brake rotor CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 24 of 1938

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING RECOMMENDATIONS

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACH-

MENT DEVICES TO CONTACT THE FUEL TANK OR

LINES, FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER, OR BUMPER ENERGY ABSORBER

UNITS.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not attach towing device to front or rear sus-

pension components.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects

from a damaged vehicle before towing.

Refer to state and local rules and regulations

before towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

RECOMMENDED TOWING EQUIPMENT

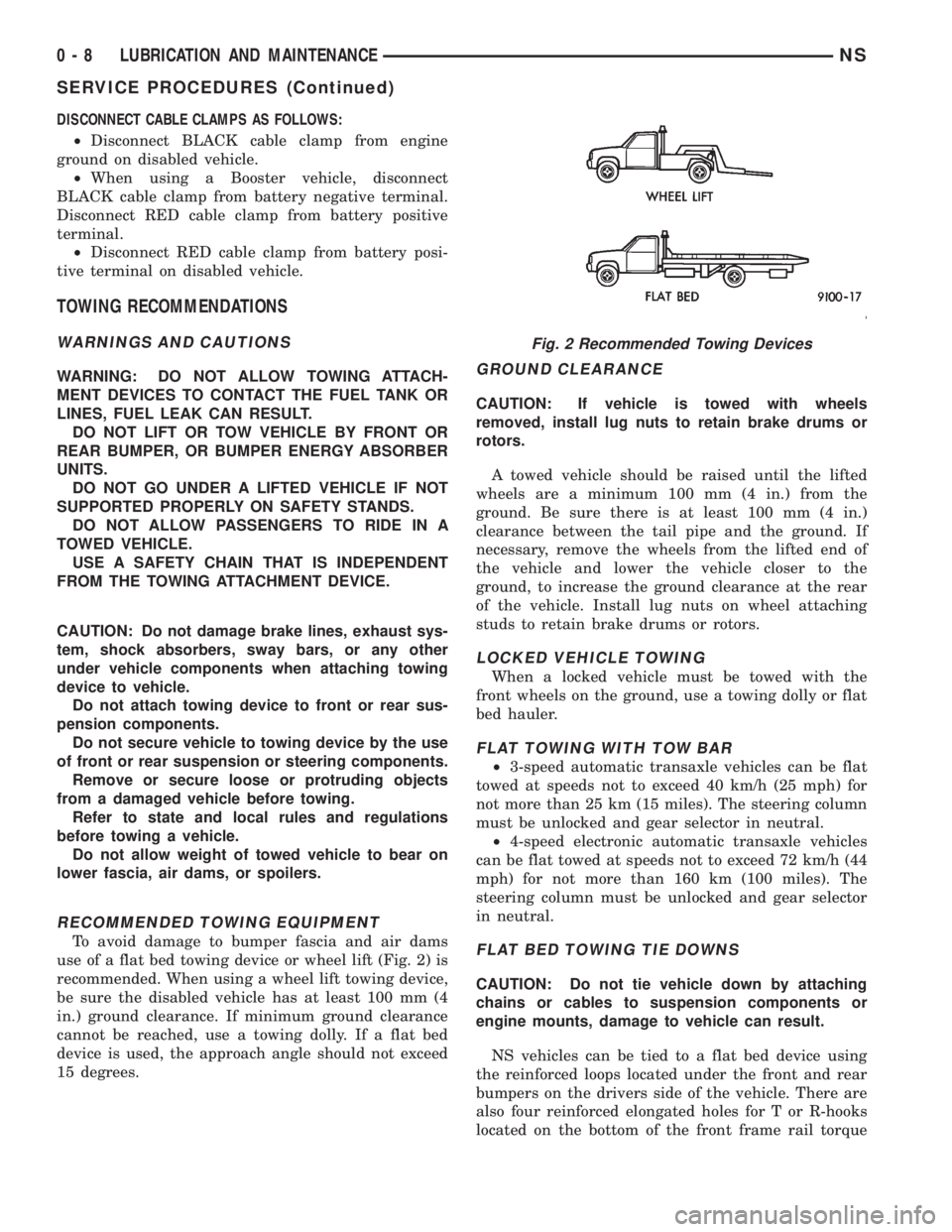

To avoid damage to bumper fascia and air dams

use of a flat bed towing device or wheel lift (Fig. 2) is

recommended. When using a wheel lift towing device,

be sure the disabled vehicle has at least 100 mm (4

in.) ground clearance. If minimum ground clearance

cannot be reached, use a towing dolly. If a flat bed

device is used, the approach angle should not exceed

15 degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels

removed, install lug nuts to retain brake drums or

rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the lifted end of

the vehicle and lower the vehicle closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²3-speed automatic transaxle vehicles can be flat

towed at speeds not to exceed 40 km/h (25 mph) for

not more than 25 km (15 miles). The steering column

must be unlocked and gear selector in neutral.

²4-speed electronic automatic transaxle vehicles

can be flat towed at speeds not to exceed 72 km/h (44

mph) for not more than 160 km (100 miles). The

steering column must be unlocked and gear selector

in neutral.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

NS vehicles can be tied to a flat bed device using

the reinforced loops located under the front and rear

bumpers on the drivers side of the vehicle. There are

also four reinforced elongated holes for T or R-hooks

located on the bottom of the front frame rail torque

Fig. 2 Recommended Towing Devices

0 - 8 LUBRICATION AND MAINTENANCENS

SERVICE PROCEDURES (Continued)

Page 31 of 1938

JUMP STARTING, HOISTING AND TOWING

INDEX

page

SERVICE PROCEDURES

TOWING RECOMMENDATIONS............. 5

SERVICE PROCEDURES

TOWING RECOMMENDATIONS

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACH-

MENT DEVICES TO CONTACT THE FUEL TANK OR

LINES, FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER, OR BUMPER ENERGY ABSORBER

UNITS.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not attach towing device to front or rear sus-

pension components.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects

from a damaged vehicle before towing.

Refer to state and local rules and regulations

before towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

RECOMMENDED TOWING EQUIPMENT

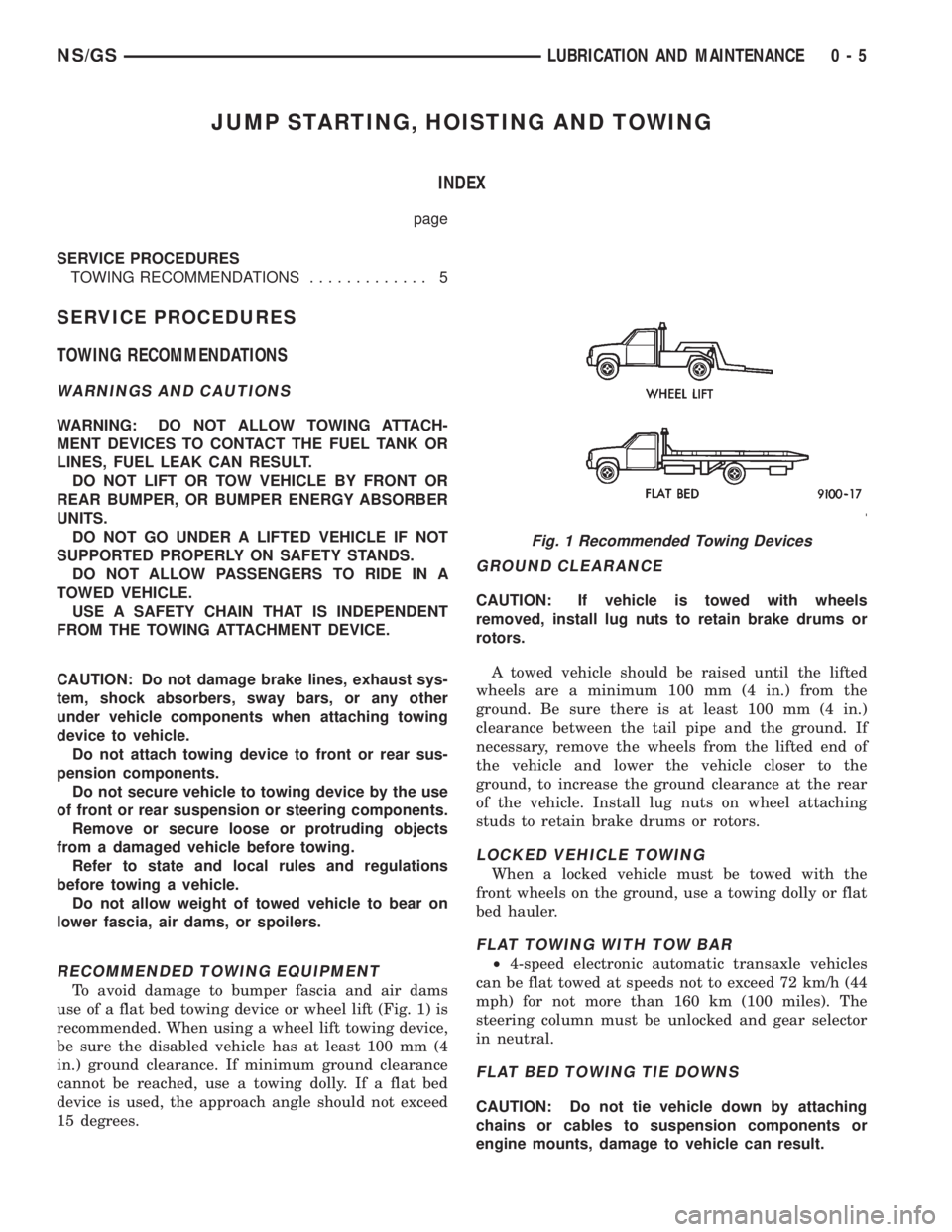

To avoid damage to bumper fascia and air dams

use of a flat bed towing device or wheel lift (Fig. 1) is

recommended. When using a wheel lift towing device,

be sure the disabled vehicle has at least 100 mm (4

in.) ground clearance. If minimum ground clearance

cannot be reached, use a towing dolly. If a flat bed

device is used, the approach angle should not exceed

15 degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels

removed, install lug nuts to retain brake drums or

rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the lifted end of

the vehicle and lower the vehicle closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²4-speed electronic automatic transaxle vehicles

can be flat towed at speeds not to exceed 72 km/h (44

mph) for not more than 160 km (100 miles). The

steering column must be unlocked and gear selector

in neutral.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

Fig. 1 Recommended Towing Devices

NS/GSLUBRICATION AND MAINTENANCE 0 - 5

Page 48 of 1938

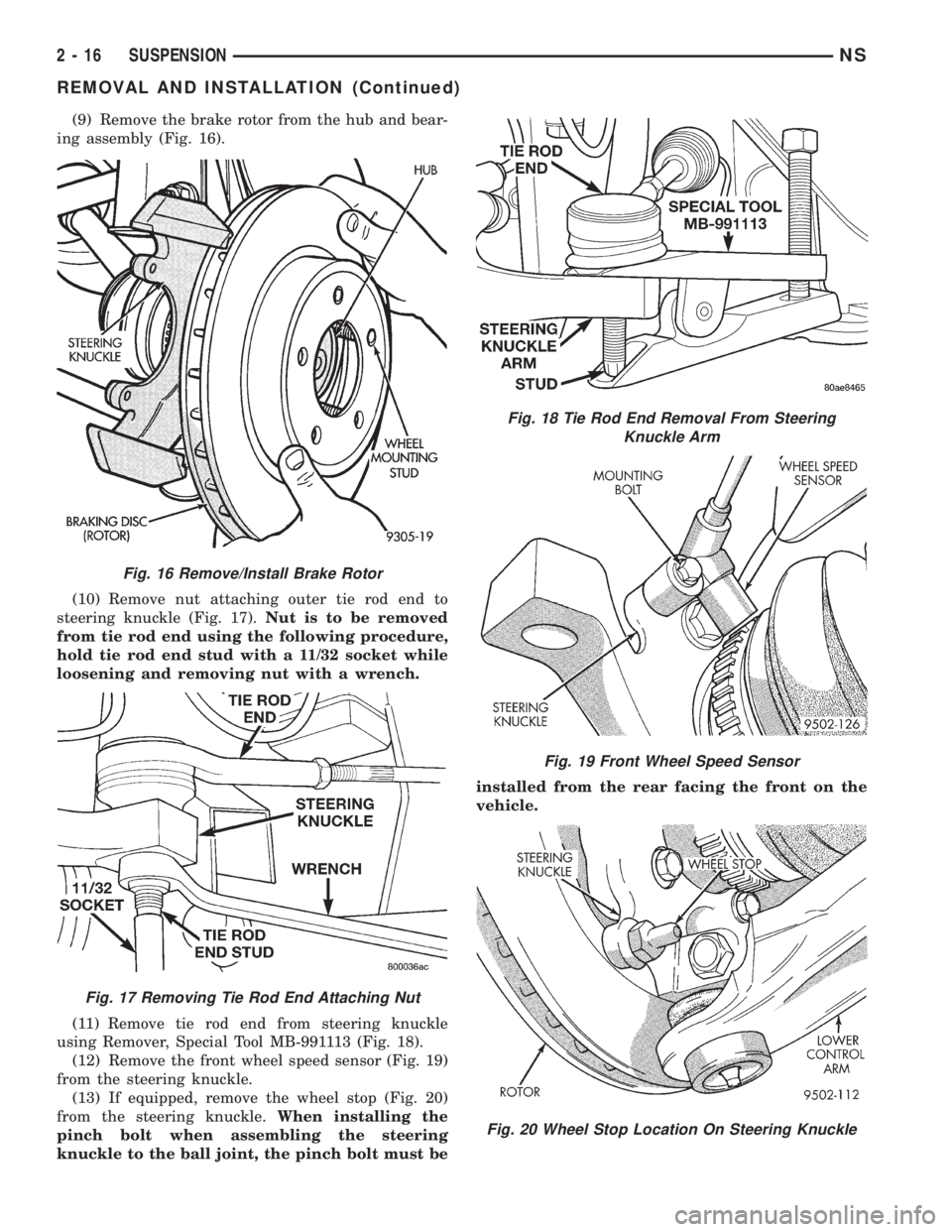

(9) Remove the brake rotor from the hub and bear-

ing assembly (Fig. 16).

(10) Remove nut attaching outer tie rod end to

steering knuckle (Fig. 17).Nut is to be removed

from tie rod end using the following procedure,

hold tie rod end stud with a 11/32 socket while

loosening and removing nut with a wrench.

(11) Remove tie rod end from steering knuckle

using Remover, Special Tool MB-991113 (Fig. 18).

(12) Remove the front wheel speed sensor (Fig. 19)

from the steering knuckle.

(13) If equipped, remove the wheel stop (Fig. 20)

from the steering knuckle.When installing the

pinch bolt when assembling the steering

knuckle to the ball joint, the pinch bolt must beinstalled from the rear facing the front on the

vehicle.

Fig. 16 Remove/Install Brake Rotor

Fig. 17 Removing Tie Rod End Attaching Nut

Fig. 18 Tie Rod End Removal From Steering

Knuckle Arm

Fig. 19 Front Wheel Speed Sensor

Fig. 20 Wheel Stop Location On Steering Knuckle

2 - 16 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 60 of 1938

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 129 N´m (95 ft. lbs.).

(7) Lower vehicle to the ground.

CAUTION: When tightening hub/bearing assembly

to stub shaft retaining nut, do not exceed the max-

imum torque of 244 N´m (180 ft. lbs.).

(8) With vehicle brakes applied to keep vehicle

from moving, torque stub shaft to hub/bearing assem-

bly retaining nut to 244 N´m (180 ft. lbs.).

(9) Check the Toe setting on the vehicle and reset

if not within specifications.

FRONT WHEEL MOUNTING STUDS

REMOVE

CAUTION: If a wheel attaching stud needs to be

replaced in the hub and bearing assembly the studs

CAN NOT be hammered out of the hub flange. If a

stud is removed by hammering it out of the bearing

flange, damage to the hub and bearing assembly

will occur leading to premature bearing failure.

The following procedure and special tools shown

MUST BEused when replacing wheel attaching

studs.

The hub and bearing assembly does not require

removal from the steering knuckle to replace wheel

attaching studs in the hub and bearing assembly.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual for

the required lifting procedure to be used for this

vehicle.

(2) Remove the front wheel and tire assembly from

the vehicle.

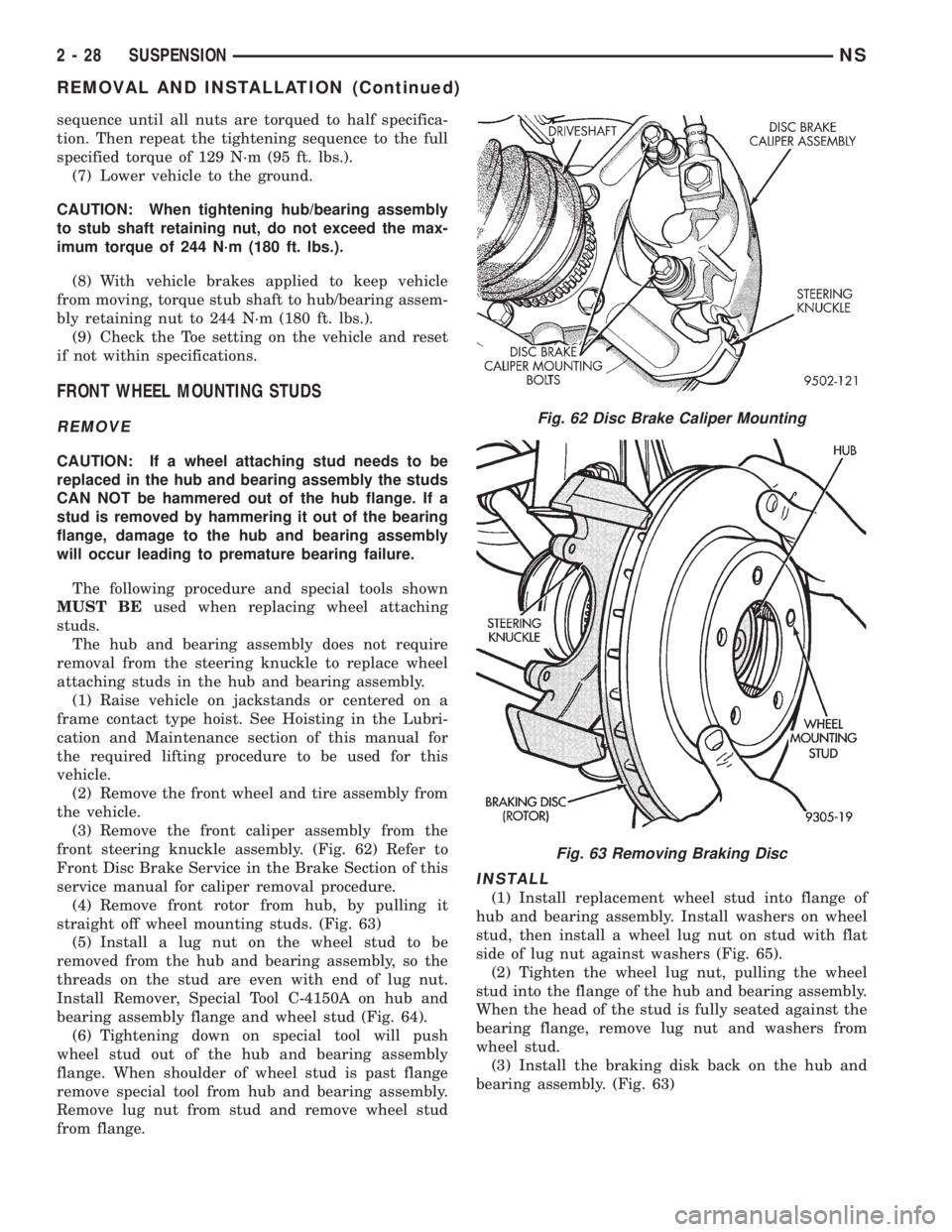

(3) Remove the front caliper assembly from the

front steering knuckle assembly. (Fig. 62) Refer to

Front Disc Brake Service in the Brake Section of this

service manual for caliper removal procedure.

(4) Remove front rotor from hub, by pulling it

straight off wheel mounting studs. (Fig. 63)

(5) Install a lug nut on the wheel stud to be

removed from the hub and bearing assembly, so the

threads on the stud are even with end of lug nut.

Install Remover, Special Tool C-4150A on hub and

bearing assembly flange and wheel stud (Fig. 64).

(6) Tightening down on special tool will push

wheel stud out of the hub and bearing assembly

flange. When shoulder of wheel stud is past flange

remove special tool from hub and bearing assembly.

Remove lug nut from stud and remove wheel stud

from flange.

INSTALL

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheel

stud, then install a wheel lug nut on stud with flat

side of lug nut against washers (Fig. 65).

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.

(3) Install the braking disk back on the hub and

bearing assembly. (Fig. 63)

Fig. 62 Disc Brake Caliper Mounting

Fig. 63 Removing Braking Disc

2 - 28 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 85 of 1938

BASE BRAKE SYSTEM

INDEX

page page

DESCRIPTION AND OPERATION

CHASSIS TUBES AND HOSES.............. 7

FRONT DISC BRAKE SYSTEM.............. 4

HUB/BEARING REAR WHEEL............... 9

MASTER CYLINDER...................... 7

PARKING BRAKE SYSTEM OPERATION....... 5

POWER BRAKE VACUUM BOOSTER

OPERATION........................... 8

PROPORTIONING VALVES................. 5

REAR DISC BRAKES...................... 5

REAR DRUM BRAKES..................... 5

RED BRAKE WARNING LAMP OPERATION..... 8

STOP LAMP SWITCH...................... 9

DIAGNOSIS AND TESTING

ADJUSTER REAR DRUM BRAKE

(AUTOMATIC)......................... 14

BRAKE FLUID CONTAMINATION............ 19

BRAKE ROTOR......................... 14

BRAKE SYSTEM BASIC DIAGNOSIS GUIDE.... 9

BRAKE SYSTEM DIAGNOSIS CHARTS....... 10

PROPORTIONING VALVES................ 16

RED BRAKE WARNING LAMP TEST......... 19

STOP LAMP SWITCH TEST PROCEDURE..... 19

TRACTION CONTROL LAMP TEST.......... 19

SERVICE PROCEDURES

BLEEDING BASE BRAKE

HYDRAULIC SYSTEM................... 20

BRAKE DRUM MACHINING................ 24

BRAKE TUBE REPAIR PROCEDURE......... 24

MASTER CYLINDER BLEEDING

PROCEDURE......................... 22

MASTER CYLINDER FLUID LEVEL CHECK.... 20

PARK BRAKE AUTO ADJUSTER

MECHANISM RELEASE................. 26

ROTOR MACHINING (FRONT/REAR)......... 22

REMOVAL AND INSTALLATION

BRAKE SUPPORT PLATE (REAR DRUM

BRAKES)............................ 37

FRONT DISC BRAKE CALIPER............. 27

FRONT DISC BRAKE PADS................ 30

FRONT PARK BRAKE CABLE.............. 65

HUB/BEARING.......................... 40

HYDRAULIC BRAKE TUBES AND HOSES..... 58

INTERMEDIATE PARK BRAKE CABLE....... 66

JUNCTION BLOCK....................... 55

LEFT REAR PARK BRAKE CABLE........... 67

MASTER CYLINDER..................... 44

PARK BRAKE PEDAL MECHANISM.......... 58PARK BRAKE SHOES (WITH REAR DISC

BRAKES)............................ 60

PROPORTIONING VALVE (W/ABS BRAKES) . . . 56

PROPORTIONING VALVE

(W/O ABS BRAKES).................... 57

REAR BRAKE DRUM..................... 33

REAR BRAKE WHEEL CYLINDER........... 39

REAR DISC BRAKE CALIPER.............. 28

REAR DISC BRAKE SHOES................ 31

REAR DRUM BRAKE SHOES............... 34

RIGHT REAR PARK BRAKE CABLE......... 66

STOP LAMP SWITCH..................... 69

VACUUM BOOSTER 2.4 LITER ENGINE...... 47

VACUUM BOOSTER 3.0 LITER ENGINE...... 49

VACUUM BOOSTER 3.3/3.8 LITER ENGINE.... 52

WHEEL AND TIRE INSTALLATION........... 27

DISASSEMBLY AND ASSEMBLY

FRONT DISC BRAKE CALIPER............. 71

MASTER CYLINDER BRAKE FLUID LEVEL

SWITCH............................. 71

MASTER CYLINDER FLUID RESERVOIR

FILL TUBE............................ 71

MASTER CYLINDER FLUID RESERVOIR...... 70

MASTER CYLINDER TO POWER BRAKE

BOOSTER VACUUM SEAL............... 69

WHEEL CYLINDER REAR DRUM BRAKE...... 76

CLEANING AND INSPECTION

BRAKE HOSE AND BRAKE LINES

INSPECTION.......................... 78

FRONT DISC BRAKE PAD LINING

INSPECTION.......................... 76

REAR DISC BRAKES..................... 76

REAR DRUM BRAKE SHOE LINING

INSPECTION.......................... 77

REAR DRUM BRAKE WHEEL CYLINDER...... 78

REAR WHEEL HUB AND BEARING

ASSEMBLY........................... 78

ADJUSTMENTS

PARK BRAKE CABLE ADJUSTMENT......... 81

PARK BRAKE SHOES (WITH REAR DISC

BRAKES)............................ 79

PROPORTIONING VALVE

(HEIGHT SENSING).................... 81

REAR DRUM BRAKE SHOE ADJUSTMENT.... 79

STOP LAMP SWITCH..................... 78

SPECIFICATIONS

BRAKE ACTUATION SYSTEM.............. 83

BRAKE FASTENER TORQUE

SPECIFICATIONS...................... 83

NSBRAKES 5 - 3

Page 86 of 1938

BRAKE FLUID.......................... 82

VEHICLE BRAKE SYSTEM COMPONENT

SPECIFICATIONS...................... 82SPECIAL TOOLS

BASE BRAKES.......................... 84

DESCRIPTION AND OPERATION

FRONT DISC BRAKE SYSTEM

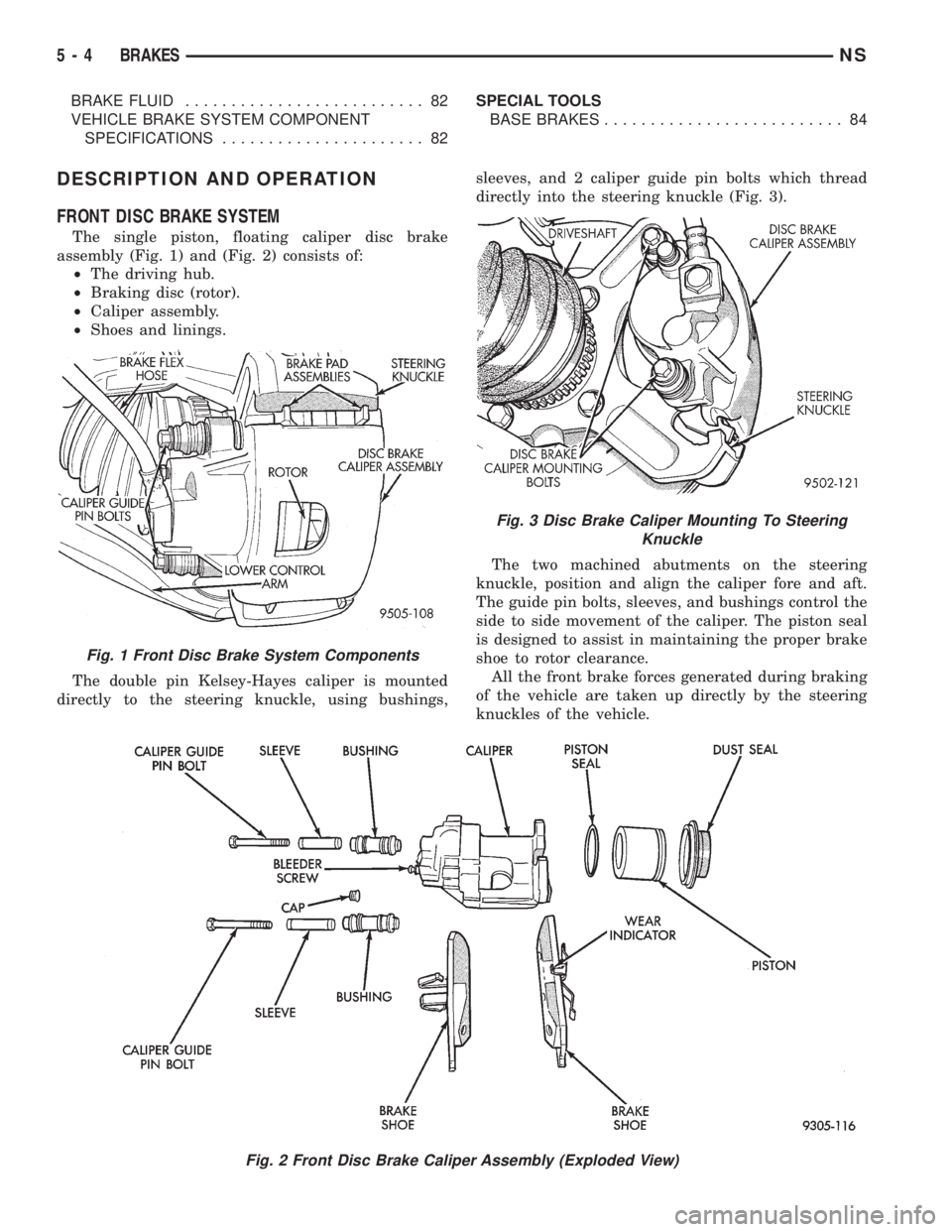

The single piston, floating caliper disc brake

assembly (Fig. 1) and (Fig. 2) consists of:

²The driving hub.

²Braking disc (rotor).

²Caliper assembly.

²Shoes and linings.

The double pin Kelsey-Hayes caliper is mounted

directly to the steering knuckle, using bushings,sleeves, and 2 caliper guide pin bolts which thread

directly into the steering knuckle (Fig. 3).

The two machined abutments on the steering

knuckle, position and align the caliper fore and aft.

The guide pin bolts, sleeves, and bushings control the

side to side movement of the caliper. The piston seal

is designed to assist in maintaining the proper brake

shoe to rotor clearance.

All the front brake forces generated during braking

of the vehicle are taken up directly by the steering

knuckles of the vehicle.

Fig. 2 Front Disc Brake Caliper Assembly (Exploded View)

Fig. 1 Front Disc Brake System Components

Fig. 3 Disc Brake Caliper Mounting To Steering

Knuckle

5 - 4 BRAKESNS

Page 87 of 1938

The caliper is a one piece casting with the inboard

side containing a single piston cylinder bore.

The phenolic piston is 60 mm (2.36 inch) in diam-

eter.

A square cut rubber piston seal is located in a

machined groove in the cylinder bore. It provides a

hydraulic seal between the piston and the cylinder

wall (Fig. 4).

The molded rubber dust boot mounts in a counter

bore of the cylinder bore opening and in a groove

which is machined in the outer surface of the piston

(Fig. 4). This prevents contamination of the piston

and the bore area.

As lining wears, reservoir level will go down. If

fluid has been added, reservoir overflow may occur

when the piston is pushed back into the new lining

position. Overflowing can be avoided by removing a

small amount of fluid from the master cylinder res-

ervoir.

REAR DRUM BRAKES

The rear wheel drum brakes are a two shoe, inter-

nal expanding type with an automatic adjuster screw.

The automatic adjuster screw is actuated each time

the brakes are applied. The automatic adjuster screw

is located directly below the wheel cylinder.

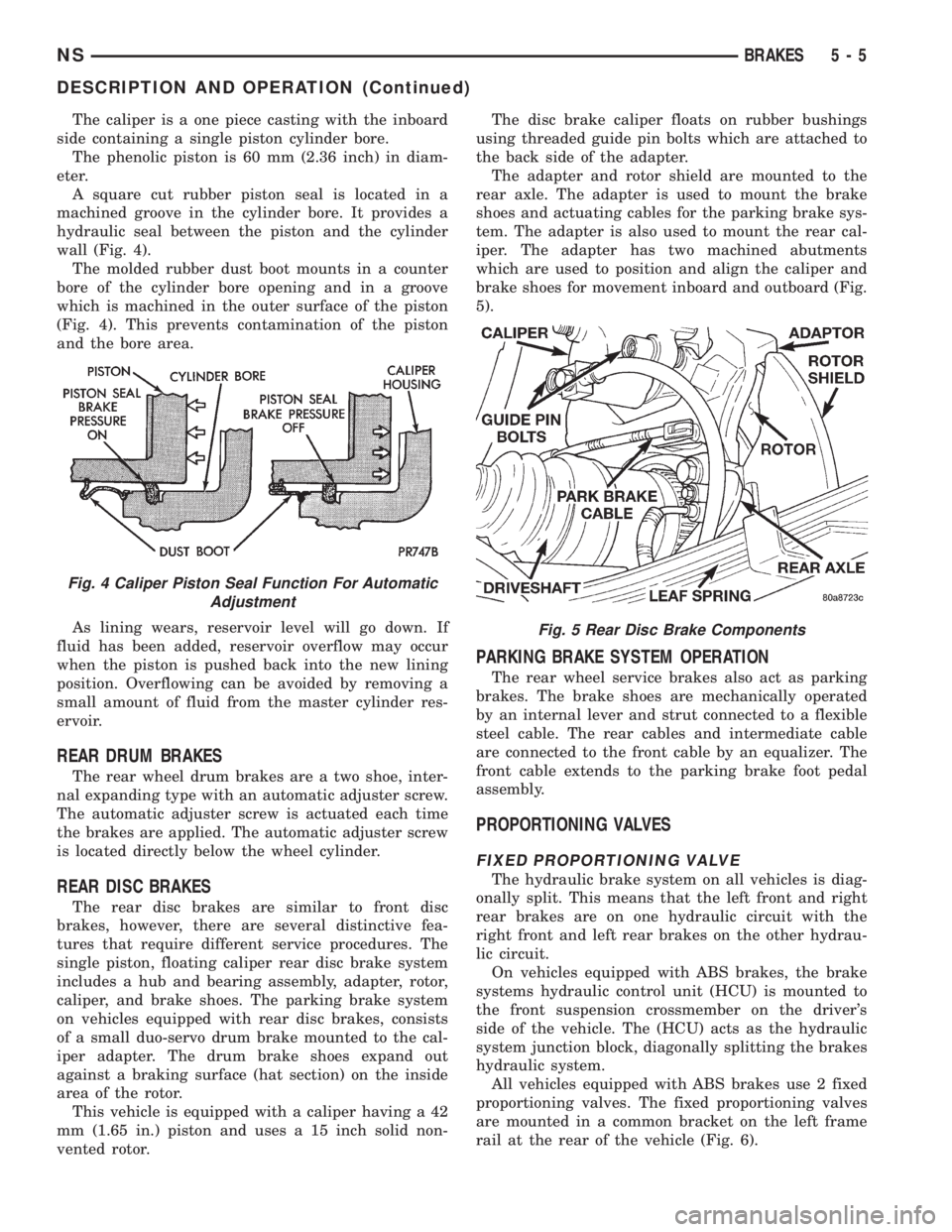

REAR DISC BRAKES

The rear disc brakes are similar to front disc

brakes, however, there are several distinctive fea-

tures that require different service procedures. The

single piston, floating caliper rear disc brake system

includes a hub and bearing assembly, adapter, rotor,

caliper, and brake shoes. The parking brake system

on vehicles equipped with rear disc brakes, consists

of a small duo-servo drum brake mounted to the cal-

iper adapter. The drum brake shoes expand out

against a braking surface (hat section) on the inside

area of the rotor.

This vehicle is equipped with a caliper having a 42

mm (1.65 in.) piston and uses a 15 inch solid non-

vented rotor.The disc brake caliper floats on rubber bushings

using threaded guide pin bolts which are attached to

the back side of the adapter.

The adapter and rotor shield are mounted to the

rear axle. The adapter is used to mount the brake

shoes and actuating cables for the parking brake sys-

tem. The adapter is also used to mount the rear cal-

iper. The adapter has two machined abutments

which are used to position and align the caliper and

brake shoes for movement inboard and outboard (Fig.

5).

PARKING BRAKE SYSTEM OPERATION

The rear wheel service brakes also act as parking

brakes. The brake shoes are mechanically operated

by an internal lever and strut connected to a flexible

steel cable. The rear cables and intermediate cable

are connected to the front cable by an equalizer. The

front cable extends to the parking brake foot pedal

assembly.

PROPORTIONING VALVES

FIXED PROPORTIONING VALVE

The hydraulic brake system on all vehicles is diag-

onally split. This means that the left front and right

rear brakes are on one hydraulic circuit with the

right front and left rear brakes on the other hydrau-

lic circuit.

On vehicles equipped with ABS brakes, the brake

systems hydraulic control unit (HCU) is mounted to

the front suspension crossmember on the driver's

side of the vehicle. The (HCU) acts as the hydraulic

system junction block, diagonally splitting the brakes

hydraulic system.

All vehicles equipped with ABS brakes use 2 fixed

proportioning valves. The fixed proportioning valves

are mounted in a common bracket on the left frame

rail at the rear of the vehicle (Fig. 6).

Fig. 4 Caliper Piston Seal Function For Automatic

Adjustment

Fig. 5 Rear Disc Brake Components

NSBRAKES 5 - 5

DESCRIPTION AND OPERATION (Continued)

Page 96 of 1938

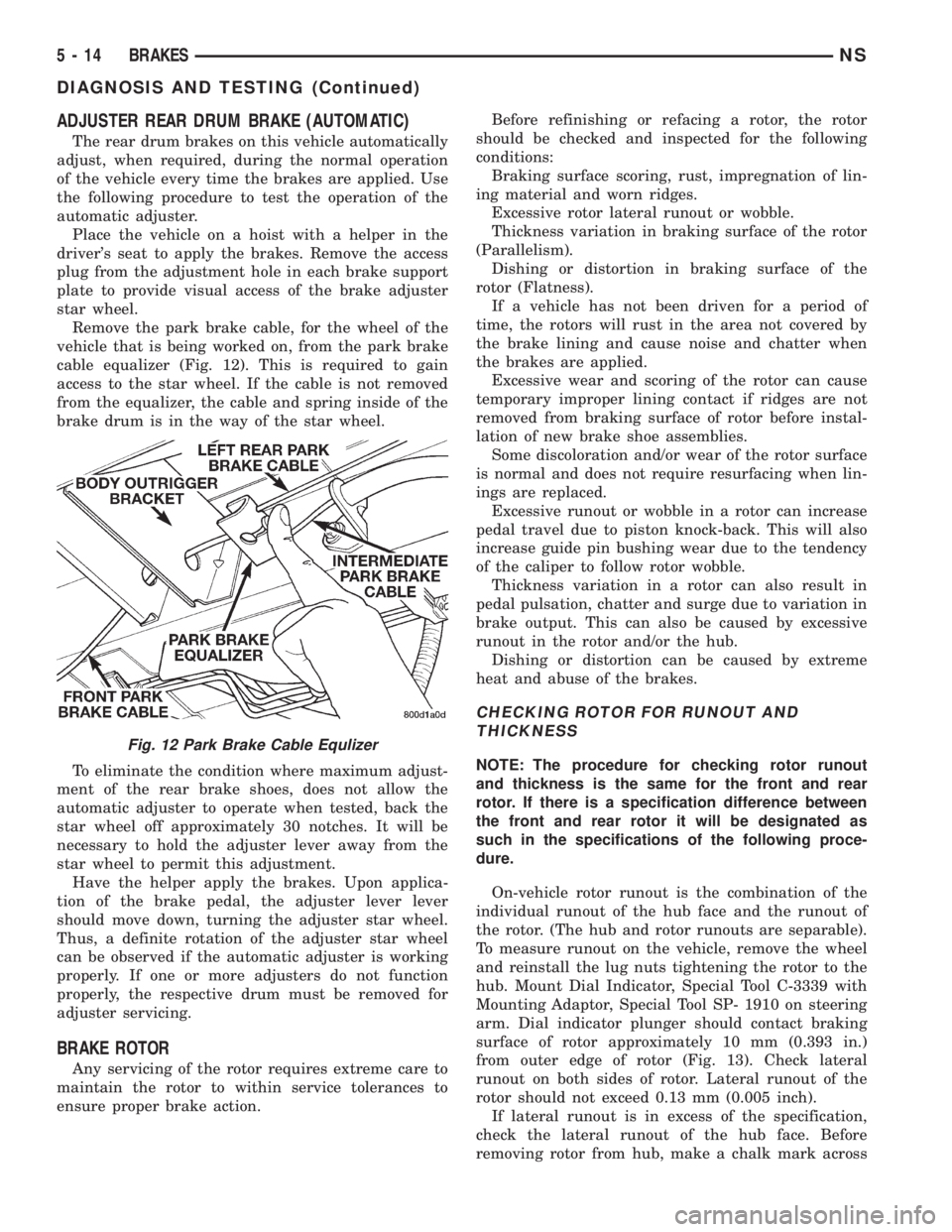

ADJUSTER REAR DRUM BRAKE (AUTOMATIC)

The rear drum brakes on this vehicle automatically

adjust, when required, during the normal operation

of the vehicle every time the brakes are applied. Use

the following procedure to test the operation of the

automatic adjuster.

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the adjustment hole in each brake support

plate to provide visual access of the brake adjuster

star wheel.

Remove the park brake cable, for the wheel of the

vehicle that is being worked on, from the park brake

cable equalizer (Fig. 12). This is required to gain

access to the star wheel. If the cable is not removed

from the equalizer, the cable and spring inside of the

brake drum is in the way of the star wheel.

To eliminate the condition where maximum adjust-

ment of the rear brake shoes, does not allow the

automatic adjuster to operate when tested, back the

star wheel off approximately 30 notches. It will be

necessary to hold the adjuster lever away from the

star wheel to permit this adjustment.

Have the helper apply the brakes. Upon applica-

tion of the brake pedal, the adjuster lever lever

should move down, turning the adjuster star wheel.

Thus, a definite rotation of the adjuster star wheel

can be observed if the automatic adjuster is working

properly. If one or more adjusters do not function

properly, the respective drum must be removed for

adjuster servicing.

BRAKE ROTOR

Any servicing of the rotor requires extreme care to

maintain the rotor to within service tolerances to

ensure proper brake action.Before refinishing or refacing a rotor, the rotor

should be checked and inspected for the following

conditions:

Braking surface scoring, rust, impregnation of lin-

ing material and worn ridges.

Excessive rotor lateral runout or wobble.

Thickness variation in braking surface of the rotor

(Parallelism).

Dishing or distortion in braking surface of the

rotor (Flatness).

If a vehicle has not been driven for a period of

time, the rotors will rust in the area not covered by

the brake lining and cause noise and chatter when

the brakes are applied.

Excessive wear and scoring of the rotor can cause

temporary improper lining contact if ridges are not

removed from braking surface of rotor before instal-

lation of new brake shoe assemblies.

Some discoloration and/or wear of the rotor surface

is normal and does not require resurfacing when lin-

ings are replaced.

Excessive runout or wobble in a rotor can increase

pedal travel due to piston knock-back. This will also

increase guide pin bushing wear due to the tendency

of the caliper to follow rotor wobble.

Thickness variation in a rotor can also result in

pedal pulsation, chatter and surge due to variation in

brake output. This can also be caused by excessive

runout in the rotor and/or the hub.

Dishing or distortion can be caused by extreme

heat and abuse of the brakes.

CHECKING ROTOR FOR RUNOUT AND

THICKNESS

NOTE: The procedure for checking rotor runout

and thickness is the same for the front and rear

rotor. If there is a specification difference between

the front and rear rotor it will be designated as

such in the specifications of the following proce-

dure.

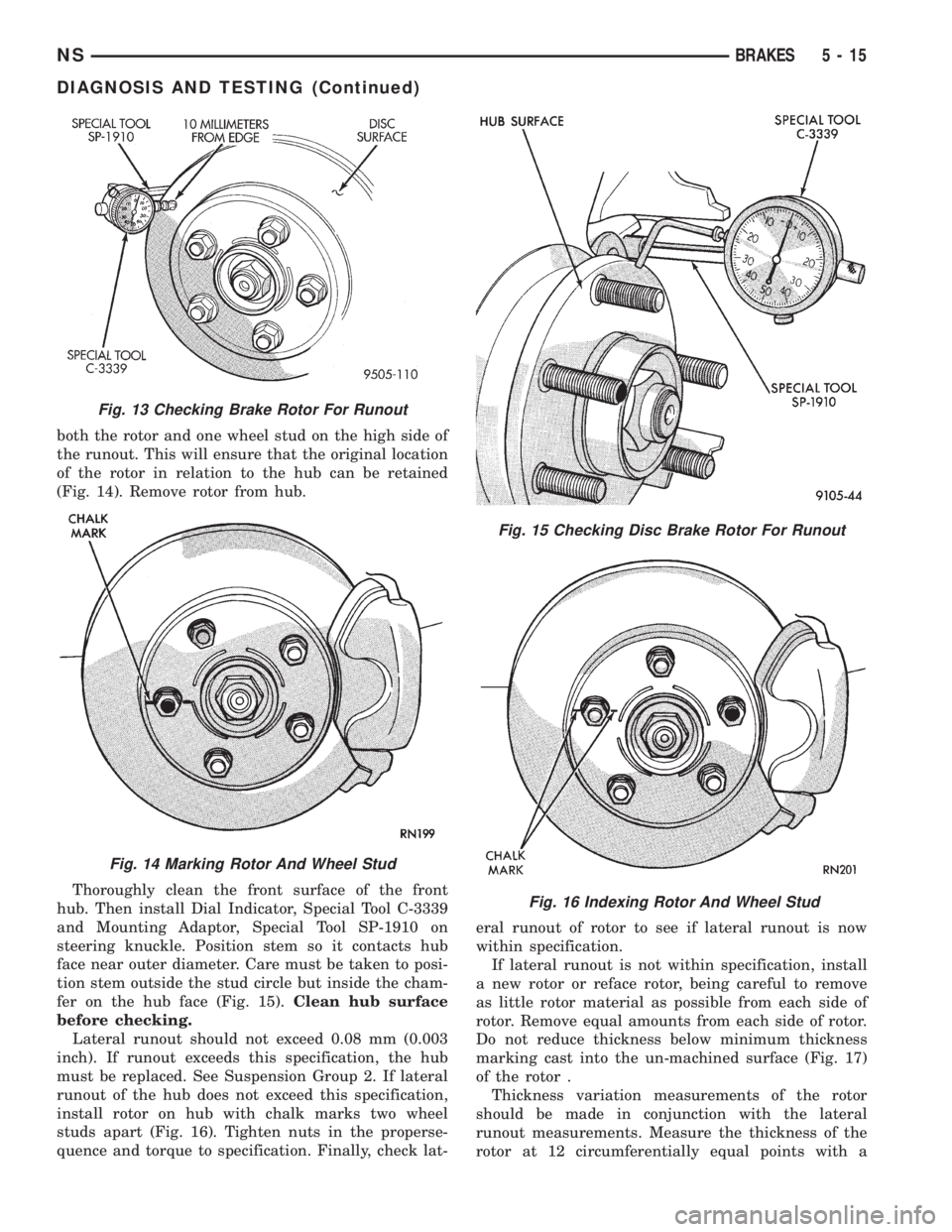

On-vehicle rotor runout is the combination of the

individual runout of the hub face and the runout of

the rotor. (The hub and rotor runouts are separable).

To measure runout on the vehicle, remove the wheel

and reinstall the lug nuts tightening the rotor to the

hub. Mount Dial Indicator, Special Tool C-3339 with

Mounting Adaptor, Special Tool SP- 1910 on steering

arm. Dial indicator plunger should contact braking

surface of rotor approximately 10 mm (0.393 in.)

from outer edge of rotor (Fig. 13). Check lateral

runout on both sides of rotor. Lateral runout of the

rotor should not exceed 0.13 mm (0.005 inch).

If lateral runout is in excess of the specification,

check the lateral runout of the hub face. Before

removing rotor from hub, make a chalk mark across

Fig. 12 Park Brake Cable Equlizer

5 - 14 BRAKESNS

DIAGNOSIS AND TESTING (Continued)

Page 97 of 1938

both the rotor and one wheel stud on the high side of

the runout. This will ensure that the original location

of the rotor in relation to the hub can be retained

(Fig. 14). Remove rotor from hub.

Thoroughly clean the front surface of the front

hub. Then install Dial Indicator, Special Tool C-3339

and Mounting Adaptor, Special Tool SP-1910 on

steering knuckle. Position stem so it contacts hub

face near outer diameter. Care must be taken to posi-

tion stem outside the stud circle but inside the cham-

fer on the hub face (Fig. 15).Clean hub surface

before checking.

Lateral runout should not exceed 0.08 mm (0.003

inch). If runout exceeds this specification, the hub

must be replaced. See Suspension Group 2. If lateral

runout of the hub does not exceed this specification,

install rotor on hub with chalk marks two wheel

studs apart (Fig. 16). Tighten nuts in the properse-

quence and torque to specification. Finally, check lat-eral runout of rotor to see if lateral runout is now

within specification.

If lateral runout is not within specification, install

a new rotor or reface rotor, being careful to remove

as little rotor material as possible from each side of

rotor. Remove equal amounts from each side of rotor.

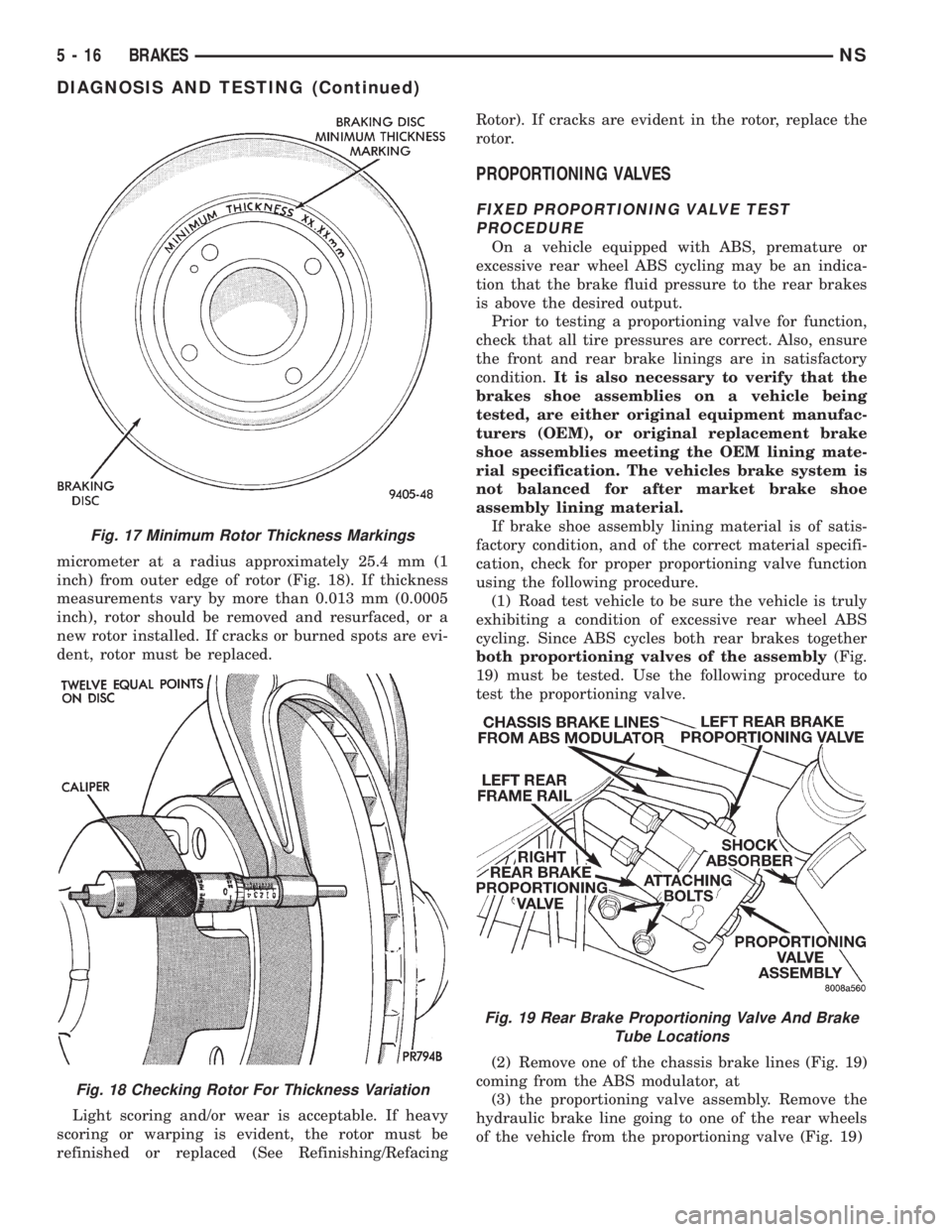

Do not reduce thickness below minimum thickness

marking cast into the un-machined surface (Fig. 17)

of the rotor .

Thickness variation measurements of the rotor

should be made in conjunction with the lateral

runout measurements. Measure the thickness of the

rotor at 12 circumferentially equal points with a

Fig. 16 Indexing Rotor And Wheel Stud

Fig. 13 Checking Brake Rotor For Runout

Fig. 14 Marking Rotor And Wheel Stud

Fig. 15 Checking Disc Brake Rotor For Runout

NSBRAKES 5 - 15

DIAGNOSIS AND TESTING (Continued)

Page 98 of 1938

micrometer at a radius approximately 25.4 mm (1

inch) from outer edge of rotor (Fig. 18). If thickness

measurements vary by more than 0.013 mm (0.0005

inch), rotor should be removed and resurfaced, or a

new rotor installed. If cracks or burned spots are evi-

dent, rotor must be replaced.

Light scoring and/or wear is acceptable. If heavy

scoring or warping is evident, the rotor must be

refinished or replaced (See Refinishing/RefacingRotor). If cracks are evident in the rotor, replace the

rotor.

PROPORTIONING VALVES

FIXED PROPORTIONING VALVE TEST

PROCEDURE

On a vehicle equipped with ABS, premature or

excessive rear wheel ABS cycling may be an indica-

tion that the brake fluid pressure to the rear brakes

is above the desired output.

Prior to testing a proportioning valve for function,

check that all tire pressures are correct. Also, ensure

the front and rear brake linings are in satisfactory

condition.It is also necessary to verify that the

brakes shoe assemblies on a vehicle being

tested, are either original equipment manufac-

turers (OEM), or original replacement brake

shoe assemblies meeting the OEM lining mate-

rial specification. The vehicles brake system is

not balanced for after market brake shoe

assembly lining material.

If brake shoe assembly lining material is of satis-

factory condition, and of the correct material specifi-

cation, check for proper proportioning valve function

using the following procedure.

(1) Road test vehicle to be sure the vehicle is truly

exhibiting a condition of excessive rear wheel ABS

cycling. Since ABS cycles both rear brakes together

both proportioning valves of the assembly(Fig.

19) must be tested. Use the following procedure to

test the proportioning valve.

(2) Remove one of the chassis brake lines (Fig. 19)

coming from the ABS modulator, at

(3) the proportioning valve assembly. Remove the

hydraulic brake line going to one of the rear wheels

of the vehicle from the proportioning valve (Fig. 19)

Fig. 17 Minimum Rotor Thickness Markings

Fig. 18 Checking Rotor For Thickness Variation

Fig. 19 Rear Brake Proportioning Valve And Brake

Tube Locations

5 - 16 BRAKESNS

DIAGNOSIS AND TESTING (Continued)