low beam CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 955 of 1938

31

(BUILT-UP-EXPORT) RIGHT FRONT PARK/

TURN SIGNAL LAMP

BLACK

FUSED B(+) CIRCUIT FUNCTION

CAV

L78 20DG/YL

1

2Z1 18BK

3L60 18TN RIGHT TURN SIGNALGROUND

(EXCEPT BUILT-UP-EXPORT)SIGNAL LAMPPARK/TURN RIGHT FRONT

31BLACK

Z1 20BK L78 20DG/YL L60 18TN

3 2 1 CAV GROUND

FUSED B(+) RIGHT TURN SIGNAL CIRCUIT

FUNCTION

RIGHT FRONT

SPEAKER

(BASE)

14

BLACK

FUNCTIONCIRCUIT

-

RIGHT FRONT SPEAKER (-)CAV

1

2-

X56 20DB/RD

RIGHT FRONT SPEAKER (+)

- X54 20VT

- 4 3

32 1

FUSED RIGHT HIGH BEAM RELAY OUTPUT CIRCUIT FUNCTION

CAV

L34 20RD/OR

1

2L44 20VT/RD

3Z1 20BK GROUND

RIGHT HEADLAMP

(BUILT-UP-EXPORT)

FUSED RIGHT LOW BEAM OUTPUT BLACK

WHEEL SPEED SENSORRIGHT FRONT

1 2BLACKB7 18WT B6 18WT/DB

2 1 CAV RIGHT FRONT WHEEL SPEED SENSOR (+) RIGHT FRONT WHEEL SPEED SENSOR (-) CIRCUIT

FUNCTION

NS/GS8W-80 CONNECTOR PIN-OUTS 8W - 80 - 79

NSGS8079J988W-3

Page 956 of 1938

21 3BLACKL34 20RD/OR Z1 20BK

L44 20VT/RD

3 2 1 CAV FUSED RIGHT HIGH BEAM OUTPUT

GROUND

FUSED RIGHT LOW BEAM OUTPUT CIRCUIT

FUNCTION

RIGHT HEADLAMP

(EXCEPT BUILT-UP-EXPORT)

B

A

FUNCTION

A CAV

L44 20VT/RDCIRCUIT

B

Z1 20BK

GROUND FUSED RIGHT LOW BEAM OUTPUT

FLOOD LAMP RIGHT LIFTGATE

1BLACK2

Z1 20BK M11 20PK/LB

2 1 CAV GROUND

COURTESY LAMP RELAY OUTPUT CIRCUIT

FUNCTION

(EXCEPT BUILT-UP-EXPORT)HEADLAMP (CHRYSLER)RIGHT HIGH

FUNCTION

B A CAV

Z1 20BK L34 20RD/ORCIRCUIT

GROUND FUSED RIGHT HIGH BEAM OUTPUT

BA

1

3

(BUILT-UP-EXPORT)

GROUND CIRCUIT FUNCTION

CAV

Z1 20BK

1

2L13 18BR/YL

3L44 20VT/RD FUSED RIGHT LOW BEAM OUTPUT

RIGHT HEADLAMP

LEVELING MOTOR

HEADLAMP ADJUST SIGNAL BLACK

RIGHT LOW

HEADLAMP (CHRYSLER)

(EXCEPT BUILT-UP-EXPORT)

8W - 80 - 80 8W-80 CONNECTOR PIN-OUTSNS/GS

J988W-3NSGS8080

Page 1111 of 1938

3.0L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

ENGINE COMPONENTS.................. 61

ENGINE IDENTIFICATION NUMBER......... 61

ENGINE LUBRICATION................... 61

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE......... 62

SERVICE PROCEDURES

AUTO LASH ADJUSTER................... 62

CHECKING CRANKSHAFT END PLAY........ 65

FITTING CONNECTING ROD BEARINGS...... 63

FITTING MAIN BEARING.................. 63

VALVE SERVICE RECONDITION............ 66

REMOVAL AND INSTALLATION

CAMSHAFT SEAL....................... 72

CAMSHAFT............................ 71

CRANKSHAFT.......................... 81

CYLINDER HEAD COVER................. 70

CYLINDER HEAD........................ 73

ENGINE ASSEMBLY...................... 69

ENGINE MOUNTS....................... 68

FRONT CRANKSHAFT OIL SEAL............ 83OIL FILTER AND ADAPTOR................ 84

OILPAN ............................... 77

OIL PUMP............................. 84

PISTON AND CONNECTING ROD........... 78

REAR CRANKSHAFT SEAL................ 83

ROCKER ARMS......................... 72

TIMING BELT........................... 75

DISASSEMBLY AND ASSEMBLY

ROCKER ARMS AND SHAFTS.............. 85

CLEANING AND INSPECTION

CYLINDER BORE........................ 87

CYLINDER HEAD........................ 86

OIL PUMP............................. 87

TIMING BELT........................... 86

ADJUSTMENTS

ENGINE MOUNTS....................... 88

SPECIFICATIONS

3.0L ENGINE........................... 89

TORQUE CHART 3.0L.................... 90

SPECIAL TOOLS

3.0L ENGINE........................... 91

DESCRIPTION AND OPERATION

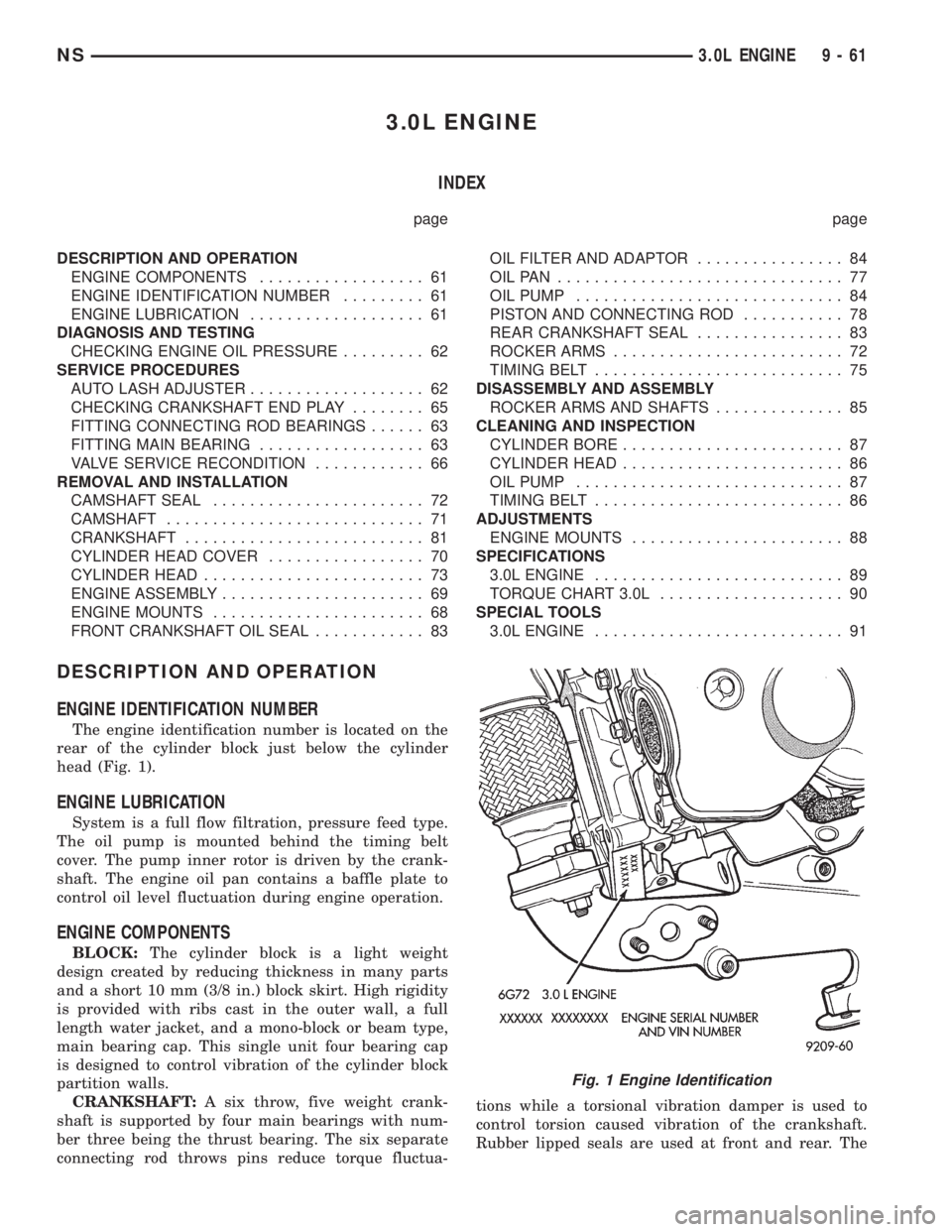

ENGINE IDENTIFICATION NUMBER

The engine identification number is located on the

rear of the cylinder block just below the cylinder

head (Fig. 1).

ENGINE LUBRICATION

System is a full flow filtration, pressure feed type.

The oil pump is mounted behind the timing belt

cover. The pump inner rotor is driven by the crank-

shaft. The engine oil pan contains a baffle plate to

control oil level fluctuation during engine operation.

ENGINE COMPONENTS

BLOCK:The cylinder block is a light weight

design created by reducing thickness in many parts

and a short 10 mm (3/8 in.) block skirt. High rigidity

is provided with ribs cast in the outer wall, a full

length water jacket, and a mono-block or beam type,

main bearing cap. This single unit four bearing cap

is designed to control vibration of the cylinder block

partition walls.

CRANKSHAFT:A six throw, five weight crank-

shaft is supported by four main bearings with num-

ber three being the thrust bearing. The six separate

connecting rod throws pins reduce torque fluctua-tions while a torsional vibration damper is used to

control torsion caused vibration of the crankshaft.

Rubber lipped seals are used at front and rear. The

Fig. 1 Engine Identification

NS3.0L ENGINE 9 - 61