ECO mode CHRYSLER VOYAGER 1996 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1182 of 1938

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

SERVICE PROCEDURES

CYLINDER BORE AND PISTON SIZING

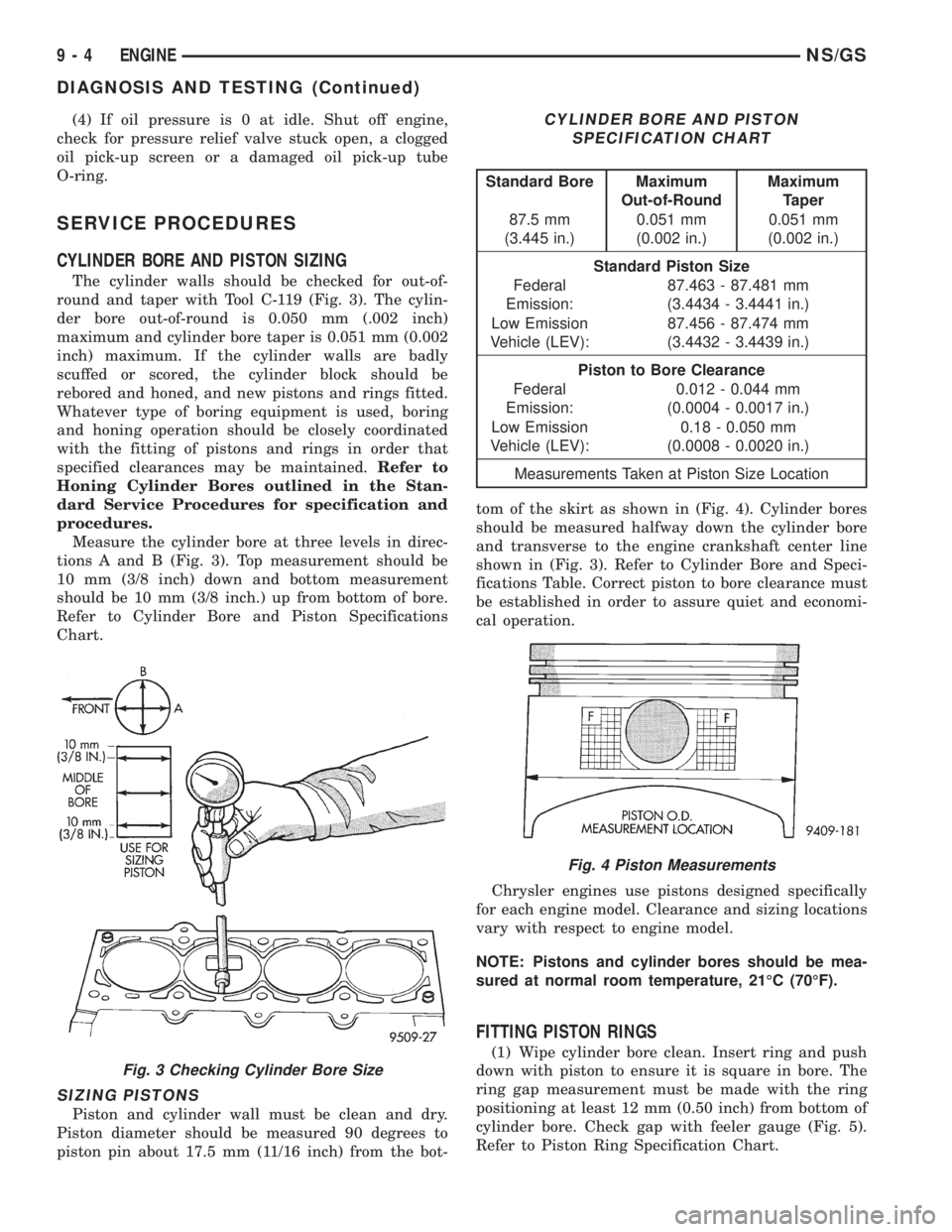

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 3). The cylin-

der bore out-of-round is 0.050 mm (.002 inch)

maximum and cylinder bore taper is 0.051 mm (0.002

inch) maximum. If the cylinder walls are badly

scuffed or scored, the cylinder block should be

rebored and honed, and new pistons and rings fitted.

Whatever type of boring equipment is used, boring

and honing operation should be closely coordinated

with the fitting of pistons and rings in order that

specified clearances may be maintained.Refer to

Honing Cylinder Bores outlined in the Stan-

dard Service Procedures for specification and

procedures.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 3). Top measurement should be

10 mm (3/8 inch) down and bottom measurement

should be 10 mm (3/8 inch.) up from bottom of bore.

Refer to Cylinder Bore and Piston Specifications

Chart.

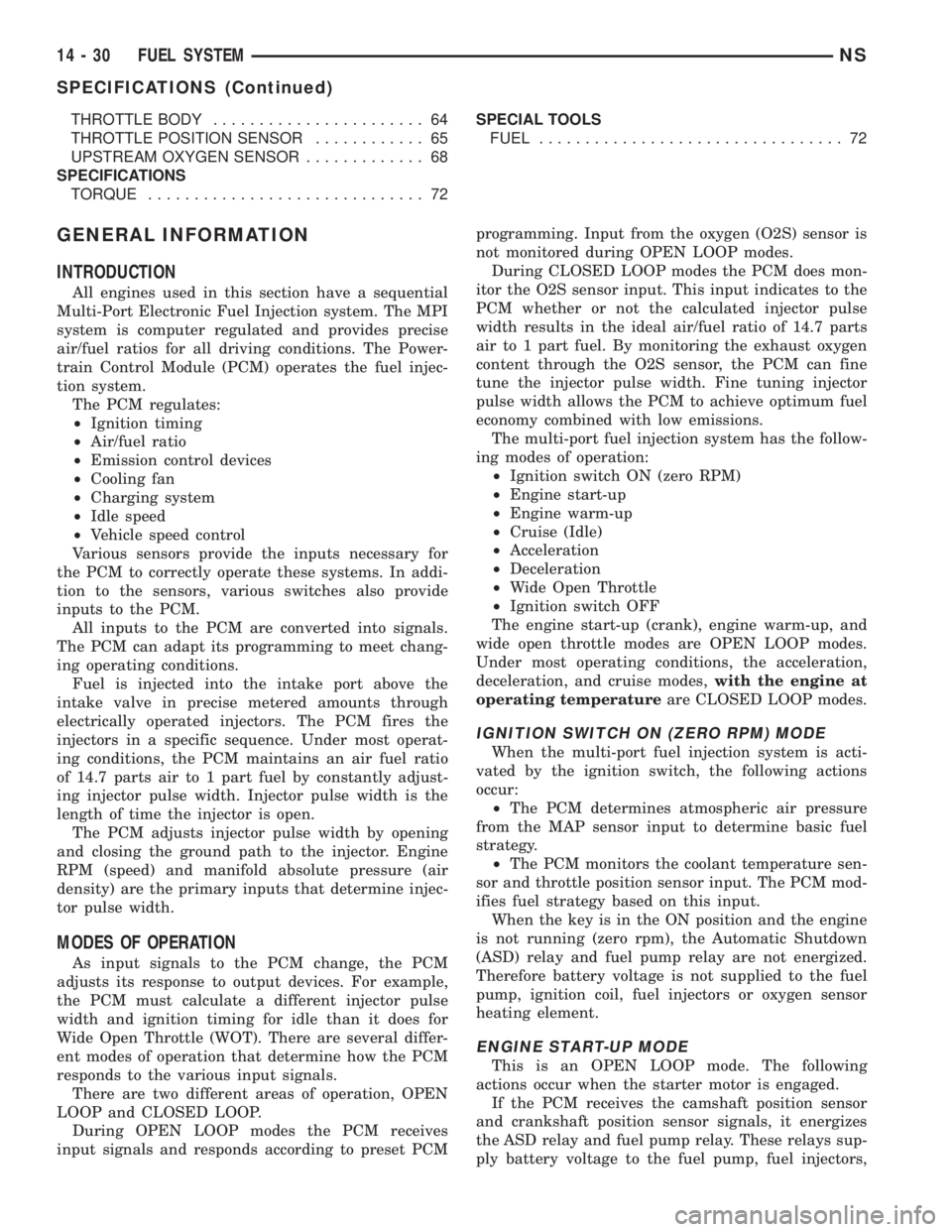

SIZING PISTONS

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin about 17.5 mm (11/16 inch) from the bot-tom of the skirt as shown in (Fig. 4). Cylinder bores

should be measured halfway down the cylinder bore

and transverse to the engine crankshaft center line

shown in (Fig. 3). Refer to Cylinder Bore and Speci-

fications Table. Correct piston to bore clearance must

be established in order to assure quiet and economi-

cal operation.

Chrysler engines use pistons designed specifically

for each engine model. Clearance and sizing locations

vary with respect to engine model.

NOTE: Pistons and cylinder bores should be mea-

sured at normal room temperature, 21ÉC (70ÉF).

FITTING PISTON RINGS

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 12 mm (0.50 inch) from bottom of

cylinder bore. Check gap with feeler gauge (Fig. 5).

Refer to Piston Ring Specification Chart.

Fig. 3 Checking Cylinder Bore Size

CYLINDER BORE AND PISTON

SPECIFICATION CHART

Standard Bore Maximum

Out-of-RoundMaximum

Taper

87.5 mm

(3.445 in.)0.051 mm

(0.002 in.)0.051 mm

(0.002 in.)

Standard Piston Size

Federal

Emission:87.463 - 87.481 mm

(3.4434 - 3.4441 in.)

Low Emission

Vehicle (LEV):87.456 - 87.474 mm

(3.4432 - 3.4439 in.)

Piston to Bore Clearance

Federal

Emission:0.012 - 0.044 mm

(0.0004 - 0.0017 in.)

Low Emission

Vehicle (LEV):0.18 - 0.050 mm

(0.0008 - 0.0020 in.)

Measurements Taken at Piston Size Location

Fig. 4 Piston Measurements

9 - 4 ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1324 of 1938

THROTTLE BODY....................... 64

THROTTLE POSITION SENSOR............ 65

UPSTREAM OXYGEN SENSOR............. 68

SPECIFICATIONS

TORQUE.............................. 72SPECIAL TOOLS

FUEL................................. 72

GENERAL INFORMATION

INTRODUCTION

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

All inputs to the PCM are converted into signals.

The PCM can adapt its programming to meet chang-

ing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are the primary inputs that determine injec-

tor pulse width.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCMprogramming. Input from the oxygen (O2S) sensor is

not monitored during OPEN LOOP modes.

During CLOSED LOOP modes the PCM does mon-

itor the O2S sensor input. This input indicates to the

PCM whether or not the calculated injector pulse

width results in the ideal air/fuel ratio of 14.7 parts

air to 1 part fuel. By monitoring the exhaust oxygen

content through the O2S sensor, the PCM can fine

tune the injector pulse width. Fine tuning injector

pulse width allows the PCM to achieve optimum fuel

economy combined with low emissions.

The multi-port fuel injection system has the follow-

ing modes of operation:

²Ignition switch ON (zero RPM)

²Engine start-up

²Engine warm-up

²Cruise (Idle)

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes.

Under most operating conditions, the acceleration,

deceleration, and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the multi-port fuel injection system is acti-

vated by the ignition switch, the following actions

occur:

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the coolant temperature sen-

sor and throttle position sensor input. The PCM mod-

ifies fuel strategy based on this input.

When the key is in the ON position and the engine

is not running (zero rpm), the Automatic Shutdown

(ASD) relay and fuel pump relay are not energized.

Therefore battery voltage is not supplied to the fuel

pump, ignition coil, fuel injectors or oxygen sensor

heating element.

ENGINE START-UP MODE

This is an OPEN LOOP mode. The following

actions occur when the starter motor is engaged.

If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the ASD relay and fuel pump relay. These relays sup-

ply battery voltage to the fuel pump, fuel injectors,

14 - 30 FUEL SYSTEMNS

SPECIFICATIONS (Continued)

Page 1325 of 1938

ignition coil, and oxygen sensor heating element. If

the PCM does not receive the camshaft position sen-

sor and crankshaft position sensor signals within

approximately one second, it de-energizes the ASD

relay and fuel pump relay.

The PCM energizes all injectors until it determines

crankshaft position from the camshaft position sen-

sor and crankshaft position sensor signals. The PCM

determines crankshaft position within 1 engine revo-

lution.

After determining crankshaft position, the PCM

begins energizing the injectors in sequence. The PCM

adjusts injector pulse width and controls injector syn-

chronization by turning the individual ground paths

to the injectors On and Off.

When the engine idles within664 RPM of its tar-

get RPM, the PCM compares current MAP sensor

value with the atmospheric pressure value received

during the Ignition Switch On (zero RPM) mode. If

the PCM does not detect a minimum difference

between the two values, it sets a MAP diagnostic

trouble code into memory.

Once the ASD and fuel pump relays have been

energized, the PCM:

²Determines injector pulse width based on engine

coolant temperature, MAP and the number of engine

revolutions since cranking was initiated.

²Monitors the engine coolant temperature sensor,

camshaft position sensor, crankshaft position sensor,

MAP sensor, and throttle position sensor to deter-

mine correct ignition timing.

ENGINE WARM-UP MODE

This is a OPEN LOOP mode. The following inputs

are received by the PCM:

²Engine coolant temperature

²Manifold absolute pressure

²Engine speed (crankshaft position sensor)

²Throttle position

²A/C switch

²Battery voltage

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts ignition timing and engine idle

speed. Engine idle speed is adjusted through the idle

air control motor.

CRUISE OR IDLE MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in throttle position or MAP

pressure as a demand for increased engine output

and vehicle acceleration. The PCM increases injector

pulse width in response to increased fuel demand.

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising speed the

following inputs are received by the PCM:²Engine coolant temperature

²Manifold absolute pressure

²Engine speed (crankshaft position sensor)

²Throttle position

²Exhaust gas oxygen content

²A/C control positions

²Battery voltage

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts engine idle speed and ignition

timing. The PCM adjusts the air/fuel ratio according

to the oxygen content in the exhaust gas.

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in throttle position or MAP

pressure as a demand for increased engine output

and vehicle acceleration. The PCM increases injector

pulse width in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²Engine coolant temperature

²Manifold absolute pressure

²Engine speed

²Throttle position

²Exhaust gas oxygen content

²A/C control positions

²Battery voltage

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. The PCM may reduce injector

pulse width or the number of injectors firing per

engine revolution. This helps maintain better control

of the air/fuel mixture (as sensed through the O2S

sensor).

WIDE OPEN THROTTLE (WOT) MODE

This is an OPEN LOOP mode. During WOT oper-

ation, the following inputs are received by the PCM:

²Engine coolant temperature

²Manifold absolute pressure

²Engine speed

²Throttle position

When the PCM senses WOT condition through the

Throttle Position Sensor (TPS) it will:

²De-energize the air conditioning relay. This dis-

ables the air conditioning system.

The exhaust gas oxygen content input is not

accepted by the PCM during WOT operation. The

PCM will adjust injector pulse width to supply a pre-

determined amount of additional fuel.

NSFUEL SYSTEM 14 - 31

GENERAL INFORMATION (Continued)

Page 1340 of 1938

Shutdown (ASD) RelayÐPCM Output in this section

for relay operation.

TORQUE CONVERTER CLUTCH SOLENOIDÐPCM

OUTPUT

Three-speed automatic transaxles use a torque con-

verter clutch solenoid. The PCM controls the engage-

ment of the torque converter clutch through the

solenoid. The torque converter clutch is engaged only

in direct drive mode. Refer to Group 21 for transaxle

information.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

The PCM supplies the malfunction indicator (check

engine) lamp on/off signal to the instrument panel

through the CCD Bus. The CCD Bus is a communi-

cations port. Various modules use the CCD Bus to

exchange information.

The Check Engine lamp comes on each time the

ignition key is turned ON and stays on for 3 seconds

as a bulb test.

The Malfunction Indicator Lamp (MIL) stays on

continuously, when the PCM has entered a Limp-In

mode or identified a failed emission component. Dur-

ing Limp-in Mode, the PCM attempts to keep the

system operational. The MIL signals the need for

immediate service. In limp-in mode, the PCM com-

pensates for the failure of certain components that

send incorrect signals. The PCM substitutes for the

incorrect signals with inputs from other sensors.

If the PCM detects active engine misfire severe

enough to cause catalyst damage, it flashes the MIL.

At the same time the PCM also sets a Diagnostic

Trouble Code (DTC).

For signals that can trigger the MIL (Check

Engine Lamp) refer to Group 25, On-Board

Dianostics.

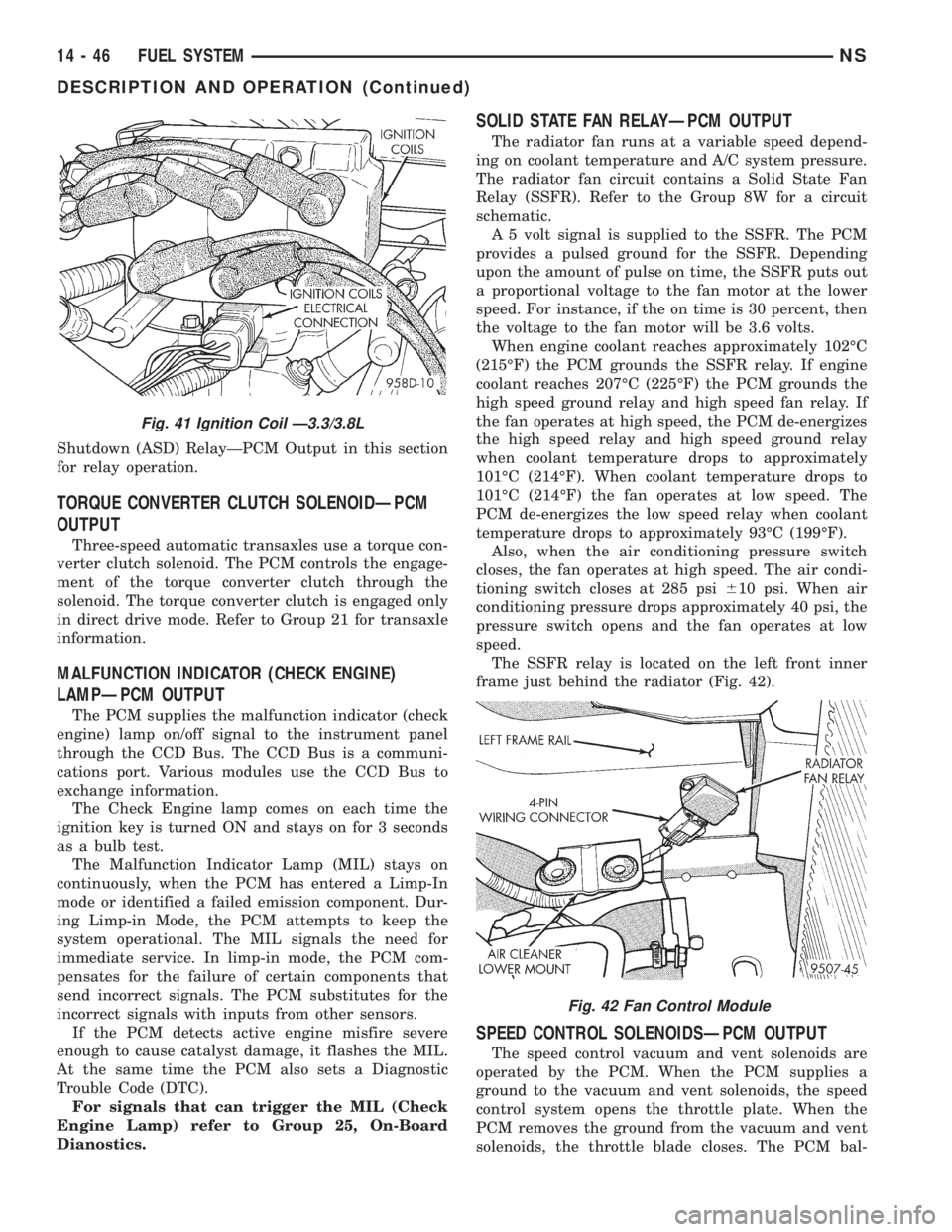

SOLID STATE FAN RELAYÐPCM OUTPUT

The radiator fan runs at a variable speed depend-

ing on coolant temperature and A/C system pressure.

The radiator fan circuit contains a Solid State Fan

Relay (SSFR). Refer to the Group 8W for a circuit

schematic.

A 5 volt signal is supplied to the SSFR. The PCM

provides a pulsed ground for the SSFR. Depending

upon the amount of pulse on time, the SSFR puts out

a proportional voltage to the fan motor at the lower

speed. For instance, if the on time is 30 percent, then

the voltage to the fan motor will be 3.6 volts.

When engine coolant reaches approximately 102ÉC

(215ÉF) the PCM grounds the SSFR relay. If engine

coolant reaches 207ÉC (225ÉF) the PCM grounds the

high speed ground relay and high speed fan relay. If

the fan operates at high speed, the PCM de-energizes

the high speed relay and high speed ground relay

when coolant temperature drops to approximately

101ÉC (214ÉF). When coolant temperature drops to

101ÉC (214ÉF) the fan operates at low speed. The

PCM de-energizes the low speed relay when coolant

temperature drops to approximately 93ÉC (199ÉF).

Also, when the air conditioning pressure switch

closes, the fan operates at high speed. The air condi-

tioning switch closes at 285 psi610 psi. When air

conditioning pressure drops approximately 40 psi, the

pressure switch opens and the fan operates at low

speed.

The SSFR relay is located on the left front inner

frame just behind the radiator (Fig. 42).

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a

ground to the vacuum and vent solenoids, the speed

control system opens the throttle plate. When the

PCM removes the ground from the vacuum and vent

solenoids, the throttle blade closes. The PCM bal-

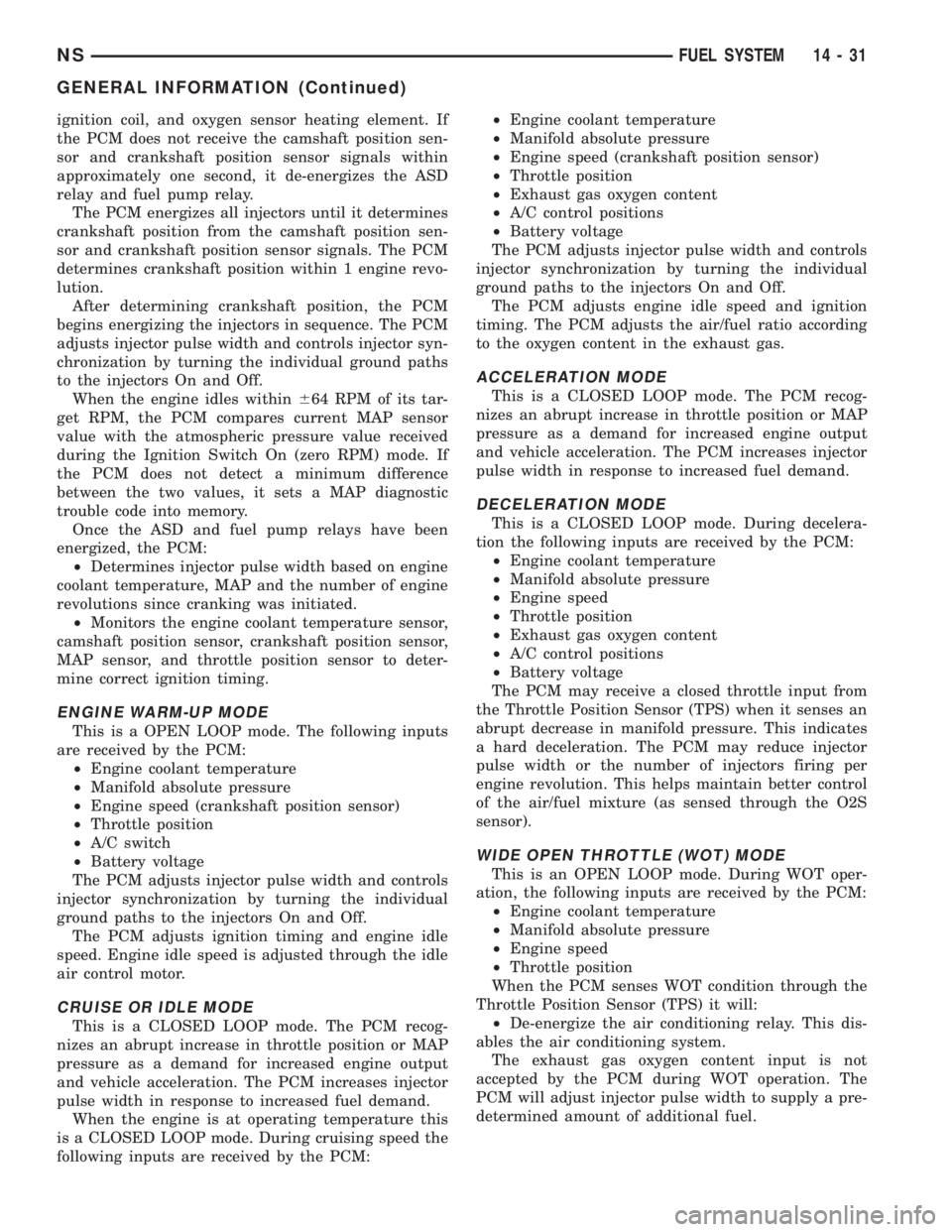

Fig. 41 Ignition Coil Ð3.3/3.8L

Fig. 42 Fan Control Module

14 - 46 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1381 of 1938

A defective fuel injection pump, defective fuel tim-

ing solenoid or misadjusted mechanical pump timing

can cause starting problems or prevent the engine

from revving up. It can also cause:

²Engine surge at idle

²Rough idle (warm engine)

²Low power

²Excessive fuel consumption

²Poor performance

²Low power

²Black smoke from the exhaust

²Blue or white fog like exhaust

²Incorrect idle or maximum speed

The electronically controlled fuel pump has no

mechanical governor like older mechanically con-

trolled fuel pumps. Do not remove the top cover of

the fuel pump, or the screws fastening the wiring

pigtail to the side of the pump.The warranty of

the injection pump and the engine may be void

if those seals have been removed or tampered

with.

FUEL SUPPLY RESTRICTIONS

LOW±PRESSURE LINES

Restricted or Plugged supply lines or fuel filter can

cause a timing fault that will cause the PCM to oper-

ate the engine in a ªLimp Homeº mode. See the

introduction of the Fuel Injection System in this

group for more information on the Limp Home mode.

Fuel supply line restrictions can cause starting prob-

lems and prevent the engine from revving up. The

starting problems include; low power and blue or

white fog like exhaust. Test all fuel supply lines for

restrictions or blockage. Flush or replace as neces-

sary. Bleed the fuel system of air once a fuel supply

line has been replaced. Refer to the Air Bleed Proce-

dure section of this group for procedures.

HIGH±PRESSURE LINES

Restricted (kinked or bent) high±pressure lines can

cause starting problems, poor engine performance

and black smoke from exhaust.

Examine all high±pressure lines for any damage.

Each radius on each high±pressure line must be

smooth and free of any bends or kinks.

Replace damaged, restricted or leaking high±pres-

sure fuel lines with the correct replacement line.

CAUTION: The high±pressure fuel lines must be

clamped securely in place in the holders. The lines

cannot contact each other or other components. Do

not attempt to weld high±pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high±pressure

fuel line is necessary.

FUEL SHUTDOWN SOLENOID TEST

Since diesel fuel injection does not use spark plugs

to start combustion, the only way to stop the engine

is to cut off the fuel supply. This is done with the

Fuel Shutdown Solenoid. If the engine cranks, but

refuses to start, it may be caused by a defective fuel

shutdown solenoid.

The fuel shutdown solenoid is not controlled

or operated by the PCM.Voltage to operate the

solenoid is supplied from the ignition (key) switch.

NOTE: Although the fuel shutdown solenoid is not

operated by the PCM, if the Fuel Shutdown Solenoid

has been disconnected, and the key turned on, the

PCM will sense that the solenoid is not in the circuit,

and will switch to a ªLimp Homeº mode. After recon-

necting the solenoid, the PCM will have to be reset

by clearing the codes with the DRBIII scan tool, or

disconnecting the vehicle's battery for several min-

utes. The DRBIII scan tool is the preferred method

for resetting the PCM. Refer to the 1998 GS 2.5L Die-

sel Powertrain Diagnostic Manual for procedure.

The fuel shutdown (shut±off) solenoid is used to

electrically shut off the diesel fuel supply to the high-

±pressure fuel injection pump. The solenoid is

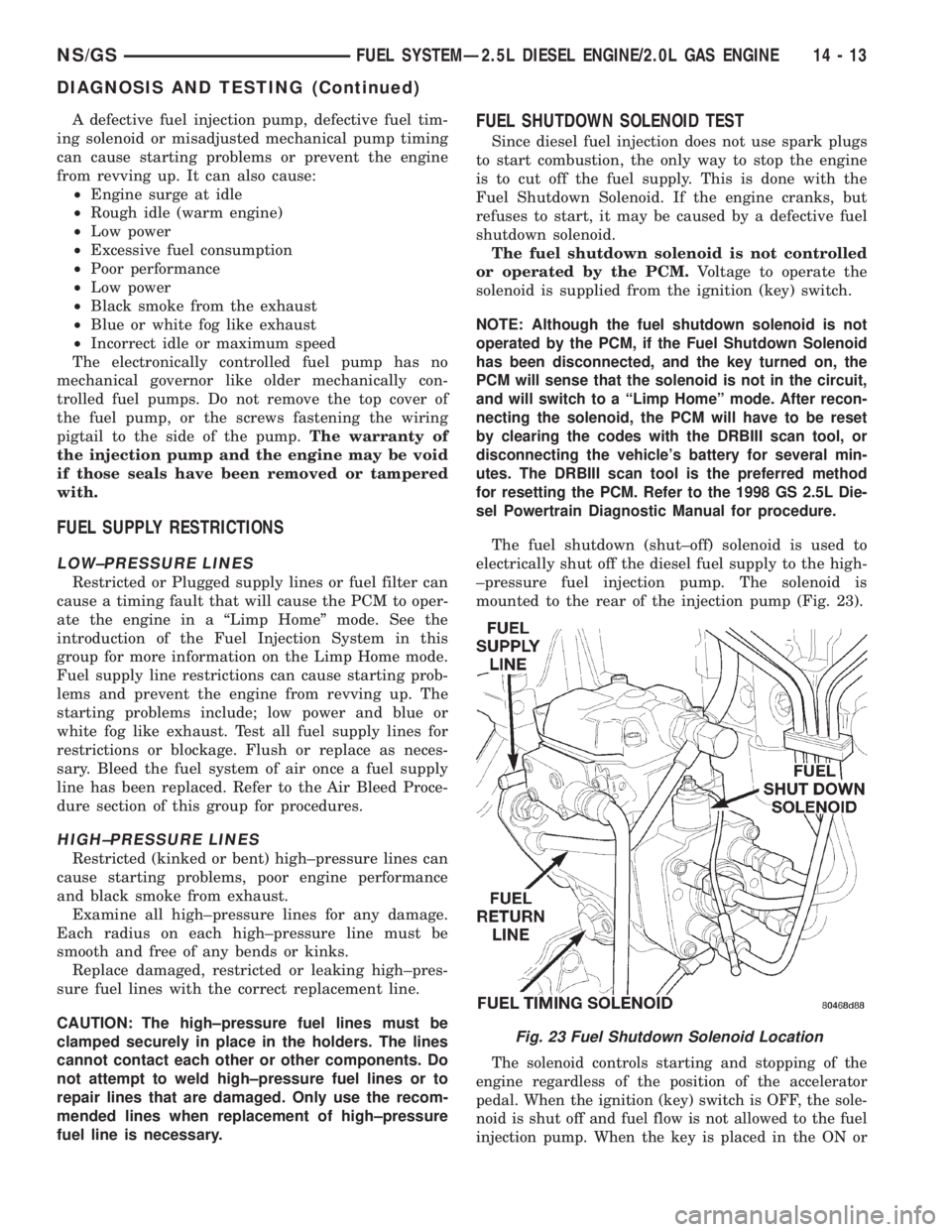

mounted to the rear of the injection pump (Fig. 23).

The solenoid controls starting and stopping of the

engine regardless of the position of the accelerator

pedal. When the ignition (key) switch is OFF, the sole-

noid is shut off and fuel flow is not allowed to the fuel

injection pump. When the key is placed in the ON or

Fig. 23 Fuel Shutdown Solenoid Location

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 13

DIAGNOSIS AND TESTING (Continued)

Page 1415 of 1938

AIR CONDITIONING (A/C) CONTROLSÐPCM

INPUTS

The A/C control system information applies to fac-

tory installed air conditioning units.

A/C REQUEST SIGNAL:When either the A/C or

Defrost mode has been selected and the A/C low and

high±pressure switches are closed, an input signal is

sent to the powertrain control module (PCM). The

PCM uses this input to cycle the A/C compressor

through the A/C relay.

If the A/C low or high±pressure switch opens, the

PCM will not receive an A/C request signal. The

PCM will then remove the ground from the A/C relay.

This will deactivate the A/C compressor clutch. Also,

if the engine coolant reaches a temperature outside

normal of its normal range, or it overheats, the PCM

will deactivate the A/C clutch.

BRAKE SWITCHÐPCM INPUT

When the brake light switch is activated, the PCM

receives an input indicating that the brakes are

being applied. After receiving this input, the PCM is

used to control the speed control system. There is a

Primary and a Secondary brake switch. The Second-

ary brake switch is closed until the brake pedal is

pressed.

DATA LINK CONNECTORÐPCM INPUT AND

OUTPUT

The 16±way data link connector (diagnostic scan

tool connector) links the Diagnostic Readout Box(DRB) scan tool with the PCM. The data link connec-

tor is located under the instrument panel near the

bottom of steering column (Fig. 7).

VEHICLE SPEED SENSORÐPCM INPUT

The vehicle speed sensor (Fig. 8) is located in the

extension housing of the transmission. The sensor

input is used by the PCM to determine vehicle speed

and distance traveled.

Fig. 6 Speed Sensor Operation

Fig. 7 Data Link Connector Location

Fig. 8 Vehicle Speed SensorÐTypical

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 47

DESCRIPTION AND OPERATION (Continued)

Page 1421 of 1938

²When the PCM energizes the Diesel PCM and

other relays, terminal 87 connects to terminal 30.

This is the On position. Terminal 87 supplies voltage

to the rest of the circuit.

TESTING

The following procedure applies to the Diesel PCM

and other relays.

(1) Remove relay from connector before testing.

(2) With the relay removed from the vehicle, use

an ohmmeter to check the resistance between termi-

nals 85 and 86. The resistance should be between 75

65 ohms.

(3) Connect the ohmmeter between terminals 30

and 87A. The ohmmeter should show continuity

between terminals 30 and 87A.

(4) Connect the ohmmeter between terminals 87

and 30. The ohmmeter should not show continuity at

this time.

(5) Connect one end of a jumper wire (16 gauge or

smaller) to relay terminal 85. Connect the other end

of the jumper wire to the ground side of a 12 volt

power source.

(6) Connect one end of another jumper wire (16

gauge or smaller) to the power side of the 12 volt

power source.Do not attach the other end of the

jumper wire to the relay at this time.

WARNING: DO NOT ALLOW OHMMETER TO CON-

TACT TERMINALS 85 OR 86 DURING THIS TEST.

(7) Attach the other end of the jumper wire to

relay terminal 86. This activates the relay. The ohm-meter should now show continuity between relay ter-

minals 87 and 30. The ohmmeter should not show

continuity between relay terminals 87A and 30.

(8) Disconnect jumper wires.

(9) Replace the relay if it did not pass the continu-

ity and resistance tests. If the relay passed the tests,

it operates properly. Check the remainder of the Die-

sel PCM and other relay circuits. Refer to group 8W,

Wiring Diagrams.

BOOST PRESSURE SENSOR

If the boost pressure sensor fails, the PCM records

a DTC into memory and continues to operate the

engine in one of the three ªlimp-inº modes. When the

PCM is operating in this mode, a loss of power will

be present, as if the turbocharger was not operating.

The best method for diagnosing faults with the boost

pressure sensor is with the DRB III scan tool.

Diagnostic Trouble Codes:Refer to On-Board

Diagnostics in Group 25, Emission Control System

for a list of Diagnostic Trouble Codes (DTC's) for cer-

tain fuel system components.

VEHICLE SPEED SENSOR TEST

To perform a test of the sensor and its related cir-

cuitry, refer to DRB scan tool.

Diagnostic Trouble Codes:Refer to On-Board

Diagnostics in Group 25, Emission Control System

for a list of Diagnostic Trouble Codes (DTC's) for cer-

tain fuel system components.

DIAGNOSTIC TROUBLE CODES

For a list of Diagnostic Trouble Codes (DTC's),

refer to Group 25, Emission Control System for infor-

mation. See On-Board Diagnostics.

REMOVAL AND INSTALLATION

DIESEL PCM RELAY

The Diesel PCM relay is located in the PDC. For

the location of the relay within the PDC, refer to

label on PDC cover.

A/C CLUTCH RELAY

The A/C clutch relay is located in the PDC. For the

location of the relay within the PDC, refer to label on

PDC cover.

ENGINE SPEED SENSOR

The engine speed sensor is mounted to the trans-

mission bellhousing at the rear of the engine block

(Fig. 18).

REMOVAL

(1) Disconnect the harness (on the sensor) from

the main electrical harness.

Fig. 17 Diesel PCM and Other Relay Terminals

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 53

DIAGNOSIS AND TESTING (Continued)

Page 1547 of 1938

CAUTION: Some clutch packs appear similar, but

they are not the same. Do not interchange clutch

components, as they might fail.

HYDRAULICS

The hydraulics of the transaxle provide:

²Manual shift lever select function

²Main line pressure regulation

²Torque converter and cooler flow control

Oil flow to the friction elements is controlled

directly by four solenoid valves. The hydraulics also

include a unique logic- controlled solenoid torque con-

verter clutch control valve. This valve locks out the

1st gear reaction element with the application of 2nd,

direct, or overdrive gear elements. It also redirects

the 1st gear solenoid output so that it can control

torque converter clutch operation. To regain access to

1st gear, a sequence of commands must be used to

move the solenoid TCC control valve. This precludes

any application of the 1st gear reaction element with

other elements applied. It also allows one solenoid to

control two friction elements.

Small, high-rate accumulators are provided in each

controlled friction element circuit. These serve to

absorb the pressure responses, and allow the controls

to read and respond to changes that are occurring.

SOLENOIDS

The solenoid valves perform most control functions,

these valves must be extremely durable and tolerant

of dirt. For that reason hardened-steel poppet and

ball valves are used. These are free from any close

operating clearances. The solenoids operate the

valves directly without any intermediate element.

Direct operation means that these units must have

very high output. They must close against the size-

able flow areas and high line pressures. Fast

response is also required to meet the control require-

ments.

Two of the solenoids are normally-venting and two

are normally-applying; this was done to provide a

default mode of operation. With no electrical power,

the transmission provides 2nd gear in (OD), (3), or

(L) shift lever positions. All other transmission lever

positions will operate normally. The choice of 2nd

gear was made to provide adequate breakaway per-

formance while still accommodating highway speeds.

SENSORS

There are three pressure switches to identify sole-

noid application. There are two speed sensors to read

input (torque converter turbine) and output (parking

sprag) speeds. There is also a transmission range

sensor to indicate the manual shift lever position.

The pressure switches are incorporated in an assem-

bly with the solenoids. Engine speed, throttle posi-tion, temperature, etc., are also observed. Some of

these signals are read directly from the engine con-

trol sensors; others are read from a multiplex circuit

with the powertrain control module.

ELECTRONICS

The 41TE Transmission Control Module (TCM) is

located underhood in a potted, die-cast aluminum

housing. The module used is a new controller called

EATX III. The TCM has a sealed, 60-way connector.

ADAPTIVE CONTROLS

These controls function by reading the input and

output speeds over 140 times a second and respond-

ing to each new reading. This provides the precise

and sophisticated friction element control needed to

make smooth clutch-to-clutch shifts for all gear

changes. The use of overrunning clutches or other

shift quality aids are not required. As with most

automatic transaxles, all shifts involve releasing one

element and applying a different element. In simpli-

fied terms, the upshift logic allows the releasing ele-

ment to slip backwards slightly. This ensures that it

does not have excess capacity. The apply element is

filled until it begins to make the speed change to the

higher gear. The apply pressure is then controlled to

maintain the desired rate of speed change. This con-

tinues until the shift is made. The key to providing

excellent shift quality is precision. For example, the

release element for upshifts is allowed to slip back-

wards slightly. The amount of that slip is typically

less than a total of 20 degrees. To achieve that pre-

cision, the TCM learns the traits of the transaxle

that it is controlling. It learns the release rate of the

releasing element and the apply time of the applying

element. It also learns the rate at which the apply

element builds pressure sufficient to begin making

the speed change. This method achieves more preci-

sion than would be possible with exacting tolerances.

It can also adapt to any changes that occur with age

or environment.

For kickdown shifts, the control logic allows the

releasing element to slip. Then controls the rate at

which the input (and engine) accelerate. When the

lower gear speed is achieved, the releasing element

reapplies to maintain that speed until the apply ele-

ment is filled. This provides quick response since the

engine begins to accelerate immediately. This also

provides a smooth torque exchange since the release

element can control the rate of torque increase. This

control can make any powertrain feel more respon-

sive without increasing harshness.

Adaptive controls respond to input speed changes.

They compensate for changes in engine or friction

element torque and provide good, consistent shift

quality for the life of the transaxle.

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 73

DESCRIPTION AND OPERATION (Continued)

Page 1658 of 1938

GENERAL INFORMATION

A-598 MANUAL TRANSAXLE

Safety goggles should be worn at all times

when working on these transaxles.The A-598

manual transaxle uses SAE 5W-30 engine oil, meet-

ing SG and/or SG-CD qualifications, as the factory

fill lubricant. SAE G5 10W-40 engine oil is a suitable

service fill alternative.

This transaxle combines gear reduction, ratio selec-

tion, and differential functions in one unit. It is

housed in a die-cast aluminum case.

A-558 MANUAL TRANSAXLEÐRHD VEHICLES

Safety goggles should be worn at all times

when working on these transaxles.The A-558

manual transaxle uses SAE 5W-30 engine oil, meet-

ing SG and/or SG-CD qualifications, as the factory

fill lubricant. SAE G5 10W-40 engine oil is a suitable

service fill alternative.

This transaxle combines gear reduction, ratio selec-

tion, and differential functions in one unit. It is

housed in a die-cast aluminum case.

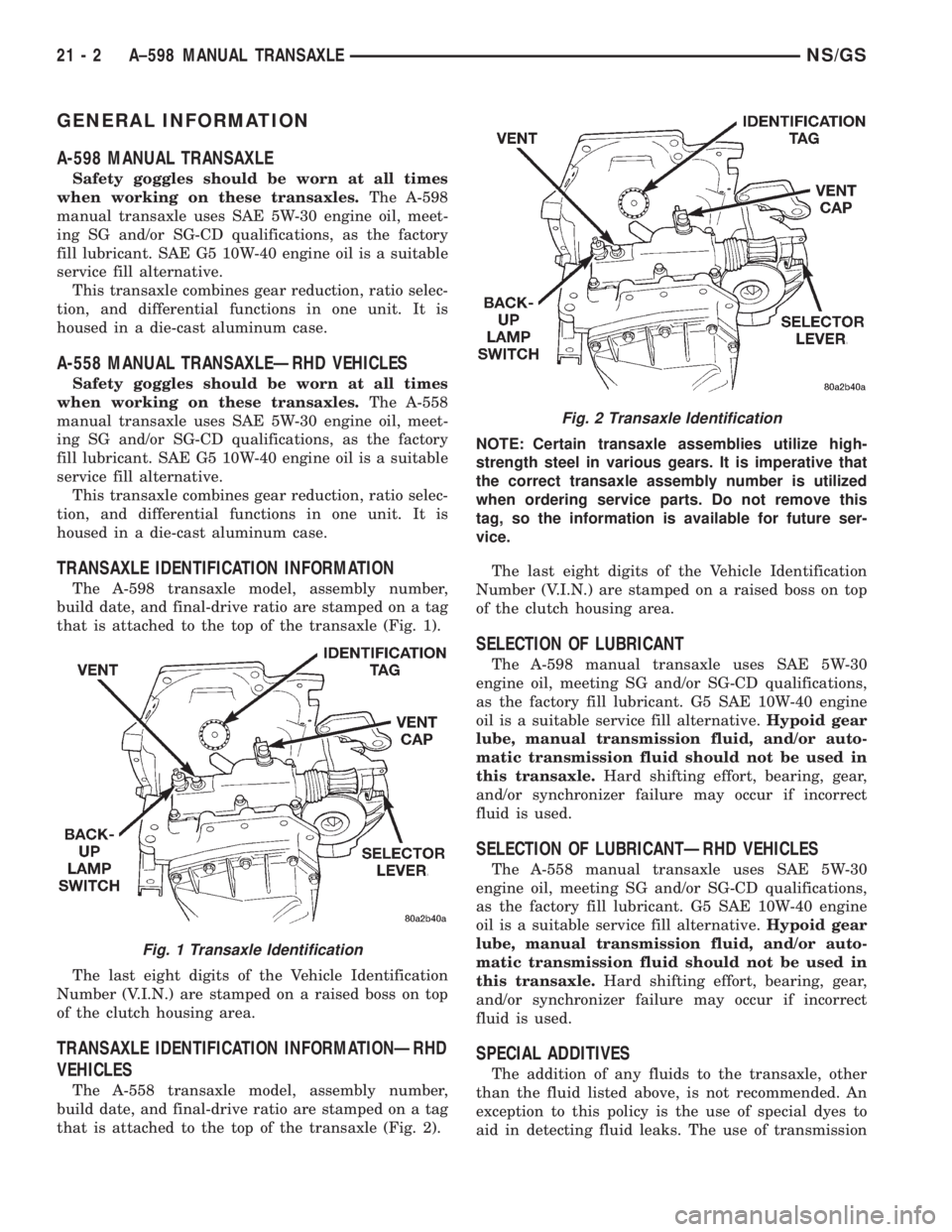

TRANSAXLE IDENTIFICATION INFORMATION

The A-598 transaxle model, assembly number,

build date, and final-drive ratio are stamped on a tag

that is attached to the top of the transaxle (Fig. 1).

The last eight digits of the Vehicle Identification

Number (V.I.N.) are stamped on a raised boss on top

of the clutch housing area.

TRANSAXLE IDENTIFICATION INFORMATIONÐRHD

VEHICLES

The A-558 transaxle model, assembly number,

build date, and final-drive ratio are stamped on a tag

that is attached to the top of the transaxle (Fig. 2).NOTE: Certain transaxle assemblies utilize high-

strength steel in various gears. It is imperative that

the correct transaxle assembly number is utilized

when ordering service parts. Do not remove this

tag, so the information is available for future ser-

vice.

The last eight digits of the Vehicle Identification

Number (V.I.N.) are stamped on a raised boss on top

of the clutch housing area.

SELECTION OF LUBRICANT

The A-598 manual transaxle uses SAE 5W-30

engine oil, meeting SG and/or SG-CD qualifications,

as the factory fill lubricant. G5 SAE 10W-40 engine

oil is a suitable service fill alternative.Hypoid gear

lube, manual transmission fluid, and/or auto-

matic transmission fluid should not be used in

this transaxle.Hard shifting effort, bearing, gear,

and/or synchronizer failure may occur if incorrect

fluid is used.

SELECTION OF LUBRICANTÐRHD VEHICLES

The A-558 manual transaxle uses SAE 5W-30

engine oil, meeting SG and/or SG-CD qualifications,

as the factory fill lubricant. G5 SAE 10W-40 engine

oil is a suitable service fill alternative.Hypoid gear

lube, manual transmission fluid, and/or auto-

matic transmission fluid should not be used in

this transaxle.Hard shifting effort, bearing, gear,

and/or synchronizer failure may occur if incorrect

fluid is used.

SPECIAL ADDITIVES

The addition of any fluids to the transaxle, other

than the fluid listed above, is not recommended. An

exception to this policy is the use of special dyes to

aid in detecting fluid leaks. The use of transmission

Fig. 1 Transaxle Identification

Fig. 2 Transaxle Identification

21 - 2 A±598 MANUAL TRANSAXLENS/GS

Page 1659 of 1938

sealers should be avoided, since they may adversely

affect seals.

SPECIAL ADDITIVESÐRHD VEHICLES

The addition of any fluids to the transaxle, other

than the fluid listed above, is not recommended. An

exception to this policy is the use of special dyes to

aid in detecting fluid leaks. The use of transmission

sealers should be avoided, since they may adversely

affect seals.

GEAR RATIOS

Gear ratios for the 2.4L gasoline engine and 2.5L

Turbo Diesel MTX are as follows:

²1stÐ3.36

²2ndÐ1.90

²3rdÐ1.28

²4thÐ0.92

²5thÐ0.71

²ReverseÐ3.17

Final drive ratio of 3.88 was selected for maximum

performance. All forward gears are synchronized.

Gear ratios for the 2.0L GAS MTX are as follows:

²1stÐ3.69

²2ndÐ2.24

²3rdÐ1.45

²4thÐ1.03

²5thÐ0.81

²ReverseÐ3.17

Final drive ratio of 4.08 was selected for maximum

performance. All forward gears are synchronized.

GEAR RATIOSÐRHD VEHICLES

Gear ratios for the 2.0L GAS MTX are as follows:

²1stÐ3.69

²2ndÐ2.24

²3rdÐ1.45

²4thÐ0.1.03

²5thÐ0.81

²ReverseÐ3.17

Final drive ratio of 4.08 was selected for maximum

performance. All forward gears are synchronized.

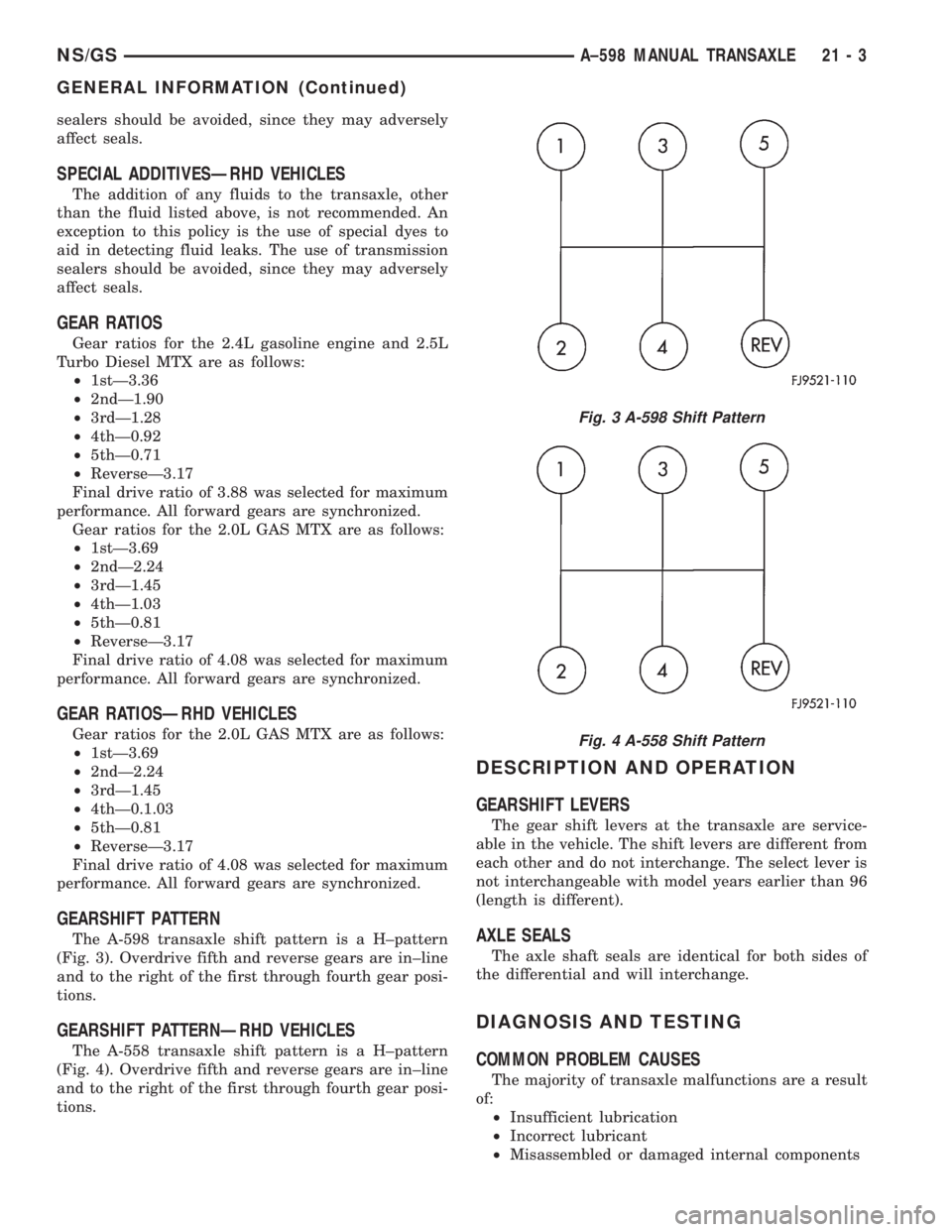

GEARSHIFT PATTERN

The A-598 transaxle shift pattern is a H±pattern

(Fig. 3). Overdrive fifth and reverse gears are in±line

and to the right of the first through fourth gear posi-

tions.

GEARSHIFT PATTERNÐRHD VEHICLES

The A-558 transaxle shift pattern is a H±pattern

(Fig. 4). Overdrive fifth and reverse gears are in±line

and to the right of the first through fourth gear posi-

tions.

DESCRIPTION AND OPERATION

GEARSHIFT LEVERS

The gear shift levers at the transaxle are service-

able in the vehicle. The shift levers are different from

each other and do not interchange. The select lever is

not interchangeable with model years earlier than 96

(length is different).

AXLE SEALS

The axle shaft seals are identical for both sides of

the differential and will interchange.

DIAGNOSIS AND TESTING

COMMON PROBLEM CAUSES

The majority of transaxle malfunctions are a result

of:

²Insufficient lubrication

²Incorrect lubricant

²Misassembled or damaged internal components

Fig. 3 A-598 Shift Pattern

Fig. 4 A-558 Shift Pattern

NS/GSA±598 MANUAL TRANSAXLE 21 - 3

GENERAL INFORMATION (Continued)