ECO mode CHRYSLER VOYAGER 1996 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1906 of 1938

cranking. Whenever the Powertrain Control Module

(PCM) sets a Diagnostic Trouble Code (DTC) that

affects vehicle emissions, it illuminates the MIL. If a

problem is detected, the PCM sends a message over

the CCD Bus to the instrument cluster to illuminate

the lamp. The PCM illuminates the MIL only for

DTC's that affect vehicle emissions. The MIL stays

on continuously when the PCM has entered a

Limp-In mode or identified a failed emission compo-

nent or system. The MIL remains on until the DTC

is erased. Refer to the Diagnostic Trouble Code

charts in this group for emission related codes.

Also, the MIL either flashes or illuminates contin-

uously when the PCM detects active engine misfire.

Refer to Misfire Monitoring in this section.

Additionally, the PCM may reset (turn off) the MIL

when one of the following occur:

²PCM does not detect the malfunction for 3 con-

secutive trips (except misfire and fuel system moni-

tors).

²PCM does not detect a malfunction while per-

forming three successive engine misfire or fuel sys-

tem tests. The PCM performs these tests while the

engine is operating within6375 RPM of and within

10 % of the load of the operating condition at which

the malfunction was first detected.

STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRB scan tool to the data link connec-

tor and access the State Display screen. Then access

Inputs and Outputs. The following list contains the

PCM system functions accessible through the Inputs

and Outputs screen.

Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

S/C Vent Solenoid

Actual S/C Vent Sol.

S/C Vacuum Solenoid

Actual S/C Vacuum Sol.

S/C Cancel

S/C Last Cutout

S/C Working Status

S/C Denied Status

A/C Clutch Relay

Actual A/C Clutch Relay

EGR Solenoid

Actual EGR Sol.

Automatic Shutdown Relay

Actual Automatic Shutdown Relay

Automatic Shutdown Relay Sense

Radiator Fan Control Module

Actual Radiator Fan Control Module

Duty Cycle EVAP Purge Solenoid

Actual EVAP Purge Sol.

Torque Converter Clutch Solenoid

Power Steering Switch

Closed Loop State

Current CMP Edge

Current CKP State

Current Sync State

Fuel Pump Relay

Actual Fuel Pump Relay

Ignition Sense (A21)

Malfunction Lamp

Limp-in Reason

STATE DISPLAY SENSORS

Connect the DRB scan tool to the vehicle and

access the State Display screen. Then access Sensor

Display. The following list contains the PCM system

functions accessible through the Sensor Display

screen.

Battery Temperature

Engine Coolant Temperature

Engine Coolant Temp Sensor

Throttle Position Volts

Minimum Throttle

Knock Sensor Volts

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

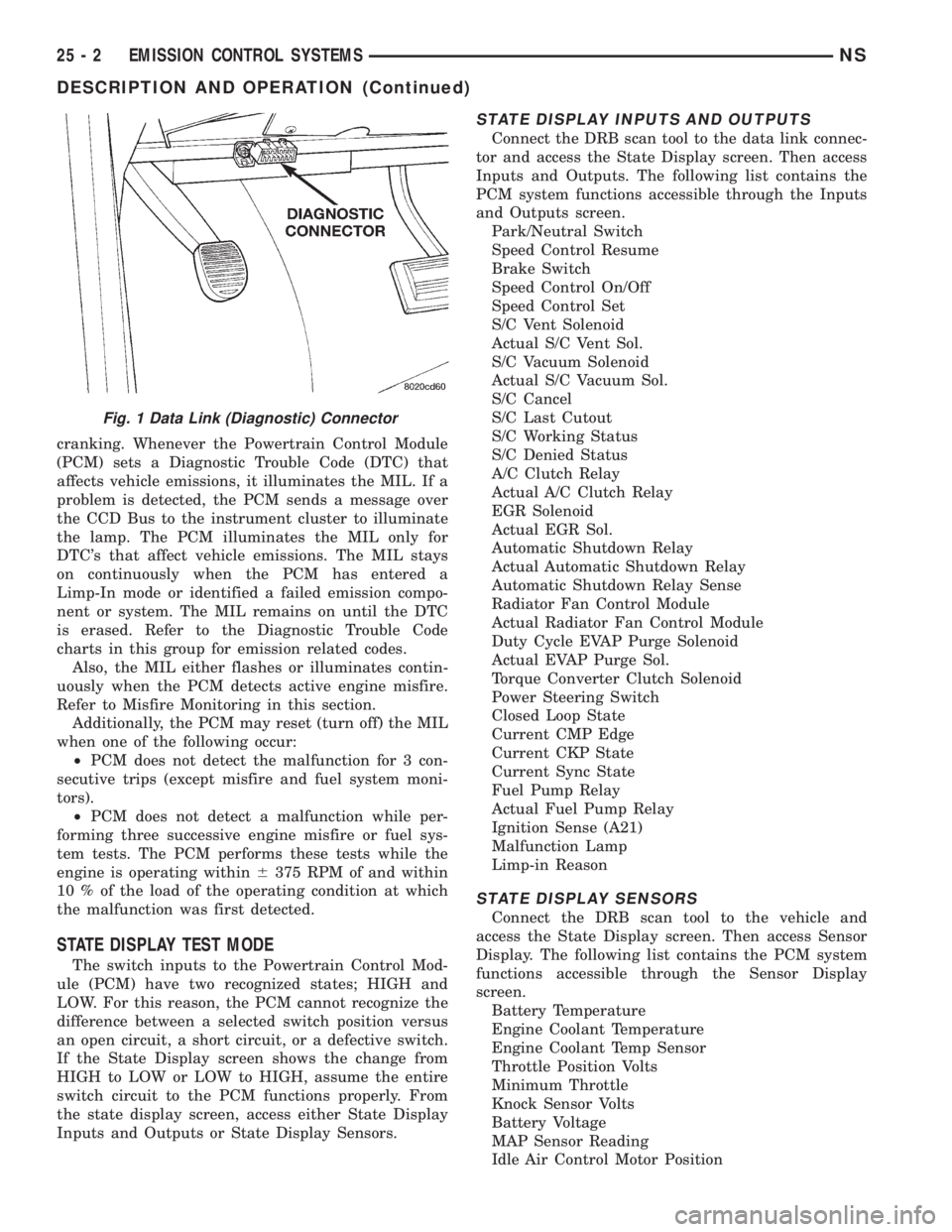

Fig. 1 Data Link (Diagnostic) Connector

25 - 2 EMISSION CONTROL SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)

Page 1907 of 1938

Adaptive Fuel Factor

Barometric Pressure

Engine Speed

Module Spark Advance

Speed Control Target

Intake Air Temp Degrees

Intake Air Temp Volts

Charging System Goal

Theft Alarm Status

Map Sensor Voltage

Vehicle Speed

Throttle Opening (percentage)

TPS Calculated

Cam Timing Position

Target Idle

Time From Start To Run

Run Time At Stall

Injector Pulse-width

Upstream O2S Volts

Downstream O2S Volts

Closed Loop Timer

Short Term Adaptive

Current Adaptive Cell

Adaptive Memory Cell 0

Adaptive Memory Cell 1

Adaptive Memory Cell 2

Adaptive Memory Cell 3

Adaptive Memory Cell 4

Adaptive Memory Cell 5

Adaptive Memory Cell 6

Adaptive Memory Cell 7

Adaptive Memory Cell 8

Adaptive Memory Cell 9

Adaptive Memory Cell 10

Adaptive Memory Cell 11

Adaptive Memory Cell 12

Adaptive Memory Cell 13

Adaptive Memory Cell 14

Adaptive Memory Cell 15

Purge Free Idle Cell

Purge Free Cell 2 (corresponds to memory cell 2)

Purge Free Cell 3 (corresponds to memory cell 5)

Target IAC Steps

Retard Cylinder (1)

Retard Cylinder (2)

Retard Cylinder (3)

Retard Cylinder (4)

Retard Cylinder (5)

Retard Cylinder (6)CIRCUIT ACTUATION TEST MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly.

DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.

The preferred and most accurate method of retriev-

ing a DTC is by using the DRB scan tool. The scan

tool supplies detailed diagnostic information which

can be used to more accurately diagnose causes for a

DTC.

Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

NSEMISSION CONTROL SYSTEMS 25 - 3

DESCRIPTION AND OPERATION (Continued)

Page 1915 of 1938

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum

and 1600 rpm.

Any component that has an associated limp in will

set a fault after 1 trip with the malfunction present.

Refer to the Diagnostic Trouble Codes Description

Charts in this section and the appropriate Power-

train Diagnostic Procedure Manual for diagnostic

procedures.

NON-MONITORED CIRCUITS

The PCM does not monitor all circuits, systems

and conditions that could have malfunctions causing

driveability problems. However, problems with these

systems may cause the PCM to store diagnostic trou-

ble codes for other systems or components. For exam-

ple, a fuel pressure problem will not register a fault

directly, but could cause a rich/lean condition or mis-

fire. This could cause the PCM to store an oxygen

sensor or misfire diagnostic trouble code.

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR or Fuel

system fault or O2S.

FUEL INJECTOR MECHANICAL

MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times, also

during diagnostic.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for

the device. If the input voltage is not within limits

and other criteria are met, the PCM stores a diagnos-

tic trouble code in memory. Other diagnostic trouble

code criteria might include engine RPM limits or

input voltages from other sensors or switches that

must be present before verifying a diagnostic trouble

code condition.

NSEMISSION CONTROL SYSTEMS 25 - 11

DESCRIPTION AND OPERATION (Continued)

Page 1918 of 1938

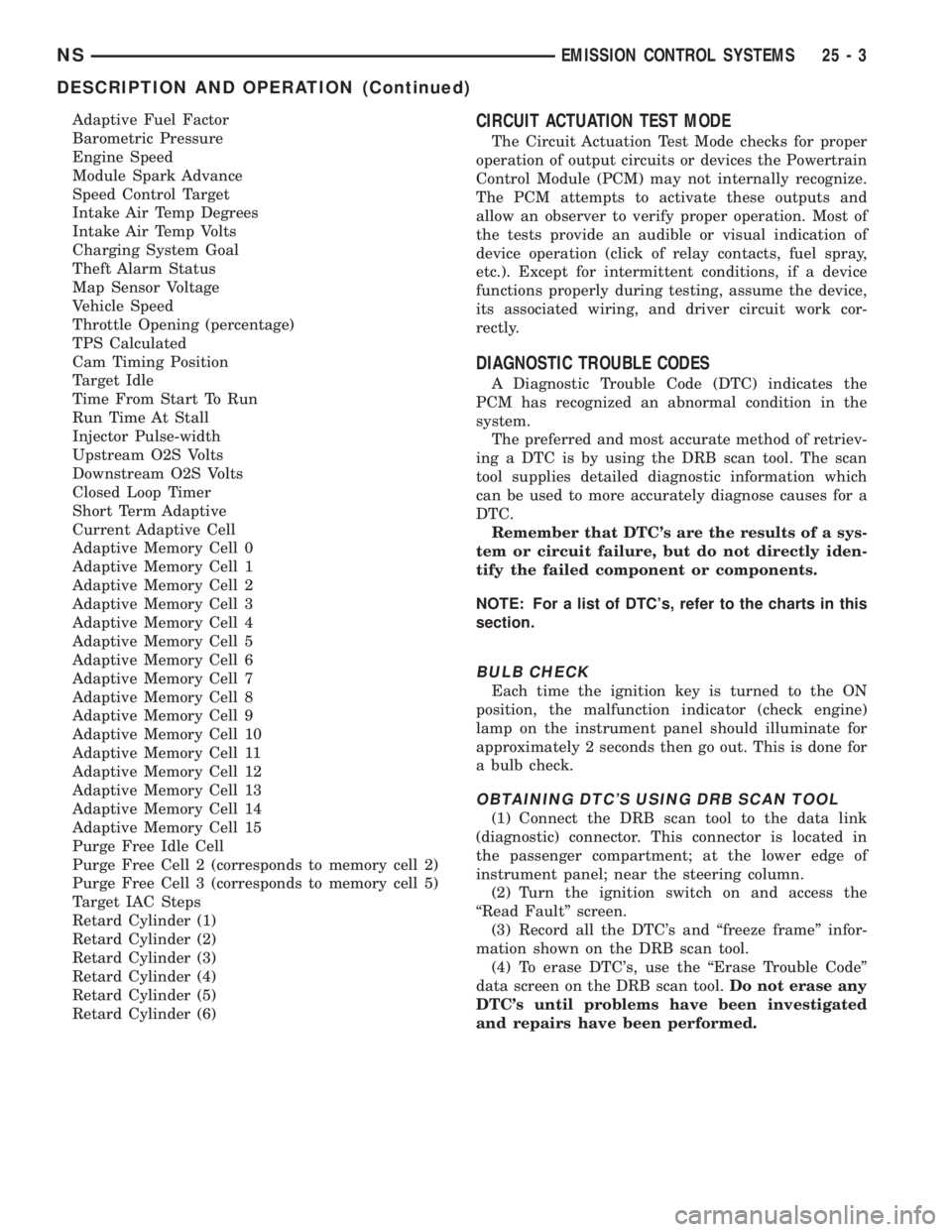

The proportional purge solenoid operates at a fre-

quency of 200hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid and then adjusts

that current to achieve the desired purge flow. The

proportional purge solenoid controls the purge rate of

fuel vapors from the vapor canister and fuel tank to

the engine intake manifold.

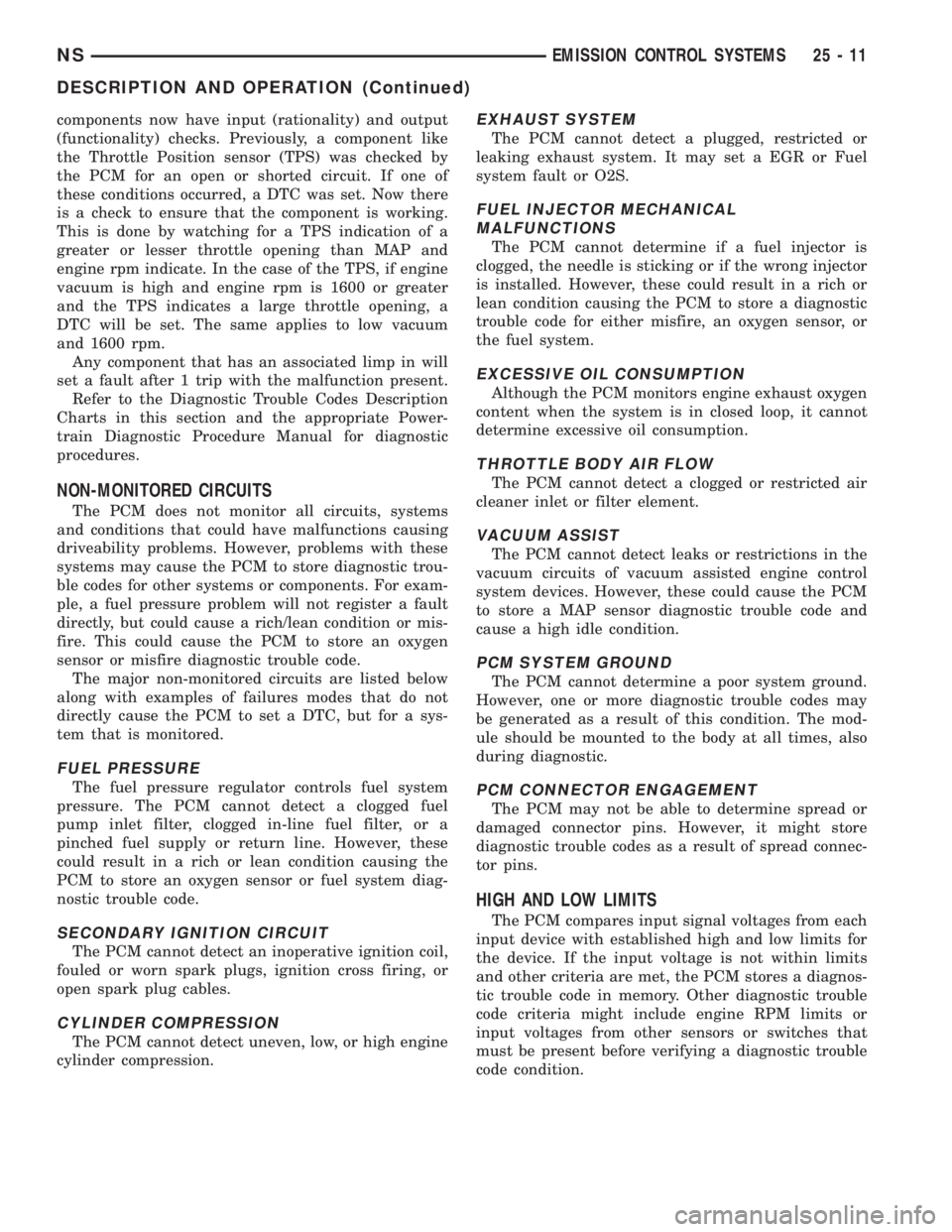

PRESSURE-VACUUM FILLER CAP

CAUTION: Remove the fuel filler cap to relieve fuel

tank pressure. The cap must be removed prior to

disconnecting any fuel system component or ser-

vicing the fuel tank.

A pressure-vacuum relief cap seals the fuel tank

(Fig. 3). Tightening the cap on the fuel filler tube

forms a seal between them. The relief valves in the

cap are a safety feature. They prevent possible exces-

sive pressure or vacuum in the tank. Excessive fuel

tank pressure could be caused by a malfunction in

the system or damage to the vent lines.

The seal between the cap and filler tube breaks

when the cap is removed and relieves fuel tank pres-

sure.

If the filler cap needs replacement, only use the

correct part.

LEAK DETECTION PUMP

The leak detection pump is a device used to detect

a leak in the evaporative system.

The pump contains a 3 port solenoid, a pump that

contains a switch, a spring loaded canister vent valve

seal, 2 check valves and a spring/diaphragm.

Immediately after a cold start, when the engine

temperature is between 40ÉF and 86ÉF, the 3 portsolenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non-test test conditions,

the vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling. This is due to the operation of the 3

port solenoid which prevents the diaphragm assem-

bly from reaching full travel. After the brief initial-

ization period, the solenoid is de-energized, allowing

atmospheric pressure to enter the pump cavity. This

permits the spring to drive the diaphragm which

forces air out of the pump cavity and into the vent

system. When the solenoid is energized and de-ener-

gized, the cycle is repeated creating flow in typical

diaphragm pump fashion. The pump is controlled in

2 modes:

PUMP MODE:The pump is cycled at a fixed rate

to achieve a rapid pressure build in order to shorten

the overall test time.

TEST MODE:The solenoid is energized with a

fixed duration pulse. Subsequent fixed pulses occur

when the diaphragm reaches the switch closure

point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5 inches

of water.

When the pump starts, the cycle rate is quite high.

As the system becomes pressurized, pump rate drops.

If there is no leak, the pump will quit. If there is a

leak, the test is terminated at the end of the test

mode.

If there is no leak, the purge monitor is run. If the

cycle rate increases due to the flow through the

purge system, the test is passed and the diagnostic is

complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

Fig. 2 Proportional Purge Solenoid

Fig. 3 Pressure Vacuum Filler Cap

25 - 14 EMISSION CONTROL SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)

Page 1919 of 1938

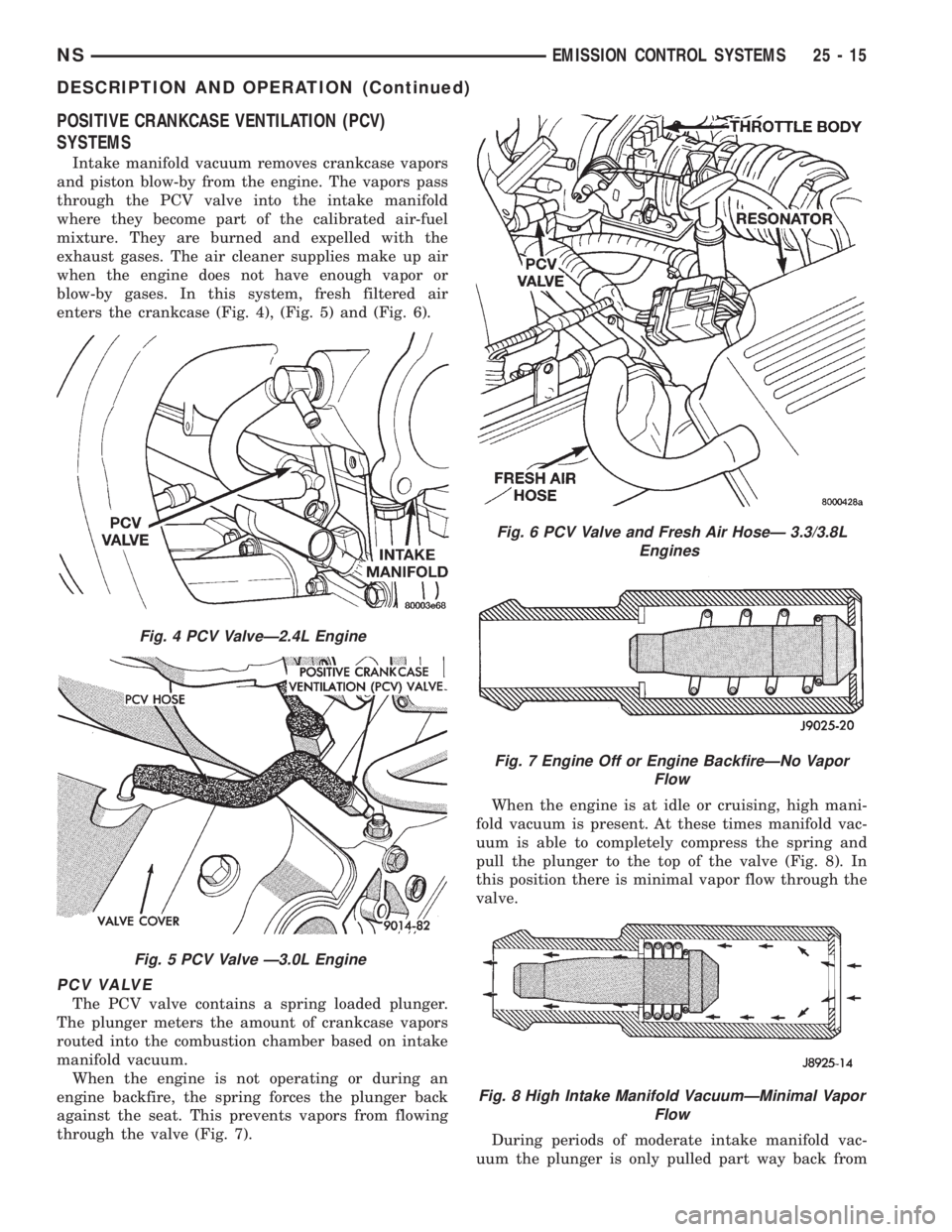

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEMS

Intake manifold vacuum removes crankcase vapors

and piston blow-by from the engine. The vapors pass

through the PCV valve into the intake manifold

where they become part of the calibrated air-fuel

mixture. They are burned and expelled with the

exhaust gases. The air cleaner supplies make up air

when the engine does not have enough vapor or

blow-by gases. In this system, fresh filtered air

enters the crankcase (Fig. 4), (Fig. 5) and (Fig. 6).

PCV VALVE

The PCV valve contains a spring loaded plunger.

The plunger meters the amount of crankcase vapors

routed into the combustion chamber based on intake

manifold vacuum.

When the engine is not operating or during an

engine backfire, the spring forces the plunger back

against the seat. This prevents vapors from flowing

through the valve (Fig. 7).When the engine is at idle or cruising, high mani-

fold vacuum is present. At these times manifold vac-

uum is able to completely compress the spring and

pull the plunger to the top of the valve (Fig. 8). In

this position there is minimal vapor flow through the

valve.

During periods of moderate intake manifold vac-

uum the plunger is only pulled part way back from

Fig. 4 PCV ValveÐ2.4L Engine

Fig. 5 PCV Valve Ð3.0L Engine

Fig. 6 PCV Valve and Fresh Air HoseÐ 3.3/3.8L

Engines

Fig. 7 Engine Off or Engine BackfireÐNo Vapor

Flow

Fig. 8 High Intake Manifold VacuumÐMinimal Vapor

Flow

NSEMISSION CONTROL SYSTEMS 25 - 15

DESCRIPTION AND OPERATION (Continued)