ESP CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 7 of 1938

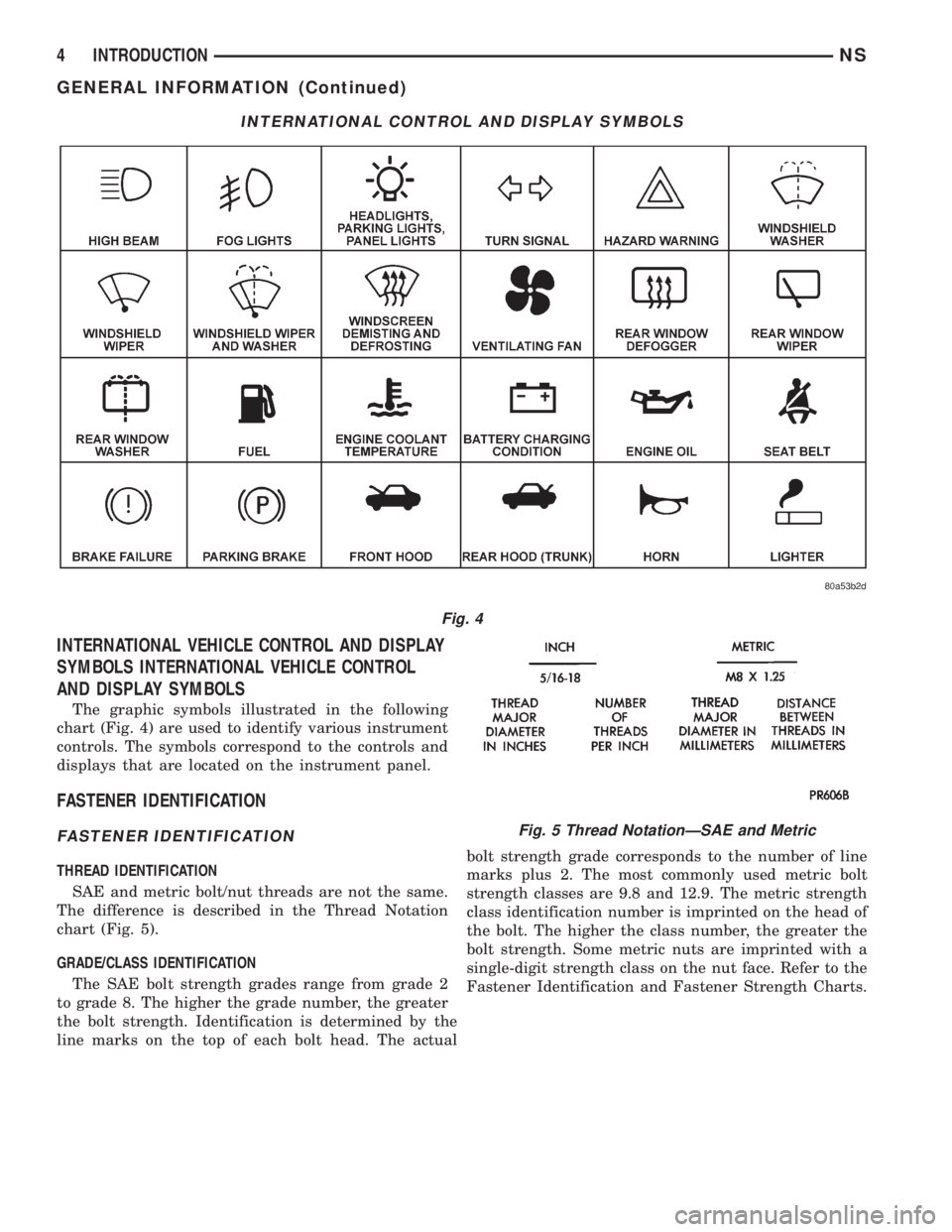

INTERNATIONAL VEHICLE CONTROL AND DISPLAY

SYMBOLS INTERNATIONAL VEHICLE CONTROL

AND DISPLAY SYMBOLS

The graphic symbols illustrated in the following

chart (Fig. 4) are used to identify various instrument

controls. The symbols correspond to the controls and

displays that are located on the instrument panel.

FASTENER IDENTIFICATION

FASTENER IDENTIFICATION

THREAD IDENTIFICATION

SAE and metric bolt/nut threads are not the same.

The difference is described in the Thread Notation

chart (Fig. 5).

GRADE/CLASS IDENTIFICATION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actualbolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 12.9. The metric strength

class identification number is imprinted on the head of

the bolt. The higher the class number, the greater the

bolt strength. Some metric nuts are imprinted with a

single-digit strength class on the nut face. Refer to the

Fastener Identification and Fastener Strength Charts.

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

Fig. 4

Fig. 5 Thread NotationÐSAE and Metric

4 INTRODUCTIONNS

GENERAL INFORMATION (Continued)

Page 96 of 1938

ADJUSTER REAR DRUM BRAKE (AUTOMATIC)

The rear drum brakes on this vehicle automatically

adjust, when required, during the normal operation

of the vehicle every time the brakes are applied. Use

the following procedure to test the operation of the

automatic adjuster.

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the adjustment hole in each brake support

plate to provide visual access of the brake adjuster

star wheel.

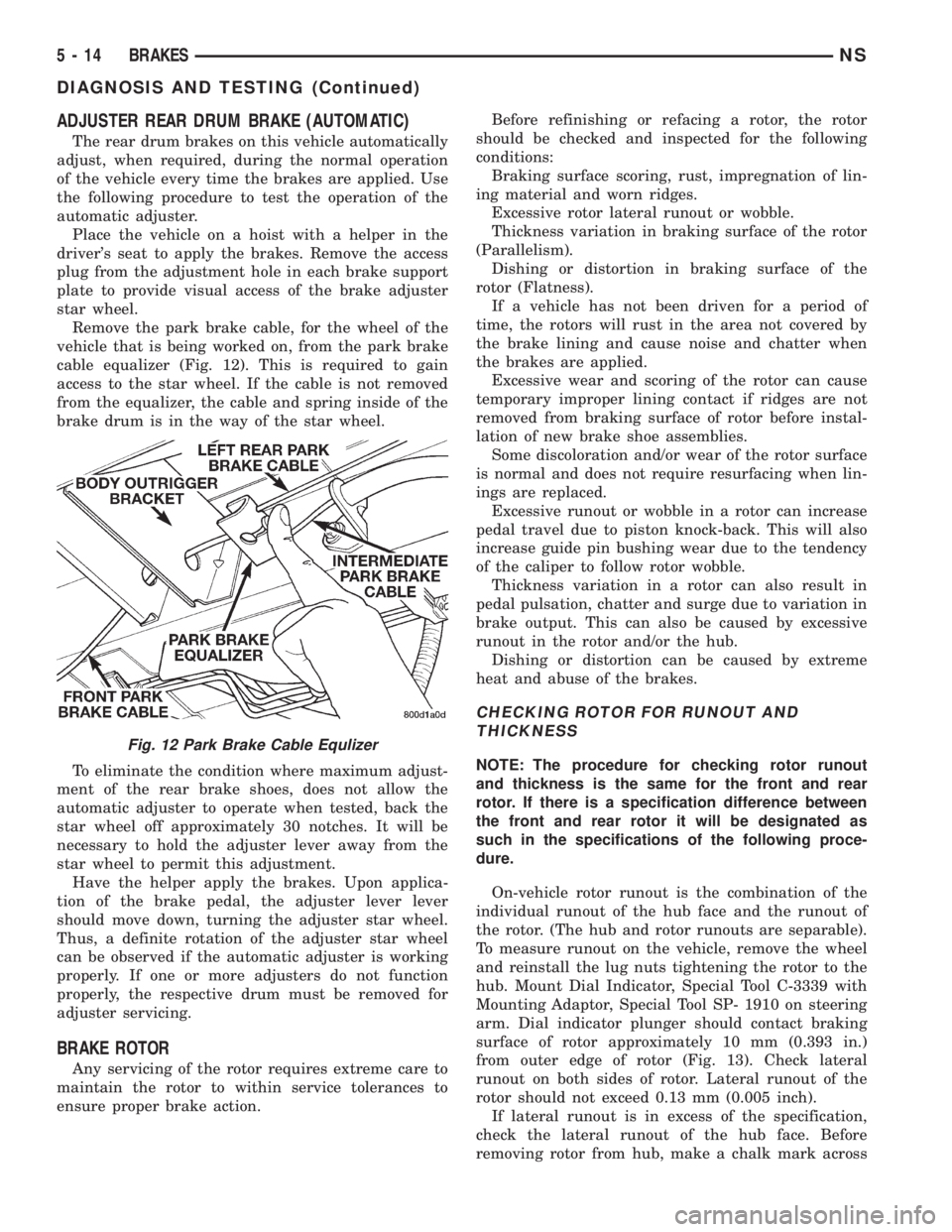

Remove the park brake cable, for the wheel of the

vehicle that is being worked on, from the park brake

cable equalizer (Fig. 12). This is required to gain

access to the star wheel. If the cable is not removed

from the equalizer, the cable and spring inside of the

brake drum is in the way of the star wheel.

To eliminate the condition where maximum adjust-

ment of the rear brake shoes, does not allow the

automatic adjuster to operate when tested, back the

star wheel off approximately 30 notches. It will be

necessary to hold the adjuster lever away from the

star wheel to permit this adjustment.

Have the helper apply the brakes. Upon applica-

tion of the brake pedal, the adjuster lever lever

should move down, turning the adjuster star wheel.

Thus, a definite rotation of the adjuster star wheel

can be observed if the automatic adjuster is working

properly. If one or more adjusters do not function

properly, the respective drum must be removed for

adjuster servicing.

BRAKE ROTOR

Any servicing of the rotor requires extreme care to

maintain the rotor to within service tolerances to

ensure proper brake action.Before refinishing or refacing a rotor, the rotor

should be checked and inspected for the following

conditions:

Braking surface scoring, rust, impregnation of lin-

ing material and worn ridges.

Excessive rotor lateral runout or wobble.

Thickness variation in braking surface of the rotor

(Parallelism).

Dishing or distortion in braking surface of the

rotor (Flatness).

If a vehicle has not been driven for a period of

time, the rotors will rust in the area not covered by

the brake lining and cause noise and chatter when

the brakes are applied.

Excessive wear and scoring of the rotor can cause

temporary improper lining contact if ridges are not

removed from braking surface of rotor before instal-

lation of new brake shoe assemblies.

Some discoloration and/or wear of the rotor surface

is normal and does not require resurfacing when lin-

ings are replaced.

Excessive runout or wobble in a rotor can increase

pedal travel due to piston knock-back. This will also

increase guide pin bushing wear due to the tendency

of the caliper to follow rotor wobble.

Thickness variation in a rotor can also result in

pedal pulsation, chatter and surge due to variation in

brake output. This can also be caused by excessive

runout in the rotor and/or the hub.

Dishing or distortion can be caused by extreme

heat and abuse of the brakes.

CHECKING ROTOR FOR RUNOUT AND

THICKNESS

NOTE: The procedure for checking rotor runout

and thickness is the same for the front and rear

rotor. If there is a specification difference between

the front and rear rotor it will be designated as

such in the specifications of the following proce-

dure.

On-vehicle rotor runout is the combination of the

individual runout of the hub face and the runout of

the rotor. (The hub and rotor runouts are separable).

To measure runout on the vehicle, remove the wheel

and reinstall the lug nuts tightening the rotor to the

hub. Mount Dial Indicator, Special Tool C-3339 with

Mounting Adaptor, Special Tool SP- 1910 on steering

arm. Dial indicator plunger should contact braking

surface of rotor approximately 10 mm (0.393 in.)

from outer edge of rotor (Fig. 13). Check lateral

runout on both sides of rotor. Lateral runout of the

rotor should not exceed 0.13 mm (0.005 inch).

If lateral runout is in excess of the specification,

check the lateral runout of the hub face. Before

removing rotor from hub, make a chalk mark across

Fig. 12 Park Brake Cable Equlizer

5 - 14 BRAKESNS

DIAGNOSIS AND TESTING (Continued)

Page 109 of 1938

(4) Remove the locking pliers from the front park

brake cable. This will allow the adjuster in the park

brake pedal mechanism to rotate around to its stop.

This will remove the tension from the adjuster and

front park brake cable.

Use the following procedure to reset the auto

adjuster in the park brake pedal mechanism.

(5) Grasp the exposed section of the front park

brake cable and pull rearward on it. While holding

the park brake in this position, install a pair of lock-

ing pliers on the front park brake cable just rearward

of the second body outrigger bracket (Fig. 42).

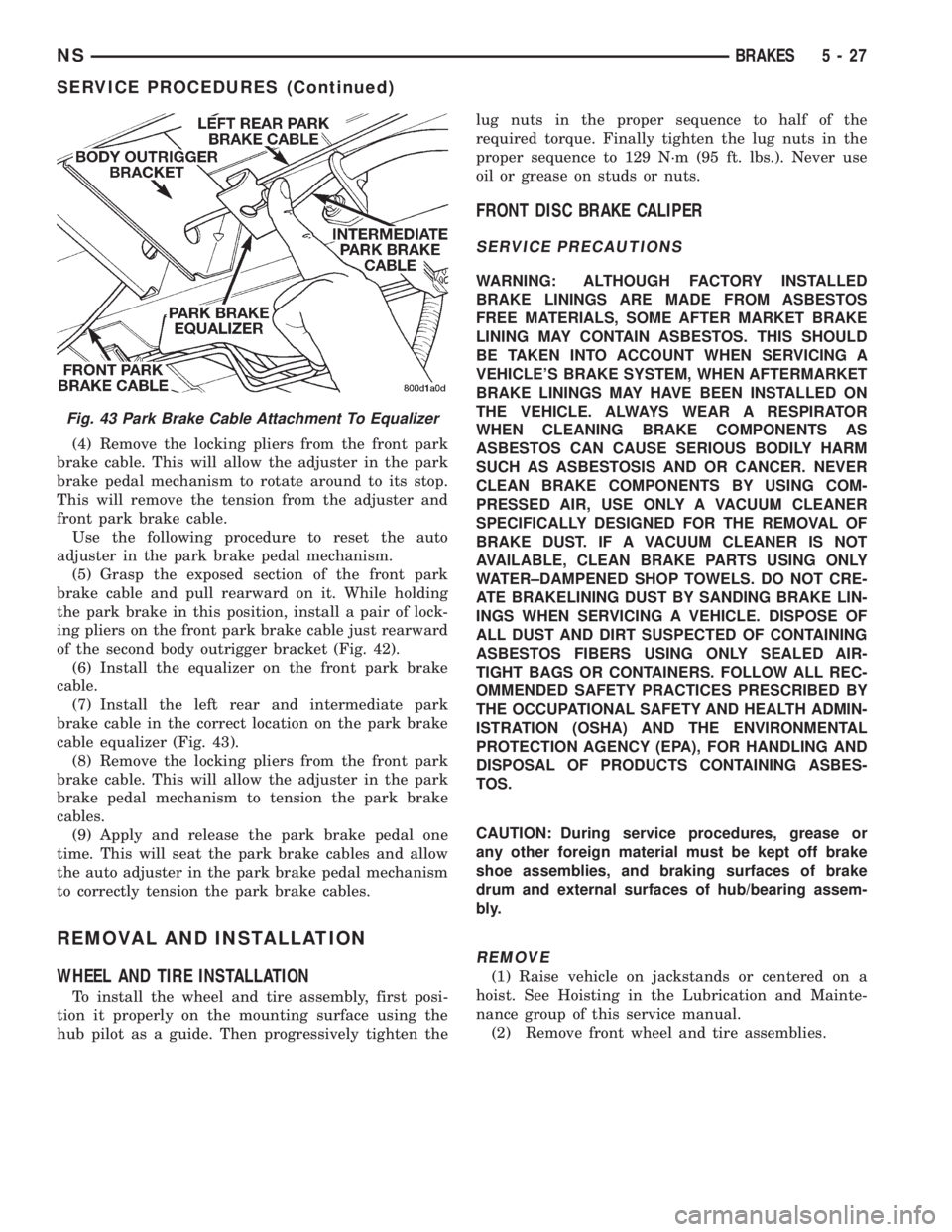

(6) Install the equalizer on the front park brake

cable.

(7) Install the left rear and intermediate park

brake cable in the correct location on the park brake

cable equalizer (Fig. 43).

(8) Remove the locking pliers from the front park

brake cable. This will allow the adjuster in the park

brake pedal mechanism to tension the park brake

cables.

(9) Apply and release the park brake pedal one

time. This will seat the park brake cables and allow

the auto adjuster in the park brake pedal mechanism

to correctly tension the park brake cables.

REMOVAL AND INSTALLATION

WHEEL AND TIRE INSTALLATION

To install the wheel and tire assembly, first posi-

tion it properly on the mounting surface using the

hub pilot as a guide. Then progressively tighten thelug nuts in the proper sequence to half of the

required torque. Finally tighten the lug nuts in the

proper sequence to 129 N´m (95 ft. lbs.). Never use

oil or grease on studs or nuts.

FRONT DISC BRAKE CALIPER

SERVICE PRECAUTIONS

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKE LININGS ARE MADE FROM ASBESTOS

FREE MATERIALS, SOME AFTER MARKET BRAKE

LINING MAY CONTAIN ASBESTOS. THIS SHOULD

BE TAKEN INTO ACCOUNT WHEN SERVICING A

VEHICLE'S BRAKE SYSTEM, WHEN AFTERMARKET

BRAKE LININGS MAY HAVE BEEN INSTALLED ON

THE VEHICLE. ALWAYS WEAR A RESPIRATOR

WHEN CLEANING BRAKE COMPONENTS AS

ASBESTOS CAN CAUSE SERIOUS BODILY HARM

SUCH AS ASBESTOSIS AND OR CANCER. NEVER

CLEAN BRAKE COMPONENTS BY USING COM-

PRESSED AIR, USE ONLY A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR THE REMOVAL OF

BRAKE DUST. IF A VACUUM CLEANER IS NOT

AVAILABLE, CLEAN BRAKE PARTS USING ONLY

WATER±DAMPENED SHOP TOWELS. DO NOT CRE-

ATE BRAKELINING DUST BY SANDING BRAKE LIN-

INGS WHEN SERVICING A VEHICLE. DISPOSE OF

ALL DUST AND DIRT SUSPECTED OF CONTAINING

ASBESTOS FIBERS USING ONLY SEALED AIR-

TIGHT BAGS OR CONTAINERS. FOLLOW ALL REC-

OMMENDED SAFETY PRACTICES PRESCRIBED BY

THE OCCUPATIONAL SAFETY AND HEALTH ADMIN-

ISTRATION (OSHA) AND THE ENVIRONMENTAL

PROTECTION AGENCY (EPA), FOR HANDLING AND

DISPOSAL OF PRODUCTS CONTAINING ASBES-

TOS.

CAUTION: During service procedures, grease or

any other foreign material must be kept off brake

shoe assemblies, and braking surfaces of brake

drum and external surfaces of hub/bearing assem-

bly.

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Remove front wheel and tire assemblies.

Fig. 43 Park Brake Cable Attachment To Equalizer

NSBRAKES 5 - 27

SERVICE PROCEDURES (Continued)

Page 112 of 1938

(9) Road test the vehicle and make several stops to

wear off any foreign material on the brakes and to

seat the brake shoe linings.

FRONT DISC BRAKE PADS

REMOVE

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKE LININGS ARE MADE FROM ASBESTOS

FREE MATERIALS, SOME AFTERMARKET BRAKE

LININGS MAY CONTAIN ASBESTOS. THIS SHOULD

BE TAKEN INTO ACCOUNT WHEN SERVICING A

VEHICLE'S BRAKE SYSTEM, WHEN AFTERMARKET

BRAKE LININGS MAY HAVE BEEN INSTALLED ON

THE VEHICLE. ALWAYS WEAR A RESPIRATOR

WHEN CLEANING BRAKE COMPONENTS AS

ASBESTOS CAN CAUSE SERIOUS BODILY HARM

SUCH AS ASBESTOSIS AND OR CANCER. NEVER

CLEAN BRAKE COMPONENTS BY USING COM-

PRESSED AIR, USE ONLY A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR THE REMOVAL OF

BRAKE DUST. IF A VACUUM CLEANER IS NOT

AVAILABLE, CLEAN BRAKE PARTS USING ONLY

WATER±DAMPENED SHOP TOWELS. DO NOT CRE-

ATE BRAKELINING DUST BY SANDING BRAKE LIN-

INGS WHEN SERVICING A VEHICLE. DISPOSE OF

ALL DUST AND DIRT SUSPECTED OF CONTAINING

ASBESTOS FIBERS USING ONLY SEALED AIR-

TIGHT BAGS OR CONTAINERS. FOLLOW ALL REC-

OMMENDED SAFETY PRACTICES PRESCRIBED BY

THE OCCUPATIONAL SAFETY AND HEALTH ADMIN-

ISTRATION (OSHA) AND THE ENVIRONMENTAL

PROTECTION AGENCY (EPA), FOR HANDLING AND

DISPOSAL OF PRODUCTS CONTAINING ASBES-

TOS.

CAUTION: During service procedures, grease or

any other foreign material must be kept off brake

shoe assemblies, and braking surfaces of brake

drum and external surfaces of hub/bearing assem-

bly.

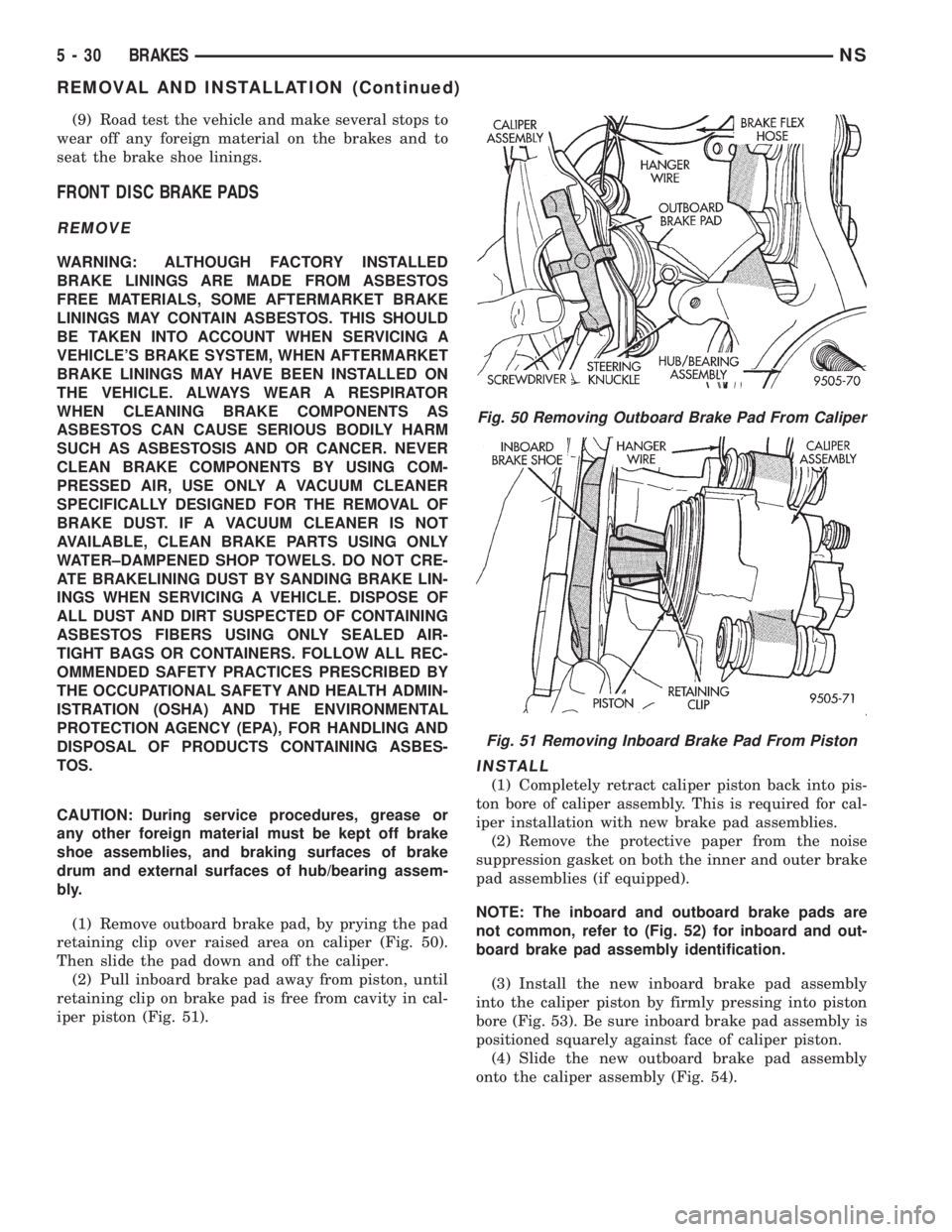

(1) Remove outboard brake pad, by prying the pad

retaining clip over raised area on caliper (Fig. 50).

Then slide the pad down and off the caliper.

(2) Pull inboard brake pad away from piston, until

retaining clip on brake pad is free from cavity in cal-

iper piston (Fig. 51).

INSTALL

(1) Completely retract caliper piston back into pis-

ton bore of caliper assembly. This is required for cal-

iper installation with new brake pad assemblies.

(2) Remove the protective paper from the noise

suppression gasket on both the inner and outer brake

pad assemblies (if equipped).

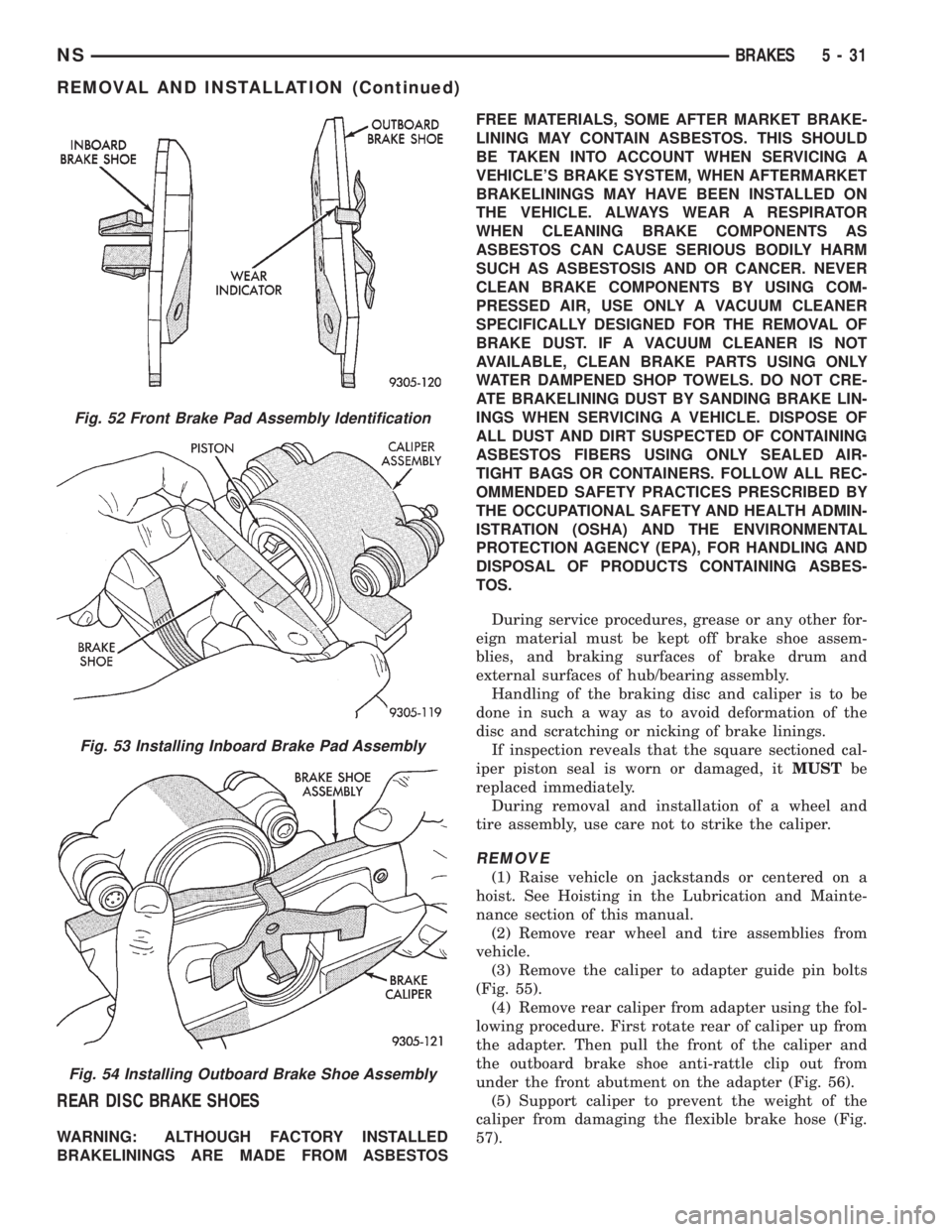

NOTE: The inboard and outboard brake pads are

not common, refer to (Fig. 52) for inboard and out-

board brake pad assembly identification.

(3) Install the new inboard brake pad assembly

into the caliper piston by firmly pressing into piston

bore (Fig. 53). Be sure inboard brake pad assembly is

positioned squarely against face of caliper piston.

(4) Slide the new outboard brake pad assembly

onto the caliper assembly (Fig. 54).

Fig. 50 Removing Outboard Brake Pad From Caliper

Fig. 51 Removing Inboard Brake Pad From Piston

5 - 30 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 113 of 1938

REAR DISC BRAKE SHOES

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKELININGS ARE MADE FROM ASBESTOSFREE MATERIALS, SOME AFTER MARKET BRAKE-

LINING MAY CONTAIN ASBESTOS. THIS SHOULD

BE TAKEN INTO ACCOUNT WHEN SERVICING A

VEHICLE'S BRAKE SYSTEM, WHEN AFTERMARKET

BRAKELININGS MAY HAVE BEEN INSTALLED ON

THE VEHICLE. ALWAYS WEAR A RESPIRATOR

WHEN CLEANING BRAKE COMPONENTS AS

ASBESTOS CAN CAUSE SERIOUS BODILY HARM

SUCH AS ASBESTOSIS AND OR CANCER. NEVER

CLEAN BRAKE COMPONENTS BY USING COM-

PRESSED AIR, USE ONLY A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR THE REMOVAL OF

BRAKE DUST. IF A VACUUM CLEANER IS NOT

AVAILABLE, CLEAN BRAKE PARTS USING ONLY

WATER DAMPENED SHOP TOWELS. DO NOT CRE-

ATE BRAKELINING DUST BY SANDING BRAKE LIN-

INGS WHEN SERVICING A VEHICLE. DISPOSE OF

ALL DUST AND DIRT SUSPECTED OF CONTAINING

ASBESTOS FIBERS USING ONLY SEALED AIR-

TIGHT BAGS OR CONTAINERS. FOLLOW ALL REC-

OMMENDED SAFETY PRACTICES PRESCRIBED BY

THE OCCUPATIONAL SAFETY AND HEALTH ADMIN-

ISTRATION (OSHA) AND THE ENVIRONMENTAL

PROTECTION AGENCY (EPA), FOR HANDLING AND

DISPOSAL OF PRODUCTS CONTAINING ASBES-

TOS.

During service procedures, grease or any other for-

eign material must be kept off brake shoe assem-

blies, and braking surfaces of brake drum and

external surfaces of hub/bearing assembly.

Handling of the braking disc and caliper is to be

done in such a way as to avoid deformation of the

disc and scratching or nicking of brake linings.

If inspection reveals that the square sectioned cal-

iper piston seal is worn or damaged, itMUSTbe

replaced immediately.

During removal and installation of a wheel and

tire assembly, use care not to strike the caliper.

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this manual.

(2) Remove rear wheel and tire assemblies from

vehicle.

(3) Remove the caliper to adapter guide pin bolts

(Fig. 55).

(4) Remove rear caliper from adapter using the fol-

lowing procedure. First rotate rear of caliper up from

the adapter. Then pull the front of the caliper and

the outboard brake shoe anti-rattle clip out from

under the front abutment on the adapter (Fig. 56).

(5) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

57).

Fig. 52 Front Brake Pad Assembly Identification

Fig. 53 Installing Inboard Brake Pad Assembly

Fig. 54 Installing Outboard Brake Shoe Assembly

NSBRAKES 5 - 31

REMOVAL AND INSTALLATION (Continued)

Page 116 of 1938

REAR DRUM BRAKE SHOES

REMOVE

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKE LININGS ARE MADE FROM ASBESTOS

FREE MATERIALS, SOME AFTERMARKET BRAK-

LINING MAY CONTAIN ASBESTOS. THIS SHOULD

BE TAKEN INTO ACCOUNT WHEN SERVICING A

VEHICLE'S BRAKE SYSTEM, WHEN AFTERMARKET

BRAKE LININGS MAY HAVE BEEN INSTALLED ON

THE VEHICLE. ALWAYS WEAR A RESPIRATOR

WHEN CLEANING BRAKE COMPONENTS AS

ASBESTOS CAN CAUSE SERIOUS BODILY HARM

SUCH AS ASBESTOSIS AND OR CANCER. NEVER

CLEAN BRAKE COMPONENTS BY USING COM-

PRESSED AIR, USE ONLY A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR THE REMOVAL OF

BRAKE DUST. IF A VACUUM CLEANER IS NOT

AVAILABLE, CLEAN BRAKE PARTS USING ONLY

WATER±DAMPENED SHOP TOWELS. DO NOT CRE-

ATE BRAKE LINING DUST BY SANDING BRAKE

LININGS WHEN SERVICING A VEHICLE. DISPOSE

OF ALL DUST AND DIRT SUSPECTED OF CONTAIN-

ING ASBESTOS FIBERS USING ONLY SEALED AIR-

TIGHT BAGS OR CONTAINERS. FOLLOW ALL

RECOMMENDED SAFETY PRACTICES PRE-

SCRIBED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION (OSHA) AND THE ENVI-

RONMENTAL PROTECTION AGENCY (EPA), FOR

HANDLING AND DISPOSAL OF PRODUCTS CON-

TAINING ASBESTOS.

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this manual.

(2) Remove the rear wheel and tire assemblies

from the vehicle.

(3) Remove rear brake drum to hub retaining nuts

(if equipped). Then remove rear brake drums from

hub and bearing assemblies.

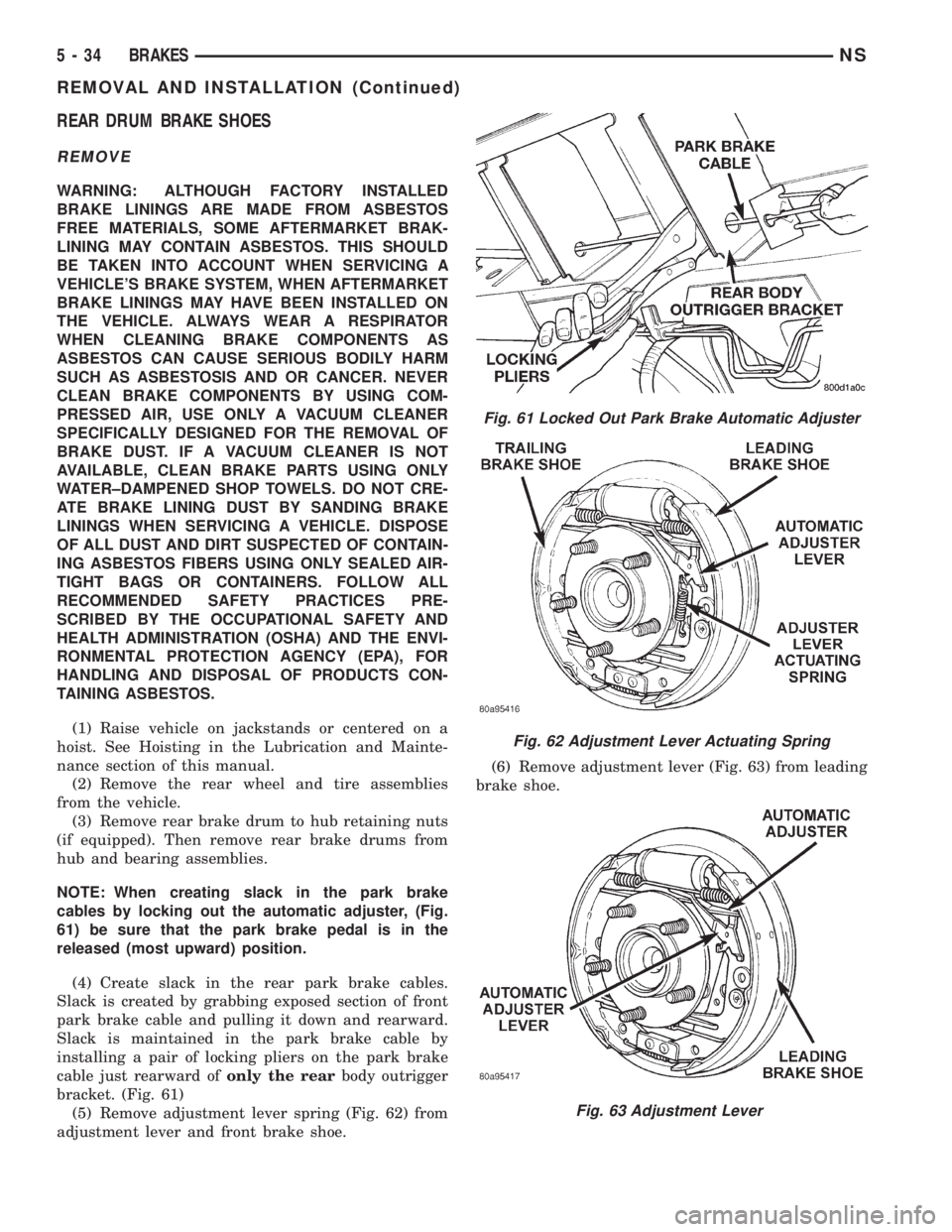

NOTE: When creating slack in the park brake

cables by locking out the automatic adjuster, (Fig.

61) be sure that the park brake pedal is in the

released (most upward) position.

(4) Create slack in the rear park brake cables.

Slack is created by grabbing exposed section of front

park brake cable and pulling it down and rearward.

Slack is maintained in the park brake cable by

installing a pair of locking pliers on the park brake

cable just rearward ofonly the rearbody outrigger

bracket. (Fig. 61)

(5) Remove adjustment lever spring (Fig. 62) from

adjustment lever and front brake shoe.(6) Remove adjustment lever (Fig. 63) from leading

brake shoe.

Fig. 61 Locked Out Park Brake Automatic Adjuster

Fig. 62 Adjustment Lever Actuating Spring

Fig. 63 Adjustment Lever

5 - 34 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 196 of 1938

Upon application of the brake pedal, the lever

should move down, turning the star wheel. A definite

rotation of the star wheel should be seen if the auto-

matic adjuster is working properly. If no rotation of

the star wheel is observed when the pedal is consec-

utively pressed and released, the respective drum

will have to be removed and the adjuster serviced.

MASTER CYLINDER FLUID LEVEL CHECK

The master cylinder used in this vehicle has the

same fluid level markings as the master cylinders

used in other brake systems on the side of the fluid

resevoir. Refer to the Master Cylinder Fluid Level

Check in the Diagnosis and Testing section of group

5 for more information

REMOVAL AND INSTALLATION

FRONT PARK BRAKE CABLE AND LEVER

ASSEMBLY-RHD&LHD VEHICLES

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Remove the intermediate and left rear park

brake cable from the park brake cable equalizer (Fig.

2).

(3) Remove the front park cable housing retainer

from body outrigger bracket (Fig. 3). Cable is remov-

able by sliding a 14 mm box wrench over cable

retainer and compressing the three retaining fingers.

Alternate method is to use an aircraft type hose

clamp and screwdriver.(4) Remove the two (2) retaining nuts and (2)

retaining bolts from the bottom of the parking brake/

gearshift lever bracket.

(5) Lower vehicle.

(6) Carefully lift the base of the gearshift boot

from the gearshift console to access the screws (Fig.

4).

Fig. 2 Park Brake Cable Attachment To Equalizer

Fig. 3 Front Park Brake Cable Attachment To Body

Fig. 4 Console and Gearshift boot

5 - 2 BRAKESNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 300 of 1938

²available manifold vacuum

²barometric pressure

²engine coolant temperature

²engine RPM

²intake air temperature (2.4L only)

²throttle position

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

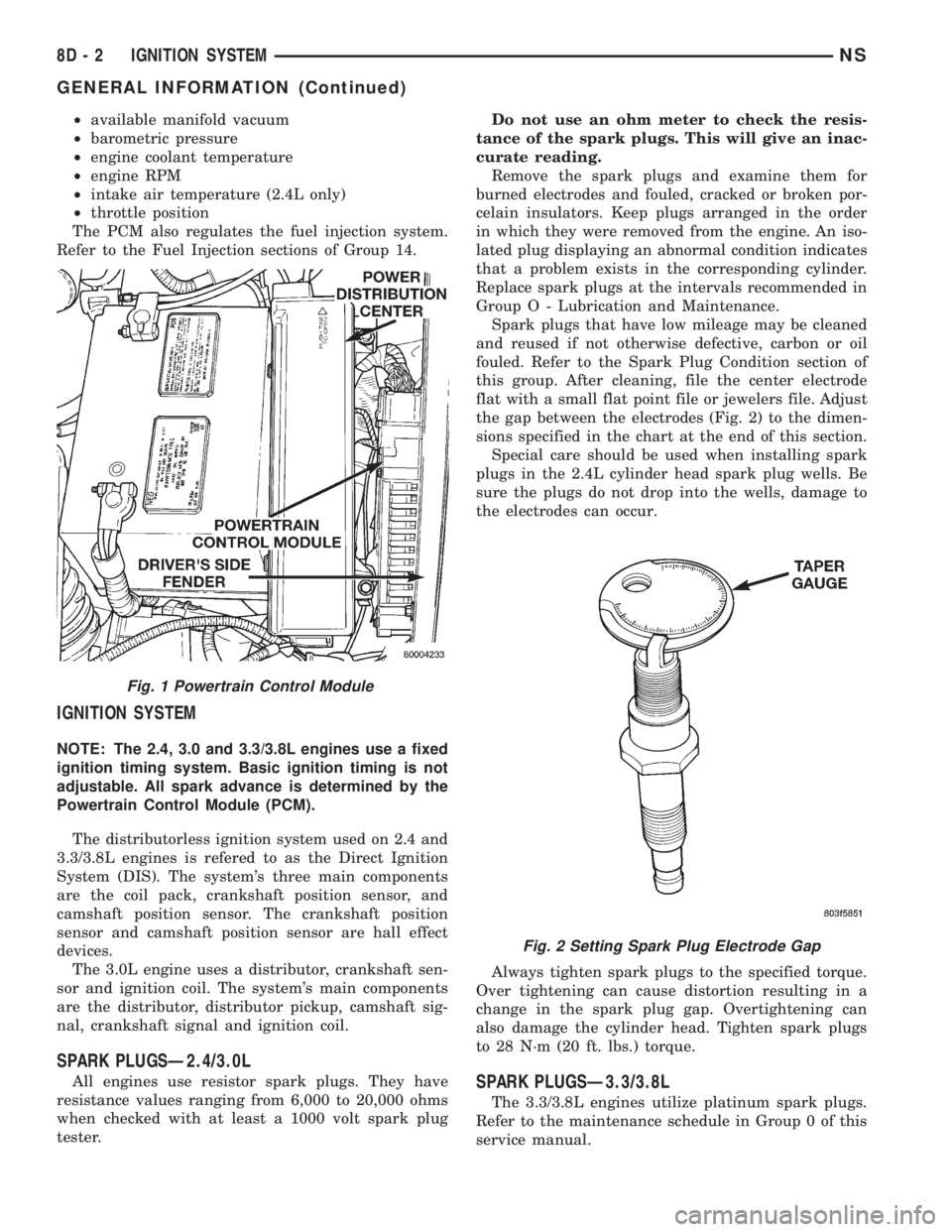

IGNITION SYSTEM

NOTE: The 2.4, 3.0 and 3.3/3.8L engines use a fixed

ignition timing system. Basic ignition timing is not

adjustable. All spark advance is determined by the

Powertrain Control Module (PCM).

The distributorless ignition system used on 2.4 and

3.3/3.8L engines is refered to as the Direct Ignition

System (DIS). The system's three main components

are the coil pack, crankshaft position sensor, and

camshaft position sensor. The crankshaft position

sensor and camshaft position sensor are hall effect

devices.

The 3.0L engine uses a distributor, crankshaft sen-

sor and ignition coil. The system's main components

are the distributor, distributor pickup, camshaft sig-

nal, crankshaft signal and ignition coil.

SPARK PLUGSÐ2.4/3.0L

All engines use resistor spark plugs. They have

resistance values ranging from 6,000 to 20,000 ohms

when checked with at least a 1000 volt spark plug

tester.Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

curate reading.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O - Lubrication and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective, carbon or oil

fouled. Refer to the Spark Plug Condition section of

this group. After cleaning, file the center electrode

flat with a small flat point file or jewelers file. Adjust

the gap between the electrodes (Fig. 2) to the dimen-

sions specified in the chart at the end of this section.

Special care should be used when installing spark

plugs in the 2.4L cylinder head spark plug wells. Be

sure the plugs do not drop into the wells, damage to

the electrodes can occur.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap. Overtightening can

also damage the cylinder head. Tighten spark plugs

to 28 N´m (20 ft. lbs.) torque.SPARK PLUGSÐ3.3/3.8L

The 3.3/3.8L engines utilize platinum spark plugs.

Refer to the maintenance schedule in Group 0 of this

service manual.

Fig. 1 Powertrain Control Module

Fig. 2 Setting Spark Plug Electrode Gap

8D - 2 IGNITION SYSTEMNS

GENERAL INFORMATION (Continued)

Page 301 of 1938

All engines use resistor spark plugs. They have

resistance values ranging from 6,000 to 20,000 ohms

when checked with at least a 1000 volt spark plug

tester.

Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

curate reading.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O - Lubrication and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective, carbon or oil

fouled. Refer to the Spark Plug Condition section of

this group.

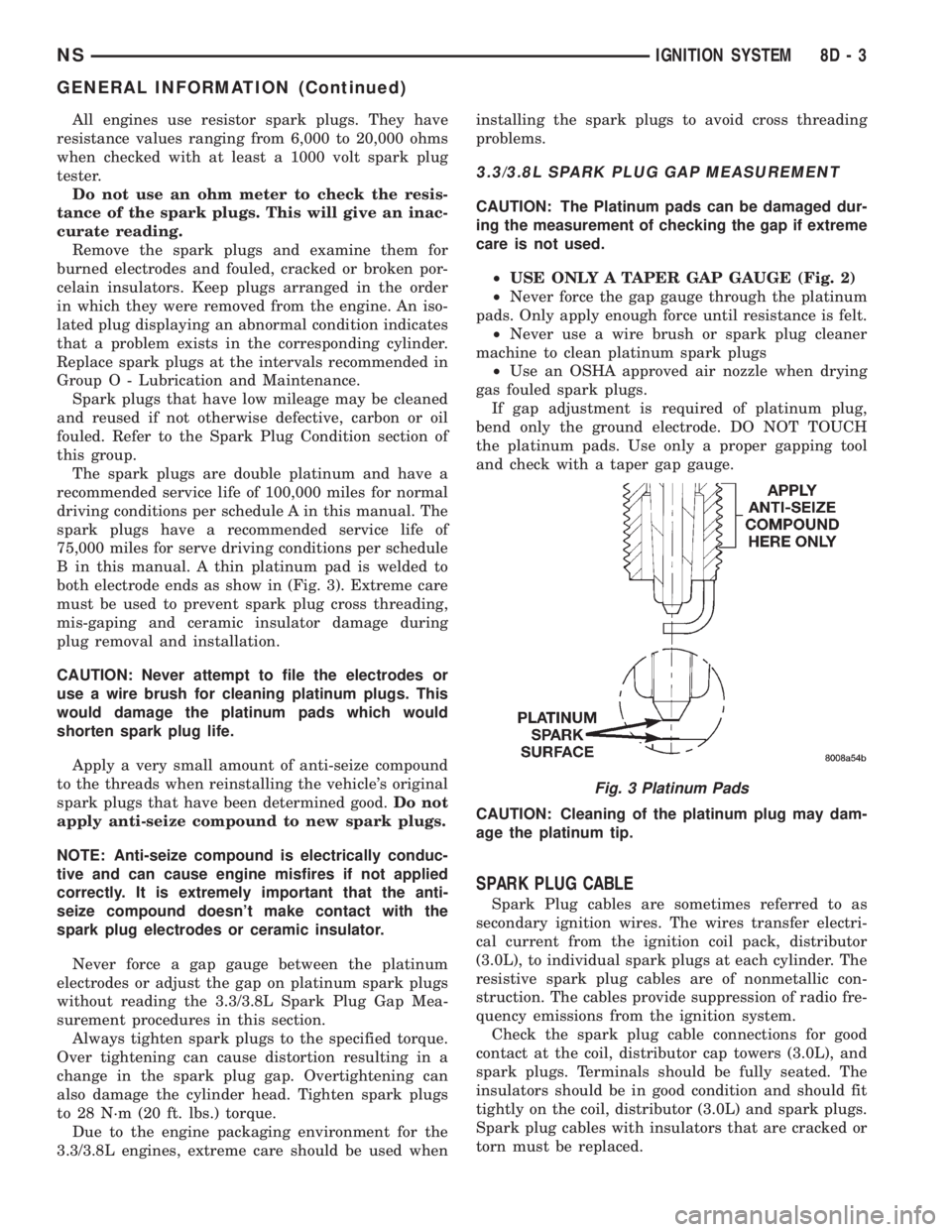

The spark plugs are double platinum and have a

recommended service life of 100,000 miles for normal

driving conditions per schedule A in this manual. The

spark plugs have a recommended service life of

75,000 miles for serve driving conditions per schedule

B in this manual. A thin platinum pad is welded to

both electrode ends as show in (Fig. 3). Extreme care

must be used to prevent spark plug cross threading,

mis-gaping and ceramic insulator damage during

plug removal and installation.

CAUTION: Never attempt to file the electrodes or

use a wire brush for cleaning platinum plugs. This

would damage the platinum pads which would

shorten spark plug life.

Apply a very small amount of anti-seize compound

to the threads when reinstalling the vehicle's original

spark plugs that have been determined good.Do not

apply anti-seize compound to new spark plugs.

NOTE: Anti-seize compound is electrically conduc-

tive and can cause engine misfires if not applied

correctly. It is extremely important that the anti-

seize compound doesn't make contact with the

spark plug electrodes or ceramic insulator.

Never force a gap gauge between the platinum

electrodes or adjust the gap on platinum spark plugs

without reading the 3.3/3.8L Spark Plug Gap Mea-

surement procedures in this section.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap. Overtightening can

also damage the cylinder head. Tighten spark plugs

to 28 N´m (20 ft. lbs.) torque.

Due to the engine packaging environment for the

3.3/3.8L engines, extreme care should be used wheninstalling the spark plugs to avoid cross threading

problems.

3.3/3.8L SPARK PLUG GAP MEASUREMENT

CAUTION: The Platinum pads can be damaged dur-

ing the measurement of checking the gap if extreme

care is not used.

²USE ONLY A TAPER GAP GAUGE (Fig. 2)

²Never force the gap gauge through the platinum

pads. Only apply enough force until resistance is felt.

²Never use a wire brush or spark plug cleaner

machine to clean platinum spark plugs

²Use an OSHA approved air nozzle when drying

gas fouled spark plugs.

If gap adjustment is required of platinum plug,

bend only the ground electrode. DO NOT TOUCH

the platinum pads. Use only a proper gapping tool

and check with a taper gap gauge.

CAUTION: Cleaning of the platinum plug may dam-

age the platinum tip.

SPARK PLUG CABLE

Spark Plug cables are sometimes referred to as

secondary ignition wires. The wires transfer electri-

cal current from the ignition coil pack, distributor

(3.0L), to individual spark plugs at each cylinder. The

resistive spark plug cables are of nonmetallic con-

struction. The cables provide suppression of radio fre-

quency emissions from the ignition system.

Check the spark plug cable connections for good

contact at the coil, distributor cap towers (3.0L), and

spark plugs. Terminals should be fully seated. The

insulators should be in good condition and should fit

tightly on the coil, distributor (3.0L) and spark plugs.

Spark plug cables with insulators that are cracked or

torn must be replaced.

Fig. 3 Platinum Pads

NSIGNITION SYSTEM 8D - 3

GENERAL INFORMATION (Continued)

Page 305 of 1938

THROTTLE POSITION SENSOR (TPS)

The TPS mounts to the side of the throttle body

(Fig. 13).

The TPS connects to the throttle blade shaft. The

TPS is a variable resistor that provides the Power-

train Control Module (PCM) with an input signal

(voltage). The signal represents throttle blade posi-

tion. As the position of the throttle blade changes,

the resistance of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

powertrain control module) represents throttle blade

position. The TPS output voltage to the PCM varies

from approximately 0.40 volt at minimum throttle

opening (idle) to a maximum of 3.80 volts at wide

open throttle.

Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine oper-

ating conditions. The PCM also adjusts fuel injector

pulse width and ignition timing based on these

inputs.

LOCK KEY CYLINDER

The lock cylinder is inserted in the end of the

housing opposite the ignition switch. The ignition key

rotates the cylinder to 5 different detents (Fig. 14):

²Accessory

²Off (lock)

²Unlock

²On/Run

²Start

KNOCK SENSOR

The knock sensor threads into the side of the cyl-

inder block in front of the starter motor. When the

knock sensor detects a knock in one of the cylinders,

it sends an input signal to the PCM. In response, the

PCM retards ignition timing for all cylinders by a

scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increase, the knock

sensor output voltage also increases.

Fig. 12 Engine Coolant Temperature SensorÐ3.3/

3.8LFig. 13 Throttle Position Sensor and Idle Air Control

Motor

Fig. 14 Ignition Lock Cylinder Detents

NSIGNITION SYSTEM 8D - 7

GENERAL INFORMATION (Continued)