seats CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 861 of 1938

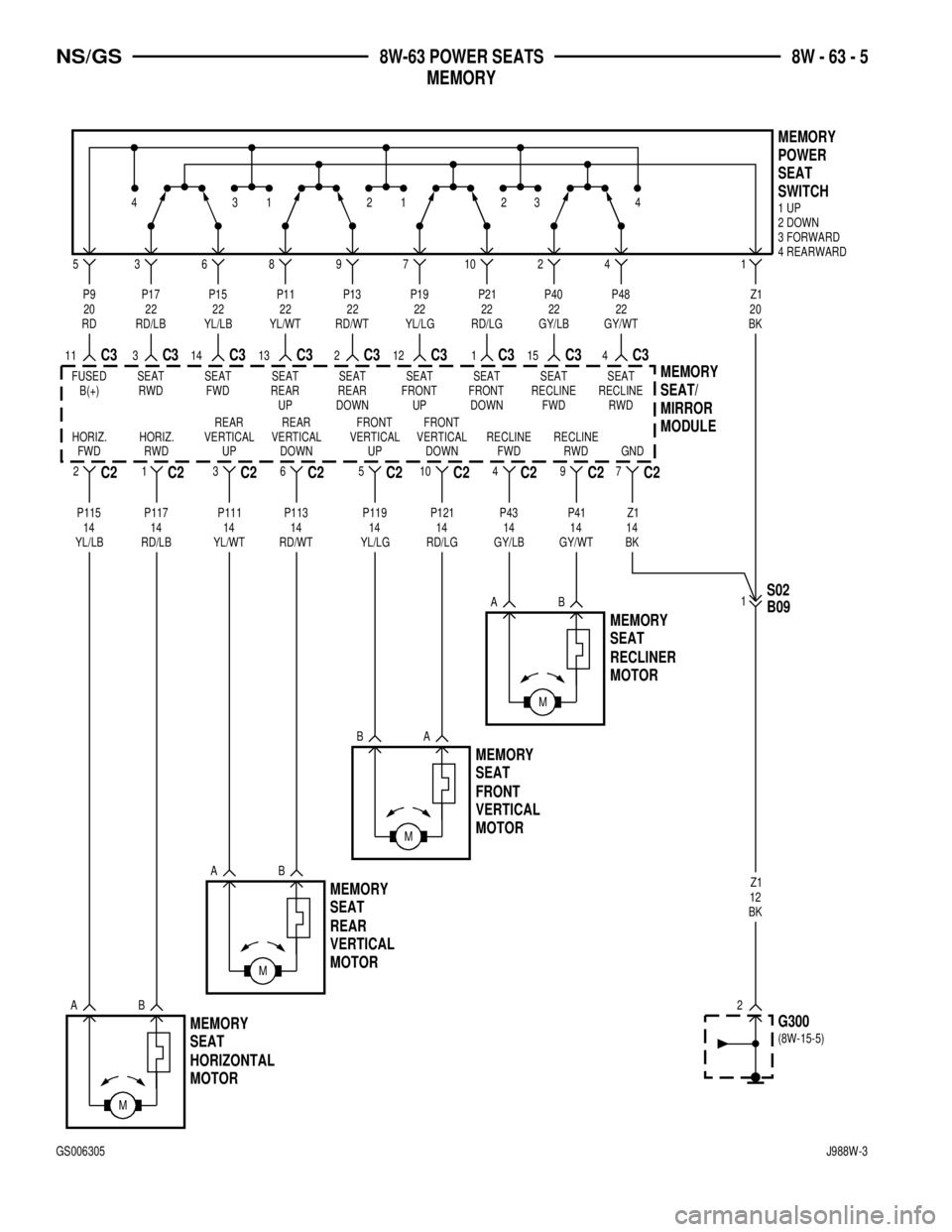

BK12Z1

BK20Z1

B09 S021

BK14Z1 GND

C27

P117

14

RD/LBP115

14

YL/LB

YL/WT14 P111RD/WT14 P113 P121

14

RD/LG

P119

14

YL/LG

GY/LB14 P43GY/WT14 P41

BA

M

9C2

RECLINE

RWD FWD RECLINE

C24

DOWN VERTICALFRONT

C210

UP VERTICALFRONT

C25

DOWN VERTICALREAR

C26

UP VERTICALREAR

C231C2

HORIZ.

RWD FWD HORIZ.

C22

G300

2

MOTOR

RECLINER

BA

M

M

BA

M

AB

MOTOR

HORIZONTALFRONT

VERTICAL

MOTOR

REAR

VERTICAL

MOTOR

RD20 P9

P17

22

RD/LBP15

22

YL/LB

RD/WT22 P13YL/WT22 P11 P48

22

GY/WT

P40

22

GY/LB

RD/LG22 P21YL/LG22 P19

SEAT

RECLINE

RWD

4C3

SEAT

RECLINE

FWD

15C3

SEAT

FRONT

DOWN

1C3

SEAT

FRONT

UP

12C3 C313

UP REARSEAT

C32

DOWNREARSEAT SEAT

FWD

14C3

SEAT

RWD

3C3 C311

B(+) FUSED

5

POWER

SEAT

SWITCH

3619824107

MEMORY

MODULE MIRROR

SEAT/

MEMORY

43121234

SEAT

MEMORY

SEAT MEMORY

SEAT MEMORY

MEMORY

SEAT

4 REARWARD 2 DOWN 1 UP

3 FORWARD

(8W-15-5)

NS/GS8W-63 POWER SEATS

MEMORY8W - 63 - 5

GS006305J988W-3

Page 862 of 1938

BR22 P26LB/RD22 P27VT/RD22 P25LB22 P47BR/RD20 P28

BR/RD20 P28BR/RD20 P28BR/RD20 P28BR/RD20 P28

BR/WT20 P29BR/WT20 P29BR/WT20 P29BR/WT20 P29BR/WT20 P29

SS01 SS02

SENSOR POSITION

RECLINE

SEAT

MEMORY MEMORY

SEAT

HORIZONTAL

POSITION

SENSOR

SENSOR MEMORY

SEAT

FRONT

VERTICAL

POSITION

POSITION VERTICAL

REAR

SEAT

MEMORY

SENSORA B

C

C

BA

A B

C

C317C318C310C37C38 20C3

A

BC

SENSE POSITION RECLINER

HORIZONTAL

POSITION

SENSE FRONT

SENSE POSITIONSEAT

VERTICAL 6V

SUPPLY

MEMORY

SEAT/

MIRROR

MODULE

VERTICALSEAT

POSITION

SENSEREAR SEAT

COMMONSENSE POSITIONSEAT SEAT

8W - 63 - 6 8W-63 POWER SEATS

MEMORYNS/GS

J988W-3GS006306

Page 863 of 1938

SWITCH SEAT

HEATED

DRIVER

DRIVER

HEATED

SEAT

CUSHION

DRIVER

HEATED

SEAT

BACK

DRIVER

HEATED

SEAT

MODULE

A (8W-63-2)

FUSIBLE

LINK

FROM

DAEFCB

AB

D

DB

AFE

ACB2

G300

FUSED

B(+)GROUND FEED

BACKHEATED

SEAT

DRIVERGROUND DRIVERSEAT HEATED GROUND

HS1

F35

18

RDP86

20

VTP7

20

WT/BKZ1

18

BK

Z1

18

BKZ1

14

BK

P87

18

RD/WT

P89

20

BK/RDP88

18

RD/WT

Z1

18

BK

B09 HS5D1

Z1

12

BK

Z1

18

BK

HEATED

SEAT

BACK DRIVERSEAT HEATED GROUND FUSED

IGNITION

(RUN) (RUN)IGNITIONFUSED

HS2

4B09

HS5D

F20

20

WT

10A

FUSE

12

RUN A22

JUNCTION

BLOCK

14C2

1S02

HS6D

Z1

14

BK

MODULE MIRROR

SEAT/

MEMORY

Z1

14

BK

7

BK20Z1 1

MEMORY

POWER

SEAT

SWITCH

HEATED

SEAT

DRIVER

C2

HEATED

SEAT

TEMPERATURE

SENSOR SWITCHSEAT HEATEDDRIVER

DRIVER

HEATED

SEAT

SWITCH SENSOR TEMPERATURESEAT HEATEDGROUND GROUND

(8W-15-5) (8W-12-12)(8W-12-2) (8W-10-14)

(8W-63-5) (8W-63-5)

NS/GS8W-63 POWER SEATS

HEATED8W - 63 - 7

GS006307J988W-3

Page 864 of 1938

SWITCH SEAT

HEATED

PASSENGER

PASSENGER

HEATED

SEAT

CUSHION

PASSENGER

HEATED

SEAT

BACK

PASSENGER

HEATED

SEAT

MODULE

B (8W-63-3)

FUSIBLE

LINK

FROM

DAEFCB

AB

D

DB

AFE

ACB7

G300

FUSED

B(+)GROUNDHEATED

SEAT

DRIVERGROUND DRIVERSEAT HEATED GROUND

HS3

F35

18

RDP86

20

VTP8

20

WT/BKZ1

18

BK

Z1

18

BKZ1

14

BK

P87

18

RD/WT

P89

20

BK/RDP88

18

RD/WTZ1

18

BK

B56 HS5P1

Z1

12

BK

Z1

18

BK

HEATED

SEAT

BACK DRIVERSEAT HEATED GROUND FUSED

IGNITION

(RUN) (RUN)IGNITIONFUSED

HS4

4B56

HS5P

F20

20

WT

10A

FUSE

12

RUN A22

JUNCTION

BLOCK

7C2

HEATED

SEAT

DRIVER HEATED

SEAT

TEMPERATURE

SENSOR SWITCHSEAT HEATED PASSENGER

PASSENGER

HEATED

SEAT

SWITCH SENSOR TEMPERATURESEAT HEATED

BACKSEAT HEATED(8W-15-9) (8W-12-12)(8W-12-2) (8W-10-14)

8W - 63 - 8 8W-63 POWER SEATS

HEATEDNS/GS

J988W-3GS006308

Page 1062 of 1938

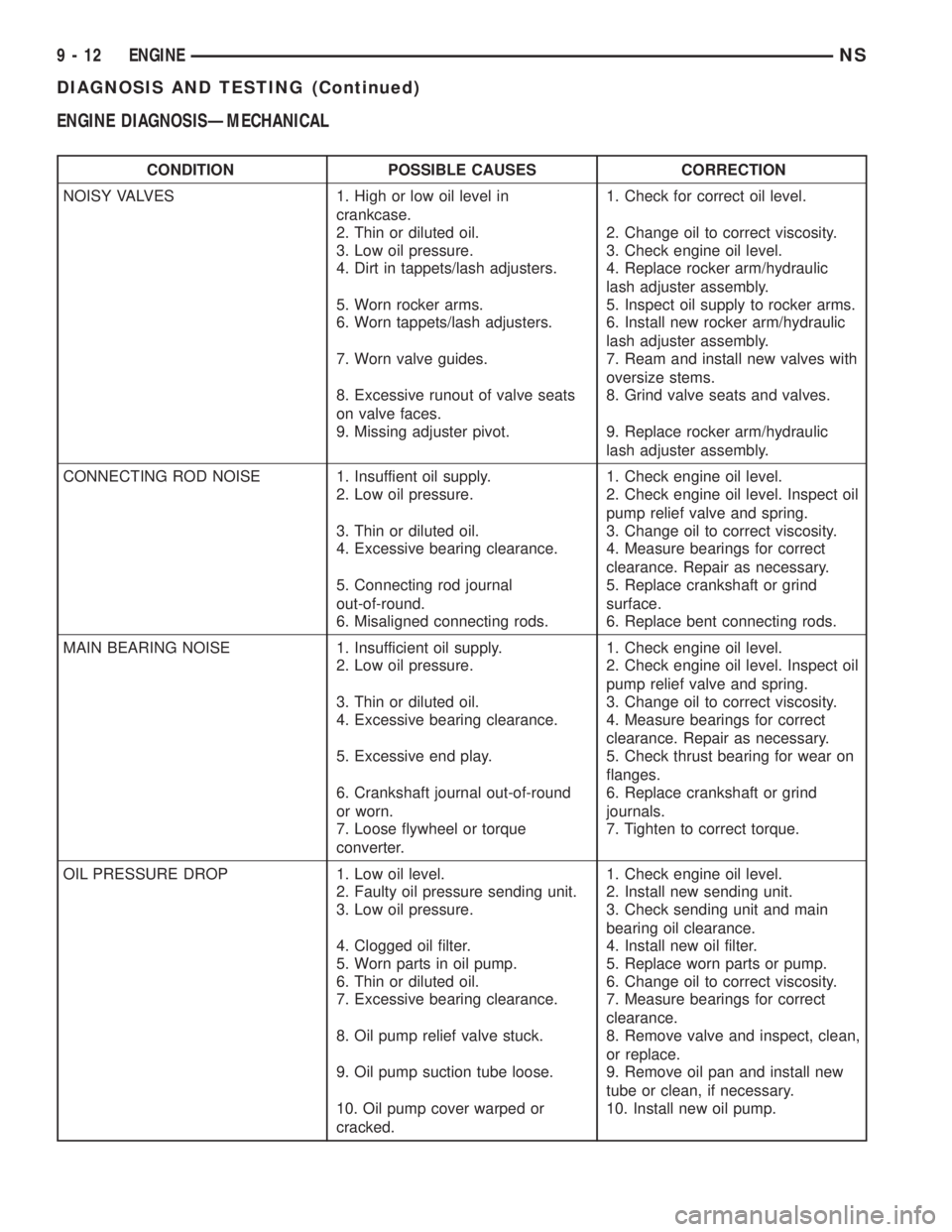

ENGINE DIAGNOSISÐMECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check for correct oil level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Low oil pressure. 3. Check engine oil level.

4. Dirt in tappets/lash adjusters. 4. Replace rocker arm/hydraulic

lash adjuster assembly.

5. Worn rocker arms. 5. Inspect oil supply to rocker arms.

6. Worn tappets/lash adjusters. 6. Install new rocker arm/hydraulic

lash adjuster assembly.

7. Worn valve guides. 7. Ream and install new valves with

oversize stems.

8. Excessive runout of valve seats

on valve faces.8. Grind valve seats and valves.

9. Missing adjuster pivot. 9. Replace rocker arm/hydraulic

lash adjuster assembly.

CONNECTING ROD NOISE 1. Insuffient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Connecting rod journal

out-of-round.5. Replace crankshaft or grind

surface.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Excessive end play. 5. Check thrust bearing for wear on

flanges.

6. Crankshaft journal out-of-round

or worn.6. Replace crankshaft or grind

journals.

7. Loose flywheel or torque

converter.7. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sending unit. 2. Install new sending unit.

3. Low oil pressure. 3. Check sending unit and main

bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Excessive bearing clearance. 7. Measure bearings for correct

clearance.

8. Oil pump relief valve stuck. 8. Remove valve and inspect, clean,

or replace.

9. Oil pump suction tube loose. 9. Remove oil pan and install new

tube or clean, if necessary.

10. Oil pump cover warped or

cracked.10. Install new oil pump.

9 - 12 ENGINENS

DIAGNOSIS AND TESTING (Continued)

Page 1066 of 1938

sealing and a chrome plated taper faced intermediate

ring for additional cylinder pressure control. There

are also standard oil control rings.

CYLINDER HEAD:Features a Dual Over Head

Camshaft (DOHC) 4 valves per cylinder cross flow

design. The valves are arranged in two inline banks,

with the ports of the bank of two intake valves per

cylinder facing toward the radiator side of engine

and ports of the bank of two exhaust valves per cyl-

inder facing toward the dash panel. Incorporates

powder metal valve guides and seats. Integral oil gal-

leys within the cylinder head supplies oil to the

hydraulic lash adjusters, camshaft and valve mecha-

nisms.

CAMSHAFTS:The nodular iron camshafts have

six bearing journals and 2 cam lobes per cylinder.

Flanges at the rear journals control camshaft end

play. Provision for cam position sensor is located on

the intake camshaft at the rear of cylinder head. A

hydrodynamic oil seal is used for oil control at the

front of the camshaft.

VALVES:4 valves per cylinder are actuated by

roller cam followers which pivot on stationary

hydraulic lash adjusters. All valves have 6 mm diam-

eter chrome plated valve stems. The valve sizes are

34.8 mm (1.370 inch.) diameter intake valves and

30.5 mm (1.20 inch.) diameter exhaust valves. Viton

rubber valve stem seals are integral with the spring

seats. Valve springs, spring retainers, and locks are

conventional.

INTAKE MANIFOLD:The intake manifold is a

two piece aluminum casting, attached to the cylinder

head with ten screws. This long branch fan design

enhances low and midspeed torque, while minimizing

undesirable inlet noise.

EXHAUST MANIFOLD:The exhaust manifold is

made of cast iron for strength and high tempera-

tures.

ENGINE LUBRICATION:Refer to Group 0

Lubrication and Maintenance for recommended oil to

be used in various engine application. System is full

flow filtration, pressure feed type. The oil pump is

mounted in the front engine cover and driven by the

crankshaft. Pressurized oil is then routed through

the main oil gallery, running the length of the cylin-

der block, supplying main and rod bearings with fur-

ther routing. Pistons are lubricated from rod bearing

throw off and lubricating slots on the connecting rod

assemblies. Camshaft and valve mechanisms are

lubricated from a full length cylinder head oil gallery

supplied from the crankcase main oil gallery.DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure sending unit and install

gauge assembly C-3292.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not Run

engine at 3000 RPM

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170/550 kPa (25/80 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open or a

clogged oil pickup screen.

SERVICE PROCEDURES

FITTING PISTONS

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin about 14 mm (9/16 inch.) from the bottom

of the skirt as shown in (Fig. 3). Cylinder bores

should be measured halfway down the cylinder bore

and transverse to the engine crankshaft center line

shown in (Fig. 2). Refer to Cylinder Bore and Piston

Specification Chart.

Correct piston to bore clearance must be estab-

lished in order to assure quiet and economical oper-

ation.

Chrysler engines use pistons designed specifically

for each engine model. Clearance and sizing locations

vary with respect to engine model.

NOTE: Pistons and cylinder bores should be mea-

sured at normal room temperature, 70ÉF (21ÉC).

FITTING PISTON RINGS

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 12 mm (0.50 inch) from bottom of

cylinder bore. Check gap with feeler gauge (Fig. 4).

Refer to specification in Piston Ring Specification

Chart.

(2) Check piston ring to groove side clearance (Fig.

5). Refer to specification in Piston Ring Specification

Chart.

9 - 16 2.4L ENGINENS

DESCRIPTION AND OPERATION (Continued)

Page 1071 of 1938

OPTIONAL CRANKSHAFT END PLAY CHECK

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearing

cap and a crankshaft cheek, using care not to dam-

age any bearing surface.DO NOTloosen main bear-

ing cap.

(2) Use a feeler gauge between number three

thrust bearing and machined crankshaft surface to

determine end play.

VALVE SERVICE RECONDITION

VALVE REMOVAL

(1) With cylinder head removed, compress valve

springs using Special Tool C-3422-B or equivalent.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

VALVE INSPECTION

(1) Clean valves thoroughly and discard burned,

warped and cracked valves.

(2) Measure valve stems for wear. Measure stem

about 60 mm beneath the valve lock grooves.

(3) If valve stems are worn more than 0.05 mm

(0.002 in.), replace valve.

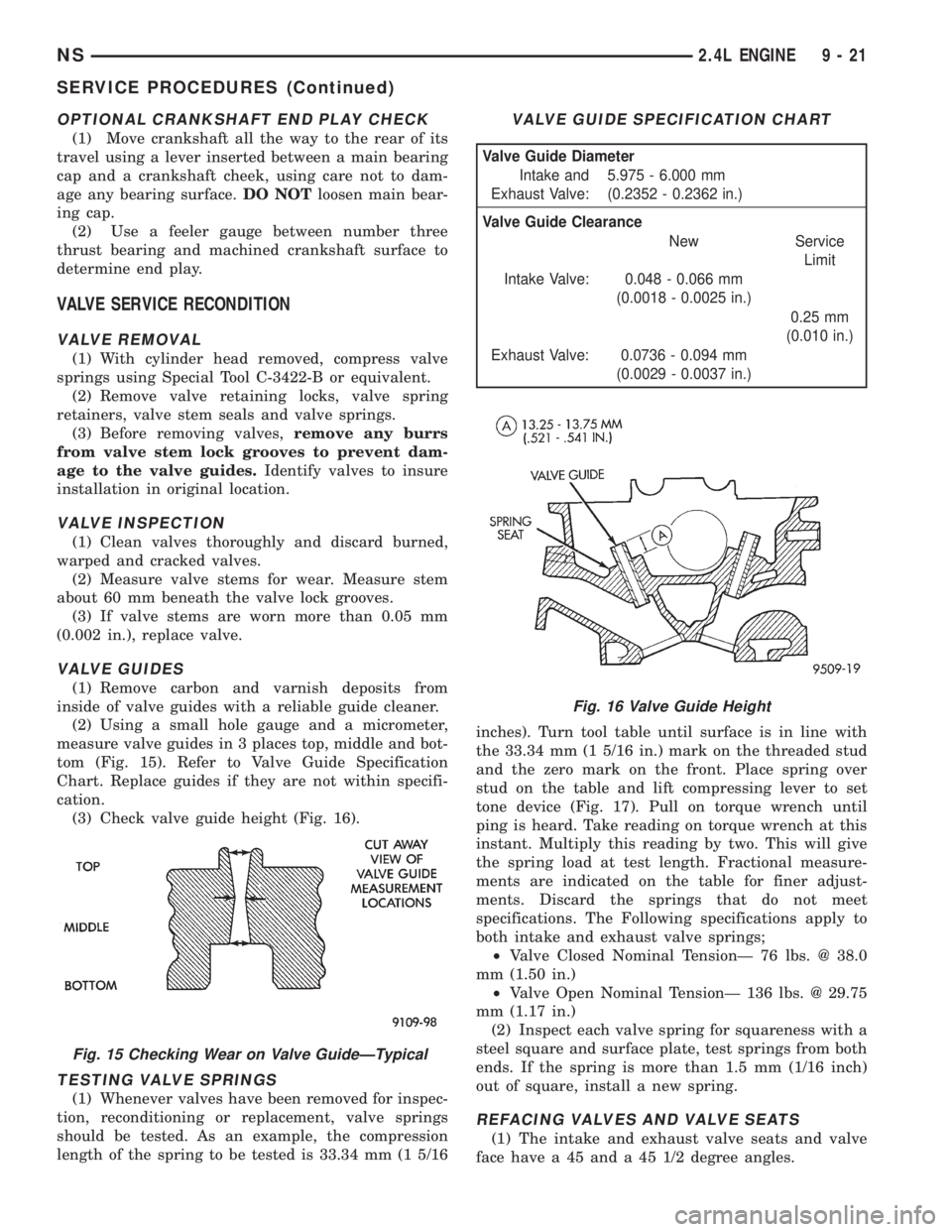

VALVE GUIDES

(1) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(2) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 15). Refer to Valve Guide Specification

Chart. Replace guides if they are not within specifi-

cation.

(3) Check valve guide height (Fig. 16).

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested. As an example, the compression

length of the spring to be tested is 33.34 mm (1 5/16inches). Turn tool table until surface is in line with

the 33.34 mm (1 5/16 in.) mark on the threaded stud

and the zero mark on the front. Place spring over

stud on the table and lift compressing lever to set

tone device (Fig. 17). Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by two. This will give

the spring load at test length. Fractional measure-

ments are indicated on the table for finer adjust-

ments. Discard the springs that do not meet

specifications. The Following specifications apply to

both intake and exhaust valve springs;

²Valve Closed Nominal TensionÐ 76 lbs. @ 38.0

mm (1.50 in.)

²Valve Open Nominal TensionÐ 136 lbs. @ 29.75

mm (1.17 in.)

(2) Inspect each valve spring for squareness with a

steel square and surface plate, test springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 and a 45 1/2 degree angles.

Fig. 15 Checking Wear on Valve GuideÐTypical

VALVE GUIDE SPECIFICATION CHART

Valve Guide Diameter

Intake and

Exhaust Valve:5.975 - 6.000 mm

(0.2352 - 0.2362 in.)

Valve Guide Clearance

New Service

Limit

Intake Valve: 0.048 - 0.066 mm

(0.0018 - 0.0025 in.)

0.25 mm

(0.010 in.)

Exhaust Valve: 0.0736 - 0.094 mm

(0.0029 - 0.0037 in.)

Fig. 16 Valve Guide Height

NS2.4L ENGINE 9 - 21

SERVICE PROCEDURES (Continued)

Page 1072 of 1938

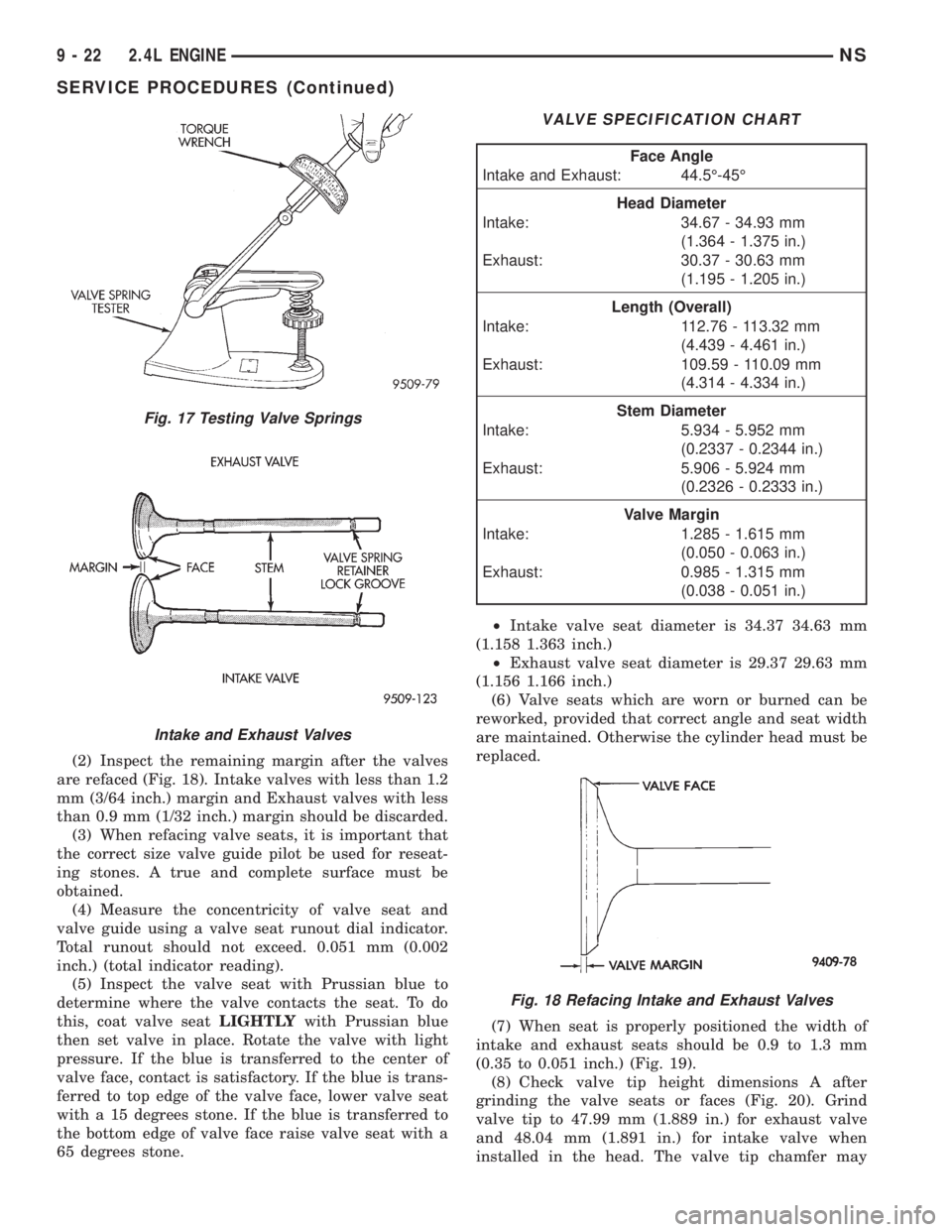

(2) Inspect the remaining margin after the valves

are refaced (Fig. 18). Intake valves with less than 1.2

mm (3/64 inch.) margin and Exhaust valves with less

than 0.9 mm (1/32 inch.) margin should be discarded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed. 0.051 mm (0.002

inch.) (total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.²Intake valve seat diameter is 34.37 34.63 mm

(1.158 1.363 inch.)

²Exhaust valve seat diameter is 29.37 29.63 mm

(1.156 1.166 inch.)

(6) Valve seats which are worn or burned can be

reworked, provided that correct angle and seat width

are maintained. Otherwise the cylinder head must be

replaced.

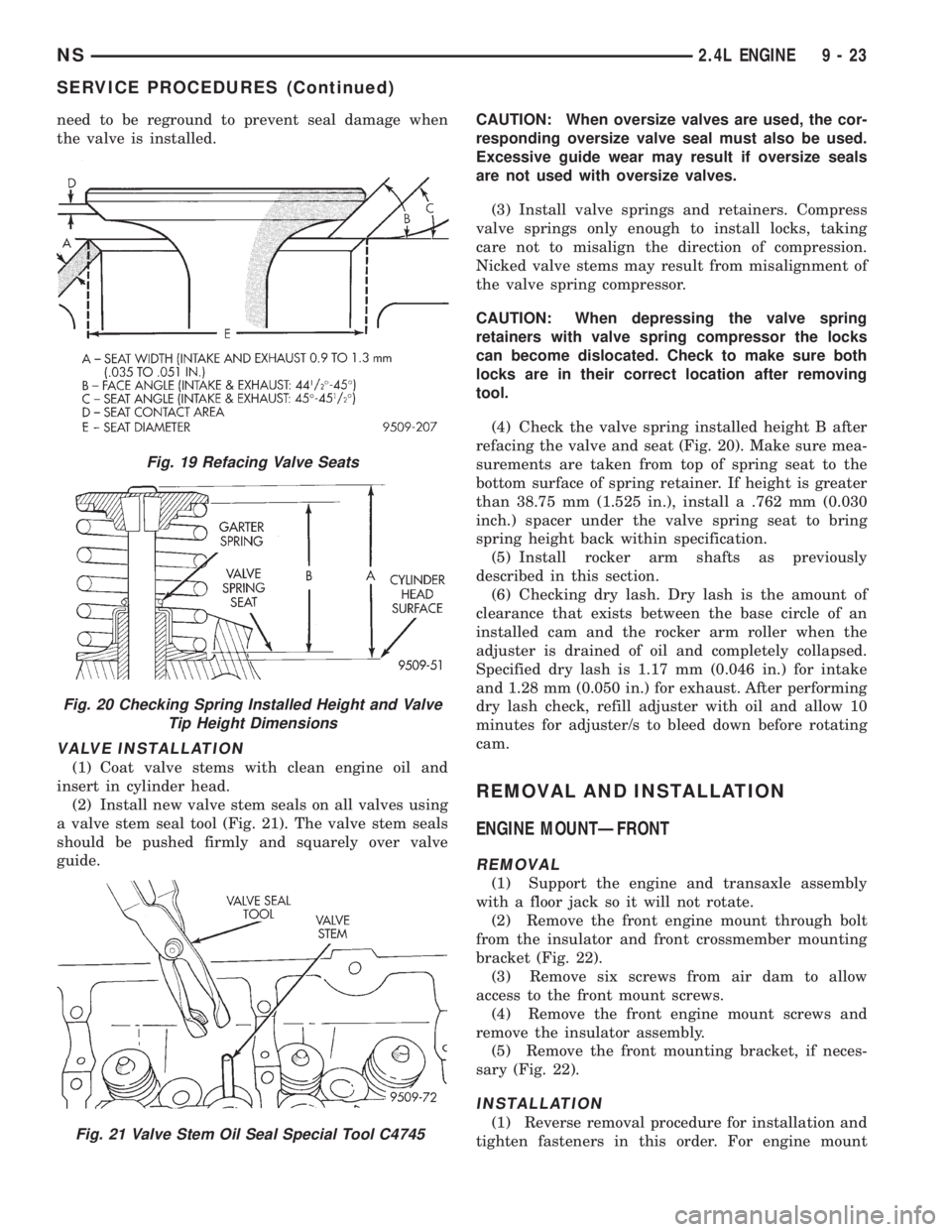

(7) When seat is properly positioned the width of

intake and exhaust seats should be 0.9 to 1.3 mm

(0.35 to 0.051 inch.) (Fig. 19).

(8) Check valve tip height dimensions A after

grinding the valve seats or faces (Fig. 20). Grind

valve tip to 47.99 mm (1.889 in.) for exhaust valve

and 48.04 mm (1.891 in.) for intake valve when

installed in the head. The valve tip chamfer may

Fig. 17 Testing Valve Springs

Intake and Exhaust Valves

VALVE SPECIFICATION CHART

Face Angle

Intake and Exhaust: 44.5É-45É

Head Diameter

Intake: 34.67 - 34.93 mm

(1.364 - 1.375 in.)

Exhaust: 30.37 - 30.63 mm

(1.195 - 1.205 in.)

Length (Overall)

Intake: 112.76 - 113.32 mm

(4.439 - 4.461 in.)

Exhaust: 109.59 - 110.09 mm

(4.314 - 4.334 in.)

Stem Diameter

Intake: 5.934 - 5.952 mm

(0.2337 - 0.2344 in.)

Exhaust: 5.906 - 5.924 mm

(0.2326 - 0.2333 in.)

Valve Margin

Intake: 1.285 - 1.615 mm

(0.050 - 0.063 in.)

Exhaust: 0.985 - 1.315 mm

(0.038 - 0.051 in.)

Fig. 18 Refacing Intake and Exhaust Valves

9 - 22 2.4L ENGINENS

SERVICE PROCEDURES (Continued)

Page 1073 of 1938

need to be reground to prevent seal damage when

the valve is installed.

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

(2) Install new valve stem seals on all valves using

a valve stem seal tool (Fig. 21). The valve stem seals

should be pushed firmly and squarely over valve

guide.CAUTION: When oversize valves are used, the cor-

responding oversize valve seal must also be used.

Excessive guide wear may result if oversize seals

are not used with oversize valves.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 20). Make sure mea-

surements are taken from top of spring seat to the

bottom surface of spring retainer. If height is greater

than 38.75 mm (1.525 in.), install a .762 mm (0.030

inch.) spacer under the valve spring seat to bring

spring height back within specification.

(5) Install rocker arm shafts as previously

described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster/s to bleed down before rotating

cam.

REMOVAL AND INSTALLATION

ENGINE MOUNTÐFRONT

REMOVAL

(1) Support the engine and transaxle assembly

with a floor jack so it will not rotate.

(2) Remove the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 22).

(3) Remove six screws from air dam to allow

access to the front mount screws.

(4) Remove the front engine mount screws and

remove the insulator assembly.

(5) Remove the front mounting bracket, if neces-

sary (Fig. 22).

INSTALLATION

(1) Reverse removal procedure for installation and

tighten fasteners in this order. For engine mount

Fig. 19 Refacing Valve Seats

Fig. 20 Checking Spring Installed Height and Valve

Tip Height Dimensions

Fig. 21 Valve Stem Oil Seal Special Tool C4745

NS2.4L ENGINE 9 - 23

SERVICE PROCEDURES (Continued)

Page 1151 of 1938

dure of 0.15 mm (0.005 in.), 0.40 mm (0.015 in.)

and 0.80 mm (0.030 in.) so the valve guides may

be reamed true in relation to the valve seat.

After reaming guides, the seat runout should be

measured and resurfaced if necessary. See

Refacing Valves and Valve Seats.VALVE GUIDES

NOTE: Replace cylinder head if guide does not

clean up with 0.80 mm (0.030 in.) oversize reamer,

or if guide is loose in cylinder head.

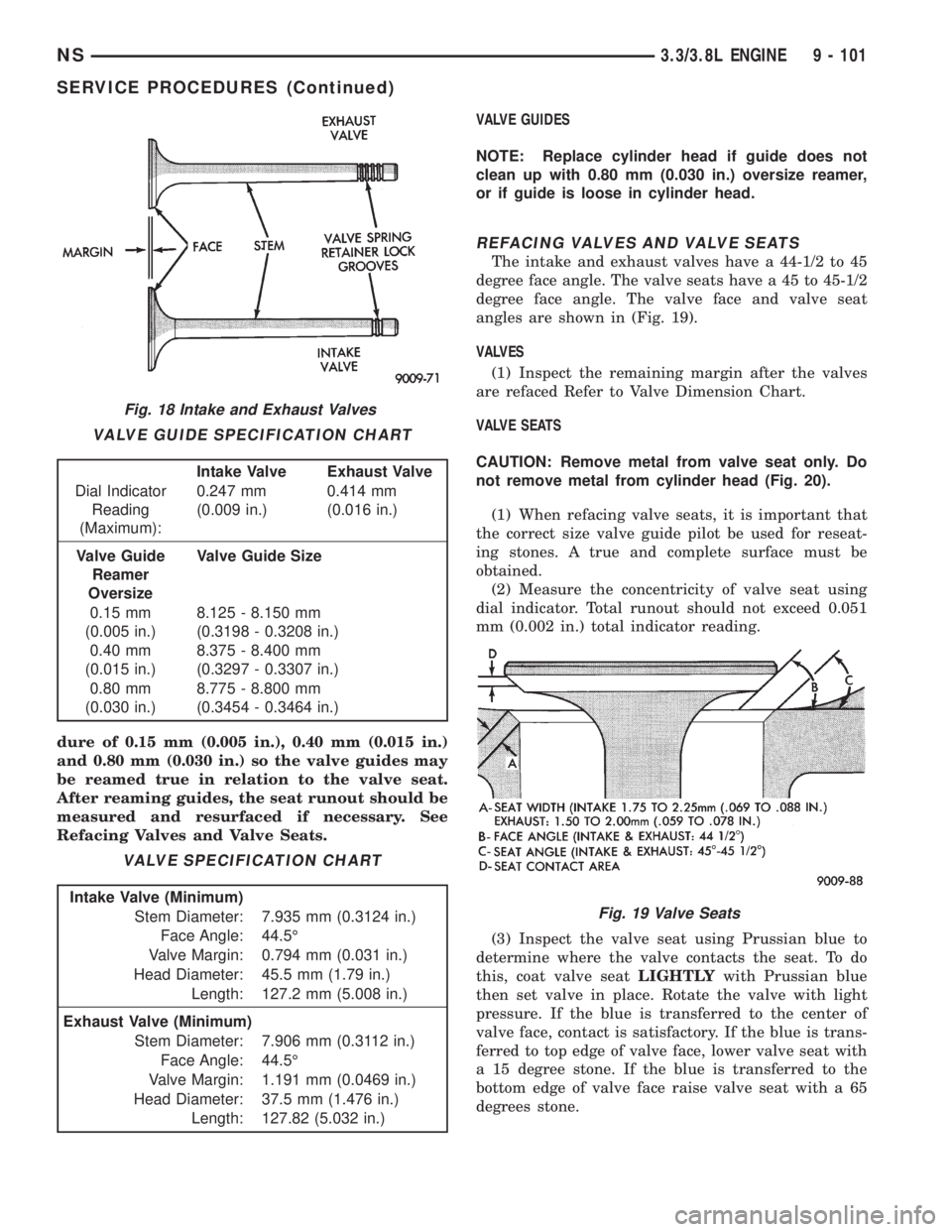

REFACING VALVES AND VALVE SEATS

The intake and exhaust valves have a 44-1/2 to 45

degree face angle. The valve seats have a 45 to 45-1/2

degree face angle. The valve face and valve seat

angles are shown in (Fig. 19).

VALVES

(1) Inspect the remaining margin after the valves

are refaced Refer to Valve Dimension Chart.

VALVE SEATS

CAUTION: Remove metal from valve seat only. Do

not remove metal from cylinder head (Fig. 20).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained.

(2) Measure the concentricity of valve seat using

dial indicator. Total runout should not exceed 0.051

mm (0.002 in.) total indicator reading.

(3) Inspect the valve seat using Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of valve face, lower valve seat with

a 15 degree stone. If the blue is transferred to the

bottom edge of valve face raise valve seat with a 65

degrees stone.

Fig. 18 Intake and Exhaust Valves

VALVE GUIDE SPECIFICATION CHART

Intake Valve Exhaust Valve

Dial Indicator

Reading

(Maximum):0.247 mm

(0.009 in.)0.414 mm

(0.016 in.)

Valve Guide

Reamer

OversizeValve Guide Size

0.15 mm

(0.005 in.)8.125 - 8.150 mm

(0.3198 - 0.3208 in.)

0.40 mm

(0.015 in.)8.375 - 8.400 mm

(0.3297 - 0.3307 in.)

0.80 mm

(0.030 in.)8.775 - 8.800 mm

(0.3454 - 0.3464 in.)

VALVE SPECIFICATION CHART

Intake Valve (Minimum)

Stem Diameter: 7.935 mm (0.3124 in.)

Face Angle: 44.5É

Valve Margin: 0.794 mm (0.031 in.)

Head Diameter: 45.5 mm (1.79 in.)

Length: 127.2 mm (5.008 in.)

Exhaust Valve (Minimum)

Stem Diameter: 7.906 mm (0.3112 in.)

Face Angle: 44.5É

Valve Margin: 1.191 mm (0.0469 in.)

Head Diameter: 37.5 mm (1.476 in.)

Length: 127.82 (5.032 in.)

Fig. 19 Valve Seats

NS3.3/3.8L ENGINE 9 - 101

SERVICE PROCEDURES (Continued)