check engine CHRYSLER VOYAGER 2001 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1008 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off to the lock position.

Disconnect the Rear Washer Pump Motor harness connector.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Using a 12-volt test light connected to ground, check the Fused Accessory Relay

Output circuit in the Rear Washer Pump Motor harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 4

No®Repair the Fused Accessory Relay Output circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

4 Turn the ignition off to the lock position.

Disconnect the Rear Washer Pump Motor harness connector.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Using a 12-volt test light connected to 12 Volts, check the Rear Washer Pump Motor

Control circuit in the Rear Washer Pump Motor harness connector while pressing the

Rear Washer Switch.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Replace the Rear Washer Pump Motor in accordance with the

Service Information.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 Turn the ignition off to the lock position.

Disconnect the Front Control Module harness connector.

Disconnect the Rear Washer Pump Motor harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Rear Washer Pump Motor Control Circuit from the

Front Control Module connector to the Rear Washer Pump Motor harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Rear Washer Pump Motor Control Circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 6

6 Turn the ignition off to the lock position.

Disconnect the Front Control Module connector.

Disconnect the Rear Washer Pump Motor harness connector.

Note: Check connectors - Clean/repair as necessary.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Rear Washer Pump Motor

Control circuit.

Does the test light illuminate brightly?All

Ye s®Repair the Rear Washer Pump Motor Control Circuit for a short

to voltage.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

979

WINDSHIELD WIPER & WASHER

REAR WASHER OUTPUT OPEN ÐContinued

Page 1009 of 4284

Symptom:

REAR WIPER OUTPUT OPEN

When Monitored and Set Condition:

REAR WIPER OUTPUT OPEN

When Monitored: Ignition on.

Set Condition: The Output is ON, the Output Driver Status is LOW and there is no Park

signal.

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

REAR WIPER MOTOR CONTROL CIRCUIT OPEN

REAR WIPER MOTOR GROUND OPEN

REAR WIPER MOTOR CONTROL CIRCUIT SHORT TO VOLTAGE

REAR WIPER MOTOR

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Ignition on, engine not running.

Turn on the Rear Wiper.

Does the Rear Wiper Function?All

Ye s®Go To 2

No®Go To 3

2 Turn the ignition on.

With the DRBIIIt, erase all BCM and FCM DTCs.

Turn the ignition off.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this

circuit.

Wiggle the wiring while checking for shorts and open circuits.

Were there any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

980

WINDSHIELD WIPER & WASHER

Page 1010 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off to the lock position.

Disconnect the Rear Wiper Motor harness connector.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Using a 12-volt test light connected to ground, check the Rear Wiper Motor Control

circuit in the Rear Wiper Motor harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Turn ON the Rear Wiper Motor.

Does the test light illuminate brightly?All

Ye s®Go To 4

No®Go To 5

4 Turn the ignition off to the lock position.

Disconnect the Rear Wiper Motor harness connector.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Using a 12-volt test light connected to 12 Volts, check the Rear Wiper Motor ground

circuit in the Rear Wiper Motor harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Replace the Rear Wiper Motor in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

No®Repair the Rear Wiper Motor ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

5 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Rear Wiper Motor harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Rear Wiper Motor Control Circuit from the Body

Control Module harness connector to the Rear Wiper Motor harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Rear Wiper Motor Control Circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 6

6 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Rear Wiper Motor harness connector.

Note: Check connectors - Clean/repair as necessary.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Rear Wiper Motor Control

circuit.

Is the test light on?All

Ye s®Repair the Rear Wiper Motor Control Circuit for a short to

voltage.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Body Control Module in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

981

WINDSHIELD WIPER & WASHER

REAR WIPER OUTPUT OPEN ÐContinued

Page 1011 of 4284

Symptom:

REAR WIPER OUTPUT SHORT TO GROUND

When Monitored and Set Condition:

REAR WIPER OUTPUT SHORT TO GROUND

When Monitored: Ignition ON

Set Condition:

POSSIBLE CAUSES

REAR WIPER MOTOR FUNCTION

INTERMITTENT WIRING AND CONNECTORS

REAR WIPER MOTOR CONTROL CIRCUIT SHORT TO GROUND

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Ignition on, engine not running.

Turn on the Rear Wiper.

Does the Rear Wiper Function?All

Ye s®Go To 2

No®Go To 3

2 Turn the ignition on.

With the DRBIIIt, erase all BCM and FCM DTCs.

Turn the ignition off.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this

circuit.

Wiggle the wiring while checking for shorts and open circuits.

Were there any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

3 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Rear Wiper Motor harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between ground and the Rear Wiper Motor Control circuit.

Is the resistance less than 5.0 ohms?All

Ye s®Repair the Rear Wiper Motor Control Circuit for a short to

ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

982

WINDSHIELD WIPER & WASHER

Page 1017 of 4284

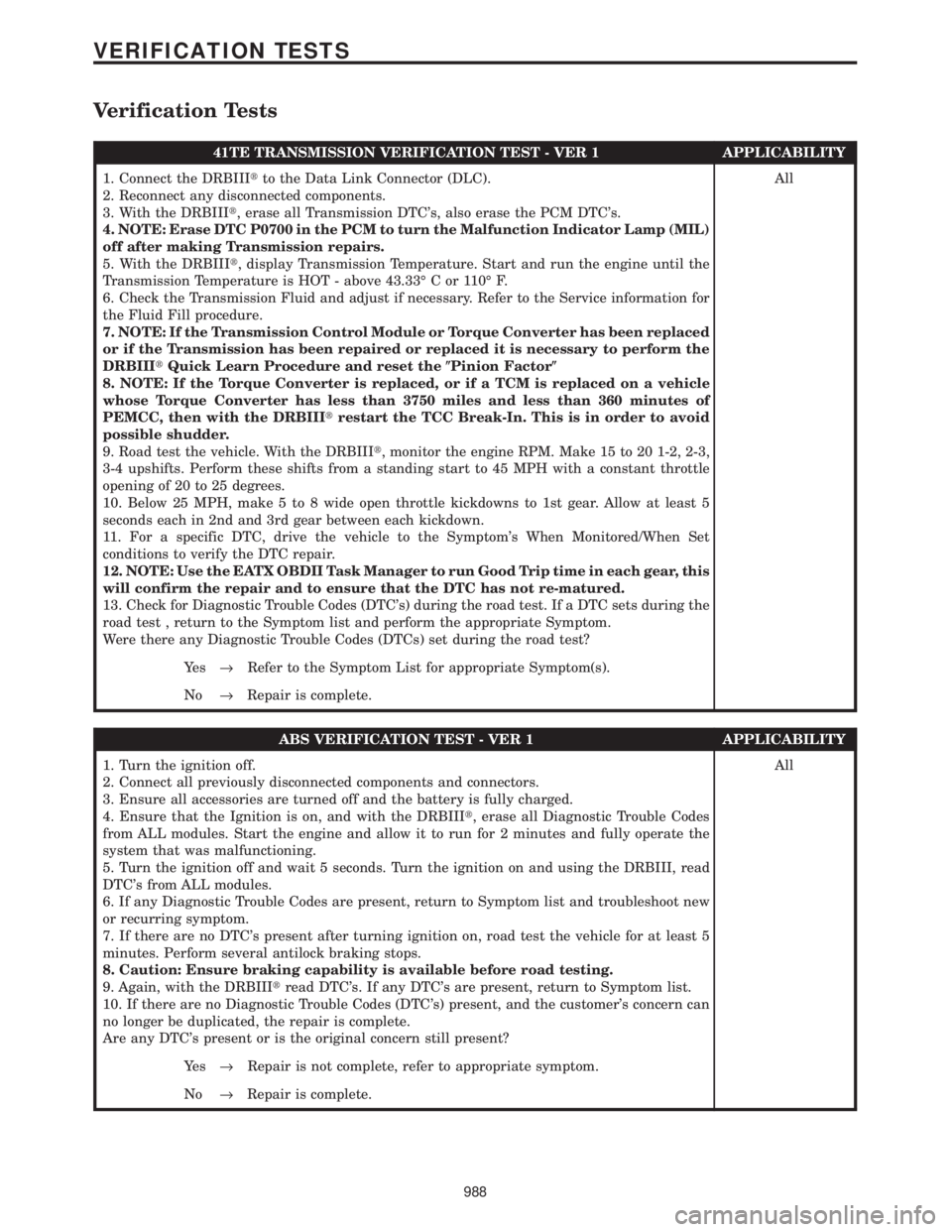

Verification Tests

41TE TRANSMISSION VERIFICATION TEST - VER 1 APPLICABILITY

1. Connect the DRBIIItto the Data Link Connector (DLC).

2. Reconnect any disconnected components.

3. With the DRBIIIt, erase all Transmission DTC's, also erase the PCM DTC's.

4. NOTE: Erase DTC P0700 in the PCM to turn the Malfunction Indicator Lamp (MIL)

off after making Transmission repairs.

5. With the DRBIIIt, display Transmission Temperature. Start and run the engine until the

Transmission Temperature is HOT - above 43.33É C or 110É F.

6. Check the Transmission Fluid and adjust if necessary. Refer to the Service information for

the Fluid Fill procedure.

7. NOTE: If the Transmission Control Module or Torque Converter has been replaced

or if the Transmission has been repaired or replaced it is necessary to perform the

DRBIIItQuick Learn Procedure and reset the(Pinion Factor(

8. NOTE: If the Torque Converter is replaced, or if a TCM is replaced on a vehicle

whose Torque Converter has less than 3750 miles and less than 360 minutes of

PEMCC, then with the DRBIIItrestart the TCC Break-In. This is in order to avoid

possible shudder.

9. Road test the vehicle. With the DRBIIIt, monitor the engine RPM. Make 15 to 20 1-2, 2-3,

3-4 upshifts. Perform these shifts from a standing start to 45 MPH with a constant throttle

opening of 20 to 25 degrees.

10. Below 25 MPH, make 5 to 8 wide open throttle kickdowns to 1st gear. Allow at least 5

seconds each in 2nd and 3rd gear between each kickdown.

11. For a specific DTC, drive the vehicle to the Symptom's When Monitored/When Set

conditions to verify the DTC repair.

12. NOTE: Use the EATX OBDII Task Manager to run Good Trip time in each gear, this

will confirm the repair and to ensure that the DTC has not re-matured.

13. Check for Diagnostic Trouble Codes (DTC's) during the road test. If a DTC sets during the

road test , return to the Symptom list and perform the appropriate Symptom.

Were there any Diagnostic Trouble Codes (DTCs) set during the road test?All

Ye s®Refer to the Symptom List for appropriate Symptom(s).

No®Repair is complete.

ABS VERIFICATION TEST - VER 1 APPLICABILITY

1. Turn the ignition off.

2. Connect all previously disconnected components and connectors.

3. Ensure all accessories are turned off and the battery is fully charged.

4. Ensure that the Ignition is on, and with the DRBIIIt, erase all Diagnostic Trouble Codes

from ALL modules. Start the engine and allow it to run for 2 minutes and fully operate the

system that was malfunctioning.

5. Turn the ignition off and wait 5 seconds. Turn the ignition on and using the DRBIII, read

DTC's from ALL modules.

6. If any Diagnostic Trouble Codes are present, return to Symptom list and troubleshoot new

or recurring symptom.

7. If there are no DTC's present after turning ignition on, road test the vehicle for at least 5

minutes. Perform several antilock braking stops.

8. Caution: Ensure braking capability is available before road testing.

9. Again, with the DRBIIItread DTC's. If any DTC's are present, return to Symptom list.

10. If there are no Diagnostic Trouble Codes (DTC's) present, and the customer's concern can

no longer be duplicated, the repair is complete.

Are any DTC's present or is the original concern still present?All

Ye s®Repair is not complete, refer to appropriate symptom.

No®Repair is complete.

988

VERIFICATION TESTS

Page 1022 of 4284

ROAD TEST VERIFICATION - VER-2 APPLICABILITY

1. Inspect the vehicle to ensure that all engine components are properly installed and

connected. Reassemble and reconnect components as necessary.

2. If this verification procedure is being performed after a non-DTC test, perform steps 3 and

4.

3. Check to see if the initial symptom still exists. If there are no trouble codes and the symptom

no longer exists, the repair was successful and testing is now complete.

4. If the initial or another symptom exists, the repair is not complete. Check all pertinent

Technical Service Bulletins (TSBs) and return to the Symptom List if necessary.

5. For previously read DTCs that have not been dealt with, return to the Symptom List and

follow the diagnostic path for that DTC; otherwise, continue.

6. If the Engine Control Module (ECM) (diesel only) or Powertrain Control Module (PCM) has

not been changed, perform steps 7 and 8, otherwise, continue with step 9.

7. With the DRB, erase all diagnostic trouble codes (DTCs), then disconnect the DRB.

8. Turn the ignition off for at least 10 seconds.

9. Ensure no DTCs remain by performing steps 10 through 13.

10. Road test the vehicle. For some of the road test, go at least 64 km/h (40 MPH). If this test

is for an A/C Relay Control Circuit, drive the vehicle for at least 5 minutes with the A/C on.

11. At some point, stop the vehicle and turn the engine off for at least 10 seconds, then restart

the engine and continue.

12. Upon completion of the road test, turn the engine off and check for DTCs with the DRB.

13. If the repaired DTC has reset, the repair is not complete. Check for any pertinent Technical

Service Bulletins (TSBs) and return to the Symptom List. If there are no DTCs, the repair was

successful and is now complete.

Are any DTCs or symptoms remaining?All

Ye s®Repair is not complete, refer to appropriate symptom.

No®Repair is complete.

SKIS VERIFICATION APPLICABILITY

1. Reconnect all previously disconnected components and connectors.

2. Obtain the vehicle's unique Personal Identification Number (PIN) assigned to it's original

SKIM. This number can be obtained from the vehicle's invoice or Chrysler's Customer Center

(1-800-992-1997).

3. NOTE: When entering the PIN, care should be taken because the SKIM will only

allow 3 consecutive attempts to enter the correct PIN. If 3 consecutive incorrect

PIN's are entered the SKIM will Lock Out the DRB III for 1 hour.

4. To exit Lock Out mode, the ignition key must remain in the Run position continually for 1

hour. Turn off all accessories and connect a battery charger if necessary.

5. With the DRB III, select Theft Alarm, SKIM and Miscellaneous. Then select desired

procedure and follow the steps that will be displayed.

6. If the SKIM has been replaced, ensure all of the vehicle ignition keys are programmed to the

new SKIM.

7. NOTE: Prior to returning vehicle to the costumer, perform a module scan to be

sure that all DTC's are erased. Erase any DTC's that are found.

8. With the DRB III erase all DTC's. Perform 5 ignition key cycles leaving the key on for at least

90 seconds per cycle.

9. With the DRB III, read the SKIM DTC's.

Are there any SKIM DTC's?All

Ye s®Repair is not complete, refer to appropriate symptom.

No®Repair is complete.

993

VERIFICATION TESTS

Verification Tests ÐContinued

Page 1174 of 4284

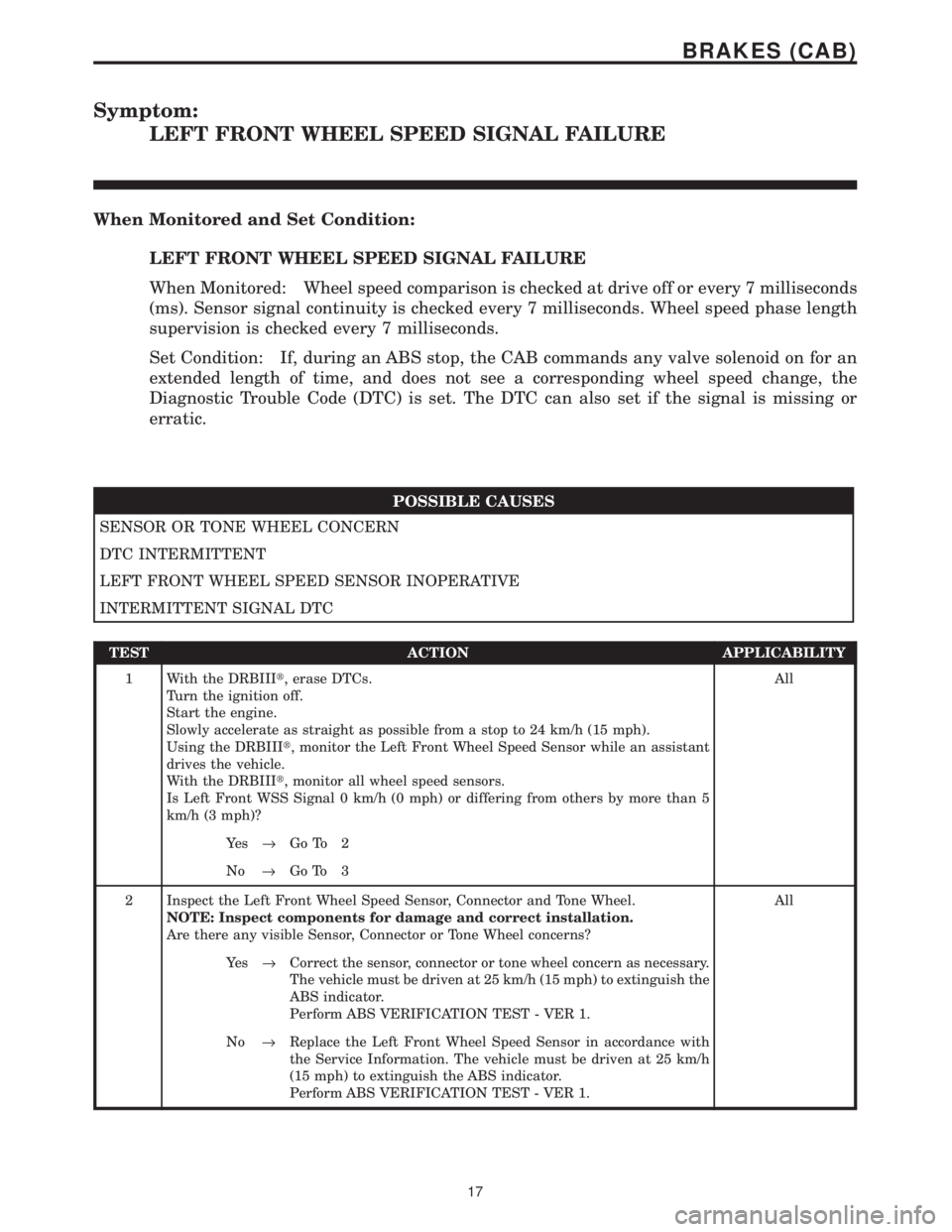

Symptom:

LEFT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

LEFT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Sensor signal continuity is checked every 7 milliseconds. Wheel speed phase length

supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

LEFT FRONT WHEEL SPEED SENSOR INOPERATIVE

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Left Front Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Left Front WSS Signal 0 km/h (0 mph) or differing from others by more than 5

km/h (3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Left Front Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Left Front Wheel Speed Sensor in accordance with

the Service Information. The vehicle must be driven at 25 km/h

(15 mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

17

BRAKES (CAB)

Page 1176 of 4284

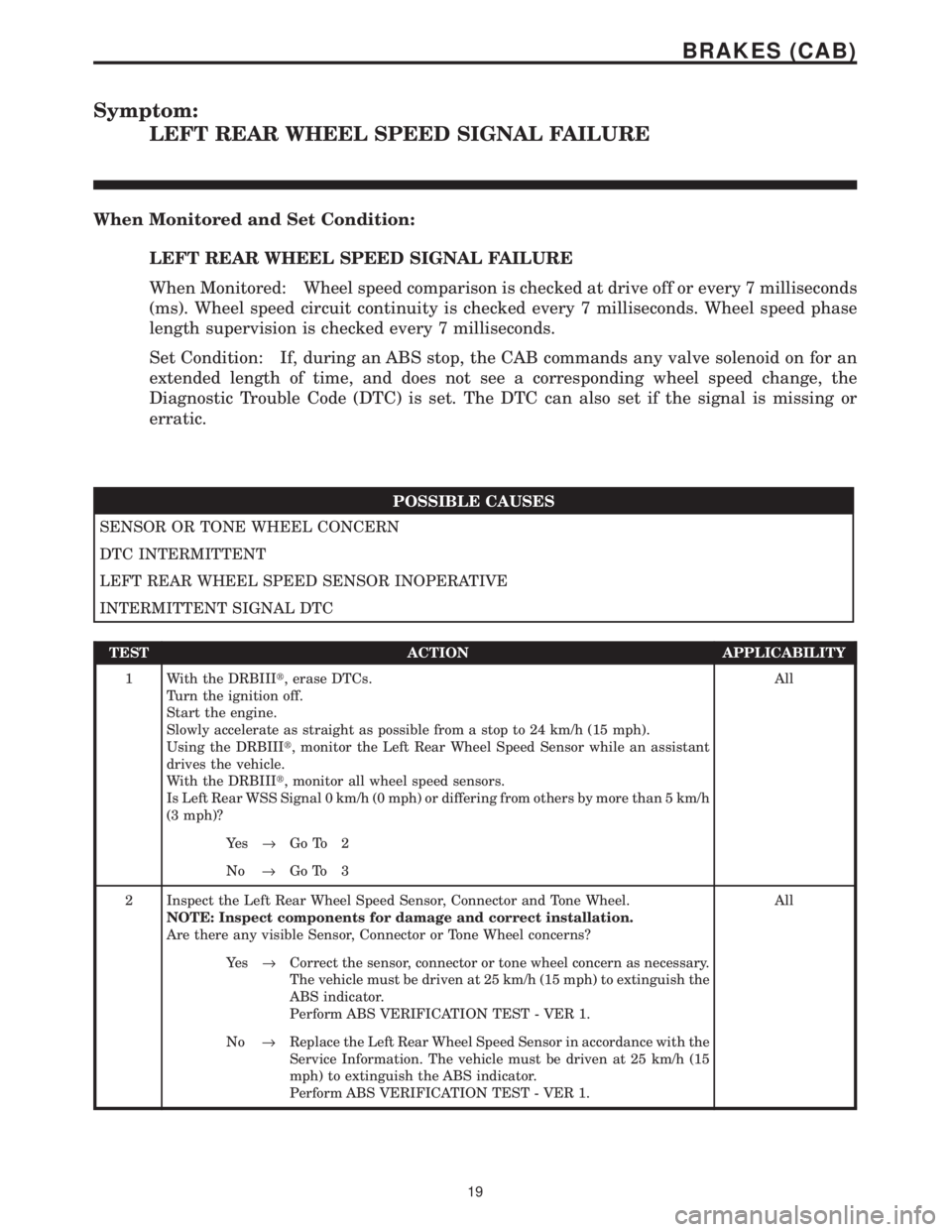

Symptom:

LEFT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

LEFT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Wheel speed circuit continuity is checked every 7 milliseconds. Wheel speed phase

length supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

LEFT REAR WHEEL SPEED SENSOR INOPERATIVE

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Left Rear Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Left Rear WSS Signal 0 km/h (0 mph) or differing from others by more than 5 km/h

(3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Left Rear Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Left Rear Wheel Speed Sensor in accordance with the

Service Information. The vehicle must be driven at 25 km/h (15

mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

19

BRAKES (CAB)

Page 1181 of 4284

Symptom:

RIGHT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

RIGHT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Wheel speed continuity is checked every 7 milliseconds. Wheel speed phase length

supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

RIGHT FRONT WHEEL SPEED SENSOR INOPERATIVE

CAB - WON'T RESPOND TO RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Right Front Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Right Front WSS Signal 0 km/h (0 mph) or differing from others by more than 5

km/h (3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Right Front Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Right Front Wheel Speed Sensor in accordance with

the Service Information. The vehicle must be driven at 25 km/h

(15 mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

24

BRAKES (CAB)

Page 1183 of 4284

Symptom:

RIGHT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

RIGHT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Wheel speed circuit continuity is checked every 7 milliseconds. Wheel speed phase

length supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

RIGHT REAR WHEEL SPEED SENSOR INOPERATIVE

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Right Rear Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Right Rear WSS Signal 0 km/h (0 mph) or differing from others by more than 5

km/h (3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Right Rear Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Left Rear Wheel Speed Sensor in accordance with the

Service Information. The vehicle must be driven at 25 km/h (15

mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

26

BRAKES (CAB)