belt CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2444 of 4284

Component Page

Passenger Door Lock Switch........... 8W-80-91

Passenger Folding Mirror Relay

(Built-Up-Export)................. 8W-80-91

Passenger Heated Seat Back........... 8W-80-92

Passenger Heated Seat Cushion........ 8W-80-92

Passenger Heated Seat Module C1...... 8W-80-92

Passenger Heated Seat Module C2...... 8W-80-92

Passenger Heated Seat Module C3...... 8W-80-93

Passenger Power Seat Front Riser Motor . 8W-80-93

Passenger Power Seat Horizontal Motor . . 8W-80-93

Passenger Power Seat Rear Riser Motor . . 8W-80-93

Passenger Power Seat Recliner Motor.... 8W-80-93

Passenger Power Seat Switch.......... 8W-80-94

Passenger Power Window Motor........ 8W-80-94

Passenger Power Window Switch....... 8W-80-94

Passenger Seat Belt Switch........... 8W-80-94

Passenger Seat Belt Tensioner......... 8W-80-95

Power Folding Mirror Switch

(Built-Up-Export)................. 8W-80-95

Power Liftgate Module C1............ 8W-80-95

Power Liftgate Module C2............ 8W-80-96

Power Liftgate Motor................ 8W-80-96

Power Mirror Switch................. 8W-80-97

Power Outlet....................... 8W-80-97

Power Seat Circuit Breaker (30A)....... 8W-80-97

Powertrain Control Module C1

(2.4L/3.3L/3.8L)................... 8W-80-98

Powertrain Control Module C2

(2.4L/3.3L/3.8L)................... 8W-80-99

Power Window Circuit Breaker (25A) . . . 8W-80-100

Radiator Fan No. 1 (Diesel)........... 8W-80-100

Radiator Fan No. 1 (Gas)............ 8W-80-100

Radiator Fan No. 2 (Diesel)........... 8W-80-100

Radiator Fan No. 2 (Gas)............ 8W-80-100

Radiator Fan Relay (Gas)............ 8W-80-101

Radiator Fan Relay No. 1 (Diesel)...... 8W-80-101

Radiator Fan Relay No. 2 (Diesel)...... 8W-80-101

Radiator Fan Relay No. 3 (Diesel)...... 8W-80-102

Radio C1......................... 8W-80-102

Radio C2......................... 8W-80-102

Radio C3......................... 8W-80-102

Radio C4......................... 8W-80-103

Radio Choke...................... 8W-80-103

Rear A/C-Heater Unit (3 Zone HVAC) . . . 8W-80-103

Rear Auto Temp Control Switch (ATC) . . 8W-80-104

Rear Blower Front Control Switch

(3 Zone HVAC).................. 8W-80-104

Rear Blower Motor Power Module

C1(ATC) ....................... 8W-80-104

Rear Blower Motor Power Module

C2(ATC) ....................... 8W-80-104

Rear Blower Rear Control Switch

C1 (3 Zone HVAC)................ 8W-80-105

Rear Blower Rear Control Switch C2

(3 Zone HVAC).................. 8W-80-105Component Page

Rear Dome Lamp (Except Luxury)..... 8W-80-105

Rear Mode Motor (ATC)............. 8W-80-105

Rear Power Outlet................. 8W-80-105

Rear Temperature Motor (ATC)........ 8W-80-106

Rear Washer Pump Motor............ 8W-80-106

Rear Wiper Motor.................. 8W-80-106

Recirculation Door Actuator (ATC)..... 8W-80-106

Recirculation Door Actuator (MTC)..... 8W-80-106

Remote Keyless Entry Antenna

(Japan)........................ 8W-80-107

Remote Keyless Entry Module........ 8W-80-107

Right B-Pillar Switch............... 8W-80-107

Right Cinch/Release Motor

(Power Sliding Door).............. 8W-80-107

Right Combination Relay

(Trailer Tow).................... 8W-80-107

Right Cylinder Lock Switch.......... 8W-80-108

Right Door Speaker................. 8W-80-108

Right Fog Lamp................... 8W-80-108

Right Front Door Ajar Switch (Base).... 8W-80-108

Right Front Door Lock Motor/Ajar Switch

(Except Base)................... 8W-80-108

Right Front Park/Turn Signal Lamp

(Except Built-Up-Export).......... 8W-80-109

Right Front Wheel Speed Sensor...... 8W-80-109

Right Full Open Switch

(Power Sliding Door).............. 8W-80-109

Right Headlamp (Except

Built-Up-Export)................. 8W-80-109

Right Headlamp Leveling Motor

(Built-Up-Export)................ 8W-80-110

Right High Beam Lamp

(Built-Up-Export)................ 8W-80-110

Right Instrument Panel Speaker....... 8W-80-110

Right Liftgate Flood Lamp........... 8W-80-110

Right Low Beam Lamp

(Built-Up-Export)................ 8W-80-110

Right Mid Reading Lamp

(Premium/Luxury)................ 8W-80-111

Right Park Lamp (Built-Up-Export).... 8W-80-111

Right Power Mirror................. 8W-80-111

Right Rear Lamp Assembly........... 8W-80-111

Right Rear Pillar Speaker............ 8W-80-112

Right Rear Reading Lamp (Luxury).... 8W-80-112

Right Rear Speaker................. 8W-80-112

Right Rear Vent Motor.............. 8W-80-112

Right Rear Wheel Speed Sensor....... 8W-80-112

Right Remote Radio Switch........... 8W-80-113

Right Repeater Lamp (Built-Up-Export) . 8W-80-113

Right Seat Airbag.................. 8W-80-113

Right Side Impact Airbag

Control Module.................. 8W-80-113

Right Sliding Door Control Module C1

(Power Sliding Door).............. 8W-80-113

8Wa - 80 - 4 8W-80 CONNECTOR PIN-OUTSRG

Page 2494 of 4284

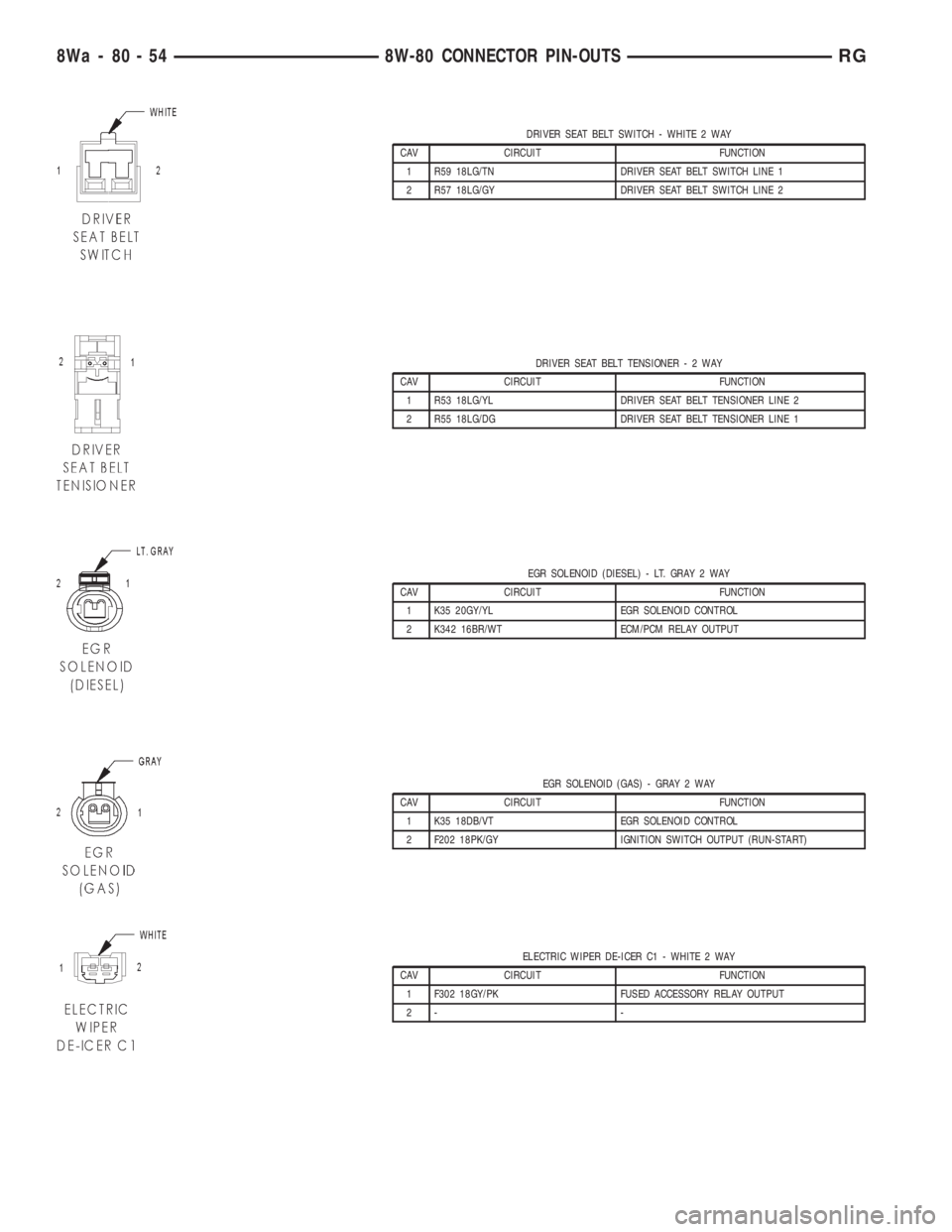

DRIVER SEAT BELT SWITCH - WHITE 2 WAY

CAV CIRCUIT FUNCTION

1 R59 18LG/TN DRIVER SEAT BELT SWITCH LINE 1

2 R57 18LG/GY DRIVER SEAT BELT SWITCH LINE 2

DRIVER SEAT BELT TENSIONER-2WAY

CAV CIRCUIT FUNCTION

1 R53 18LG/YL DRIVER SEAT BELT TENSIONER LINE 2

2 R55 18LG/DG DRIVER SEAT BELT TENSIONER LINE 1

EGR SOLENOID (DIESEL) - LT. GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 K35 20GY/YL EGR SOLENOID CONTROL

2 K342 16BR/WT ECM/PCM RELAY OUTPUT

EGR SOLENOID (GAS) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 K35 18DB/VT EGR SOLENOID CONTROL

2 F202 18PK/GY IGNITION SWITCH OUTPUT (RUN-START)

ELECTRIC WIPER DE-ICER C1 - WHITE 2 WAY

CAV CIRCUIT FUNCTION

1 F302 18GY/PK FUSED ACCESSORY RELAY OUTPUT

2- -

8Wa - 80 - 54 8W-80 CONNECTOR PIN-OUTSRG

Page 2529 of 4284

OCCUPANT RESTRAINT CONTROLLER - YELLOW/RED 23 WAY

CAV CIRCUIT FUNCTION

1 R54 18LB/YL PASSENGER SEAT BELT TENSIONER LINE 2

2 R56 18LB/DG PASSENGER SEAT BELT TENSIONER LINE 1

3 R62 18LB/VT PASSENGER SQUIB 2 LINE 2

4 R64 18LB/WT PASSENGER SQUIB 2 LINE 1

5 R42 18LB/BR PASSENGER SQUIB 1 LINE 2

6 R44 18LB/OR PASSENGER SQUIB 1 LINE 1

7 R53 18LG/YL DRIVER SEAT BELT TENSIONER LINE 2

8 R55 18LG/DG DRIVER SEAT BELT TENSIONER LINE 1

9 R61 18LG/VT DRIVER SQUIB 2 LINE 1

10 R63 18LG/WT DRIVER SQUIB 2 LINE 2

11 R43 18LG/BR DRIVER SQUIB 1 LINE 1

12 R45 18LG/OR DRIVER SQUIB 1 LINE 2

13 - -

14 F201 18PK/OR FCM OUTPUT (RUN-START)

15 F100 18PK/VT FCM OUTPUT (RUN)

16 Z12 18BK/OR GROUND

17 R59 18LG/TN DRIVER SEAT BELT SWITCH LINE 1

18 R57 18LG/GY DRIVER SEAT BELT SWITCH LINE 2

19 R60 18LB/TN PASSENGER SEAT BELT SWITCH LINE 1

20 R58 18LB/GY PASSENGER SEAT BELT SWITCH LINE 2

21 D25 18WT/VT PCI BUS

22 - -

23 - -

OVERHEAD CONSOLE (EXCEPT BASE) - BLACK 12 WAY

CAV CIRCUIT FUNCTION

1 G23 20VT/DB SLIDING DOORS OVERHEAD SWITCH MUX

2 G25 20VT/TN LIFTGATE SWITCH MUX

3 D25 20WT/VT PCI BUS

4 Z113 20BK/DB GROUND

5 A114 20GY/RD FUSED B(+) (I.O.D.)

6 F503 20WT/PK IGNITION SWITCH OUTPUT (RUN)

7 Z13 20BK/WT GROUND

8 E15 20OR/DB ASH/RECEIVER LAMP FEED

9- -

10 - -

11 L24 20BK/GY (EXCEPT BUILT-UP-EX-

PORT) (PREMIUM/LUXURY)AUTOMATIC HEADLAMP SWITCH SENSOR

12 L1 20BK/WT (PREMIUM/LUXURY) BACK-UP LAMP FEED

RADIATOR FAN RELAY NO. 1 (DIESEL) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2 N201 12DB/LG RADIATOR FAN RELAY NO. 1 OUTPUT

3- -

4 K342 16BR/WT ECM/PCM RELAY OUTPUT

5- -

6 N210 18DB/DG LOW SPEED RADIATOR FAN RELAY CONTROL

7- -

8 A201 12RD/LG FUSED B(+)

9- -

RG8W-80 CONNECTOR PIN-OUTS8Wa-80-89

Page 2534 of 4284

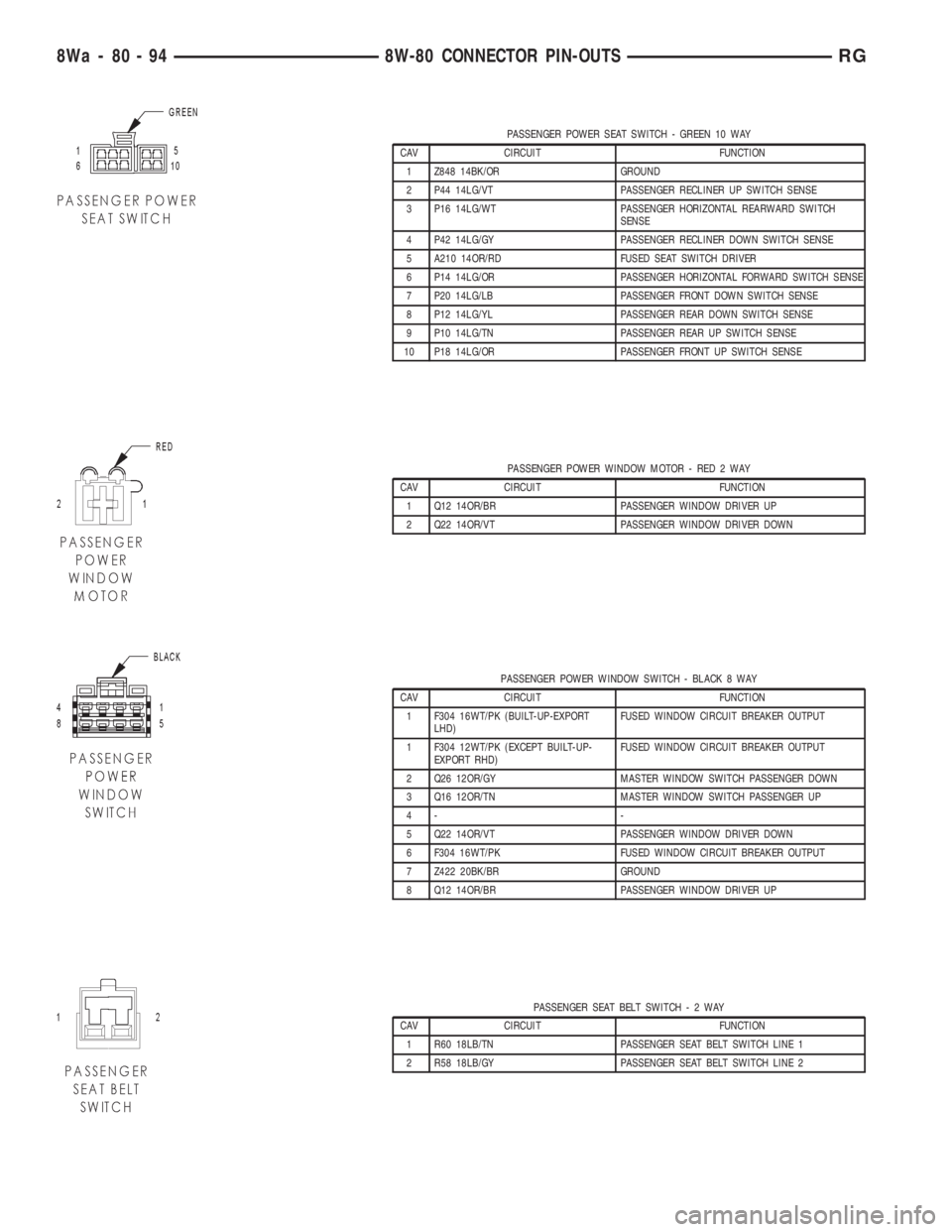

PASSENGER POWER SEAT SWITCH - GREEN 10 WAY

CAV CIRCUIT FUNCTION

1 Z848 14BK/OR GROUND

2 P44 14LG/VT PASSENGER RECLINER UP SWITCH SENSE

3 P16 14LG/WT PASSENGER HORIZONTAL REARWARD SWITCH

SENSE

4 P42 14LG/GY PASSENGER RECLINER DOWN SWITCH SENSE

5 A210 14OR/RD FUSED SEAT SWITCH DRIVER

6 P14 14LG/OR PASSENGER HORIZONTAL FORWARD SWITCH SENSE

7 P20 14LG/LB PASSENGER FRONT DOWN SWITCH SENSE

8 P12 14LG/YL PASSENGER REAR DOWN SWITCH SENSE

9 P10 14LG/TN PASSENGER REAR UP SWITCH SENSE

10 P18 14LG/OR PASSENGER FRONT UP SWITCH SENSE

PASSENGER POWER WINDOW MOTOR - RED 2 WAY

CAV CIRCUIT FUNCTION

1 Q12 14OR/BR PASSENGER WINDOW DRIVER UP

2 Q22 14OR/VT PASSENGER WINDOW DRIVER DOWN

PASSENGER POWER WINDOW SWITCH - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1 F304 16WT/PK (BUILT-UP-EXPORT

LHD)FUSED WINDOW CIRCUIT BREAKER OUTPUT

1 F304 12WT/PK (EXCEPT BUILT-UP-

EXPORT RHD)FUSED WINDOW CIRCUIT BREAKER OUTPUT

2 Q26 12OR/GY MASTER WINDOW SWITCH PASSENGER DOWN

3 Q16 12OR/TN MASTER WINDOW SWITCH PASSENGER UP

4- -

5 Q22 14OR/VT PASSENGER WINDOW DRIVER DOWN

6 F304 16WT/PK FUSED WINDOW CIRCUIT BREAKER OUTPUT

7 Z422 20BK/BR GROUND

8 Q12 14OR/BR PASSENGER WINDOW DRIVER UP

PASSENGER SEAT BELT SWITCH-2WAY

CAV CIRCUIT FUNCTION

1 R60 18LB/TN PASSENGER SEAT BELT SWITCH LINE 1

2 R58 18LB/GY PASSENGER SEAT BELT SWITCH LINE 2

8Wa - 80 - 94 8W-80 CONNECTOR PIN-OUTSRG

Page 2535 of 4284

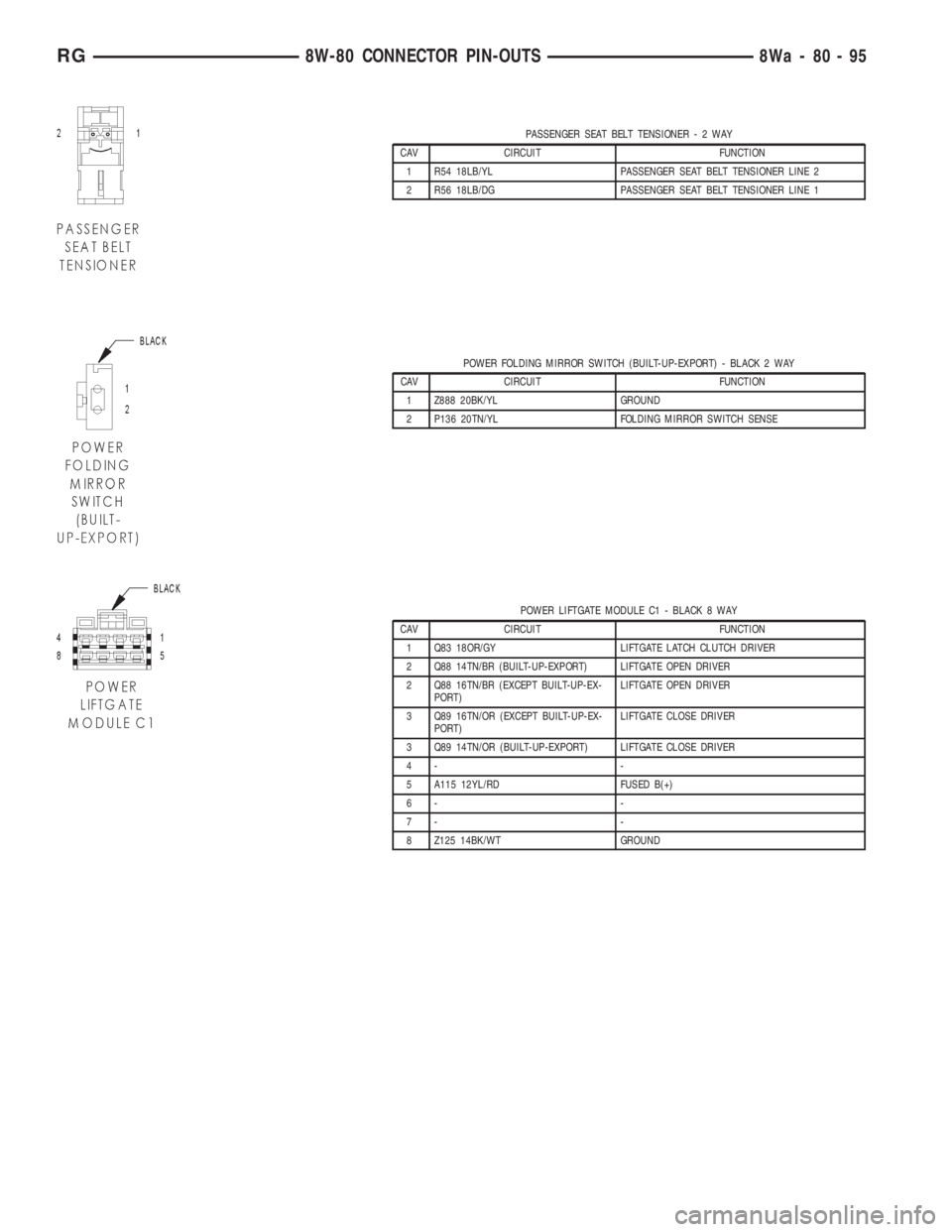

PASSENGER SEAT BELT TENSIONER-2WAY

CAV CIRCUIT FUNCTION

1 R54 18LB/YL PASSENGER SEAT BELT TENSIONER LINE 2

2 R56 18LB/DG PASSENGER SEAT BELT TENSIONER LINE 1

POWER FOLDING MIRROR SWITCH (BUILT-UP-EXPORT) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z888 20BK/YL GROUND

2 P136 20TN/YL FOLDING MIRROR SWITCH SENSE

POWER LIFTGATE MODULE C1 - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1 Q83 18OR/GY LIFTGATE LATCH CLUTCH DRIVER

2 Q88 14TN/BR (BUILT-UP-EXPORT) LIFTGATE OPEN DRIVER

2 Q88 16TN/BR (EXCEPT BUILT-UP-EX-

PORT)LIFTGATE OPEN DRIVER

3 Q89 16TN/OR (EXCEPT BUILT-UP-EX-

PORT)LIFTGATE CLOSE DRIVER

3 Q89 14TN/OR (BUILT-UP-EXPORT) LIFTGATE CLOSE DRIVER

4- -

5 A115 12YL/RD FUSED B(+)

6- -

7- -

8 Z125 14BK/WT GROUND

RG8W-80 CONNECTOR PIN-OUTS8Wa-80-95

Page 2566 of 4284

Component/Ground Color Location Fig.

Driver Heated Seat Module C3 GN At Seat N/S

Driver Power Seat Front Riser

MotorRD At Seat N/S

Driver Power Seat Horizontal

MotorBK At Seat N/S

Driver Power Seat Rear Riser

MotorRD At Seat N/S

Driver Power Seat Recliner Motor GN At Seat N/S

Driver Power Seat Switch GN At Switch N/S

Driver Power Window Motor RD At Motor N/S

Driver Power Window Switch GN At Switch N/S

Driver Power Window Switch

(RHD)NAT At Switch N/S

Driver Seatbelt Switch WT At Switch on Seat Harness N/S

Driver Seatbelt Tensioner On Seat Harness N/S

EGR Solenoid (Diesel) BK Above Transmission

Right Side of EngineN/S

EGR Solenoid GY Above Transmission

Right Side of Engine10, 11, 12,

14

Electric Wiper De-Icer-C1 WT Right Side Instrument Panel 16, 20, 23

Electric Wiper De-Icer-C2 WT Left Side Instrument Panel 16, 17 22

Engine Control Module C1

(Diesel)BK Right Side of Engine 12

Engine Control Module C2

(Diesel)BK Right Side of Engine 12

Engine Coolant Temperature

Sensor (Gas)BK On Cylinder Block N/S

Engine Coolant Temperature

Sensor (Diesel)BL On Cylinder Block 12

Engine Oil Pressure Sensor

(Diesel)BK Rear of Engine 13

Engine Oil Pressure Switch LTGN On Cylinder Block 10

Engine Oil Temperature Sensor

(Diesel)BK Rear of Engine 13

EVAP/Purge Solenoid BK Right Motor Mount 10, 14

Evaporator Temperature Sensor BK Right Side of HVAC N/S

Floor Console Lamp BK At Lamp N/S

Floor Console Power Outlet RD At Front Console N/S

Front Blower Module C1 (ATC) BK On HVAC N/S

Front Blower Module C2 (ATC) BK On HVAC N/S

Front Cigar Lighter RD/NAT Rear of Lighter 16, 19, 21

Front Reading Lamps/Switch BK At Switch N/S

Front Washer Pump Motor BK Right Fender Well 4

Fuel Heater (Diesel) BK Left Rear Engine Compartment N/S

Fuel Injector No.1 BK At Fuel Injector N/S

8Wa - 90 - 4 8W-90 CONNECTOR/GROUND LOCATIONS BUXRG

CONNECTOR/GROUND LOCATIONS BUX (Continued)

Page 2570 of 4284

Component/Ground Color Location Fig.

Memory Seat Rear Vertical Motor RD Under Seat N/S

Memory Seat Rear Vertical

Position SensorBK Under Seat N/S

Memory Seat Recliner Motor GN Under Seat N/S

Memory Seat Recliner Position

SensorBK Under Seat N/S

Memory Seat Switch BK At Switch Driver Door N/S

Message Center WT Rear of Message Center 16, 17, 23

Mode Door Actuator BK Left Side of HVAC N/S

Multi Function Switch BK At Steering Column 16, 17, 18,

19, 26

Occupant Restraint Controller YL/RD Right Side of Instrument Panel 16, 20, 21

Output Speed Sensor GY Front of Transmission 15

Overhead Console BK Front of Console N/S

Oxygen Sensor 1/1 Upstream GY Rear of Engine 10, 11, 15

Oxygen Sensor 1/2 Downstream BK Rear of Engine 10, 11, 15

Park/Neutral Positon Switch BK Front of Transmission 11

Passenger Airbag YL Passenger Side of Instrument Panel 16, 19, 20,

25

Passenger Blend Door Actuator On HVAC N/S

Passenger Door Courtesy Lamp BK At Lamp 33

Passenger Door Lock Switch BK At Switch 33

Passenger Folding Mirror Relay BL Right Kick Panel N/S

Passenger Heated Seat Back GN At Seat N/S

Passenger Heated Seat Cushion BK At Seat N/S

Passenger Heated Seat Module

C1GY At Heated Seat N/S

Passenger Heated Seat Module

C2GY At Heated Seat Back N/S

Passenger Heated Seat Module

C3GN At Heated Seat N/S

Passenger Power Seat Front

Riser MotorRD Under Seat N/S

Passenger Power Seat Horizontal

MotorBK Under Seat N/S

Passenger Power Seat Rear

Riser MotorRD Under Seat N/S

Passenger Power Seat Recliner

MotorGN Under Seat N/S

Passenger Power Seat Switch GN At Switch N/S

Passenger Power Window Motor RD At Motor 33

Passenger Power Window Switch BK At Switch 33

Passenger Seatbelt Switch On Seat Harness N/S

Passenger Seatbelt Tensioner On Seat Harness N/S

Power Folding Mirror Switch BK Near Steering Column 26

8Wa - 90 - 8 8W-90 CONNECTOR/GROUND LOCATIONS BUXRG

CONNECTOR/GROUND LOCATIONS BUX (Continued)

Page 2626 of 4284

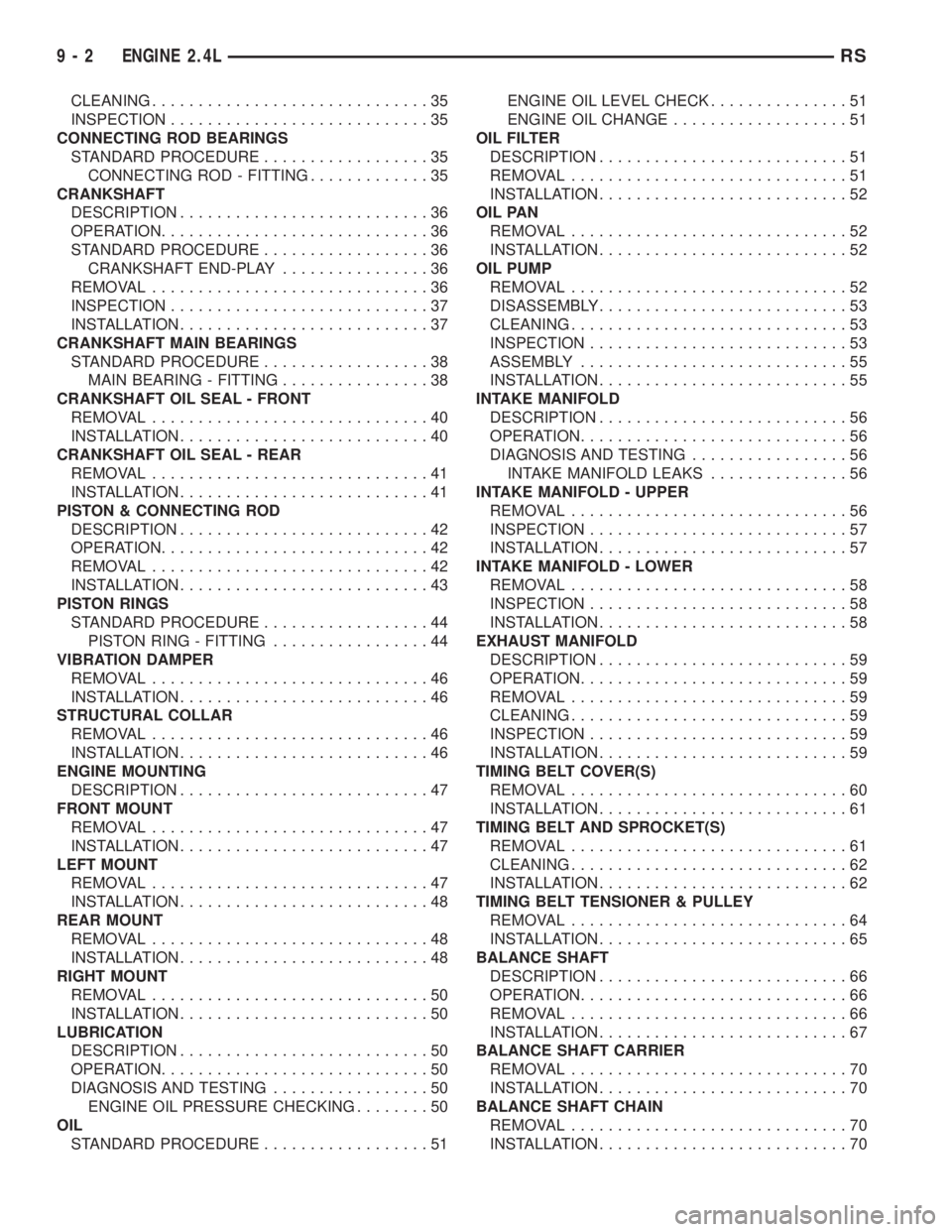

CLEANING..............................35

INSPECTION............................35

CONNECTING ROD BEARINGS

STANDARD PROCEDURE..................35

CONNECTING ROD - FITTING.............35

CRANKSHAFT

DESCRIPTION...........................36

OPERATION.............................36

STANDARD PROCEDURE..................36

CRANKSHAFT END-PLAY................36

REMOVAL..............................36

INSPECTION............................37

INSTALLATION...........................37

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE..................38

MAIN BEARING - FITTING................38

CRANKSHAFT OIL SEAL - FRONT

REMOVAL..............................40

INSTALLATION...........................40

CRANKSHAFT OIL SEAL - REAR

REMOVAL..............................41

INSTALLATION...........................41

PISTON & CONNECTING ROD

DESCRIPTION...........................42

OPERATION.............................42

REMOVAL..............................42

INSTALLATION...........................43

PISTON RINGS

STANDARD PROCEDURE..................44

PISTON RING - FITTING.................44

VIBRATION DAMPER

REMOVAL..............................46

INSTALLATION...........................46

STRUCTURAL COLLAR

REMOVAL..............................46

INSTALLATION...........................46

ENGINE MOUNTING

DESCRIPTION...........................47

FRONT MOUNT

REMOVAL..............................47

INSTALLATION...........................47

LEFT MOUNT

REMOVAL..............................47

INSTALLATION...........................48

REAR MOUNT

REMOVAL..............................48

INSTALLATION...........................48

RIGHT MOUNT

REMOVAL..............................50

INSTALLATION...........................50

LUBRICATION

DESCRIPTION...........................50

OPERATION.............................50

DIAGNOSIS AND TESTING.................50

ENGINE OIL PRESSURE CHECKING........50

OIL

STANDARD PROCEDURE..................51ENGINE OIL LEVEL CHECK...............51

ENGINE OIL CHANGE...................51

OIL FILTER

DESCRIPTION...........................51

REMOVAL..............................51

INSTALLATION...........................52

OIL PAN

REMOVAL..............................52

INSTALLATION...........................52

OIL PUMP

REMOVAL..............................52

DISASSEMBLY...........................53

CLEANING..............................53

INSPECTION............................53

ASSEMBLY.............................55

INSTALLATION...........................55

INTAKE MANIFOLD

DESCRIPTION...........................56

OPERATION.............................56

DIAGNOSIS AND TESTING.................56

INTAKE MANIFOLD LEAKS...............56

INTAKE MANIFOLD - UPPER

REMOVAL..............................56

INSPECTION............................57

INSTALLATION...........................57

INTAKE MANIFOLD - LOWER

REMOVAL..............................58

INSPECTION............................58

INSTALLATION...........................58

EXHAUST MANIFOLD

DESCRIPTION...........................59

OPERATION.............................59

REMOVAL..............................59

CLEANING..............................59

INSPECTION............................59

INSTALLATION...........................59

TIMING BELT COVER(S)

REMOVAL..............................60

INSTALLATION...........................61

TIMING BELT AND SPROCKET(S)

REMOVAL..............................61

CLEANING..............................62

INSTALLATION...........................62

TIMING BELT TENSIONER & PULLEY

REMOVAL..............................64

INSTALLATION...........................65

BALANCE SHAFT

DESCRIPTION...........................66

OPERATION.............................66

REMOVAL..............................66

INSTALLATION...........................67

BALANCE SHAFT CARRIER

REMOVAL..............................70

INSTALLATION...........................70

BALANCE SHAFT CHAIN

REMOVAL..............................70

INSTALLATION...........................70

9 - 2 ENGINE 2.4LRS

Page 2629 of 4284

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - ENGINE

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Engine Mechanical and the Engine

Performance diagnostic charts, for possible causes

and corrections of malfunctions (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING - MECHANICAL)

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING

- PERFORMANCE).For fuel system diagnosis, (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Lash Adjuster (Tappet) Noise Diagnosis

²Engine Oil Leak Inspection

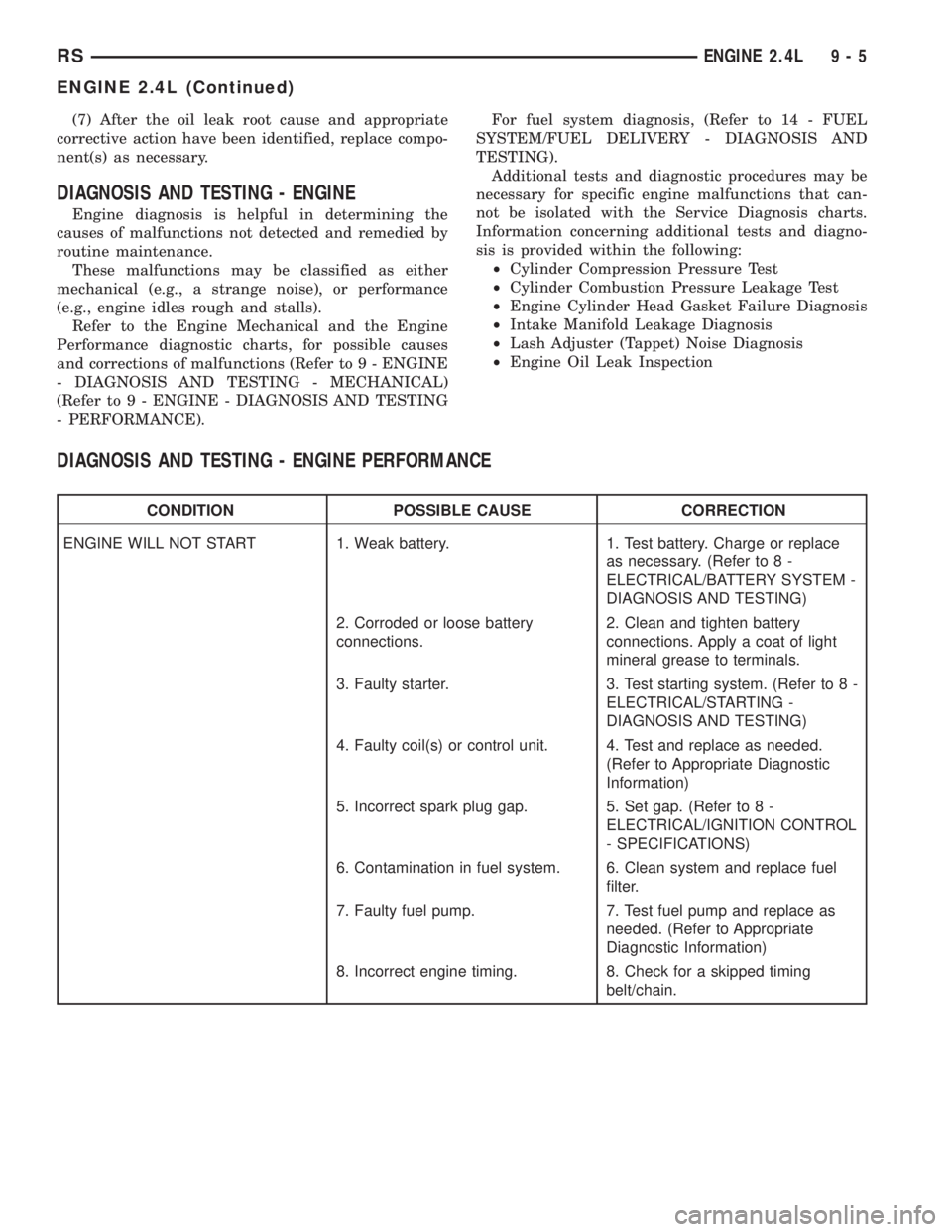

DIAGNOSIS AND TESTING - ENGINE PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery. 1. Test battery. Charge or replace

as necessary. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM -

DIAGNOSIS AND TESTING)

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to terminals.

3. Faulty starter. 3. Test starting system. (Refer to 8 -

ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING)

4. Faulty coil(s) or control unit. 4. Test and replace as needed.

(Refer to Appropriate Diagnostic

Information)

5. Incorrect spark plug gap. 5. Set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL

- SPECIFICATIONS)

6. Contamination in fuel system. 6. Clean system and replace fuel

filter.

7. Faulty fuel pump. 7. Test fuel pump and replace as

needed. (Refer to Appropriate

Diagnostic Information)

8. Incorrect engine timing. 8. Check for a skipped timing

belt/chain.

RSENGINE 2.4L9-5

ENGINE 2.4L (Continued)

Page 2636 of 4284

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) (Refer to 9

- ENGINE/ENGINE BLOCK/CONNECTING ROD

BEARINGS - STANDARD PROCEDURE)

REMOVAL - ENGINE ASSEMBLY

(1) Perform fuel pressure release procedure (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE)

(2) Disconnect battery negative cable.

(3) Remove air cleaner housing and inlet tube.

(4) Disconnect the fuel line from fuel rail. (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- STANDARD PROCEDURE)

(5) Disconnect all vacuum hoses.

(6) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(7) Remove radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL)

(8) Remove radiator upper and lower hoses.

(9) Disconnect automatic transmission cooler lines

and plug.(10) Disconnect transmission shift linkage and

electrical connectors.

(11) Disconnect throttle body linkage.

(12) Disconnect engine wiring harness.

(13) Disconnect heater hoses from heater (Fig. 5).

(14) Discharge air conditioning system. (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE)

(15) Hoist vehicle and remove front wheels and

tires.

(16) Remove accessory drive belt splash shield.

(17) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(18) Remove axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - REMOVAL)

(19) Drain engine oil and remove oil filter. (Refer

to 9 - ENGINE/LUBRICATION/OIL - STANDARD

PROCEDURE)

(20) Remove crossmember cradle plate (Fig. 6).

(21) Disconnect exhaust pipe from manifold (Fig.

7).

(22) Remove engine front mount and bracket from

engine. (Refer to 9 - ENGINE/ENGINE MOUNTING/

FRONT MOUNT - REMOVAL)

(23) Remove structural collar. (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

Fig. 5 HEATER HOSES - 2.4L

1 - HEATER HOSES TO HEATER 3 - HEATER HOSE TO ENGINE - SUPPLY AND RETURN

2 - BOLT - HEATER TUBE SUPPORT

9 - 12 ENGINE 2.4LRS

ENGINE 2.4L (Continued)