service CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1688 of 1938

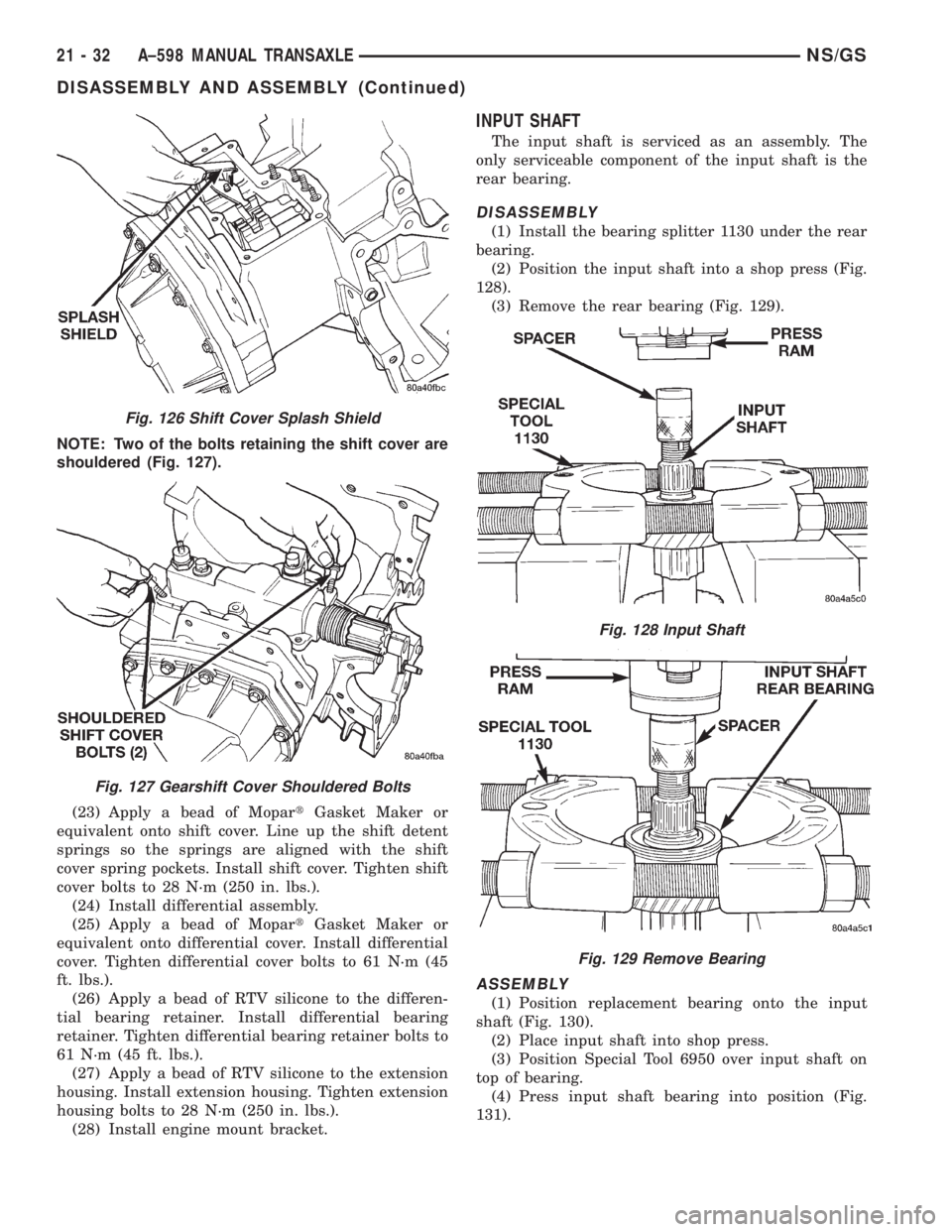

NOTE: Two of the bolts retaining the shift cover are

shouldered (Fig. 127).

(23) Apply a bead of MopartGasket Maker or

equivalent onto shift cover. Line up the shift detent

springs so the springs are aligned with the shift

cover spring pockets. Install shift cover. Tighten shift

cover bolts to 28 N´m (250 in. lbs.).

(24) Install differential assembly.

(25) Apply a bead of MopartGasket Maker or

equivalent onto differential cover. Install differential

cover. Tighten differential cover bolts to 61 N´m (45

ft. lbs.).

(26) Apply a bead of RTV silicone to the differen-

tial bearing retainer. Install differential bearing

retainer. Tighten differential bearing retainer bolts to

61 N´m (45 ft. lbs.).

(27) Apply a bead of RTV silicone to the extension

housing. Install extension housing. Tighten extension

housing bolts to 28 N´m (250 in. lbs.).

(28) Install engine mount bracket.

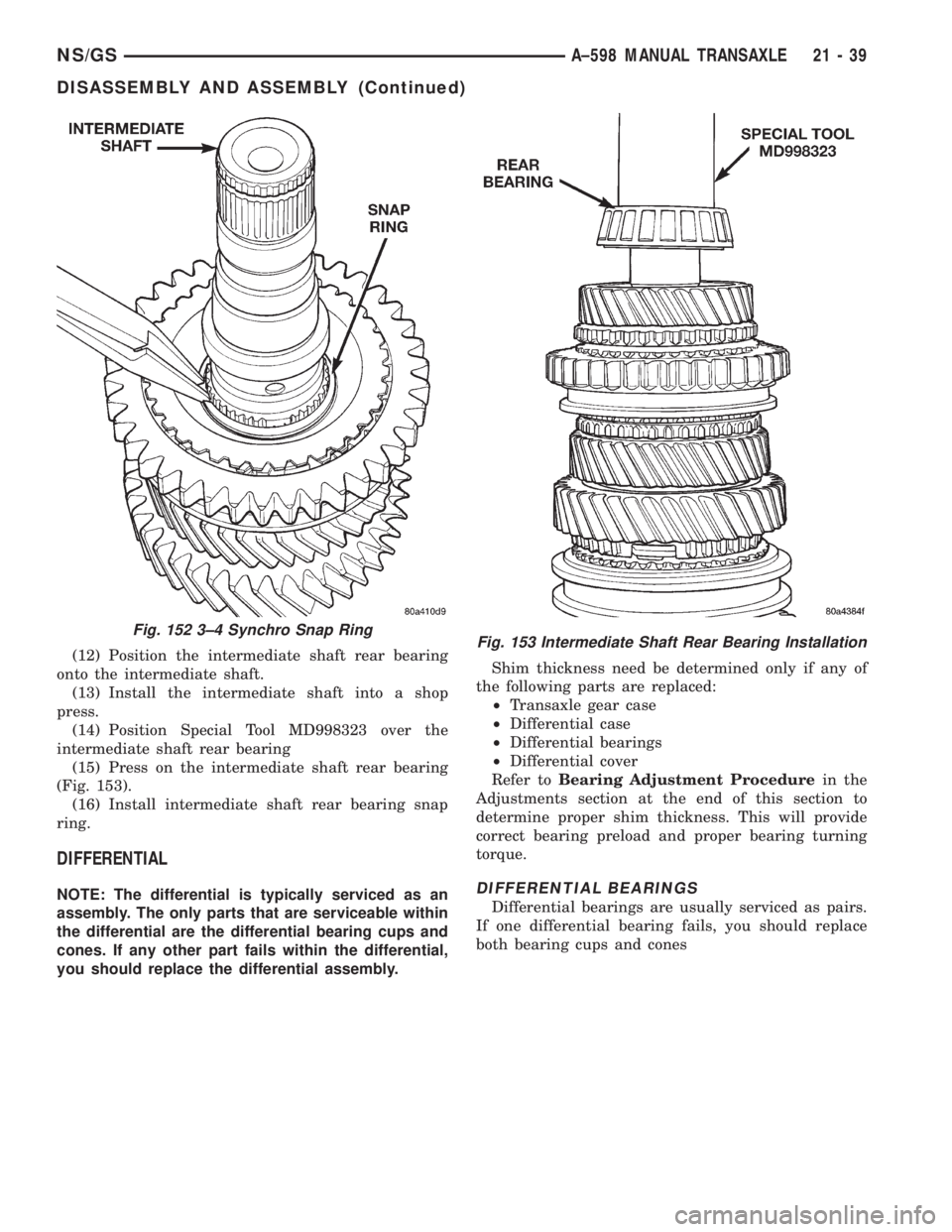

INPUT SHAFT

The input shaft is serviced as an assembly. The

only serviceable component of the input shaft is the

rear bearing.

DISASSEMBLY

(1) Install the bearing splitter 1130 under the rear

bearing.

(2) Position the input shaft into a shop press (Fig.

128).

(3) Remove the rear bearing (Fig. 129).

ASSEMBLY

(1) Position replacement bearing onto the input

shaft (Fig. 130).

(2) Place input shaft into shop press.

(3) Position Special Tool 6950 over input shaft on

top of bearing.

(4) Press input shaft bearing into position (Fig.

131).

Fig. 126 Shift Cover Splash Shield

Fig. 127 Gearshift Cover Shouldered Bolts

Fig. 128 Input Shaft

Fig. 129 Remove Bearing

21 - 32 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1695 of 1938

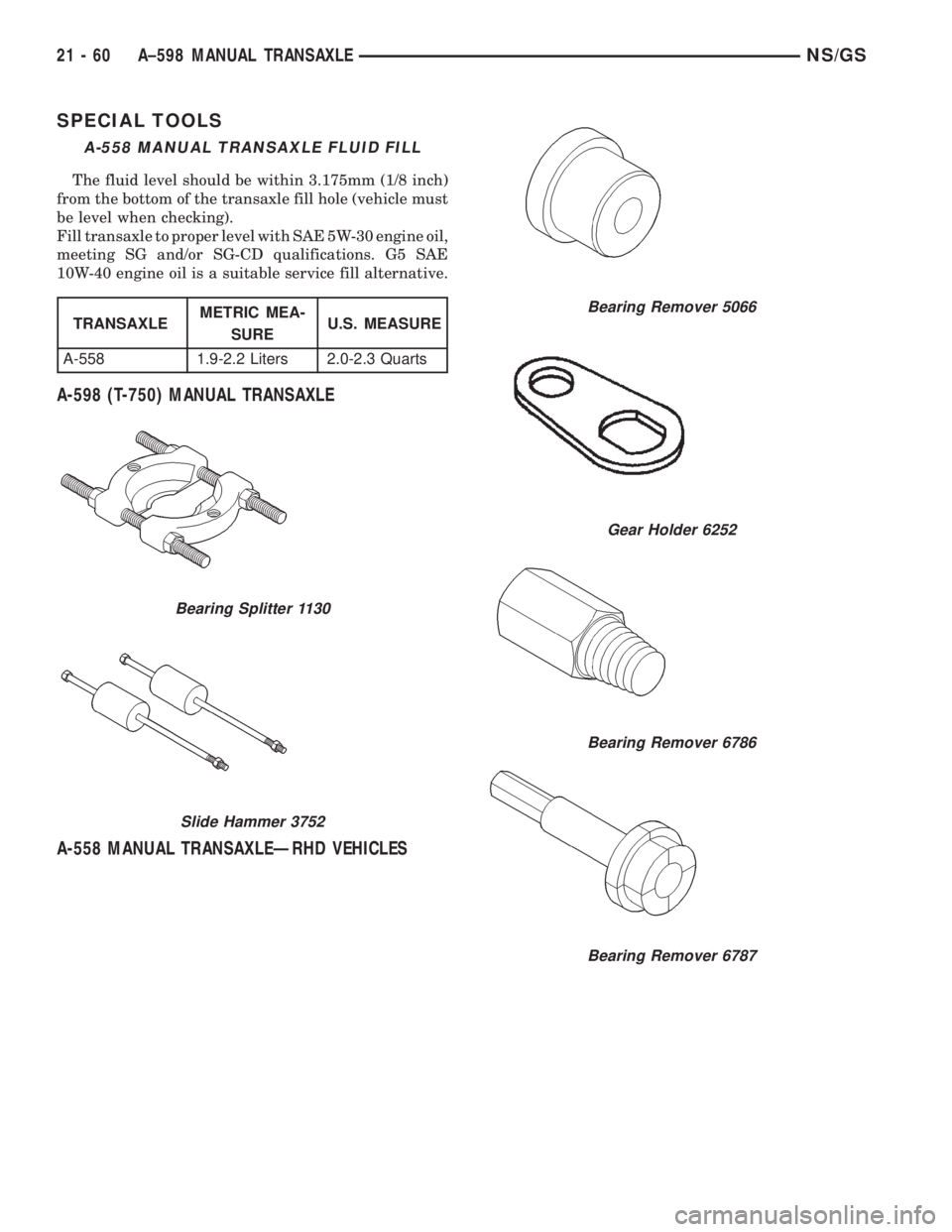

(12) Position the intermediate shaft rear bearing

onto the intermediate shaft.

(13) Install the intermediate shaft into a shop

press.

(14) Position Special Tool MD998323 over the

intermediate shaft rear bearing

(15) Press on the intermediate shaft rear bearing

(Fig. 153).

(16) Install intermediate shaft rear bearing snap

ring.

DIFFERENTIAL

NOTE: The differential is typically serviced as an

assembly. The only parts that are serviceable within

the differential are the differential bearing cups and

cones. If any other part fails within the differential,

you should replace the differential assembly.Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle gear case

²Differential case

²Differential bearings

²Differential cover

Refer toBearing Adjustment Procedurein the

Adjustments section at the end of this section to

determine proper shim thickness. This will provide

correct bearing preload and proper bearing turning

torque.DIFFERENTIAL BEARINGS

Differential bearings are usually serviced as pairs.

If one differential bearing fails, you should replace

both bearing cups and cones

Fig. 152 3±4 Synchro Snap RingFig. 153 Intermediate Shaft Rear Bearing Installation

NS/GSA±598 MANUAL TRANSAXLE 21 - 39

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1716 of 1938

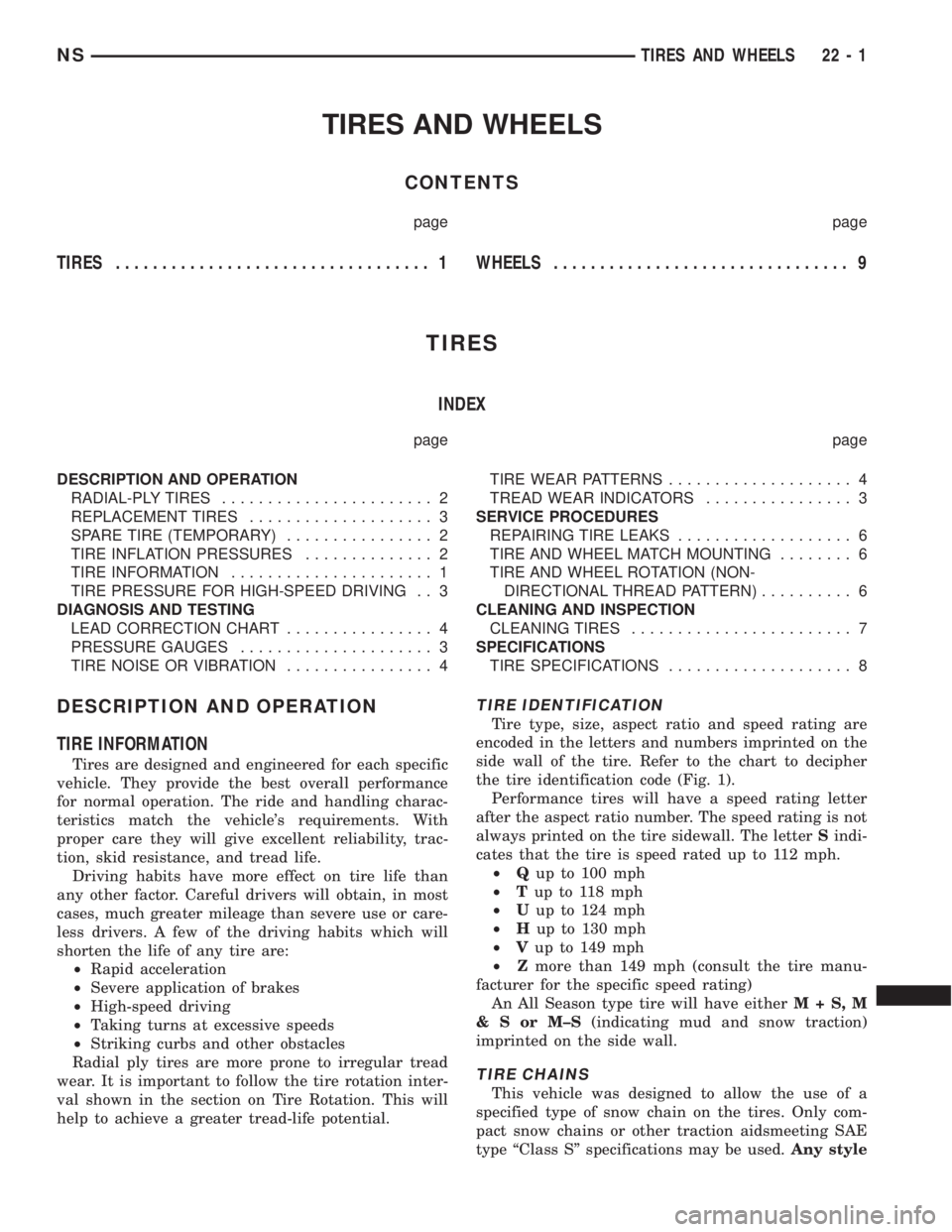

SPECIAL TOOLS

A-598 (T-750) MANUAL TRANSAXLE

A-558 MANUAL TRANSAXLEÐRHD VEHICLES

A-558 MANUAL TRANSAXLE FLUID FILL

The fluid level should be within 3.175mm (1/8 inch)

from the bottom of the transaxle fill hole (vehicle must

be level when checking).

Fill transaxle to proper level with SAE 5W-30 engine oil,

meeting SG and/or SG-CD qualifications. G5 SAE

10W-40 engine oil is a suitable service fill alternative.

TRANSAXLEMETRIC MEA-

SUREU.S. MEASURE

A-558 1.9-2.2 Liters 2.0-2.3 Quarts

Bearing Splitter 1130

Slide Hammer 3752

Bearing Remover 5066

Gear Holder 6252

Bearing Remover 6786

Bearing Remover 6787

21 - 60 A±598 MANUAL TRANSAXLENS/GS

Page 1719 of 1938

TIRES AND WHEELS

CONTENTS

page page

TIRES.................................. 1WHEELS................................ 9

TIRES

INDEX

page page

DESCRIPTION AND OPERATION

RADIAL-PLY TIRES....................... 2

REPLACEMENT TIRES.................... 3

SPARE TIRE (TEMPORARY)................ 2

TIRE INFLATION PRESSURES.............. 2

TIRE INFORMATION...................... 1

TIRE PRESSURE FOR HIGH-SPEED DRIVING . . 3

DIAGNOSIS AND TESTING

LEAD CORRECTION CHART................ 4

PRESSURE GAUGES..................... 3

TIRE NOISE OR VIBRATION................ 4TIRE WEAR PATTERNS.................... 4

TREAD WEAR INDICATORS................ 3

SERVICE PROCEDURES

REPAIRING TIRE LEAKS................... 6

TIRE AND WHEEL MATCH MOUNTING........ 6

TIRE AND WHEEL ROTATION (NON-

DIRECTIONAL THREAD PATTERN).......... 6

CLEANING AND INSPECTION

CLEANING TIRES........................ 7

SPECIFICATIONS

TIRE SPECIFICATIONS.................... 8

DESCRIPTION AND OPERATION

TIRE INFORMATION

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain, in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe application of brakes

²High-speed driving

²Taking turns at excessive speeds

²Striking curbs and other obstacles

Radial ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation. This will

help to achieve a greater tread-life potential.

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 1).

Performance tires will have a speed rating letter

after the aspect ratio number. The speed rating is not

always printed on the tire sidewall. The letterSindi-

cates that the tire is speed rated up to 112 mph.

²Qup to 100 mph

²Tup to 118 mph

²Uup to 124 mph

²Hup to 130 mph

²Vup to 149 mph

²Zmore than 149 mph (consult the tire manu-

facturer for the specific speed rating)

An All Season type tire will have eitherM+S,M

&SorM±S(indicating mud and snow traction)

imprinted on the side wall.

TIRE CHAINS

This vehicle was designed to allow the use of a

specified type of snow chain on the tires. Only com-

pact snow chains or other traction aidsmeeting SAE

type ªClass Sº specifications may be used.Any style

NSTIRES AND WHEELS 22 - 1

Page 1724 of 1938

SERVICE PROCEDURES

TIRE AND WHEEL ROTATION (NON-DIRECTIONAL

THREAD PATTERN)

Tires on the front and rear axles operate at differ-

ent loads and perform different functions. For these

reasons, they wear at unequal rates, and tend to

develop irregular wear patterns. These effects can be

reduced by timely rotation of tires. The benefits of

rotation are especially worthwhile. Rotation will

increase tread life, help to maintain mud, snow, and

wet traction levels, and contribute to a smooth, quiet

ride.

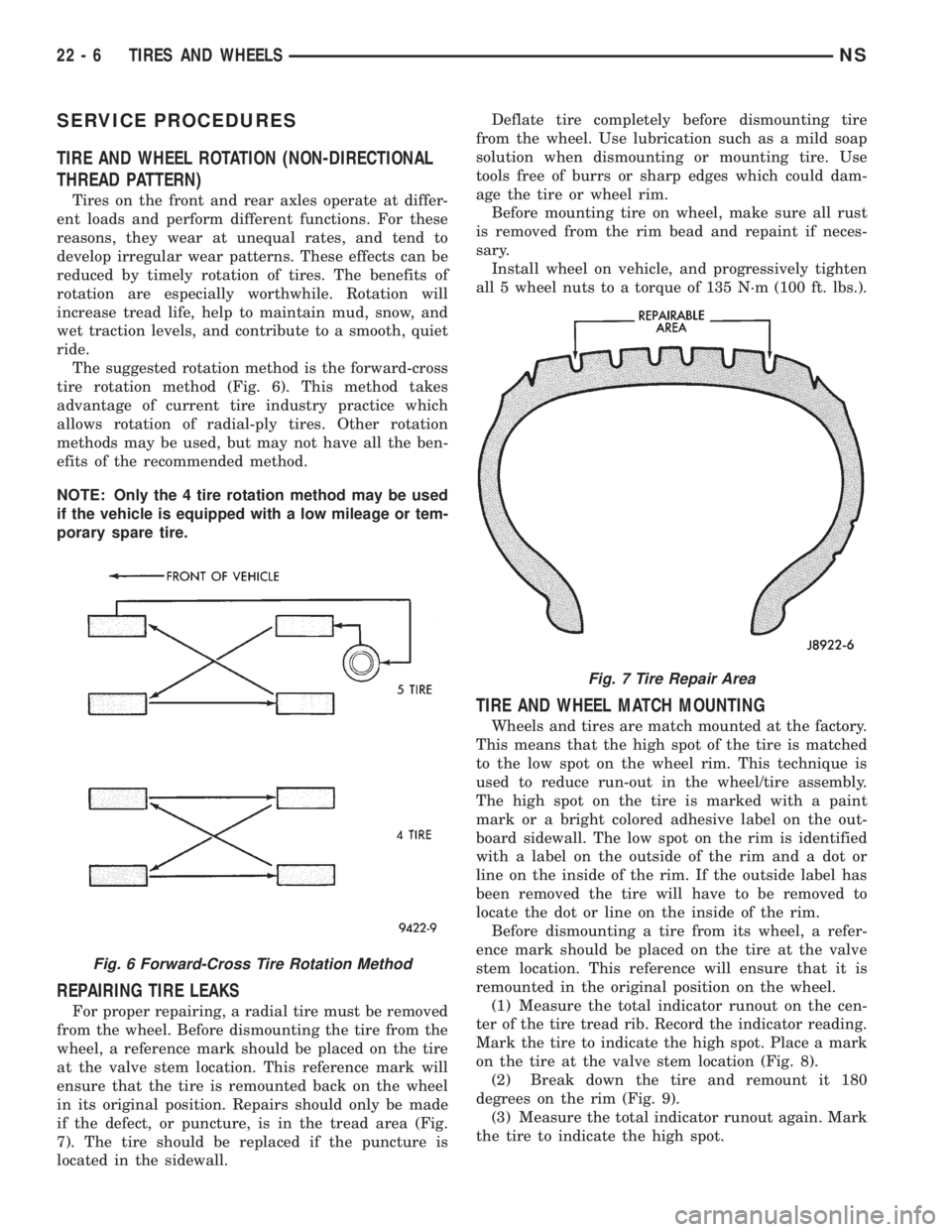

The suggested rotation method is the forward-cross

tire rotation method (Fig. 6). This method takes

advantage of current tire industry practice which

allows rotation of radial-ply tires. Other rotation

methods may be used, but may not have all the ben-

efits of the recommended method.

NOTE: Only the 4 tire rotation method may be used

if the vehicle is equipped with a low mileage or tem-

porary spare tire.

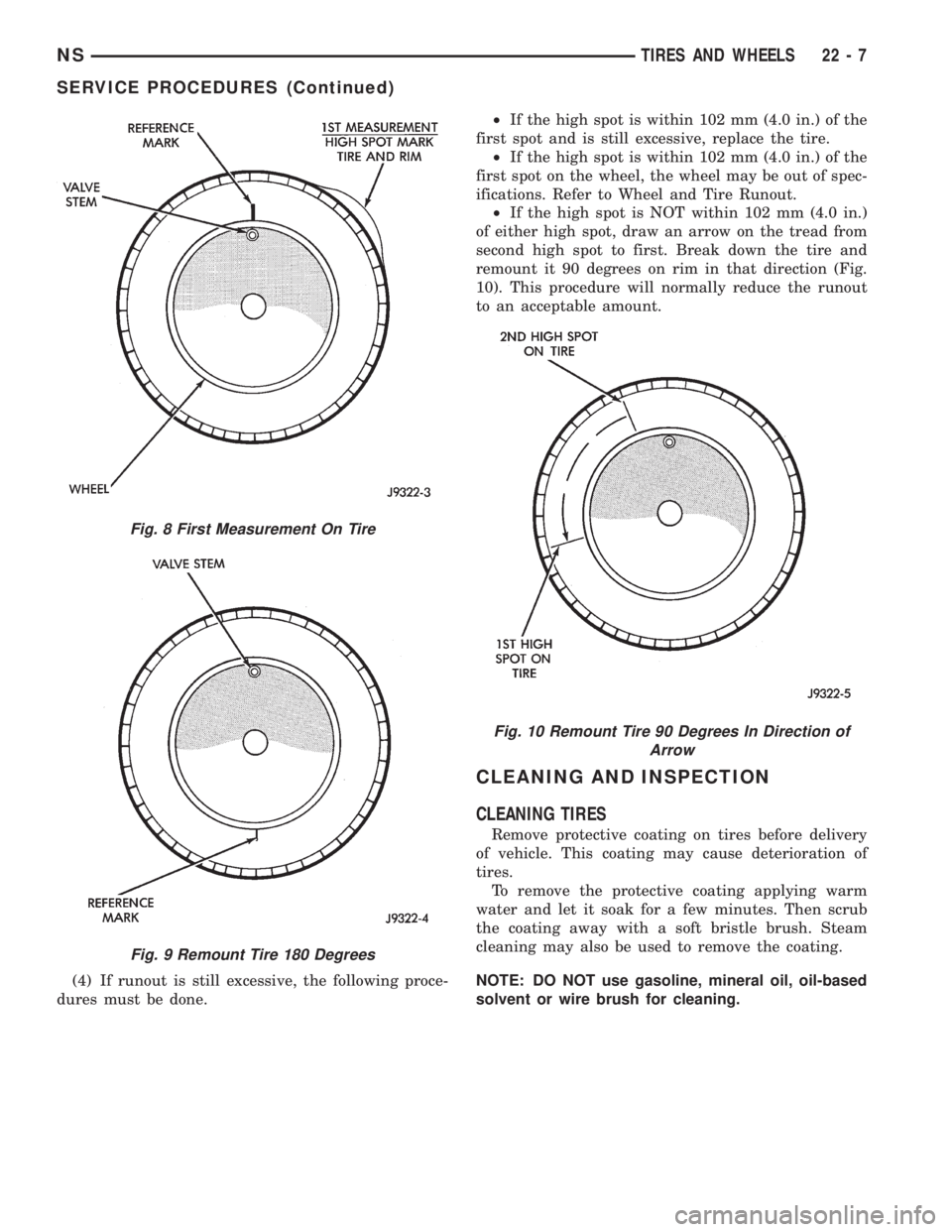

REPAIRING TIRE LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Before dismounting the tire from the

wheel, a reference mark should be placed on the tire

at the valve stem location. This reference mark will

ensure that the tire is remounted back on the wheel

in its original position. Repairs should only be made

if the defect, or puncture, is in the tread area (Fig.

7). The tire should be replaced if the puncture is

located in the sidewall.Deflate tire completely before dismounting tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges which could dam-

age the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.

Install wheel on vehicle, and progressively tighten

all 5 wheel nuts to a torque of 135 N´m (100 ft. lbs.).

TIRE AND WHEEL MATCH MOUNTING

Wheels and tires are match mounted at the factory.

This means that the high spot of the tire is matched

to the low spot on the wheel rim. This technique is

used to reduce run-out in the wheel/tire assembly.

The high spot on the tire is marked with a paint

mark or a bright colored adhesive label on the out-

board sidewall. The low spot on the rim is identified

with a label on the outside of the rim and a dot or

line on the inside of the rim. If the outside label has

been removed the tire will have to be removed to

locate the dot or line on the inside of the rim.

Before dismounting a tire from its wheel, a refer-

ence mark should be placed on the tire at the valve

stem location. This reference will ensure that it is

remounted in the original position on the wheel.

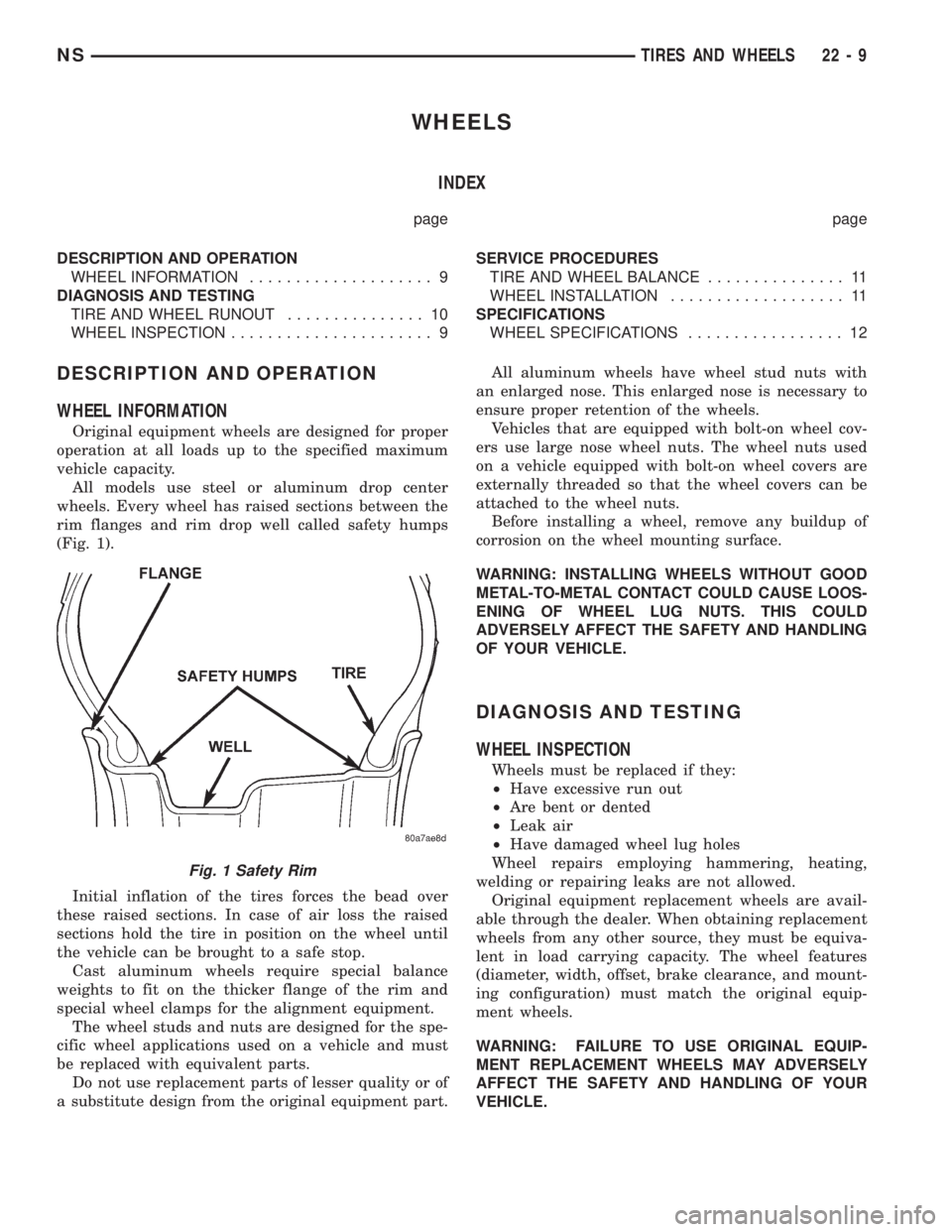

(1) Measure the total indicator runout on the cen-

ter of the tire tread rib. Record the indicator reading.

Mark the tire to indicate the high spot. Place a mark

on the tire at the valve stem location (Fig. 8).

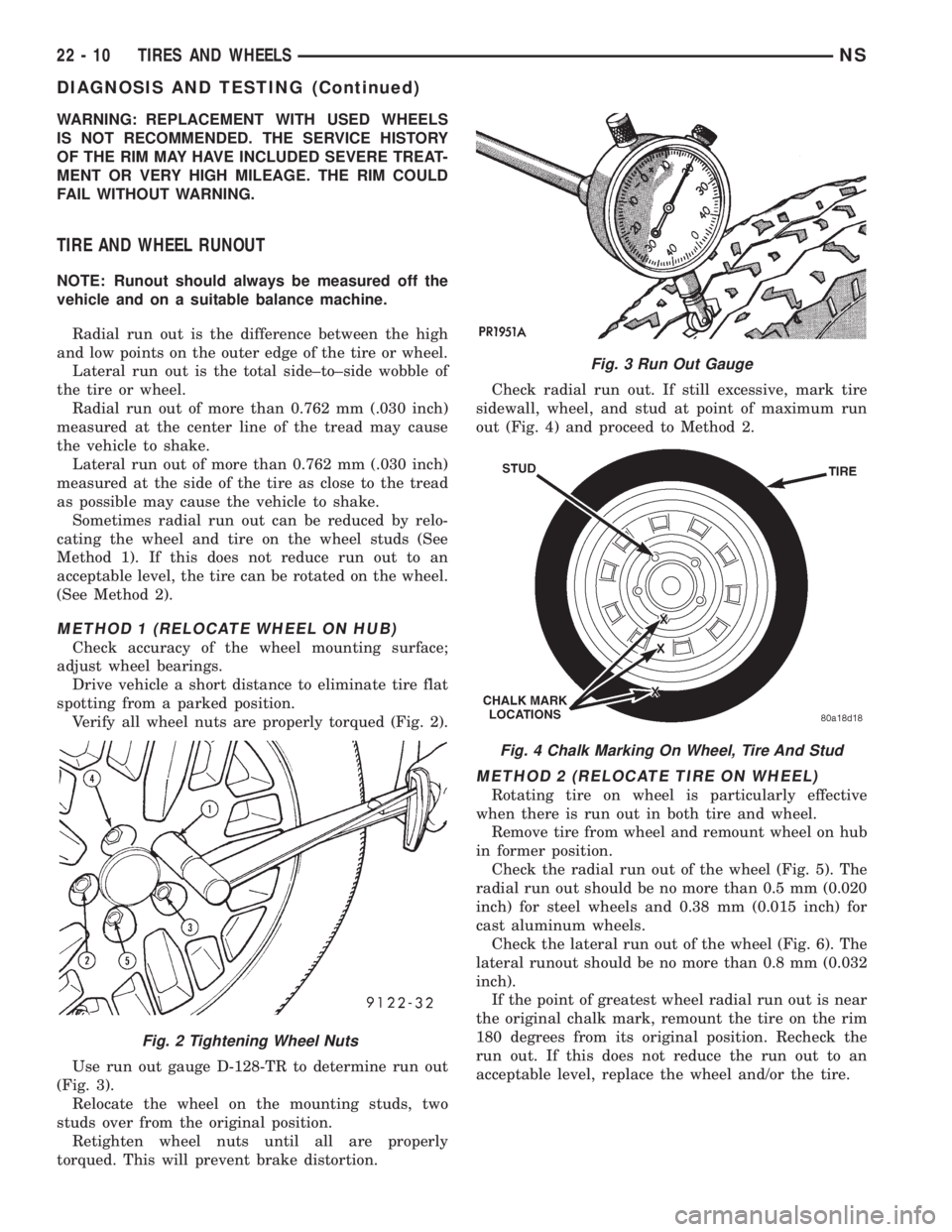

(2) Break down the tire and remount it 180

degrees on the rim (Fig. 9).

(3) Measure the total indicator runout again. Mark

the tire to indicate the high spot.

Fig. 6 Forward-Cross Tire Rotation Method

Fig. 7 Tire Repair Area

22 - 6 TIRES AND WHEELSNS

Page 1725 of 1938

(4) If runout is still excessive, the following proce-

dures must be done.²If the high spot is within 102 mm (4.0 in.) of the

first spot and is still excessive, replace the tire.

²If the high spot is within 102 mm (4.0 in.) of the

first spot on the wheel, the wheel may be out of spec-

ifications. Refer to Wheel and Tire Runout.

²If the high spot is NOT within 102 mm (4.0 in.)

of either high spot, draw an arrow on the tread from

second high spot to first. Break down the tire and

remount it 90 degrees on rim in that direction (Fig.

10). This procedure will normally reduce the runout

to an acceptable amount.

CLEANING AND INSPECTION

CLEANING TIRES

Remove protective coating on tires before delivery

of vehicle. This coating may cause deterioration of

tires.

To remove the protective coating applying warm

water and let it soak for a few minutes. Then scrub

the coating away with a soft bristle brush. Steam

cleaning may also be used to remove the coating.

NOTE: DO NOT use gasoline, mineral oil, oil-based

solvent or wire brush for cleaning.

Fig. 8 First Measurement On Tire

Fig. 9 Remount Tire 180 Degrees

Fig. 10 Remount Tire 90 Degrees In Direction of

Arrow

NSTIRES AND WHEELS 22 - 7

SERVICE PROCEDURES (Continued)

Page 1727 of 1938

WHEELS

INDEX

page page

DESCRIPTION AND OPERATION

WHEEL INFORMATION.................... 9

DIAGNOSIS AND TESTING

TIRE AND WHEEL RUNOUT............... 10

WHEEL INSPECTION...................... 9SERVICE PROCEDURES

TIRE AND WHEEL BALANCE............... 11

WHEEL INSTALLATION................... 11

SPECIFICATIONS

WHEEL SPECIFICATIONS................. 12

DESCRIPTION AND OPERATION

WHEEL INFORMATION

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

vehicle capacity.

All models use steel or aluminum drop center

wheels. Every wheel has raised sections between the

rim flanges and rim drop well called safety humps

(Fig. 1).

Initial inflation of the tires forces the bead over

these raised sections. In case of air loss the raised

sections hold the tire in position on the wheel until

the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights to fit on the thicker flange of the rim and

special wheel clamps for the alignment equipment.

The wheel studs and nuts are designed for the spe-

cific wheel applications used on a vehicle and must

be replaced with equivalent parts.

Do not use replacement parts of lesser quality or of

a substitute design from the original equipment part.All aluminum wheels have wheel stud nuts with

an enlarged nose. This enlarged nose is necessary to

ensure proper retention of the wheels.

Vehicles that are equipped with bolt-on wheel cov-

ers use large nose wheel nuts. The wheel nuts used

on a vehicle equipped with bolt-on wheel covers are

externally threaded so that the wheel covers can be

attached to the wheel nuts.

Before installing a wheel, remove any buildup of

corrosion on the wheel mounting surface.

WARNING: INSTALLING WHEELS WITHOUT GOOD

METAL-TO-METAL CONTACT COULD CAUSE LOOS-

ENING OF WHEEL LUG NUTS. THIS COULD

ADVERSELY AFFECT THE SAFETY AND HANDLING

OF YOUR VEHICLE.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Wheels must be replaced if they:

²Have excessive run out

²Are bent or dented

²Leak air

²Have damaged wheel lug holes

Wheel repairs employing hammering, heating,

welding or repairing leaks are not allowed.

Original equipment replacement wheels are avail-

able through the dealer. When obtaining replacement

wheels from any other source, they must be equiva-

lent in load carrying capacity. The wheel features

(diameter, width, offset, brake clearance, and mount-

ing configuration) must match the original equip-

ment wheels.

WARNING: FAILURE TO USE ORIGINAL EQUIP-

MENT REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF YOUR

VEHICLE.

Fig. 1 Safety Rim

NSTIRES AND WHEELS 22 - 9

Page 1728 of 1938

WARNING: REPLACEMENT WITH USED WHEELS

IS NOT RECOMMENDED. THE SERVICE HISTORY

OF THE RIM MAY HAVE INCLUDED SEVERE TREAT-

MENT OR VERY HIGH MILEAGE. THE RIM COULD

FAIL WITHOUT WARNING.

TIRE AND WHEEL RUNOUT

NOTE: Runout should always be measured off the

vehicle and on a suitable balance machine.

Radial run out is the difference between the high

and low points on the outer edge of the tire or wheel.

Lateral run out is the total side±to±side wobble of

the tire or wheel.

Radial run out of more than 0.762 mm (.030 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral run out of more than 0.762 mm (.030 inch)

measured at the side of the tire as close to the tread

as possible may cause the vehicle to shake.

Sometimes radial run out can be reduced by relo-

cating the wheel and tire on the wheel studs (See

Method 1). If this does not reduce run out to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

Check accuracy of the wheel mounting surface;

adjust wheel bearings.

Drive vehicle a short distance to eliminate tire flat

spotting from a parked position.

Verify all wheel nuts are properly torqued (Fig. 2).

Use run out gauge D-128-TR to determine run out

(Fig. 3).

Relocate the wheel on the mounting studs, two

studs over from the original position.

Retighten wheel nuts until all are properly

torqued. This will prevent brake distortion.Check radial run out. If still excessive, mark tire

sidewall, wheel, and stud at point of maximum run

out (Fig. 4) and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

Rotating tire on wheel is particularly effective

when there is run out in both tire and wheel.

Remove tire from wheel and remount wheel on hub

in former position.

Check the radial run out of the wheel (Fig. 5). The

radial run out should be no more than 0.5 mm (0.020

inch) for steel wheels and 0.38 mm (0.015 inch) for

cast aluminum wheels.

Check the lateral run out of the wheel (Fig. 6). The

lateral runout should be no more than 0.8 mm (0.032

inch).

If the point of greatest wheel radial run out is near

the original chalk mark, remount the tire on the rim

180 degrees from its original position. Recheck the

run out. If this does not reduce the run out to an

acceptable level, replace the wheel and/or the tire.

Fig. 2 Tightening Wheel Nuts

Fig. 3 Run Out Gauge

Fig. 4 Chalk Marking On Wheel, Tire And Stud

22 - 10 TIRES AND WHEELSNS

DIAGNOSIS AND TESTING (Continued)

Page 1729 of 1938

SERVICE PROCEDURES

WHEEL INSTALLATION

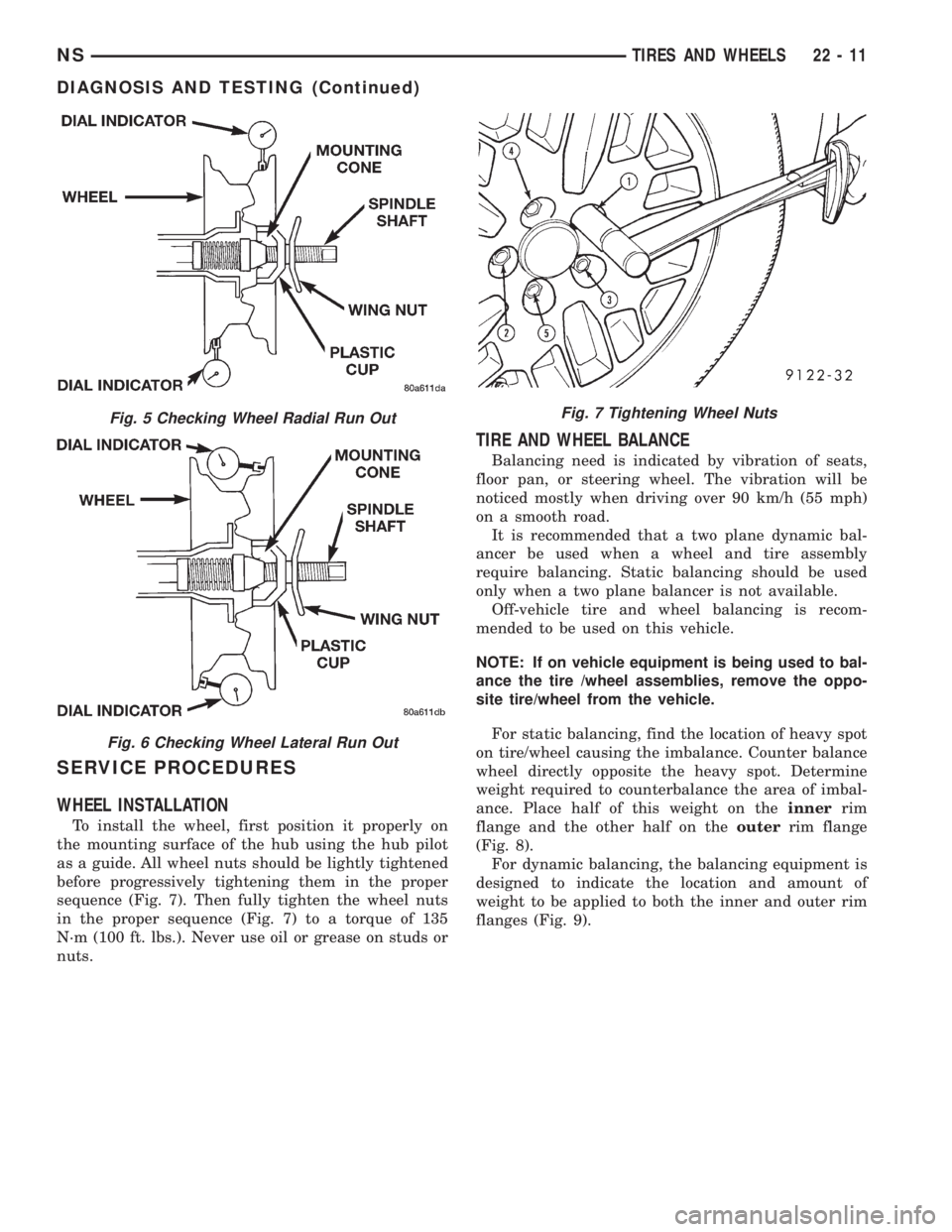

To install the wheel, first position it properly on

the mounting surface of the hub using the hub pilot

as a guide. All wheel nuts should be lightly tightened

before progressively tightening them in the proper

sequence (Fig. 7). Then fully tighten the wheel nuts

in the proper sequence (Fig. 7) to a torque of 135

N´m (100 ft. lbs.). Never use oil or grease on studs or

nuts.

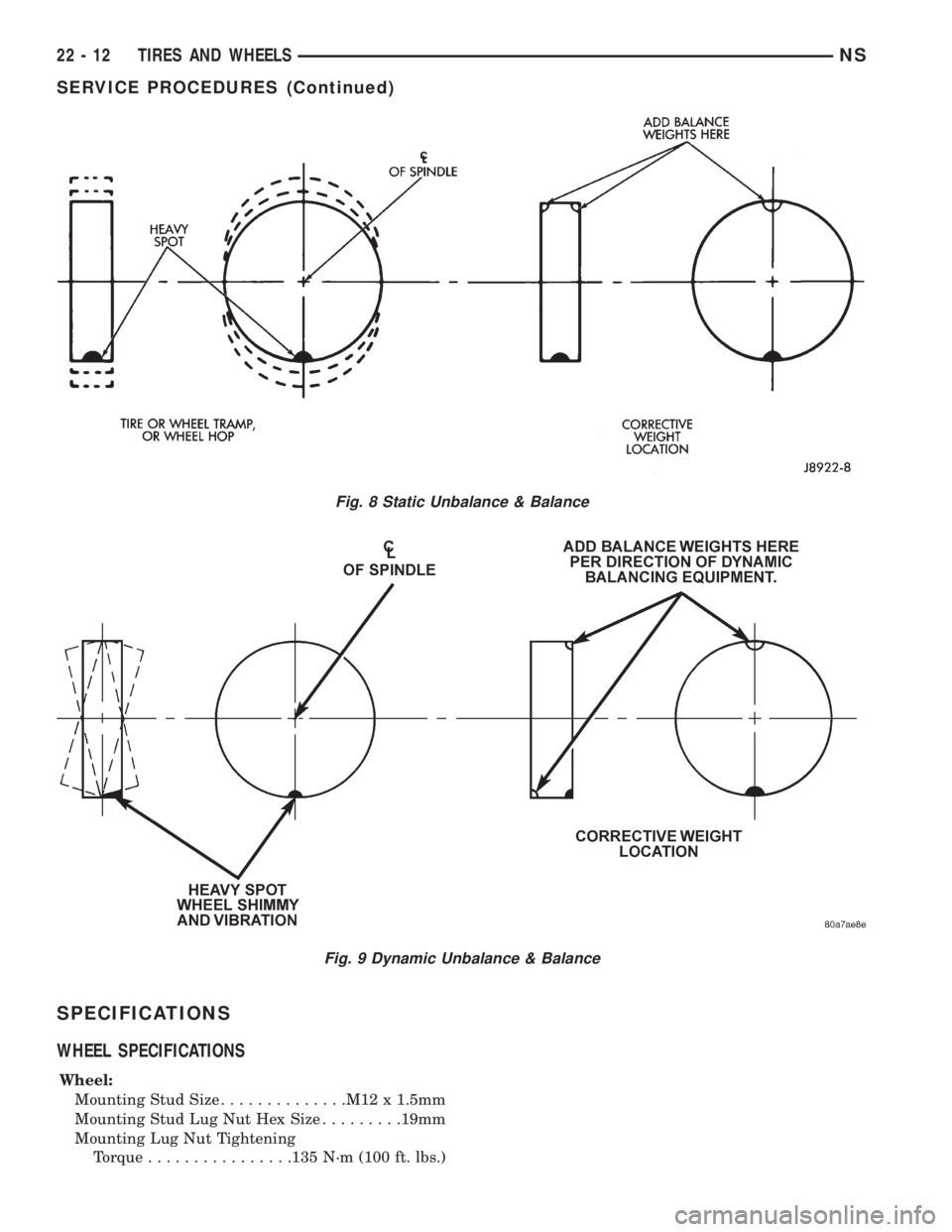

TIRE AND WHEEL BALANCE

Balancing need is indicated by vibration of seats,

floor pan, or steering wheel. The vibration will be

noticed mostly when driving over 90 km/h (55 mph)

on a smooth road.

It is recommended that a two plane dynamic bal-

ancer be used when a wheel and tire assembly

require balancing. Static balancing should be used

only when a two plane balancer is not available.

Off-vehicle tire and wheel balancing is recom-

mended to be used on this vehicle.

NOTE: If on vehicle equipment is being used to bal-

ance the tire /wheel assemblies, remove the oppo-

site tire/wheel from the vehicle.

For static balancing, find the location of heavy spot

on tire/wheel causing the imbalance. Counter balance

wheel directly opposite the heavy spot. Determine

weight required to counterbalance the area of imbal-

ance. Place half of this weight on theinnerrim

flange and the other half on theouterrim flange

(Fig. 8).

For dynamic balancing, the balancing equipment is

designed to indicate the location and amount of

weight to be applied to both the inner and outer rim

flanges (Fig. 9).

Fig. 5 Checking Wheel Radial Run Out

Fig. 6 Checking Wheel Lateral Run Out

Fig. 7 Tightening Wheel Nuts

NSTIRES AND WHEELS 22 - 11

DIAGNOSIS AND TESTING (Continued)

Page 1730 of 1938

SPECIFICATIONS

WHEEL SPECIFICATIONS

Wheel:

Mounting Stud Size..............M12 x 1.5mm

Mounting Stud Lug Nut Hex Size.........19mm

Mounting Lug Nut Tightening

Torque................135 N´m (100 ft. lbs.)

Fig. 8 Static Unbalance & Balance

Fig. 9 Dynamic Unbalance & Balance

22 - 12 TIRES AND WHEELSNS

SERVICE PROCEDURES (Continued)