belt CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2689 of 4284

(4) Remove rear timing belt cover fasteners and

remove cover from engine (Fig. 125).

(5) Remove lower bolt attaching timing belt ten-

sioner assembly to engine and remove tensioneras

an assembly(Fig. 126).

INSTALLATION

(1) Align timing belt tensioner assembly to engine

and install lower mounting boltbut do not tighten

(Fig. 126). To properly align tensioner assemblyÐin-

stall one of the engine bracket mounting bolts (M10)

5 to 7 turns into the tensioner's upper mounting loca-

tion (Fig. 126).

(2) Torque the tensioner's lower mounting bolt to

61 N´m (45 ft. lbs.). Remove the upper bolt used for

tensioner alignment.

(3) Install rear timing belt cover and fasteners.

(4) Install timing belt idler pulley and torque

mounting bolt to 61 N´m (45 ft. lbs.).

(5) Install camshaft sprockets. Use Special Tool

6847 to hold sprockets (Fig. 124), torque bolts to 101

N´m (75 ft. lbs.).

(6) Install the timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

Fig. 124 Camshaft Sprocket - Removal/Installation

1 - SPECIAL TOOL 6847

Fig. 125 Rear Timing Belt Cover Fasteners

1 - BOLTS - REAR COVER 7 N´m (60 in. lbs.)

2 - BOLTS - REAR COVER 28 N´m (250 in .lbs.)

3 - TIMING BELT TENSIONER

Fig. 126 Timing Belt Tensioner AssemblyÐRemoval/

Installation

1 - TIMING BELT TENSIONER ASSEMBLY

2 - TENSIONER ASSEMBLY UPPER BOLT

3 - TENSIONER ASSEMBLY LOWER BOLT

RSENGINE 2.4L9-65

TIMING BELT TENSIONER & PULLEY (Continued)

Page 2698 of 4284

DIAGNOSIS AND TESTING - ENGINE

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Engine Mechanical and the Engine

Performance diagnostic charts, for possible causes

and corrections of malfunctions (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING - MECHANICAL)

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING

- PERFORMANCE).

For fuel system diagnosis, (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Lash Adjuster (Tappet) Noise Diagnosis

²Engine Oil Leak Inspection

DIAGNOSIS AND TESTING - ENGINE PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL

NOT START1. Weak battery. 1. Test battery. Charge or replace as

necessary. (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM - DIAGNOSIS AND

TESTING)

2. Corroded or loose battery connections. 2. Clean and tighten battery connections.

Apply a coat of light mineral grease to

terminals.

3. Faulty starter. 3. Test starting system. (Refer to 8 -

ELECTRICAL/STARTING - DIAGNOSIS

AND TESTING)

4. Faulty coil(s) or control unit. 4. Test and replace as needed. (Refer to

Appropriate Diagnostic Information)

5. Incorrect spark plug gap. 5. Set gap. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL - SPECIFICATIONS)

6. Contamination in fuel system. 6. Clean system and replace fuel filter.

7. Faulty fuel pump. 7. Test fuel pump and replace as needed.

(Refer to Appropriate Diagnostic Information)

8. Incorrect engine timing. 8. Check for a skipped timing belt/chain.

Fig. 2 Engine Identification

9 - 74 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 2707 of 4284

(36) Remove front engine mount and bracket as an

assembly.

(37) Remove the engine rear mount bracket.

(38) Remove the engine to transaxle struts (Fig. 8).

(39) Remove transaxle case cover (Fig. 8).

(40) Remove flex plate to torque converter bolts.

(41) Remove the power steering pressure hose sup-

port clip attaching bolt.

(42) Disconnect the knock sensor electrical connec-

tor (3.8L only).

(43) Disconnect the engine block heater electrical

connector, if equipped.

(44) Remove the accessory belt splash shield.

(45) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(46) Disconnect the radiator lower hose.

(47) Remove air conditioning compressor from

engine.

(48) Remove the generator. (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL)

(49) Remove the water pump pulley attaching

bolts and position pulley between pump hub and

housing.

(50) Disconnect the oil pressure switch electrical

connector.

(51) Disconnect wiring harness support clip from

dipstick tube.(52) Install Special Tools 6912 and 8444 Adapters

on the right side (rear) of engine block (Fig. 9).

Fig. 7 Catalytic Converter to Exhaust Manifold

1 - FLAG NUT

2 - GASKET

3 - BOLT

4 - CATALYTIC CONVERTER

Fig. 8 POWERTRAIN SUPPORTS AND DUST COVER

1 - BRACKET - ENGINE REAR MOUNT

2 - BOLT - TRANSAXLE CASE COVER

3 - STRUT - TRANSAXLE TO ENGINE HORIZONTAL

4 - BOLT - HORIZONTAL STRUT

5 - BOLT - STRUT TO TRANSAXLE

6 - COVER - TRANSAXLE CASE LOWER

7 - STRUT - TRANSAXLE TO ENGINE

8 - BOLT - STRUT TO ENGINE

9 - BOLT - ENGINE REAR MOUNT BRACKET

Fig. 9 ADAPTER TOOLS MOUNTED ON BLOCK

1 - SPECIAL TOOL 6912

2 - SPECIAL TOOL 8444

RSENGINE 3.3/3.8L9-83

ENGINE 3.3/3.8L (Continued)

Page 2709 of 4284

(4) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135, 6710,

6848 and 6909 (Fig. 10).

(5) Remove Special Tools 6912 and 8444.

(6) Lower the vehicle.

(7) Install power steering pump and pressure line

support.(8) Install the generator and wiring harness.

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION)

(9) Raise vehicle.

(10) Attach wiring harness support clip to the dip-

stick tube.

(11) Connect oil pressure switch electrical connec-

tor.

(12) Install the A/C compressor.

(13) Install the water pump pulley.

(14) Connect the radiator lower hose.

(15) Install the accessory drive belt and splash

shield. (Refer to 7 - COOLING/ACCESSORY DRIVE/

DRIVE BELTS - INSTALLATION)

(16) Connect the engine block heater electrical con-

nector, if equipped.

(17) Connect the knock sensor electrical connector

(3.8L only).

(18) Install the torque converter to flex plate bolts.

(19) Install the transaxle case cover (Fig. 8).

(20) Install the powertrain struts (Fig. 8).

(21) Install the engine rear mount bracket.

(22) Install the engine front mount and bracket

assembly.

(23)AWD equipped;Install the power transfer

unit (PTU).

(24) Install the axle shafts. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(25) Connect exhaust pipe to manifold (Fig. 7).

(26) Install crossmember cradle plate (Fig. 6).

(27) Lower vehicle.

(28) Connect transaxle shift linkage.

(29) Connect transaxle electrical connectors.

(30) Connect transaxle cooler hoses.

(31) Install transaxle dipstick tube and attach

electrical harness clip.

(32) Connect the radiator upper hose.

(33) Connect the A/C lines to compressor.

(34) Connect the A/C compressor electrical connec-

tor.

(35) Evacuate and recharge A/C system.

(36) Connect crankshaft and camshaft position

sensors.

(37) Connect the fuel injector electrical harness

connector and engage clip to support bracket.

(38) Connect engine coolant temperature (ECT)

sensor and ignition coil electrical connectors.

(39) Connect the ground strap to rear of cylinder

head.

(40) Install power steering reservoir.

(41) Engage wire harness clip to engine right side

mount.

(42) Connect the brake booster and speed control

vacuum hoses.

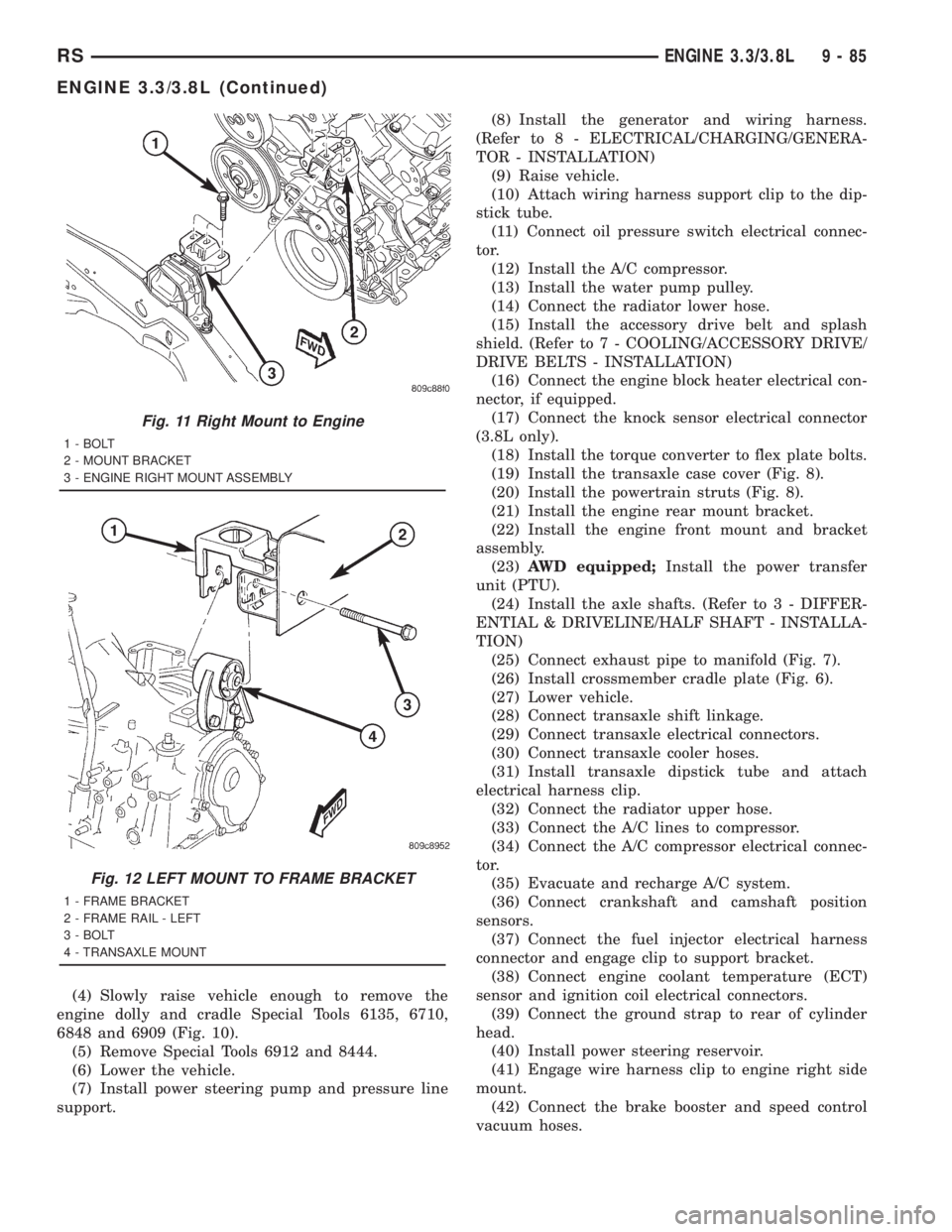

Fig. 11 Right Mount to Engine

1 - BOLT

2 - MOUNT BRACKET

3 - ENGINE RIGHT MOUNT ASSEMBLY

Fig. 12 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

RSENGINE 3.3/3.8L9-85

ENGINE 3.3/3.8L (Continued)

Page 2732 of 4284

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL)

(3) Remove the hydraulic lifters. (Refer to 9 -

ENGINE/ENGINE BLOCK/HYDRAULIC LIFTERS

(CAM IN BLOCK) - REMOVAL). Identify each tappet

for reinstallation in original location.

(4) Remove camshaft thrust plate (Fig. 45).

(5) Install a long bolt into front of camshaft to

facilitate removal of the camshaft.

(6) Remove the camshaft (Fig. 45), being careful

not to damage cam bearings with the cam lobes.

NOTE: The camshaft bearings are serviced with the

engine block.

INSPECTION

(1) Check the cam lobes and bearing surfaces for

abnormal wear and damage (Fig. 47). Replace cam-

shaft as required.

NOTE: If camshaft is replaced due to lobe wear or

damage, always replace the lifters.

(2) Measure the lobe actual wear (unworn area -

wear zone = actual wear) (Fig. 47) and replace cam-

shaft if out of limit. Standard value is 0.0254 mm

(0.001 in.), wearlimitis 0.254 mm (0.010 in.).

INSTALLATION

(1) Lubricate camshaft lobes and camshaft bearing

journals with engine oil.

(2) Install a long bolt into the camshaft to assist in

the installation of the camshaft.

(3) Carefully install the camshaft in engine block.

(4) Install camshaft thrust plate and bolts (Fig.

45). Tighten to 12 N´m (105 in. lbs.) torque.

(5) Measure camshaft end play. (Refer to 9 -

ENGINE - SPECIFICATIONS) If not within specifi-

cations, replace thrust plate.

(6) Install the timing chain and sprockets. (Refer

to 9 - ENGINE/VALVE TIMING/TIMING BELT/

CHAIN AND SPROCKETS - INSTALLATION)

NOTE: When camshaft is replaced, all of the

hydraulic lifters must be replaced also.

(7) Install the hydraulic lifters (Refer to 9 -

ENGINE/ENGINE BLOCK/HYDRAULIC LIFTERS

(CAM IN BLOCK) - INSTALLATION). Each lifter

Fig. 45 CAMSHAFT AND BEARINGS

1 - CAMSHAFT

2 - THRUST PLATE

3 - BOLT

4 - CAMSHAFT BEARINGS (SERVICED WITH BLOCK)

Fig. 46 CAMSHAFT IDENTIFICATION

1 - CAMSHAFT - 3.3L ENGINE

2 - CAST-IN RING

3 - CAMSHAFT - 3.8L ENGINE

4 - MACHINED CAST-IN RING

Fig. 47 Checking Camshaft for Wear (Typical)

1 - UNWORN AREA

2 - ACTUAL WEAR

3 - BEARING JOURNAL

4 - LOBE

5 - WEAR ZONE

9 - 108 ENGINE 3.3/3.8LRS

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 2733 of 4284

reused must be installed in the same position from

which it was removed.

(8) Install the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

(9) Install the cylinder heads. (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION)

(10) Install the cylinder head covers. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(11) Install the lower and upper intake manifolds.

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - INSTALLATION)

(12) Install the engine assembly. (Refer to 9 -

ENGINE - INSTALLATION)

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - MEASURING

CONNECTING ROD BEARING CLEARANCE

The bearing caps are not interchangeable and

should be marked at removal to ensure correct

assembly. The bearing shells must be installed with

the tangs inserted into the machined grooves in the

rods and caps. Install cap with the tangs on the same

side as the rod. Fit all rods on one bank until com-

plete. Connecting rod bearings are available in the

standard size and the following undersizes: 0.025

mm (0.001 in.) and 0.250 mm (0.010 in.).

CAUTION: Install the bearings in pairs. Do not use a

new bearing half with an old bearing half. Do not

file the rods or bearing caps.

Measure connecting rod journal for taper and out-

of-round. (Refer to 9 - ENGINE/ENGINE BLOCK/

CRANKSHAFT - INSPECTION)

The connecting rod bearing clearances can be

determined by use of Plastigage or the equivalent.

The following is the recommended procedure for the

use of Plastigage:

(1) Rotate the crankshaft until the connecting rod

to be checked is at the bottom of its stroke.

(2) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(3) Place a piece of Plastigage across the entire

width of the bearing shell in the bearing cap approx-

imately 6.35 mm (1/4 in.) off center and away from

the oil hole. In addition, suspect areas can be

checked by placing Plastigage in that area.

(4) Assemble the rod cap with Plastigage in place.

Tighten the rod cap to the specified torque.Do not

rotate the crankshaft while assembling the cap

or the Plastigage may be smeared, giving inac-

curate results.(5) Remove the bearing cap and compare the

width of the flattened Plastigage with the scale pro-

vided on the package (Fig. 48). Locate the band clos-

est to the same width. This band indicates the

amount of oil clearance. Differences in readings

between the ends indicate the amount of taper

present. Record all readings taken. Refer to Engine

Specifications (Refer to 9 - ENGINE - SPECIFICA-

TIONS).Plastigage generally is accompanied by

two scales. One scale is in inches, the other is a

metric scale. If the bearing clearance exceeds

wear limit specification, replace the bearing.

CRANKSHAFT

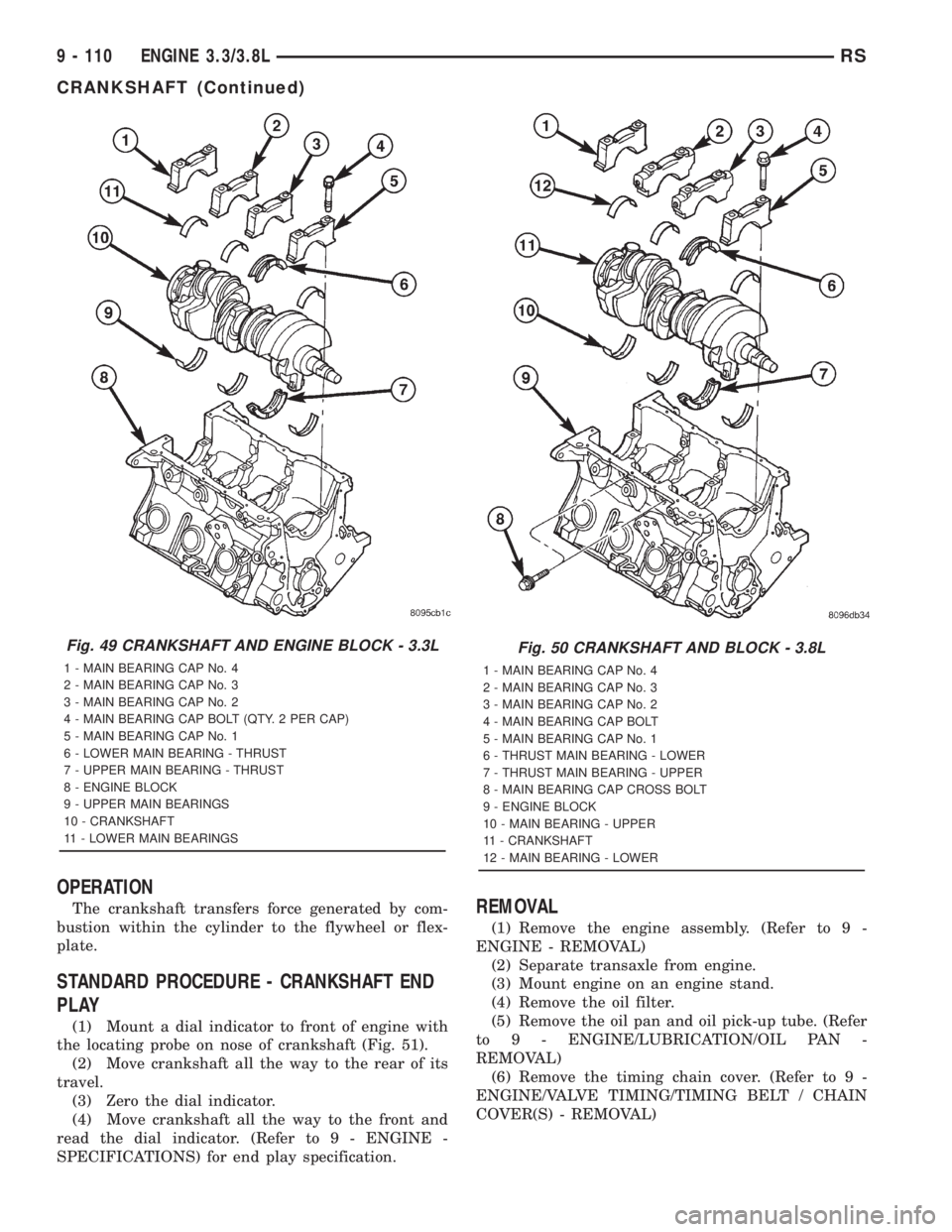

DESCRIPTION - 3.3L

The nodular iron crankshaft is supported by four

main bearings, with number two position the thrust

bearing (Fig. 49). Crankshaft end sealing is provided

by front and rear rubber seals.

DESCRIPTION - 3.8L

The nodular iron crankshaft is supported by four

main bearings, with number two position providing

thrust bearing location (Fig. 50). Each main bearing

cap has two vertical retaining bolts. The two center

main caps have horizontal bolts to add increased

rigidity to the lower engine block (Fig. 50). Crank-

shaft end sealing is provided by front and rear rub-

ber seals.

Fig. 48 Measuring Connecting Rod Bearing

Clearance

RSENGINE 3.3/3.8L9 - 109

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 2734 of 4284

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder to the flywheel or flex-

plate.

STANDARD PROCEDURE - CRANKSHAFT END

PLAY

(1) Mount a dial indicator to front of engine with

the locating probe on nose of crankshaft (Fig. 51).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. (Refer to 9 - ENGINE -

SPECIFICATIONS) for end play specification.

REMOVAL

(1) Remove the engine assembly. (Refer to 9 -

ENGINE - REMOVAL)

(2) Separate transaxle from engine.

(3) Mount engine on an engine stand.

(4) Remove the oil filter.

(5) Remove the oil pan and oil pick-up tube. (Refer

to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL)

(6) Remove the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

Fig. 49 CRANKSHAFT AND ENGINE BLOCK - 3.3L

1 - MAIN BEARING CAP No. 4

2 - MAIN BEARING CAP No. 3

3 - MAIN BEARING CAP No. 2

4 - MAIN BEARING CAP BOLT (QTY. 2 PER CAP)

5 - MAIN BEARING CAP No. 1

6 - LOWER MAIN BEARING - THRUST

7 - UPPER MAIN BEARING - THRUST

8 - ENGINE BLOCK

9 - UPPER MAIN BEARINGS

10 - CRANKSHAFT

11 - LOWER MAIN BEARINGS

Fig. 50 CRANKSHAFT AND BLOCK - 3.8L

1 - MAIN BEARING CAP No. 4

2 - MAIN BEARING CAP No. 3

3 - MAIN BEARING CAP No. 2

4 - MAIN BEARING CAP BOLT

5 - MAIN BEARING CAP No. 1

6 - THRUST MAIN BEARING - LOWER

7 - THRUST MAIN BEARING - UPPER

8 - MAIN BEARING CAP CROSS BOLT

9 - ENGINE BLOCK

10 - MAIN BEARING - UPPER

11 - CRANKSHAFT

12 - MAIN BEARING - LOWER

9 - 110 ENGINE 3.3/3.8LRS

CRANKSHAFT (Continued)

Page 2735 of 4284

(7) Remove timing chain and sprockets. (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - REMOVAL)

(8) Remove crankshaft rear oil seal and retainer.

(Refer to 9 - ENGINE/ENGINE BLOCK/CRANK-

SHAFT OIL SEAL - REAR - REMOVAL)

(9) Rotate the crankshaft until connecting rod cap

is accessible.

(10) Mark connecting rod cap position using a suit-

able marker/scribe tool.

(11) Remove connecting rod bearing cap. Use care

to prevent damage to the crankshaft bearing sur-

faces.

(12) Repeat removal procedure for each connecting

rod cap.

(13) Remove and discard the main bearing cross

bolts and washers (3.8L engine only).

NOTE: Install new cross bolt and washer assembly

(3.8L engine only) upon reassembly.

(14) Remove the main bearing cap bolts

(15) Remove the main bearing caps.

(16) Remove the crankshaft from engine block.

INSPECTION

The crankshaft journals should be checked for

excessive wear, taper and scoring (Fig. 52). Limits of

taper or out of round on any crankshaft journals

should within specitifications. (Refer to 9 - ENGINE -

SPECIFICATIONS) Journal grinding should not

exceed 0.305 mm (0.012 in.) under the standard jour-

nal diameter. DO NOT grind thrust faces of No. 3

main bearing. DO NOT nick crank pin or bearing fil-

lets. After grinding, remove rough edges from crank-

shaft oil holes and clean out all passages.

CAUTION: With the nodular cast iron crankshafts, it

is important that the final paper or cloth polish bein the same direction as normal rotation in the

engine.

INSTALLATION

(1) Lubricate with engine oil and install the crank-

shaft main bearing halves in the engine block.

(2) Position the crankshaft in engine block (Fig.

54).

(3) Perform main bearing fitting procedure. (Refer

to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT

MAIN BEARINGS - STANDARD PROCEDURE)

(4) Inspect main cap bolts for stretching (Fig. 53).

Replace bolts that are stretched.

NOTE: The main cap bolts should be examined

before reuse. Bolt stretch can be checked by hold-

ing a scale or straight edge against the threads. If

all the threads do not contact the scale the bolt

must be replaced (Fig. 53).

(5) Install the main bearing caps and bolts.

Tighten bolts to 41 N´m (30 ft. lbs.) plus

1¤4turn.

Fig. 51 Checking Crankshaft End PlayÐTypical

Fig. 52 Crankshaft Journal Measurements

Fig. 53 Check for Stretched (Necked) Bolts

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

RSENGINE 3.3/3.8L9 - 111

CRANKSHAFT (Continued)

Page 2736 of 4284

NOTE: Install new cross bolt and washer assembly

(3.8L engine only) upon reassembly.

(6) Install and tighten the NEW cross bolts and

washer assemblies (3.8L engine only) to 61 N´m (45

ft. lbs.) (Fig. 55).

(7) Position and install the connecting rod and

bearing caps on the crankshaft. (Refer to 9 -

ENGINE/ENGINE BLOCK/CONNECTING ROD

BEARINGS - STANDARD PROCEDURE)

(8) Install the crankshaft rear oil seal. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - INSTALLATION)(9) Install the crankshaft sprocket. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION)

(10) Install the timing chain and camshaft

sprocket. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION)

(11) Install the timing chain cover.

(12) Install the oil pick-up tube and oil pan. (Refer

to 9 - ENGINE/LUBRICATION/OIL PAN - INSTAL-

LATION)

(13) Install the transaxle to the engine.

(14) Install the engine assembly. (Refer to 9 -

ENGINE - INSTALLATION)

Fig. 54 CRANKSHAFT AND BLOCK - 3.3L

1 - MAIN BEARING CAP No. 4

2 - MAIN BEARING CAP No. 3

3 - MAIN BEARING CAP No. 2

4 - MAIN BEARING CAP BOLT (QTY. 2 PER CAP)

5 - MAIN BEARING CAP No. 1

6 - LOWER MAIN BEARING - THRUST

7 - UPPER MAIN BEARING - THRUST

8 - ENGINE BLOCK

9 - UPPER MAIN BEARINGS

10 - CRANKSHAFT

11 - LOWER MAIN BEARINGS

Fig. 55 CRANKSHAFT AND BLOCK - 3.8L

1 - MAIN BEARING CAP No. 4

2 - MAIN BEARING CAP No. 3

3 - MAIN BEARING CAP No. 2

4 - MAIN BEARING CAP BOLT

5 - MAIN BEARING CAP No. 1

6 - THRUST MAIN BEARING - LOWER

7 - THRUST MAIN BEARING - UPPER

8 - MAIN BEARING CAP CROSS BOLT

9 - ENGINE BLOCK

10 - MAIN BEARING - UPPER

11 - CRANKSHAFT

12 - MAIN BEARING - LOWER

9 - 112 ENGINE 3.3/3.8LRS

CRANKSHAFT (Continued)

Page 2739 of 4284

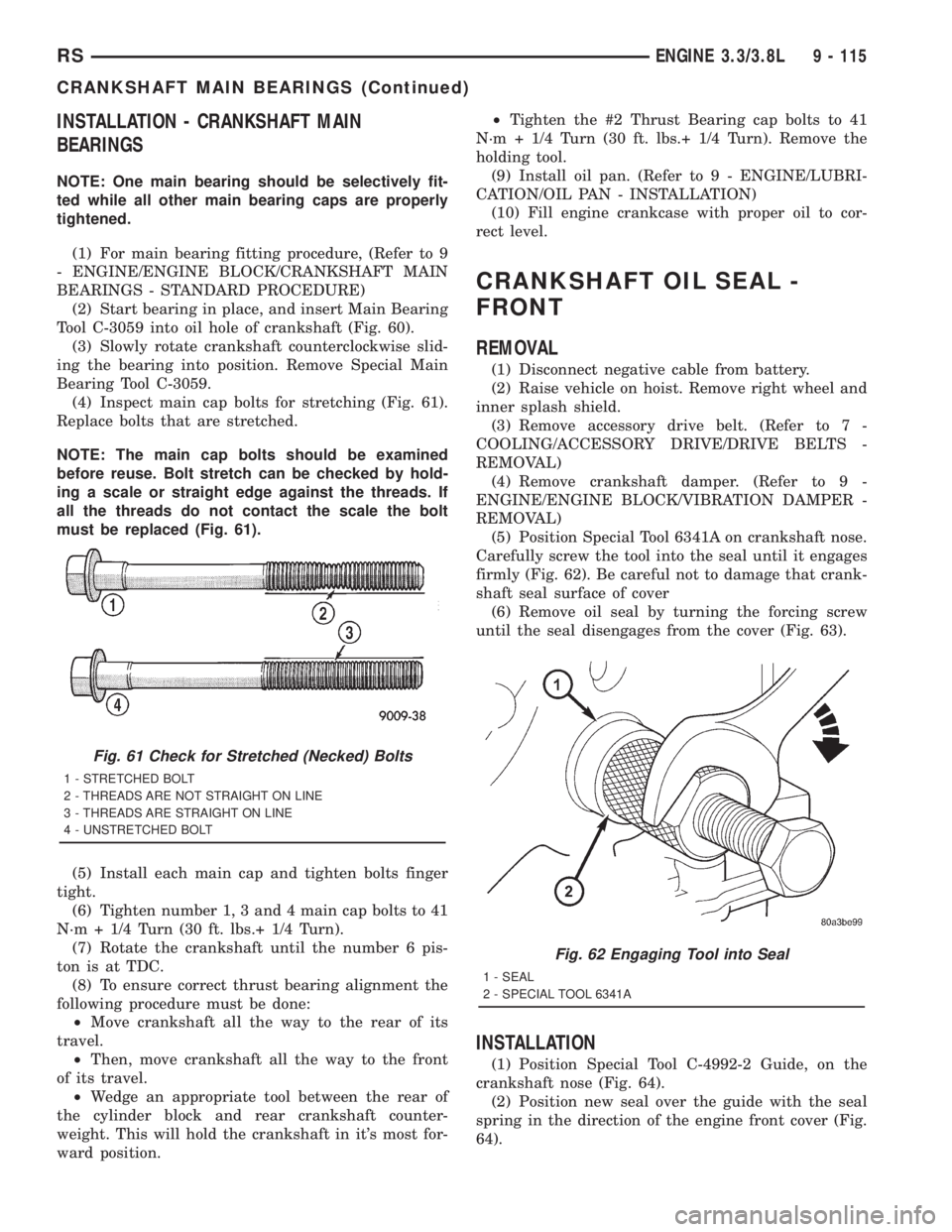

INSTALLATION - CRANKSHAFT MAIN

BEARINGS

NOTE: One main bearing should be selectively fit-

ted while all other main bearing caps are properly

tightened.

(1) For main bearing fitting procedure, (Refer to 9

- ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE)

(2) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 60).

(3) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

(4) Inspect main cap bolts for stretching (Fig. 61).

Replace bolts that are stretched.

NOTE: The main cap bolts should be examined

before reuse. Bolt stretch can be checked by hold-

ing a scale or straight edge against the threads. If

all the threads do not contact the scale the bolt

must be replaced (Fig. 61).

(5) Install each main cap and tighten bolts finger

tight.

(6) Tighten number 1, 3 and 4 main cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn).

(7) Rotate the crankshaft until the number 6 pis-

ton is at TDC.

(8) To ensure correct thrust bearing alignment the

following procedure must be done:

²Move crankshaft all the way to the rear of its

travel.

²Then, move crankshaft all the way to the front

of its travel.

²Wedge an appropriate tool between the rear of

the cylinder block and rear crankshaft counter-

weight. This will hold the crankshaft in it's most for-

ward position.²Tighten the #2 Thrust Bearing cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn). Remove the

holding tool.

(9) Install oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION)

(10) Fill engine crankcase with proper oil to cor-

rect level.

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist. Remove right wheel and

inner splash shield.

(3) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(4) Remove crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL)

(5) Position Special Tool 6341A on crankshaft nose.

Carefully screw the tool into the seal until it engages

firmly (Fig. 62). Be careful not to damage that crank-

shaft seal surface of cover

(6) Remove oil seal by turning the forcing screw

until the seal disengages from the cover (Fig. 63).

INSTALLATION

(1) Position Special Tool C-4992-2 Guide, on the

crankshaft nose (Fig. 64).

(2) Position new seal over the guide with the seal

spring in the direction of the engine front cover (Fig.

64).

Fig. 61 Check for Stretched (Necked) Bolts

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 62 Engaging Tool into Seal

1 - SEAL

2 - SPECIAL TOOL 6341A

RSENGINE 3.3/3.8L9 - 115

CRANKSHAFT MAIN BEARINGS (Continued)