fuse CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1358 of 1938

REMOVAL AND INSTALLATION

THROTTLE BODY

REMOVAL

(1) Disconnect negative cable from battery cable.

(2) Remove air inlet to throttle body hose clamp.

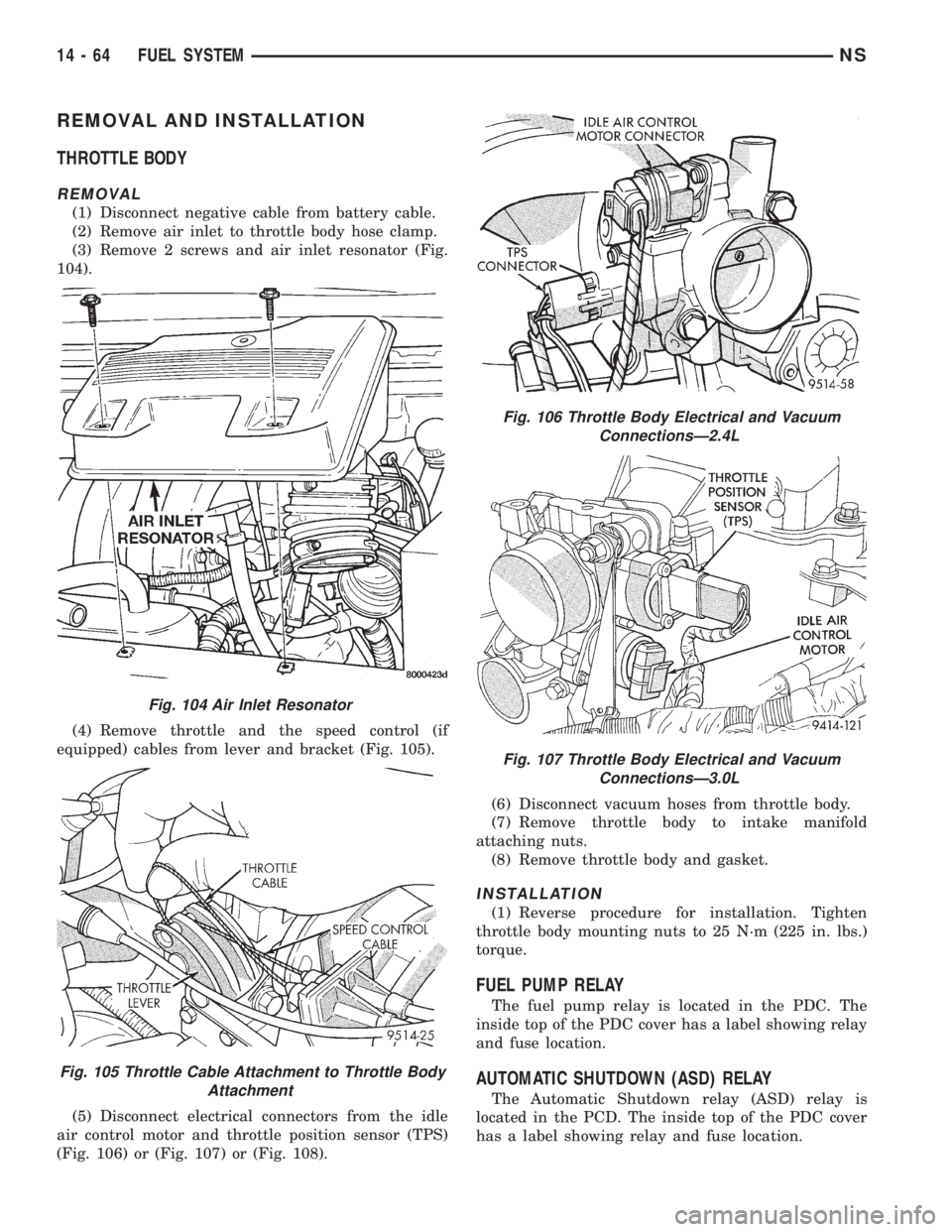

(3) Remove 2 screws and air inlet resonator (Fig.

104).

(4) Remove throttle and the speed control (if

equipped) cables from lever and bracket (Fig. 105).

(5) Disconnect electrical connectors from the idle

air control motor and throttle position sensor (TPS)

(Fig. 106) or (Fig. 107) or (Fig. 108).(6) Disconnect vacuum hoses from throttle body.

(7) Remove throttle body to intake manifold

attaching nuts.

(8) Remove throttle body and gasket.

INSTALLATION

(1) Reverse procedure for installation. Tighten

throttle body mounting nuts to 25 N´m (225 in. lbs.)

torque.

FUEL PUMP RELAY

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

AUTOMATIC SHUTDOWN (ASD) RELAY

The Automatic Shutdown relay (ASD) relay is

located in the PCD. The inside top of the PDC cover

has a label showing relay and fuse location.

Fig. 104 Air Inlet Resonator

Fig. 105 Throttle Cable Attachment to Throttle Body

Attachment

Fig. 106 Throttle Body Electrical and Vacuum

ConnectionsÐ2.4L

Fig. 107 Throttle Body Electrical and Vacuum

ConnectionsÐ3.0L

14 - 64 FUEL SYSTEMNS

Page 1381 of 1938

A defective fuel injection pump, defective fuel tim-

ing solenoid or misadjusted mechanical pump timing

can cause starting problems or prevent the engine

from revving up. It can also cause:

²Engine surge at idle

²Rough idle (warm engine)

²Low power

²Excessive fuel consumption

²Poor performance

²Low power

²Black smoke from the exhaust

²Blue or white fog like exhaust

²Incorrect idle or maximum speed

The electronically controlled fuel pump has no

mechanical governor like older mechanically con-

trolled fuel pumps. Do not remove the top cover of

the fuel pump, or the screws fastening the wiring

pigtail to the side of the pump.The warranty of

the injection pump and the engine may be void

if those seals have been removed or tampered

with.

FUEL SUPPLY RESTRICTIONS

LOW±PRESSURE LINES

Restricted or Plugged supply lines or fuel filter can

cause a timing fault that will cause the PCM to oper-

ate the engine in a ªLimp Homeº mode. See the

introduction of the Fuel Injection System in this

group for more information on the Limp Home mode.

Fuel supply line restrictions can cause starting prob-

lems and prevent the engine from revving up. The

starting problems include; low power and blue or

white fog like exhaust. Test all fuel supply lines for

restrictions or blockage. Flush or replace as neces-

sary. Bleed the fuel system of air once a fuel supply

line has been replaced. Refer to the Air Bleed Proce-

dure section of this group for procedures.

HIGH±PRESSURE LINES

Restricted (kinked or bent) high±pressure lines can

cause starting problems, poor engine performance

and black smoke from exhaust.

Examine all high±pressure lines for any damage.

Each radius on each high±pressure line must be

smooth and free of any bends or kinks.

Replace damaged, restricted or leaking high±pres-

sure fuel lines with the correct replacement line.

CAUTION: The high±pressure fuel lines must be

clamped securely in place in the holders. The lines

cannot contact each other or other components. Do

not attempt to weld high±pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high±pressure

fuel line is necessary.

FUEL SHUTDOWN SOLENOID TEST

Since diesel fuel injection does not use spark plugs

to start combustion, the only way to stop the engine

is to cut off the fuel supply. This is done with the

Fuel Shutdown Solenoid. If the engine cranks, but

refuses to start, it may be caused by a defective fuel

shutdown solenoid.

The fuel shutdown solenoid is not controlled

or operated by the PCM.Voltage to operate the

solenoid is supplied from the ignition (key) switch.

NOTE: Although the fuel shutdown solenoid is not

operated by the PCM, if the Fuel Shutdown Solenoid

has been disconnected, and the key turned on, the

PCM will sense that the solenoid is not in the circuit,

and will switch to a ªLimp Homeº mode. After recon-

necting the solenoid, the PCM will have to be reset

by clearing the codes with the DRBIII scan tool, or

disconnecting the vehicle's battery for several min-

utes. The DRBIII scan tool is the preferred method

for resetting the PCM. Refer to the 1998 GS 2.5L Die-

sel Powertrain Diagnostic Manual for procedure.

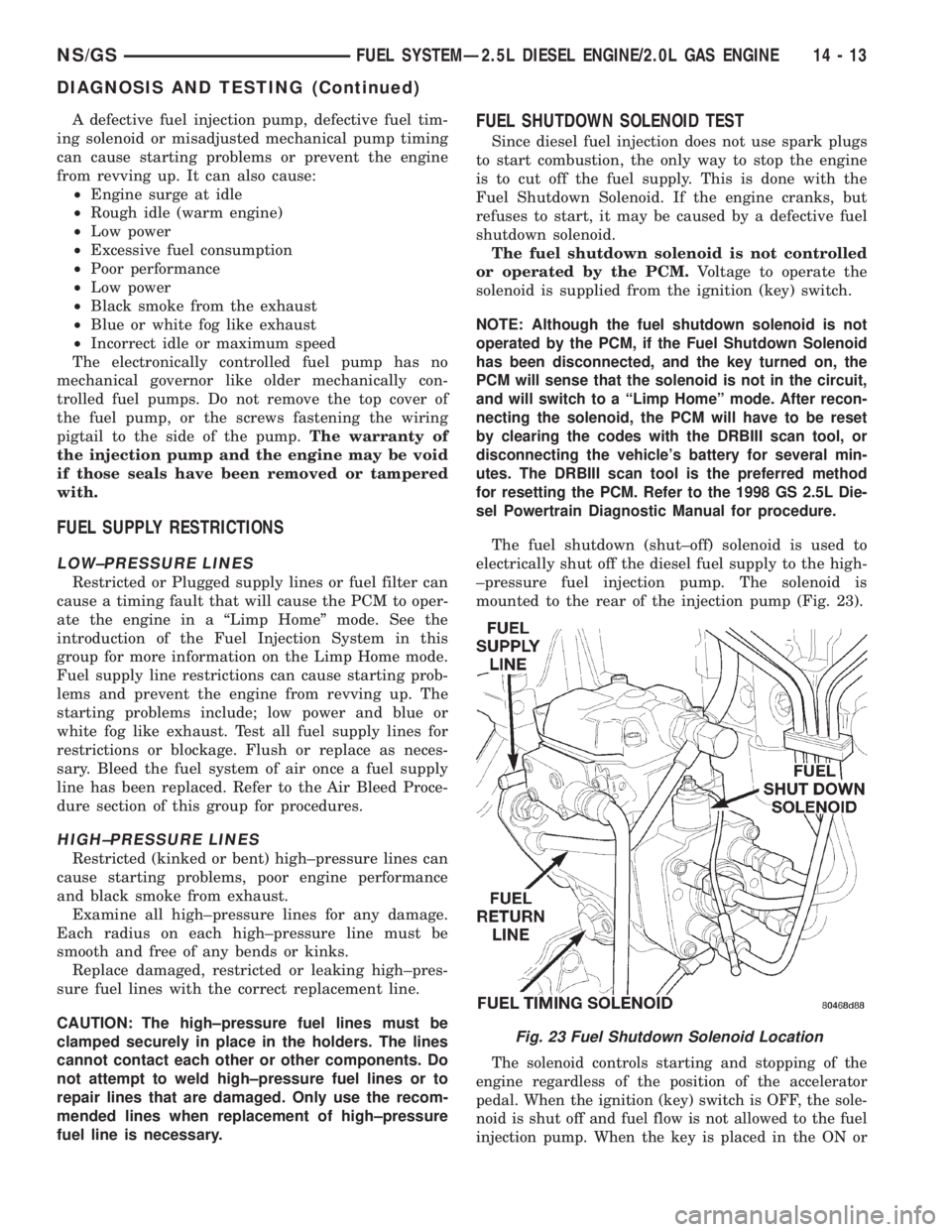

The fuel shutdown (shut±off) solenoid is used to

electrically shut off the diesel fuel supply to the high-

±pressure fuel injection pump. The solenoid is

mounted to the rear of the injection pump (Fig. 23).

The solenoid controls starting and stopping of the

engine regardless of the position of the accelerator

pedal. When the ignition (key) switch is OFF, the sole-

noid is shut off and fuel flow is not allowed to the fuel

injection pump. When the key is placed in the ON or

Fig. 23 Fuel Shutdown Solenoid Location

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 13

DIAGNOSIS AND TESTING (Continued)

Page 1404 of 1938

IGNITION COILÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Ignition Coil for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Malfunction Indicator Lamp for 2.4/

3.0/3.3/3.8L engines under Description and Operation

in the Fuel Injection System section of group 14 for

more information.

RADIATOR FAN CONTROL MODULEÐPCM

OUTPUTÐ2.0L ENGINE

Refer to the Radiator Fan Control Module for 2.4/

3.0/3.3/3.8L engines under Description and Operation

in the Fuel Injection System section of group 14 for

more information.

SPEED CONTROL SOLENOIDSÐPCM OUTPUTÐ

2.0L ENGINE

Refer to the Speed Control Solenoids for 2.4/3.0/3.3/

3.8L engines under Description and Operation in the

Fuel Injection System section of group 14 for more

information.

TACHOMETERÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Tachometer for 2.4/3.0/3.3/3.8L engines

under Description and Operation in the Fuel Injec-

tion System section of group 14 for more information.

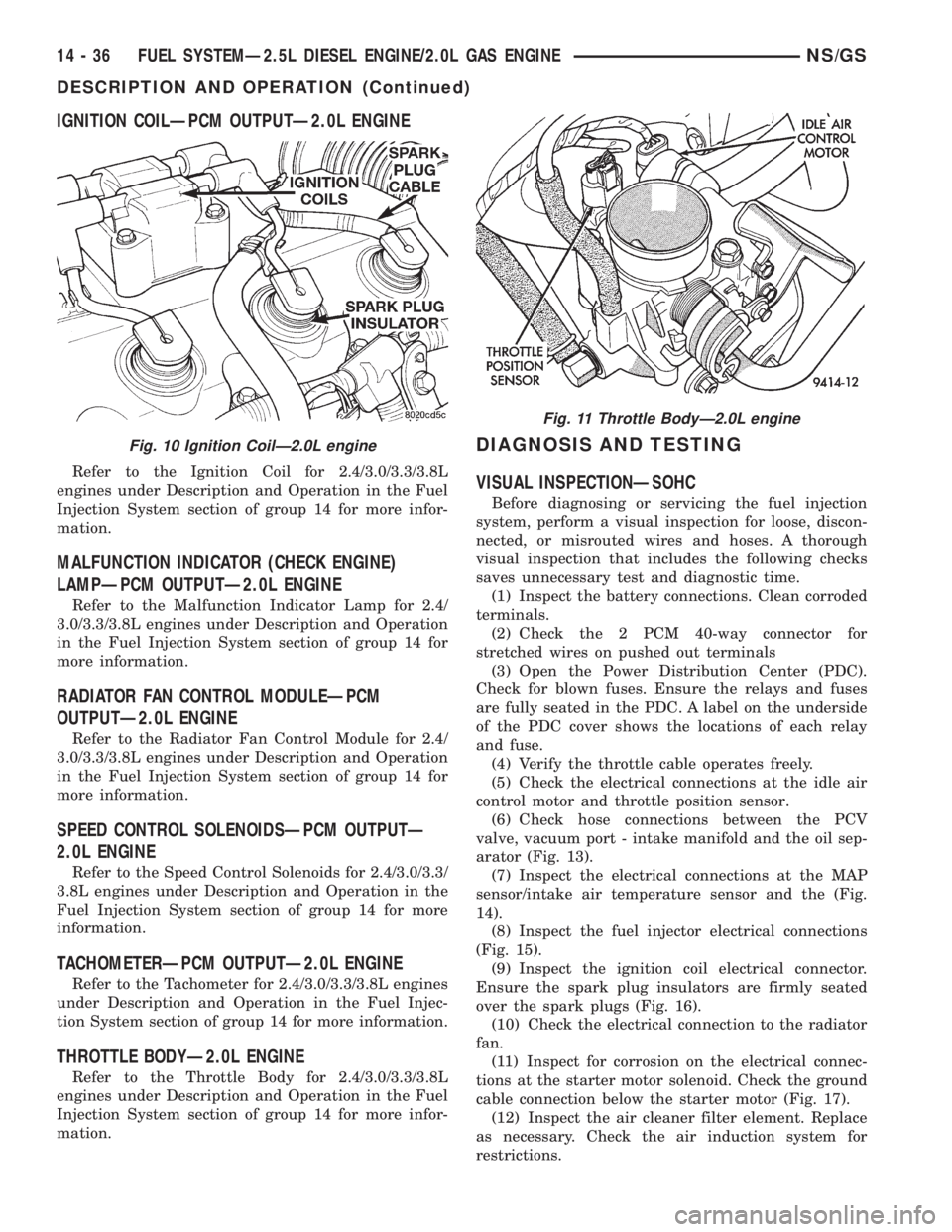

THROTTLE BODYÐ2.0L ENGINE

Refer to the Throttle Body for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

DIAGNOSIS AND TESTING

VISUAL INSPECTIONÐSOHC

Before diagnosing or servicing the fuel injection

system, perform a visual inspection for loose, discon-

nected, or misrouted wires and hoses. A thorough

visual inspection that includes the following checks

saves unnecessary test and diagnostic time.

(1) Inspect the battery connections. Clean corroded

terminals.

(2) Check the 2 PCM 40-way connector for

stretched wires on pushed out terminals

(3) Open the Power Distribution Center (PDC).

Check for blown fuses. Ensure the relays and fuses

are fully seated in the PDC. A label on the underside

of the PDC cover shows the locations of each relay

and fuse.

(4) Verify the throttle cable operates freely.

(5) Check the electrical connections at the idle air

control motor and throttle position sensor.

(6) Check hose connections between the PCV

valve, vacuum port - intake manifold and the oil sep-

arator (Fig. 13).

(7) Inspect the electrical connections at the MAP

sensor/intake air temperature sensor and the (Fig.

14).

(8) Inspect the fuel injector electrical connections

(Fig. 15).

(9) Inspect the ignition coil electrical connector.

Ensure the spark plug insulators are firmly seated

over the spark plugs (Fig. 16).

(10) Check the electrical connection to the radiator

fan.

(11) Inspect for corrosion on the electrical connec-

tions at the starter motor solenoid. Check the ground

cable connection below the starter motor (Fig. 17).

(12) Inspect the air cleaner filter element. Replace

as necessary. Check the air induction system for

restrictions.

Fig. 10 Ignition CoilÐ2.0L engine

Fig. 11 Throttle BodyÐ2.0L engine

14 - 36 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1829 of 1938

BLOWER MOTOR AND WHEEL ASSEMBLY

VIBRATION AND/OR NOISE DIAGNOSIS

The blower speed switch, in conjunction with the

resistor block, supplies the blower motor with varied

voltage.

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater A/C

housing.

Refer to the Blower Motor Vibration/Noise chart in

this section for diagnosis.

COMPRESSOR NOISE DIAGNOSIS

Excessive noise while the A/C is being used, can be

caused by loose mounts, loose clutch, or high operat-

ing pressure. Verify compressor drive belt condition,

proper refrigerant charge and head pressure before

compressor repair is performed.

If the A/C drive belt slips at initial start-up, it does

not necessarily mean the compressor has failed.

With the close tolerances of a compressor it is pos-

sible to experience a temporary lockup. The longer

the A/C system is inactive, the more likely the condi-

tion to occur.

This condition is the result of normal refrigerant

movement within the A/C system caused by temper-

ature changes. The refrigerant movement may wash

the oil out of the compressor.

COMPRESSOR CLUTCH/COIL

The air conditioning compressor clutch electrical

circuit is controlled by the Powertrain Control Mod-

ule. It is located in the engine compartment outboard

of the battery.If the compressor clutch does not engage verify

refrigerant charge.

If the compressor clutch still does not engage check

for battery voltage at the pressure transducer located

on the liquid line. If voltage is not detected, refer to:

²Group 8W, Wiring diagrams.

²Powertrain Diagnostic Procedures manual for

diagnostic information.

If voltage is detected at the pressure transducer,

connect pressure transducer and check for battery

voltage between the compressor clutch connector ter-

minals.

If voltage is detected, perform A/C Clutch Coil

Tests.

TESTS

(1) Verify battery state of charge. (Test indicator in

battery should be green).

(2) Connect an ampmeter (0-10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0-20 volt scale) with clip leads measuring voltage

across the battery and A/C clutch.

(3) With A/C control in A/C mode and blower at

low speed, start the engine and run at normal idle.

(4) The A/C clutch should engage immediately and

the clutch voltage should be within two volts of the

battery voltage. If the A/C clutch does not engage,

test the fuse.

(5) The A/C clutch coil is acceptable if the current

draw is 2.0 to 3.7 amperes at 11.5-12.5 volts at clutch

coil. This is with the work area temperature at 21ÉC

(70ÉF). If voltage is more than 12.5 volts, add electri-

cal loads by turning on electrical accessories until

voltage reads below 12.5 volts.

(6) If coil current reads zero, the coil is open and

should be replaced. If the ammeter reading is 4

amperes or more, the coil is shorted and should be

replaced. If the coil voltage is not within two volts of

the battery voltage, test clutch coil feed circuit for

excessive voltage drop.

EXPANSION VALVE

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

TESTS

NOTE: Expansion valve tests should be performed

after compressor tests.

Review Safety Precautions and Warnings in this

group. The work area and vehicle temperature must

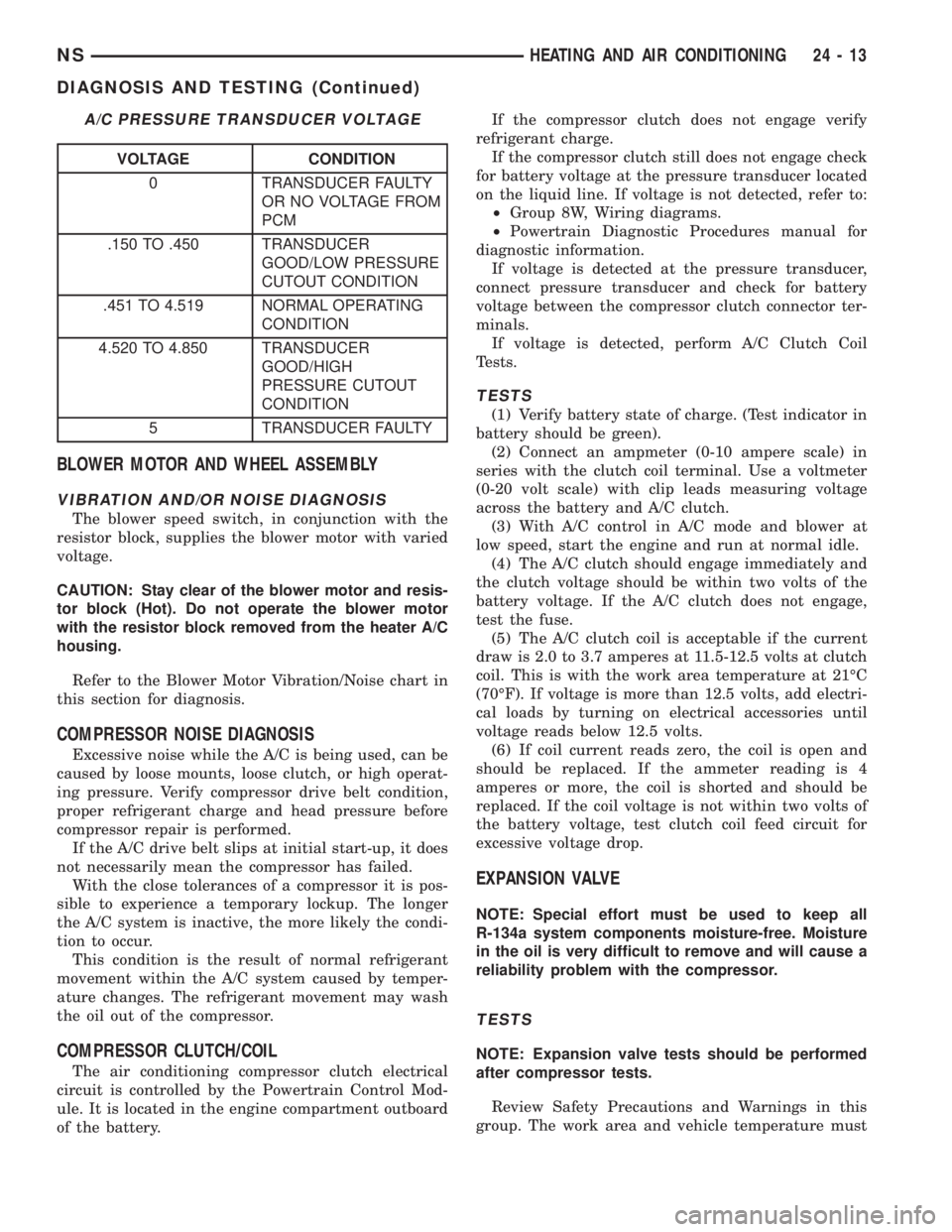

A/C PRESSURE TRANSDUCER VOLTAGE

VOLTAGE CONDITION

0 TRANSDUCER FAULTY

OR NO VOLTAGE FROM

PCM

.150 TO .450 TRANSDUCER

GOOD/LOW PRESSURE

CUTOUT CONDITION

.451 TO 4.519 NORMAL OPERATING

CONDITION

4.520 TO 4.850 TRANSDUCER

GOOD/HIGH

PRESSURE CUTOUT

CONDITION

5 TRANSDUCER FAULTY

NSHEATING AND AIR CONDITIONING 24 - 13

DIAGNOSIS AND TESTING (Continued)

Page 1878 of 1938

BLOWER MOTOR AND WHEEL ASSEMBLY

VIBRATION AND/OR NOISE DIAGNOSIS

The blower speed switch, in conjunction with the

resistor block, supplies the blower motor with varied

voltage.

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater A/C

housing.

Refer to the Blower Motor Vibration/Noise chart in

this section for diagnosis.

COMPRESSOR NOISE DIAGNOSIS

Excessive noise while the A/C is being used, can be

caused by loose mounts, clutch, or high operating

pressure. Verify compressor drive belt condition,

proper refrigerant charge and head pressure before

compressor repair is performed.

COMPRESSOR CLUTCH/COIL

The air conditioning compressor clutch electrical

circuit is controlled by the Powertrain Control Mod-ule. It is located in the engine compartment outboard

of the battery.

If the compressor clutch does not engage verify

refrigerant charge.

If the compressor clutch still does not engage check

for battery voltage at the pressure transducer located

on the liquid line. If voltage is not detected, refer to:

²Group 8W, Wiring diagrams.

²Powertrain Diagnostic Procedures manual for

diagnostic information.

If voltage is detected at the pressure transducer,

connect pressure transducer and check for battery

voltage between the compressor clutch connector ter-

minals.

If voltage is detected, perform A/C Clutch Coil

Tests.

TESTS

(1) Verify battery state of charge. (Test indicator in

battery should be green).

(2) Connect an ampmeter (0-10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0-20 volt scale) with clip leads measuring voltage

across the battery and A/C clutch.

(3) With A/C control in A/C mode and blower at

low speed, start the engine and run at normal idle.

(4) The A/C clutch should engage immediately and

the clutch voltage should be within two volts of the

battery voltage. If the A/C clutch does not engage,

test the fuse.

(5) The A/C clutch coil is acceptable if the current

draw is 2.0 to 3.7 amperes at 11.5-12.5 volts at clutch

coil. This is with the work area temperature at 21ÉC

(70ÉF). If voltage is more than 12.5 volts, add electri-

cal loads by turning on electrical accessories until

voltage reads below 12.5 volts.

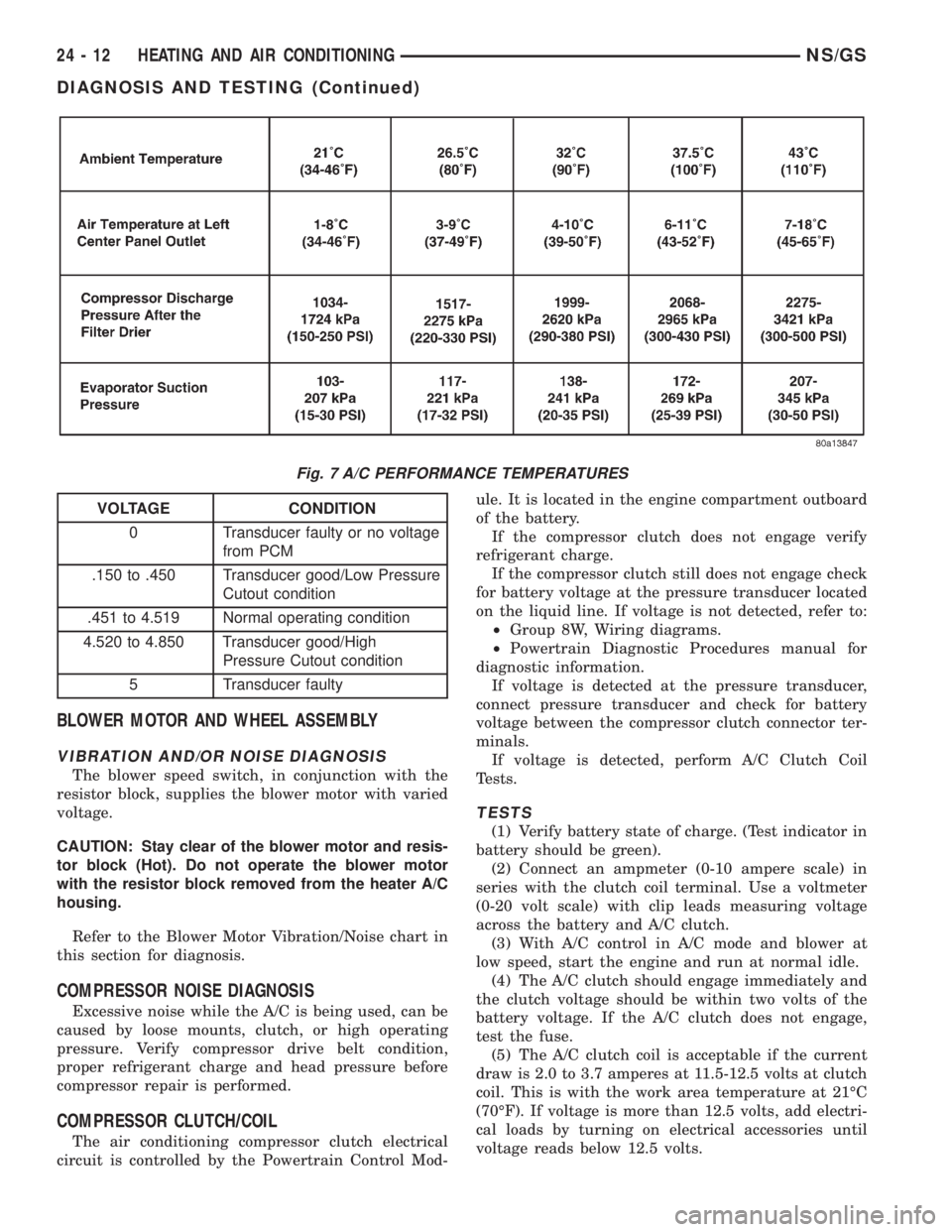

Fig. 7 A/C PERFORMANCE TEMPERATURES

VOLTAGE CONDITION

0 Transducer faulty or no voltage

from PCM

.150 to .450 Transducer good/Low Pressure

Cutout condition

.451 to 4.519 Normal operating condition

4.520 to 4.850 Transducer good/High

Pressure Cutout condition

5 Transducer faulty

24 - 12 HEATING AND AIR CONDITIONINGNS/GS

DIAGNOSIS AND TESTING (Continued)