belt CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2056 of 4284

SEAT BELT FIRST ROW

OUTBOARD - LWB FOUR DOOR

REMOVAL

(1) Remove first and second row seats. Refer to

Owner's manual for proper procedures.

(2) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(3) Slide floor anchor cover from over the anchor

bolt.

(4) Remove floor anchor bolt.

(5) Remove anchor from floor.

(6) Open clam shell cover from over seat belt turn-

ing loop.

(7) Remove bolt attaching turning loop to shoulder

belt height adjuster.

(8) Remove turning loop from C-pillar.

(9) Remove lower quarter trim panel.

(10) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(11) Remove bolt attaching seat belt retractor to

quarter panel.(12) Lift retractor upward and disengage arrow

head retainer attaching retractor to quarter panel.

(13) Remove seat belt from vehicle.

INSTALLATION

(1) Position seat belt to vehicle.

(2) Install arrow head retainer to quarter panel

and push downward to seat retainer.

(3) Install bolt attaching seat belt retractor to

quarter panel.

(4) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(5) Install lower quarter trim panel.

(6) Position turning loop to C-pillar.

(7) Install bolt attaching turning loop to shoulder

belt height adjuster.

(8) Close clam shell cover from over seat belt turn-

ing loop.

(9) Position anchor to floor.

(10) Install floor anchor bolt.

(11) Slide floor anchor cover over the anchor bolt.

(12) Install shoulder harness height adjuster knob

by pushing it straight onto adjuster.

(13) Install first and second row seats. Refer to

Owner's manual for proper procedures.

NOTE: The tightening specification for all seat belt

anchor bolts is 39 N´m (29 ft. lbs.) torque.

SEAT BELT SECOND RIGHT

ROW OUTBOARD - LWB

REMOVAL

(1) Remove second row seat from vehicle. Refer to

Owner's Manual for proper procedures.

(2) Slide lower anchor cover from over the anchor

shoulder-nut.

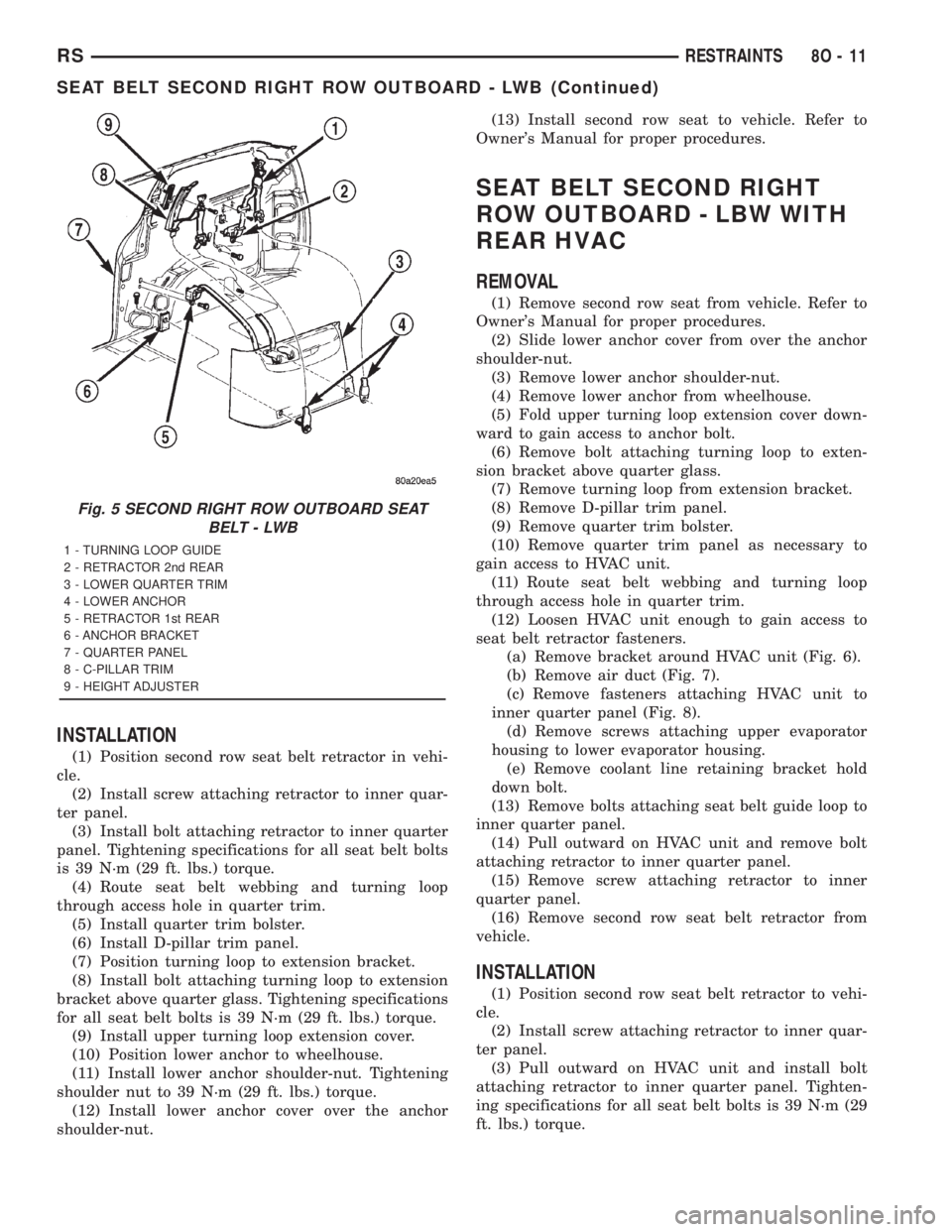

(3) Remove lower anchor shoulder-nut (Fig. 5).

(4) Remove lower anchor from wheelhouse.

(5) Fold upper turning loop extension cover down-

ward to gain access to anchor bolt.

(6) Remove bolt attaching turning loop to exten-

sion bracket above quarter glass (Fig. 5).

(7) Remove turning loop from extension bracket.

(8) Remove D-pillar trim panel.

(9) Remove quarter trim bolster.

(10) Route seat belt webbing and turning loop

through access hole in quarter trim.

(11) Remove bolt attaching retractor to inner quar-

ter panel (Fig. 5).

(12) Remove screw attaching retractor to inner

quarter panel.

(13) Remove second row seat belt retractor from

vehicle.

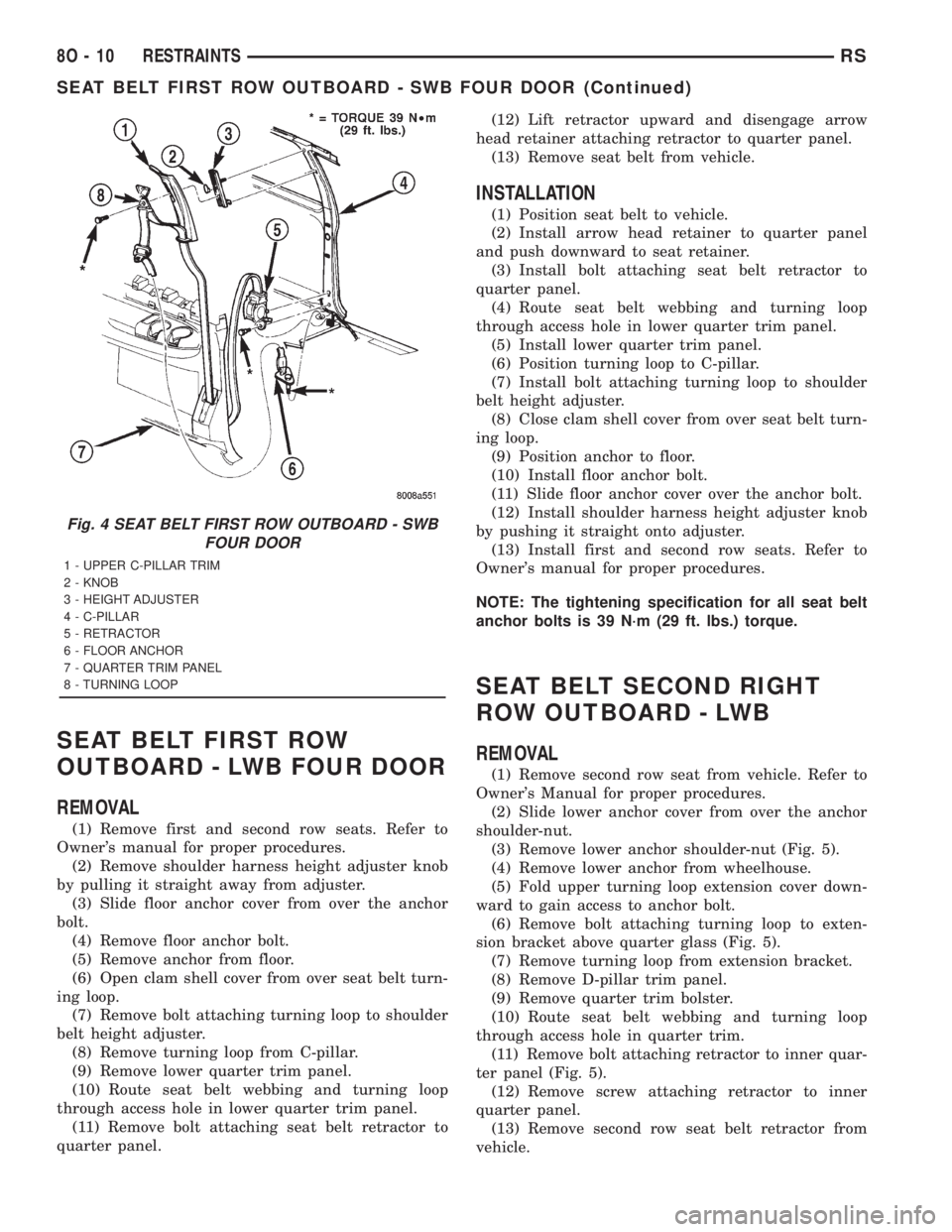

Fig. 4 SEAT BELT FIRST ROW OUTBOARD - SWB

FOUR DOOR

1 - UPPER C-PILLAR TRIM

2 - KNOB

3 - HEIGHT ADJUSTER

4 - C-PILLAR

5 - RETRACTOR

6 - FLOOR ANCHOR

7 - QUARTER TRIM PANEL

8 - TURNING LOOP

8O - 10 RESTRAINTSRS

SEAT BELT FIRST ROW OUTBOARD - SWB FOUR DOOR (Continued)

Page 2057 of 4284

INSTALLATION

(1) Position second row seat belt retractor in vehi-

cle.

(2) Install screw attaching retractor to inner quar-

ter panel.

(3) Install bolt attaching retractor to inner quarter

panel. Tightening specifications for all seat belt bolts

is 39 N´m (29 ft. lbs.) torque.

(4) Route seat belt webbing and turning loop

through access hole in quarter trim.

(5) Install quarter trim bolster.

(6) Install D-pillar trim panel.

(7) Position turning loop to extension bracket.

(8) Install bolt attaching turning loop to extension

bracket above quarter glass. Tightening specifications

for all seat belt bolts is 39 N´m (29 ft. lbs.) torque.

(9) Install upper turning loop extension cover.

(10) Position lower anchor to wheelhouse.

(11) Install lower anchor shoulder-nut. Tightening

shoulder nut to 39 N´m (29 ft. lbs.) torque.

(12) Install lower anchor cover over the anchor

shoulder-nut.(13) Install second row seat to vehicle. Refer to

Owner's Manual for proper procedures.

SEAT BELT SECOND RIGHT

ROW OUTBOARD - LBW WITH

REAR HVAC

REMOVAL

(1) Remove second row seat from vehicle. Refer to

Owner's Manual for proper procedures.

(2) Slide lower anchor cover from over the anchor

shoulder-nut.

(3) Remove lower anchor shoulder-nut.

(4) Remove lower anchor from wheelhouse.

(5) Fold upper turning loop extension cover down-

ward to gain access to anchor bolt.

(6) Remove bolt attaching turning loop to exten-

sion bracket above quarter glass.

(7) Remove turning loop from extension bracket.

(8) Remove D-pillar trim panel.

(9) Remove quarter trim bolster.

(10) Remove quarter trim panel as necessary to

gain access to HVAC unit.

(11) Route seat belt webbing and turning loop

through access hole in quarter trim.

(12) Loosen HVAC unit enough to gain access to

seat belt retractor fasteners.

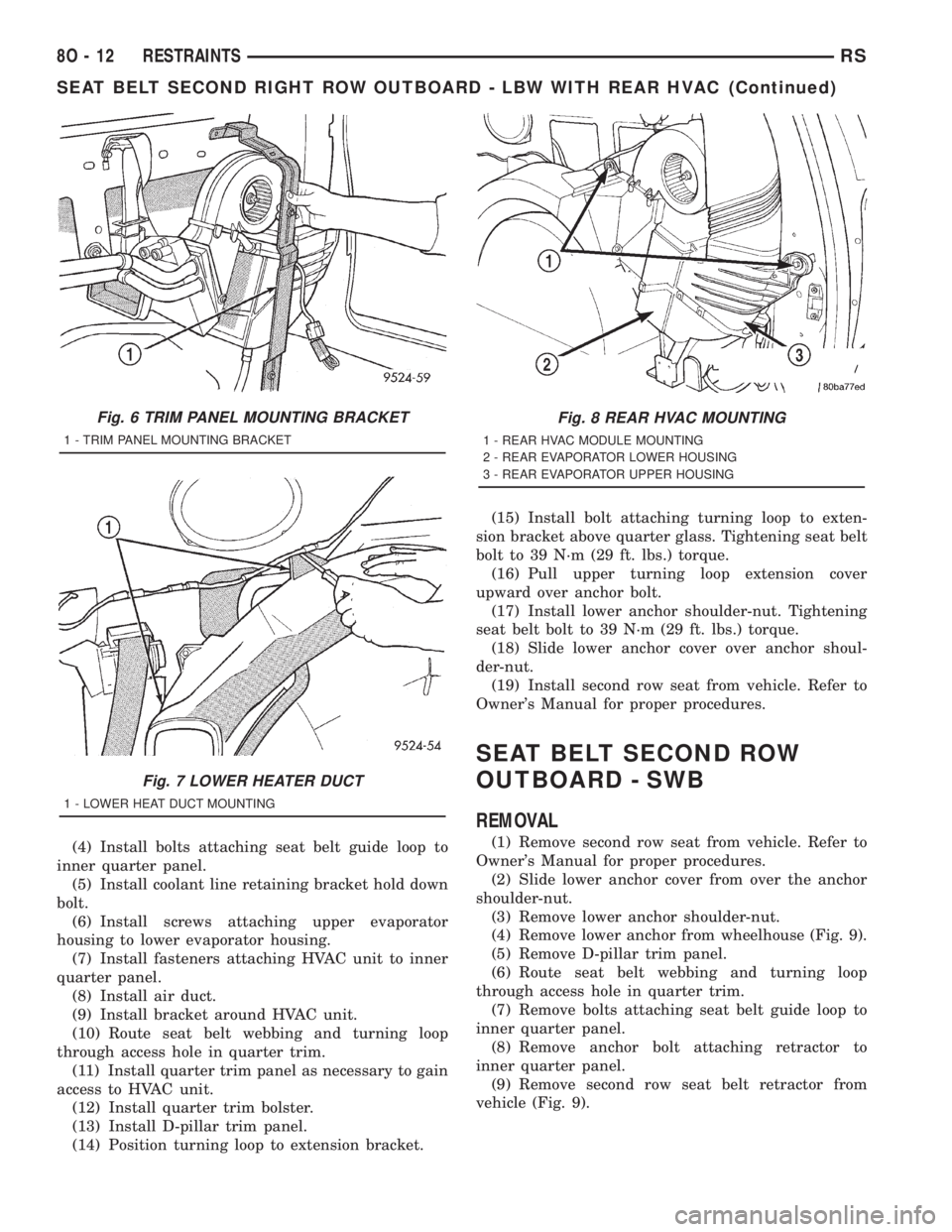

(a) Remove bracket around HVAC unit (Fig. 6).

(b) Remove air duct (Fig. 7).

(c) Remove fasteners attaching HVAC unit to

inner quarter panel (Fig. 8).

(d) Remove screws attaching upper evaporator

housing to lower evaporator housing.

(e) Remove coolant line retaining bracket hold

down bolt.

(13) Remove bolts attaching seat belt guide loop to

inner quarter panel.

(14) Pull outward on HVAC unit and remove bolt

attaching retractor to inner quarter panel.

(15) Remove screw attaching retractor to inner

quarter panel.

(16) Remove second row seat belt retractor from

vehicle.

INSTALLATION

(1) Position second row seat belt retractor to vehi-

cle.

(2) Install screw attaching retractor to inner quar-

ter panel.

(3) Pull outward on HVAC unit and install bolt

attaching retractor to inner quarter panel. Tighten-

ing specifications for all seat belt bolts is 39 N´m (29

ft. lbs.) torque.

Fig. 5 SECOND RIGHT ROW OUTBOARD SEAT

BELT - LWB

1 - TURNING LOOP GUIDE

2 - RETRACTOR 2nd REAR

3 - LOWER QUARTER TRIM

4 - LOWER ANCHOR

5 - RETRACTOR 1st REAR

6 - ANCHOR BRACKET

7 - QUARTER PANEL

8 - C-PILLAR TRIM

9 - HEIGHT ADJUSTER

RSRESTRAINTS8O-11

SEAT BELT SECOND RIGHT ROW OUTBOARD - LWB (Continued)

Page 2058 of 4284

(4) Install bolts attaching seat belt guide loop to

inner quarter panel.

(5) Install coolant line retaining bracket hold down

bolt.

(6) Install screws attaching upper evaporator

housing to lower evaporator housing.

(7) Install fasteners attaching HVAC unit to inner

quarter panel.

(8) Install air duct.

(9) Install bracket around HVAC unit.

(10) Route seat belt webbing and turning loop

through access hole in quarter trim.

(11) Install quarter trim panel as necessary to gain

access to HVAC unit.

(12) Install quarter trim bolster.

(13) Install D-pillar trim panel.

(14) Position turning loop to extension bracket.(15) Install bolt attaching turning loop to exten-

sion bracket above quarter glass. Tightening seat belt

bolt to 39 N´m (29 ft. lbs.) torque.

(16) Pull upper turning loop extension cover

upward over anchor bolt.

(17) Install lower anchor shoulder-nut. Tightening

seat belt bolt to 39 N´m (29 ft. lbs.) torque.

(18) Slide lower anchor cover over anchor shoul-

der-nut.

(19) Install second row seat from vehicle. Refer to

Owner's Manual for proper procedures.

SEAT BELT SECOND ROW

OUTBOARD - SWB

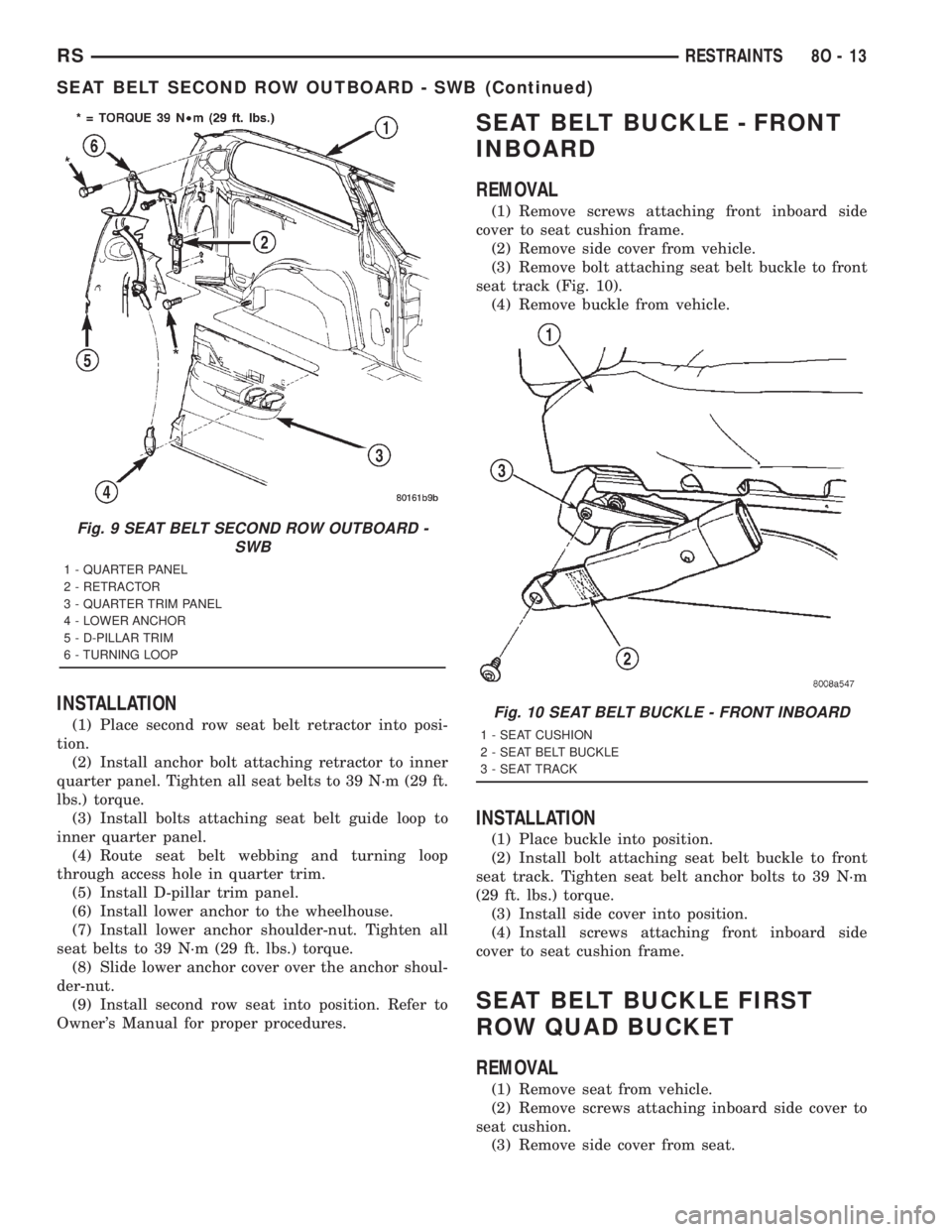

REMOVAL

(1) Remove second row seat from vehicle. Refer to

Owner's Manual for proper procedures.

(2) Slide lower anchor cover from over the anchor

shoulder-nut.

(3) Remove lower anchor shoulder-nut.

(4) Remove lower anchor from wheelhouse (Fig. 9).

(5) Remove D-pillar trim panel.

(6) Route seat belt webbing and turning loop

through access hole in quarter trim.

(7) Remove bolts attaching seat belt guide loop to

inner quarter panel.

(8) Remove anchor bolt attaching retractor to

inner quarter panel.

(9) Remove second row seat belt retractor from

vehicle (Fig. 9).

Fig. 6 TRIM PANEL MOUNTING BRACKET

1 - TRIM PANEL MOUNTING BRACKET

Fig. 7 LOWER HEATER DUCT

1 - LOWER HEAT DUCT MOUNTING

Fig. 8 REAR HVAC MOUNTING

1 - REAR HVAC MODULE MOUNTING

2 - REAR EVAPORATOR LOWER HOUSING

3 - REAR EVAPORATOR UPPER HOUSING

8O - 12 RESTRAINTSRS

SEAT BELT SECOND RIGHT ROW OUTBOARD - LBW WITH REAR HVAC (Continued)

Page 2059 of 4284

INSTALLATION

(1) Place second row seat belt retractor into posi-

tion.

(2) Install anchor bolt attaching retractor to inner

quarter panel. Tighten all seat belts to 39 N´m (29 ft.

lbs.) torque.

(3) Install bolts attaching seat belt guide loop to

inner quarter panel.

(4) Route seat belt webbing and turning loop

through access hole in quarter trim.

(5) Install D-pillar trim panel.

(6) Install lower anchor to the wheelhouse.

(7) Install lower anchor shoulder-nut. Tighten all

seat belts to 39 N´m (29 ft. lbs.) torque.

(8) Slide lower anchor cover over the anchor shoul-

der-nut.

(9) Install second row seat into position. Refer to

Owner's Manual for proper procedures.

SEAT BELT BUCKLE - FRONT

INBOARD

REMOVAL

(1) Remove screws attaching front inboard side

cover to seat cushion frame.

(2) Remove side cover from vehicle.

(3) Remove bolt attaching seat belt buckle to front

seat track (Fig. 10).

(4) Remove buckle from vehicle.

INSTALLATION

(1) Place buckle into position.

(2) Install bolt attaching seat belt buckle to front

seat track. Tighten seat belt anchor bolts to 39 N´m

(29 ft. lbs.) torque.

(3) Install side cover into position.

(4) Install screws attaching front inboard side

cover to seat cushion frame.

SEAT BELT BUCKLE FIRST

ROW QUAD BUCKET

REMOVAL

(1) Remove seat from vehicle.

(2) Remove screws attaching inboard side cover to

seat cushion.

(3) Remove side cover from seat.

Fig. 9 SEAT BELT SECOND ROW OUTBOARD -

SWB

1 - QUARTER PANEL

2 - RETRACTOR

3 - QUARTER TRIM PANEL

4 - LOWER ANCHOR

5 - D-PILLAR TRIM

6 - TURNING LOOP

Fig. 10 SEAT BELT BUCKLE - FRONT INBOARD

1 - SEAT CUSHION

2 - SEAT BELT BUCKLE

3 - SEAT TRACK

RSRESTRAINTS8O-13

SEAT BELT SECOND ROW OUTBOARD - SWB (Continued)

Page 2060 of 4284

(4) Remove bolts attaching recliner bracket to seat

cushion.

(5) Remove recliner bracket from seat.

(6) Remove bolt attaching seat belt buckle to seat

track (Fig. 10).

(7) Remove buckle from vehicle.

INSTALLATION

(1) Place buckle into position.

(2) Install bolt attaching seat belt buckle to seat

track. Tighten all seat belt anchor bolts to 39 N´m

(29 ft. lbs.) torque.

(3) Install recliner bracket onto the seat.

(4) Install bolts attaching recliner bracket to seat

cushion.

(5) Install side cover from seat.

(6) Install screws attaching inboard side cover to

seat cushion.

(7) Install seat into position. Tighten all seat belt

anchor bolts to 39 N´m (29 ft. lbs.) torque.

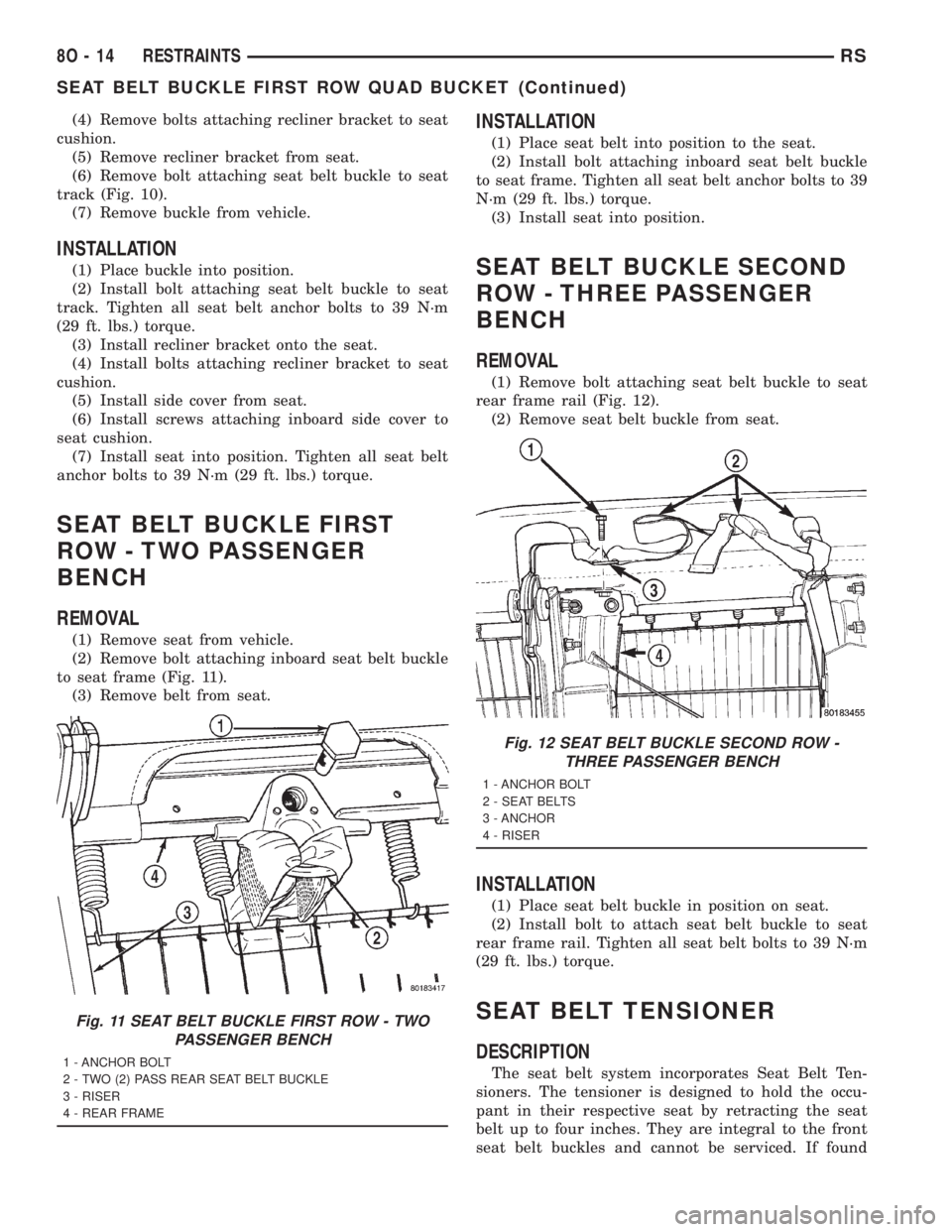

SEAT BELT BUCKLE FIRST

ROW - TWO PASSENGER

BENCH

REMOVAL

(1) Remove seat from vehicle.

(2) Remove bolt attaching inboard seat belt buckle

to seat frame (Fig. 11).

(3) Remove belt from seat.

INSTALLATION

(1) Place seat belt into position to the seat.

(2) Install bolt attaching inboard seat belt buckle

to seat frame. Tighten all seat belt anchor bolts to 39

N´m (29 ft. lbs.) torque.

(3) Install seat into position.

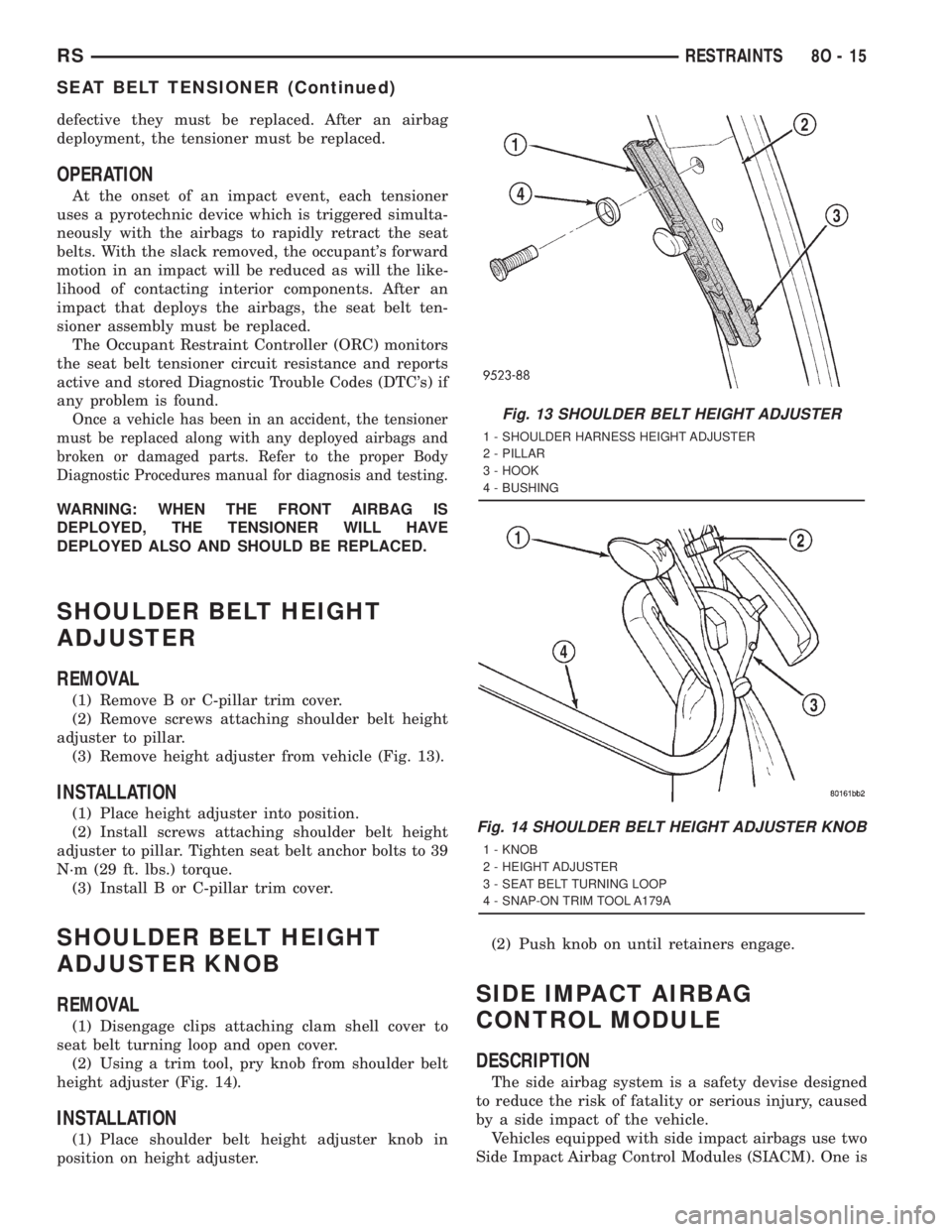

SEAT BELT BUCKLE SECOND

ROW - THREE PASSENGER

BENCH

REMOVAL

(1) Remove bolt attaching seat belt buckle to seat

rear frame rail (Fig. 12).

(2) Remove seat belt buckle from seat.

INSTALLATION

(1) Place seat belt buckle in position on seat.

(2) Install bolt to attach seat belt buckle to seat

rear frame rail. Tighten all seat belt bolts to 39 N´m

(29 ft. lbs.) torque.

SEAT BELT TENSIONER

DESCRIPTION

The seat belt system incorporates Seat Belt Ten-

sioners. The tensioner is designed to hold the occu-

pant in their respective seat by retracting the seat

belt up to four inches. They are integral to the front

seat belt buckles and cannot be serviced. If found

Fig. 11 SEAT BELT BUCKLE FIRST ROW - TWO

PASSENGER BENCH

1 - ANCHOR BOLT

2 - TWO (2) PASS REAR SEAT BELT BUCKLE

3 - RISER

4 - REAR FRAME

Fig. 12 SEAT BELT BUCKLE SECOND ROW -

THREE PASSENGER BENCH

1 - ANCHOR BOLT

2 - SEAT BELTS

3 - ANCHOR

4 - RISER

8O - 14 RESTRAINTSRS

SEAT BELT BUCKLE FIRST ROW QUAD BUCKET (Continued)

Page 2061 of 4284

defective they must be replaced. After an airbag

deployment, the tensioner must be replaced.

OPERATION

At the onset of an impact event, each tensioner

uses a pyrotechnic device which is triggered simulta-

neously with the airbags to rapidly retract the seat

belts. With the slack removed, the occupant's forward

motion in an impact will be reduced as will the like-

lihood of contacting interior components. After an

impact that deploys the airbags, the seat belt ten-

sioner assembly must be replaced.

The Occupant Restraint Controller (ORC) monitors

the seat belt tensioner circuit resistance and reports

active and stored Diagnostic Trouble Codes (DTC's) if

any problem is found.

Once a vehicle has been in an accident, the tensioner

must be replaced along with any deployed airbags and

broken or damaged parts. Refer to the proper Body

Diagnostic Procedures manual for diagnosis and testing.

WARNING: WHEN THE FRONT AIRBAG IS

DEPLOYED, THE TENSIONER WILL HAVE

DEPLOYED ALSO AND SHOULD BE REPLACED.

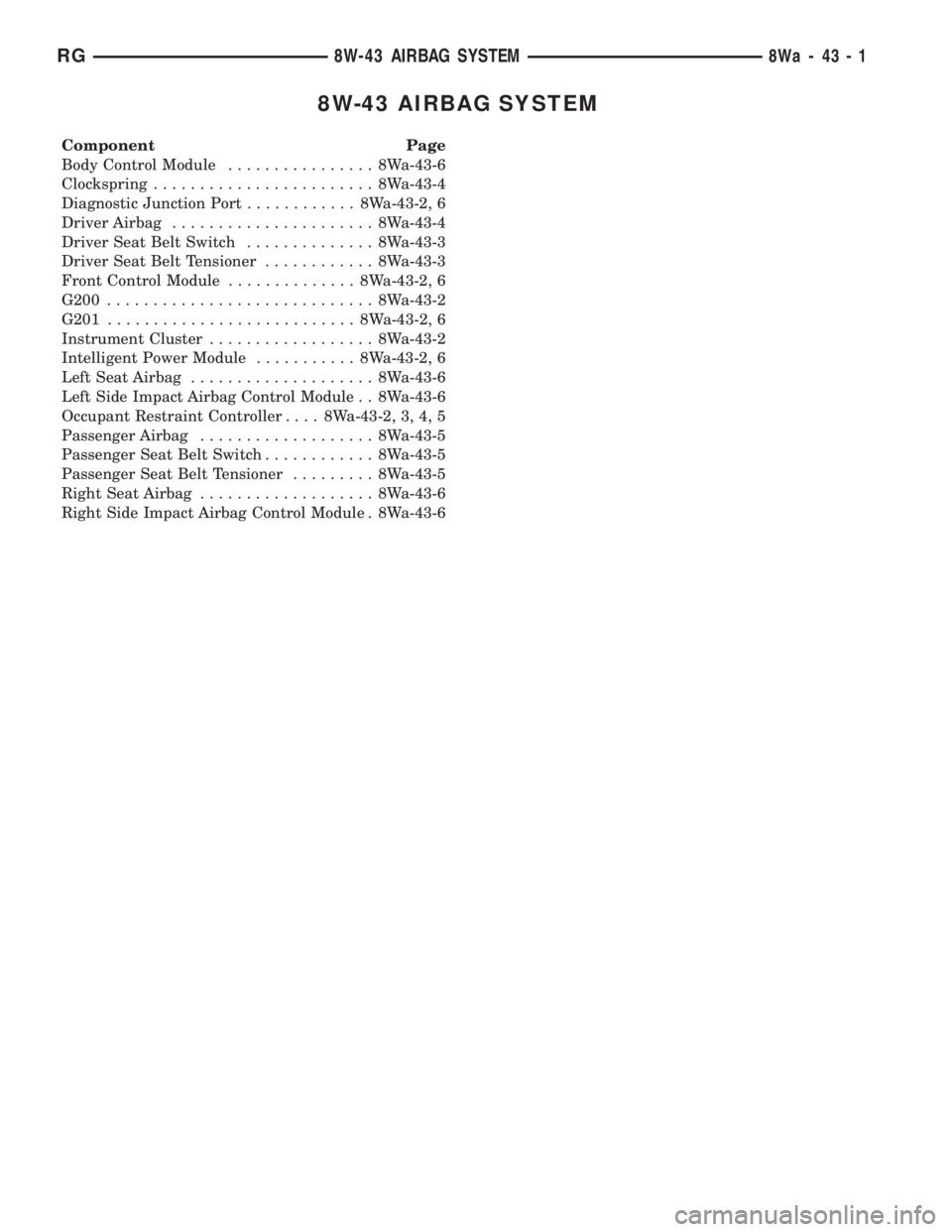

SHOULDER BELT HEIGHT

ADJUSTER

REMOVAL

(1) Remove B or C-pillar trim cover.

(2) Remove screws attaching shoulder belt height

adjuster to pillar.

(3) Remove height adjuster from vehicle (Fig. 13).

INSTALLATION

(1) Place height adjuster into position.

(2) Install screws attaching shoulder belt height

adjuster to pillar. Tighten seat belt anchor bolts to 39

N´m (29 ft. lbs.) torque.

(3) Install B or C-pillar trim cover.

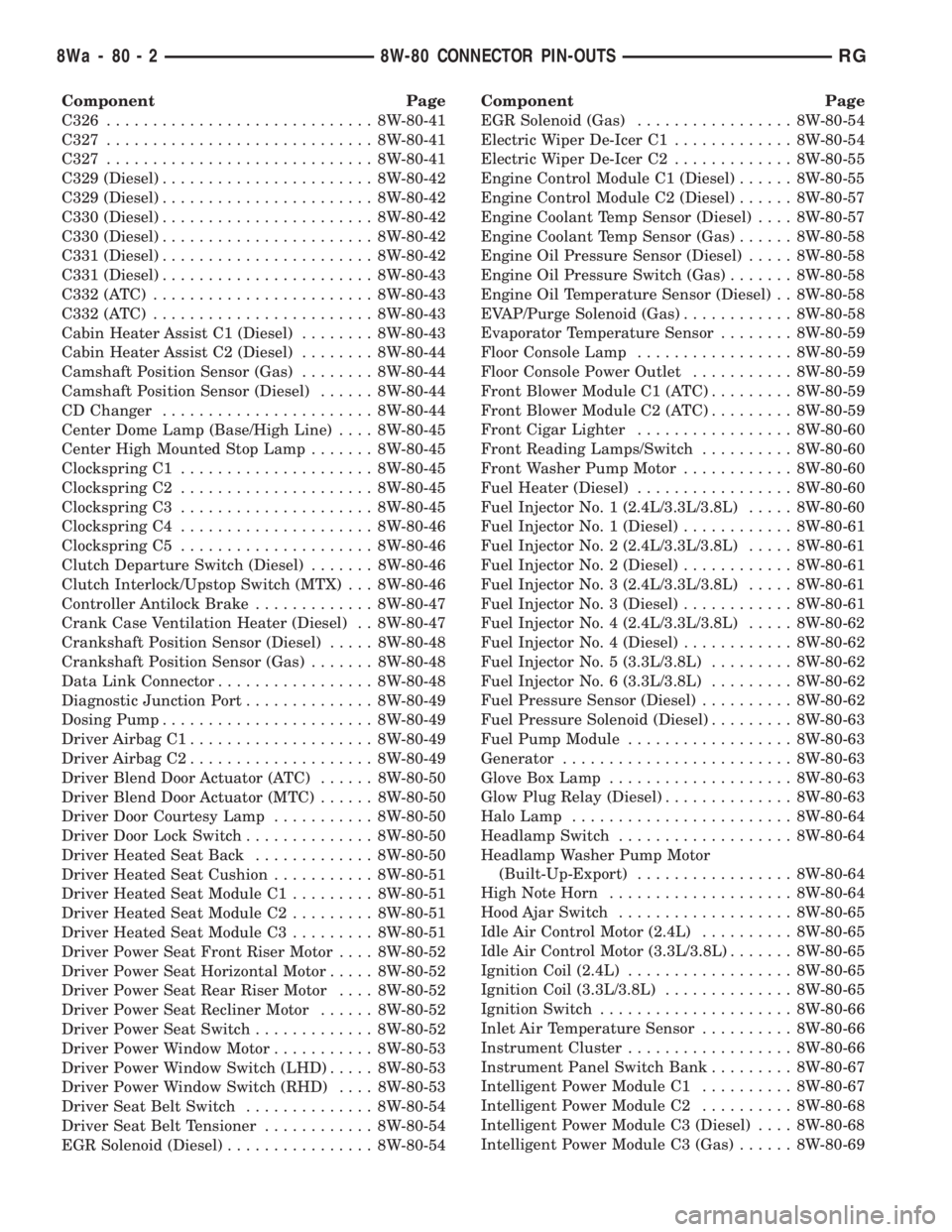

SHOULDER BELT HEIGHT

ADJUSTER KNOB

REMOVAL

(1) Disengage clips attaching clam shell cover to

seat belt turning loop and open cover.

(2) Using a trim tool, pry knob from shoulder belt

height adjuster (Fig. 14).

INSTALLATION

(1) Place shoulder belt height adjuster knob in

position on height adjuster.(2) Push knob on until retainers engage.

SIDE IMPACT AIRBAG

CONTROL MODULE

DESCRIPTION

The side airbag system is a safety devise designed

to reduce the risk of fatality or serious injury, caused

by a side impact of the vehicle.

Vehicles equipped with side impact airbags use two

Side Impact Airbag Control Modules (SIACM). One is

Fig. 13 SHOULDER BELT HEIGHT ADJUSTER

1 - SHOULDER HARNESS HEIGHT ADJUSTER

2 - PILLAR

3 - HOOK

4 - BUSHING

Fig. 14 SHOULDER BELT HEIGHT ADJUSTER KNOB

1 - KNOB

2 - HEIGHT ADJUSTER

3 - SEAT BELT TURNING LOOP

4 - SNAP-ON TRIM TOOL A179A

RSRESTRAINTS8O-15

SEAT BELT TENSIONER (Continued)

Page 2091 of 4284

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD .................Left Hand Drive Vehicles

RHD................Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX....Manual Transmissions-Front Wheel Drive

AT ....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export.......... Vehicles Built For Sale

In Markets Other Than North America

Except-Built-Up-Export.... Vehicles Built For Sale

In North America

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING:: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.

WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND LOOSE CLOTH-

ING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

resistance in these circuits use a meter with a 10 -

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle's

electrical system can cause damage to the equip-

ment and provide false readings.

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 4)Select the proper size

tool from Special Tool Package 6807, and insert it

into the terminal being tested. Use the other end of

the tool to insert the meter probe.

RG8W-01 WIRING DIAGRAM INFORMATION8Wa-01-5

WIRING DIAGRAM INFORMATION (Continued)

Page 2100 of 4284

Component Page

Ignition Switch....................... 8Wa-10

Inlet Air Temperature Sensor............ 8Wa-30

Instrument Cluster................... 8Wa-40

Instrument Panel Switch Bank . . 8Wa-44, 52, 53, 63

Intelligent Power Module............... 8Wa-10

Knock Sensor........................ 8Wa-30

Leak Detection Pump.................. 8Wa-30

License Lamp........................ 8Wa-51

Lift Pump Motor..................... 8Wa-30

Lift Pump Relay...................... 8Wa-30

Liftgate Ajar Switch................... 8Wa-61

Liftgate Cinch/Release Motor............ 8Wa-61

Liftgate Cylinder Lock Switch........... 8Wa-39

Liftgate Flood Lamps.................. 8Wa-44

Liftgate Left Pinch Sensor.............. 8Wa-61

Low Beam Lamps.................... 8Wa-50

Manifold Absolute Pressure Sensor....... 8Wa-30

Mass Air Flow Sensor................. 8Wa-30

Memory Power Seat Switch............. 8Wa-63

Memory Seat Front Vertical Motor........ 8Wa-63

Memory Seat Front Vertical Position

Sensor........................... 8Wa-63

Memory Seat Horizontal Motor.......... 8Wa-63

Memory Seat Horizontal Position Sensor . . . 8Wa-63

Memory Seat Rear Vertical Motor........ 8Wa-63

Memory Seat Rear Vertical Position

Sensor........................... 8Wa-63

Memory Seat Recliner Motor............ 8Wa-63

Memory Seat Recliner Position Sensor..... 8Wa-63

Memory Seat Switch.................. 8Wa-63

Memory Seat/Mirror Module............ 8Wa-62

Message Center...................... 8Wa-46

Mode Door Actuator................... 8Wa-42

Multi- Function Switch................ 8Wa-50

Name Brand Speaker Relay............. 8Wa-47

Occupant Restraint Controller........... 8Wa-43

Overhead Console.................... 8Wa-49

Oxygen Sensors...................... 8Wa-30

Park Lamp Relay..................... 8Wa-10

Park Lamps......................... 8Wa-50

Park/Neutral Position Switch............ 8Wa-31

Park/Turn Signal Lamps............... 8Wa-50

Parking Brake Switch................. 8Wa-40

Passenger Folding Mirror Relay.......... 8Wa-62

Power Folding Mirror Switch............ 8Wa-62

Power Liftgate Motor.................. 8Wa-61

Power Mirror Switch.................. 8Wa-62

Power Mirrors....................... 8Wa-62

Power Outlets....................... 8Wa-41

Power Seat Circuit Breaker............. 8Wa-10

Power Seat Front Riser Motors.......... 8Wa-63

Power Seat Horizontal Motors........... 8Wa-63

Power Seat Rear Riser Motors........... 8Wa-63

Power Seat Recliner Motors............. 8Wa-63Component Page

Power Seat Switches.................. 8Wa-63

Power Window Circuit Breaker.......... 8Wa-10

Power Window Motors................. 8Wa-60

Power Window Switches................ 8Wa-60

Powertrain Control Module............. 8Wa-30

PTC ............................... 8Wa-10

Radiator Fan Relays.................. 8Wa-42

Radiator Fans....................... 8Wa-42

Radio Choke......................... 8Wa-47

Radio.............................. 8Wa-47

Reading Lamps...................... 8Wa-44

Rear A/C-Heater Unit................. 8Wa-42

Rear Auto Temp Control Switch.......... 8Wa-42

Rear Blower Front Control Switch........ 8Wa-42

Rear Blower Motor Power Module........ 8Wa-42

Rear Blower Motor Relay............... 8Wa-42

Rear Blower Motor.................... 8Wa-42

Rear Blower Rear Control Switch........ 8Wa-42

Rear Intrusion Sensor................. 8Wa-39

Rear Lamp Assemblies................. 8Wa-51

Rear Mode Motor..................... 8Wa-42

Rear Temperature Motor............... 8Wa-42

Rear Washer Pump Motor.............. 8Wa-53

Rear Window Defogger Grid............. 8Wa-48

Rear Wiper Motor.................... 8Wa-53

Recirculation Door Actuator............. 8Wa-42

Remote Keyless Entry Antenna.......... 8Wa-61

Remote Keyless Entry Module........... 8Wa-61

Remote Radio Switches................ 8Wa-47

Repeater Lamps...................... 8Wa-52

Seat Airbags......................... 8Wa-43

Seat Belt Switches.................... 8Wa-43

Seat Belt Tensioners.................. 8Wa-43

Sentry Key Immobilizer Module.......... 8Wa-39

Side Impact Airbag Control Module....... 8Wa-43

Siren.............................. 8Wa-39

Sliding Door Control Modules........... 8Wa-61

Sliding Door Latch Sensing Switches...... 8Wa-61

Sliding Door Lock Motor/Ajar Switches.... 8Wa-61

Sliding Door Lock Motors............... 8Wa-61

Sliding Door Motors................... 8Wa-61

Solenoid/Pressure Switch Assy........... 8Wa-31

Speakers........................... 8Wa-47

Speed Control Servo................... 8Wa-33

Speed Control Switches................ 8Wa-33

Speed Sensor- Input................... 8Wa-31

Speed Sensor- Output................. 8Wa-31

Splice Information.................... 8Wa-70

Starter Motor Relay................... 8Wa-21

Starter Motor........................ 8Wa-21

Stop/Turn Signal Relays................ 8Wa-54

Thatcham Alarm Indicator.............. 8Wa-39

Thatcham Alarm Module............... 8Wa-39

Throttle Position Sensor................ 8Wa-30

8Wa - 02 - 2 8W-02 COMPONENT INDEXRG

Page 2303 of 4284

8W-43 AIRBAG SYSTEM

Component Page

Body Control Module................ 8Wa-43-6

Clockspring........................ 8Wa-43-4

Diagnostic Junction Port............ 8Wa-43-2, 6

Driver Airbag...................... 8Wa-43-4

Driver Seat Belt Switch.............. 8Wa-43-3

Driver Seat Belt Tensioner............ 8Wa-43-3

Front Control Module.............. 8Wa-43-2, 6

G200............................. 8Wa-43-2

G201........................... 8Wa-43-2, 6

Instrument Cluster.................. 8Wa-43-2

Intelligent Power Module........... 8Wa-43-2, 6

Left Seat Airbag.................... 8Wa-43-6

Left Side Impact Airbag Control Module . . 8Wa-43-6

Occupant Restraint Controller.... 8Wa-43-2, 3, 4, 5

Passenger Airbag................... 8Wa-43-5

Passenger Seat Belt Switch............ 8Wa-43-5

Passenger Seat Belt Tensioner......... 8Wa-43-5

Right Seat Airbag................... 8Wa-43-6

Right Side Impact Airbag Control Module . 8Wa-43-6

RG8W-43 AIRBAG SYSTEM8Wa-43-1

Page 2442 of 4284

Component Page

C326............................. 8W-80-41

C327............................. 8W-80-41

C327............................. 8W-80-41

C329 (Diesel)....................... 8W-80-42

C329 (Diesel)....................... 8W-80-42

C330 (Diesel)....................... 8W-80-42

C330 (Diesel)....................... 8W-80-42

C331 (Diesel)....................... 8W-80-42

C331 (Diesel)....................... 8W-80-43

C332 (ATC)........................ 8W-80-43

C332 (ATC)........................ 8W-80-43

Cabin Heater Assist C1 (Diesel)........ 8W-80-43

Cabin Heater Assist C2 (Diesel)........ 8W-80-44

Camshaft Position Sensor (Gas)........ 8W-80-44

Camshaft Position Sensor (Diesel)...... 8W-80-44

CD Changer....................... 8W-80-44

Center Dome Lamp (Base/High Line).... 8W-80-45

Center High Mounted Stop Lamp....... 8W-80-45

Clockspring C1..................... 8W-80-45

Clockspring C2..................... 8W-80-45

Clockspring C3..................... 8W-80-45

Clockspring C4..................... 8W-80-46

Clockspring C5..................... 8W-80-46

Clutch Departure Switch (Diesel)....... 8W-80-46

Clutch Interlock/Upstop Switch (MTX) . . . 8W-80-46

Controller Antilock Brake............. 8W-80-47

Crank Case Ventilation Heater (Diesel) . . 8W-80-47

Crankshaft Position Sensor (Diesel)..... 8W-80-48

Crankshaft Position Sensor (Gas)....... 8W-80-48

Data Link Connector................. 8W-80-48

Diagnostic Junction Port.............. 8W-80-49

Dosing Pump....................... 8W-80-49

Driver Airbag C1.................... 8W-80-49

Driver Airbag C2.................... 8W-80-49

Driver Blend Door Actuator (ATC)...... 8W-80-50

Driver Blend Door Actuator (MTC)...... 8W-80-50

Driver Door Courtesy Lamp........... 8W-80-50

Driver Door Lock Switch.............. 8W-80-50

Driver Heated Seat Back............. 8W-80-50

Driver Heated Seat Cushion........... 8W-80-51

Driver Heated Seat Module C1......... 8W-80-51

Driver Heated Seat Module C2......... 8W-80-51

Driver Heated Seat Module C3......... 8W-80-51

Driver Power Seat Front Riser Motor.... 8W-80-52

Driver Power Seat Horizontal Motor..... 8W-80-52

Driver Power Seat Rear Riser Motor.... 8W-80-52

Driver Power Seat Recliner Motor...... 8W-80-52

Driver Power Seat Switch............. 8W-80-52

Driver Power Window Motor........... 8W-80-53

Driver Power Window Switch (LHD)..... 8W-80-53

Driver Power Window Switch (RHD).... 8W-80-53

Driver Seat Belt Switch.............. 8W-80-54

Driver Seat Belt Tensioner............ 8W-80-54

EGR Solenoid (Diesel)................ 8W-80-54Component Page

EGR Solenoid (Gas)................. 8W-80-54

Electric Wiper De-Icer C1............. 8W-80-54

Electric Wiper De-Icer C2............. 8W-80-55

Engine Control Module C1 (Diesel)...... 8W-80-55

Engine Control Module C2 (Diesel)...... 8W-80-57

Engine Coolant Temp Sensor (Diesel).... 8W-80-57

Engine Coolant Temp Sensor (Gas)...... 8W-80-58

Engine Oil Pressure Sensor (Diesel)..... 8W-80-58

Engine Oil Pressure Switch (Gas)....... 8W-80-58

Engine Oil Temperature Sensor (Diesel) . . 8W-80-58

EVAP/Purge Solenoid (Gas)............ 8W-80-58

Evaporator Temperature Sensor........ 8W-80-59

Floor Console Lamp................. 8W-80-59

Floor Console Power Outlet........... 8W-80-59

Front Blower Module C1 (ATC)......... 8W-80-59

Front Blower Module C2 (ATC)......... 8W-80-59

Front Cigar Lighter................. 8W-80-60

Front Reading Lamps/Switch.......... 8W-80-60

Front Washer Pump Motor............ 8W-80-60

Fuel Heater (Diesel)................. 8W-80-60

Fuel Injector No. 1 (2.4L/3.3L/3.8L)..... 8W-80-60

Fuel Injector No. 1 (Diesel)............ 8W-80-61

Fuel Injector No. 2 (2.4L/3.3L/3.8L)..... 8W-80-61

Fuel Injector No. 2 (Diesel)............ 8W-80-61

Fuel Injector No. 3 (2.4L/3.3L/3.8L)..... 8W-80-61

Fuel Injector No. 3 (Diesel)............ 8W-80-61

Fuel Injector No. 4 (2.4L/3.3L/3.8L)..... 8W-80-62

Fuel Injector No. 4 (Diesel)............ 8W-80-62

Fuel Injector No. 5 (3.3L/3.8L)......... 8W-80-62

Fuel Injector No. 6 (3.3L/3.8L)......... 8W-80-62

Fuel Pressure Sensor (Diesel).......... 8W-80-62

Fuel Pressure Solenoid (Diesel)......... 8W-80-63

Fuel Pump Module.................. 8W-80-63

Generator......................... 8W-80-63

Glove Box Lamp.................... 8W-80-63

Glow Plug Relay (Diesel).............. 8W-80-63

Halo Lamp........................ 8W-80-64

Headlamp Switch................... 8W-80-64

Headlamp Washer Pump Motor

(Built-Up-Export)................. 8W-80-64

High Note Horn.................... 8W-80-64

Hood Ajar Switch................... 8W-80-65

Idle Air Control Motor (2.4L).......... 8W-80-65

Idle Air Control Motor (3.3L/3.8L)....... 8W-80-65

Ignition Coil (2.4L).................. 8W-80-65

Ignition Coil (3.3L/3.8L).............. 8W-80-65

Ignition Switch..................... 8W-80-66

Inlet Air Temperature Sensor.......... 8W-80-66

Instrument Cluster.................. 8W-80-66

Instrument Panel Switch Bank......... 8W-80-67

Intelligent Power Module C1.......... 8W-80-67

Intelligent Power Module C2.......... 8W-80-68

Intelligent Power Module C3 (Diesel).... 8W-80-68

Intelligent Power Module C3 (Gas)...... 8W-80-69

8Wa - 80 - 2 8W-80 CONNECTOR PIN-OUTSRG