heating CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2903 of 4284

The downstream heated oxygen sensor threads into

the outlet pipe at the rear of the catalytic convertor

(Fig. 19).

OPERATION

Separate controlled ground circuits are run

through the PCM for the upstream O2 sensors.

As vehicles accumulate mileage, the catalytic con-

vertor deteriorates. The deterioration results in a

less efficient catalyst. To monitor catalytic convertor

deterioration, the fuel injection system uses two

heated oxygen sensors. One sensor upstream of the

catalytic convertor, one downstream of the convertor.

The PCM compares the reading from the sensors to

calculate the catalytic convertor oxygen storage

capacity and converter efficiency. Also, the PCM uses

the upstream heated oxygen sensor input when

adjusting injector pulse width.

When the catalytic converter efficiency drops below

emission standards, the PCM stores a diagnostic

trouble code and illuminates the malfunction indica-

tor lamp (MIL).

The O2S produce voltages from 0 to 1 volt, depend-

ing upon the oxygen content of the exhaust gas in

the exhaust manifold. When a large amount of oxy-

gen is present (caused by a lean air/fuel mixture), the

sensors produces a low voltage. When there is a

lesser amount present (rich air/fuel mixture) it pro-

duces a higher voltage. By monitoring the oxygen

content and converting it to electrical voltage, the

sensors act as a rich-lean switch.The oxygen sensors are equipped with a heating

element that keeps the sensors at proper operating

temperature during all operating modes. Maintaining

correct sensor temperature at all times allows the

system to enter into closed loop operation sooner.

Also, it allows the system to remain in closed loop

operation during periods of extended idle.

In Closed Loop operation the PCM monitors the

O2S input (along with other inputs) and adjusts the

injector pulse width accordingly. During Open Loop

operation the PCM ignores the O2 sensor input. The

PCM adjusts injector pulse width based on prepro-

grammed (fixed) values and inputs from other sen-

sors.

The Automatic Shutdown (ASD) relay supplies bat-

tery voltage to both the upstream and downstream

heated oxygen sensors. The oxygen sensors are

equipped with a heating element. The heating ele-

ments reduce the time required for the sensors to

reach operating temperature.

UPSTREAM OXYGEN SENSOR

The input from the upstream heated oxygen sensor

tells the PCM the oxygen content of the exhaust gas.

Based on this input, the PCM fine tunes the air-fuel

ratio by adjusting injector pulse width.

The sensor input switches from 0 to 1 volt, depend-

ing upon the oxygen content of the exhaust gas in

the exhaust manifold. When a large amount of oxy-

gen is present (caused by a lean air-fuel mixture), the

sensor produces voltage as low as 0.1 volt. When

there is a lesser amount of oxygen present (rich air-

fuel mixture) the sensor produces a voltage as high

as 1.0 volt. By monitoring the oxygen content and

converting it to electrical voltage, the sensor acts as

a rich-lean switch.

The heating element in the sensor provides heat to

the sensor ceramic element. Heating the sensor

allows the system to enter into closed loop operation

sooner. Also, it allows the system to remain in closed

loop operation during periods of extended idle.

In Closed Loop, the PCM adjusts injector pulse

width based on the upstream heated oxygen sensor

input along with other inputs. In Open Loop, the

PCM adjusts injector pulse width based on prepro-

grammed (fixed) values and inputs from other sen-

sors.

DOWNSTREAM OXYGEN SENSOR

The downstream heated oxygen sensor input is

used to detect catalytic convertor deterioration. As

the convertor deteriorates, the input from the down-

stream sensor begins to match the upstream sensor

input except for a slight time delay. By comparing

the downstream heated oxygen sensor input to the

Fig. 19 O2 SENSOR DOWNSTREAM 1/2 - 2.4/3.3/

3.8L

1 - 1/2 02S

2 - 1/1 02S

RSFUEL INJECTION14-31

O2 SENSOR (Continued)

Page 3210 of 4284

FLUID

STANDARD PROCEDURE - FLUID LEVEL AND

CONDITION CHECK

NOTE: Only transmission fluid of the type labeled

Mopar ATF+4 (Automatic Transmission Fluid±Type

9602) should be used in this transaxle.

FLUID LEVEL CHECK

The transmission sump has a fluid level indicator

(dipstick) to check oil similar to most automatic

transmissions. It is located on the left side of the

engine. Be sure to wipe all dirt from dipstick handle

before removing.

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground.At normal operating temperature (approxi-

mately 82 C. or 180 F.), the fluid level is correct if it

is in the HOT region (cross-hatched area) on the oil

level indicator (Fig. 214). The fluid level should be

within the WARM range of the dipstick at 70É F fluid

temperature.

FLUID LEVEL CHECK USING DRB

NOTE: Engine and Transaxle should be at normal

operating temperature before performing this proce-

dure.

(1) Start engine and apply parking brake.

(2) Hook up DRB scan tool and select transmis-

sion.(3) Select sensors.

(4) Read the transmission temperature value.

(5) Compare the fluid temperature value with the

fluid temperature chart (Fig. 215).

(6) Adjust transmission fluid level shown on the

indicator according to the chart.

(7) Check transmission for leaks.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.

FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is proba-

bly required. Be sure to examine the fluid on the dip-

stick closely. If there is any doubt about its condition,

drain out a sample for a double check.

Moparž ATF+4 (Automatic Transmission Fluid-

Type 9602) when new is red in color. The ATF is dyed

red so it can be identified from other fluids used in

the vehicle such as engine oil or antifreeze. The red

color is not permanent and is not an indicator of fluid

condition. As the vehicle is driven, the ATF will begin

to look darker in color and may eventually become

brown. This is normal. A dark brown/black fluid

accompanied with a burnt odor and/or deterioration

in shift quality may indicate fluid deterioration or

transmission component failure.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

STANDARD PROCEDURE - FLUID AND FILTER

SERVICE

NOTE: Refer to the maintenance schedules in

LUBRICATION and MAINTENANCE, or the vehicle

owner's manual, for the recommended maintenance

(fluid/filter change) intervals for this transaxle.

Fig. 214 Transaxle Fluid Level Indicator

1 - TRANSAXLE DIPSTICK

21 - 246 AUTOMATIC - 41TERS

Page 3375 of 4284

CLEANING - TIRES

Before delivery of a vehicle, remove the protective

coating on the tires with white sidewalls or raised

white letters. To remove the protective coating, apply

warm water and let it soak for a few minutes. After-

wards, scrub the coating away with a soft bristle

brush. Steam cleaning may also be used to remove

the coating.

CAUTION: DO NOT use gasoline, mineral oil, oil-

based solvent or a wire brush for cleaning.

WHEELS

DESCRIPTION - WHEEL

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

vehicle capacity.

All models use either steel or aluminum drop-cen-

ter wheels. Every wheel has raised sections between

the rim flanges and rim drop well called safety

humps (Fig. 23). Initial inflation of the tires forces

the bead over these raised sections. In case of air

loss, the safety humps hold the tire in position on the

wheel until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights to fit on the flange of the rim (Fig. 24).

When wheel alignment is necessary on a vehicle

with cast aluminum wheels, special wheel clamps are

required to avoid damage to the wheel's finish.The wheel studs and nuts are designed for specific

wheel applications and must be replaced with equiv-

alent parts.

All aluminum wheels have wheel mounting (lug)

nuts with an enlarged nose. This enlarged nose is

necessary to ensure proper retention of the wheels.

DIAGNOSIS AND TESTING - WHEEL

INSPECTION

Inspect wheels for:

²Excessive runout

²Dents, cracks or irregular bends

²Damaged wheel stud (lug) holes

²Air Leaks

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged, an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE.

WARNING: REPLACEMENT WITH USED WHEELS IS

NOT RECOMMENDED. THE SERVICE HISTORY OF

THE WHEEL MAY HAVE INCLUDED SEVERE TREAT-

MENT OR VERY HIGH MILEAGE. THE RIM COULD

FAIL WITHOUT WARNING.

Fig. 23 Safety Rim

1 - TIRE

2 - WELL

3 - SAFETY HUMPS

4 - FLANGE

Fig. 24 Styled Aluminum Wheel Weight

1 - TIRE

2 - WHEEL

3 - STYLED WHEEL WEIGHT

RSTIRES/WHEELS22-13

TIRES (Continued)

Page 3384 of 4284

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR

Resin Transfer Molded (RTM) body panels are rein-

forced with a continuous fiberglass mesh. Epoxy

resin is injected into a gel-coated and fiberglass lined

mold to form a body panel. Sheet molded compound

(SMC) body panels are constructed with fiberglass

strands usually 1 inch or shorter, epoxy resin formed

into sheet stock and pressed in mold flowing material

to form a sheet molded compound (SMC) body panel.

RTM and SMC body panels can be repaired with

epoxy adhesive after market products. Refer to

instructions provided by the manufacturer of prod-

ucts being used to repair RTM or SMC.

DaimlerChrysler Corporation recommends that a

trained automotive body technician perform body

panel repair procedures (Fig. 1).

SAFETY PRECAUTION AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING RTM AND SMC COMPONENTS.

PERSONAL INJURE CAN RESULT.USE AN OSHA

APPROVED BREATHING DEVICE WHEN MIXING

EPOXY, GRINDING RTM AND SMC, AND SPRAYING

PAINT OR SOLVENTS IN A CONFINED AREA. PER-

SONAL INJURY CAN RESULT.AVOID PROLONGEDSKIN CONTACT WITH EPOXY RESIN, PETROLEUM,

OR ALCOHOL BASED SOLVENTS. PERSONAL

INJURY CAN RESULT.DO NOT VENTURE UNDER A

HOISTED VEHICLE THAT IS NOT PROPERLY SUP-

PORTED ON SAFETY STANDS. PERSONAL INJURY

CAN RESULT.

²When holes must be drilled or cut in body pan-

els, verify locations of internal body components and

electrical wiring. Damage to vehicle can result.

²Do not use abrasive chemicals or compounds on

undamaged painted surfaces around repair areas.

Damage to finish can result.

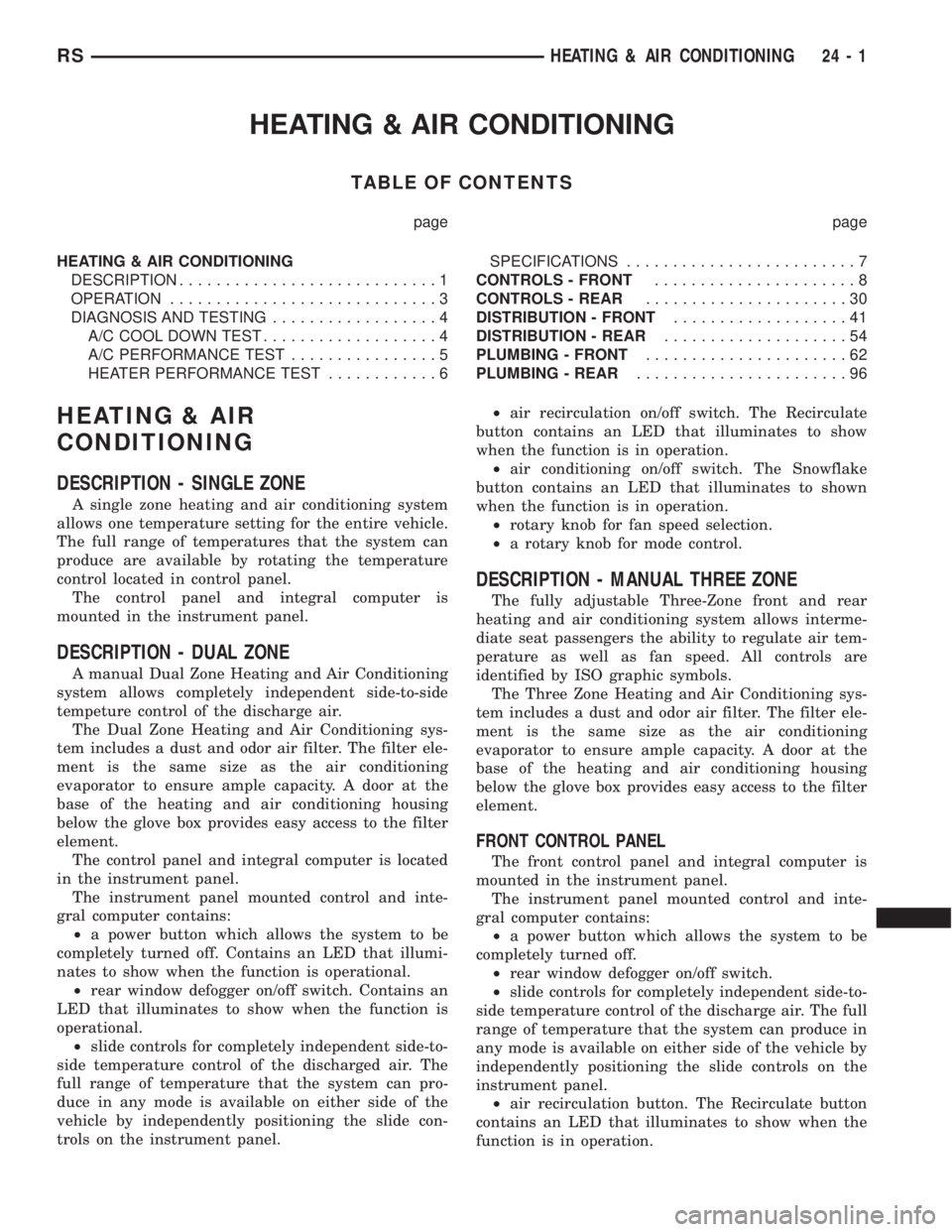

If it is required to section a large panel for an SMC

or RTM repair, it will be necessary to reinforce the

panel with epoxy structural adhesive (rigid repair

adhesive) (Fig. 2). To bond two plastic panels

together, a reinforcement must overlap both panels.

The panels must be ªV'dº at a 20 degree angle. The

area to be reinforced should be washed, then sanded.

Be sure to wipe off any excess soap and water when

finished. Lightly sand or abrade the plastic with an

abrasive pad or sandpaper. Blow off any dust with

compressed air or wipe with a clean dry rag.

When bonding SMC or RTM panels, use a two-part

epoxy adhesive. Properly mix parts A and B, and

apply it to the panels being repaired. Be sure that

enough adhesive has been applied to allow squeeze

out and to fill the full bond line. Once the pieces

have been brought together, do not move them until

the adhesive is cured. The assembly can be held

together with clamps, rivets, etc. A faster cure can be

obtained by heating with a heat lamp or heat gun.

After the parts have been bonded and have had

time to cure, rough sand the seam and apply the

final adhesive filler to the area being repaired.

Fig. 1 Panel Repair

Fig. 2 Panel Sectioning

1 - EXISTING PANEL

2 - NEW PANEL

3 - PANEL ADHESIVE

4 - BONDING STRIP

23 - 4 BODYRS

BODY (Continued)

Page 3631 of 4284

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION............................1

OPERATION.............................3

DIAGNOSIS AND TESTING..................4

A/C COOL DOWN TEST...................4

A/C PERFORMANCE TEST................5

HEATER PERFORMANCE TEST............6SPECIFICATIONS.........................7

CONTROLS - FRONT......................8

CONTROLS - REAR......................30

DISTRIBUTION - FRONT...................41

DISTRIBUTION - REAR....................54

PLUMBING - FRONT......................62

PLUMBING - REAR.......................96

HEATING & AIR

CONDITIONING

DESCRIPTION - SINGLE ZONE

A single zone heating and air conditioning system

allows one temperature setting for the entire vehicle.

The full range of temperatures that the system can

produce are available by rotating the temperature

control located in control panel.

The control panel and integral computer is

mounted in the instrument panel.

DESCRIPTION - DUAL ZONE

A manual Dual Zone Heating and Air Conditioning

system allows completely independent side-to-side

tempeture control of the discharge air.

The Dual Zone Heating and Air Conditioning sys-

tem includes a dust and odor air filter. The filter ele-

ment is the same size as the air conditioning

evaporator to ensure ample capacity. A door at the

base of the heating and air conditioning housing

below the glove box provides easy access to the filter

element.

The control panel and integral computer is located

in the instrument panel.

The instrument panel mounted control and inte-

gral computer contains:

²a power button which allows the system to be

completely turned off. Contains an LED that illumi-

nates to show when the function is operational.

²rear window defogger on/off switch. Contains an

LED that illuminates to show when the function is

operational.

²slide controls for completely independent side-to-

side temperature control of the discharged air. The

full range of temperature that the system can pro-

duce in any mode is available on either side of the

vehicle by independently positioning the slide con-

trols on the instrument panel.²air recirculation on/off switch. The Recirculate

button contains an LED that illuminates to show

when the function is in operation.

²air conditioning on/off switch. The Snowflake

button contains an LED that illuminates to shown

when the function is in operation.

²rotary knob for fan speed selection.

²a rotary knob for mode control.

DESCRIPTION - MANUAL THREE ZONE

The fully adjustable Three-Zone front and rear

heating and air conditioning system allows interme-

diate seat passengers the ability to regulate air tem-

perature as well as fan speed. All controls are

identified by ISO graphic symbols.

The Three Zone Heating and Air Conditioning sys-

tem includes a dust and odor air filter. The filter ele-

ment is the same size as the air conditioning

evaporator to ensure ample capacity. A door at the

base of the heating and air conditioning housing

below the glove box provides easy access to the filter

element.

FRONT CONTROL PANEL

The front control panel and integral computer is

mounted in the instrument panel.

The instrument panel mounted control and inte-

gral computer contains:

²a power button which allows the system to be

completely turned off.

²rear window defogger on/off switch.

²slide controls for completely independent side-to-

side temperature control of the discharge air. The full

range of temperature that the system can produce in

any mode is available on either side of the vehicle by

independently positioning the slide controls on the

instrument panel.

²air recirculation button. The Recirculate button

contains an LED that illuminates to show when the

function is in operation.

RSHEATING & AIR CONDITIONING24-1

Page 3632 of 4284

²an air conditioning button that allows the com-

pressor to be turned on/off. The Snowflake button

contains an LED that illuminates to shown when the

function is in operation.

²rotary knobs for front and rear fan speed selec-

tion.

²a rotary knob for mode control.

REAR CONTROL PANEL

A rear control panel centrally mounted on the

headliner has a rotary adjustment for temperature

and fan speed control of the rear unit by intermedi-

ate seat passengers when the front control rear knob

is set to the rear position.

DESCRIPTION - THREE ZONE Automatic

Temperature Control

The Three-Zone Automatic Temperature Control

(ATC) allows occupants to select a comfort tempera-

ture, which is the perceived temperature level not

the actual passenger compartment air temperature.

The Three Zone Automatic Temperature Control

system includes a dust and odor air filter. The filter

element is the same size as the air conditioning evap-

orator to ensure ample capacity. A door at the base of

the heater and air conditioning housing below the

glove box provides easy access to the filter element.

The ATC computer utilizes integrated circuitry and

information carried on the Programmable Communi-

cations Interface (PCI) data bus network to monitor

many sensors and switch inputs throughout the vehi-

cle. In response to those inputs, the internal circuitry

and programming of the ATC computer allow it to

control electronic functions and features of the ATC

system. The inputs to the ATC computer are:

²Vehicle Speed/Engine RPM± The ATC com-

puter monitors engine RPM, vehicle speed and Man-

ifold Absolute Pressure information from the PCM.

²Coolant Temperature± ATC computer moni-

tors Coolant temperature received from the PCM and

converts it to degrees Fahrenheit.

²Ambient Temperature± ATC computer moni-

tors Ambient temperature from the Compass Mini

Trip Computer (CMTC) and converts it to degrees

Fahrenheit.

²Engine Miscellaneous Sensor Status±ATC

computer monitors A/C disable information from the

PCM.

²Refrigerant Pressure± ATC computer moni-

tors Barometric Pressure, Intake Air Temperature,

High Side Pressure and Methanol Content as broad-

cast by the PCM.

²Door Ajar Status± The ATC computer moni-

tors Driver Front Door, Passenger Front Door, Left

Rear Door, Right Rear Door and Liftgate ajar infor-

mation, as identified by the Body Control Module(BCM), to determine if all in-car temperatures should

be maintained.

²Dimming± The ATC computer monitors dim-

ming status from the BCM to determine the required

level of brightness and will dim accordingly.

²Vehicle Odometer± The ATC computer moni-

tors the vehicle odometer information from the BCM

to prevent flashing the VF tube icons if the manual

motor calibration or manual cooldown tests have

failed. Flashing of the display icons will cease when

the vehicle odometer is greater than 3 miles.

²English Metric± The ATC computer monitors

the English/Metric information broadcast by the

CMTC. The set temp displays for both the front and

rear control heads will be set accordingly.

²Vehicle Identification Number± The ATC

computer monitors the last eight characters of the

VIN broadcast by the PCM and compares it to the

information stored in EEPROM. If it is different, the

new number will be stored over the old one and a

motor calibration shall be initiated.

²A/C System Information± The ATC computer

will send a message for Evaporator Temperature too

Low, Fan Blower Relay status, Evaporator Sensor

Failure, Rear Window Defogger Relay and A/C Select.

FRONT CONTROL PANEL

The front control panel and integral computer is

mounted in the instrument panel.

The instrument panel mounted control and inte-

gral computer contains:

²A power button which allows the system to be

completely turned off. The display is blank when the

system is off.

²Three rocker switches that select comfort tem-

peratures from 15É to 30É C (59É to 85É F), which are

shown in the vacuum-fluorescent digital control dis-

play. If the set temp is 59 and the down button is

pressed, the set temp value will become 55 but the

display will show LO. If the set temp is 85 and the

up button is pressed, the set temp value will become

90 but the display will show HIGH. Temperatures

can be displayed in either metric or fahrenheit,

which is controlled from the overhead console.

²A rocker switch that selects a cool-down rate.

LO-AUTO or HI-AUTO are displayed when the sys-

tem is in automatic operation.

²A defroster button which turns on the defroster

independently during full automatic control. A

defroster symbol illuminates in the display when the

button is pressed.

²Air recirculation button. A Recirculation symbol

appears in the display when the button is pressed, or

when the system exceeds 80 percent circulated air

under automatic control due to high air conditioning

demand.

24 - 2 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

Page 3633 of 4284

²Rear window defogger on/off switch. A graphic

symbol shows when the defroster is on.

²An air conditioning button that allows the com-

pressor to be turned off. A Snowflake symbol is illu-

minated when air conditioning is on, whether under

manual or automatic control.

²Rotary knob for front fan speed selection can

override the automatic controls. LEDs surrounding

the knob show the current setting.

²Rotary knob for control of the Rear system.

²A rotary knob for mode control can override the

automatic controls. LEDs surrounding the knob show

the current setting.

²Computer logic remembers the settings of the

controls when the ignition is turned off and retains

those settings after a restart. If the system is off

when the ignition is turned of, it will be off when the

engine is restarted, etc.

²Computer logic provides variable air recircula-

tion under high temperature and humidity condi-

tions. Because recirculation is generally accompanied

by increased fan noise, the proportion of recirculated

to outside air gradually approaches full recirculation

over a broad temperature range.

²A graphic symbol of the windshield that illumi-

nates when the windshield wiper deicer is active.

REAR CONTROL PANEL

A rear control panel centrally mounted on the

headliner includes a vacuum-flourescent digital dis-

play, a rocker control for temperature and rotary con-

trols for adjustment of mode and fan speed control of

the rear unit by intermediate seat passengers.

OPERATION - DUAL ZONE

²The mode control knob enables continously vari-

able proportioning of air flow between modes but has

detents adjacent to each icon.

²The blower control provides five separate speeds.

²When the fan is off, the HVAC computer closes

the recirculation door to prevent outside air from

entering the passenger compartment.

²Interior air may be recirculated to speed up

heating or cooling in all modes exccept defrost and

mix by pressing the Recirculate button on the control

panel.

²To reduce humidity for rapid defogging the A/C

compressor runs automatically in modes from ªmix'

to full defrost when outside temperautres are above

freezing.

²Air conditioning is available in any mode by

pressing the snowflake, A/C on/off, button.

OPERATION - MANUAL THREE ZONE

FRONT CONTROL PANEL

²Primary control of the rear compartment unit is

on the instrument panel. This control allows the

driver to set the rear compartment fan speed, to turn

the rear unit off, or to give control to the intermedi-

ate seat occupants by switching to the REAR posi-

tion. When the rear unit is controlled from the

instrument panel, rear air temperature is based on

the driver-side temperature control position, and the

mode (floor or overhead air) is based on the front

control's mode position.

²The mode control knob enables continously vari-

able proportioning of air flow between modes but has

detents adjacent to each icon.

²The blower control provides five separate speeds

and Off. When the fan is off, the HVAC computer

closes the recirculation door to prevent outside air

from entering the passenger compartment.

²Interior air may be recirculated to speed up

heating or cooling in all modes exccept defrost and

mix by pressing the Recirculate button on the control

panel.

²To reduce humidity for rapid defogging the A/C

compressor runs automatically in modes from ªmix'

to full defrost when outside temperautres are above

freezing.

²Air conditioning is available in any mode by

pressing the snowflake, A/C on/off, button.

REAR CONTROL PANEL

With the rear control active, temperature selection

dictates indirectly the mode (floor or overhead air) of

the rear unit: a low temperature setting directs flow

to the overhead outlets and a high temperature set-

ting to the floor.

OPERATION - THREE ZONE ATC

Comfort temperature or perceived temperature is

affected by air flow, sun impinging on exposed skin,

etc. The air temperature may be higher or lower than

the comfort temperature. Three infrared sensors, two

in the instrument panel center stack, and one in the

overhead-mounted rear control panel, independently

measure the temperature of the driver, front passen-

ger, and rear compartment occupants to determine

their comfort level relative to the selected comfort

temperature. The HVAC computer in the control

module adjusts the air flow rate and temperature to

maintain the customer-perceived comfort tempera-

ture. The air temperature in the passenger compart-

ment at any time may be slightly higher or lower

than the comfort temperature. For instance, on

sunny summer days the air flow will probably be

cooler than the comfort temperature; on cold or

RSHEATING & AIR CONDITIONING24-3

HEATING & AIR CONDITIONING (Continued)

Page 3634 of 4284

cloudy days and at night it will probably be slightly

warmer. Infrared Three-Zone Temperature Control

provides side-to-side and front-to-rear variation in

comfort temperature settings. The Infrared Three-

Zone Automatic Temperature Control fan provides a

continuously variable air flow rate to meet occupant

comfort requirements.

FRONT CONTROL PANEL

²AUTO HI/LO± This system features two sets of

automatic control logic that allow either a rapid cool-

down rate or a somewhat slower cool-down rate with

less fan noise. HI-AUTO controls the system to reach

its assigned temperature quickly with a higher fan

speed. LO-AUTO controls the system to reach its

assigned temperature somewhat slower with less fan

noise. Both modes will automatically engage auto

recirculation.

²DE-FROST± The front de-frost function is

active when the rear window defogger function is

active or when the defog/defrost mode is selected.

²RECIRC± The RECIRC button will close the

air inlet door. If the system is in auto recirc (indica-

tor being displayed automatically), pressing the man-

ual recirc button will disable the auto recirc function

until one of the auto keys are pressed or the ignition

is cycled. If Auto HI/LO is pressed while manual

recirc is active, manual recirc will be deactivated.

²REAR WINDOW DEFOGGER± Pushing the

button sends a PCI bus message to the Intelligent

Power Module which controls the Rear Window

Defogger and side view mirror (if equipped) circuitry.

The defogger function will be active for 10 minutes

and can be turned off by a switch press. The defogger

will function while the control is in the OFF mode.

²FAN/MODE± The Fan and Mode knobs have

17 manual selectable positions. Manually changing

either of the rotary knobs for mode or fan speed set-

tings makes control of that function alone manual for

as long as the ignition is on. If only one is changed

manually, the other remains under automatic control.

Pressing the HI-AUTO/LO-AUTO rocker switch

restores full automatic control.

²REAR CONTROL± When the Rear System

control knob is moved to the OFF position, there will

be a delay of approximately 1 second before the sys-

tem actually turns off. This delay is to prevent an

undesired blower dropout if the knob is moved

through OFF to the other selections.

²BLOWER DELAY TIMER± The word DELAY

is displayed at start-up to signify that the system is

waiting so that cold air will not be blowing. This tells

the operator that it is unnecessary to turn the sys-

tem off, raise the temperature setting or turn the fan

speed setting down to prevent cold air from blowing.

A countdown in minutes and seconds until the engineis warm enough to begin delivering heat to the pas-

sengers alternates with the DELAY message at 25

second intervals. This countdown is based on actual

measurement of the rate of engine coolant tempera-

ture change. During the delay time, Defrost mode is

selected and the fan operates at a low speed to keep

the windshield fog free.

REAR CONTROL PANEL

Primary control of the rear compartment unit is in

the instrument panel center stack. The rear unit con-

trol knob there allows the driver to turn the rear

unit off, allow control by the intermediate seat occu-

pants by switching to the REAR position, or provide

fully automatic control based on the temperature set-

ting shown on the front control display.

²REAR CONTROL± Selecting automatic control

of the rear unit at the instrument panel, illuminates

a Locked Padlock in the rear control panel display.

Selecting REAR activates the rear control panel and

the Padlock then appears unlocked.

²FAN KNOB± The rear fan control has Off and

AUTO positions and a range of manual speed set-

tings that override the AUTO setting.

²MODE KNOB± The mode control allows inter-

mediate seat occupants to manually override the

automatic mode and select any balance of air flow

between overhead and floor outlets from full over-

head to full floor.

²SET TEMP± The rear set temp control will

operate identical to the front controls. If the front

control rear set temp button is pressed simulta-

neously with the rear control head, then the front

control head press events shall have priority, i.e. if

the front user presses Rear Set Temp down and the

rear user presses Set Temp up, then the rear set

temp will decrease.

DIAGNOSIS AND TESTING - A/C COOL DOWN

TEST

The heater-A/C control module can perform an A/C

cool down test, which is a test performed during the

manufacturing process to confirm that the air condi-

tioning system is performing satisfactorily. This test

can also provide a quick confirmation of air condi-

tioning system performance to the service technician.

If the test is completed satisfactorily, no further ser-

vice is required. If the test is failed, proceed to the

A/C Performance Test to confirm the a/c system is

operating properly, or use a DRBIIItscan tool to

diagnose the A/C system control and distribution sys-

tems. Refer to the appropriate diagnostic informa-

tion.

24 - 4 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

Page 3635 of 4284

MANUAL TEMPERATURE CONTROL

The front blower speed must be set to High and

the evaporator temperature sensor must be greater

than 55É F or the test will fail immediately. The test

is activated by depressing the A/C and PWR buttons

simultaneously and holding them depressed for no

less than five seconds. The PWR and A/C LEDs will

blink on and off until the test is complete. If the

LEDs stop blinking after two minutes, then the cool

down test has been completed successfully. If the two

minutes expire without the evaporator temperature

reaching 20É F less than the outside air temperature,

then the cool down test has been failed and further

A/C system diagnosis is required. If the test is failed,

the LEDs will continue to blink across ignition cycles

until the vehicle has been driven for greater than (3

miles).

AUTOMATIC TEMPERATURE CONTROL

The outside air temperature shown in the ATC dis-

play must not be lower than 53É F or the test will not

begin. The ambient air temperature in the room

where the vehicle will be tested must be a minimum

of 21É C (70ÉF) for this test.The test is activated by

depressing the A/C and PWR buttons simultaneously

and holding them depressed for no less than four sec-

onds. The snowflake icon and the DELAY text in the

ATC display will blink on and off alternately until

the test is complete. If the snowflake icon and the

DELAY text stop blinking after two minutes, then

the cool down test has been completed successfully. If

the two minutes expire without the evaporator tem-

perature reaching 20É F less than the evaporator ini-

tial temperature, then the cool down test has been

failed and further A/C system diagnosis is required.

If the test is failed, the snowflake icon and the

DELAY text will continue to blink across ignition

cycles until the vehicle has been driven for greater

than (3 miles).

DIAGNOSIS AND TESTING - A/C

PERFORMANCE TEST

An air conditioning performance test is the best

way to determine whether the system is performing

up to standard. This test also provides valuable clues

as to the possible cause of trouble with the air con-

ditioning system. The ambient air temperature in the

location where the vehicle will be tested must be a

minimum of 21É C (70ÉF) for this test.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer to monitor the engine

speed.

(2) Remove the caps from the refrigerant system

service ports and attach a manifold gauge set to

monitor the refrigerant system pressures.

(3) Set the heater-air conditioner controls so that

the compressor is engaged, the air within the vehicle

is being recirculated, the output air is directed

through the panel outlets, the temperature control is

in the full cool position, and the blower motor is oper-

ating at its highest speed.

(4) Start the engine and allow the engine to oper-

ate for about five minutes or until it reaches normal

operating temperature. Then hold the engine speed

at 1000 rpm with the compressor clutch engaged. If

the compressor clutch does not engage, proceed with

diagnosis of the compressor clutch coil. (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS -

FRONT/COMPRESSOR CLUTCH COIL - DIAGNO-

SIS AND TESTING).

(5) Close all the vehicle windows and doors.

(6) Insert a thermometer in the left center panel

outlet and operate the engine for five minutes.

(7) With the compressor clutch engaged, record the

left center panel outlet discharge air temperature,

the discharge pressure (high side service port), and

the suction pressure (low side service port). The com-

pressor clutch may cycle, depending upon the ambi-

ent temperature and humidity. If the clutch cycles,

use the readings obtained before the clutch disen-

gaged.

(8) Compare the discharge air temperature read-

ing to the Performance Temperature and Pressure

chart. If the temperature reading is high, check the

refrigerant system for leaks and proper refrigerant

charge level. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - FRONT/REFRIGERANT -

DIAGNOSIS AND TESTING - REFRIGERANT SYS-

TEM LEAKS) and (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - FRONT/REFRIGER-

ANT - DIAGNOSIS AND TESTING - REFRIGER-

ANT SYSTEM CHARGE LEVEL).

RSHEATING & AIR CONDITIONING24-5

HEATING & AIR CONDITIONING (Continued)

Page 3636 of 4284

Performance Temperature and Pressure

Ambient Temperature 21É C

(70É F)27É C

(80É F)32É C

(90É F)38É C

(100É F)43É C

(110É F)

Left Center Panel

Outlet Discharge Air

Temperature1to8ÉC

(34 to 46É F)3to9ÉC

(37 to 49É F)4 to 10ÉC

(39 to 50É F)6to11ÉC

(43 to 52É F)7 to 18É C

(45 to 65É F)

Discharge Pressure

(High Side Service

Port)1034 to 1724

kPa

(150 to 250

psi)1517 to 2275

kPa

(220 to 330

psi)1999 to 2620

kPa

(290 to 380

psi)2068 to 2965

kPa

(300 to 430

psi)2275 to 3421

kPa

(330 to 450 psi)

Suction Pressure (Low

Side Service Port)103 to 207 kPa

(15 to 30 psi)117 to 221 kPa

(17 to 32 psi)138 to 241 kPa

(20 to 35 psi)172 to 269 kPa

(25 to 39 psi)207 to 345 kPa

(30 to 50 psi)

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE TEST

PRE-DIAGNOSTIC PREPARATIONS

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

Check the coolant level, drive belt tension, radiator

air flow, and cooling fan operation. Start the engine

and allow it to warm up to normal temperature.

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With the engine idling at normal running tempera-

ture, set the heater-A/C controls as follows. Temper-

ature control to full Heat, Mode control to Floor,

Blower control to the highest speed setting. Using a

test thermometer, check the air temperature coming

from the center floor outlets and compare this read-

ing to the Temperature Reference table.

TEMPERATURE REFERENCE

AMBIENT

TEMPERATUREMINIMUM FLOOR

OUTLET TEMPERATURE

CELSIUS FAHRENHEIT CELSIUS FAHRENHEIT

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153ÉIf the floor outlet air temperature is insufficient,

check that the cooling system is operating to specifi-

cations. (Refer to 7 - COOLING/ENGINE - DIAGNO-

SIS AND TESTING). Both heater hoses should be

HOT to the touch (the coolant return hose should be

slightly cooler than the supply hose). If the coolant

return hose is much cooler than the supply hose,

locate and repair the engine coolant flow obstruction

in heater system.

POSSIBLE LOCATIONS OR CAUSE OF OBSTRUCTED

COOLANT FLOW

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at cooling system connections.

²Plugged heater core.

²Air locked heater core.

²Restrictor in backwards.

If coolant flow is verified and the heater floor out-

let temperature is insufficient, a mechanical problem

may exist.

POSSIBLE LOCATION OR CAUSE OF INSUFFICIENT HEAT

²Obstructed cowl air intake.

²Obstructed heater system outlets.

²Blend-air door not functioning properly.

TEMPERATURE CONTROL

If heater floor outlet temperature cannot be

adjusted with the heater-A/C control temperature

control lever, one of the following could require ser-

vice:

²Blend-air door binding.

²Faulty blend-air door motor.

²Improper engine coolant temperature.

²Faulty heater-A/C control.

24 - 6 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)