seats CHRYSLER VOYAGER 1996 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1152 of 1938

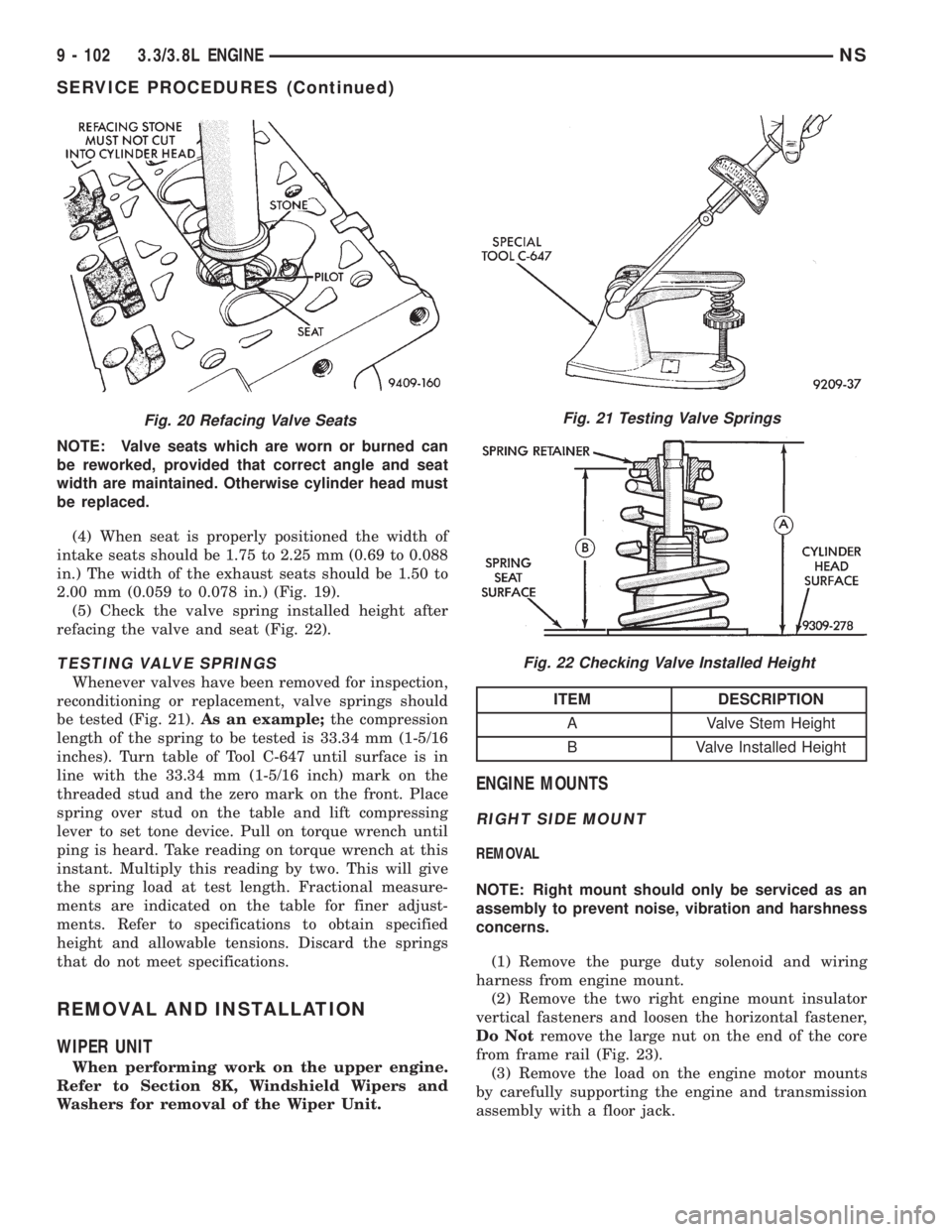

NOTE: Valve seats which are worn or burned can

be reworked, provided that correct angle and seat

width are maintained. Otherwise cylinder head must

be replaced.

(4) When seat is properly positioned the width of

intake seats should be 1.75 to 2.25 mm (0.69 to 0.088

in.) The width of the exhaust seats should be 1.50 to

2.00 mm (0.059 to 0.078 in.) (Fig. 19).

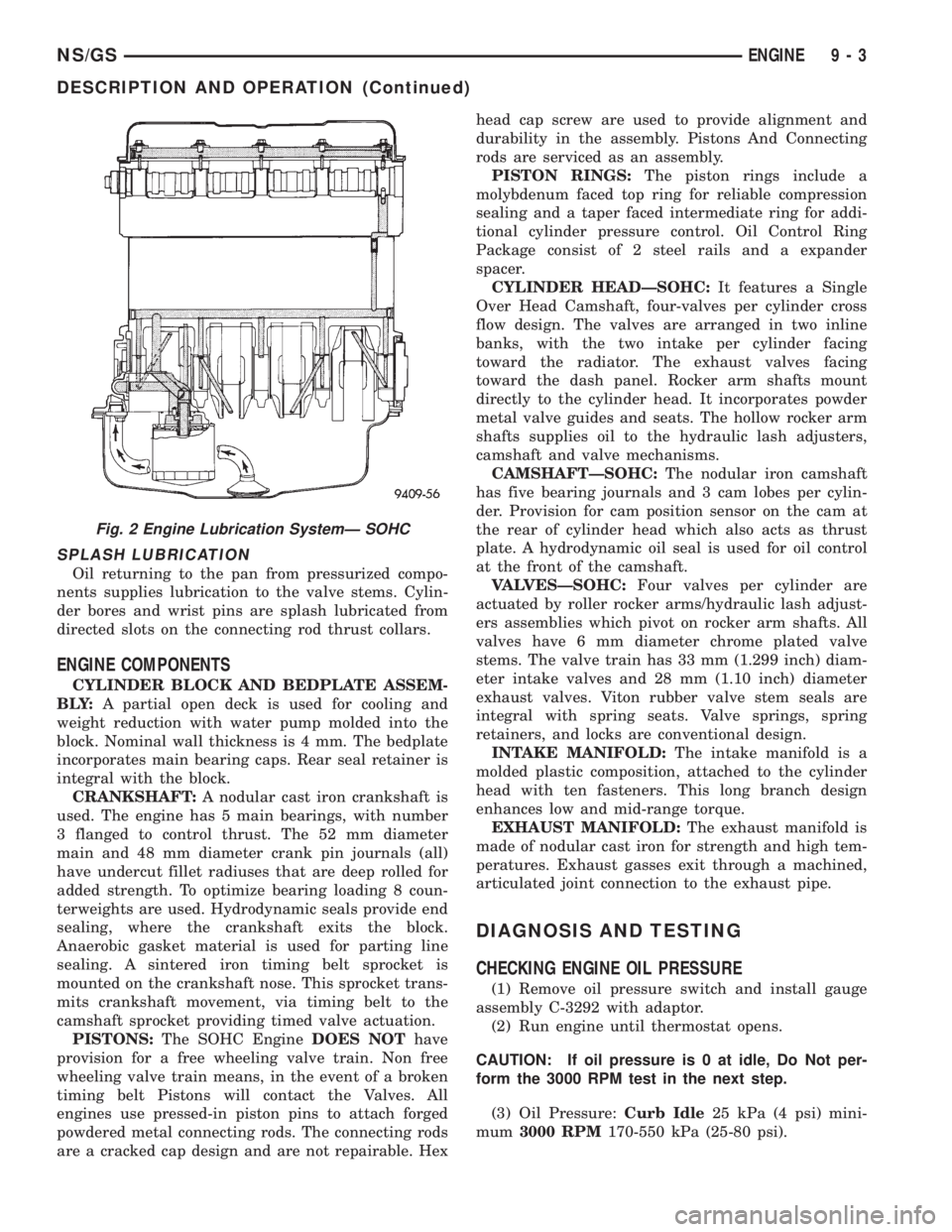

(5) Check the valve spring installed height after

refacing the valve and seat (Fig. 22).

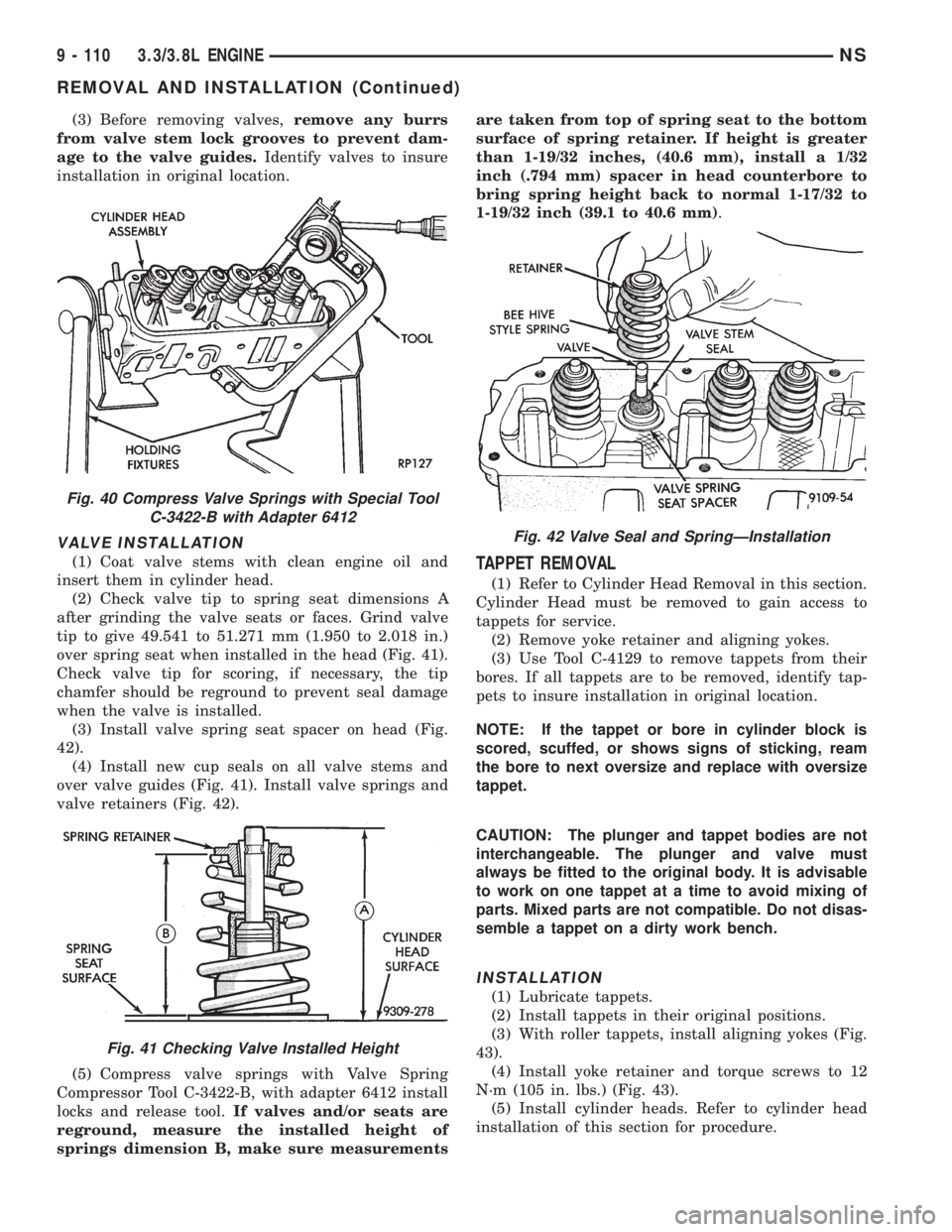

TESTING VALVE SPRINGS

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested (Fig. 21).As an example;the compression

length of the spring to be tested is 33.34 mm (1-5/16

inches). Turn table of Tool C-647 until surface is in

line with the 33.34 mm (1-5/16 inch) mark on the

threaded stud and the zero mark on the front. Place

spring over stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by two. This will give

the spring load at test length. Fractional measure-

ments are indicated on the table for finer adjust-

ments. Refer to specifications to obtain specified

height and allowable tensions. Discard the springs

that do not meet specifications.

REMOVAL AND INSTALLATION

WIPER UNIT

When performing work on the upper engine.

Refer to Section 8K, Windshield Wipers and

Washers for removal of the Wiper Unit.

ENGINE MOUNTS

RIGHT SIDE MOUNT

REMOVAL

NOTE: Right mount should only be serviced as an

assembly to prevent noise, vibration and harshness

concerns.

(1) Remove the purge duty solenoid and wiring

harness from engine mount.

(2) Remove the two right engine mount insulator

vertical fasteners and loosen the horizontal fastener,

Do Notremove the large nut on the end of the core

from frame rail (Fig. 23).

(3) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

Fig. 20 Refacing Valve SeatsFig. 21 Testing Valve Springs

Fig. 22 Checking Valve Installed Height

ITEM DESCRIPTION

A Valve Stem Height

B Valve Installed Height

9 - 102 3.3/3.8L ENGINENS

SERVICE PROCEDURES (Continued)

Page 1160 of 1938

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and

insert them in cylinder head.

(2) Check valve tip to spring seat dimensions A

after grinding the valve seats or faces. Grind valve

tip to give 49.541 to 51.271 mm (1.950 to 2.018 in.)

over spring seat when installed in the head (Fig. 41).

Check valve tip for scoring, if necessary, the tip

chamfer should be reground to prevent seal damage

when the valve is installed.

(3) Install valve spring seat spacer on head (Fig.

42).

(4) Install new cup seals on all valve stems and

over valve guides (Fig. 41). Install valve springs and

valve retainers (Fig. 42).

(5) Compress valve springs with Valve Spring

Compressor Tool C-3422-B, with adapter 6412 install

locks and release tool.If valves and/or seats are

reground, measure the installed height of

springs dimension B, make sure measurementsare taken from top of spring seat to the bottom

surface of spring retainer. If height is greater

than 1-19/32 inches, (40.6 mm), install a 1/32

inch (.794 mm) spacer in head counterbore to

bring spring height back to normal 1-17/32 to

1-19/32 inch (39.1 to 40.6 mm).TAPPET REMOVAL

(1) Refer to Cylinder Head Removal in this section.

Cylinder Head must be removed to gain access to

tappets for service.

(2) Remove yoke retainer and aligning yokes.

(3) Use Tool C-4129 to remove tappets from their

bores. If all tappets are to be removed, identify tap-

pets to insure installation in original location.

NOTE: If the tappet or bore in cylinder block is

scored, scuffed, or shows signs of sticking, ream

the bore to next oversize and replace with oversize

tappet.

CAUTION: The plunger and tappet bodies are not

interchangeable. The plunger and valve must

always be fitted to the original body. It is advisable

to work on one tappet at a time to avoid mixing of

parts. Mixed parts are not compatible. Do not disas-

semble a tappet on a dirty work bench.

INSTALLATION

(1) Lubricate tappets.

(2) Install tappets in their original positions.

(3) With roller tappets, install aligning yokes (Fig.

43).

(4) Install yoke retainer and torque screws to 12

N´m (105 in. lbs.) (Fig. 43).

(5) Install cylinder heads. Refer to cylinder head

installation of this section for procedure.

Fig. 40 Compress Valve Springs with Special Tool

C-3422-B with Adapter 6412

Fig. 41 Checking Valve Installed Height

Fig. 42 Valve Seal and SpringÐInstallation

9 - 110 3.3/3.8L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1181 of 1938

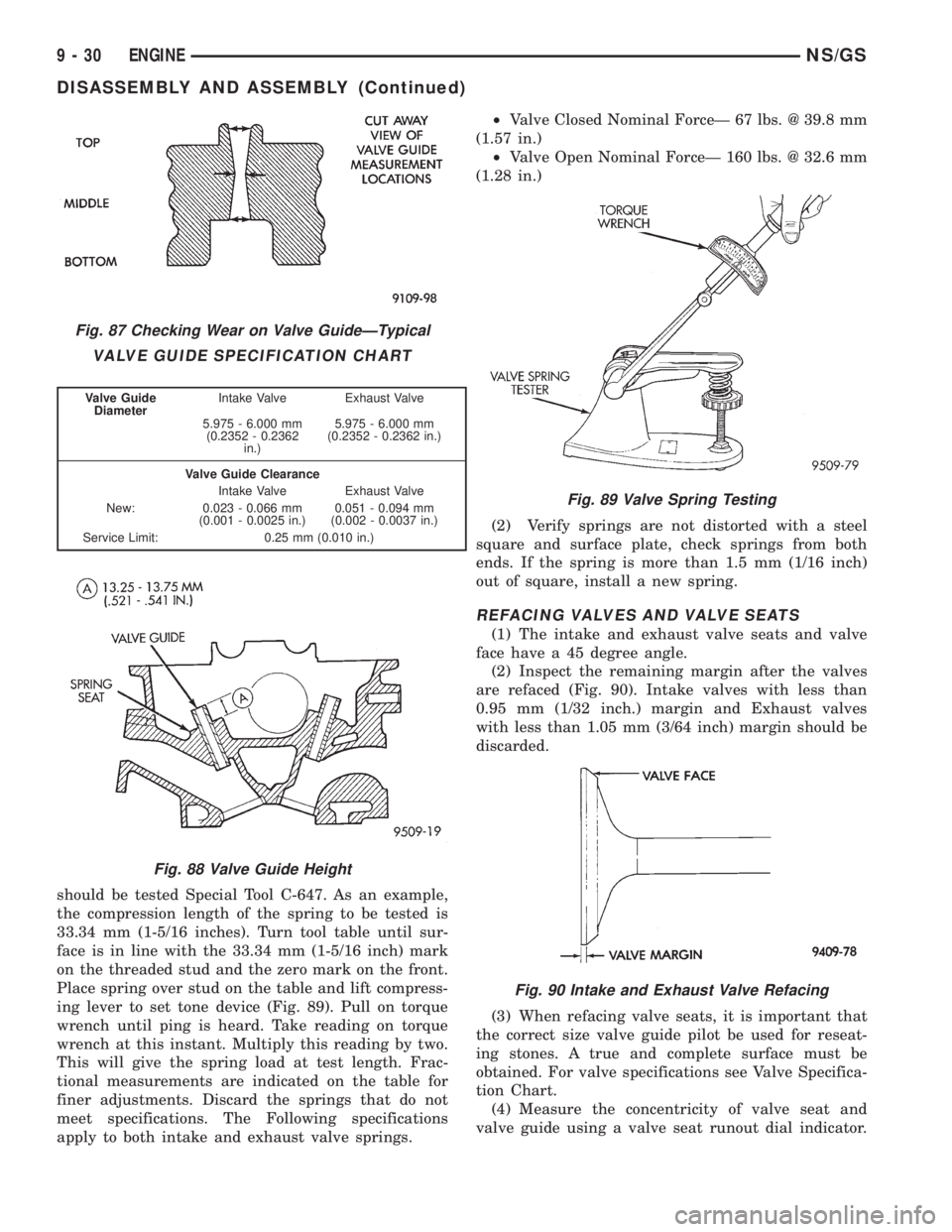

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylin-

der bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

ENGINE COMPONENTS

CYLINDER BLOCK AND BEDPLATE ASSEM-

B LY:A partial open deck is used for cooling and

weight reduction with water pump molded into the

block. Nominal wall thickness is 4 mm. The bedplate

incorporates main bearing caps. Rear seal retainer is

integral with the block.

CRANKSHAFT:A nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 52 mm diameter

main and 48 mm diameter crank pin journals (all)

have undercut fillet radiuses that are deep rolled for

added strength. To optimize bearing loading 8 coun-

terweights are used. Hydrodynamic seals provide end

sealing, where the crankshaft exits the block.

Anaerobic gasket material is used for parting line

sealing. A sintered iron timing belt sprocket is

mounted on the crankshaft nose. This sprocket trans-

mits crankshaft movement, via timing belt to the

camshaft sprocket providing timed valve actuation.

PISTONS:The SOHC EngineDOES NOThave

provision for a free wheeling valve train. Non free

wheeling valve train means, in the event of a broken

timing belt Pistons will contact the Valves. All

engines use pressed-in piston pins to attach forged

powdered metal connecting rods. The connecting rods

are a cracked cap design and are not repairable. Hexhead cap screw are used to provide alignment and

durability in the assembly. Pistons And Connecting

rods are serviced as an assembly.

PISTON RINGS:The piston rings include a

molybdenum faced top ring for reliable compression

sealing and a taper faced intermediate ring for addi-

tional cylinder pressure control. Oil Control Ring

Package consist of 2 steel rails and a expander

spacer.

CYLINDER HEADÐSOHC:It features a Single

Over Head Camshaft, four-valves per cylinder cross

flow design. The valves are arranged in two inline

banks, with the two intake per cylinder facing

toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFTÐSOHC:The nodular iron camshaft

has five bearing journals and 3 cam lobes per cylin-

der. Provision for cam position sensor on the cam at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVESÐSOHC:Four valves per cylinder are

actuated by roller rocker arms/hydraulic lash adjust-

ers assemblies which pivot on rocker arm shafts. All

valves have 6 mm diameter chrome plated valve

stems. The valve train has 33 mm (1.299 inch) diam-

eter intake valves and 28 mm (1.10 inch) diameter

exhaust valves. Viton rubber valve stem seals are

integral with spring seats. Valve springs, spring

retainers, and locks are conventional design.

INTAKE MANIFOLD:The intake manifold is a

molded plastic composition, attached to the cylinder

head with ten fasteners. This long branch design

enhances low and mid-range torque.

EXHAUST MANIFOLD:The exhaust manifold is

made of nodular cast iron for strength and high tem-

peratures. Exhaust gasses exit through a machined,

articulated joint connection to the exhaust pipe.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

Fig. 2 Engine Lubrication SystemÐ SOHC

NS/GSENGINE 9 - 3

DESCRIPTION AND OPERATION (Continued)

Page 1208 of 1938

should be tested Special Tool C-647. As an example,

the compression length of the spring to be tested is

33.34 mm (1-5/16 inches). Turn tool table until sur-

face is in line with the 33.34 mm (1-5/16 inch) mark

on the threaded stud and the zero mark on the front.

Place spring over stud on the table and lift compress-

ing lever to set tone device (Fig. 89). Pull on torque

wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two.

This will give the spring load at test length. Frac-

tional measurements are indicated on the table for

finer adjustments. Discard the springs that do not

meet specifications. The Following specifications

apply to both intake and exhaust valve springs.²Valve Closed Nominal ForceÐ 67 lbs. @ 39.8 mm

(1.57 in.)

²Valve Open Nominal ForceÐ 160 lbs. @ 32.6 mm

(1.28 in.)

(2) Verify springs are not distorted with a steel

square and surface plate, check springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 degree angle.

(2) Inspect the remaining margin after the valves

are refaced (Fig. 90). Intake valves with less than

0.95 mm (1/32 inch.) margin and Exhaust valves

with less than 1.05 mm (3/64 inch) margin should be

discarded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained. For valve specifications see Valve Specifica-

tion Chart.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Fig. 87 Checking Wear on Valve GuideÐTypical

VALVE GUIDE SPECIFICATION CHART

Valve Guide

DiameterIntake Valve Exhaust Valve

5.975 - 6.000 mm

(0.2352 - 0.2362

in.)5.975 - 6.000 mm

(0.2352 - 0.2362 in.)

Valve Guide Clearance

Intake Valve Exhaust Valve

New: 0.023 - 0.066 mm

(0.001 - 0.0025 in.)0.051 - 0.094 mm

(0.002 - 0.0037 in.)

Service Limit: 0.25 mm (0.010 in.)

Fig. 88 Valve Guide Height

Fig. 89 Valve Spring Testing

Fig. 90 Intake and Exhaust Valve Refacing

9 - 30 ENGINENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1209 of 1938

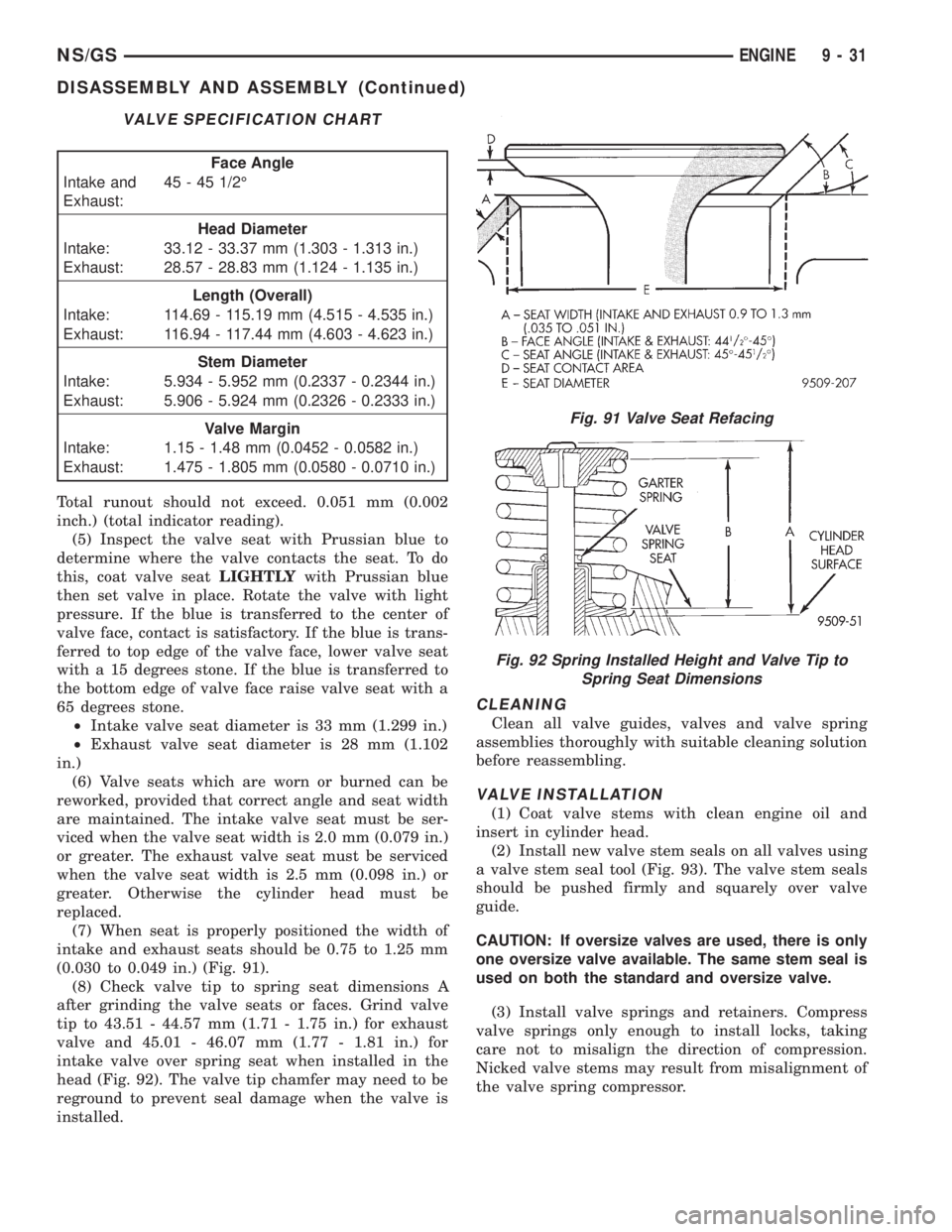

Total runout should not exceed. 0.051 mm (0.002

inch.) (total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

²Intake valve seat diameter is 33 mm (1.299 in.)

²Exhaust valve seat diameter is 28 mm (1.102

in.)

(6) Valve seats which are worn or burned can be

reworked, provided that correct angle and seat width

are maintained. The intake valve seat must be ser-

viced when the valve seat width is 2.0 mm (0.079 in.)

or greater. The exhaust valve seat must be serviced

when the valve seat width is 2.5 mm (0.098 in.) or

greater. Otherwise the cylinder head must be

replaced.

(7) When seat is properly positioned the width of

intake and exhaust seats should be 0.75 to 1.25 mm

(0.030 to 0.049 in.) (Fig. 91).

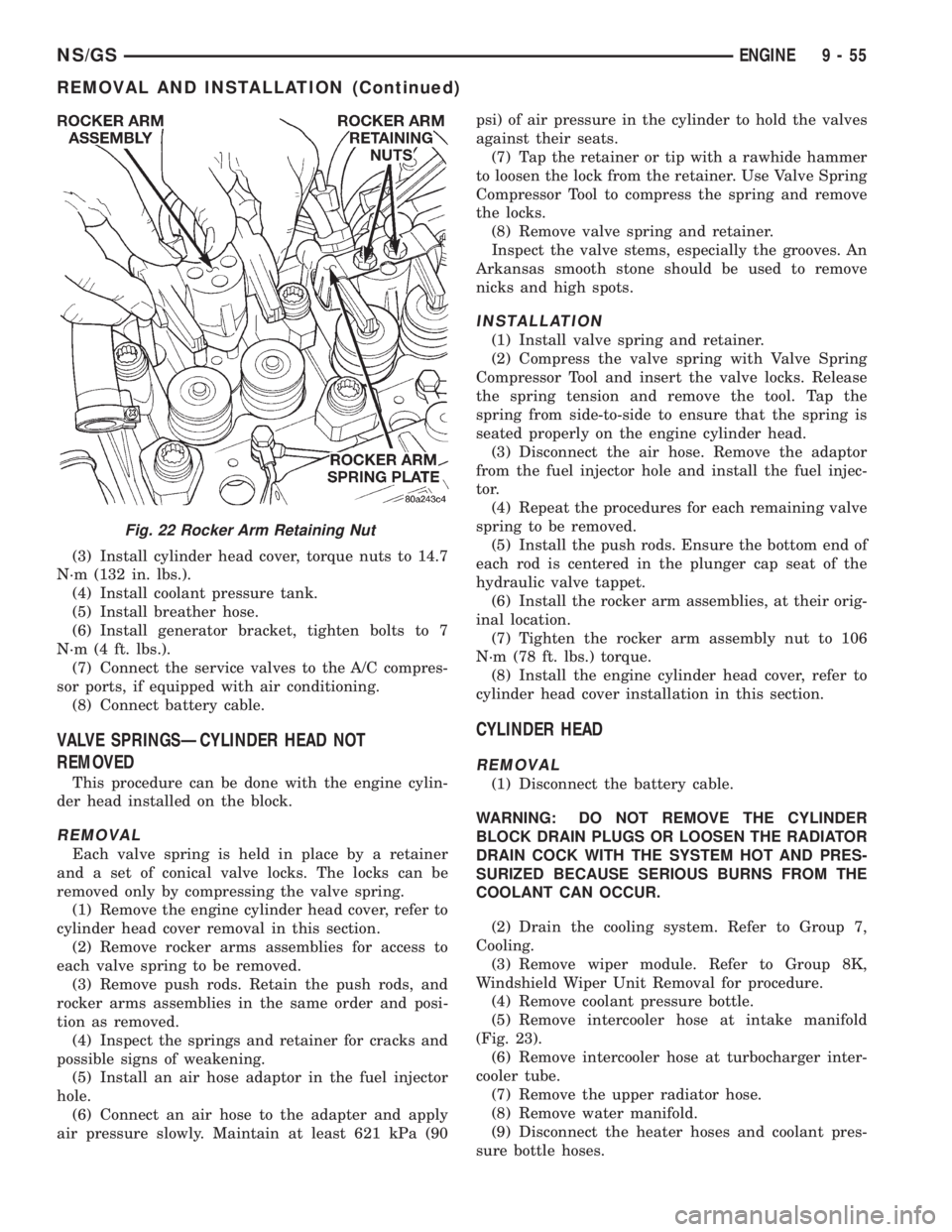

(8) Check valve tip to spring seat dimensions A

after grinding the valve seats or faces. Grind valve

tip to 43.51 - 44.57 mm (1.71 - 1.75 in.) for exhaust

valve and 45.01 - 46.07 mm (1.77 - 1.81 in.) for

intake valve over spring seat when installed in the

head (Fig. 92). The valve tip chamfer may need to be

reground to prevent seal damage when the valve is

installed.

CLEANING

Clean all valve guides, valves and valve spring

assemblies thoroughly with suitable cleaning solution

before reassembling.

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

(2) Install new valve stem seals on all valves using

a valve stem seal tool (Fig. 93). The valve stem seals

should be pushed firmly and squarely over valve

guide.

CAUTION: If oversize valves are used, there is only

one oversize valve available. The same stem seal is

used on both the standard and oversize valve.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

VALVE SPECIFICATION CHART

Face Angle

Intake and

Exhaust:45 - 45 1/2É

Head Diameter

Intake: 33.12 - 33.37 mm (1.303 - 1.313 in.)

Exhaust: 28.57 - 28.83 mm (1.124 - 1.135 in.)

Length (Overall)

Intake: 114.69 - 115.19 mm (4.515 - 4.535 in.)

Exhaust: 116.94 - 117.44 mm (4.603 - 4.623 in.)

Stem Diameter

Intake: 5.934 - 5.952 mm (0.2337 - 0.2344 in.)

Exhaust: 5.906 - 5.924 mm (0.2326 - 0.2333 in.)

Valve Margin

Intake: 1.15 - 1.48 mm (0.0452 - 0.0582 in.)

Exhaust: 1.475 - 1.805 mm (0.0580 - 0.0710 in.)

Fig. 91 Valve Seat Refacing

Fig. 92 Spring Installed Height and Valve Tip to

Spring Seat Dimensions

NS/GSENGINE 9 - 31

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1233 of 1938

(3) Install cylinder head cover, torque nuts to 14.7

N´m (132 in. lbs.).

(4) Install coolant pressure tank.

(5) Install breather hose.

(6) Install generator bracket, tighten bolts to 7

N´m (4 ft. lbs.).

(7) Connect the service valves to the A/C compres-

sor ports, if equipped with air conditioning.

(8) Connect battery cable.

VALVE SPRINGSÐCYLINDER HEAD NOT

REMOVED

This procedure can be done with the engine cylin-

der head installed on the block.

REMOVAL

Each valve spring is held in place by a retainer

and a set of conical valve locks. The locks can be

removed only by compressing the valve spring.

(1) Remove the engine cylinder head cover, refer to

cylinder head cover removal in this section.

(2) Remove rocker arms assemblies for access to

each valve spring to be removed.

(3) Remove push rods. Retain the push rods, and

rocker arms assemblies in the same order and posi-

tion as removed.

(4) Inspect the springs and retainer for cracks and

possible signs of weakening.

(5) Install an air hose adaptor in the fuel injector

hole.

(6) Connect an air hose to the adapter and apply

air pressure slowly. Maintain at least 621 kPa (90psi) of air pressure in the cylinder to hold the valves

against their seats.

(7) Tap the retainer or tip with a rawhide hammer

to loosen the lock from the retainer. Use Valve Spring

Compressor Tool to compress the spring and remove

the locks.

(8) Remove valve spring and retainer.

Inspect the valve stems, especially the grooves. An

Arkansas smooth stone should be used to remove

nicks and high spots.

INSTALLATION

(1) Install valve spring and retainer.

(2) Compress the valve spring with Valve Spring

Compressor Tool and insert the valve locks. Release

the spring tension and remove the tool. Tap the

spring from side-to-side to ensure that the spring is

seated properly on the engine cylinder head.

(3) Disconnect the air hose. Remove the adaptor

from the fuel injector hole and install the fuel injec-

tor.

(4) Repeat the procedures for each remaining valve

spring to be removed.

(5) Install the push rods. Ensure the bottom end of

each rod is centered in the plunger cap seat of the

hydraulic valve tappet.

(6) Install the rocker arm assemblies, at their orig-

inal location.

(7) Tighten the rocker arm assembly nut to 106

N´m (78 ft. lbs.) torque.

(8) Install the engine cylinder head cover, refer to

cylinder head cover installation in this section.

CYLINDER HEAD

REMOVAL

(1) Disconnect the battery cable.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

(2) Drain the cooling system. Refer to Group 7,

Cooling.

(3) Remove wiper module. Refer to Group 8K,

Windshield Wiper Unit Removal for procedure.

(4) Remove coolant pressure bottle.

(5) Remove intercooler hose at intake manifold

(Fig. 23).

(6) Remove intercooler hose at turbocharger inter-

cooler tube.

(7) Remove the upper radiator hose.

(8) Remove water manifold.

(9) Disconnect the heater hoses and coolant pres-

sure bottle hoses.

Fig. 22 Rocker Arm Retaining Nut

NS/GSENGINE 9 - 55

REMOVAL AND INSTALLATION (Continued)

Page 1238 of 1938

(36) Operate the engine with the radiator cap off.

Inspect for leaks and continue operating the engine

until the thermostat opens. Add coolant, if required.

VALVES AND VALVE SPRINGSÐHEAD OFF

This procedure is done with the engine cylinder

head removed from the block.

REMOVAL

(1) Remove the engine cylinder head from the cyl-

inder block. Refer to cylinder head removal in this

section.

(2) Use Valve Spring Compressor Tool and com-

press each valve spring.

(3) Remove the valve locks, retainers, and springs.

(4) Use an Arkansas smooth stone or a jewelers

file to remove any burrs on the top of the valve stem,

especially around the groove for the locks.

(5) Remove the valves, and place them in a rack in

the same order as removed.

INSTALLATION

(1) Fit each valve to its respective valve guide.

NOTE: If valves and valve seats have been refaced

refer to Service Procedures in this section. Follow

The Valve Stand Down procedure.

(2) Install lower, washer and spring.

(3) Install upper spring collar, and compress valve

spring with spring compressor tool. Install split cone

retainers.

HYDRAULIC TAPPETS

REMOVAL

(1) Remove coolant pressure bottle.

(2) Remove cylinder head cover. Refer to cylinder

head cover removal in this section.

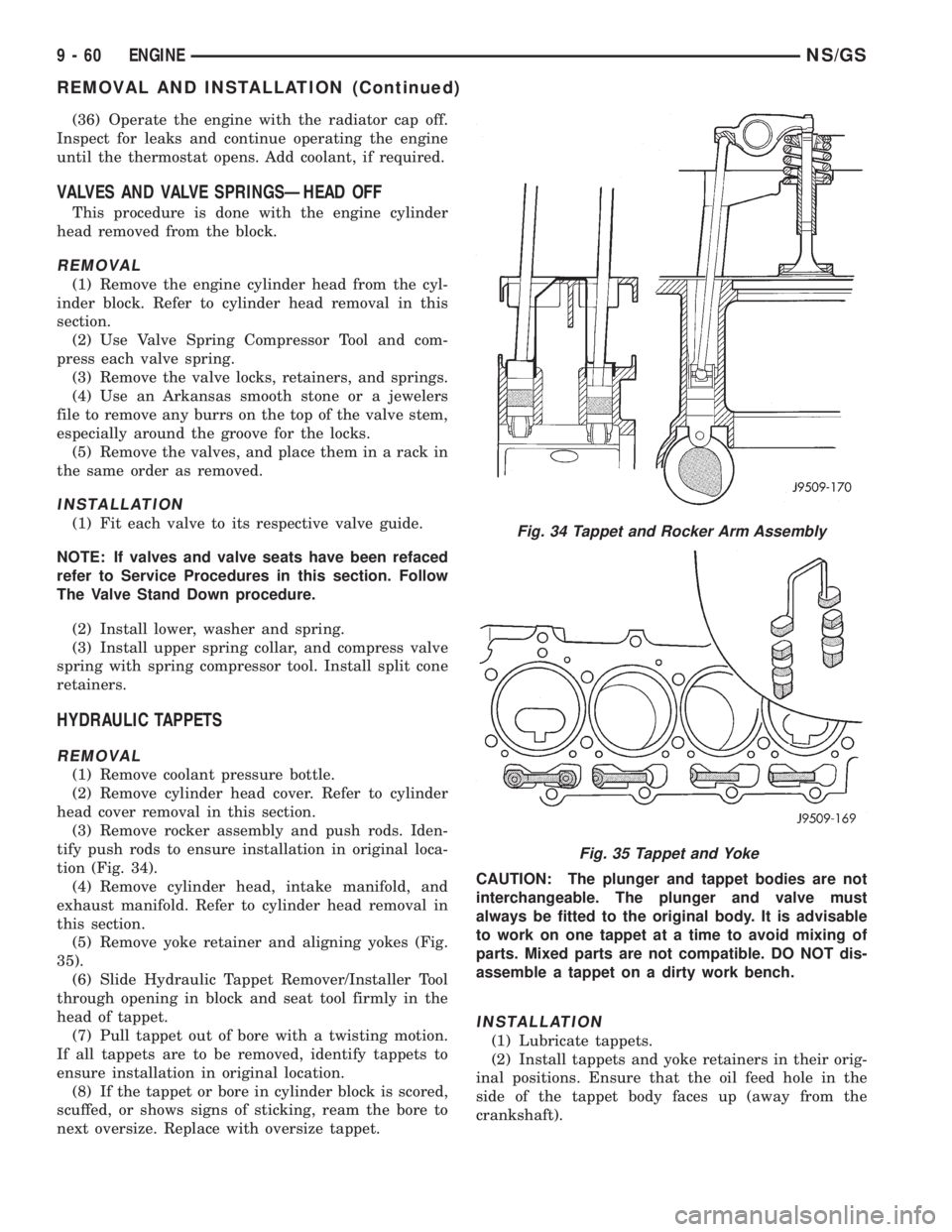

(3) Remove rocker assembly and push rods. Iden-

tify push rods to ensure installation in original loca-

tion (Fig. 34).

(4) Remove cylinder head, intake manifold, and

exhaust manifold. Refer to cylinder head removal in

this section.

(5) Remove yoke retainer and aligning yokes (Fig.

35).

(6) Slide Hydraulic Tappet Remover/Installer Tool

through opening in block and seat tool firmly in the

head of tappet.

(7) Pull tappet out of bore with a twisting motion.

If all tappets are to be removed, identify tappets to

ensure installation in original location.

(8) If the tappet or bore in cylinder block is scored,

scuffed, or shows signs of sticking, ream the bore to

next oversize. Replace with oversize tappet.CAUTION: The plunger and tappet bodies are not

interchangeable. The plunger and valve must

always be fitted to the original body. It is advisable

to work on one tappet at a time to avoid mixing of

parts. Mixed parts are not compatible. DO NOT dis-

assemble a tappet on a dirty work bench.

INSTALLATION

(1) Lubricate tappets.

(2) Install tappets and yoke retainers in their orig-

inal positions. Ensure that the oil feed hole in the

side of the tappet body faces up (away from the

crankshaft).

Fig. 34 Tappet and Rocker Arm Assembly

Fig. 35 Tappet and Yoke

9 - 60 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1306 of 1938

(9) Momentarily touch the other end of this

jumper wire to the negative terminal of the battery

for no more than 4 seconds.

(10) Place a rag or towel below the fuel line at the

quick connect to the rail.

(11) Disconnect the quick connect fitting to the

rail. Refer to Quick-Connect Fittings in this section.

(12) Return the fuel pump relay to the PDC.

(13) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in the PCM memory due to the

fuel pump relay removal. The DRB scan tool must be

used to erase a DTC. Refer to group 25, On-Board

Diagnostics.

HOSES AND CLAMPS

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that cause

abrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

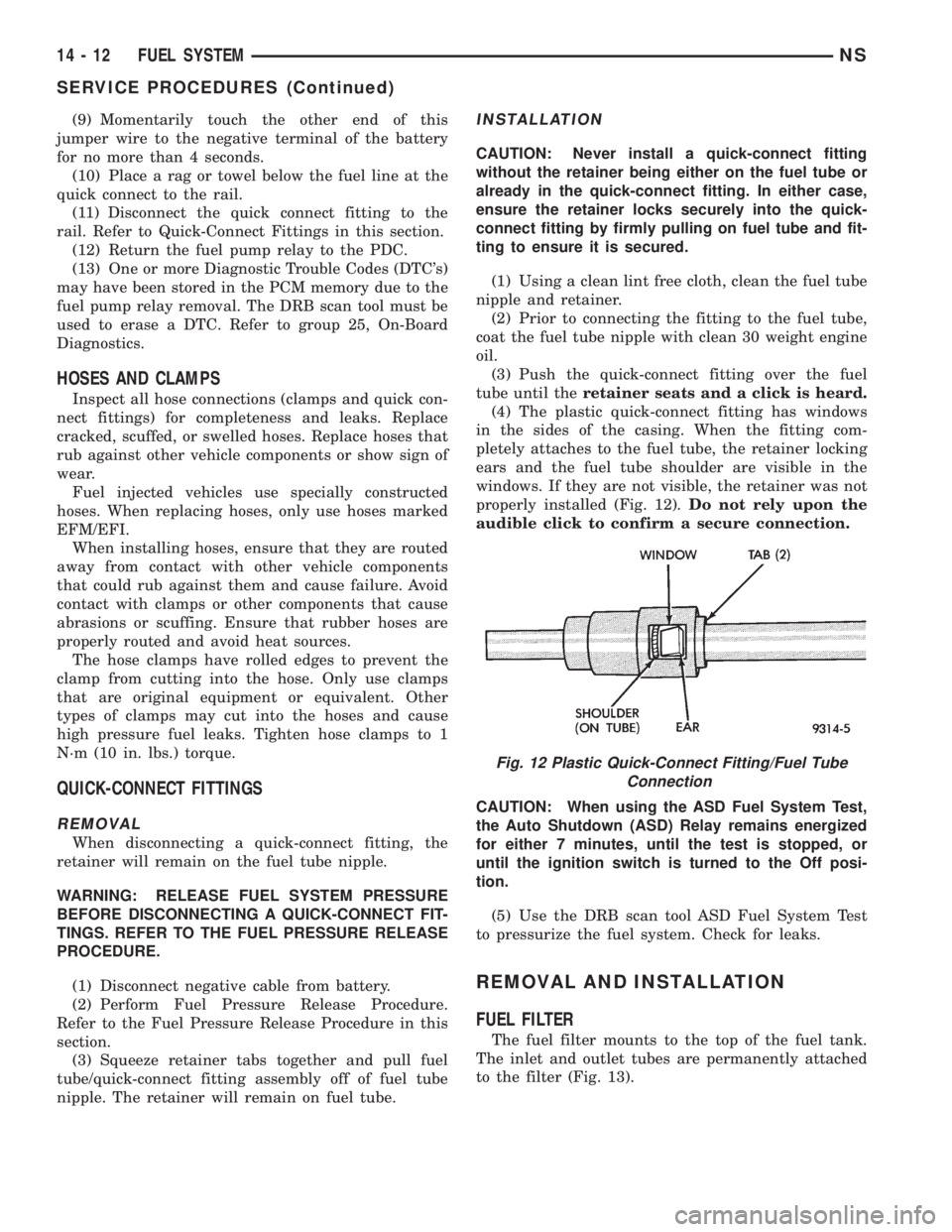

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 12).Do not rely upon the

audible click to confirm a secure connection.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(5) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

REMOVAL AND INSTALLATION

FUEL FILTER

The fuel filter mounts to the top of the fuel tank.

The inlet and outlet tubes are permanently attached

to the filter (Fig. 13).

Fig. 12 Plastic Quick-Connect Fitting/Fuel Tube

Connection

14 - 12 FUEL SYSTEMNS

SERVICE PROCEDURES (Continued)

Page 1380 of 1938

FUEL HEATER RELAY TEST

The fuel heater relay is located in the Power Dis-

tribution Center (PDC). Refer to RelaysÐOperation/

Testing in Fuel Ingection System section of this

group for test procedures.

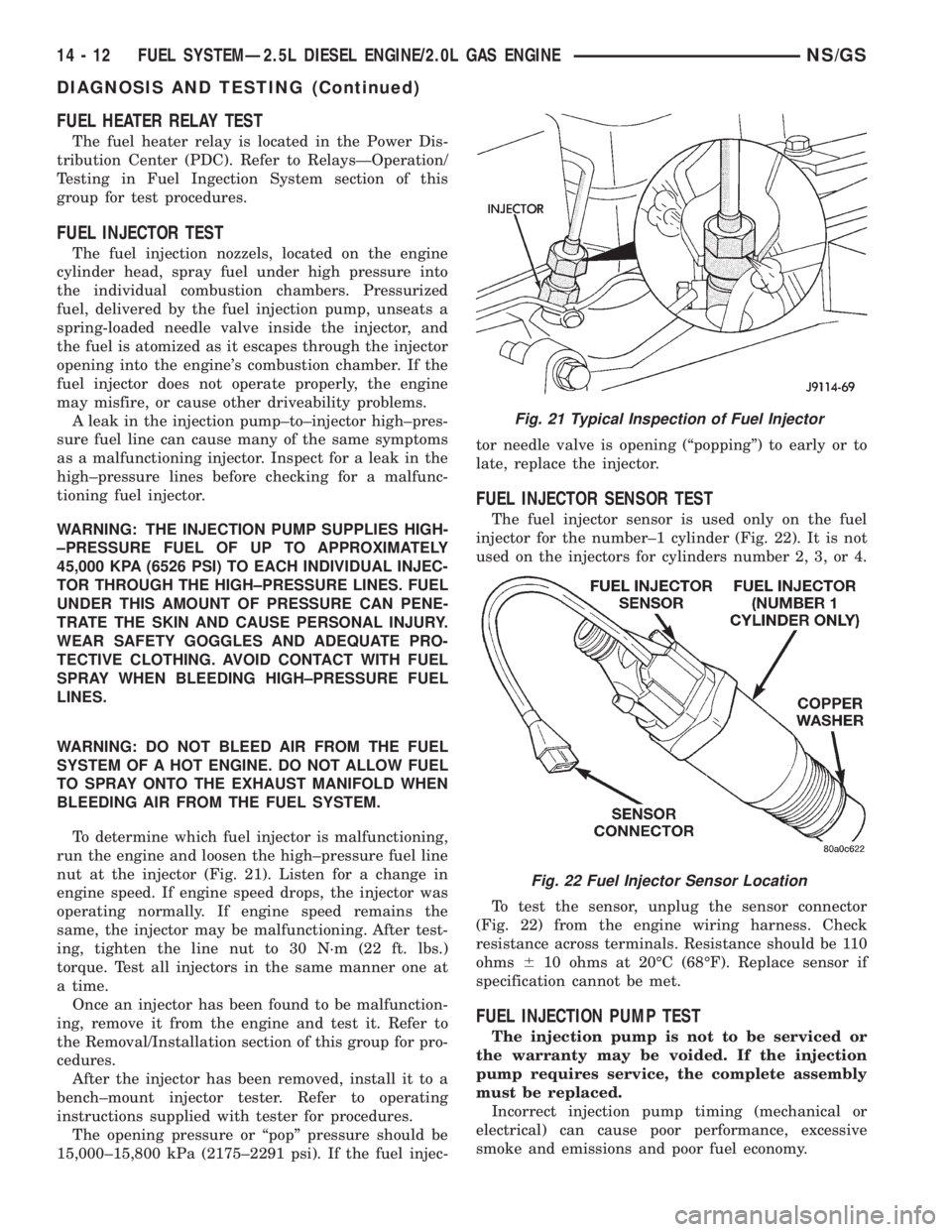

FUEL INJECTOR TEST

The fuel injection nozzels, located on the engine

cylinder head, spray fuel under high pressure into

the individual combustion chambers. Pressurized

fuel, delivered by the fuel injection pump, unseats a

spring-loaded needle valve inside the injector, and

the fuel is atomized as it escapes through the injector

opening into the engine's combustion chamber. If the

fuel injector does not operate properly, the engine

may misfire, or cause other driveability problems.

A leak in the injection pump±to±injector high±pres-

sure fuel line can cause many of the same symptoms

as a malfunctioning injector. Inspect for a leak in the

high±pressure lines before checking for a malfunc-

tioning fuel injector.

WARNING: THE INJECTION PUMP SUPPLIES HIGH-

±PRESSURE FUEL OF UP TO APPROXIMATELY

45,000 KPA (6526 PSI) TO EACH INDIVIDUAL INJEC-

TOR THROUGH THE HIGH±PRESSURE LINES. FUEL

UNDER THIS AMOUNT OF PRESSURE CAN PENE-

TRATE THE SKIN AND CAUSE PERSONAL INJURY.

WEAR SAFETY GOGGLES AND ADEQUATE PRO-

TECTIVE CLOTHING. AVOID CONTACT WITH FUEL

SPRAY WHEN BLEEDING HIGH±PRESSURE FUEL

LINES.

WARNING: DO NOT BLEED AIR FROM THE FUEL

SYSTEM OF A HOT ENGINE. DO NOT ALLOW FUEL

TO SPRAY ONTO THE EXHAUST MANIFOLD WHEN

BLEEDING AIR FROM THE FUEL SYSTEM.

To determine which fuel injector is malfunctioning,

run the engine and loosen the high±pressure fuel line

nut at the injector (Fig. 21). Listen for a change in

engine speed. If engine speed drops, the injector was

operating normally. If engine speed remains the

same, the injector may be malfunctioning. After test-

ing, tighten the line nut to 30 N´m (22 ft. lbs.)

torque. Test all injectors in the same manner one at

a time.

Once an injector has been found to be malfunction-

ing, remove it from the engine and test it. Refer to

the Removal/Installation section of this group for pro-

cedures.

After the injector has been removed, install it to a

bench±mount injector tester. Refer to operating

instructions supplied with tester for procedures.

The opening pressure or ªpopº pressure should be

15,000±15,800 kPa (2175±2291 psi). If the fuel injec-tor needle valve is opening (ªpoppingº) to early or to

late, replace the injector.

FUEL INJECTOR SENSOR TEST

The fuel injector sensor is used only on the fuel

injector for the number±1 cylinder (Fig. 22). It is not

used on the injectors for cylinders number 2, 3, or 4.

To test the sensor, unplug the sensor connector

(Fig. 22) from the engine wiring harness. Check

resistance across terminals. Resistance should be 110

ohms610 ohms at 20ÉC (68ÉF). Replace sensor if

specification cannot be met.

FUEL INJECTION PUMP TEST

The injection pump is not to be serviced or

the warranty may be voided. If the injection

pump requires service, the complete assembly

must be replaced.

Incorrect injection pump timing (mechanical or

electrical) can cause poor performance, excessive

smoke and emissions and poor fuel economy.

Fig. 21 Typical Inspection of Fuel Injector

Fig. 22 Fuel Injector Sensor Location

14 - 12 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1729 of 1938

SERVICE PROCEDURES

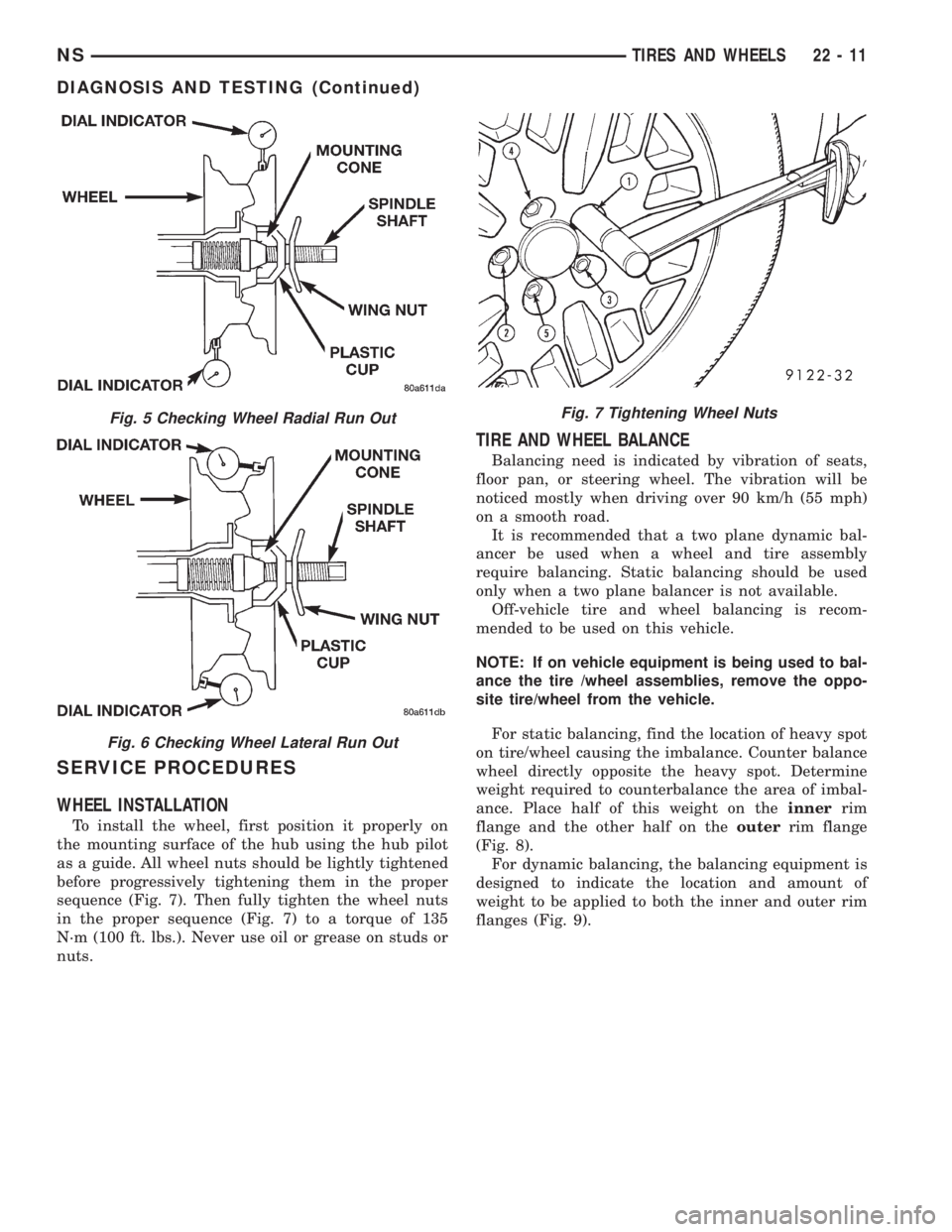

WHEEL INSTALLATION

To install the wheel, first position it properly on

the mounting surface of the hub using the hub pilot

as a guide. All wheel nuts should be lightly tightened

before progressively tightening them in the proper

sequence (Fig. 7). Then fully tighten the wheel nuts

in the proper sequence (Fig. 7) to a torque of 135

N´m (100 ft. lbs.). Never use oil or grease on studs or

nuts.

TIRE AND WHEEL BALANCE

Balancing need is indicated by vibration of seats,

floor pan, or steering wheel. The vibration will be

noticed mostly when driving over 90 km/h (55 mph)

on a smooth road.

It is recommended that a two plane dynamic bal-

ancer be used when a wheel and tire assembly

require balancing. Static balancing should be used

only when a two plane balancer is not available.

Off-vehicle tire and wheel balancing is recom-

mended to be used on this vehicle.

NOTE: If on vehicle equipment is being used to bal-

ance the tire /wheel assemblies, remove the oppo-

site tire/wheel from the vehicle.

For static balancing, find the location of heavy spot

on tire/wheel causing the imbalance. Counter balance

wheel directly opposite the heavy spot. Determine

weight required to counterbalance the area of imbal-

ance. Place half of this weight on theinnerrim

flange and the other half on theouterrim flange

(Fig. 8).

For dynamic balancing, the balancing equipment is

designed to indicate the location and amount of

weight to be applied to both the inner and outer rim

flanges (Fig. 9).

Fig. 5 Checking Wheel Radial Run Out

Fig. 6 Checking Wheel Lateral Run Out

Fig. 7 Tightening Wheel Nuts

NSTIRES AND WHEELS 22 - 11

DIAGNOSIS AND TESTING (Continued)