service CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1731 of 1938

BODY

CONTENTS

page page

BODY COMPONENT SERVICE.............. 22

GENERAL SERVICE INFORMATION........... 1

PAINT.................................. 2SEATS .................................. 9

STATIONARY GLASS....................... 4

GENERAL SERVICE INFORMATION

INDEX

page

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS...... 1

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use

when welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

Chrysler Corporation uses many different types of

push-in fasteners to secure the interior and exterior

trim to the body. Most of these fasteners can be

reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

NSBODY 23 - 1

Page 1744 of 1938

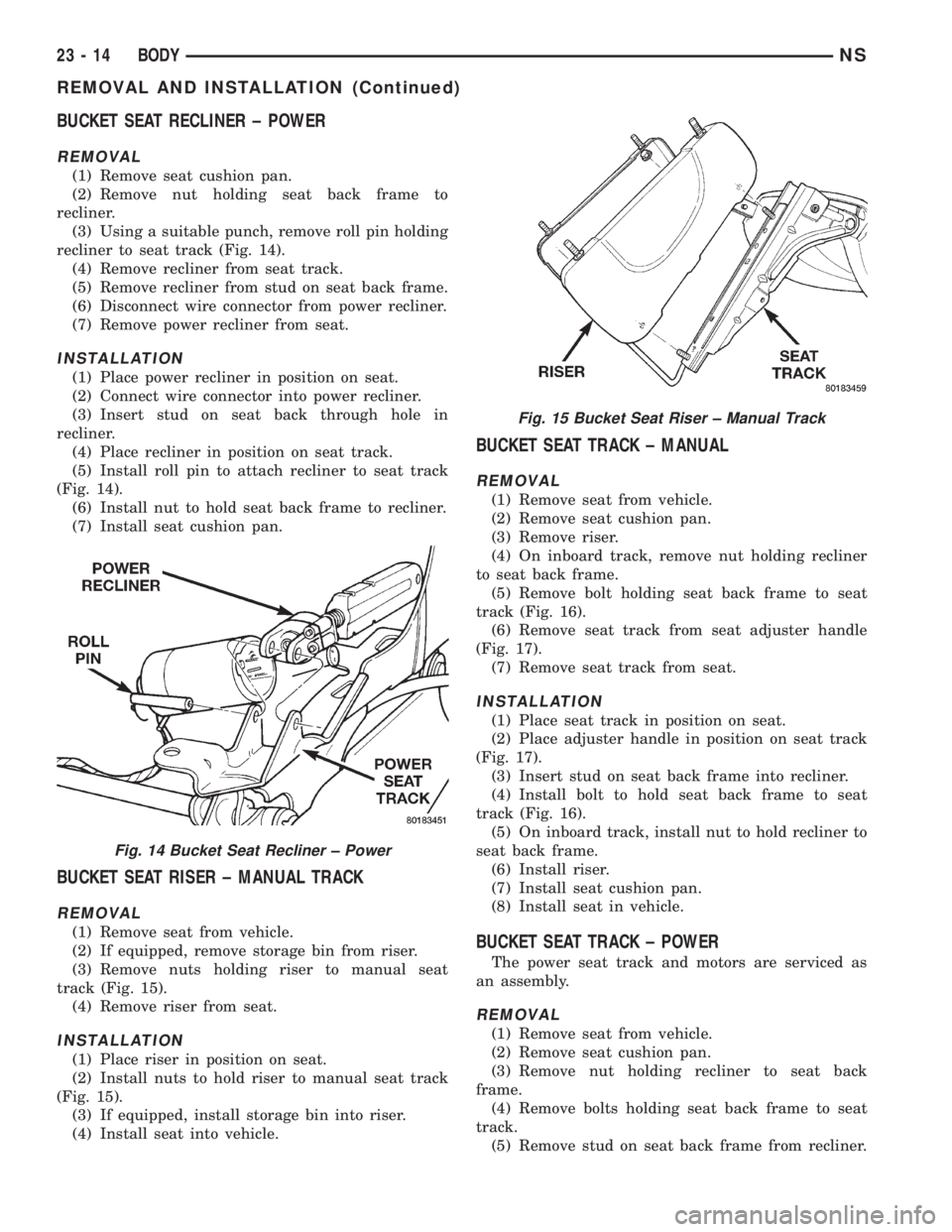

BUCKET SEAT RECLINER ± POWER

REMOVAL

(1) Remove seat cushion pan.

(2) Remove nut holding seat back frame to

recliner.

(3) Using a suitable punch, remove roll pin holding

recliner to seat track (Fig. 14).

(4) Remove recliner from seat track.

(5) Remove recliner from stud on seat back frame.

(6) Disconnect wire connector from power recliner.

(7) Remove power recliner from seat.

INSTALLATION

(1) Place power recliner in position on seat.

(2) Connect wire connector into power recliner.

(3) Insert stud on seat back through hole in

recliner.

(4) Place recliner in position on seat track.

(5) Install roll pin to attach recliner to seat track

(Fig. 14).

(6) Install nut to hold seat back frame to recliner.

(7) Install seat cushion pan.

BUCKET SEAT RISER ± MANUAL TRACK

REMOVAL

(1) Remove seat from vehicle.

(2) If equipped, remove storage bin from riser.

(3) Remove nuts holding riser to manual seat

track (Fig. 15).

(4) Remove riser from seat.

INSTALLATION

(1) Place riser in position on seat.

(2) Install nuts to hold riser to manual seat track

(Fig. 15).

(3) If equipped, install storage bin into riser.

(4) Install seat into vehicle.

BUCKET SEAT TRACK ± MANUAL

REMOVAL

(1) Remove seat from vehicle.

(2) Remove seat cushion pan.

(3) Remove riser.

(4) On inboard track, remove nut holding recliner

to seat back frame.

(5) Remove bolt holding seat back frame to seat

track (Fig. 16).

(6) Remove seat track from seat adjuster handle

(Fig. 17).

(7) Remove seat track from seat.

INSTALLATION

(1) Place seat track in position on seat.

(2) Place adjuster handle in position on seat track

(Fig. 17).

(3) Insert stud on seat back frame into recliner.

(4) Install bolt to hold seat back frame to seat

track (Fig. 16).

(5) On inboard track, install nut to hold recliner to

seat back frame.

(6) Install riser.

(7) Install seat cushion pan.

(8) Install seat in vehicle.

BUCKET SEAT TRACK ± POWER

The power seat track and motors are serviced as

an assembly.

REMOVAL

(1) Remove seat from vehicle.

(2) Remove seat cushion pan.

(3) Remove nut holding recliner to seat back

frame.

(4) Remove bolts holding seat back frame to seat

track.

(5) Remove stud on seat back frame from recliner.

Fig. 14 Bucket Seat Recliner ± Power

Fig. 15 Bucket Seat Riser ± Manual Track

23 - 14 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1752 of 1938

BODY COMPONENT SERVICE

INDEX

page page

DIAGNOSIS AND TESTING

WATER LEAKS.......................... 23

WIND NOISE........................... 24

SERVICE PROCEDURES

HEAT STAKING......................... 24

REMOVAL AND INSTALLATION

A-PILLAR LOWER EXTENSION TRIM........ 25

A-PILLAR TRIM PANEL................... 25

COWL COVER.......................... 25

COWL TRIM............................ 25

FLOOR CARPET........................ 26

FRONT DOOR APPLIQUE................. 28

FRONT DOOR CHECK STRAP.............. 28

FRONT DOOR FRAME CLOSEOUT MOLDINGS . 29

FRONT DOOR GLASS RUN WEATHER-STRIP . . 30

FRONT DOOR GLASS.................... 29

FRONT DOOR HINGE.................... 30

FRONT DOOR INNER BELT MOLDING....... 31

FRONT DOOR LATCH STRIKER............ 32

FRONT DOOR LATCH.................... 31

FRONT DOOR LOCK CYLINDER............ 32

FRONT DOOR OUTER BELT MOLDING....... 33

FRONT DOOR OUTSIDE HANDLE........... 33

FRONT DOOR REFLECTOR............... 34

FRONT DOOR SILL PLATE................ 34

FRONT DOOR TRIM PANEL................ 34

FRONT DOOR WEATHER-STRIP............ 36

FRONT DOOR WINDOW CRANK............ 36

FRONT DOOR WINDOW REGULATOR....... 36

FRONT DOOR.......................... 27

FRONT SEAT........................... 37

FRONT WHEELHOUSE SPLASH SHIELD..... 37

FUEL FILL DOOR BLOCKER LATCH STRIKER . . 38

FUEL FILL DOOR BLOCKER LATCH......... 38

FUEL FILL DOOR BLOCKER LOCKOUT LINK . . 38

FUEL FILLER HOUSING ± WITH BLOCKER

LATCH .............................. 39

GRILLE............................... 39

HEADLINING........................... 39

HOOD HINGE.......................... 41

HOOD LATCH STRIKER................... 42

HOOD LATCH.......................... 41

HOOD RELEASE CABLE.................. 42

HOOD RELEASE HANDLE................. 42

HOOD................................ 40

JACK STORAGE COVER.................. 43

LEFT D-PILLAR TRIM PANEL............... 43

LEFT QUARTER TRIM PANEL.............. 44

LIFTGATE CHMSL ACCESS PANEL.......... 47

LIFTGATE HINGE........................ 47LIFTGATE LATCH STRIKER................ 47

LIFTGATE LATCH........................ 47

LIFTGATE LOCK CYLINDER............... 48

LIFTGATE OUTSIDE HANDLE.............. 48

LIFTGATE PROP ASSEMBLY............... 49

LIFTGATE SILL PLATE.................... 49

LIFTGATE STABILIZER WEDGE STRIKER..... 49

LIFTGATE STABILIZER WEDGE............. 49

LIFTGATE TRIM PANEL................... 50

LIFTGATE UPPER FRAME MOLDING........ 50

LIFTGATE UPPER FRAME SIDE MOLDINGS . . . 51

LIFTGATE............................. 46

LOWER B-PILLAR TRIM COVER............ 51

LUGGAGE RACK CROSSBAR.............. 51

LUGGAGE RACK RISER COVER............ 52

LUGGAGE RACK SIDE RAIL............... 52

OVERHEAD GRAB-HANDLES.............. 52

QUARTER GLASS....................... 52

QUARTER TRIM BOLSTER................ 53

RADIATOR CLOSURE PANEL CROSSMEMBER . 53

RAIL LAMP MODULE..................... 54

REAR HEADER TRIM..................... 55

REAR HVAC LOUVER AND BEZEL.......... 55

RIGHT D-PILLAR TRIM PANEL.............. 55

RIGHT QUARTER TRIM PANEL............. 56

ROOF APERTURE (RAP) MOLDING.......... 57

SEAT BELT BUCKLE FIRST REAR QUAD

BUCKET............................. 58

SEAT BELT BUCKLE FIRST REAR ± TWO

PASSENGER BENCH................... 58

SEAT BELT BUCKLE SECOND REAR ± THREE

PASSENGER BENCH................... 59

SEAT BELT BUCKLE ± FRONT INBOARD..... 57

SEAT BELT FIRST REAR ANCHOR BRACKET ±

LWB ................................ 59

SEAT BELT FIRST REAR OUTBOARD ± LWB

FOUR DOOR.......................... 60

SEAT BELT FIRST REAR OUTBOARD ± SWB

FOUR DOOR.......................... 60

SEAT BELT LEFT FIRST REAR OUTBOARD ±

LWB THREE DOOR..................... 61

SEAT BELT LEFT FIRST REAR OUTBOARD ±

SWB THREE DOOR.................... 61

SEAT BELT SECOND REAR OUTBOARD ±

SWB ................................ 61

SEAT BELT SECOND RIGHT REAR OUTBOARD

±LWB ............................... 62

SEAT BELT ± OUTBOARD FRONT........... 59

SECOND RIGHT REAR OUTBOARD SEAT BELT

± LWB W/REAR HVAC................... 62

23 - 22 BODYNS

Page 1754 of 1938

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during highcrosswinds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

Wind noise can also be caused by improperly fitted

exterior moldings or body ornamentation. Loose

moldings can flutter, creating a buzzing or chattering

noise. An open cavity or protruding edge can create a

whistling or howling noise. Inspect the exterior of the

vehicle to verify that these conditions do not exist.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If component

alignment or sealing is necessary, refer to the appro-

priate section of this group for proper procedures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

SERVICE PROCEDURES

HEAT STAKING

(1) Remove trim panel.

(2) Bend or move the trim panel components at

the heat staked joints. Observe the heat staked loca-

tions and/or component seams for looseness.

(3) Heat stake the components.

(a) If the heat staked or component seam loca-

tion is loose, hold the two components tightly

together and using a soldering gun with a flat tip,

melt the material securing the components

together. Do not over heat the affected area, dam-

age to the exterior of the trim panel may occur.

(b) If the heat staked material is broken or miss-

ing, use a hot glue gun to apply new material to

the area to be repaired. The panels that are being

heat staked must be held together while the apply-

ing the glue. Once the new material is in place, it

23 - 24 BODYNS

DIAGNOSIS AND TESTING (Continued)

Page 1755 of 1938

may be necessary to use a soldering gun to melt

the newly applied material. Do not over heat the

affected area, damage to the exterior of the trim

panel may occur.

(4) Allow the repaired area to cool and verify the

repair.

(5) Install trim panel.

REMOVAL AND INSTALLATION

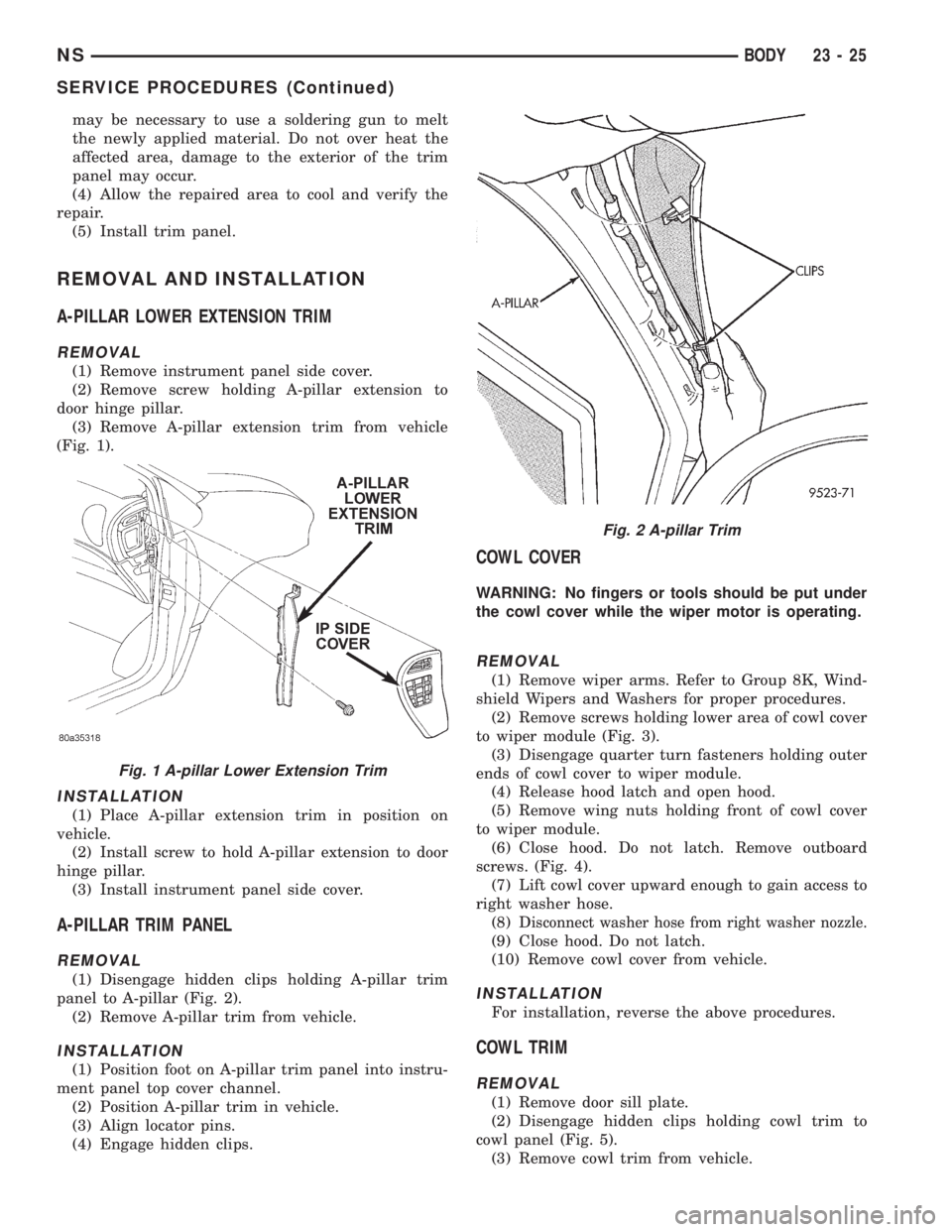

A-PILLAR LOWER EXTENSION TRIM

REMOVAL

(1) Remove instrument panel side cover.

(2) Remove screw holding A-pillar extension to

door hinge pillar.

(3) Remove A-pillar extension trim from vehicle

(Fig. 1).

INSTALLATION

(1) Place A-pillar extension trim in position on

vehicle.

(2) Install screw to hold A-pillar extension to door

hinge pillar.

(3) Install instrument panel side cover.

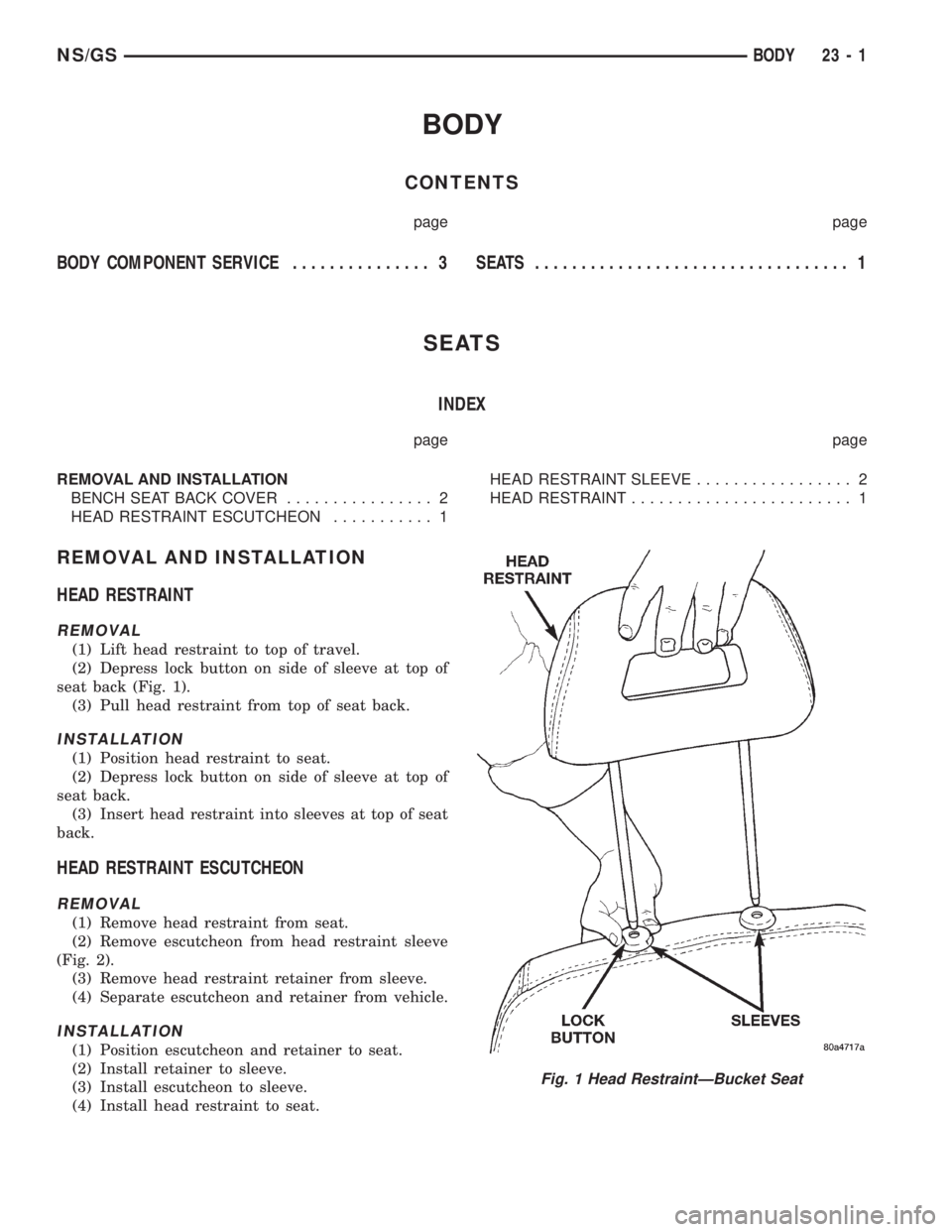

A-PILLAR TRIM PANEL

REMOVAL

(1) Disengage hidden clips holding A-pillar trim

panel to A-pillar (Fig. 2).

(2) Remove A-pillar trim from vehicle.

INSTALLATION

(1) Position foot on A-pillar trim panel into instru-

ment panel top cover channel.

(2) Position A-pillar trim in vehicle.

(3) Align locator pins.

(4) Engage hidden clips.

COWL COVER

WARNING: No fingers or tools should be put under

the cowl cover while the wiper motor is operating.

REMOVAL

(1) Remove wiper arms. Refer to Group 8K, Wind-

shield Wipers and Washers for proper procedures.

(2) Remove screws holding lower area of cowl cover

to wiper module (Fig. 3).

(3) Disengage quarter turn fasteners holding outer

ends of cowl cover to wiper module.

(4) Release hood latch and open hood.

(5) Remove wing nuts holding front of cowl cover

to wiper module.

(6) Close hood. Do not latch. Remove outboard

screws. (Fig. 4).

(7) Lift cowl cover upward enough to gain access to

right washer hose.

(8) D

isconnect washer hose from right washer nozzle.

(9) Close hood. Do not latch.

(10) Remove cowl cover from vehicle.

INSTALLATION

For installation, reverse the above procedures.

COWL TRIM

REMOVAL

(1) Remove door sill plate.

(2) Disengage hidden clips holding cowl trim to

cowl panel (Fig. 5).

(3) Remove cowl trim from vehicle.

Fig. 1 A-pillar Lower Extension Trim

Fig. 2 A-pillar Trim

NSBODY 23 - 25

SERVICE PROCEDURES (Continued)

Page 1813 of 1938

BODY

CONTENTS

page page

BODY COMPONENT SERVICE............... 3 SEATS .................................. 1

SEATS

INDEX

page page

REMOVAL AND INSTALLATION

BENCH SEAT BACK COVER................ 2

HEAD RESTRAINT ESCUTCHEON........... 1HEAD RESTRAINT SLEEVE................. 2

HEAD RESTRAINT........................ 1

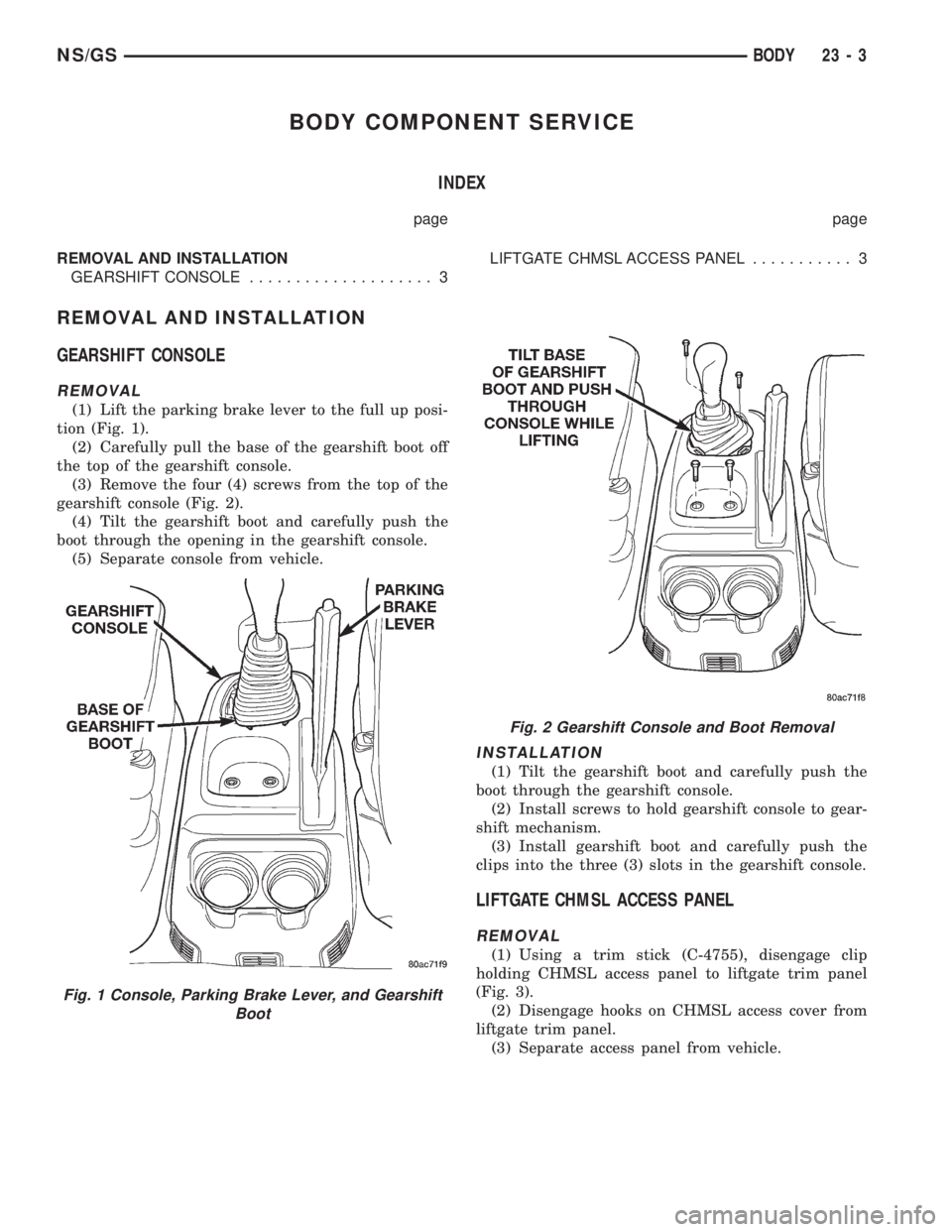

REMOVAL AND INSTALLATION

HEAD RESTRAINT

REMOVAL

(1) Lift head restraint to top of travel.

(2) Depress lock button on side of sleeve at top of

seat back (Fig. 1).

(3) Pull head restraint from top of seat back.

INSTALLATION

(1) Position head restraint to seat.

(2) Depress lock button on side of sleeve at top of

seat back.

(3) Insert head restraint into sleeves at top of seat

back.

HEAD RESTRAINT ESCUTCHEON

REMOVAL

(1) Remove head restraint from seat.

(2) Remove escutcheon from head restraint sleeve

(Fig. 2).

(3) Remove head restraint retainer from sleeve.

(4) Separate escutcheon and retainer from vehicle.

INSTALLATION

(1) Position escutcheon and retainer to seat.

(2) Install retainer to sleeve.

(3) Install escutcheon to sleeve.

(4) Install head restraint to seat.

Fig. 1 Head RestraintÐBucket Seat

NS/GSBODY 23 - 1

Page 1815 of 1938

BODY COMPONENT SERVICE

INDEX

page page

REMOVAL AND INSTALLATION

GEARSHIFT CONSOLE.................... 3LIFTGATE CHMSL ACCESS PANEL........... 3

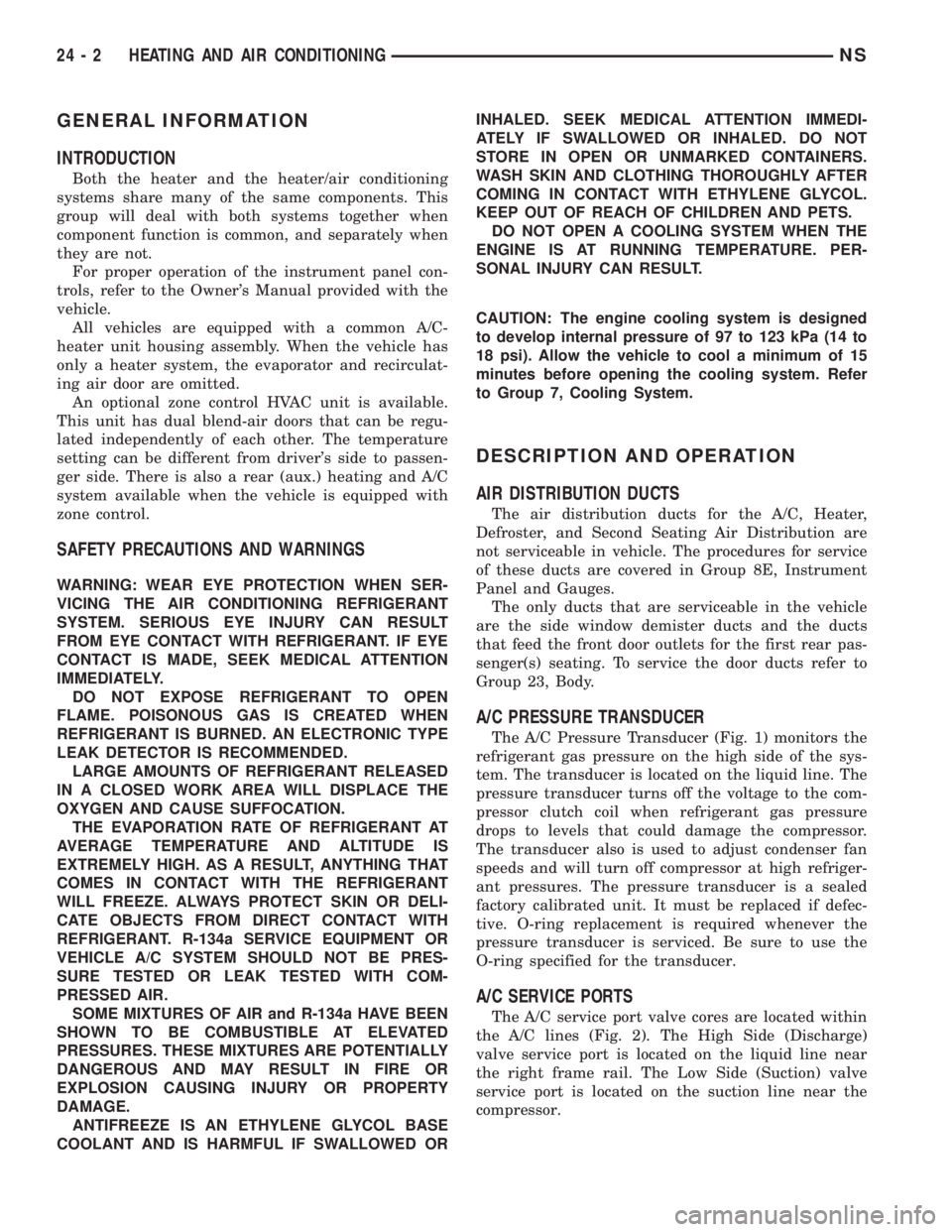

REMOVAL AND INSTALLATION

GEARSHIFT CONSOLE

REMOVAL

(1) Lift the parking brake lever to the full up posi-

tion (Fig. 1).

(2) Carefully pull the base of the gearshift boot off

the top of the gearshift console.

(3) Remove the four (4) screws from the top of the

gearshift console (Fig. 2).

(4) Tilt the gearshift boot and carefully push the

boot through the opening in the gearshift console.

(5) Separate console from vehicle.

INSTALLATION

(1) Tilt the gearshift boot and carefully push the

boot through the gearshift console.

(2) Install screws to hold gearshift console to gear-

shift mechanism.

(3) Install gearshift boot and carefully push the

clips into the three (3) slots in the gearshift console.

LIFTGATE CHMSL ACCESS PANEL

REMOVAL

(1) Using a trim stick (C-4755), disengage clip

holding CHMSL access panel to liftgate trim panel

(Fig. 3).

(2) Disengage hooks on CHMSL access cover from

liftgate trim panel.

(3) Separate access panel from vehicle.

Fig. 1 Console, Parking Brake Lever, and Gearshift

Boot

Fig. 2 Gearshift Console and Boot Removal

NS/GSBODY 23 - 3

Page 1817 of 1938

HEATING AND AIR CONDITIONING

CONTENTS

page page

FRONT HEATING AND AIR CONDITIONING

SYSTEM............................... 1REAR HEATING AND AIR CONDITIONING

SYSTEM.............................. 41

FRONT HEATING AND AIR CONDITIONING SYSTEM

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 2

SAFETY PRECAUTIONS AND WARNINGS...... 2

DESCRIPTION AND OPERATION

A/C PRESSURE TRANSDUCER.............. 2

A/C SERVICE PORTS..................... 2

AIR DISTRIBUTION DUCTS................. 2

COMPRESSOR HIGH-PRESSURE RELIEF

VALVE................................ 3

CONDENSATE DRAIN..................... 3

ENGINE COOLING SYSTEM REQUIREMENTS . . 3

EVAPORATOR PROBE..................... 3

HANDLING TUBING AND FITTINGS........... 3

HVAC CONTROL MODULE................. 4

REAR BLOWER SPEED SWITCH............ 3

SIDE DOOR HEATER A/C OUTLETS.......... 4

SIDE WINDOW DEMISTER................. 4

SYSTEM AIRFLOW....................... 4

SYSTEM OIL LEVEL...................... 5

DIAGNOSIS AND TESTING

A/C PERFORMANCE TEST................ 12

A/C PRESSURE TRANSDUCER............. 12

ACTUATOR CALIBRATION/DIAGNOSTICS AND

COOLDOWN TEST...................... 6

BLOWER MOTOR AND WHEEL ASSEMBLY.... 13

COMPRESSOR CLUTCH/COIL.............. 13

COMPRESSOR NOISE DIAGNOSIS.......... 13

EXPANSION VALVE...................... 13

HEATER PERFORMANCE TEST............ 15

HVAC CONTROL DIAGNOSTIC CONDITIONS . . . 9

SYSTEM CHARGE LEVEL TEST............ 16SERVICE PROCEDURES

CHARGING REFRIGERANT SYSTEM........ 17

EVACUATING REFRIGERANT SYSTEM....... 18

R-134a REFRIGERANT................... 16

STICKING HVAC CONTROL MODULE PUSH

BUTTONS............................ 19

SYSTEM LEAK CHECKING................ 19

THERMOCOUPLE PROBE................. 19

REMOVAL AND INSTALLATION

A/C PRESSURE TRANSDUCER............. 20

A/C SERVICE PORTS.................... 20

BLEND-AIR DOOR ACTUATOR............. 20

BLOWER MOTOR AND WHEEL ASSEMBLY.... 21

BLOWER MOTOR RESISTOR BLOCK........ 21

BLOWER MOTOR WHEEL................. 22

COMPRESSOR CLUTCH/COIL.............. 23

COMPRESSOR......................... 23

CONDENSER ASSEMBLY................. 25

DISCHARGE LINE....................... 26

EVAPORATOR PROBE.................... 27

EXPANSION VALVE...................... 28

FILTER-DRIER ASSEMBLY................. 28

HEATER A/C UNIT HOUSING............... 29

HEATER CORE......................... 30

HEATER HOSES........................ 31

LIQUID LINE........................... 32

MODE DOOR ACTUATOR................. 32

RECIRC DOOR ACTUATOR................ 34

SIDE WINDOW DEMISTER DUCTS.......... 33

SUCTION LINE.......................... 33

DISASSEMBLY AND ASSEMBLY

HEATER A/C UNIT RECONDITION........... 34

NSHEATING AND AIR CONDITIONING 24 - 1

Page 1818 of 1938

GENERAL INFORMATION

INTRODUCTION

Both the heater and the heater/air conditioning

systems share many of the same components. This

group will deal with both systems together when

component function is common, and separately when

they are not.

For proper operation of the instrument panel con-

trols, refer to the Owner's Manual provided with the

vehicle.

All vehicles are equipped with a common A/C-

heater unit housing assembly. When the vehicle has

only a heater system, the evaporator and recirculat-

ing air door are omitted.

An optional zone control HVAC unit is available.

This unit has dual blend-air doors that can be regu-

lated independently of each other. The temperature

setting can be different from driver's side to passen-

ger side. There is also a rear (aux.) heating and A/C

system available when the vehicle is equipped with

zone control.

SAFETY PRECAUTIONS AND WARNINGS

WARNING: WEAR EYE PROTECTION WHEN SER-

VICING THE AIR CONDITIONING REFRIGERANT

SYSTEM. SERIOUS EYE INJURY CAN RESULT

FROM EYE CONTACT WITH REFRIGERANT. IF EYE

CONTACT IS MADE, SEEK MEDICAL ATTENTION

IMMEDIATELY.

DO NOT EXPOSE REFRIGERANT TO OPEN

FLAME. POISONOUS GAS IS CREATED WHEN

REFRIGERANT IS BURNED. AN ELECTRONIC TYPE

LEAK DETECTOR IS RECOMMENDED.

LARGE AMOUNTS OF REFRIGERANT RELEASED

IN A CLOSED WORK AREA WILL DISPLACE THE

OXYGEN AND CAUSE SUFFOCATION.

THE EVAPORATION RATE OF REFRIGERANT AT

AVERAGE TEMPERATURE AND ALTITUDE IS

EXTREMELY HIGH. AS A RESULT, ANYTHING THAT

COMES IN CONTACT WITH THE REFRIGERANT

WILL FREEZE. ALWAYS PROTECT SKIN OR DELI-

CATE OBJECTS FROM DIRECT CONTACT WITH

REFRIGERANT. R-134a SERVICE EQUIPMENT OR

VEHICLE A/C SYSTEM SHOULD NOT BE PRES-

SURE TESTED OR LEAK TESTED WITH COM-

PRESSED AIR.

SOME MIXTURES OF AIR and R-134a HAVE BEEN

SHOWN TO BE COMBUSTIBLE AT ELEVATED

PRESSURES. THESE MIXTURES ARE POTENTIALLY

DANGEROUS AND MAY RESULT IN FIRE OR

EXPLOSION CAUSING INJURY OR PROPERTY

DAMAGE.

ANTIFREEZE IS AN ETHYLENE GLYCOL BASE

COOLANT AND IS HARMFUL IF SWALLOWED ORINHALED. SEEK MEDICAL ATTENTION IMMEDI-

ATELY IF SWALLOWED OR INHALED. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN AND PETS.

DO NOT OPEN A COOLING SYSTEM WHEN THE

ENGINE IS AT RUNNING TEMPERATURE. PER-

SONAL INJURY CAN RESULT.

CAUTION: The engine cooling system is designed

to develop internal pressure of 97 to 123 kPa (14 to

18 psi). Allow the vehicle to cool a minimum of 15

minutes before opening the cooling system. Refer

to Group 7, Cooling System.

DESCRIPTION AND OPERATION

AIR DISTRIBUTION DUCTS

The air distribution ducts for the A/C, Heater,

Defroster, and Second Seating Air Distribution are

not serviceable in vehicle. The procedures for service

of these ducts are covered in Group 8E, Instrument

Panel and Gauges.

The only ducts that are serviceable in the vehicle

are the side window demister ducts and the ducts

that feed the front door outlets for the first rear pas-

senger(s) seating. To service the door ducts refer to

Group 23, Body.

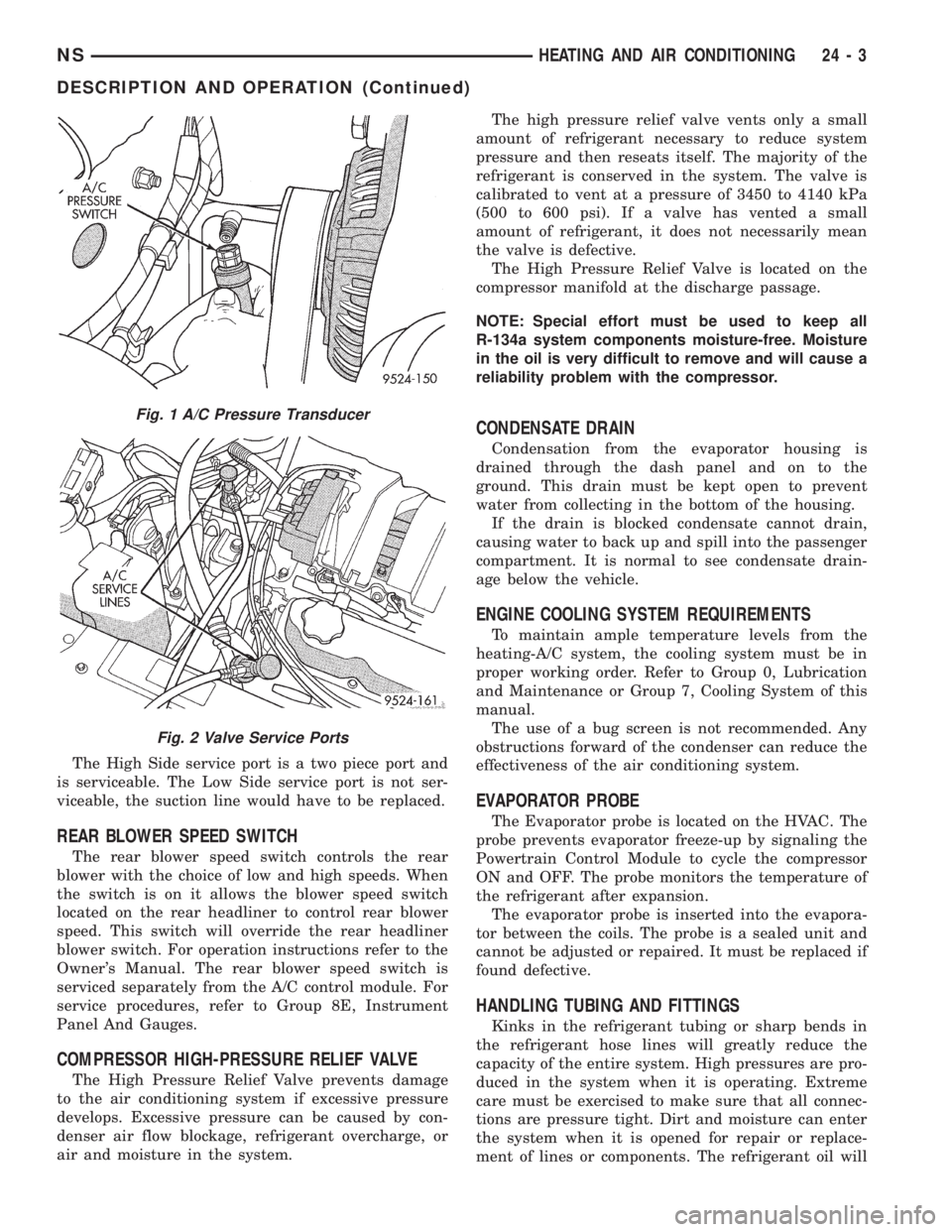

A/C PRESSURE TRANSDUCER

The A/C Pressure Transducer (Fig. 1) monitors the

refrigerant gas pressure on the high side of the sys-

tem. The transducer is located on the liquid line. The

pressure transducer turns off the voltage to the com-

pressor clutch coil when refrigerant gas pressure

drops to levels that could damage the compressor.

The transducer also is used to adjust condenser fan

speeds and will turn off compressor at high refriger-

ant pressures. The pressure transducer is a sealed

factory calibrated unit. It must be replaced if defec-

tive. O-ring replacement is required whenever the

pressure transducer is serviced. Be sure to use the

O-ring specified for the transducer.

A/C SERVICE PORTS

The A/C service port valve cores are located within

the A/C lines (Fig. 2). The High Side (Discharge)

valve service port is located on the liquid line near

the right frame rail. The Low Side (Suction) valve

service port is located on the suction line near the

compressor.

24 - 2 HEATING AND AIR CONDITIONINGNS

Page 1819 of 1938

The High Side service port is a two piece port and

is serviceable. The Low Side service port is not ser-

viceable, the suction line would have to be replaced.

REAR BLOWER SPEED SWITCH

The rear blower speed switch controls the rear

blower with the choice of low and high speeds. When

the switch is on it allows the blower speed switch

located on the rear headliner to control rear blower

speed. This switch will override the rear headliner

blower switch. For operation instructions refer to the

Owner's Manual. The rear blower speed switch is

serviced separately from the A/C control module. For

service procedures, refer to Group 8E, Instrument

Panel And Gauges.

COMPRESSOR HIGH-PRESSURE RELIEF VALVE

The High Pressure Relief Valve prevents damage

to the air conditioning system if excessive pressure

develops. Excessive pressure can be caused by con-

denser air flow blockage, refrigerant overcharge, or

air and moisture in the system.The high pressure relief valve vents only a small

amount of refrigerant necessary to reduce system

pressure and then reseats itself. The majority of the

refrigerant is conserved in the system. The valve is

calibrated to vent at a pressure of 3450 to 4140 kPa

(500 to 600 psi). If a valve has vented a small

amount of refrigerant, it does not necessarily mean

the valve is defective.

The High Pressure Relief Valve is located on the

compressor manifold at the discharge passage.

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

CONDENSATE DRAIN

Condensation from the evaporator housing is

drained through the dash panel and on to the

ground. This drain must be kept open to prevent

water from collecting in the bottom of the housing.

If the drain is blocked condensate cannot drain,

causing water to back up and spill into the passenger

compartment. It is normal to see condensate drain-

age below the vehicle.

ENGINE COOLING SYSTEM REQUIREMENTS

To maintain ample temperature levels from the

heating-A/C system, the cooling system must be in

proper working order. Refer to Group 0, Lubrication

and Maintenance or Group 7, Cooling System of this

manual.

The use of a bug screen is not recommended. Any

obstructions forward of the condenser can reduce the

effectiveness of the air conditioning system.

EVAPORATOR PROBE

The Evaporator probe is located on the HVAC. The

probe prevents evaporator freeze-up by signaling the

Powertrain Control Module to cycle the compressor

ON and OFF. The probe monitors the temperature of

the refrigerant after expansion.

The evaporator probe is inserted into the evapora-

tor between the coils. The probe is a sealed unit and

cannot be adjusted or repaired. It must be replaced if

found defective.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil will

Fig. 1 A/C Pressure Transducer

Fig. 2 Valve Service Ports

NSHEATING AND AIR CONDITIONING 24 - 3

DESCRIPTION AND OPERATION (Continued)