belt CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2740 of 4284

(3) Install seal using Special Tool C-4992-1 until

seal is flush with cover. (Fig. 64).

(4) Install crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

(5) Install accessory drive belt. (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION)

(6) Install inner splash shield and right front

wheel.

(7) Lower vehicle and connect negative cable to

battery.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Remove the transaxle. Refer to TRANSAXLE

AND POWER TRANSFER UNIT for procedure.

(2) Remove the flex plate. (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL)

(3) Insert a 3/16 flat bladed pry tool between the

dust lip and the metal case of the crankshaft seal.

Angle the pry tool (Fig. 65) through the dust lip

against metal case of the seal. Pry out seal.

CAUTION: Do not permit the pry tool blade to con-

tact crankshaft seal surface. Contact of the pry tool

blade against crankshaft edge (chamfer) is permit-

ted.

Fig. 63 Crankshaft Front Seal Removal

1 - SEAL

2 - SPECIAL TOOL 6341A

Fig. 64 CRANKSHAFT FRONT SEAL INSTALLATION

1 - SPECIAL TOOL C-4992-1

2 - SEAL

3 - SPECIAL TOOL C-4992-2

4 - CRANKSHAFT

Fig. 65 Crankshaft Rear Oil Seal - Removal

1 - REAR CRANKSHAFT SEAL

2 - ENGINE BLOCK

3 - ENGINE BLOCK

4 - REAR CRANKSHAFT SEAL METAL CASE

5 - PRY IN THIS DIRECTION

6 - CRANKSHAFT

7 - SCREWDRIVER

8 - REAR CRANKSHAFT SEAL DUST LIP

9 - SCREWDRIVER

9 - 116 ENGINE 3.3/3.8LRS

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 2750 of 4284

VIBRATION DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Remove the right front wheel and inner splash

shield.

(4) Remove the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)(5) Remove vibration damper bolt.

(6) Insert Special Tool 8450 into crankshaft nose

(Fig. 87).

(7) Position 3-jaw puller Special Tool 1026 on

damper as shown in (Fig. 87). Turn puller forcing

screw until damper releases from crankshaft.

(8) Remove the crankshaft vibration damper.

INSTALLATION

(1) Install crankshaft vibration damper using Spe-

cial Tool 8451 with thrust bearing/washer (Fig. 88).

NOTE: To minimize friction and prolong tool life,

lubricate the threads on the forcing screw of Spe-

cial Tool 8451.

(2) Position vibration damper on crankshaft.

(3) Screw Special Tool 8451 into crankshaft until

the bolt seats. Turn the nut to install damper until it

seats fully.

(4) Remove Special Tool 8451.

(5) Install the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(6) Install inner splash shield and right front

wheel.

(7) Connect negative cable to battery.

Fig. 85 Piston Ring Installation

Fig. 86 Piston Ring End Gap Position

1 - GAP OF LOWER SIDE RAIL

2 - NO. 1 RING GAP

3 - GAP OF UPPER SIDE RAIL

4 - NO. 2 RING GAP AND SPACER EXPANDER GAP

Fig. 87 Vibration Damper - Removal

1 - SPECIAL TOOL 8450 - INSERT

2 - SPECIAL TOOL 1026-3JAWPULLER

9 - 126 ENGINE 3.3/3.8LRS

PISTON RINGS (Continued)

Page 2760 of 4284

OIL PAN

REMOVAL

(1) Disconnect negative cable from battery and

remove engine oil dipstick.

(2) Raise vehicle on hoist and drain engine oil.

(3) Remove drive belt splash shield.

(4) Remove strut to transaxle attaching bolt (Fig.

106). Loosen strut to engine block attaching bolts.

(5) Remove transaxle case cover (Fig. 106).

(6) Remove oil pan fasteners (Fig. 107).

(7) Remove the oil pan and gasket (Fig. 107).

CLEANING

(1) Clean oil pan with solvent and wipe dry with a

clean cloth.

(2) Clean all gasket material from mounting sur-

faces of pan and block.

(3) Clean oil screen and pick-up tube in clean sol-

vent.

INSPECTION

(1) Inspect oil drain plug and plug hole for

stripped or damaged threads and repair as necessary.

Install a new drain plug gasket. Tighten to 27 N´m

(20 ft. lbs.).

(2) Inspect oil pan mounting flange for bends or

distortion. Straighten flange if necessary.

(3) Inspect condition of oil screen and pick-up tube.

INSTALLATION

(1) Clean sealing surfaces and apply a 1/8 inch

bead of MopartEngine RTV GEN II at the parting

line of the chain case cover and the rear seal retainer

(Fig. 108).

(2) Position a new pan gasket on oil pan (Fig. 107).

(3) Install oil pan and tighten fasteners to 12 N´m

(105 in. lbs.) (Fig. 107).

(4) Install cover to transaxle case (Fig. 106).

(5) Install the strut bolt to transaxle housing (Fig.

106). Tighten all bending brace bolts.

(6) Install the drive belt splash shield.

(7) Lower vehicle and install oil dipstick.

Fig. 105 OIL FILTER ADAPTER

1 - SEAL

2 - OIL FILTER ADAPTER

3 - OIL FILTER

4 - BOLT

5 - OIL PRESSURE SWITCH

6 - BOLT

Fig. 106 Powertrain Struts and Transaxle Case

Cover

1 - BRACKET - ENGINE REAR MOUNT

2 - BOLT - TRANSAXLE CASE COVER

3 - STRUT - TRANSAXLE TO ENGINE HORIZONTAL

4 - BOLT - HORIZONTAL STRUT

5 - BOLT - STRUT TO TRANSAXLE

6 - COVER - TRANSAXLE CASE LOWER

7 - STRUT - TRANSAXLE TO ENGINE

8 - BOLT - STRUT TO ENGINE

9 - BOLT - ENGINE REAR MOUNT BRACKET

9 - 136 ENGINE 3.3/3.8LRS

OIL FILTER ADAPTER (Continued)

Page 2762 of 4284

OPERATION

The oil pressure switch provides a ground for the

instrument cluster low oil pressure indicator light.

The switch receives oil pressure input from the

engine main oil gallery. When engine oil pressure is

greater than 27.5 Kpa (4 psi), the switch contacts

open, providing a open circuit to the low pressure

indicator light. For wiring circuits and diagnostic

information, (Refer to Appropriate Wiring/Diagnostic

Information).

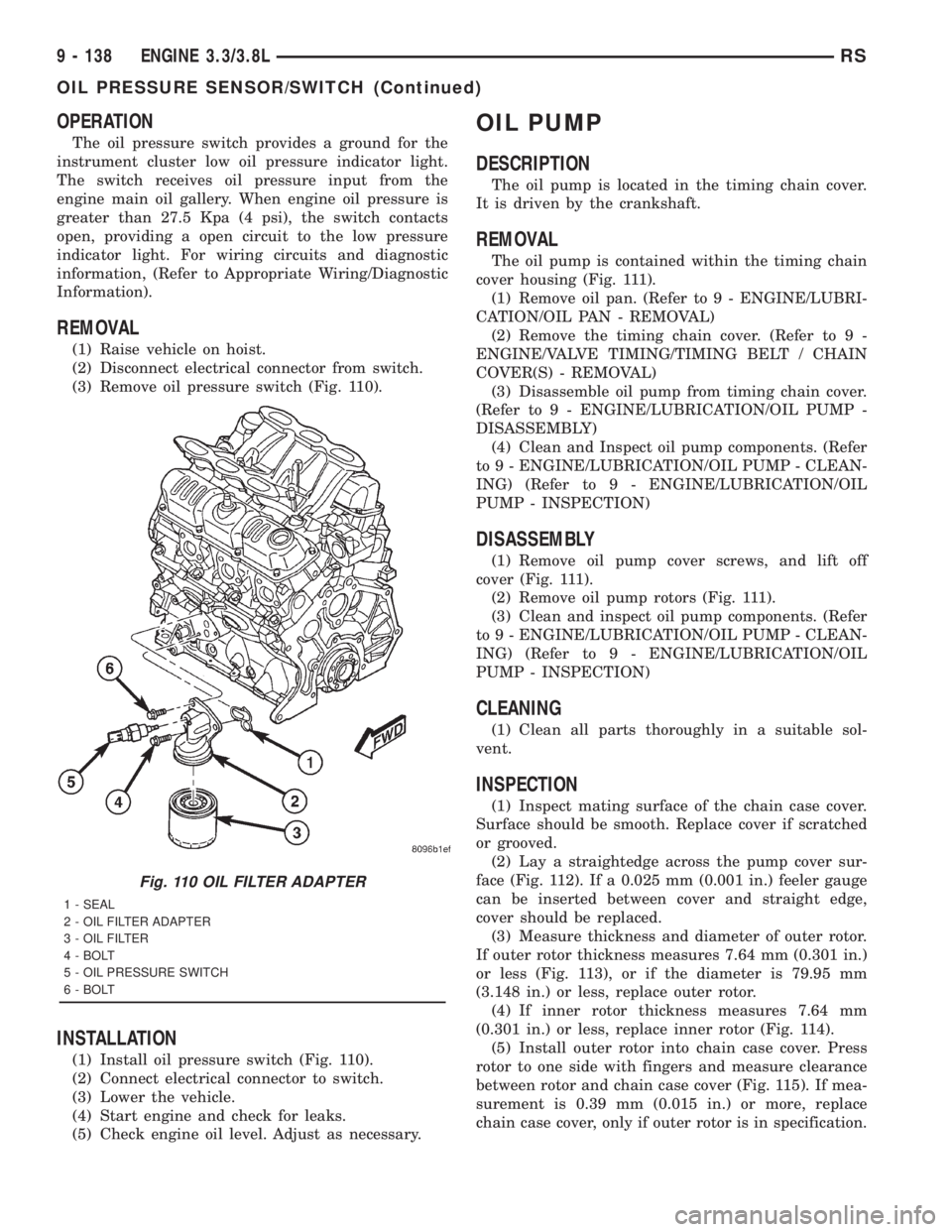

REMOVAL

(1) Raise vehicle on hoist.

(2) Disconnect electrical connector from switch.

(3) Remove oil pressure switch (Fig. 110).

INSTALLATION

(1) Install oil pressure switch (Fig. 110).

(2) Connect electrical connector to switch.

(3) Lower the vehicle.

(4) Start engine and check for leaks.

(5) Check engine oil level. Adjust as necessary.

OIL PUMP

DESCRIPTION

The oil pump is located in the timing chain cover.

It is driven by the crankshaft.

REMOVAL

The oil pump is contained within the timing chain

cover housing (Fig. 111).

(1) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL)

(2) Remove the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

(3) Disassemble oil pump from timing chain cover.

(Refer to 9 - ENGINE/LUBRICATION/OIL PUMP -

DISASSEMBLY)

(4) Clean and Inspect oil pump components. (Refer

to 9 - ENGINE/LUBRICATION/OIL PUMP - CLEAN-

ING) (Refer to 9 - ENGINE/LUBRICATION/OIL

PUMP - INSPECTION)

DISASSEMBLY

(1) Remove oil pump cover screws, and lift off

cover (Fig. 111).

(2) Remove oil pump rotors (Fig. 111).

(3) Clean and inspect oil pump components. (Refer

to 9 - ENGINE/LUBRICATION/OIL PUMP - CLEAN-

ING) (Refer to 9 - ENGINE/LUBRICATION/OIL

PUMP - INSPECTION)

CLEANING

(1) Clean all parts thoroughly in a suitable sol-

vent.

INSPECTION

(1) Inspect mating surface of the chain case cover.

Surface should be smooth. Replace cover if scratched

or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 112). If a 0.025 mm (0.001 in.) feeler gauge

can be inserted between cover and straight edge,

cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 7.64 mm (0.301 in.)

or less (Fig. 113), or if the diameter is 79.95 mm

(3.148 in.) or less, replace outer rotor.

(4) If inner rotor thickness measures 7.64 mm

(0.301 in.) or less, replace inner rotor (Fig. 114).

(5) Install outer rotor into chain case cover. Press

rotor to one side with fingers and measure clearance

between rotor and chain case cover (Fig. 115). If mea-

surement is 0.39 mm (0.015 in.) or more, replace

chain case cover, only if outer rotor is in specification.

Fig. 110 OIL FILTER ADAPTER

1 - SEAL

2 - OIL FILTER ADAPTER

3 - OIL FILTER

4 - BOLT

5 - OIL PRESSURE SWITCH

6 - BOLT

9 - 138 ENGINE 3.3/3.8LRS

OIL PRESSURE SENSOR/SWITCH (Continued)

Page 2764 of 4284

(8) Remove oil pressure relief valve. (Refer to 9 -

ENGINE/LUBRICATION/OIL PRESSURE RELIEF

VALVE - REMOVAL)

(9) Inspect oil pressure relief valve and bore.

Inspect for scoring, pitting and free valve operation

in bore (Fig. 118). Small marks may be removed with

400-grit wet or dry sandpaper.

(10) The relief valve spring has a free length of

approximately 49.5 mm (1.95 inches) it should test

between 19.5 and 20.5 pounds when compressed to

34 mm (1-11/32 inches). Replace spring that fails to

meet specifications.(11) If oil pressure is low and pump is within spec-

ifications, inspect for worn engine bearings or other

reasons for oil pressure loss.

ASSEMBLY

(1) Assemble pump, using new parts as required.

Install the inner rotor with chamfer facing the

cast iron oil pump cover.

(2) Prime oil pump before installation by filling

rotor cavity with engine oil.

(3) Install cover and tighten screws to 12 N´m (105

in. lbs.).

(4) If removed, install the oil pressure relief valve.

(Refer to 9 - ENGINE/LUBRICATION/OIL PRES-

SURE RELIEF VALVE - INSTALLATION)

INSTALLATION

(1) Install oil pump. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PUMP - ASSEMBLY)

(2) Install timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION) and oil pan (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

INTAKE MANIFOLD

DESCRIPTION

The intake system is made up of an upper and

lower intake manifold. The upper intake manifold is

made of a composite for the 3.3L engine (Fig. 119)

and aluminum for the 3.8L engine (Fig. 120). The

lower intake manifold is common between the two

engines (Fig. 121). It also provides coolant crossover

Fig. 116 Measuring Clearance Between Rotors

1 - FEELER GAUGE

2 - INNER ROTOR

3 - OUTER ROTOR

Fig. 117 Measuring Clearance Over Rotors

1 - FEELER GAUGE

2 - STRAIGHT EDGE

Fig. 118 Oil Pressure Relief Valve

1 - RELIEF VALVE

2 - SPRING

3 - RETAINER CAP

9 - 140 ENGINE 3.3/3.8LRS

OIL PUMP (Continued)

Page 2765 of 4284

between cylinder heads and houses the coolant ther-

mostat (Fig. 121).

The intake manifold utilizes a compact design with

very low restriction and outstanding flow balance.

This design allows the engine to perform with a wide

torque curve while increasing higher rpm horse-

power.

The composite upper intake for the 3.3L engine has

a unique cover over the upper portion of the manifold

(Fig. 119). This cover is designed to absorb intake

noises and also offers styling to the engine. This

cover, under any circumstance, should never be

removed. The fasteners attaching the upper intake

manifold can be accessed without removing this

cover. If, for some reason, the molded-in vacuum

ports break, the composite manifold can salvaged.

The vacuum ports are designed to break at the shoul-

der, if overloaded. Additional material in the shoulder

area provides sufficient stock to repair. For more

information and procedure, (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - STANDARD

PROCEDURE). Also, if the special screws that attach

the MAP sensor, power steering reservoir, throttle

cable bracket, and the EGR tube become stripped, an

oversized screw is available to repair the stripped-out

condition. For more information and procedure,

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - STANDARD PROCEDURE)

OPERATION

The intake manifold delivers air to the combustion

chambers. This air allows the fuel delivered by the

fuel injectors to ignite when the spark plug fire.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.INTAKE MANIFOLD - UPPER

3.3L

STANDARD PROCEDURE - MANIFOLD

STRIPPED THREAD REPAIR

The composite upper intake manifold thread

bosses, if stripped out, can be repaired by utilizing a

repair screw available through Mopartparts. Repair

screws are available for the following manifold

attached components:

²MAP sensor

²Power steering reservoir

²EGR tube

²Throttle cable bracket

The repair screws require a unique tightening

torque specification from the original screw. Refer to

the following chart for specification.

Fig. 119 INTAKE MANIFOLD - UPPER 3.3L

1 - BOLT

2 - MAP SENSOR

3 - SCREW

4 - MANIFOLD - UPPER

5 - WIRE HARNESS

6 - GASKET (3 PER CYL. BANK)

RSENGINE 3.3/3.8L9 - 141

INTAKE MANIFOLD (Continued)

Page 2774 of 4284

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds are log type and made of

Hi-Sil-Moly (high temperature resistant) nodular cast

iron. The exhaust manifolds are attached directly to

the cylinder heads and a cross-over pipe connects the

two manifolds.

OPERATION

The exhaust manifolds collects the exhaust gases

exiting the combustion chambers. It then channels

the exhaust gases to the exhaust pipe that is

attached to the rear (right side) manifold.

EXHAUST MANIFOLD - RIGHT

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL)

(3) Disconnect spark plug wires.

(4) Remove bolts fastening crossover pipe to

exhaust manifold (Fig. 141).

(5) Disconnect and remove the upstream oxygen

sensor (Fig. 144).

(6) Remove the heat shield attaching screws (Fig.

144).

(7) Remove the upper heat shield (Fig. 144).

(8) Raise vehicle on hoist and remove drive belt

shield.

Fig. 139 INTAKE MANIFOLD - LOWER

1 - INTAKE MANIFOLD - LOWER

2 - BOLT - GASKET END SEAL RETAINER

3 - GASKET

4 - BOLT - LOWER INTAKE MANIFOLD

Fig. 140 LOWER MANIFOLD TIGHTENING

SEQUENCE

Fig. 141 CROSS-OVER PIPE

1 - CROSS-OVER PIPE

2 - BOLT

3 - GASKET

4 - FLAG NUT

9 - 150 ENGINE 3.3/3.8LRS

INTAKE MANIFOLD - LOWER (Continued)

Page 2776 of 4284

(3) Install the remaining manifold attaching bolts.

Tighten all bolts to 23 N´m (200 in. lbs.).

(4) Position the power steering pump support strut

and install upper bolt (Fig. 142).

(5) Install heat shield and attaching screws (Fig.

144).

(6) Install and connect upstream oxygen sensor

(Fig. 144).

(7) Raise the vehicle.

(8) Attach catalytic converter pipe to exhaust man-

ifold using new gasket and tighten bolts to 37 N´m

(27 ft. lbs.) (Fig. 143).

(9) Connect downstream oxygen sensor connector.

(10) Tighten the power steering pump support

strut lower bolt (Fig. 142).

(11) Install the belt splash shield and lower the

vehicle.

(12) Install the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION)

(13) Connect battery negative cable.

EXHAUST MANIFOLD - LEFT

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove bolts attaching crossover pipe to

exhaust manifold (Fig. 146).

(3) Disconnect left cylinder bank spark plug wires.

(4) Remove heat shield attaching bolts (Fig. 147).

(5) Remove bolts attaching exhaust manifold to

cylinder head (Fig. 147).

(6) Remove the exhaust manifold (Fig. 147).(7) Inspect and clean manifold. (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

INSPECTION) (Refer to 9 - ENGINE/MANIFOLDS/

EXHAUST MANIFOLD - CLEANING)

CLEANING

(1) Discard gasket (if equipped) and clean all sur-

faces of manifold and cylinder head.

Fig. 145 Check Exhaust Manifold Mounting

1 - STRAIGHT EDGE

2 - CROSSOVER PIPE MOUNTING SURFACE

3 - FEELER GAUGE

Fig. 146 CROSS-OVER PIPE

1 - CROSS-OVER PIPE

2 - BOLT

3 - GASKET

4 - FLAG NUT

Fig. 147 EXHAUST MANIFOLD - LEFT

1 - EXHAUST MANIFOLD - LEFT BANK

2 - HEAT SHIELD

3 - NUT - HEAT SHIELD

4 - BOLT - EXHAUST MANIFOLD

9 - 152 ENGINE 3.3/3.8LRS

EXHAUST MANIFOLD - RIGHT (Continued)

Page 2777 of 4284

INSPECTION

Inspect exhaust manifolds for damage or cracks

and check distortion of the cylinder head mounting

surface and exhaust crossover mounting surface with

a straightedge and thickness gauge (Fig. 148).

Manifold surface flatness limits should not exceed

1.0 mm (0.039 in.).

INSTALLATION

(1) Position exhaust manifold on cylinder head

(Fig. 147). Install bolts to center runner (cylinder #4)

and initial tighten to 2.8 N´m (25 in. lbs.).

(2) Using a new gasket, attach crossover pipe to

exhaust manifold and tighten bolts to 41 N´m (30 ft.

lbs.) (Fig. 146).

NOTE: Inspect crossover pipe fasteners for damage

from heat and corrosion. The cross-over bolts are

made of a special stainless steel alloy. If replace-

ment is required, OEM bolts are highly recom-

mended.

(3) Position heat shield on manifold (Fig. 147).

(4) Install the remaining manifold attaching bolts.

Tighten all bolts to 23 N´m (200 in. lbs.).

(5) Install and tighten heat shield attaching nut to

12 N´m (105 in. lbs.) (Fig. 147).

(6) Connect battery negative cable.

VALVE TIMING

VALVE TIMING VERIFICATION

(1) Remove front cylinder head cover and all 6

spark plugs.(2) Rotate engine until the #2 piston is at TDC of

the compression stroke.

(3) Install a degree wheel on the crankshaft pulley.

(4) With proper adaptor, install a dial indicator

into #2 spark plug hole. Using the indicator find TDC

on the compression stroke.

(5) Position the degree wheel to zero.

(6) Remove dial indicator from spark plug hole.

(7) Place a 5.08 mm (0.200 in.) spacer between the

valve stem tip of #2 intake valve and rocker arm pad.

Allow tappet to bleed down to give a solid tappet

effect.

(8) Install a dial indicator so plunger contacts the

#2 intake valve spring retainer as nearly perpendic-

ular as possible. Zero the indicator.

(9) Rotate the engine clockwise until the intake

valve has lifted .254 mm (0.010 in.).

CAUTION: Do not turn crankshaft any further clock-

wise as intake valve might bottom and result in

serious damage.

(10) Degree wheel should read 6 degrees BTDC to

6 degrees ATDC.

TIMING CHAIN COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(3) Raise vehicle on hoist.

(4) Drain engine oil.

(5) Remove right wheel and inner splash shield.

(6) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL)

(7) Remove oil pick-up tube (Fig. 149).

(8) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(9) Remove A/C compressor and set aside.

(10) Remove crankshaft vibration damper. (Refer

to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL)

(11) Remove radiator lower hose.

(12) Remove heater hose from timing chain cover

housing (Fig. 150) or water pump inlet tube (if

engine oil cooler equipped) (Fig. 151).

(13) Remove the right side engine mount. (Refer to

9 - ENGINE/ENGINE MOUNTING/RIGHT MOUNT

- REMOVAL)

(14) Remove idler pulley from engine bracket (Fig.

152).

(15) Remove the engine mount bracket (Fig. 152).

(16) Remove cam sensor from timing chain cover

(Fig. 152).

Fig. 148 Check Exhaust Manifold Mounting

1 - STRAIGHT EDGE

2 - CROSSOVER PIPE MOUNTING SURFACE

3 - FEELER GAUGE

RSENGINE 3.3/3.8L9 - 153

EXHAUST MANIFOLD - LEFT (Continued)

Page 2779 of 4284

(5) Install timing cover (Fig. 154).

(6) Install timing chain cover bolts. Tighten M8

bolts to 27 N´m (20 ft. lbs.) and M10 bolts to 54 N´m

(40 ft. lbs.) (Fig. 155).

(7) Install crankshaft front oil seal. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - FRONT - INSTALLATION)(8) Install water pump and pulley. (Refer to 7 -

COOLING/ENGINE/WATER PUMP - INSTALLA-

TION)

(9) Install crankshaft vibration damper. (Refer to 9

- ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

(10) Install engine mount bracket (Fig. 152) and

tighten M10 to 54 N´m (40 ft. lbs.), M8 bolt to 28

N´m (21 ft. lb. lbs.).

(11) Install idler pulley on engine mount bracket

(Fig. 152).

(12) Install right side engine mount. (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION)

(13) Install camshaft sensor. Refer to IGNITION

SYSTEM for procedure.

(14) Connect the heater return hose at rear of tim-

ing chain cover (Fig. 150) or at water pump inlet

tube (if engine oil cooler equipped) (Fig. 151).

(15) Connect the radiator lower hose.

(16) Install A/C compressor.

(17) Install accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(18) Install oil pump pick-up tube with new

O-ring. Tighten attaching bolt to 28 N´m (250 in.

lbs.).

(19) Install oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION)

(20) Install inner splash shield and right front

wheel.

(21) Fill crankcase with engine oil to proper level.

(22) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(23) Connect negative cable to battery.

Fig. 152 Engine Mount Bracket

1 - CAMSHAFT SENSOR

2 - BOLT - CAMSHAFT SENSOR

3 - BOLT - MOUNT BRACKET (VERTICAL)

4 - BRACKET - ENGINE MOUNT

5 - BOLT - MOUNT BRACKET (HORIZONTAL)

6 - PULLEY - IDLER

7 - BOLT - IDLER PULLEY

8 - SPACER - IDLER PULLEY BOLT

9 - BOLT - MOUNT BRACKET (HORIZONTAL)

Fig. 153 Power Steering Pump Strut

1 - BOLT - LOWER

2 - STRUT - P/S PUMP

3 - BOLT - UPPER

Fig. 154 Timing Chain Cover and Gasket

1 - GASKET

2 - TIMING CHAIN COVER

RSENGINE 3.3/3.8L9 - 155

TIMING CHAIN COVER (Continued)