tow CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 240 of 1938

and the remove the splash shield to gain access to

the drive belts.

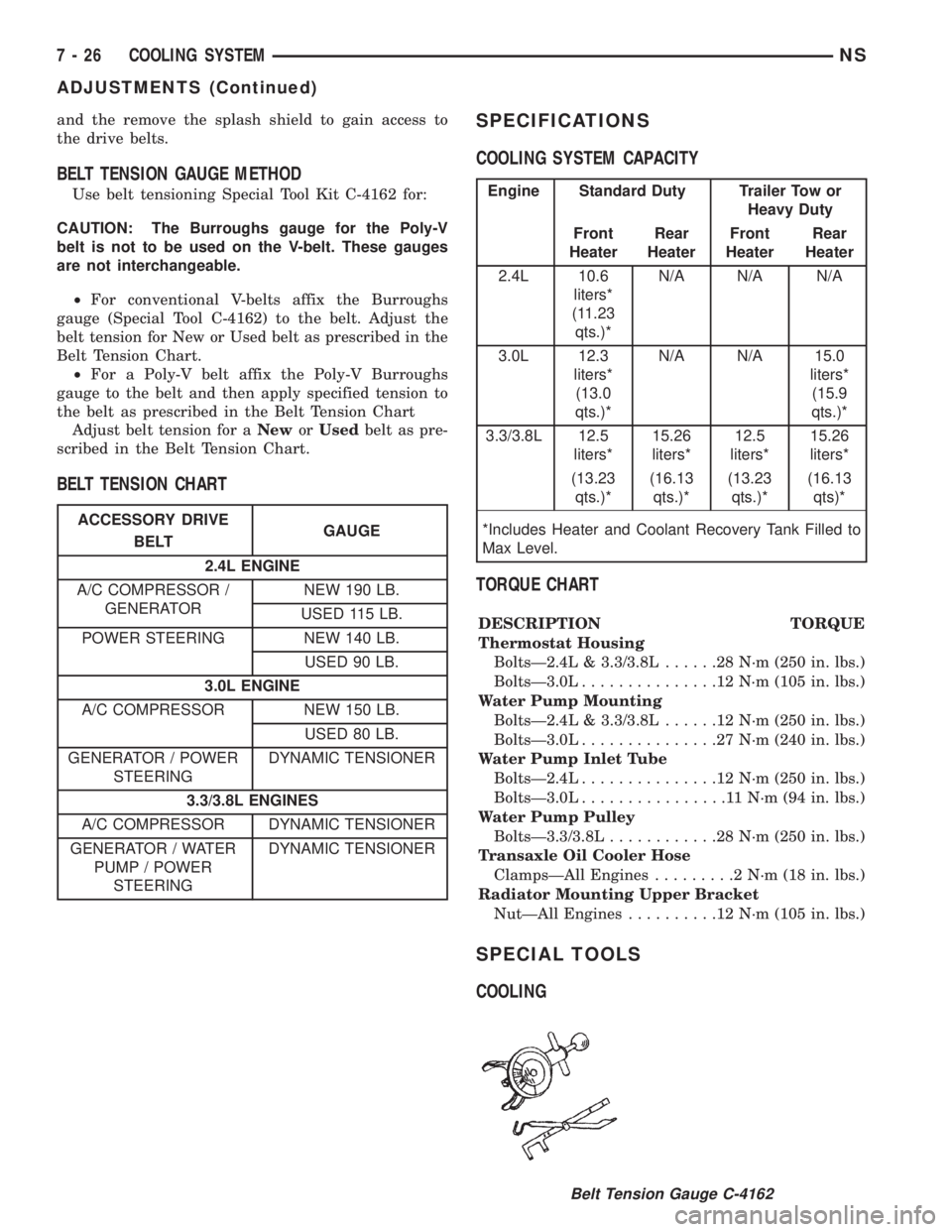

BELT TENSION GAUGE METHOD

Use belt tensioning Special Tool Kit C-4162 for:

CAUTION: The Burroughs gauge for the Poly-V

belt is not to be used on the V-belt. These gauges

are not interchangeable.

²For conventional V-belts affix the Burroughs

gauge (Special Tool C-4162) to the belt. Adjust the

belt tension for New or Used belt as prescribed in the

Belt Tension Chart.

²For a Poly-V belt affix the Poly-V Burroughs

gauge to the belt and then apply specified tension to

the belt as prescribed in the Belt Tension Chart

Adjust belt tension for aNeworUsedbelt as pre-

scribed in the Belt Tension Chart.

BELT TENSION CHARTSPECIFICATIONS

COOLING SYSTEM CAPACITY

TORQUE CHART

DESCRIPTION TORQUE

Thermostat Housing

BoltsÐ2.4L & 3.3/3.8L......28N´m(250 in. lbs.)

BoltsÐ3.0L...............12N´m(105 in. lbs.)

Water Pump Mounting

BoltsÐ2.4L & 3.3/3.8L......12N´m(250 in. lbs.)

BoltsÐ3.0L...............27N´m(240 in. lbs.)

Water Pump Inlet Tube

BoltsÐ2.4L...............12N´m(250 in. lbs.)

BoltsÐ3.0L................11N´m(94in.lbs.)

Water Pump Pulley

BoltsÐ3.3/3.8L............28N´m(250 in. lbs.)

Transaxle Oil Cooler Hose

ClampsÐAll Engines.........2N´m(18in.lbs.)

Radiator Mounting Upper Bracket

NutÐAll Engines..........12N´m(105 in. lbs.)

SPECIAL TOOLS

COOLING

ACCESSORY DRIVE

BELTGAUGE

2.4L ENGINE

A/C COMPRESSOR /

GENERATORNEW 190 LB.

USED 115 LB.

POWER STEERING NEW 140 LB.

USED 90 LB.

3.0L ENGINE

A/C COMPRESSOR NEW 150 LB.

USED 80 LB.

GENERATOR / POWER

STEERINGDYNAMIC TENSIONER

3.3/3.8L ENGINES

A/C COMPRESSOR DYNAMIC TENSIONER

GENERATOR / WATER

PUMP / POWER

STEERINGDYNAMIC TENSIONER

Engine Standard Duty Trailer Tow or

Heavy Duty

Front

HeaterRear

HeaterFront

HeaterRear

Heater

2.4L 10.6

liters*

(11.23

qts.)*N/A N/A N/A

3.0L 12.3

liters*

(13.0

qts.)*N/A N/A 15.0

liters*

(15.9

qts.)*

3.3/3.8L 12.5

liters*15.26

liters*12.5

liters*15.26

liters*

(13.23

qts.)*(16.13

qts.)*(13.23

qts.)*(16.13

qts)*

*Includes Heater and Coolant Recovery Tank Filled to

Max Level.

Belt Tension Gauge C-4162

7 - 26 COOLING SYSTEMNS

ADJUSTMENTS (Continued)

Page 259 of 1938

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine cranking

capacity. Refer to Battery Load Test in this Group. If

the battery passes the load test, return the battery to

use. If battery will not endure a load test, it must be

replaced. Properly clean and inspect battery hold

downs, tray, terminals, cables, posts, and top before

completing service.

CHARGING COMPLETELY DISCHARGED BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless procedure is

properly followed, a good battery may be needlessly

replaced. Refer to Battery Charging Rate table.

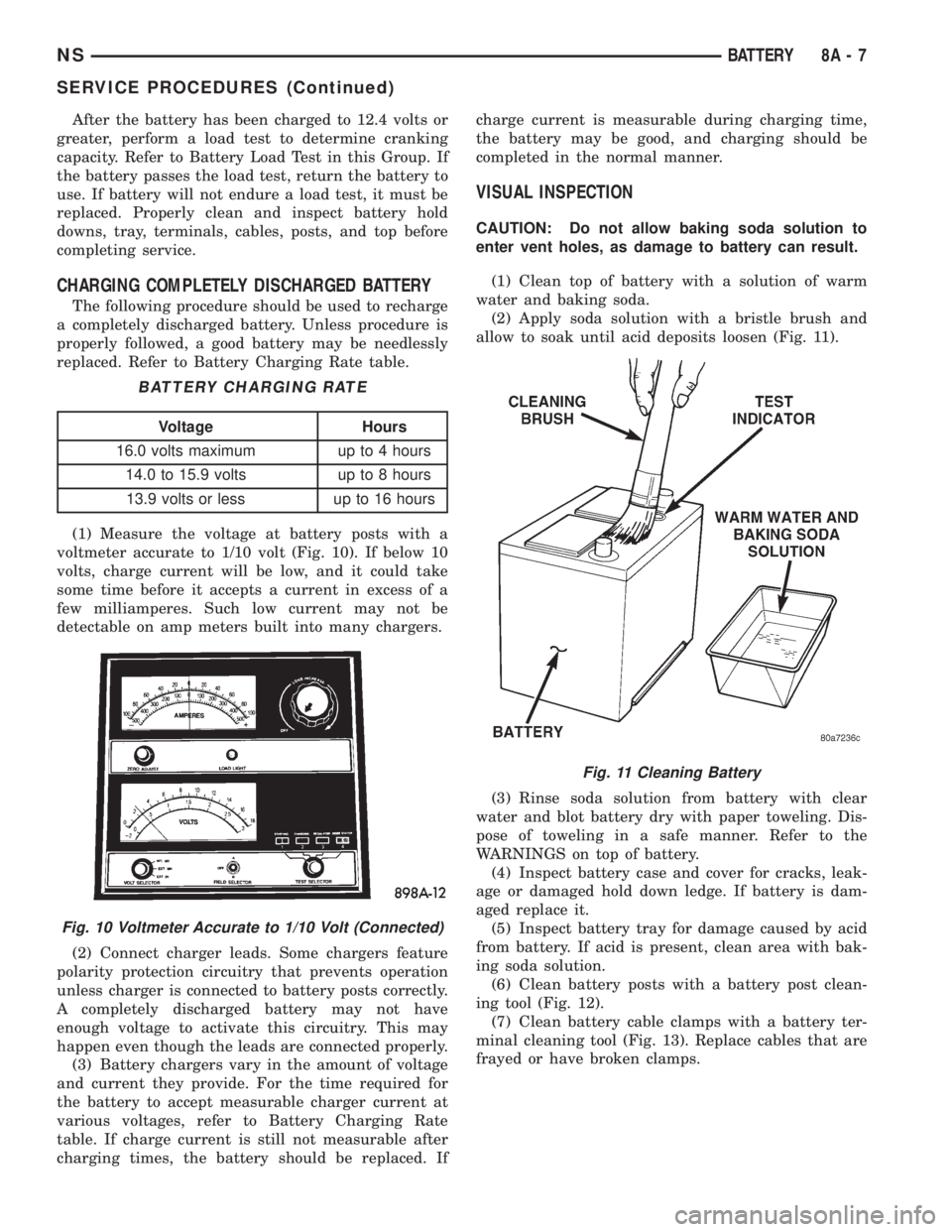

(1) Measure the voltage at battery posts with a

voltmeter accurate to 1/10 volt (Fig. 10). If below 10

volts, charge current will be low, and it could take

some time before it accepts a current in excess of a

few milliamperes. Such low current may not be

detectable on amp meters built into many chargers.

(2) Connect charger leads. Some chargers feature

polarity protection circuitry that prevents operation

unless charger is connected to battery posts correctly.

A completely discharged battery may not have

enough voltage to activate this circuitry. This may

happen even though the leads are connected properly.

(3) Battery chargers vary in the amount of voltage

and current they provide. For the time required for

the battery to accept measurable charger current at

various voltages, refer to Battery Charging Rate

table. If charge current is still not measurable after

charging times, the battery should be replaced. Ifcharge current is measurable during charging time,

the battery may be good, and charging should be

completed in the normal manner.

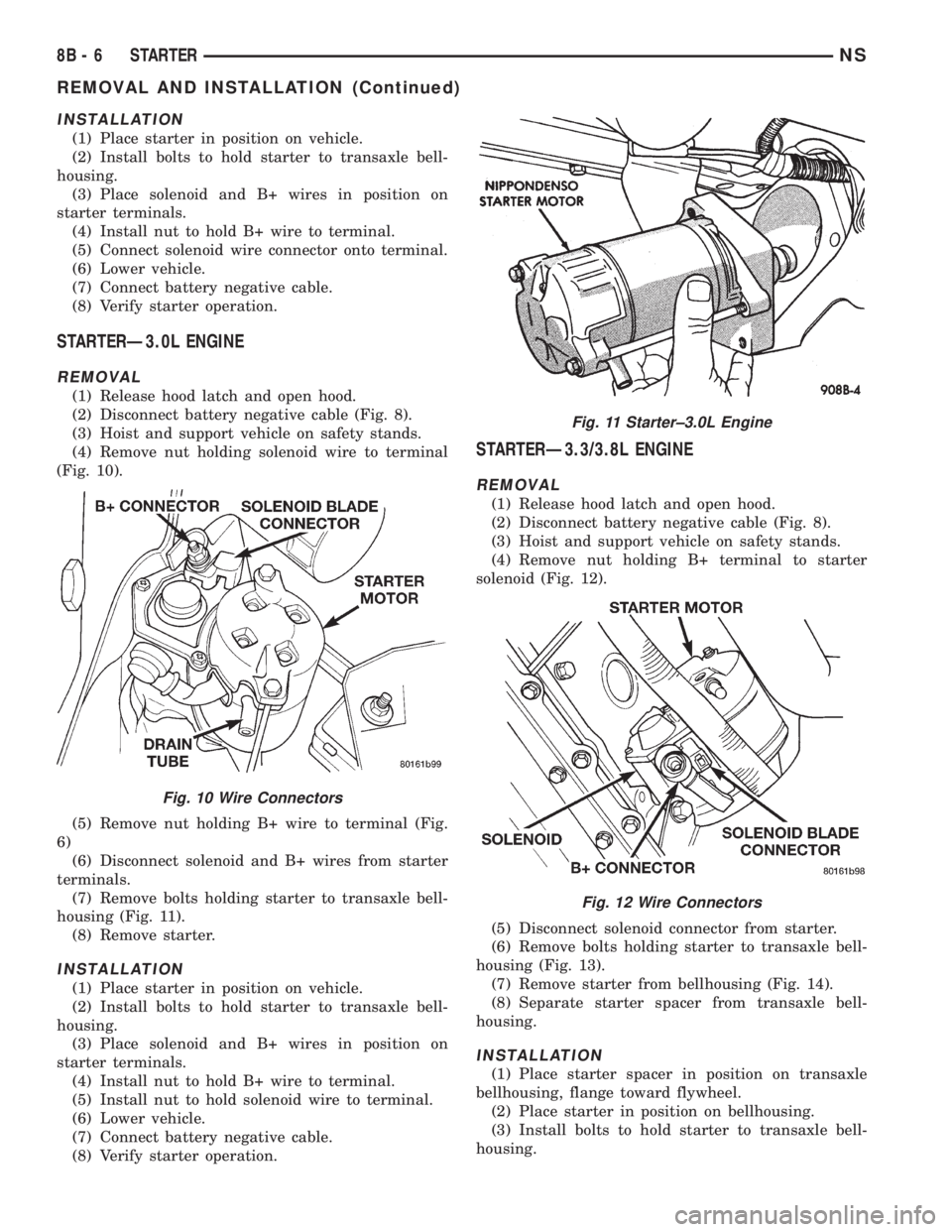

VISUAL INSPECTION

CAUTION: Do not allow baking soda solution to

enter vent holes, as damage to battery can result.

(1) Clean top of battery with a solution of warm

water and baking soda.

(2) Apply soda solution with a bristle brush and

allow to soak until acid deposits loosen (Fig. 11).

(3) Rinse soda solution from battery with clear

water and blot battery dry with paper toweling. Dis-

pose of toweling in a safe manner. Refer to the

WARNINGS on top of battery.

(4) Inspect battery case and cover for cracks, leak-

age or damaged hold down ledge. If battery is dam-

aged replace it.

(5) Inspect battery tray for damage caused by acid

from battery. If acid is present, clean area with bak-

ing soda solution.

(6) Clean battery posts with a battery post clean-

ing tool (Fig. 12).

(7) Clean battery cable clamps with a battery ter-

minal cleaning tool (Fig. 13). Replace cables that are

frayed or have broken clamps.

BATTERY CHARGING RATE

Voltage Hours

16.0 volts maximum up to 4 hours

14.0 to 15.9 volts up to 8 hours

13.9 volts or less up to 16 hours

Fig. 10 Voltmeter Accurate to 1/10 Volt (Connected)

Fig. 11 Cleaning Battery

NSBATTERY 8A - 7

SERVICE PROCEDURES (Continued)

Page 269 of 1938

CAUTION: Disconnect the battery NEGATIVE cable

first (Fig. 4) before charging battery to avoid dam-

age to electrical systems. Do not exceed 16.0 volts

while charging battery. Refer to the instructions

supplied with charging equipment

A battery is considered fully charged when it will

meet all the following requirements.

²It has an open circuit voltage charge of at least

12.4 volts (Fig. 10).

²It passes the 15 second load test, refer to the

Load Test Temperature chart.

²The specific gravity reading is 1.285 plus 0.015

or minus 0.010.

Battery electrolyte will bubble inside of battery

case while being charged properly. If the electrolyte

boils violently, or is discharged from the vent holes

while charging, immediately reduce charging rate or

turn off charger. Evaluate battery condition. Battery

damage may occur if charging is excessive.

Some battery chargers are equipped with polarity

sensing devices to protect the charger or battery from

being damaged if improperly connected. If the bat-

tery state of charge is too low for the polarity sensor

to detect, the sensor must be bypassed for charger to

operate. Refer to operating instructions provided

with battery charger being used.

CAUTION: Do not overcharge Battery.

Test the battery until the specific gravity reading

is 1.285 plus 0.015 or minus 0.010.

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine cranking

capacity. Refer to Battery Load Test in this Group. If

the battery passes the load test, return the battery to

use. If battery will not endure a load test, it must be

replaced. Properly clean and inspect battery hold

downs, tray, terminals, cables, posts, and top before

completing service.

CHARGING COMPLETELY DISCHARGED BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless procedure is

properly followed, a good battery may be needlessly

replaced (Fig. 11).

(1) Measure the voltage at battery posts with a

voltmeter accurate to 1/10 volt (Fig. 12). If below 10

volts, charge current will be low, and it could take

some time before it accepts a current in excess of a

few milliamperes. Such low current may not be

detectable on amp meters built into many chargers.

(2) Connect charger leads. Some chargers feature

polarity protection circuitry that prevents operation

unless charger is connected to battery posts correctly.

A completely discharged battery may not haveenough voltage to activate this circuitry. This may

happen even though the leads are connected properly.

(3) Battery chargers vary in the amount of voltage

and current they provide. For the time required for

the battery to accept measurable charger current at

various voltages, refer to (Fig. 11). If charge current

is still not measurable after charging times, the bat-

tery should be replaced. If charge current is measur-

able during charging time, the battery may be good,

and charging should be completed in the normal

manner.VISUAL INSPECTION

CAUTION: Do not allow baking soda solution to

enter vent holes, as damage to battery can result.

(1) Clean top of battery with a solution of warm

water and baking soda.

(2) Apply soda solution with a bristle brush and

allow to soak until acid deposits loosen (Fig. 13).

(3) Rinse soda solution from battery with clear

water and blot battery dry with paper toweling. Dis-

pose of toweling in a safe manner. Refer to the

WARNINGS on top of battery.

(4) Inspect battery case and cover for cracks, leak-

age or damaged hold down ledge. If battery is dam-

aged replace it.

Fig. 11 Charging Rate

Fig. 12 Voltmeter Accurate to 1/10 Volt (Connected)

NS/GSBATTERY 8A - 7

SERVICE PROCEDURES (Continued)

Page 278 of 1938

INSTALLATION

(1) Place starter in position on vehicle.

(2) Install bolts to hold starter to transaxle bell-

housing.

(3) Place solenoid and B+ wires in position on

starter terminals.

(4) Install nut to hold B+ wire to terminal.

(5) Connect solenoid wire connector onto terminal.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

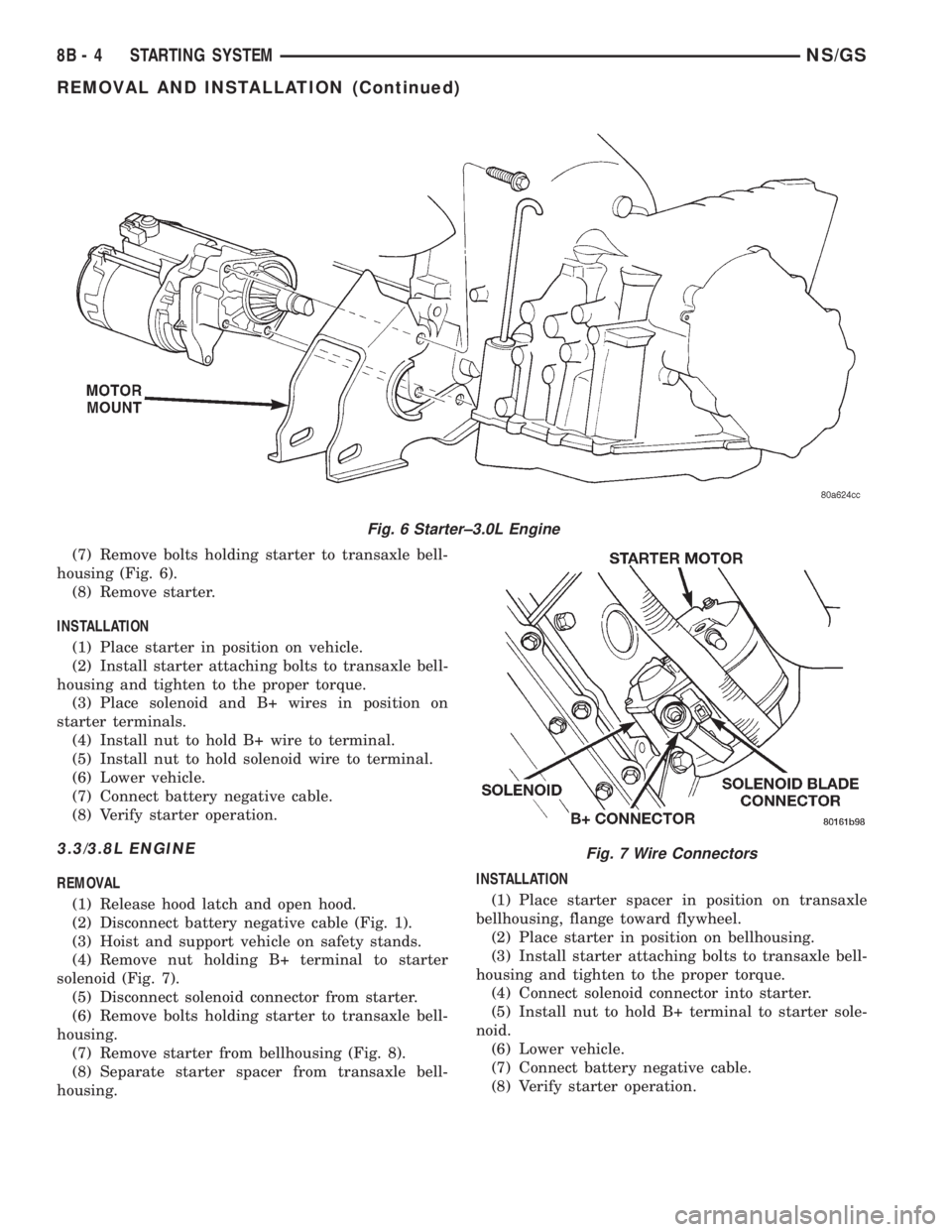

STARTERÐ3.0L ENGINE

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable (Fig. 8).

(3) Hoist and support vehicle on safety stands.

(4) Remove nut holding solenoid wire to terminal

(Fig. 10).

(5) Remove nut holding B+ wire to terminal (Fig.

6)

(6) Disconnect solenoid and B+ wires from starter

terminals.

(7) Remove bolts holding starter to transaxle bell-

housing (Fig. 11).

(8) Remove starter.

INSTALLATION

(1) Place starter in position on vehicle.

(2) Install bolts to hold starter to transaxle bell-

housing.

(3) Place solenoid and B+ wires in position on

starter terminals.

(4) Install nut to hold B+ wire to terminal.

(5) Install nut to hold solenoid wire to terminal.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

STARTERÐ3.3/3.8L ENGINE

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable (Fig. 8).

(3) Hoist and support vehicle on safety stands.

(4) Remove nut holding B+ terminal to starter

solenoid (Fig. 12).

(5) Disconnect solenoid connector from starter.

(6) Remove bolts holding starter to transaxle bell-

housing (Fig. 13).

(7) Remove starter from bellhousing (Fig. 14).

(8) Separate starter spacer from transaxle bell-

housing.

INSTALLATION

(1) Place starter spacer in position on transaxle

bellhousing, flange toward flywheel.

(2) Place starter in position on bellhousing.

(3) Install bolts to hold starter to transaxle bell-

housing.

Fig. 10 Wire Connectors

Fig. 11 Starter±3.0L Engine

Fig. 12 Wire Connectors

8B - 6 STARTERNS

REMOVAL AND INSTALLATION (Continued)

Page 284 of 1938

(7) Remove bolts holding starter to transaxle bell-

housing (Fig. 6).

(8) Remove starter.

INSTALLATION

(1) Place starter in position on vehicle.

(2) Install starter attaching bolts to transaxle bell-

housing and tighten to the proper torque.

(3) Place solenoid and B+ wires in position on

starter terminals.

(4) Install nut to hold B+ wire to terminal.

(5) Install nut to hold solenoid wire to terminal.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

3.3/3.8L ENGINE

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable (Fig. 1).

(3) Hoist and support vehicle on safety stands.

(4) Remove nut holding B+ terminal to starter

solenoid (Fig. 7).

(5) Disconnect solenoid connector from starter.

(6) Remove bolts holding starter to transaxle bell-

housing.

(7) Remove starter from bellhousing (Fig. 8).

(8) Separate starter spacer from transaxle bell-

housing.INSTALLATION

(1) Place starter spacer in position on transaxle

bellhousing, flange toward flywheel.

(2) Place starter in position on bellhousing.

(3) Install starter attaching bolts to transaxle bell-

housing and tighten to the proper torque.

(4) Connect solenoid connector into starter.

(5) Install nut to hold B+ terminal to starter sole-

noid.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

Fig. 6 Starter±3.0L Engine

Fig. 7 Wire Connectors

8B - 4 STARTING SYSTEMNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 296 of 1938

(4) Install bolt to hold bottom of generator to lower

pivot bracket.

(5) Install bolt to hold top of generator to mount

bracket.

(6) Install accessory drive belt, refer to Group 7,

Cooling System for proper procedures.

(7) Install windshield wiper housing, refer to

Group 8K, Windshield Wipers and Washers for

proper procedures.

(8) Connect battery negative cable.

(9) Verify generator charge rate.

GENERATORÐ3.3/3.8 L ENGINE

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable (Fig. 3).

(3) Remove windshield wiper housing, refer to

Group 8K, Windshield Wipers and Washers for

proper procedures.

(4) Remove accessory drive belt, refer to Group 7,

Cooling System for proper procedures.

(5) Remove bolt holding top of generator mount

bracket to engine air intake plenum (Fig. 7).

(6) Remove bolts holding outside of generator

mount bracket to generator mount plate.

(7) Remove bolt holding top of generator to mount

bracket.

(8) Remove generator mount bracket from vehicle.

(9) Rotate generator toward rear dash panel.

(10) Disconnect the push-in field wire connector

from back of generator (Fig. 6).

(11) Remove nut holding B+ wire terminal to back

of generator.

(12) Separate B+ terminal from generator.

(13) Remove bolt holding bottom of generator to

lower pivot bracket (Fig. 8).

(14) Remove generator from vehicle (Fig. 9).

INSTALLATION

(1) Place generator in position on vehicle.

Fig. 6 Generator±3.0L EngineFig. 7 Generator Mounting Bracket

Fig. 8 Generator pivot Bolt

Fig. 9 Generator±3.3/3.8 L Engine

8C - 10 CHARGING SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 301 of 1938

All engines use resistor spark plugs. They have

resistance values ranging from 6,000 to 20,000 ohms

when checked with at least a 1000 volt spark plug

tester.

Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

curate reading.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O - Lubrication and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective, carbon or oil

fouled. Refer to the Spark Plug Condition section of

this group.

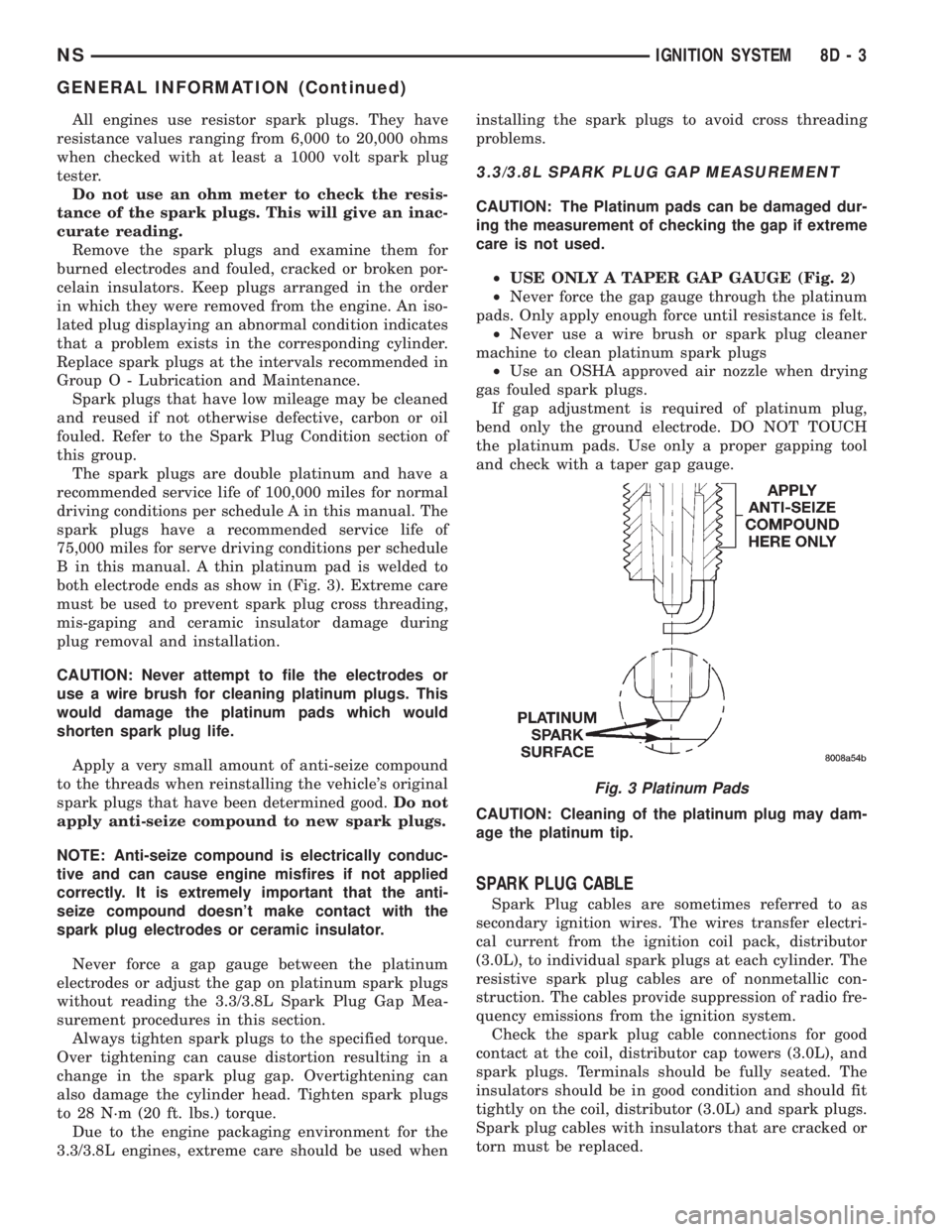

The spark plugs are double platinum and have a

recommended service life of 100,000 miles for normal

driving conditions per schedule A in this manual. The

spark plugs have a recommended service life of

75,000 miles for serve driving conditions per schedule

B in this manual. A thin platinum pad is welded to

both electrode ends as show in (Fig. 3). Extreme care

must be used to prevent spark plug cross threading,

mis-gaping and ceramic insulator damage during

plug removal and installation.

CAUTION: Never attempt to file the electrodes or

use a wire brush for cleaning platinum plugs. This

would damage the platinum pads which would

shorten spark plug life.

Apply a very small amount of anti-seize compound

to the threads when reinstalling the vehicle's original

spark plugs that have been determined good.Do not

apply anti-seize compound to new spark plugs.

NOTE: Anti-seize compound is electrically conduc-

tive and can cause engine misfires if not applied

correctly. It is extremely important that the anti-

seize compound doesn't make contact with the

spark plug electrodes or ceramic insulator.

Never force a gap gauge between the platinum

electrodes or adjust the gap on platinum spark plugs

without reading the 3.3/3.8L Spark Plug Gap Mea-

surement procedures in this section.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap. Overtightening can

also damage the cylinder head. Tighten spark plugs

to 28 N´m (20 ft. lbs.) torque.

Due to the engine packaging environment for the

3.3/3.8L engines, extreme care should be used wheninstalling the spark plugs to avoid cross threading

problems.

3.3/3.8L SPARK PLUG GAP MEASUREMENT

CAUTION: The Platinum pads can be damaged dur-

ing the measurement of checking the gap if extreme

care is not used.

²USE ONLY A TAPER GAP GAUGE (Fig. 2)

²Never force the gap gauge through the platinum

pads. Only apply enough force until resistance is felt.

²Never use a wire brush or spark plug cleaner

machine to clean platinum spark plugs

²Use an OSHA approved air nozzle when drying

gas fouled spark plugs.

If gap adjustment is required of platinum plug,

bend only the ground electrode. DO NOT TOUCH

the platinum pads. Use only a proper gapping tool

and check with a taper gap gauge.

CAUTION: Cleaning of the platinum plug may dam-

age the platinum tip.

SPARK PLUG CABLE

Spark Plug cables are sometimes referred to as

secondary ignition wires. The wires transfer electri-

cal current from the ignition coil pack, distributor

(3.0L), to individual spark plugs at each cylinder. The

resistive spark plug cables are of nonmetallic con-

struction. The cables provide suppression of radio fre-

quency emissions from the ignition system.

Check the spark plug cable connections for good

contact at the coil, distributor cap towers (3.0L), and

spark plugs. Terminals should be fully seated. The

insulators should be in good condition and should fit

tightly on the coil, distributor (3.0L) and spark plugs.

Spark plug cables with insulators that are cracked or

torn must be replaced.

Fig. 3 Platinum Pads

NSIGNITION SYSTEM 8D - 3

GENERAL INFORMATION (Continued)

Page 306 of 1938

NOTE: Over or under tightening effects knock sen-

sor performance, possibly causing improper spark

control.

DIAGNOSIS AND TESTING

TESTING FOR SPARK AT COILÐ2.4/3.3/3.8L

ENGINES

WARNING: THE DIRECT IGNITION SYSTEMS GEN-

ERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

The coil pack contains independent coils. Each coil

must be checked individually.

CAUTION: Spark plug wire damage may occur if

the spark plug is moved more than 1/4 inch away

from the engine ground.

CAUTION: Do not leave any one spark plug cable

disconnected any longer than 30 seconds or possi-

ble heat damage to catalytic converter will occur.

CAUTION: Test must be performed at idle and in

park only with the parking brake on.

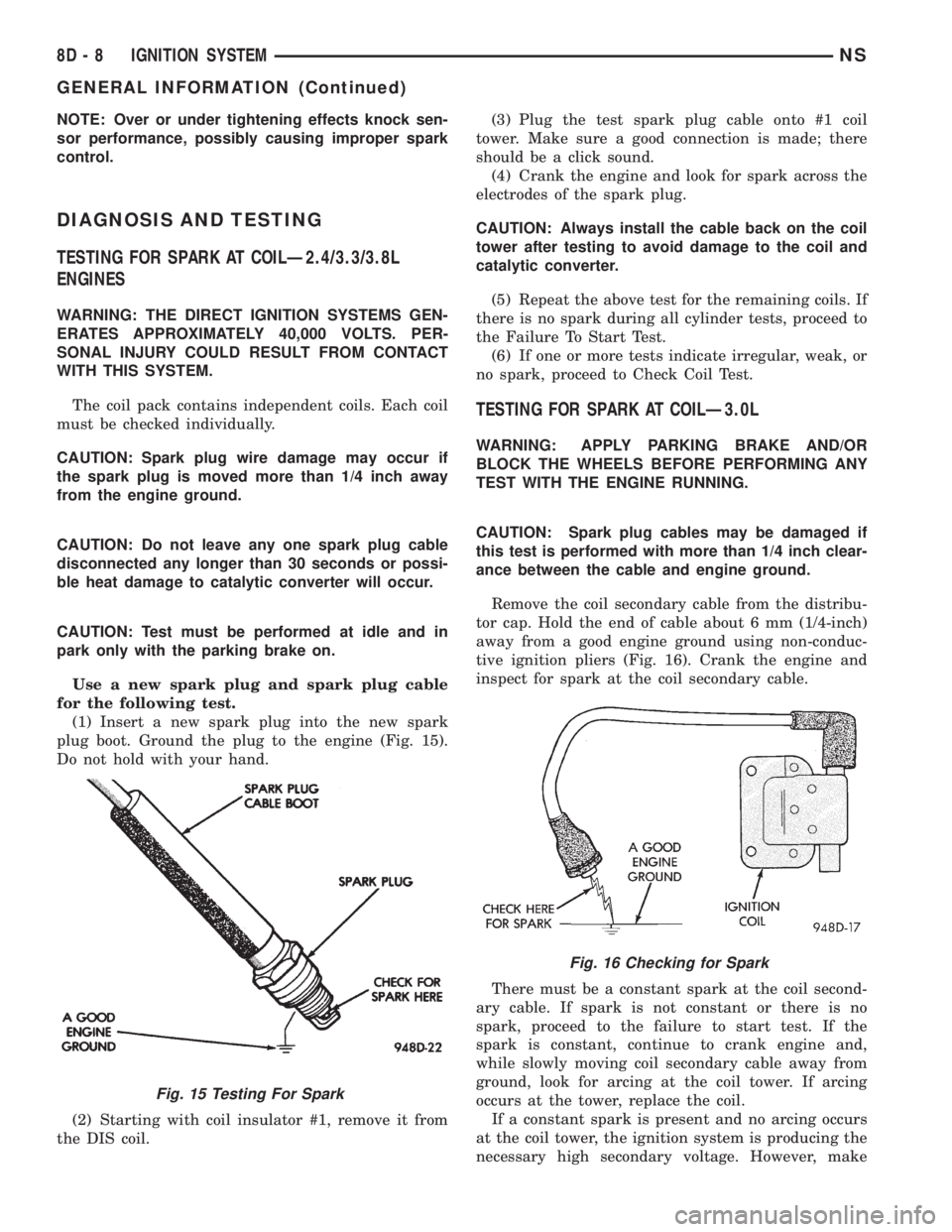

Use a new spark plug and spark plug cable

for the following test.

(1) Insert a new spark plug into the new spark

plug boot. Ground the plug to the engine (Fig. 15).

Do not hold with your hand.

(2) Starting with coil insulator #1, remove it from

the DIS coil.(3) Plug the test spark plug cable onto #1 coil

tower. Make sure a good connection is made; there

should be a click sound.

(4) Crank the engine and look for spark across the

electrodes of the spark plug.

CAUTION: Always install the cable back on the coil

tower after testing to avoid damage to the coil and

catalytic converter.

(5) Repeat the above test for the remaining coils. If

there is no spark during all cylinder tests, proceed to

the Failure To Start Test.

(6) If one or more tests indicate irregular, weak, or

no spark, proceed to Check Coil Test.

TESTING FOR SPARK AT COILÐ3.0L

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK THE WHEELS BEFORE PERFORMING ANY

TEST WITH THE ENGINE RUNNING.

CAUTION: Spark plug cables may be damaged if

this test is performed with more than 1/4 inch clear-

ance between the cable and engine ground.

Remove the coil secondary cable from the distribu-

tor cap. Hold the end of cable about 6 mm (1/4-inch)

away from a good engine ground using non-conduc-

tive ignition pliers (Fig. 16). Crank the engine and

inspect for spark at the coil secondary cable.

There must be a constant spark at the coil second-

ary cable. If spark is not constant or there is no

spark, proceed to the failure to start test. If the

spark is constant, continue to crank engine and,

while slowly moving coil secondary cable away from

ground, look for arcing at the coil tower. If arcing

occurs at the tower, replace the coil.

If a constant spark is present and no arcing occurs

at the coil tower, the ignition system is producing the

necessary high secondary voltage. However, make

Fig. 15 Testing For Spark

Fig. 16 Checking for Spark

8D - 8 IGNITION SYSTEMNS

GENERAL INFORMATION (Continued)

Page 307 of 1938

sure that the spark plugs are firing. Inspect the dis-

tributor rotor, cap, spark plug cables, and spark

plugs. If they are in proper working order, the igni-

tion system is not the reason why the engine will not

start. Inspect the fuel system and engine for proper

operation.

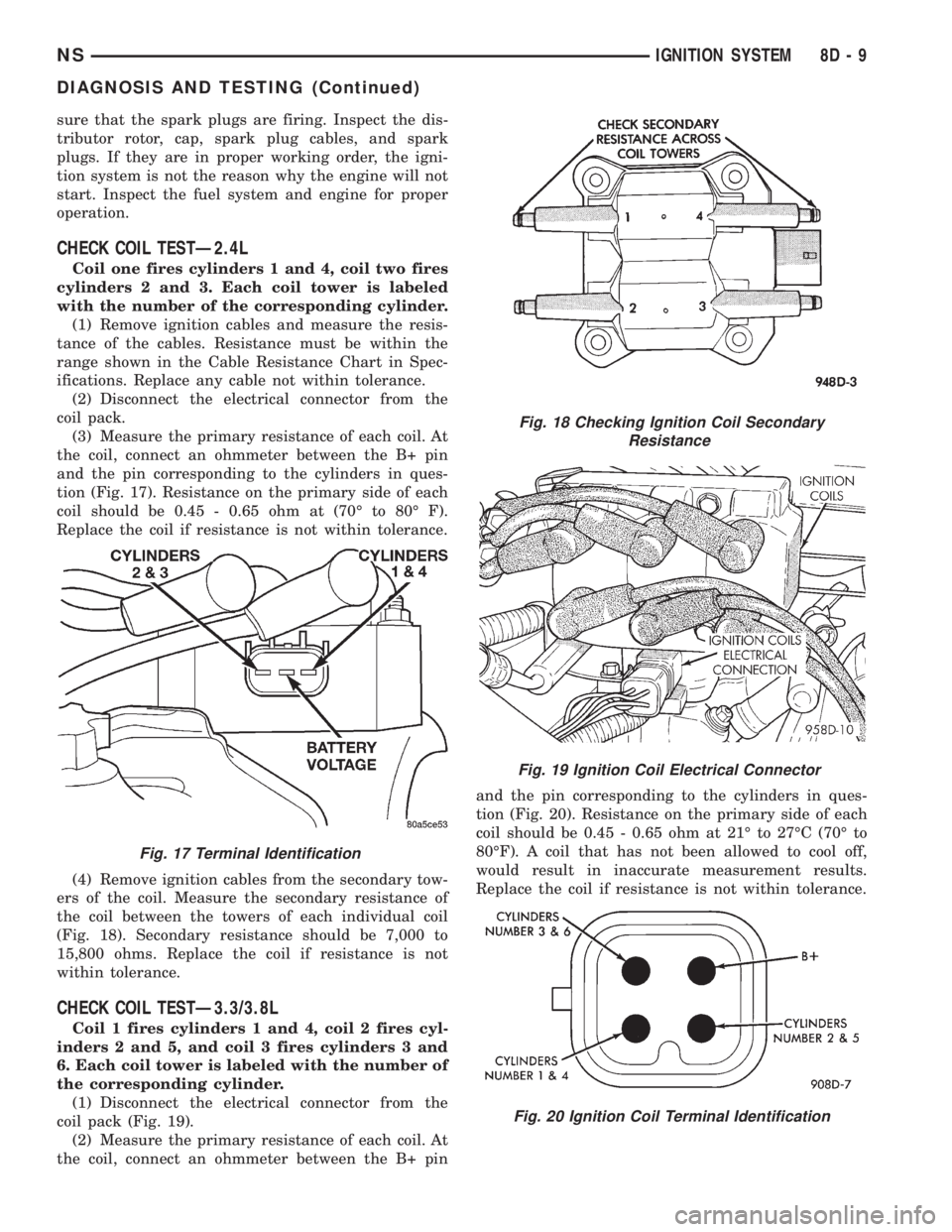

CHECK COIL TESTÐ2.4L

Coil one fires cylinders 1 and 4, coil two fires

cylinders 2 and 3. Each coil tower is labeled

with the number of the corresponding cylinder.

(1) Remove ignition cables and measure the resis-

tance of the cables. Resistance must be within the

range shown in the Cable Resistance Chart in Spec-

ifications. Replace any cable not within tolerance.

(2) Disconnect the electrical connector from the

coil pack.

(3) Measure the primary resistance of each coil. At

the coil, connect an ohmmeter between the B+ pin

and the pin corresponding to the cylinders in ques-

tion (Fig. 17). Resistance on the primary side of each

coil should be 0.45 - 0.65 ohm at (70É to 80É F).

Replace the coil if resistance is not within tolerance.

(4) Remove ignition cables from the secondary tow-

ers of the coil. Measure the secondary resistance of

the coil between the towers of each individual coil

(Fig. 18). Secondary resistance should be 7,000 to

15,800 ohms. Replace the coil if resistance is not

within tolerance.

CHECK COIL TESTÐ3.3/3.8L

Coil 1 fires cylinders 1 and 4, coil 2 fires cyl-

inders 2 and 5, and coil 3 fires cylinders 3 and

6. Each coil tower is labeled with the number of

the corresponding cylinder.

(1) Disconnect the electrical connector from the

coil pack (Fig. 19).

(2) Measure the primary resistance of each coil. At

the coil, connect an ohmmeter between the B+ pinand the pin corresponding to the cylinders in ques-

tion (Fig. 20). Resistance on the primary side of each

coil should be 0.45 - 0.65 ohm at 21É to 27ÉC (70É to

80ÉF). A coil that has not been allowed to cool off,

would result in inaccurate measurement results.

Replace the coil if resistance is not within tolerance.

Fig. 17 Terminal Identification

Fig. 18 Checking Ignition Coil Secondary

Resistance

Fig. 19 Ignition Coil Electrical Connector

Fig. 20 Ignition Coil Terminal Identification

NSIGNITION SYSTEM 8D - 9

DIAGNOSIS AND TESTING (Continued)

Page 308 of 1938

(3) Remove ignition cables from the secondary tow-

ers of the coil. Measure the secondary resistance of

the coil between the towers of each individual coil

(Fig. 21). Secondary resistance should be 7,000 to

15,800 ohms. Replace the coil if resistance is not

within tolerance.

FAILURE TO START TEST

This no-start test checks the camshaft position sen-

sor and crankshaft position sensor.

The Powertrain Control Module (PCM) supplies 8

volts to the camshaft position sensor and crankshaft

position sensor through one circuit. If the 8 volt sup-

ply circuit shorts to ground, neither sensor will pro-

duce a signal (output voltage to the PCM).

When the ignition key is turned and left in the On

position, the PCM automatically energizes the Auto

Shutdown (ASD) relay. However, the controller de-en-

ergizes the relay within one second because it has

not received a camshaft position sensor signal indi-

cating engine rotation.

During cranking, the ASD relay will not energize

until the PCM receives a camshaft position sensor

signal. Secondly, the ASD relay remains energized

only if the controller senses a crankshaft position

sensor signal immediately after detecting the cam-

shaft position sensor signal.

(1) Check battery voltage. Voltage should be

approximately 12.66 volts or higher to perform fail-

ure to start test.

(2) Disconnect the harness connector from the coil

pack.

(3) Connect a test light to the B+ (battery voltage)

terminal of the coil electrical connector and ground

as shown in (Fig. 22). The B+ wire for the DIS coil is

dark green with an orange tracer.Do not spread

the terminal with the test light probe.(4) Turn the ignition key to theON position.The

test light should flash On and then Off.Do not turn

the Key to off position, leave it in the On posi-

tion.

(a) If the test light flashes momentarily, the

PCM grounded the Auto Shutdown (ASD) relay.

Proceed to step 5.

(b) If the test light did not flash, the ASD relay

did not energize. The cause is either the relay or

one of the relay circuits. Use the DRB scan tool to

test the ASD relay and circuits. Refer to the appro-

priate Powertrain Diagnostics Procedure Manual.

Refer to the wiring diagrams section for circuit

information.

(5) Crank the engine. (If the key was placed in the

off position after step 4, place the key in the On posi-

tion before cranking. Wait for the test light to flash

once, then crank the engine.)

(6) If the test light momentarily flashes during

cranking, the PCM is not receiving a crankshaft posi-

tion sensor signal. Use the DRB scan tool to test the

crankshaft position sensor and sensor circuits. Refer

to the appropriate Powertrain Diagnostics Procedure

Manual. Refer to the wiring diagrams section for cir-

cuit information.

(7) If the test light did not flash during cranking,

unplug the crankshaft position sensor connector.

Turn the ignition key to the off position. Turn the

key to the On position, wait for the test light to

momentarily flash once, then crank the engine. If the

test light momentarily flashes, the crankshaft posi-

tion sensor is shorted and must be replaced. If the

light did not flash, the cause of the no-start is in

Fig. 21 Checking Ignition Coil Secondary

ResistanceFig. 22 Ignition Coil Engine Harness Connector

8D - 10 IGNITION SYSTEMNS

DIAGNOSIS AND TESTING (Continued)