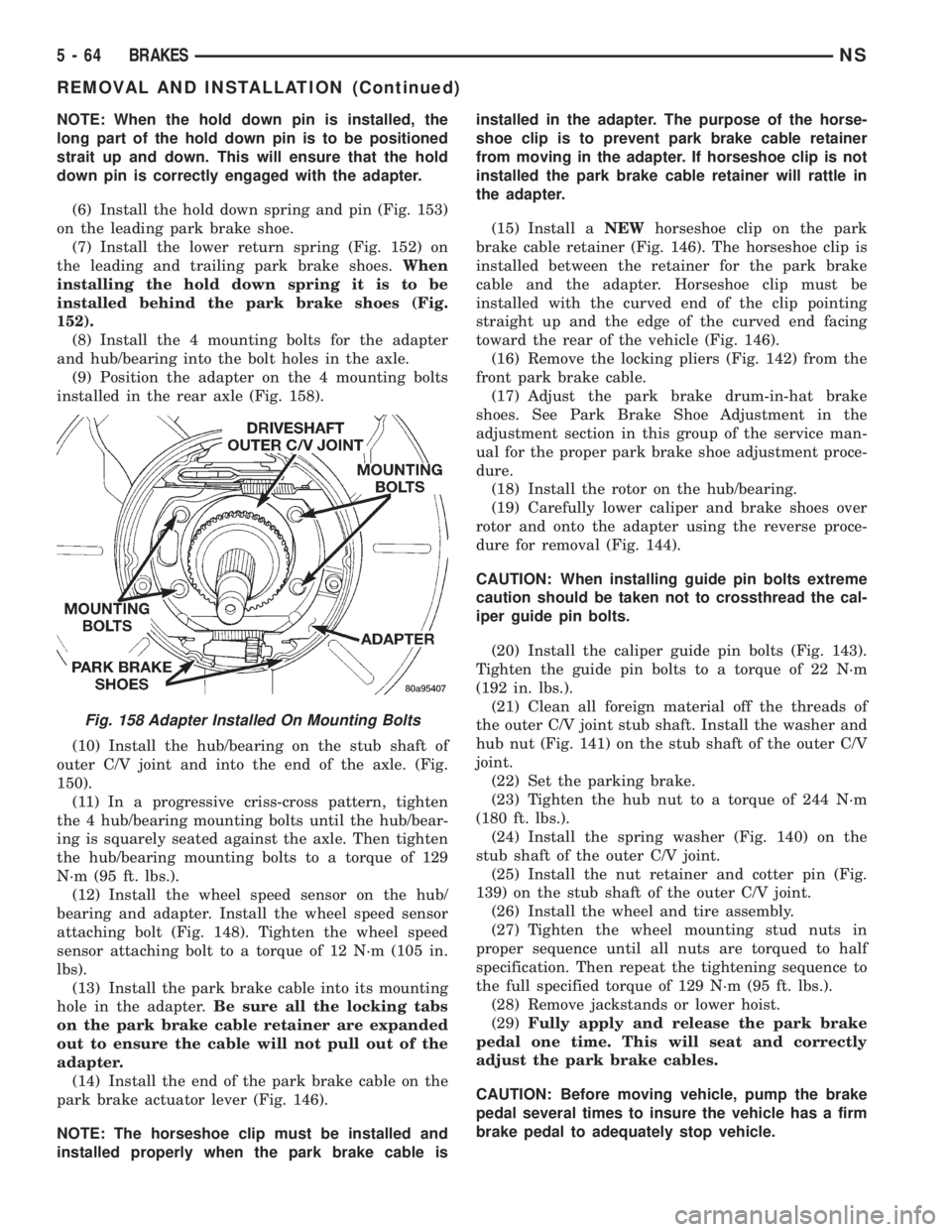

(9) Position the adapter on the 4 mounting bolts

installed in the rear axle (Fig. 158).

(10) Install the hub/bearing on the stub shaft of

outer C/V joint and into the end of the axle. (Fig.

150).

(11) In a progressive criss-cross pattern, tighten

the 4 hub/bearing mounting bolts until the hub/bear-

ing is squarely seated against the axle. Then tighten

the hub/bearing mounting bolts to a torque of 129

N´m (95 ft. lbs.).

(12) Install the wheel speed sensor on the hub/

bearing and adapter. Install the wheel speed sensor

attaching bolt (Fig. 148). Tighten the wheel speed

sensor attaching bolt to a torque of 12 N´m (105 in.

lbs).

(13) Install the park brake cable into its mounting

hole in the adapter.Be sure all the locking tabs

on the park brake cable retainer are expanded

out to ensure the cable will not pull out of the

adapter.

(14) Install the end of the park brake cable on the

park brake actuator lever (Fig. 146).

NOTE: The horseshoe clip must be installed and

installed properly when the park brake cable isinstalled in the adapter. The purpose of the horse-

shoe clip is to prevent park brake cable retainer

from moving in the adapter. If horseshoe clip is not

installed the park brake cable retainer will rattle in

the adapter.

(15) Install aNEWhorseshoe clip on the park

brake cable retainer (Fig. 146). The horseshoe clip is

installed between the retainer for the park brake

cable and the adapter. Horseshoe clip must be

installed with the curved end of the clip pointing

straight up and the edge of the curved end facing

toward the rear of the vehicle (Fig. 146).

(16) Remove the locking pliers (Fig. 142) from the

front park brake cable.

(17) Adjust the park brake drum-in-hat brake

shoes. See Park Brake Shoe Adjustment in the

adjustment section in this group of the service man-

ual for the proper park brake shoe adjustment proce-

dure.

(18) Install the rotor on the hub/bearing.

(19) Carefully lower caliper and brake shoes over

rotor and onto the adapter using the reverse proce-

dure for removal (Fig. 144).

CAUTION: When installing guide pin bolts extreme

caution should be taken not to crossthread the cal-

iper guide pin bolts.

(20) Install the caliper guide pin bolts (Fig. 143).

Tighten the guide pin bolts to a torque of 22 N´m

(192 in. lbs.).

(21) Clean all foreign material off the threads of

the outer C/V joint stub shaft. Install the washer and

hub nut (Fig. 141) on the stub shaft of the outer C/V

joint.

(22) Set the parking brake.

(23) Tighten the hub nut to a torque of 244 N´m

(180 ft. lbs.).

(24) Install the spring washer (Fig. 140) on the

stub shaft of the outer C/V joint.

(25) Install the nut retainer and cotter pin (Fig.

139) on the stub shaft of the outer C/V joint.

(26) Install the wheel and tire assembly.

(27) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 129 N´m (95 ft. lbs.).

(28) Remove jackstands or lower hoist.

(29)Fully apply and release the park brake

pedal one time. This will seat and correctly

adjust the park brake cables.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop vehicle.

Fig. 158 Adapter Installed On Mounting Bolts

5 - 64 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 163 of 1938

group of the service manual for the installation pro-

cedure.

(13) Install wheel and tire.

(14) Tighten the wheel mounting nuts in the

proper sequence until all nuts are torqued to half the

specified torque. Then repeat the tightening sequence

to the full specified torque of 129 N´m (95 ft. lbs.).

(15) Lower vehicle.

(16) Apply and release the park brake pedal one

time. This will seat and correctly adjust the park

brake cables.

CAUTION: Before moving vehicle, pump brake

pedal several times to ensure the vehicle has a firm

enough pedal to stop the vehicle.

(17) Road test the vehicle to ensure proper func-

tion of the vehicle's brake system.

PARK BRAKE CABLE ADJUSTMENT

The park brake cables on this vehicle have an

automatic self adjuster built into the park brake

pedal mechanism. When the foot operated park brake

pedal is in its released (upward most) position, a

clock spring automatically adjusts the park brake

cables. The park brake cables are adjusted (ten-

sioned) just enough to remove all the slack from the

cables. The automatic adjuster system will not over

adjust the cables causing rear brake drag.

Due to the automatic adjust feature of the park

brake pedal, adjustment of the parking brake cables

on these vehicles relies on proper drum brake and

park brake shoe adjustment. See Rear Brake Adjust-

ment and Park Brake Shoe Adjustment in the Ser-

vice Adjustments Section in this group of the service

manual.

When the park brake pedal is applied the self

adjuster is by-passed and the pedal operates nor-

mally to engage the park brakes.

When a service procedure needs to be performed on

the park brake pedal or the park brake cables, the

automatic self adjuster can be manually locked out

by the service technician.

PROPORTIONING VALVE (HEIGHT SENSING)

Proportioning valve actuator adjustment will be

required if there is a complaint of premature rear

wheel lockup and the front and rear brake shoe lin-

ings checked OK during inspection, the height sens-

ing proportioning valve required replacement, or

there is a complaint of excessive pedal effort and the

vacuum booster and brake pedal checked OK. Make

sure the proportioning valve and the mounting

bracket are firmly attached to the vehicle. Then, pro-

ceed with the following procedure to perform the

adjustment of the actuator.(1) Raise vehicle. Vehicle is to be raised and sup-

ported on jackstands or with a frame contact type

hoist so the rear suspension of the vehicle is hanging

free. See hoisting in the Lubrication And Mainte-

nance section of this service manual.

(2) Remove rear wheels/tires.

(3) Using an appropriate jack, support the rear

axle prior to the removal of the track bar and shock

absorber bolts from the rear axle.

(4) Unbolt the track bar from the rear axle.

(5) Unbolt both shock absorbers from the rear

axle.

(6) Loosen (do not remove) both of the leaf spring

to front spring hanger pivot bolts.

NOTE: When lowering the rear axle be sure that the

leaf springs do not come in contact with the hoist

limiting the downward movement of the axle. If this

occurs an improper adjustment of the actuator may

result.

(7) Lower the rear axle so it is at its farthest point

of downward movement.

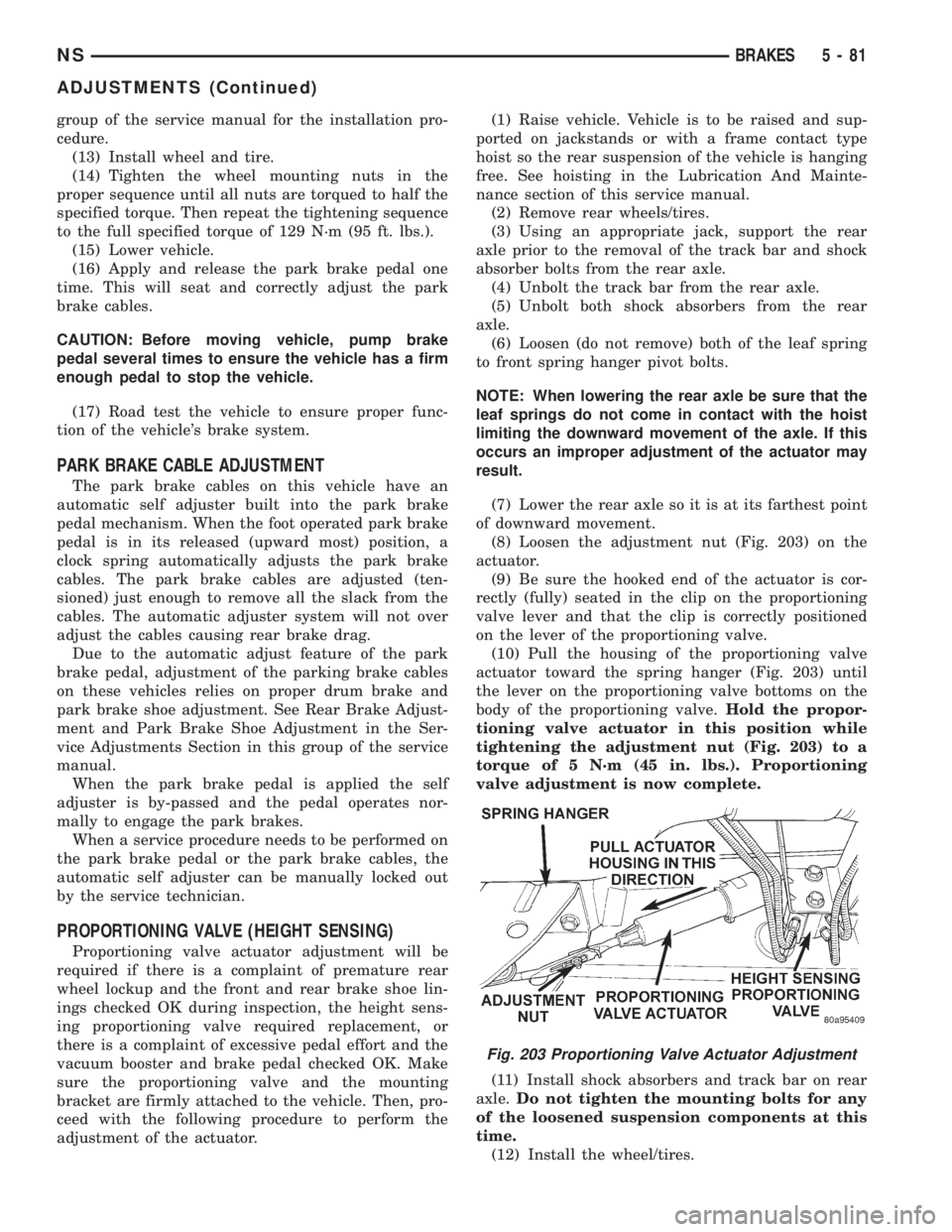

(8) Loosen the adjustment nut (Fig. 203) on the

actuator.

(9) Be sure the hooked end of the actuator is cor-

rectly (fully) seated in the clip on the proportioning

valve lever and that the clip is correctly positioned

on the lever of the proportioning valve.

(10) Pull the housing of the proportioning valve

actuator toward the spring hanger (Fig. 203) until

the lever on the proportioning valve bottoms on the

body of the proportioning valve.Hold the propor-

tioning valve actuator in this position while

tightening the adjustment nut (Fig. 203) to a

torque of 5 N´m (45 in. lbs.). Proportioning

valve adjustment is now complete.

(11) Install shock absorbers and track bar on rear

axle.Do not tighten the mounting bolts for any

of the loosened suspension components at this

time.

(12) Install the wheel/tires.

Fig. 203 Proportioning Valve Actuator Adjustment

NSBRAKES 5 - 81

ADJUSTMENTS (Continued)