service CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1820 of 1938

absorb moisture readily out of the air. This moisture

will convert into acids within a closed system.

CAUTION: The system must be completely empty

before opening any fitting or connection in the

refrigeration system. Open fittings with caution

even after the system has been emptied. If any

pressure is noticed as a fitting is loosened,

retighten fitting and evacuate the system again.

A good rule for the flexible hose lines is to keep

the radius of all bends at least 10 times the diame-

ter of the hose. Sharper bends will reduce the flow

of refrigerant. The flexible hose lines should be

routed so they are at least 3 inches (80 mm) from

the exhaust manifold. Inspect all flexible hose lines

to make sure they are in good condition and prop-

erly routed.

The use of correct wrenches when making con-

nections is very important. Improper wrenches or

improper use of wrenches can damage the fittings.

The internal parts of the A/C system will remain

stable as long as moisture-free refrigerant and

refrigerant oil is used. Abnormal amounts of dirt,

moisture or air can upset the chemical stability.

This may cause operational troubles or even seri-

ous damage if present in more than very small

quantities.

When opening a refrigeration system, have every-

thing you will need to repair the system ready. This

will minimize the amount of time the system must

be opened. Cap or plug all lines and fittings as

soon as they are opened. This will help prevent the

entrance of dirt and moisture. All new lines and

components should be capped or sealed until they

are ready to be used.

All tools, including the refrigerant dispensing

manifold, the manifold gauge set, and test hoses

should be kept clean and dry.

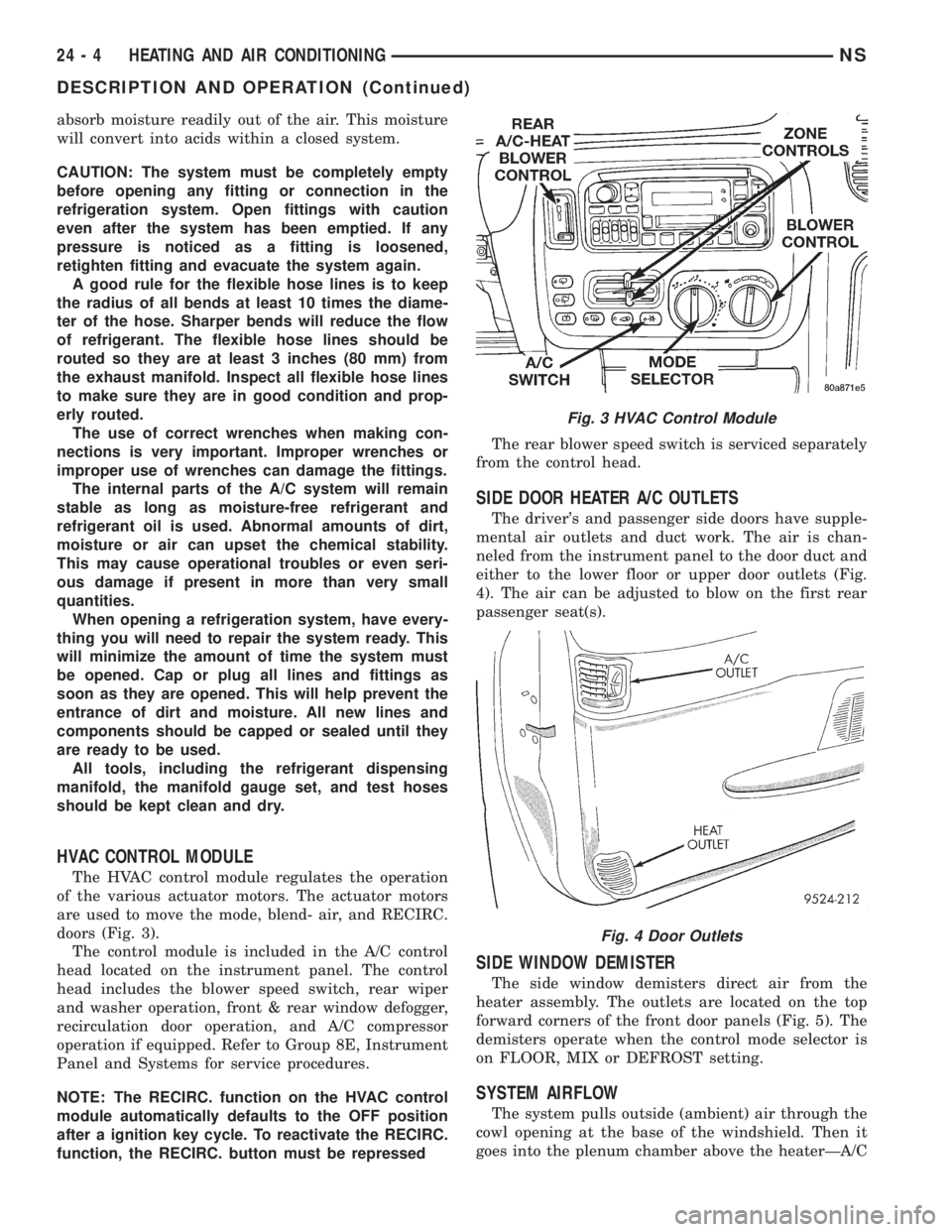

HVAC CONTROL MODULE

The HVAC control module regulates the operation

of the various actuator motors. The actuator motors

are used to move the mode, blend- air, and RECIRC.

doors (Fig. 3).

The control module is included in the A/C control

head located on the instrument panel. The control

head includes the blower speed switch, rear wiper

and washer operation, front & rear window defogger,

recirculation door operation, and A/C compressor

operation if equipped. Refer to Group 8E, Instrument

Panel and Systems for service procedures.

NOTE: The RECIRC. function on the HVAC control

module automatically defaults to the OFF position

after a ignition key cycle. To reactivate the RECIRC.

function, the RECIRC. button must be repressedThe rear blower speed switch is serviced separately

from the control head.

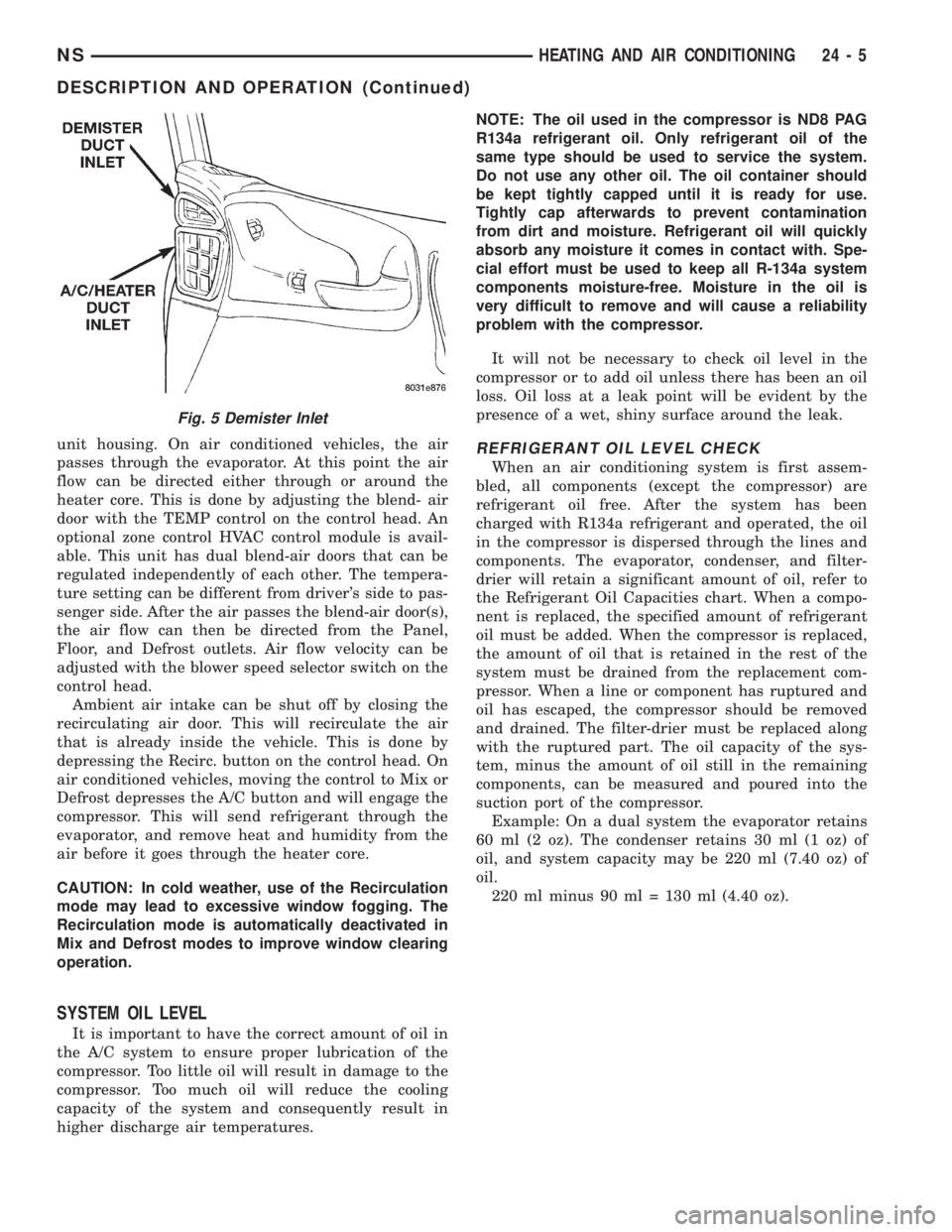

SIDE DOOR HEATER A/C OUTLETS

The driver's and passenger side doors have supple-

mental air outlets and duct work. The air is chan-

neled from the instrument panel to the door duct and

either to the lower floor or upper door outlets (Fig.

4). The air can be adjusted to blow on the first rear

passenger seat(s).

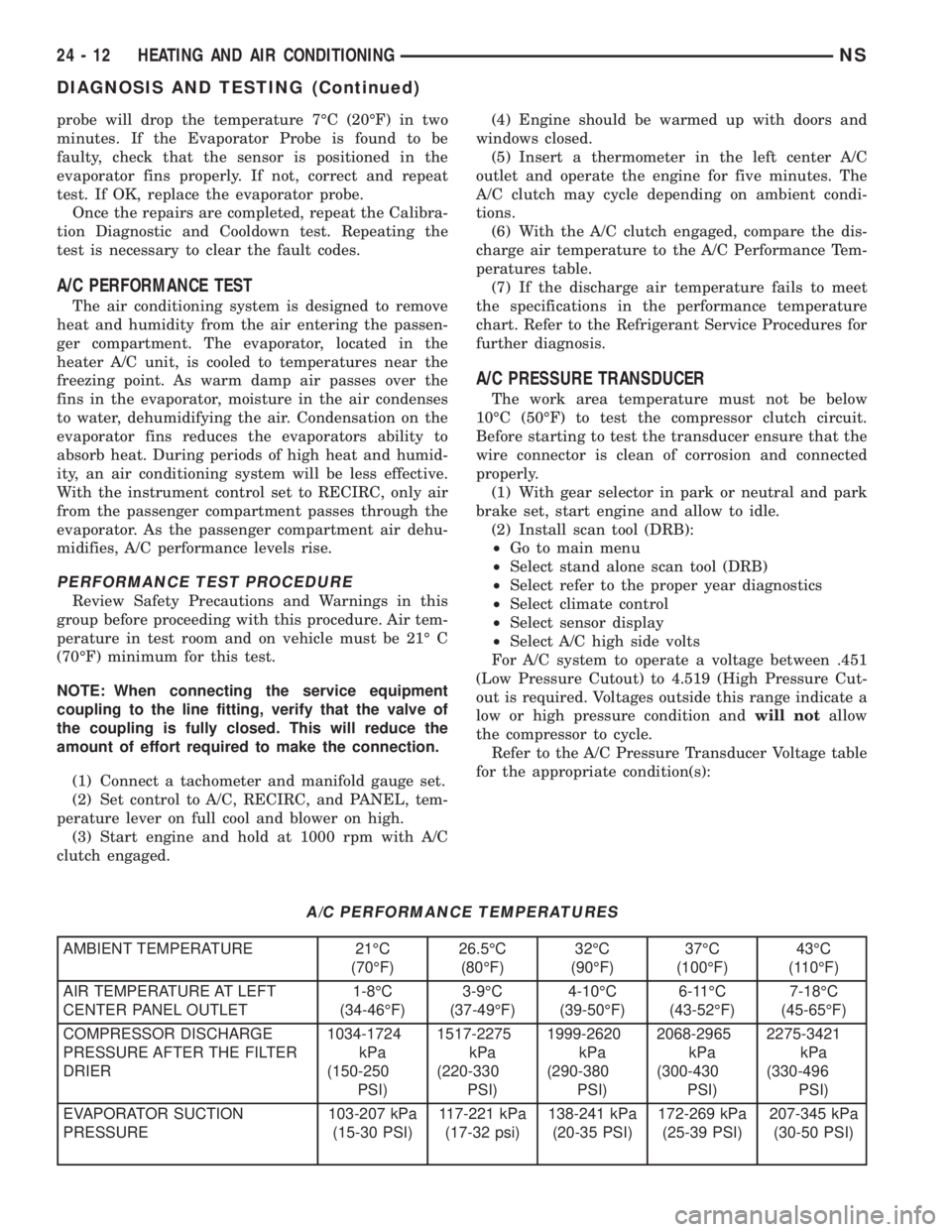

SIDE WINDOW DEMISTER

The side window demisters direct air from the

heater assembly. The outlets are located on the top

forward corners of the front door panels (Fig. 5). The

demisters operate when the control mode selector is

on FLOOR, MIX or DEFROST setting.

SYSTEM AIRFLOW

The system pulls outside (ambient) air through the

cowl opening at the base of the windshield. Then it

goes into the plenum chamber above the heaterÐA/C

Fig. 3 HVAC Control Module

Fig. 4 Door Outlets

24 - 4 HEATING AND AIR CONDITIONINGNS

DESCRIPTION AND OPERATION (Continued)

Page 1821 of 1938

unit housing. On air conditioned vehicles, the air

passes through the evaporator. At this point the air

flow can be directed either through or around the

heater core. This is done by adjusting the blend- air

door with the TEMP control on the control head. An

optional zone control HVAC control module is avail-

able. This unit has dual blend-air doors that can be

regulated independently of each other. The tempera-

ture setting can be different from driver's side to pas-

senger side. After the air passes the blend-air door(s),

the air flow can then be directed from the Panel,

Floor, and Defrost outlets. Air flow velocity can be

adjusted with the blower speed selector switch on the

control head.

Ambient air intake can be shut off by closing the

recirculating air door. This will recirculate the air

that is already inside the vehicle. This is done by

depressing the Recirc. button on the control head. On

air conditioned vehicles, moving the control to Mix or

Defrost depresses the A/C button and will engage the

compressor. This will send refrigerant through the

evaporator, and remove heat and humidity from the

air before it goes through the heater core.

CAUTION: In cold weather, use of the Recirculation

mode may lead to excessive window fogging. The

Recirculation mode is automatically deactivated in

Mix and Defrost modes to improve window clearing

operation.

SYSTEM OIL LEVEL

It is important to have the correct amount of oil in

the A/C system to ensure proper lubrication of the

compressor. Too little oil will result in damage to the

compressor. Too much oil will reduce the cooling

capacity of the system and consequently result in

higher discharge air temperatures.NOTE: The oil used in the compressor is ND8 PAG

R134a refrigerant oil. Only refrigerant oil of the

same type should be used to service the system.

Do not use any other oil. The oil container should

be kept tightly capped until it is ready for use.

Tightly cap afterwards to prevent contamination

from dirt and moisture. Refrigerant oil will quickly

absorb any moisture it comes in contact with. Spe-

cial effort must be used to keep all R-134a system

components moisture-free. Moisture in the oil is

very difficult to remove and will cause a reliability

problem with the compressor.

It will not be necessary to check oil level in the

compressor or to add oil unless there has been an oil

loss. Oil loss at a leak point will be evident by the

presence of a wet, shiny surface around the leak.

REFRIGERANT OIL LEVEL CHECK

When an air conditioning system is first assem-

bled, all components (except the compressor) are

refrigerant oil free. After the system has been

charged with R134a refrigerant and operated, the oil

in the compressor is dispersed through the lines and

components. The evaporator, condenser, and filter-

drier will retain a significant amount of oil, refer to

the Refrigerant Oil Capacities chart. When a compo-

nent is replaced, the specified amount of refrigerant

oil must be added. When the compressor is replaced,

the amount of oil that is retained in the rest of the

system must be drained from the replacement com-

pressor. When a line or component has ruptured and

oil has escaped, the compressor should be removed

and drained. The filter-drier must be replaced along

with the ruptured part. The oil capacity of the sys-

tem, minus the amount of oil still in the remaining

components, can be measured and poured into the

suction port of the compressor.

Example: On a dual system the evaporator retains

60 ml (2 oz). The condenser retains 30 ml (1 oz) of

oil, and system capacity may be 220 ml (7.40 oz) of

oil.

220 ml minus 90 ml = 130 ml (4.40 oz).

Fig. 5 Demister Inlet

NSHEATING AND AIR CONDITIONING 24 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1828 of 1938

probe will drop the temperature 7ÉC (20ÉF) in two

minutes. If the Evaporator Probe is found to be

faulty, check that the sensor is positioned in the

evaporator fins properly. If not, correct and repeat

test. If OK, replace the evaporator probe.

Once the repairs are completed, repeat the Calibra-

tion Diagnostic and Cooldown test. Repeating the

test is necessary to clear the fault codes.

A/C PERFORMANCE TEST

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

heater A/C unit, is cooled to temperatures near the

freezing point. As warm damp air passes over the

fins in the evaporator, moisture in the air condenses

to water, dehumidifying the air. Condensation on the

evaporator fins reduces the evaporators ability to

absorb heat. During periods of high heat and humid-

ity, an air conditioning system will be less effective.

With the instrument control set to RECIRC, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, A/C performance levels rise.

PERFORMANCE TEST PROCEDURE

Review Safety Precautions and Warnings in this

group before proceeding with this procedure. Air tem-

perature in test room and on vehicle must be 21É C

(70ÉF) minimum for this test.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer and manifold gauge set.

(2) Set control to A/C, RECIRC, and PANEL, tem-

perature lever on full cool and blower on high.

(3) Start engine and hold at 1000 rpm with A/C

clutch engaged.(4) Engine should be warmed up with doors and

windows closed.

(5) Insert a thermometer in the left center A/C

outlet and operate the engine for five minutes. The

A/C clutch may cycle depending on ambient condi-

tions.

(6) With the A/C clutch engaged, compare the dis-

charge air temperature to the A/C Performance Tem-

peratures table.

(7) If the discharge air temperature fails to meet

the specifications in the performance temperature

chart. Refer to the Refrigerant Service Procedures for

further diagnosis.

A/C PRESSURE TRANSDUCER

The work area temperature must not be below

10ÉC (50ÉF) to test the compressor clutch circuit.

Before starting to test the transducer ensure that the

wire connector is clean of corrosion and connected

properly.

(1) With gear selector in park or neutral and park

brake set, start engine and allow to idle.

(2) Install scan tool (DRB):

²Go to main menu

²Select stand alone scan tool (DRB)

²Select refer to the proper year diagnostics

²Select climate control

²Select sensor display

²Select A/C high side volts

For A/C system to operate a voltage between .451

(Low Pressure Cutout) to 4.519 (High Pressure Cut-

out is required. Voltages outside this range indicate a

low or high pressure condition andwill notallow

the compressor to cycle.

Refer to the A/C Pressure Transducer Voltage table

for the appropriate condition(s):

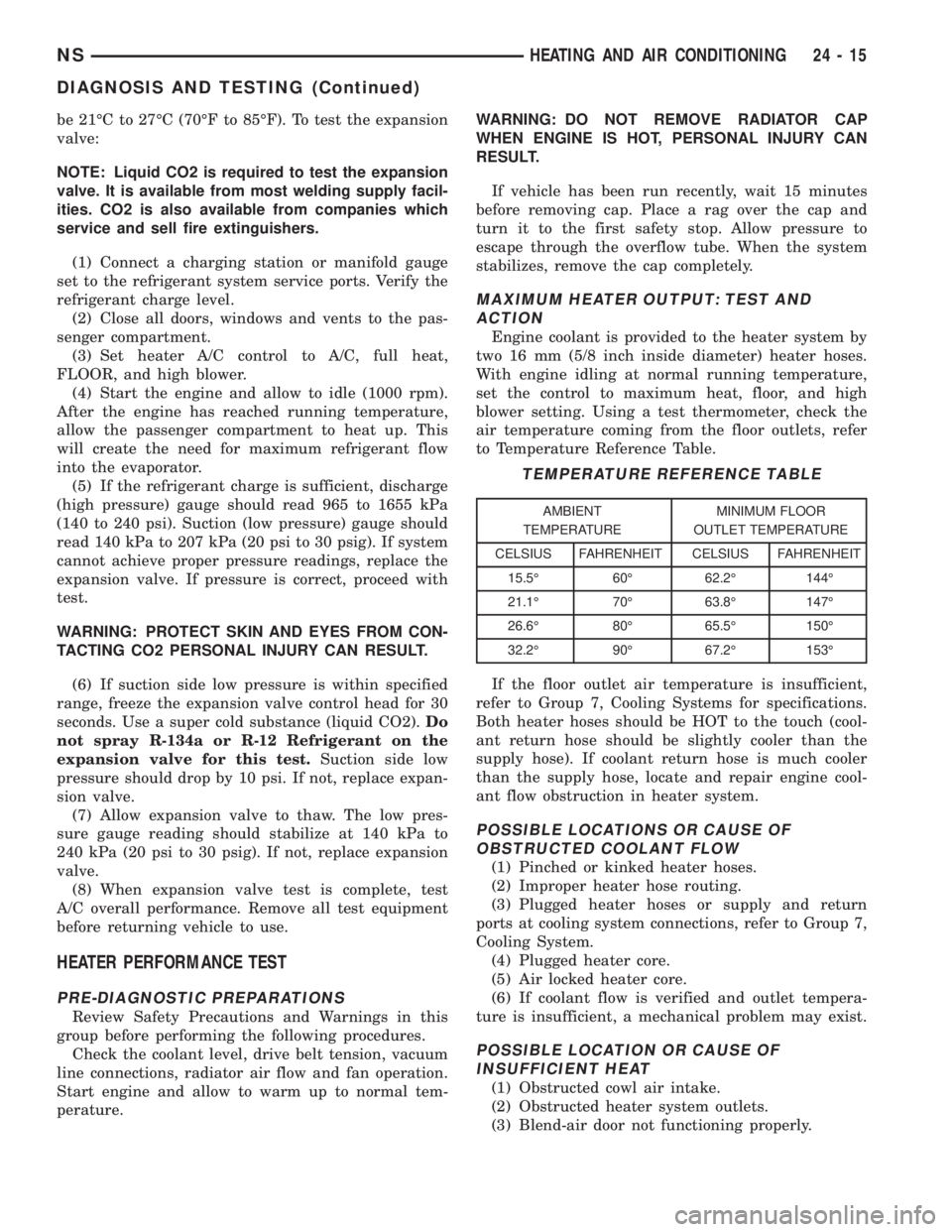

A/C PERFORMANCE TEMPERATURES

AMBIENT TEMPERATURE 21ÉC

(70ÉF)26.5ÉC

(80ÉF)32ÉC

(90ÉF)37ÉC

(100ÉF)43ÉC

(110ÉF)

AIR TEMPERATURE AT LEFT

CENTER PANEL OUTLET1-8ÉC

(34-46ÉF)3-9ÉC

(37-49ÉF)4-10ÉC

(39-50ÉF)6-11ÉC

(43-52ÉF)7-18ÉC

(45-65ÉF)

COMPRESSOR DISCHARGE

PRESSURE AFTER THE FILTER

DRIER1034-1724

kPa

(150-250

PSI)1517-2275

kPa

(220-330

PSI)1999-2620

kPa

(290-380

PSI)2068-2965

kPa

(300-430

PSI)2275-3421

kPa

(330-496

PSI)

EVAPORATOR SUCTION

PRESSURE103-207 kPa

(15-30 PSI)117-221 kPa

(17-32 psi)138-241 kPa

(20-35 PSI)172-269 kPa

(25-39 PSI)207-345 kPa

(30-50 PSI)

24 - 12 HEATING AND AIR CONDITIONINGNS

DIAGNOSIS AND TESTING (Continued)

Page 1831 of 1938

be 21ÉC to 27ÉC (70ÉF to 85ÉF). To test the expansion

valve:

NOTE: Liquid CO2 is required to test the expansion

valve. It is available from most welding supply facil-

ities. CO2 is also available from companies which

service and sell fire extinguishers.

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

(2) Close all doors, windows and vents to the pas-

senger compartment.

(3) Set heater A/C control to A/C, full heat,

FLOOR, and high blower.

(4) Start the engine and allow to idle (1000 rpm).

After the engine has reached running temperature,

allow the passenger compartment to heat up. This

will create the need for maximum refrigerant flow

into the evaporator.

(5) If the refrigerant charge is sufficient, discharge

(high pressure) gauge should read 965 to 1655 kPa

(140 to 240 psi). Suction (low pressure) gauge should

read 140 kPa to 207 kPa (20 psi to 30 psig). If system

cannot achieve proper pressure readings, replace the

expansion valve. If pressure is correct, proceed with

test.

WARNING: PROTECT SKIN AND EYES FROM CON-

TACTING CO2 PERSONAL INJURY CAN RESULT.

(6) If suction side low pressure is within specified

range, freeze the expansion valve control head for 30

seconds. Use a super cold substance (liquid CO2).Do

not spray R-134a or R-12 Refrigerant on the

expansion valve for this test.Suction side low

pressure should drop by 10 psi. If not, replace expan-

sion valve.

(7) Allow expansion valve to thaw. The low pres-

sure gauge reading should stabilize at 140 kPa to

240 kPa (20 psi to 30 psig). If not, replace expansion

valve.

(8) When expansion valve test is complete, test

A/C overall performance. Remove all test equipment

before returning vehicle to use.

HEATER PERFORMANCE TEST

PRE-DIAGNOSTIC PREPARATIONS

Review Safety Precautions and Warnings in this

group before performing the following procedures.

Check the coolant level, drive belt tension, vacuum

line connections, radiator air flow and fan operation.

Start engine and allow to warm up to normal tem-

perature.WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap and

turn it to the first safety stop. Allow pressure to

escape through the overflow tube. When the system

stabilizes, remove the cap completely.

MAXIMUM HEATER OUTPUT: TEST AND

ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference Table.

If the floor outlet air temperature is insufficient,

refer to Group 7, Cooling Systems for specifications.

Both heater hoses should be HOT to the touch (cool-

ant return hose should be slightly cooler than the

supply hose). If coolant return hose is much cooler

than the supply hose, locate and repair engine cool-

ant flow obstruction in heater system.

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.

(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF

INSUFFICIENT HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE REFERENCE TABLE

AMBIENT

TEMPERATUREMINIMUM FLOOR

OUTLET TEMPERATURE

CELSIUS FAHRENHEIT CELSIUS FAHRENHEIT

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

NSHEATING AND AIR CONDITIONING 24 - 15

DIAGNOSIS AND TESTING (Continued)

Page 1832 of 1938

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door motor.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

NOTE: The amount of R134a refrigerant that the air

conditioning system holds is:

²Without rear A/C± .96 kg (34 oz. or 2.13 lbs.)

²With Rear A/C± 1.36 kg (48 oz. or 3.00 lbs.)

NOTE: Low Charge, condition may be described

as:

²Loss of A/C performance

²Fog from A/C outlets

²evaporator may have a HISS sound

There are two different ways the system can be

tested:

²With a scan tool (DRB), thermocouple and the

Charge Determination Graph. Use the scan tool

(DRB) diagnostic topic: Engine±System Monitors, A/C

Pressure.

²Using a manifold gauge set, a thermocouple and

the Charge Determination Graph.

It is recommended to use the gauges or reclaim/re-

cycle equipment.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. SOME

MIXTURES OF AIR/R-134a HAVE BEEN SHOWN TO

BE COMBUSTIBLE AT ELEVATED PRESSURES.

THESE MIXTURES ARE POTENTIALLY DANGER-

OUS AND MAY RESULT IN FIRE OR EXPLOSION

CAUSING INJURY OR PROPERTY DAMAGE.

(1) Establish your preferred method of measuring

liquid line pressure. Use a manifold gauge set or a

DRB scan tool.(2) Attach a clamp-on thermocouple (P.S.E. 66-324-

0014 or 80PK-1A) or equivalent to the liquid line. It

must be placed as close to the A/C Pressure Trans-

ducer as possible to observe liquid line temperature.

Refer to ªThermocouple Probeº in this section for

more information on probe.

(3) The vehicle must be in the following modes:

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set to Outside Air

²Panel Mode

²Full Cool

²High Blower motor, (vehicle equipped with rear

A/C turn rear blower motor ON HIGH)

²A/C Button in the ON position

²Vehicle Windows Open.

²Recirc. button turned OFF

(4) Operate system for a couple of minutes to allow

the system to stabilize.

(5) Set system pressure to about 1793 kPa (260

psi) by placing a piece of cardboard over part of the

front side of the condenser. To place cardboard prop-

erly, remove the upper radiator-condenser cover.

Insert cardboard between condenser and radiator

front. This will maintain a constant pressure.

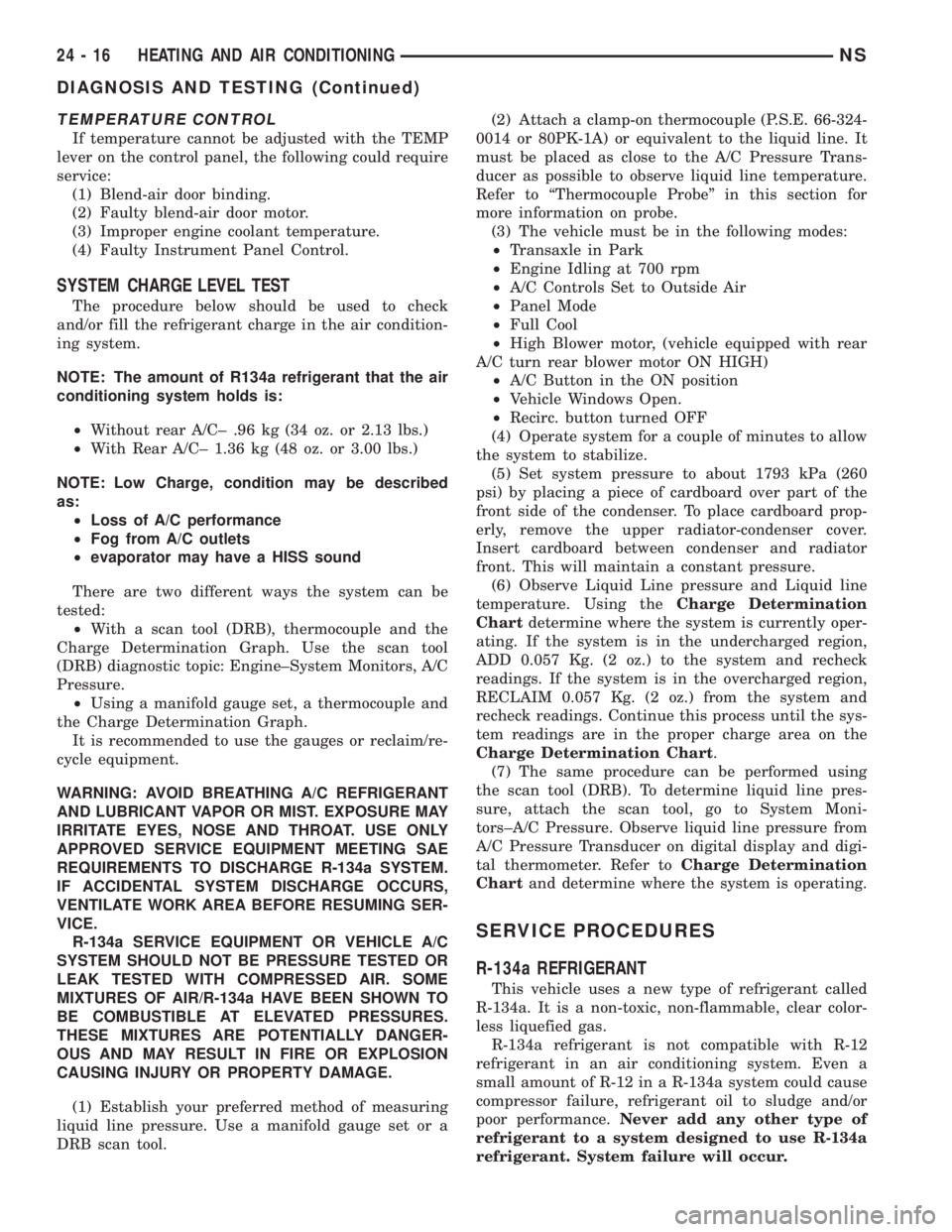

(6) Observe Liquid Line pressure and Liquid line

temperature. Using theCharge Determination

Chartdetermine where the system is currently oper-

ating. If the system is in the undercharged region,

ADD 0.057 Kg. (2 oz.) to the system and recheck

readings. If the system is in the overcharged region,

RECLAIM 0.057 Kg. (2 oz.) from the system and

recheck readings. Continue this process until the sys-

tem readings are in the proper charge area on the

Charge Determination Chart.

(7) The same procedure can be performed using

the scan tool (DRB). To determine liquid line pres-

sure, attach the scan tool, go to System Moni-

tors±A/C Pressure. Observe liquid line pressure from

A/C Pressure Transducer on digital display and digi-

tal thermometer. Refer toCharge Determination

Chartand determine where the system is operating.

SERVICE PROCEDURES

R-134a REFRIGERANT

This vehicle uses a new type of refrigerant called

R-134a. It is a non-toxic, non-flammable, clear color-

less liquefied gas.

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 in a R-134a system could cause

compressor failure, refrigerant oil to sludge and/or

poor performance.Never add any other type of

refrigerant to a system designed to use R-134a

refrigerant. System failure will occur.

24 - 16 HEATING AND AIR CONDITIONINGNS

DIAGNOSIS AND TESTING (Continued)

Page 1833 of 1938

The high pressure service port is located on the liq-

uid line near the strut tower. The low pressure ser-

vice port is located on the suction line near the

compressor manifold.

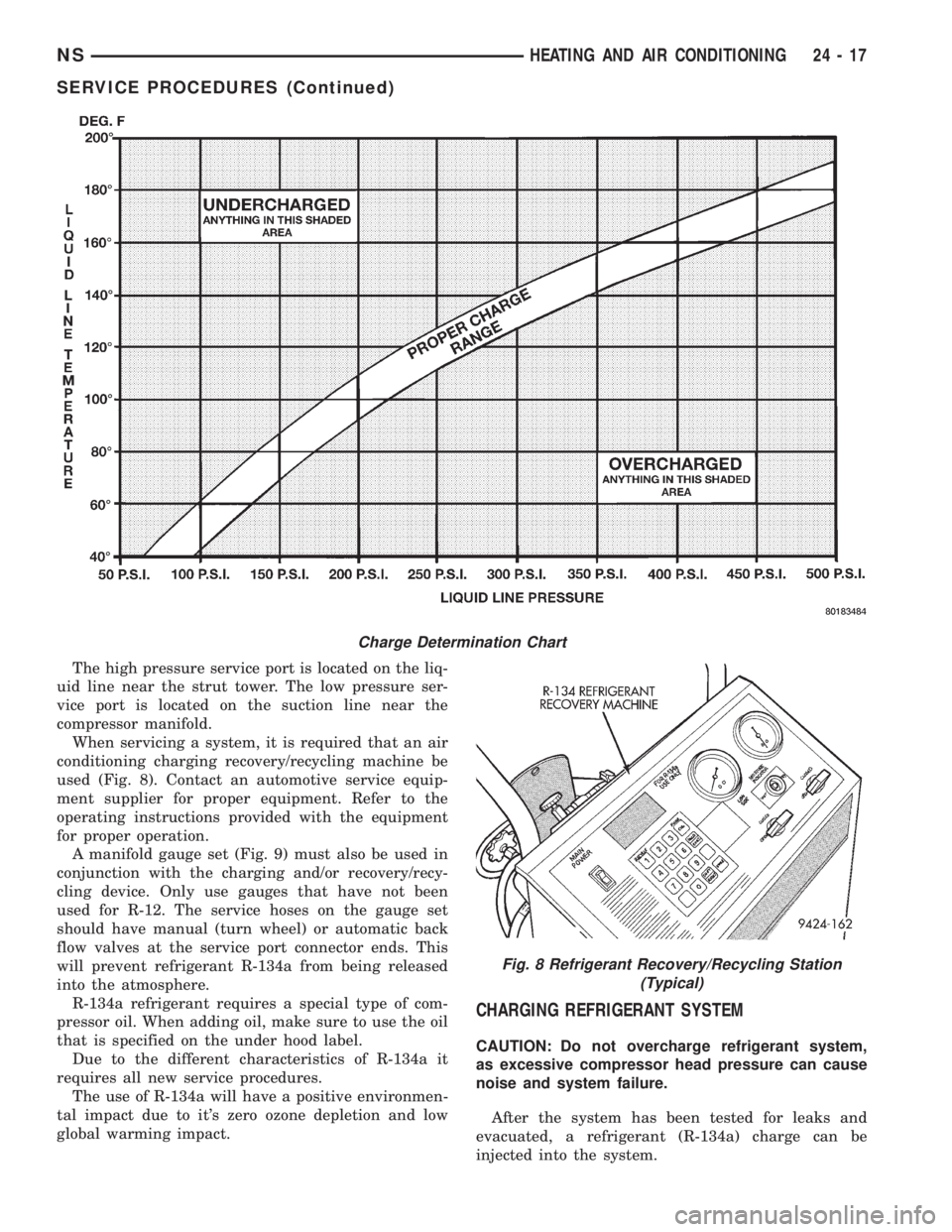

When servicing a system, it is required that an air

conditioning charging recovery/recycling machine be

used (Fig. 8). Contact an automotive service equip-

ment supplier for proper equipment. Refer to the

operating instructions provided with the equipment

for proper operation.

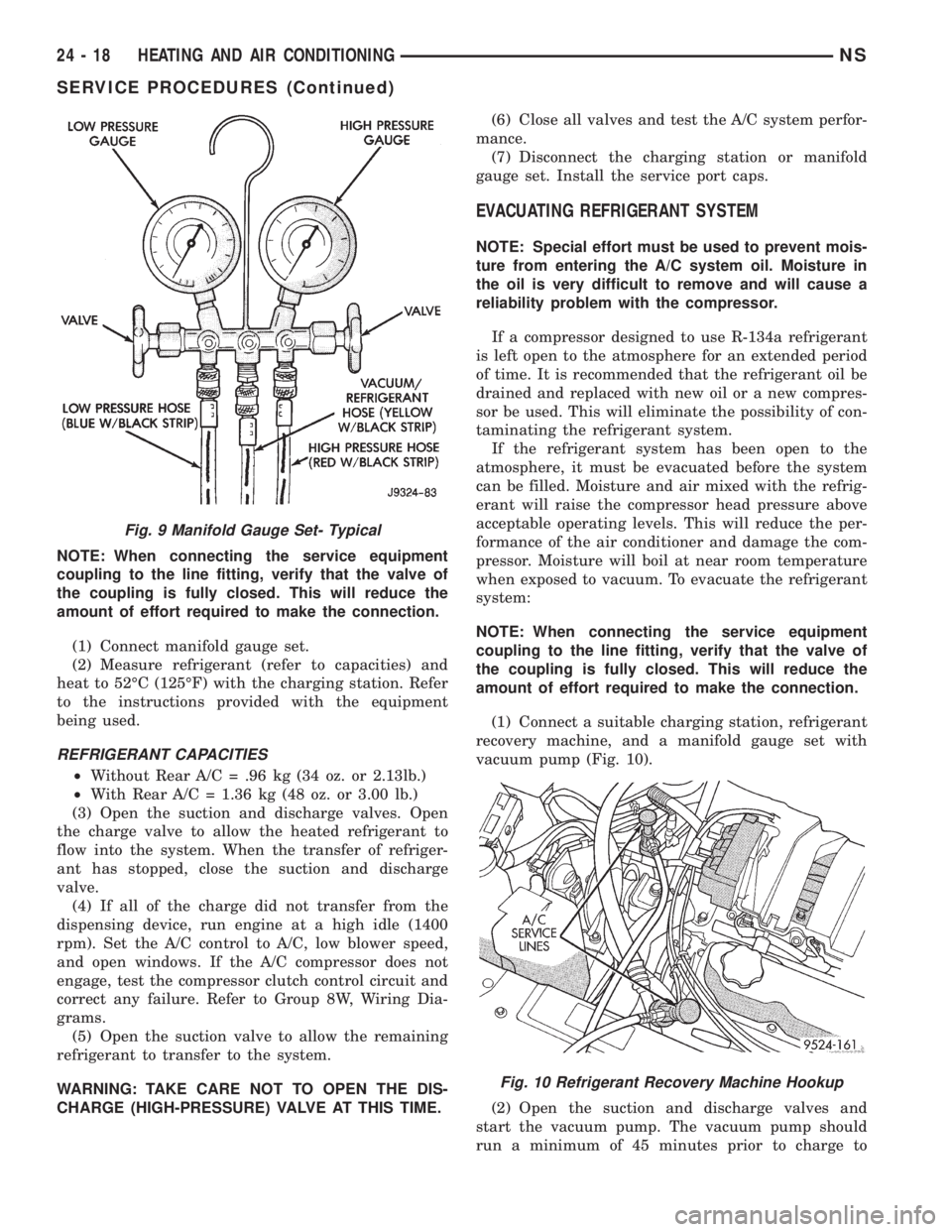

A manifold gauge set (Fig. 9) must also be used in

conjunction with the charging and/or recovery/recy-

cling device. Only use gauges that have not been

used for R-12. The service hoses on the gauge set

should have manual (turn wheel) or automatic back

flow valves at the service port connector ends. This

will prevent refrigerant R-134a from being released

into the atmosphere.

R-134a refrigerant requires a special type of com-

pressor oil. When adding oil, make sure to use the oil

that is specified on the under hood label.

Due to the different characteristics of R-134a it

requires all new service procedures.

The use of R-134a will have a positive environmen-

tal impact due to it's zero ozone depletion and low

global warming impact.

CHARGING REFRIGERANT SYSTEM

CAUTION: Do not overcharge refrigerant system,

as excessive compressor head pressure can cause

noise and system failure.

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

Charge Determination Chart

Fig. 8 Refrigerant Recovery/Recycling Station

(Typical)

NSHEATING AND AIR CONDITIONING 24 - 17

SERVICE PROCEDURES (Continued)

Page 1834 of 1938

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect manifold gauge set.

(2) Measure refrigerant (refer to capacities) and

heat to 52ÉC (125ÉF) with the charging station. Refer

to the instructions provided with the equipment

being used.

REFRIGERANT CAPACITIES

²Without Rear A/C = .96 kg (34 oz. or 2.13lb.)

²With Rear A/C = 1.36 kg (48 oz. or 3.00 lb.)

(3) Open the suction and discharge valves. Open

the charge valve to allow the heated refrigerant to

flow into the system. When the transfer of refriger-

ant has stopped, close the suction and discharge

valve.

(4) If all of the charge did not transfer from the

dispensing device, run engine at a high idle (1400

rpm). Set the A/C control to A/C, low blower speed,

and open windows. If the A/C compressor does not

engage, test the compressor clutch control circuit and

correct any failure. Refer to Group 8W, Wiring Dia-

grams.

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

EVACUATING REFRIGERANT SYSTEM

NOTE: Special effort must be used to prevent mois-

ture from entering the A/C system oil. Moisture in

the oil is very difficult to remove and will cause a

reliability problem with the compressor.

If a compressor designed to use R-134a refrigerant

is left open to the atmosphere for an extended period

of time. It is recommended that the refrigerant oil be

drained and replaced with new oil or a new compres-

sor be used. This will eliminate the possibility of con-

taminating the refrigerant system.

If the refrigerant system has been open to the

atmosphere, it must be evacuated before the system

can be filled. Moisture and air mixed with the refrig-

erant will raise the compressor head pressure above

acceptable operating levels. This will reduce the per-

formance of the air conditioner and damage the com-

pressor. Moisture will boil at near room temperature

when exposed to vacuum. To evacuate the refrigerant

system:

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a suitable charging station, refrigerant

recovery machine, and a manifold gauge set with

vacuum pump (Fig. 10).

(2) Open the suction and discharge valves and

start the vacuum pump. The vacuum pump should

run a minimum of 45 minutes prior to charge to

Fig. 9 Manifold Gauge Set- Typical

Fig. 10 Refrigerant Recovery Machine Hookup

24 - 18 HEATING AND AIR CONDITIONINGNS

SERVICE PROCEDURES (Continued)

Page 1835 of 1938

eliminate all moisture in system. When the suction

gauge reads -88 kPa (- 26 in. Hg) vacuum or greater

for 45 minutes, close all valves and turn off vacuum

pump. If the system fails to reach specified vacuum,

the refrigerant system likely has a leak that must be

corrected. If the refrigerant system maintains speci-

fied vacuum for at least 30 minutes, start the vac-

uum pump, open the suction and discharge valves.

Then allow the system to evacuate an additional 10

minutes.

(3) Close all valves. Turn off and disconnect the

vacuum pump.

(4) The refrigerant system is prepared to be

charged with refrigerant.

THERMOCOUPLE PROBE

To diagnose the A/C system, a temperature probe is

required to measure liquid line temperature. The

clamp-on type K probe shown in this manual is avail-

able through the Chrysler Professional Service

Equipment (PSE) program. This probe is compatible

with temperature-measuring instruments that accept

Type K Thermocouples and have a miniature connec-

tor input. Other temperature probes are available

through aftermarket sources. All references in this

manual will reflect the use of the probe made avail-

able through the Professional Service Equipment pro-

gram.

In order to use the temperature probe, a digital

thermometer will be required. If a digital thermome-

ter is not available, an adapter is available through

the Professional Service Equipment program. It can

convert any standard digital multimeter into a ther-

mometer. This adapter is designed to accept any

standard K-type thermocouple.

If a digital multimeter is not available, it to can be

ordered through Professional Service Equipment pro-

gram.

STICKING HVAC CONTROL MODULE PUSH

BUTTONS

To service HVAC control module push buttons that

are sticking, spray between the buttons with Mopart

MP-50. The MP-50 is a all purpose lubricant for

mechanical and electrical uses. After spraying around

the push buttons wipe any excess off the radio bezel

and HVAC control module push buttons. Operate the

buttons to ensure that they are operating freely.

SYSTEM LEAK CHECKING

WARNING: R-134a SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. SOME MIXTURES OF AIR/R-134a HAVE BEEN

SHOWN TO BE COMBUSTIBLE AT ELEVATEDPRESSURES. THESE MIXTURES ARE POTENTIALLY

DANGEROUS AND MAY RESULT IN FIRE OR

EXPLOSION CAUSING INJURY OR PROPERTY

DAMAGE.

If the A/C system is not cooling properly, determine

if the refrigerant system is fully charged with

R-134a. This is accomplished by performing a system

Charge Level-Check or Fill. If while performing this

test A/C liquid line pressure is less than 207 kPa (30

psi) proceed to Empty Refrigerant System Leak Test.

If liquid line pressure is greater than 207 kPa (30

psi) proceed to low refrigerant level leak test. If the

refrigerant system is empty or low in refrigerant

charge, a leak at any line fitting or component seal is

likely. A review of the fittings, lines and components

for oily residue is an indication of the leak location.

To detect a leak in the refrigerant system, perform

one of the following procedures as indicated by the

symptoms.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

EMPTY REFRIGERANT SYSTEM LEAK TEST

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (about 28 in Hg.). Deter-

mine if the system holds a vacuum for 15 minutes. If

vacuum is held, a leak is probably not present. If sys-

tem will not maintain vacuum level, proceed with

this procedure.

(2) Prepare a .284 Kg. (10 oz.) refrigerant charge

to be injected into the system.

(3) Connect and dispense .284 Kg. (10 oz.) of

refrigerant into the evacuated refrigerant system.

(4) Proceed to step two of Low Refrigerant Level

Leak Test.

LOW REFRIGERANT LEVEL LEAK TEST

(1) Determine if there is any (R-134a) refrigerant

in the system. Use the scan tool (DRB) under the

menu Systems Sensors±A/C Pressure test or pressure

gauge liquid line temperature partial charge check.

See system charge level check or fill for procedure.

(2) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run for five minutes with the system

set to the following:

NSHEATING AND AIR CONDITIONING 24 - 19

SERVICE PROCEDURES (Continued)

Page 1836 of 1938

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set in 100 percent outside air

²Full Panel Mode

²Blower motor ON HIGH

²A/C in the ON position

²Front Windows Open.

²Rear Air Off (If Equipped)

CAUTION: A leak detector designed for R-12 refrig-

erant will not detect leaks in a R-134a refrigerant

system.

(4) Shut off the vehicle and wait 2 to 7 minutes.

Then use an Electronic Leak Detector that is

designed to detect R-134a type refrigerant and search

for leaks. Fittings, lines, or components that appear

to be oily usually indicates a refrigerant leak. To

inspect the evaporator core for leaks, insert the leak

detector probe into the recirculating air door opening

or a heat duct.

If a thorough leak check has been completed with-

out indication of a leak, proceed to System Charge

Level-Check or Fill.

REMOVAL AND INSTALLATION

A/C PRESSURE TRANSDUCER

REMOVAL

(1) Disconnect the wire connector at the pressure

transducer.

(2) Using an open end wrench, remove the trans-

ducer from the liquid line (Fig. 11).

INSTALLATION

(1) Replace transducer O-ring.

(2) For installation, reverse the above procedures.

A/C SERVICE PORTS

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

The High Side service port is serviceable, the Low

Side is not serviceable.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Recover A/C system refrigerant.

(3) Unscrew the High Side service port from the

liquid line.

(4) Remove O-ring

INSTALLATION

For installation, reverse the above procedures.

²Install new O-ring.

²Evacuate and recharge A/C system.

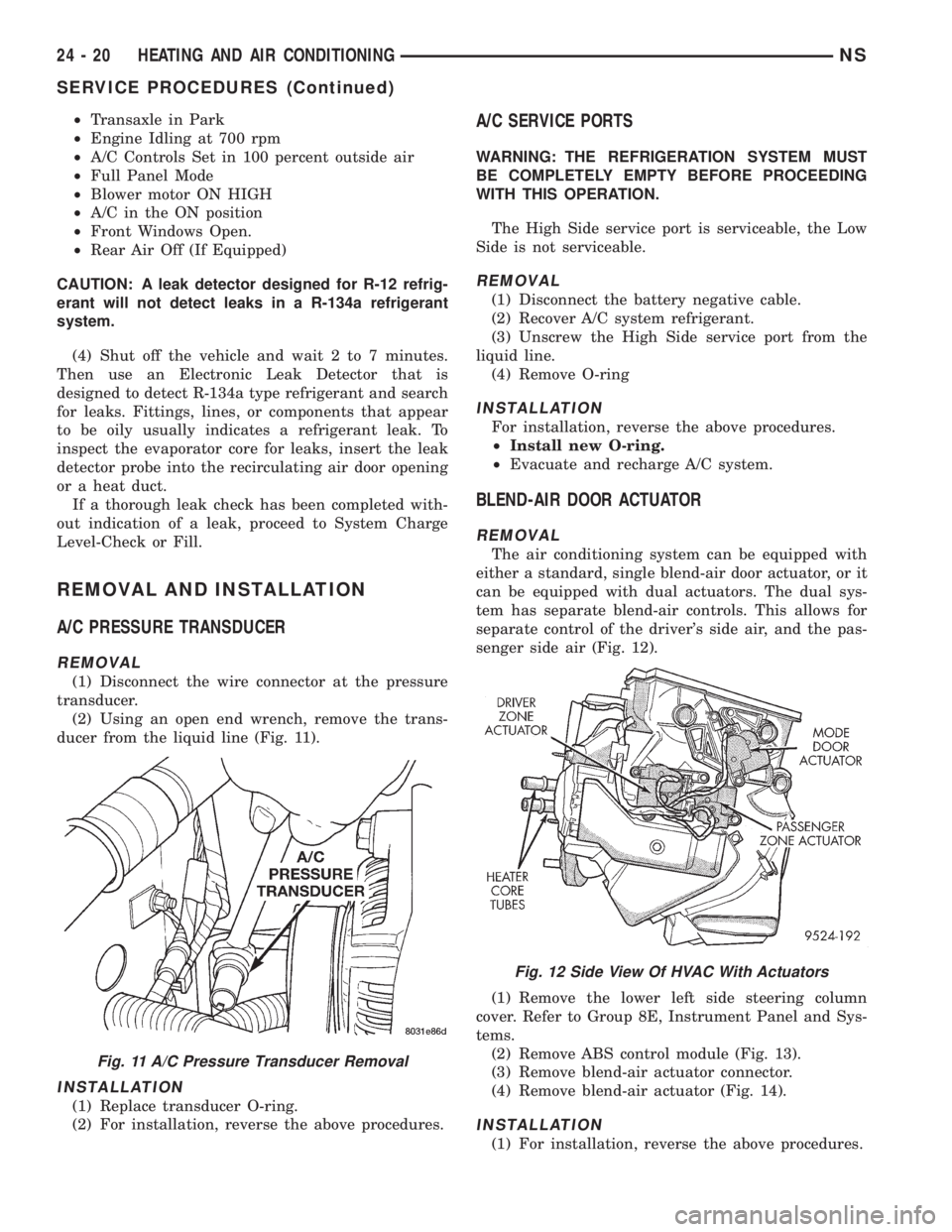

BLEND-AIR DOOR ACTUATOR

REMOVAL

The air conditioning system can be equipped with

either a standard, single blend-air door actuator, or it

can be equipped with dual actuators. The dual sys-

tem has separate blend-air controls. This allows for

separate control of the driver's side air, and the pas-

senger side air (Fig. 12).

(1) Remove the lower left side steering column

cover. Refer to Group 8E, Instrument Panel and Sys-

tems.

(2) Remove ABS control module (Fig. 13).

(3) Remove blend-air actuator connector.

(4) Remove blend-air actuator (Fig. 14).

INSTALLATION

(1) For installation, reverse the above procedures.

Fig. 11 A/C Pressure Transducer Removal

Fig. 12 Side View Of HVAC With Actuators

24 - 20 HEATING AND AIR CONDITIONINGNS

SERVICE PROCEDURES (Continued)

Page 1838 of 1938

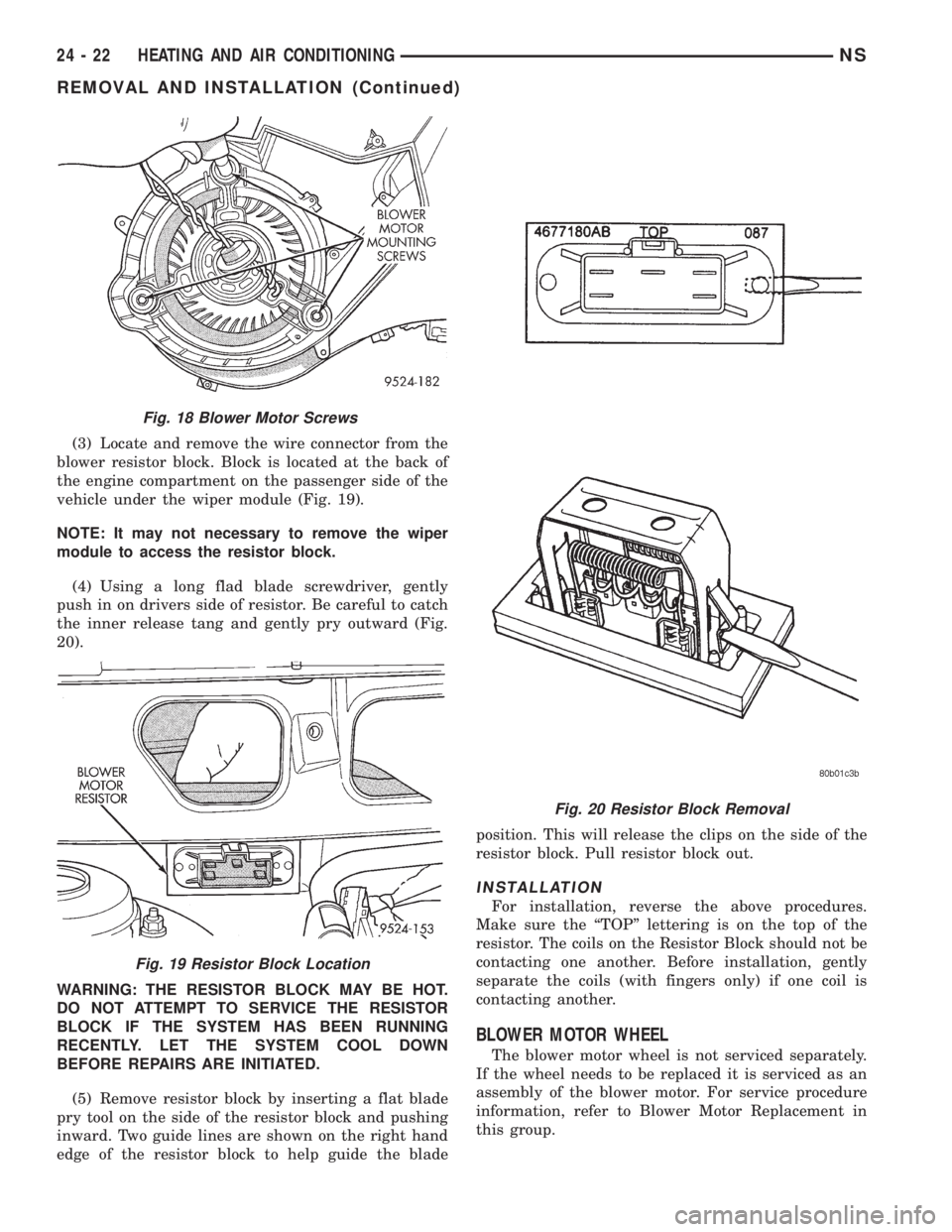

(3) Locate and remove the wire connector from the

blower resistor block. Block is located at the back of

the engine compartment on the passenger side of the

vehicle under the wiper module (Fig. 19).

NOTE: It may not necessary to remove the wiper

module to access the resistor block.

(4) Using a long flad blade screwdriver, gently

push in on drivers side of resistor. Be careful to catch

the inner release tang and gently pry outward (Fig.

20).

WARNING: THE RESISTOR BLOCK MAY BE HOT.

DO NOT ATTEMPT TO SERVICE THE RESISTOR

BLOCK IF THE SYSTEM HAS BEEN RUNNING

RECENTLY. LET THE SYSTEM COOL DOWN

BEFORE REPAIRS ARE INITIATED.

(5) Remove resistor block by inserting a flat blade

pry tool on the side of the resistor block and pushing

inward. Two guide lines are shown on the right hand

edge of the resistor block to help guide the bladeposition. This will release the clips on the side of the

resistor block. Pull resistor block out.

INSTALLATION

For installation, reverse the above procedures.

Make sure the ªTOPº lettering is on the top of the

resistor. The coils on the Resistor Block should not be

contacting one another. Before installation, gently

separate the coils (with fingers only) if one coil is

contacting another.

BLOWER MOTOR WHEEL

The blower motor wheel is not serviced separately.

If the wheel needs to be replaced it is serviced as an

assembly of the blower motor. For service procedure

information, refer to Blower Motor Replacement in

this group.

Fig. 18 Blower Motor Screws

Fig. 19 Resistor Block Location

Fig. 20 Resistor Block Removal

24 - 22 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)