WIPER CHRYSLER VOYAGER 1996 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 964 of 1938

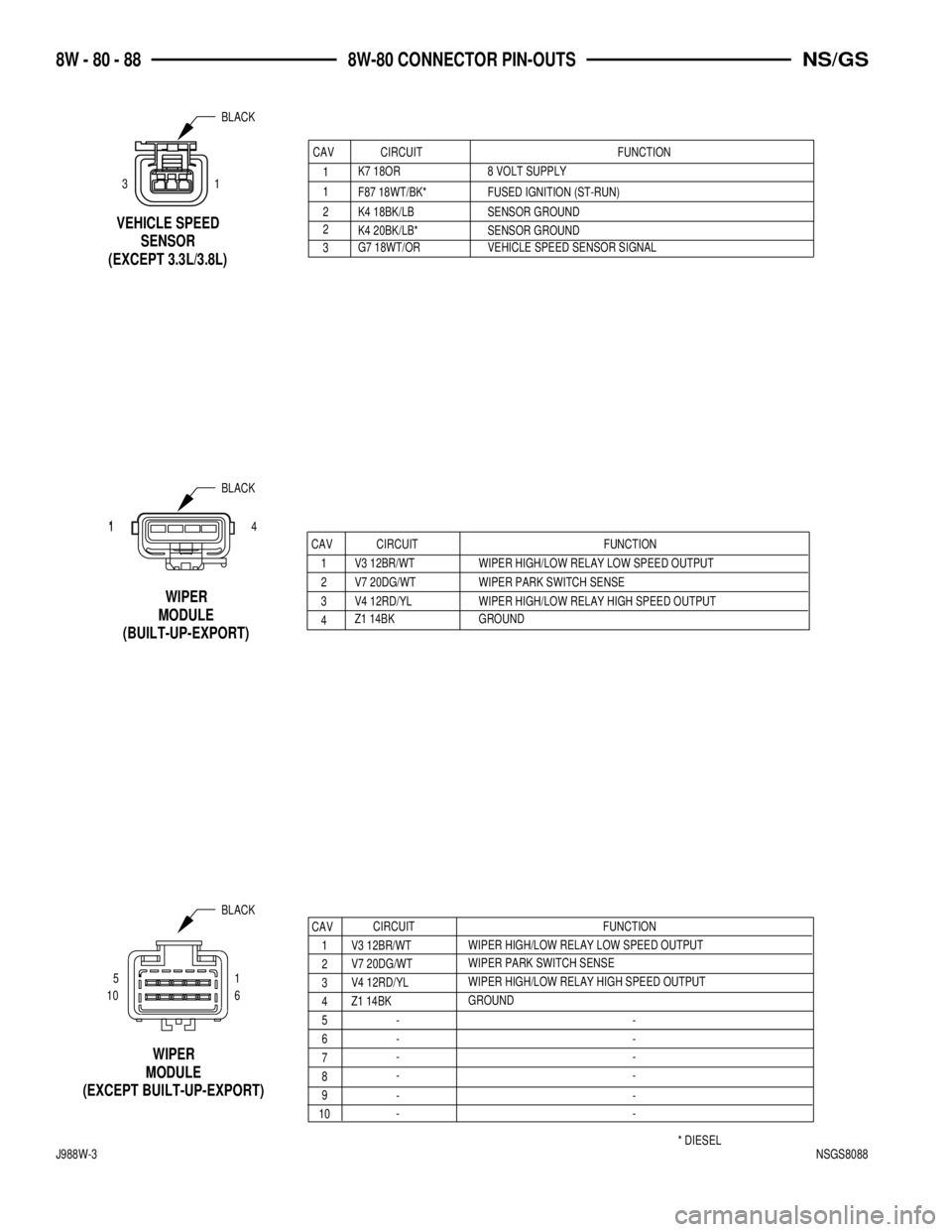

(EXCEPT BUILT-UP-EXPORT)MODULEWIPER- - - - - - - -

BLACK

GROUND WIPER HIGH/LOW RELAY HIGH SPEED OUTPUT

WIPER PARK SWITCH SENSE WIPER HIGH/LOW RELAY LOW SPEED OUTPUT105

6 1Z1 14BK V4 12RD/YL

V7 20DG/WT V3 12BR/WT

109

8 7 6

5 4 3

2 1 CAV

- - CIRCUIT - - FUNCTION

1

14

GROUND Z1 14BK(BUILT-UP-EXPORT)MODULEWIPER

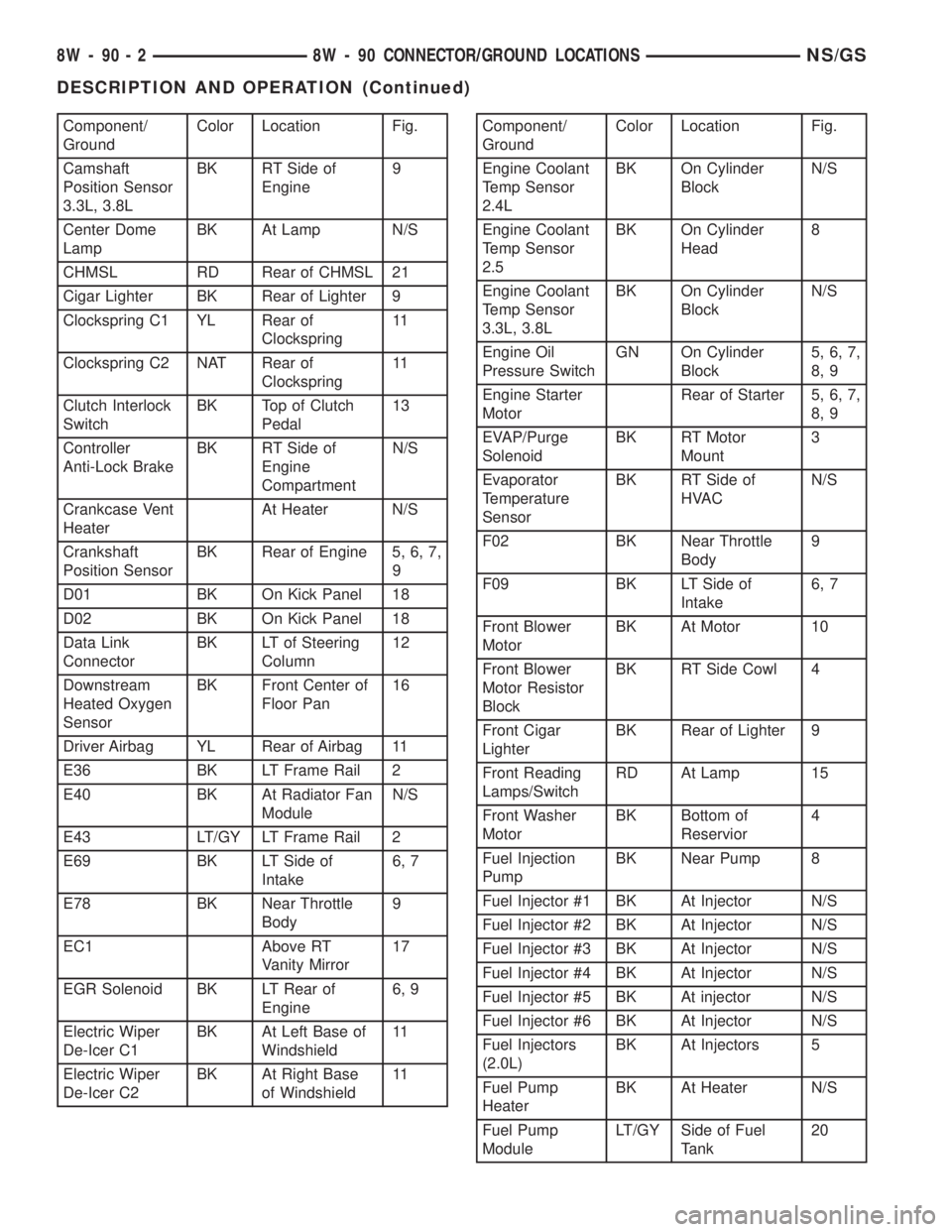

CAV CIRCUIT FUNCTION

1 V3 12BR/WT WIPER HIGH/LOW RELAY LOW SPEED OUTPUT

2 V7 20DG/WT WIPER PARK SWITCH SENSE

3 V4 12RD/YL WIPER HIGH/LOW RELAY HIGH SPEED OUTPUT

4

(EXCEPT 3.3L/3.8L)SENSOR VEHICLE SPEED3 28 VOLT SUPPLY K7 18OR

G7 18WT/OR VEHICLE SPEED SENSOR SIGNAL K4 20BK/LB* SENSOR GROUNDFUSED IGNITION (ST-RUN)

CAV CIRCUIT FUNCTION

1

F87 18WT/BK* 1

K4 18BK/LB SENSOR GROUND

2

* DIESEL BLACK

BLACK

1 3

8W - 80 - 88 8W-80 CONNECTOR PIN-OUTSNS/GS

J988W-3NSGS8088

Page 966 of 1938

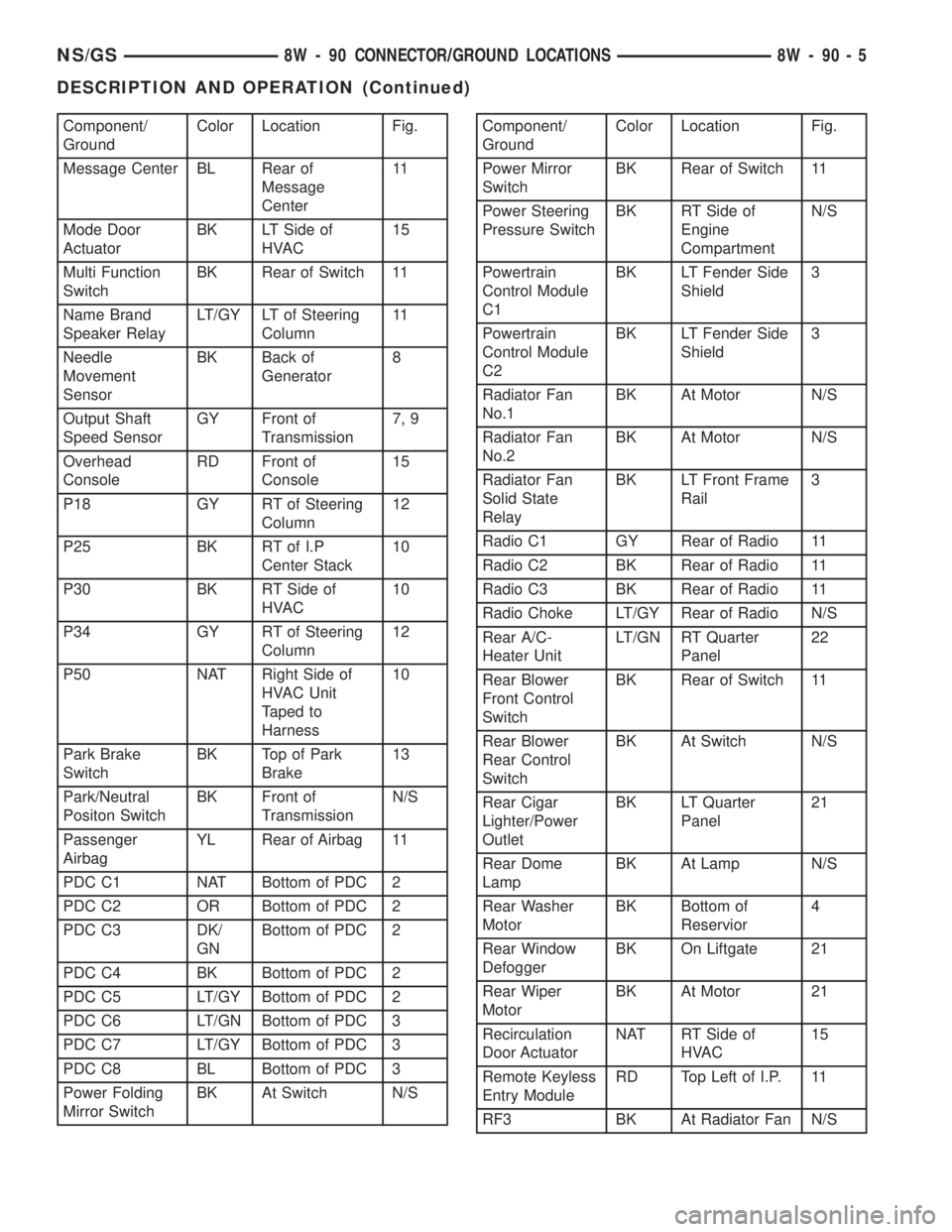

Component/

GroundColor Location Fig.

Camshaft

Position Sensor

3.3L, 3.8LBK RT Side of

Engine9

Center Dome

LampBK At Lamp N/S

CHMSL RD Rear of CHMSL 21

Cigar Lighter BK Rear of Lighter 9

Clockspring C1 YL Rear of

Clockspring11

Clockspring C2 NAT Rear of

Clockspring11

Clutch Interlock

SwitchBK Top of Clutch

Pedal13

Controller

Anti-Lock BrakeBK RT Side of

Engine

CompartmentN/S

Crankcase Vent

HeaterAt Heater N/S

Crankshaft

Position SensorBK Rear of Engine 5, 6, 7,

9

D01 BK On Kick Panel 18

D02 BK On Kick Panel 18

Data Link

ConnectorBK LT of Steering

Column12

Downstream

Heated Oxygen

SensorBK Front Center of

Floor Pan16

Driver Airbag YL Rear of Airbag 11

E36 BK LT Frame Rail 2

E40 BK At Radiator Fan

ModuleN/S

E43 LT/GY LT Frame Rail 2

E69 BK LT Side of

Intake6, 7

E78 BK Near Throttle

Body9

EC1 Above RT

Vanity Mirror17

EGR Solenoid BK LT Rear of

Engine6, 9

Electric Wiper

De-Icer C1BK At Left Base of

Windshield11

Electric Wiper

De-Icer C2BK At Right Base

of Windshield11Component/

GroundColor Location Fig.

Engine Coolant

Temp Sensor

2.4LBK On Cylinder

BlockN/S

Engine Coolant

Temp Sensor

2.5BK On Cylinder

Head8

Engine Coolant

Temp Sensor

3.3L, 3.8LBK On Cylinder

BlockN/S

Engine Oil

Pressure SwitchGN On Cylinder

Block5, 6, 7,

8, 9

Engine Starter

MotorRear of Starter 5, 6, 7,

8, 9

EVAP/Purge

SolenoidBK RT Motor

Mount3

Evaporator

Temperature

SensorBK RT Side of

HVACN/S

F02 BK Near Throttle

Body9

F09 BK LT Side of

Intake6, 7

Front Blower

MotorBK At Motor 10

Front Blower

Motor Resistor

BlockBK RT Side Cowl 4

Front Cigar

LighterBK Rear of Lighter 9

Front Reading

Lamps/SwitchRD At Lamp 15

Front Washer

MotorBK Bottom of

Reservior4

Fuel Injection

PumpBK Near Pump 8

Fuel Injector #1 BK At Injector N/S

Fuel Injector #2 BK At Injector N/S

Fuel Injector #3 BK At Injector N/S

Fuel Injector #4 BK At Injector N/S

Fuel Injector #5 BK At injector N/S

Fuel Injector #6 BK At Injector N/S

Fuel Injectors

(2.0L)BK At Injectors 5

Fuel Pump

HeaterBK At Heater N/S

Fuel Pump

ModuleLT/GY Side of Fuel

Tank20

8W - 90 - 2 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 969 of 1938

Component/

GroundColor Location Fig.

Message Center BL Rear of

Message

Center11

Mode Door

ActuatorBK LT Side of

HVAC15

Multi Function

SwitchBK Rear of Switch 11

Name Brand

Speaker RelayLT/GY LT of Steering

Column11

Needle

Movement

SensorBK Back of

Generator8

Output Shaft

Speed SensorGY Front of

Transmission7, 9

Overhead

ConsoleRD Front of

Console15

P18 GY RT of Steering

Column12

P25 BK RT of I.P

Center Stack10

P30 BK RT Side of

HVAC10

P34 GY RT of Steering

Column12

P50 NAT Right Side of

HVAC Unit

Taped to

Harness10

Park Brake

SwitchBK Top of Park

Brake13

Park/Neutral

Positon SwitchBK Front of

TransmissionN/S

Passenger

AirbagYL Rear of Airbag 11

PDC C1 NAT Bottom of PDC 2

PDC C2 OR Bottom of PDC 2

PDC C3 DK/

GNBottom of PDC 2

PDC C4 BK Bottom of PDC 2

PDC C5 LT/GY Bottom of PDC 2

PDC C6 LT/GN Bottom of PDC 3

PDC C7 LT/GY Bottom of PDC 3

PDC C8 BL Bottom of PDC 3

Power Folding

Mirror SwitchBK At Switch N/SComponent/

GroundColor Location Fig.

Power Mirror

SwitchBK Rear of Switch 11

Power Steering

Pressure SwitchBK RT Side of

Engine

CompartmentN/S

Powertrain

Control Module

C1BK LT Fender Side

Shield3

Powertrain

Control Module

C2BK LT Fender Side

Shield3

Radiator Fan

No.1BK At Motor N/S

Radiator Fan

No.2BK At Motor N/S

Radiator Fan

Solid State

RelayBK LT Front Frame

Rail3

Radio C1 GY Rear of Radio 11

Radio C2 BK Rear of Radio 11

Radio C3 BK Rear of Radio 11

Radio Choke LT/GY Rear of Radio N/S

Rear A/C-

Heater UnitLT/GN RT Quarter

Panel22

Rear Blower

Front Control

SwitchBK Rear of Switch 11

Rear Blower

Rear Control

SwitchBK At Switch N/S

Rear Cigar

Lighter/Power

OutletBK LT Quarter

Panel21

Rear Dome

LampBK At Lamp N/S

Rear Washer

MotorBK Bottom of

Reservior4

Rear Window

DefoggerBK On Liftgate 21

Rear Wiper

MotorBK At Motor 21

Recirculation

Door ActuatorNAT RT Side of

HVAC15

Remote Keyless

Entry ModuleRD Top Left of I.P. 11

RF3 BK At Radiator Fan N/S

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 5

DESCRIPTION AND OPERATION (Continued)

Page 971 of 1938

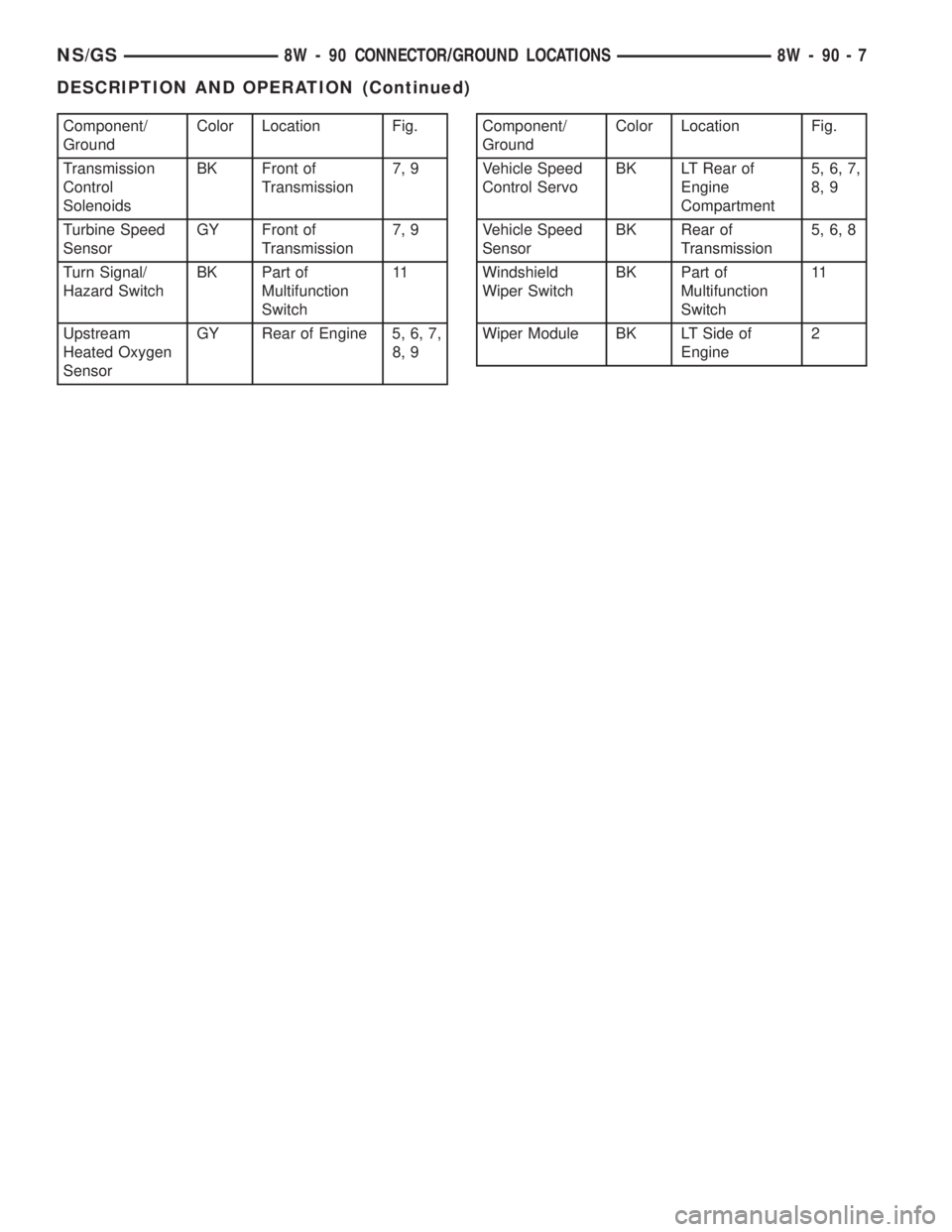

Component/

GroundColor Location Fig.

Transmission

Control

SolenoidsBK Front of

Transmission7, 9

Turbine Speed

SensorGY Front of

Transmission7, 9

Turn Signal/

Hazard SwitchBK Part of

Multifunction

Switch11

Upstream

Heated Oxygen

SensorGY Rear of Engine 5, 6, 7,

8, 9Component/

GroundColor Location Fig.

Vehicle Speed

Control ServoBK LT Rear of

Engine

Compartment5, 6, 7,

8, 9

Vehicle Speed

SensorBK Rear of

Transmission5, 6, 8

Windshield

Wiper SwitchBK Part of

Multifunction

Switch11

Wiper Module BK LT Side of

Engine2

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 7

DESCRIPTION AND OPERATION (Continued)

Page 996 of 1938

Component/

GroundColor Location Fig.

Downstream

Heated Oxygen

SensorBK Front Center of

Floor Pan16

Driver Airbag YL Rear of Airbag 11

E36 BK LT Frame Rail 2

E40 BK At Radiator Fan

ModuleN/S

E43 LT/GY LT Frame Rail 2

E69 BK LT Side of

Intake6, 7

E78 BK Near Throttle

Body9

EC1 At Top Center

of Windshield17

EGR Solenoid BK LT Rear of

Engine6, 9

Electric Wiper

De-Icer C1BK At Right Base

of Windshield11

Electric Wiper

De-Icer C2BK At Left Base of

Windshield11

Engine Coolant

Temp Sensor

2.4LBK On Cylinder

BlockN/S

Engine Coolant

Temp Sensor

3.3L, 3.8LBK On Cylinder

BlockN/S

Engine Oil

Pressure SwitchGN On Cylinder

Block5, 6, 7,

8, 9

Engine Starter

MotorRear of Starter 5, 6, 7,

8, 9

EVAP/Purge

SolenoidBK RT Motor

Mount3

Evaporator

Temperature

SensorBK RT Side of

HVACN/S

F02 BK Near Throttle

Body9

F09 BK LT Side of

Intake6, 7

Front Blower

MotorBK At Motor 10

Front Blower

Motor Resistor

BlockBK LT Side of

Engine2

Front Cigar

LighterBK Rear of Lighter 11Component/

GroundColor Location Fig.

Front Reading

Lamps/SwitchBL At Lamp 17

Front Washer

MotorBK Bottom of

Reservior4

Fuel Injector #1 BK At Injector N/S

Fuel Injector #2 BK At Injector N/S

Fuel Injector #3 BK At Injector N/S

Fuel Injector #4 BK At Injector N/S

Fuel Injector #5 BK At Injector N/S

Fuel Injector #6 BK At Injector N/S

Fuel Pump

ModuleGY Side of Fuel

Tank20

G100 LT Frame Rail 3

G101 2.4L Rear of

Cylinder Head6, 7

G101 3.3L, 3.8L Rear of

Cylinder Block9

G102 LT Frame Rail 3

G103 2.4L Rear of

Cylinder Head6, 7

G103 3.3L, 3.8L Rear of

Cylinder Block9

G104 Near T/O for

RT HeadlampN/S

G200 Left of I.P.

Center Stack10

G201 I.P. Center

Support10

G202 I.P. Center

Support10

G204 I.P. Center

Support10

G300 BK LT Kick Panel 13

G301 RT Kick Panel 13, 14

G302 BK LT Quarter

Panel21

G400 BK In Liftgate 23

Generator BK Rear of

Generator5, 6, 7,

8, 9

Glove Box

LampBL Rear of Glove

Box11

Headlamp

Dimmer SwitchBK Part of

Multifunction

Switch11

8W - 90 - 32 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 999 of 1938

Component/

GroundColor Location Fig.

Powertrain

Control Module

C1BK LT Fender Side

Shield3

Powertrain

Control Module

C2BK LT Fender Side

Shield3

Radiator Fan

No.1BK At Motor N/S

Radiator Fan

No.2BK At Motor N/S

Radiator Fan

RelayBK LT Front Frame

Rail3

Radio C1 GY Rear of Radio 11

Radio C2 BK Rear of Radio 11

Radio C3 BK Rear of Radio 11

Radio Choke LT/GY Rear of Radio N/S

Rear A/C-

Heater UnitLT/GN RT Quarter

Panel22

Rear Blower

Front Control

SwitchBK Rear of Switch 11

Rear Blower

Rear Control

SwitchBK At Switch N/S

Rear Cigar

Lighter/Power

OutletBK LT Quarter

Panel21

Rear Dome

LampBK At Lamp N/S

Rear Washer

MotorBK Bottom of

Reservior4

Rear Window

DefoggerBK On Liftgate 23

Rear Wiper

MotorBK At Motor 23

Recirculation

Door ActuatorNAT RT Side of

HVAC15

Remote Keyless

Entry ModuleRD Top RT of I.P. 11

Right

Combination

RelayBK LT Quarter

PanelN/S

Right Door

Arm/Disarm

SwitchBK At Switch 19

Right Door

Courtesy LampBK At Lamp 19Component/

GroundColor Location Fig.

Right Door

SpeakerBK At Speaker 19

RF3 BK At Radiator Fan

ModuleN/S

Right Fog Lamp GY At Lamp 4

Right Front

Door Ajar

SwitchBK RT B-Pillar 12

Right Front

Door Lock

MotorBK At Motor 19

Right Front

Panel SpeakerBK At Speaker 11

Right Front

Park/Turn

Signal LampBK At Lamp 4

Right Front

Wheel Speed

SensorBK Right Fender

Side Shield4

Right Front

Window MotorRD At Motor 19

Right Headlamp BK At Lamp 4

Right Headlamp

Leveling MotorBK At Motor N/S

Right Liftgate

Flood LampBK At Lamp 23

Right Mid

Reading LampGY At Lamp 17

Right Power

Door Lock

SwitchBK At Switch 19

Right Power

Mirror C1RD At Mirror 11

Right Power

Mirror C2BL At Mirror 11

Right Power

Window SwitchBK At Switch 19

Right Rear

Lamp AssemblyBK At Lamp 22

Right Rear Door

Ajar SwitchBK RT C-Pillar N/S

Right Rear Pillar

SpeakerBK At Speaker 22

Right Rear

Reading LampGY At Lamp 17

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 35

DESCRIPTION AND OPERATION (Continued)

Page 1000 of 1938

Component/

GroundColor Location Fig.

Right Rear

Sliding Door

ContactBK RT B-Pillar 14

Right Rear

Sliding Door

Lock MotorBK At Motor N/S

Right Rear

SpeakerBK At Speaker 22

Right Rear Vent

MotorNAT At Motor 22

Right Rear

Wheel Speed

SensorGY Center Rear of

Floor Pan16

Right Repeater

LampGY At Lamp N/S

Right Speed

Control SwitchRight Side of

Steering Wheel

Pad11

Right Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Right Visor/

Vanity LampBK At Lamp 17

S02 BK Under Seat N/S

Seat Belt Switch BK RT B-Pillar N/S

Sentry Key

Immobilizer

ModuleBK Near Steering

Column at

Module11

Stop Lamp

SwitchGY Top of Brake

Pedal12

T05 BK LT Quarter

PanelN/S

T08 BK RT Quarter

PanelN/SComponent/

GroundColor Location Fig.

Throttle Position

SensorNAT On Throttle

Body5, 6, 7,

8, 9

Trailer Tow

ConnectorBK LT Quarter

PanelN/S

Transmission

Control ModuleBK RT Fender Side

Shield3

Transmission

Range SensorBK Top of

Transmission7. 9

Transmission

Control

SolenoidsBK Front of

Transmission7, 9

Turbine Speed

SensorGY Front of

Transmission7, 9

Turn Signal/

Hazard SwitchBK Part of

Multifunction

Switch11

Upstream

Heated Oxygen

SensorGY Rear of Engine 5, 6, 7,

8, 9

Vehicle Speed

Control ServoBK LT Rear of

Engine

Compartment5, 6, 7,

8, 9

Vehicle Speed

SensorBK Rear of

Transmission5, 6, 8

Windshield

Wiper SwitchBK Part of

Multifunction

Switch11

Wiper Module BK LT Side of

Engine2

8W - 90 - 36 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1120 of 1938

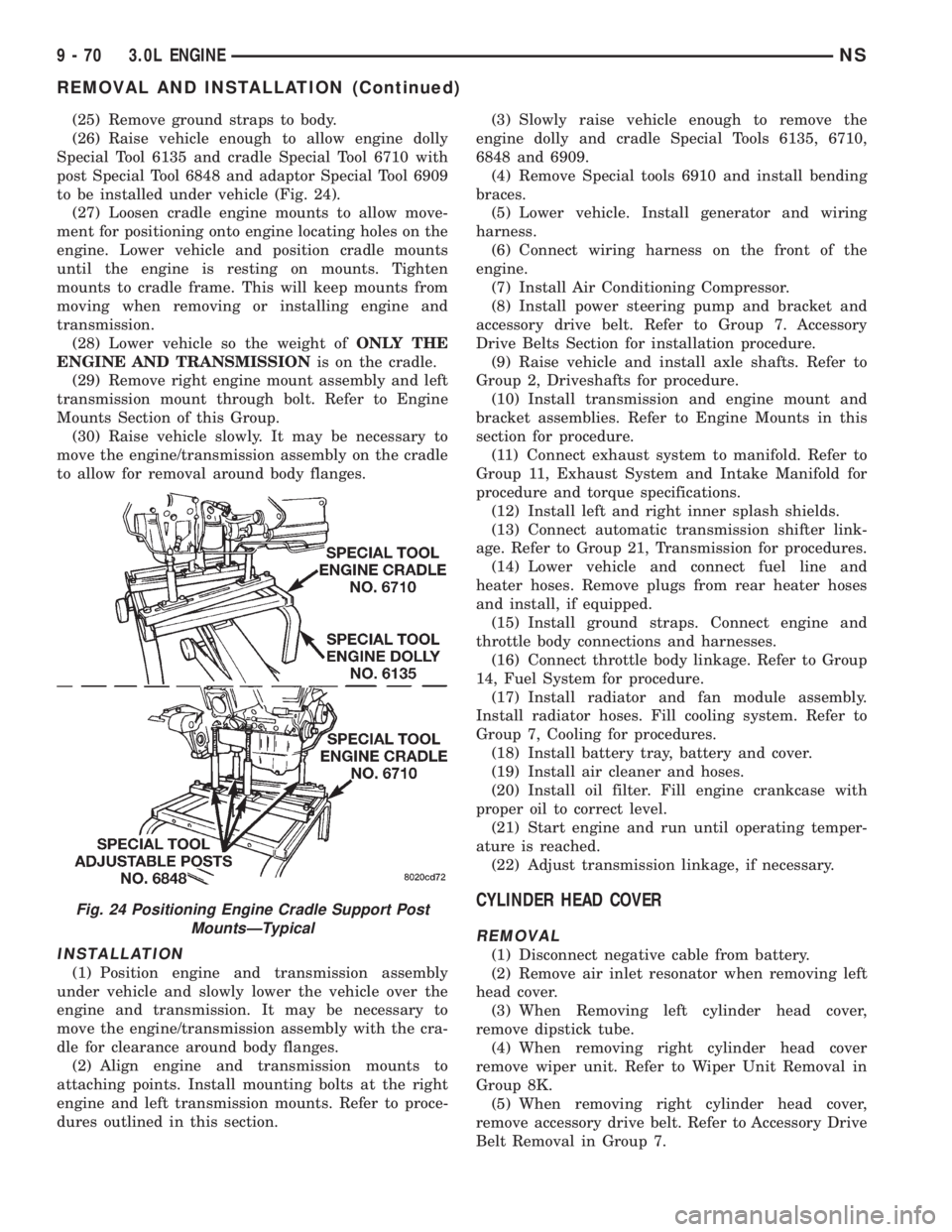

(25) Remove ground straps to body.

(26) Raise vehicle enough to allow engine dolly

Special Tool 6135 and cradle Special Tool 6710 with

post Special Tool 6848 and adaptor Special Tool 6909

to be installed under vehicle (Fig. 24).

(27) Loosen cradle engine mounts to allow move-

ment for positioning onto engine locating holes on the

engine. Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.

(28) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONis on the cradle.

(29) Remove right engine mount assembly and left

transmission mount through bolt. Refer to Engine

Mounts Section of this Group.

(30) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission. It may be necessary to

move the engine/transmission assembly with the cra-

dle for clearance around body flanges.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.(3) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135, 6710,

6848 and 6909.

(4) Remove Special tools 6910 and install bending

braces.

(5) Lower vehicle. Install generator and wiring

harness.

(6) Connect wiring harness on the front of the

engine.

(7) Install Air Conditioning Compressor.

(8) Install power steering pump and bracket and

accessory drive belt. Refer to Group 7. Accessory

Drive Belts Section for installation procedure.

(9) Raise vehicle and install axle shafts. Refer to

Group 2, Driveshafts for procedure.

(10) Install transmission and engine mount and

bracket assemblies. Refer to Engine Mounts in this

section for procedure.

(11) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(12) Install left and right inner splash shields.

(13) Connect automatic transmission shifter link-

age. Refer to Group 21, Transmission for procedures.

(14) Lower vehicle and connect fuel line and

heater hoses. Remove plugs from rear heater hoses

and install, if equipped.

(15) Install ground straps. Connect engine and

throttle body connections and harnesses.

(16) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(17) Install radiator and fan module assembly.

Install radiator hoses. Fill cooling system. Refer to

Group 7, Cooling for procedures.

(18) Install battery tray, battery and cover.

(19) Install air cleaner and hoses.

(20) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(21) Start engine and run until operating temper-

ature is reached.

(22) Adjust transmission linkage, if necessary.

CYLINDER HEAD COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove air inlet resonator when removing left

head cover.

(3) When Removing left cylinder head cover,

remove dipstick tube.

(4) When removing right cylinder head cover

remove wiper unit. Refer to Wiper Unit Removal in

Group 8K.

(5) When removing right cylinder head cover,

remove accessory drive belt. Refer to Accessory Drive

Belt Removal in Group 7.

Fig. 24 Positioning Engine Cradle Support Post

MountsÐTypical

9 - 70 3.0L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1143 of 1938

3.3/3.8L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

ENGINE COMPONENTS.................. 93

ENGINE IDENTIFICATION................. 93

ENGINE LUBRICATION SYSTEM............ 93

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE......... 96

HYDRAULIC TAPPETS.................... 94

SERVICE PROCEDURES

CRANKSHAFT END PLAY................. 99

FITTING CONNECTING ROD BEARINGS...... 97

FITTING MAIN BEARINGS................. 98

FITTING PISTONS AND RINGS............. 97

MEASURING TIMING CHAIN FOR STRETCH . . . 96

VALVE SERVICE RECONDITION........... 100

VALVE TIMING.......................... 96

REMOVAL AND INSTALLATION

CAMSHAFT BEARINGS.................. 114

CAMSHAFT........................... 113

CRANKSHAFT DAMPER................. 106

CRANKSHAFT OIL SEALÐFRONT.......... 117

CRANKSHAFT OIL SEALÐREAR........... 118

CRANKSHAFT......................... 116

CYLINDER HEAD COVER................ 107

CYLINDER HEAD....................... 108

ENGINE ASSEMBLY..................... 104

ENGINE MOUNTS...................... 102

ENGINE OIL GALLERY PLUGS............. 119OILFILTER ............................ 119

OILPAN .............................. 114

PISTON AND CONNECTING ROD.......... 115

ROCKER ARMS AND SHAFT ASSEMBLY..... 106

TAPPET REMOVAL...................... 110

TIMING CHAIN COVER................... 111

TIMING CHAIN......................... 112

VALVE STEM SEALS OR SPRINGS,

CYLINDER HEAD NOT REMOVED........ 106

VALVES AND VALVE SPRINGS............ 109

WIPER UNIT.......................... 102

DISASSEMBLY AND ASSEMBLY

HYDRAULIC TAPPETS................... 120

OIL PUMP............................ 119

CLEANING AND INSPECTION

CYLINDER HEAD....................... 120

ENGINE BLOCK AND BORE............... 121

OILPAN .............................. 121

OIL PUMP............................ 121

ADJUSTMENTS

ENGINE MOUNTS...................... 123

SPECIFICATIONS

3.3/3.8L ENGINE....................... 123

TORQUE CHART....................... 125

SPECIAL TOOLS

3.3/3.8L ENGINE....................... 127

DESCRIPTION AND OPERATION

ENGINE IDENTIFICATION

The engine identification number is located on the

rear of the cylinder block just below the cylinder

head (Fig. 1).

ENGINE LUBRICATION SYSTEM

The lubrication system is a full flow filtration pres-

sure feed type. Oil from the oil pan is pumped by a

internal gear type oil pump directly coupled to the

crankshaft. The pressure is regulated by a relief

valve located in the chain case cover. The oil is

pumped through an oil filter and feeds a main oil

galley. This oil gallery feeds oil under pressure to the

main and rod bearings, camshaft bearings. Passages

in the cylinder block feed oil to the hydraulic lifters

and rocker shaft brackets which feeds the rocker arm

pivots (Fig. 2).

ENGINE COMPONENTS

ENGINE:The 3.3L (201 Cubic Inches) and 3.8L

(231 Cubic Inches) displacement engines are 60É V

type six cylinder power plants with cast iron cylinder

blocks and aluminum cylinder heads (Fig. 3). Firing

order for these engines is 1-2-3-4-5-6. High turbu-

lence cylinder heads allow a 8.9-1 compression ratio.

CRANKSHAFT:The nodular iron crankshaft is

supported by four main bearings, with number two

being the thrust bearing. Crankshaft end sealing is

provided by front and rear rubber seals.

PISTONS:The pistons are cast aluminum alloy.

Three rings are used. Piston pins, press fitted into

place, join the pistons to forged steel connecting rods.

CAMSHAFT:The nodular iron camshaft is

mounted in four steel backed babbitt bearings. A

thrust plate located in front of the first bearing, and

bolted to the block, controls end play. Silent timing

chain drives the camshaft. This chain is enclosed by

a cast aluminum cover which also carries a front

NS3.3/3.8L ENGINE 9 - 93

Page 1152 of 1938

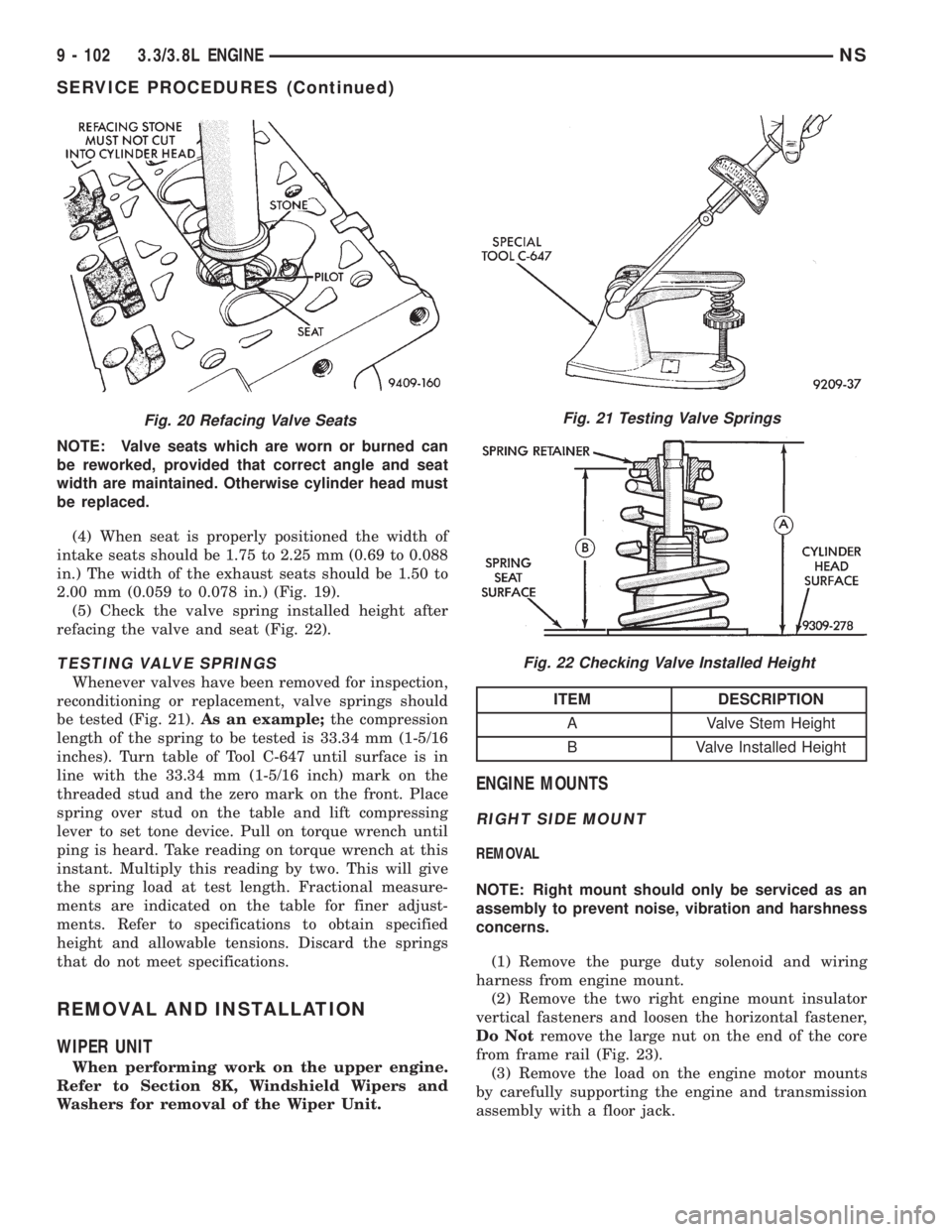

NOTE: Valve seats which are worn or burned can

be reworked, provided that correct angle and seat

width are maintained. Otherwise cylinder head must

be replaced.

(4) When seat is properly positioned the width of

intake seats should be 1.75 to 2.25 mm (0.69 to 0.088

in.) The width of the exhaust seats should be 1.50 to

2.00 mm (0.059 to 0.078 in.) (Fig. 19).

(5) Check the valve spring installed height after

refacing the valve and seat (Fig. 22).

TESTING VALVE SPRINGS

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested (Fig. 21).As an example;the compression

length of the spring to be tested is 33.34 mm (1-5/16

inches). Turn table of Tool C-647 until surface is in

line with the 33.34 mm (1-5/16 inch) mark on the

threaded stud and the zero mark on the front. Place

spring over stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by two. This will give

the spring load at test length. Fractional measure-

ments are indicated on the table for finer adjust-

ments. Refer to specifications to obtain specified

height and allowable tensions. Discard the springs

that do not meet specifications.

REMOVAL AND INSTALLATION

WIPER UNIT

When performing work on the upper engine.

Refer to Section 8K, Windshield Wipers and

Washers for removal of the Wiper Unit.

ENGINE MOUNTS

RIGHT SIDE MOUNT

REMOVAL

NOTE: Right mount should only be serviced as an

assembly to prevent noise, vibration and harshness

concerns.

(1) Remove the purge duty solenoid and wiring

harness from engine mount.

(2) Remove the two right engine mount insulator

vertical fasteners and loosen the horizontal fastener,

Do Notremove the large nut on the end of the core

from frame rail (Fig. 23).

(3) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

Fig. 20 Refacing Valve SeatsFig. 21 Testing Valve Springs

Fig. 22 Checking Valve Installed Height

ITEM DESCRIPTION

A Valve Stem Height

B Valve Installed Height

9 - 102 3.3/3.8L ENGINENS

SERVICE PROCEDURES (Continued)