check engine CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1378 of 4284

TEST ACTION APPLICABILITY

1WARNING: THE FUEL INJECTION PUMP SUPPLIES HIGH PRESSURE

FUEL TO EACH INDIVIDUAL INJECTOR THROUGH HIGH-PRESSURE

FUEL LINES. FUEL UNDER HIGH PRESSURE CAN PENETRATE SKIN

AND CAUSE PERSONAL INJURY. WEAR SAFETY GOGGLES AND ADE-

QUATE PROTECTIVE CLOTHING.

Turn the ignition on.

With the DRB, erase ECM DTCs.

Start the engine several times, turning the ignition off for at least 30 seconds

between each run cycle.

Monitor the DRB for ECM DTCs.

Did this DTC reset?All

Ye s®Go To 2

No®Go To 8

2 Turn the ignition off.

Disconnect the Fuel Pressure Solenoid harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the ECM/PCM Relay Output

circuit.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the ECM/PCM Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect the Fuel Pressure Solenoid harness connector.

Disconnect the ECM harness connectors.

Remove the ECM/PCM Relay from the PDC.

Connect a jumper wire between cavity 30 and cavity 87 of the ECM/PCM Relay

connector.

Turn the ignition on.

Measure the voltage of the Fuel Pressure Solenoid Control circuit.

Is the voltage below 1.0 volt?All

Ye s®Go To 4

No®Repair the Fuel Pressure Solenoid Control circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Disconnect the Fuel Pressure Solenoid harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between ground and the Fuel Pressure Solenoid Control

circuit.

NOTE: The Fuel Pressure Solenoid Control circuit is duplicated at ECM

cavities C2-80 and C2-81.

Is the resistance above 100k ohms?All

Ye s®Go To 5

No®Repair the Fuel Pressure Solenoid Control circuit for a short to

ground.

Perform ROAD TEST VERIFICATION - VER-2.

159

DRIVEABILITY - DIESEL

P1131-FUEL PRESSURE SOLENOID OPEN CIRCUIT ÐContinued

Page 1384 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Install a substitute relay in place of the Fuel Heater Relay.

Disconnect the ECM harness connectors.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fuel Heater Relay Output

circuit.

Is the test light on?All

Ye s®Replace the initial Fuel Heater Relay.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 5

5 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Crankcase Vent Heater harness connector.

Disconnect the Fuel Heater harness connector.

Remove the Fuel Heater Relay from the IPM.

Measure the resistance between ground and the Battery(+) Sense circuit.

Is the resistance above 100k ohms?All

Ye s®Go To 6

No®Repair the Battery(+) Sense circuit for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running and at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

165

DRIVEABILITY - DIESEL

P1511-BATTERY SENSE LINE 1 VOLTAGE TOO LOW ÐContinued

Page 1401 of 4284

Symptom:

*CHECKING THE BOOST PRESSURE SENSOR CALIBRATION

POSSIBLE CAUSES

TURBOCHARGER BOOST PRESSURE SENSOR CALIBRATION

TEST ACTION APPLICABILITY

1 Allow the engine to idle.

With the DRB, select Engine, Bosch then Sensors. Read the Boost Pressure Voltage.

Is the Boost Pressure Voltage between 1.50 and 2.00 volts?All

Ye s®Test Complete.

No®Replace the Turbocharger Boost Pressure Sensor.

Perform ROAD TEST VERIFICATION - VER-2.

182

DRIVEABILITY - DIESEL

Page 1404 of 4284

Symptom:

*CHECKING THE EGR SYSTEM

POSSIBLE CAUSES

ECM/PCM RELAY OUTPUT CIRCUIT OPEN

EGR SOLENOID CONTROL CIRCUIT OPEN

EGR VALVE

VACUUM SUPPLY HOSE

TEST ACTION APPLICABILITY

1 Disconnect the Vacuum Supply Hose at the EGR solenoid.

Connect a vacuum gauge to the Vacuum Supply Hose.

Start the engine and allow the engine to idle.

Is the vacuum above 10 inches of mercury at idle?All

Ye s®Go To 2

No®Repair leaking or restricted Vacuum Supply Hose or faulty

Vacuum Supply Pump.

Perform ROAD TEST VERIFICATION - VER-2.

2 Turn the ignition off.

Disconnect the EGR Solenoid harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the ECM/PCM Relay Output

circuit at the EGR Solenoid harness connector.

Is the test light on?All

Ye s®Go To 3

No®Repair the ECM/PCM Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect the EGR Solenoid harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the EGR Solenoid Control circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 4

No®Repair the EGR Solenoid Control circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

4NOTE: The Vacuum Output Hose must not be leaking or restricted for the

result of this test to be valid.

Turn the ignition off.

Disconnect the Vacuum Supply and Vacuum Output Hoses in the EGR Solenoid

vacuum connector.

Connect the Vacuum Supply Hose to the Vacuum Output Hose.

Test drive the vehicle and observe vehicle performance.

Is there a power reduction on vehicle acceleration?All

Ye s®Test Complete.

No®Replace the EGR Valve.

Perform ROAD TEST VERIFICATION - VER-2.

185

DRIVEABILITY - DIESEL

Page 1406 of 4284

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTCs.

Are any Radiator Fan DTCs present?All

Ye s®Refer to symptom list for problems related to Radiator Fan

control.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 2

2NOTE: The engine temperature must not be hot enough to cause the

radiator fans to be on with the key off.

Turn the ignition off.

Observe the radiator fans with the key off.

Is either radiator fan running with the key off?All

Ye s®Go To 3

No®Go To 6

3NOTE: The engine temperature must not be hot enough to cause the

radiator fans to be on with the key off.

Turn the ignition off.

Observe the radiator fans with the key off.

Which radiator fan(s) are running?All

Fan 1 and Fan 2

Go To 4

Fan 2 Only

Go To 5

4NOTE: The engine temperature must not be hot enough to cause the

radiator fans to be on with the key off.

Turn the ignition off.

Remove Radiator Fan Relay No. 1.

Observe the radiator fans.

Did the radiator fans stop running?All

Ye s®Replace Radiator Fan Relay No. 1.

Perform ROAD TEST VERIFICATION - VER-2.

No®Repair the Radiator Fan Relay No. 1 Output circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

5NOTE: The engine temperature must not be hot enough to cause the

radiator fans to be on with the key off.

Turn the ignition off.

One at a time, remove Radiator Fan Relay No. 2 and then Radiator Fan Relay No. 3.

Observe the radiator fans after disconnecting each relay.

Did the radiator fan stop running?All

Ye s®Replace Radiator Fan Relay that caused the radiator fan to stop.

Perform ROAD TEST VERIFICATION - VER-2.

No®Repair the Radiator Fan Relay No. 2 and No. 3 Common Output

circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

187

DRIVEABILITY - DIESEL

*CHECKING THE ELECTRIC RADIATOR FAN OPERATION ÐContinued

Page 1407 of 4284

TEST ACTION APPLICABILITY

6 Turn the ignition on.

With the DRB, actuate the Low Speed Rad Fan and observe the Radiator Fans.

NOTE: Both Radiator Fans should operate at low speed.

Did both Radiator Fans operate as they should?All

Ye s®Go To 7

Fans do not operate on Low

Go To 15

Fan 1 on High/Fan 2 not on

Go To 23

Fan 1 not on/Fan 2 on High

Go To 26

7 Turn the ignition on.

With the DRB, actuate the High and Low Speed Rad Fans at the same time and

observe the Radiator Fans.

NOTE: Both Radiator Fans should operate at high speed.

Did both Radiator Fans operate as they should?All

Ye s®The test is complete. Ensure the ECM will turn the fans on when

the engine is hot.

Perform ROAD TEST VERIFICATION - VER-2.

Fan 1 on High/Fan 2 not on

Go To 8

Fan 1 not on/Fan 2 on High

Go To 11

8 Turn the ignition off.

Disconnect the Radiator Fan Relay No. 2 harness connector.

Using a 12-volt test light connected to ground, check the Fused B+ circuit.

Did the test light illuminate brightly?All

Ye s®Go To 9

No®Repair the Radiator Fan Relay No. 2 Fused B+ circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

9 Turn the ignition off.

Install a substitute relay in place of Radiator Fan Relay No. 2.

Turn the ignition on.

With the DRB, actuate the High Speed Fan Relay.

Does Radiator Fan No. 2 cycle on and off?All

Ye s®Replace Radiator Fan Relay No. 2.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 10

188

DRIVEABILITY - DIESEL

*CHECKING THE ELECTRIC RADIATOR FAN OPERATION ÐContinued

Page 1412 of 4284

Symptom:

*CHECKING THE ENGINE COOLANT TEMPERATURE SENSOR

CALIBRATION

POSSIBLE CAUSES

ECT SENSOR - COLD

ECT SENSOR - HOT

TEST ACTION APPLICABILITY

1NOTE: The thermostat must be operating correctly for this test to be valid.

With the DRB, read and note the engine coolant temperature.

Using a temperature probe, measure the engine block temperature near the ECT

Sensor.

NOTE: The engine temperature should be below 50*C (120*F)

Are the readings within 7ÉC (13ÉF) of each other?All

Ye s®Go To 2

No®Replace the Engine Coolant Temperature Sensor.

Perform ROAD TEST VERIFICATION - VER-2.

2NOTE: The thermostat must be operating correctly for this test to be valid.

Start the engine and bring the engine to operating temperature (thermostat open).

Turn the engine off and wait 10 minutes to allow the engine temperature to stabilize.

Using a temperature probe, measure the engine block temperature near the ECT

Sensor.

Using the DRB, select Engine, then Sensors and read the engine coolant tempera-

ture.

Are the readings within 7ÉC (13ÉF) of each other?All

Ye s®Test Complete.

No®Replace the Engine Coolant Temperature Sensor.

Perform ROAD TEST VERIFICATION - VER-2.

193

DRIVEABILITY - DIESEL

Page 1413 of 4284

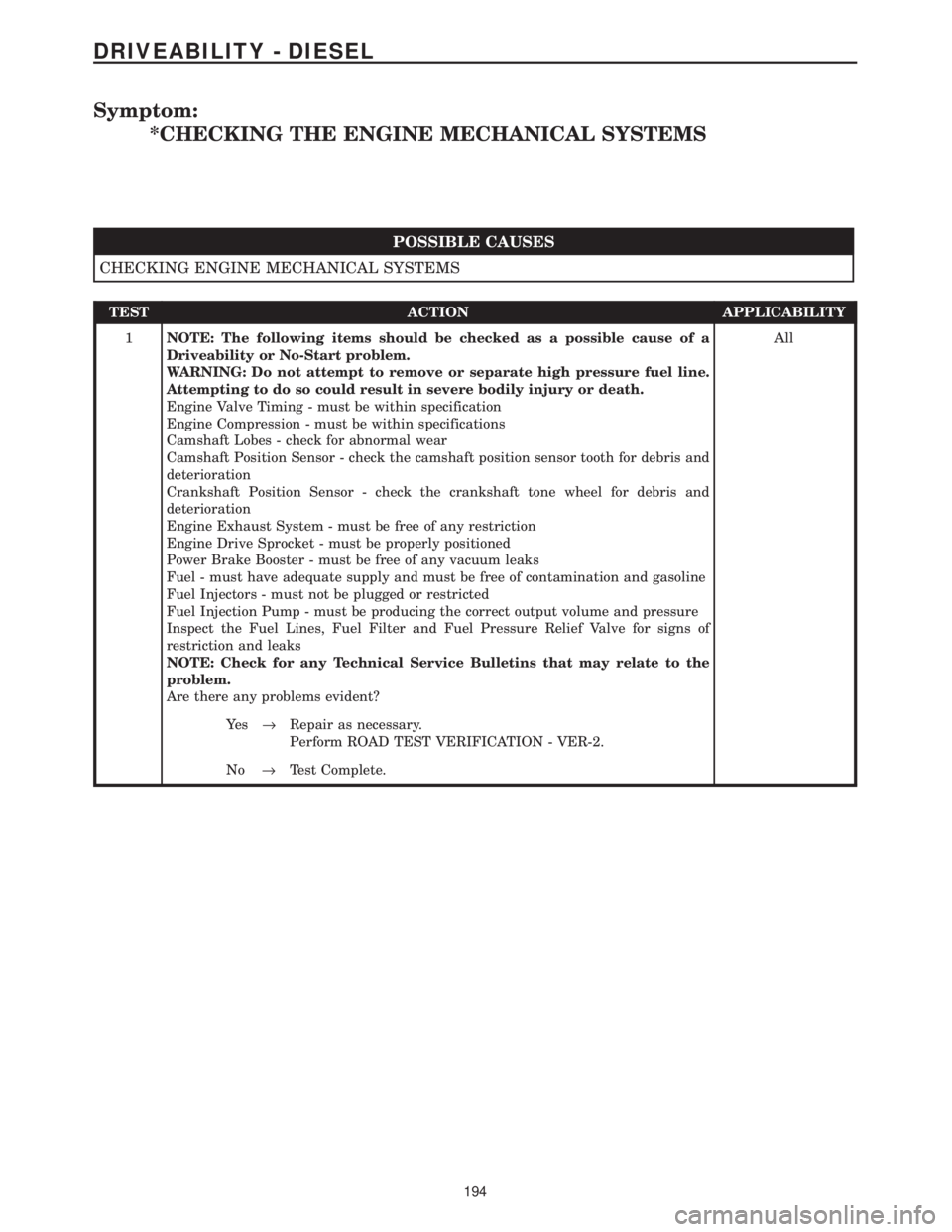

Symptom:

*CHECKING THE ENGINE MECHANICAL SYSTEMS

POSSIBLE CAUSES

CHECKING ENGINE MECHANICAL SYSTEMS

TEST ACTION APPLICABILITY

1NOTE: The following items should be checked as a possible cause of a

Driveability or No-Start problem.

WARNING: Do not attempt to remove or separate high pressure fuel line.

Attempting to do so could result in severe bodily injury or death.

Engine Valve Timing - must be within specification

Engine Compression - must be within specifications

Camshaft Lobes - check for abnormal wear

Camshaft Position Sensor - check the camshaft position sensor tooth for debris and

deterioration

Crankshaft Position Sensor - check the crankshaft tone wheel for debris and

deterioration

Engine Exhaust System - must be free of any restriction

Engine Drive Sprocket - must be properly positioned

Power Brake Booster - must be free of any vacuum leaks

Fuel - must have adequate supply and must be free of contamination and gasoline

Fuel Injectors - must not be plugged or restricted

Fuel Injection Pump - must be producing the correct output volume and pressure

Inspect the Fuel Lines, Fuel Filter and Fuel Pressure Relief Valve for signs of

restriction and leaks

NOTE: Check for any Technical Service Bulletins that may relate to the

problem.

Are there any problems evident?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

194

DRIVEABILITY - DIESEL

Page 1419 of 4284

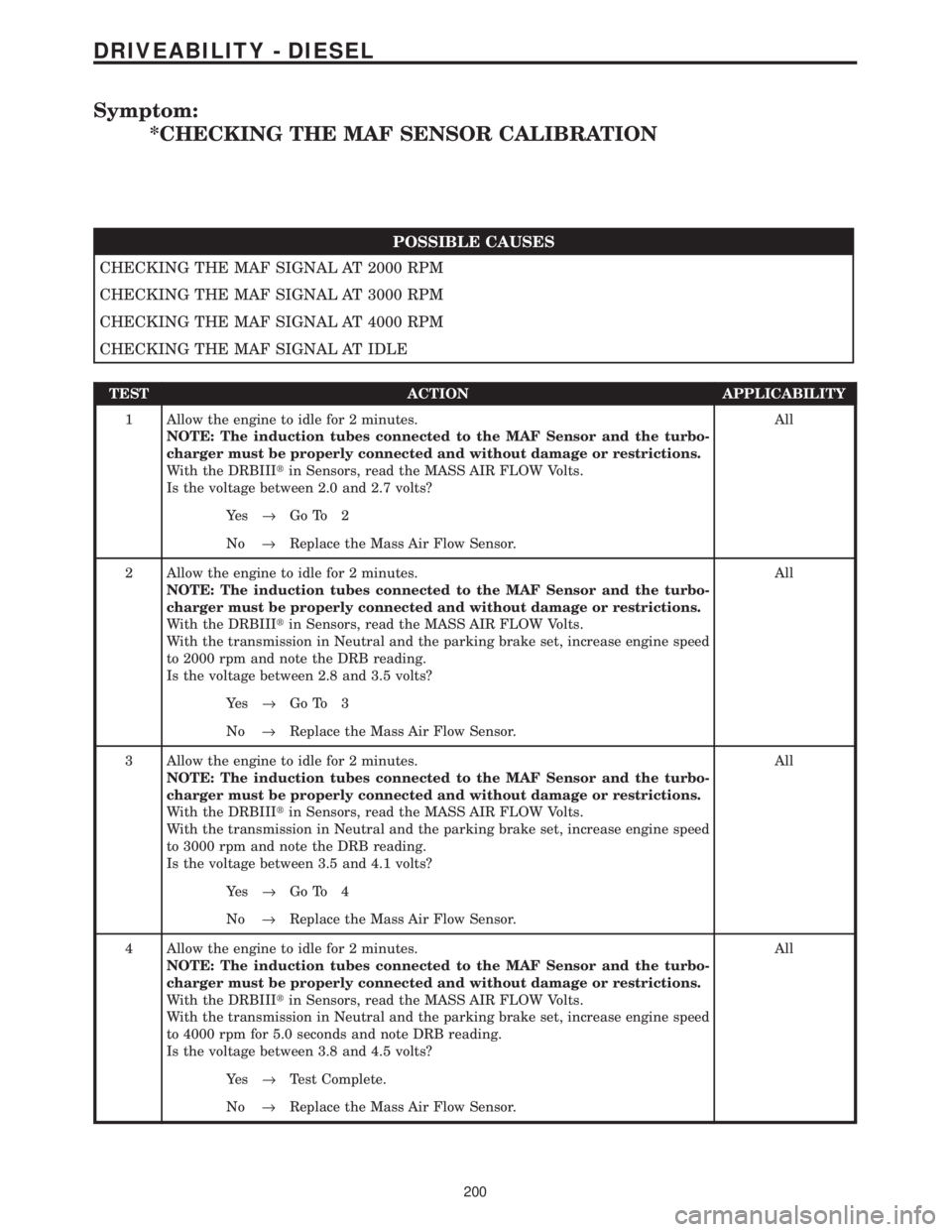

Symptom:

*CHECKING THE MAF SENSOR CALIBRATION

POSSIBLE CAUSES

CHECKING THE MAF SIGNAL AT 2000 RPM

CHECKING THE MAF SIGNAL AT 3000 RPM

CHECKING THE MAF SIGNAL AT 4000 RPM

CHECKING THE MAF SIGNAL AT IDLE

TEST ACTION APPLICABILITY

1 Allow the engine to idle for 2 minutes.

NOTE: The induction tubes connected to the MAF Sensor and the turbo-

charger must be properly connected and without damage or restrictions.

With the DRBIIItin Sensors, read the MASS AIR FLOW Volts.

Is the voltage between 2.0 and 2.7 volts?All

Ye s®Go To 2

No®Replace the Mass Air Flow Sensor.

2 Allow the engine to idle for 2 minutes.

NOTE: The induction tubes connected to the MAF Sensor and the turbo-

charger must be properly connected and without damage or restrictions.

With the DRBIIItin Sensors, read the MASS AIR FLOW Volts.

With the transmission in Neutral and the parking brake set, increase engine speed

to 2000 rpm and note the DRB reading.

Is the voltage between 2.8 and 3.5 volts?All

Ye s®Go To 3

No®Replace the Mass Air Flow Sensor.

3 Allow the engine to idle for 2 minutes.

NOTE: The induction tubes connected to the MAF Sensor and the turbo-

charger must be properly connected and without damage or restrictions.

With the DRBIIItin Sensors, read the MASS AIR FLOW Volts.

With the transmission in Neutral and the parking brake set, increase engine speed

to 3000 rpm and note the DRB reading.

Is the voltage between 3.5 and 4.1 volts?All

Ye s®Go To 4

No®Replace the Mass Air Flow Sensor.

4 Allow the engine to idle for 2 minutes.

NOTE: The induction tubes connected to the MAF Sensor and the turbo-

charger must be properly connected and without damage or restrictions.

With the DRBIIItin Sensors, read the MASS AIR FLOW Volts.

With the transmission in Neutral and the parking brake set, increase engine speed

to 4000 rpm for 5.0 seconds and note DRB reading.

Is the voltage between 3.8 and 4.5 volts?All

Ye s®Test Complete.

No®Replace the Mass Air Flow Sensor.

200

DRIVEABILITY - DIESEL

Page 1420 of 4284

Symptom:

*CHECKING THE SPEED CONTROL OPERATION

POSSIBLE CAUSES

CHECKING CRUISE SWITCHES

CHECKING THE BRAKE SWITCH INPUT

CHECKING THE ECM FOR DTC'S

CHECKING THE VSS SIGNAL

CLUTCH PEDAL SWITCH

CLUTCH PEDAL SWITCH SENSE CIRCUIT OPEN

CLUTCH PEDAL SWITCH SENSE CIRCUIT SHORTED TO GROUND

ECM

ECM

INTERMITTENT CONDITION

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read the ECM DTCs.

Are there any ECM DTC's present?All

Ye s®Refer to symptom list for problems related to the ECM DTC.

Perform SPEED CONTROL VERIFICATION - VER-4.

No®Go To 2

2 Test drive the vehicle above 60 Km/h (35 mph).

Attempt to Set the Speed Control.

Is the Speed Control function operating properly?All

Ye s®Test Complete.

No®Go To 3

3 Start the engine.

With the DRB, read the CRUISE SW VOLTS.

Observe the cruise switch volts on the DRB while pressing and holding each cruise

button separately.

NOTE: Pressing each cruise button should result in the following voltages:

ON/OFF 0.0 - 0.3v, SET 3.58 - 3.99v, RESUME/ACCEL 4.19 - 4.59v, CANCEL 1.28

- 1.68v, COAST 2.69 - 3.01v, No Button Pressed 4.8 - 5.2v

Does each switch provide the correct voltage?All

Ye s®Go To 4

No®Refer to symptom list for problems related to S/C Switches.

Perform SPEED CONTROL VERIFICATION - VER-4.

201

DRIVEABILITY - DIESEL