change time CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3949 of 4284

TEST ACTION APPLICABILITY

7 Turn the ignition off.

Disconnect the IAC Motor harness connector.

Start and idle the engine.

Using a test light connected to ground, probe the IAC Driver #1 circuit for 10 seconds.

Repeat the above test for the remaining IAC Motor Driver circuits.

Does the test light turn on and off while probing each IAC Motor Driver circuit?2.4L 4 CYL DOHC

16V MPI

Ye s®Replace the Idle Air Control Motor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

8WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?2.4L 4 CYL DOHC

16V MPI

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

155

DRIVEABILITY - GAS

P0505-IDLE AIR CONTROL MOTOR CIRCUITS ÐContinued

Page 3952 of 4284

TEST ACTION APPLICABILITY

8WARNING: KEEP CLEAR OF THE ENGINE'S MOVING PARTS.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

158

DRIVEABILITY - GAS

P0508 - IAC MOTOR SENSE CIRCUIT LOW ÐContinued

Page 3954 of 4284

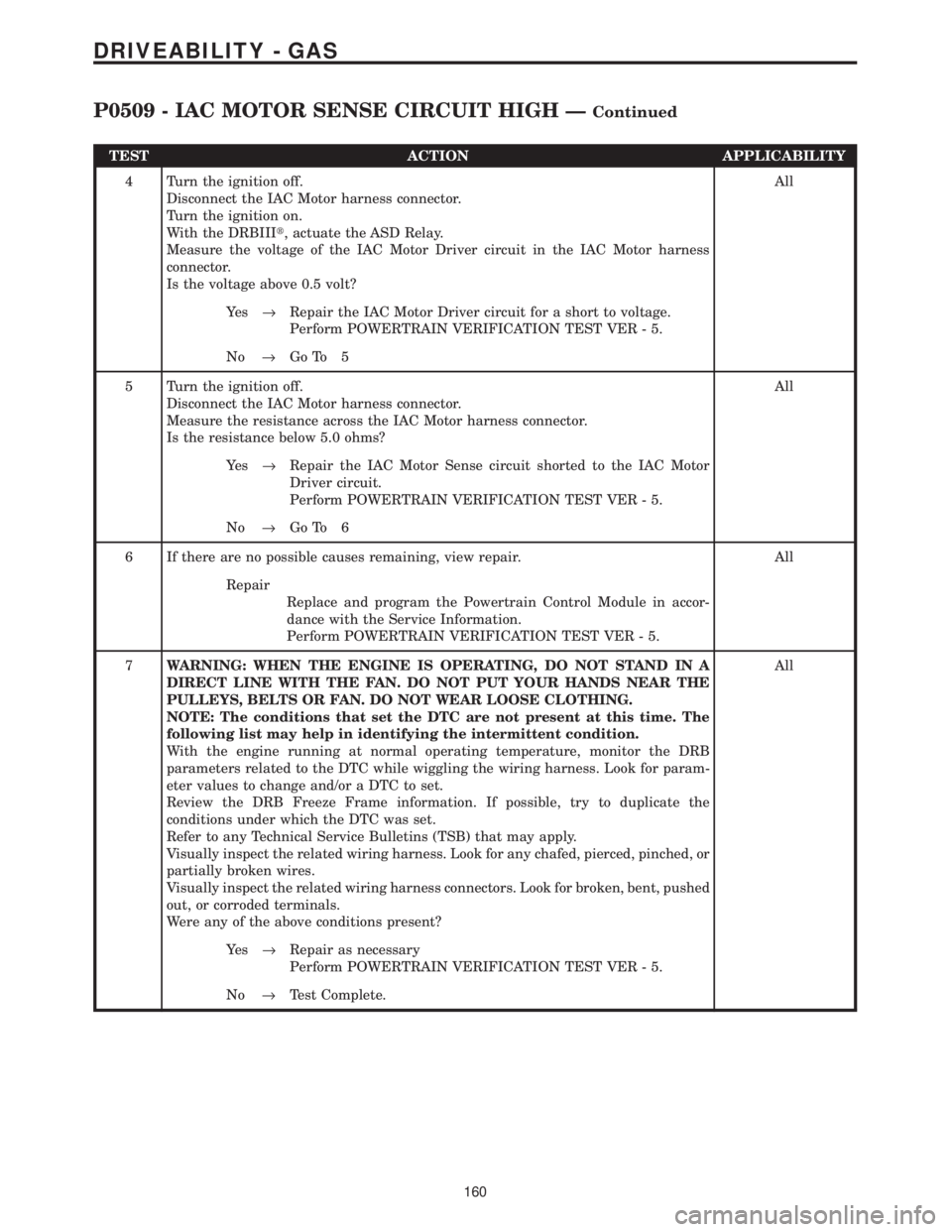

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the IAC Motor harness connector.

Turn the ignition on.

With the DRBIIIt, actuate the ASD Relay.

Measure the voltage of the IAC Motor Driver circuit in the IAC Motor harness

connector.

Is the voltage above 0.5 volt?All

Ye s®Repair the IAC Motor Driver circuit for a short to voltage.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 Turn the ignition off.

Disconnect the IAC Motor harness connector.

Measure the resistance across the IAC Motor harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Repair the IAC Motor Sense circuit shorted to the IAC Motor

Driver circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 6

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

160

DRIVEABILITY - GAS

P0509 - IAC MOTOR SENSE CIRCUIT HIGH ÐContinued

Page 3956 of 4284

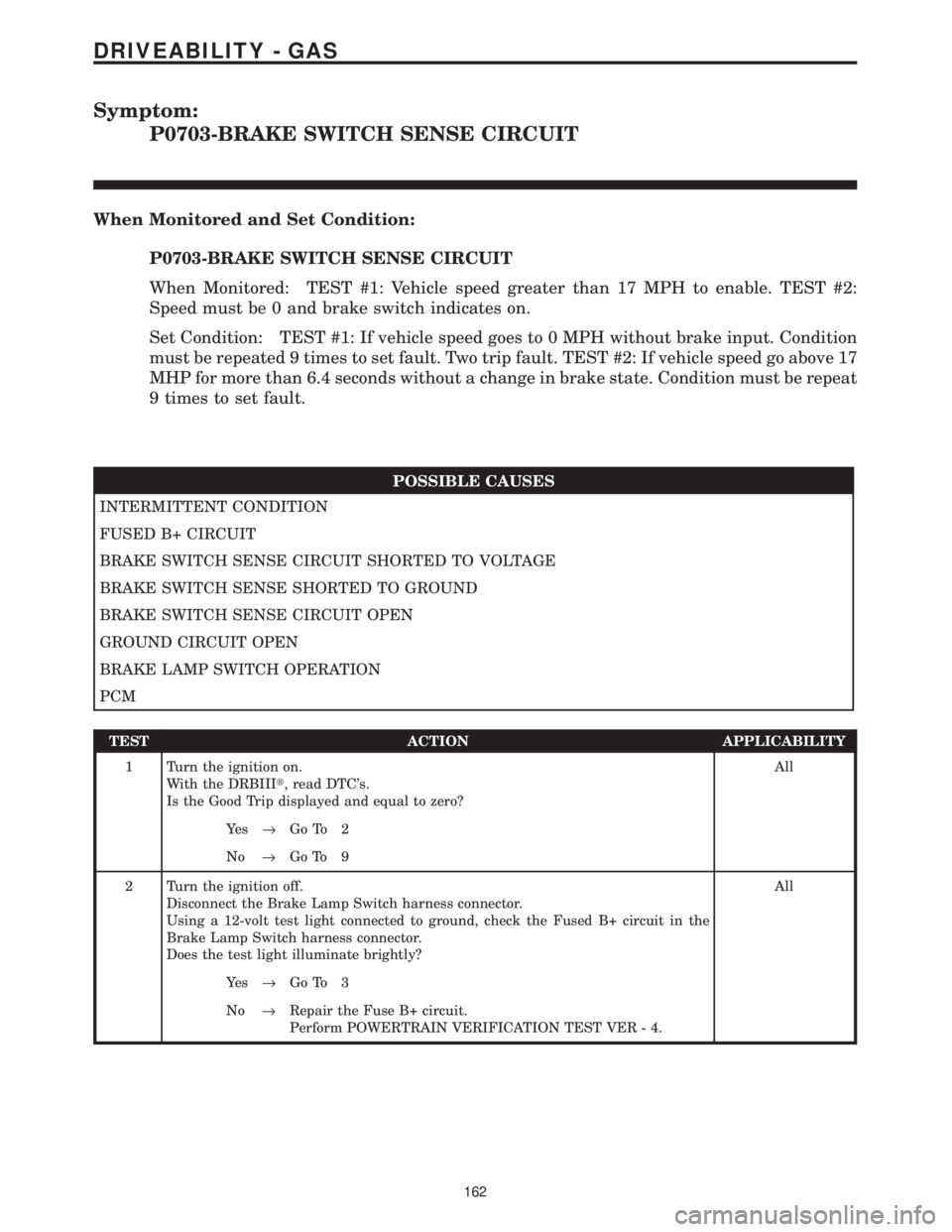

Symptom:

P0703-BRAKE SWITCH SENSE CIRCUIT

When Monitored and Set Condition:

P0703-BRAKE SWITCH SENSE CIRCUIT

When Monitored: TEST #1: Vehicle speed greater than 17 MPH to enable. TEST #2:

Speed must be 0 and brake switch indicates on.

Set Condition: TEST #1: If vehicle speed goes to 0 MPH without brake input. Condition

must be repeated 9 times to set fault. Two trip fault. TEST #2: If vehicle speed go above 17

MHP for more than 6.4 seconds without a change in brake state. Condition must be repeat

9 times to set fault.

POSSIBLE CAUSES

INTERMITTENT CONDITION

FUSED B+ CIRCUIT

BRAKE SWITCH SENSE CIRCUIT SHORTED TO VOLTAGE

BRAKE SWITCH SENSE SHORTED TO GROUND

BRAKE SWITCH SENSE CIRCUIT OPEN

GROUND CIRCUIT OPEN

BRAKE LAMP SWITCH OPERATION

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 9

2 Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Using a 12-volt test light connected to ground, check the Fused B+ circuit in the

Brake Lamp Switch harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the Fuse B+ circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 4.

162

DRIVEABILITY - GAS

Page 3958 of 4284

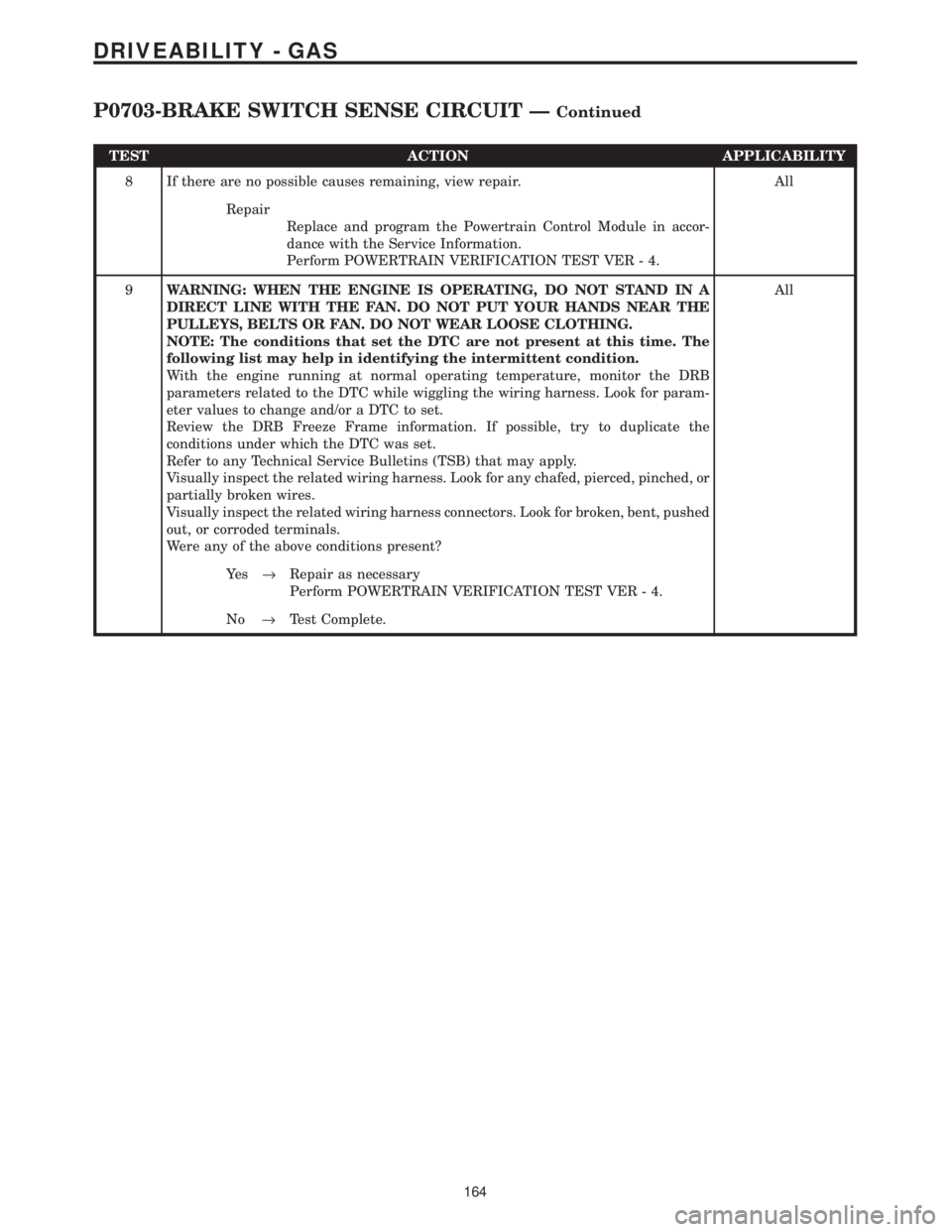

TEST ACTION APPLICABILITY

8 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 4.

9WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 4.

No®Test Complete.

164

DRIVEABILITY - GAS

P0703-BRAKE SWITCH SENSE CIRCUIT ÐContinued

Page 3964 of 4284

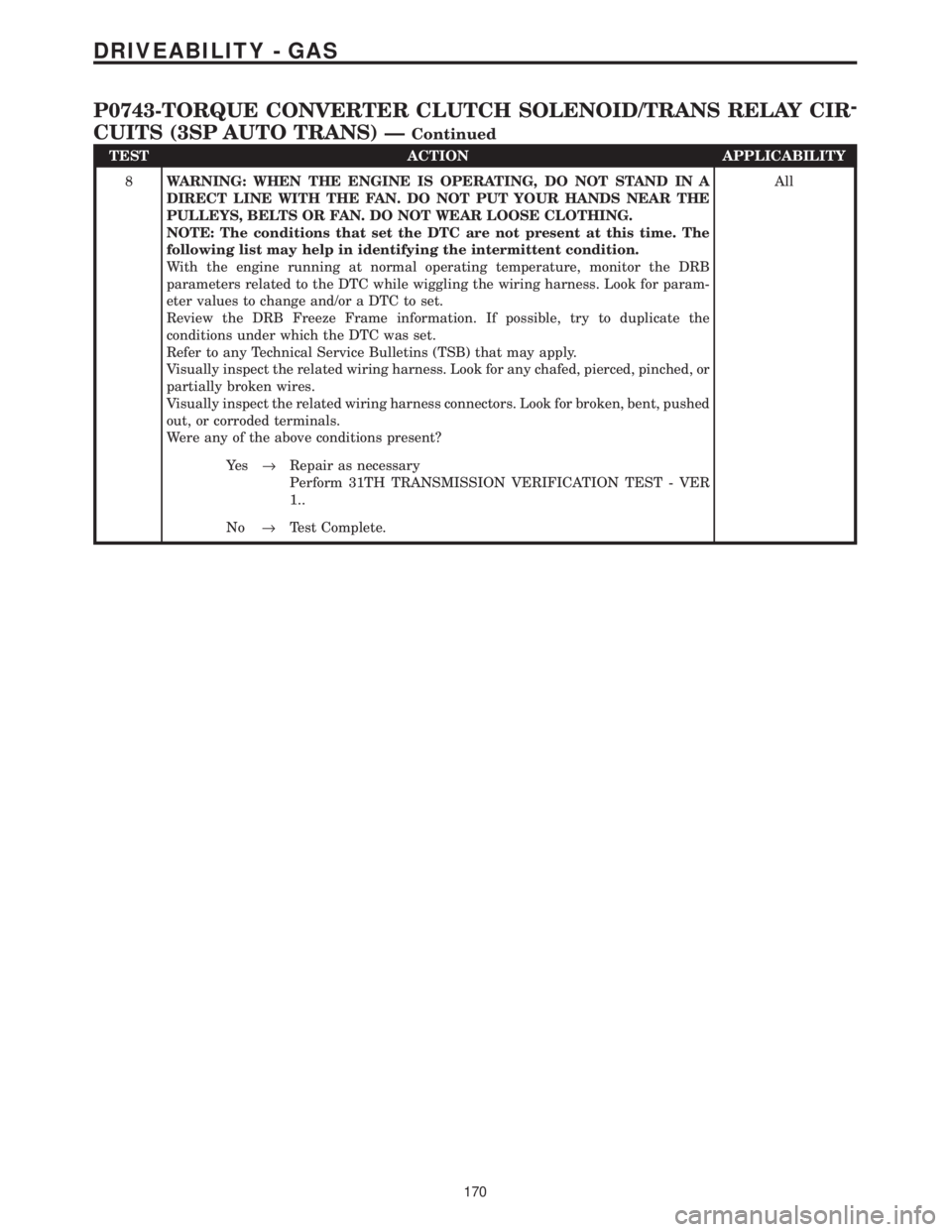

TEST ACTION APPLICABILITY

8WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

No®Test Complete.

170

DRIVEABILITY - GAS

P0743-TORQUE CONVERTER CLUTCH SOLENOID/TRANS RELAY CIR-

CUITS (3SP AUTO TRANS) Ð

Continued

Page 3965 of 4284

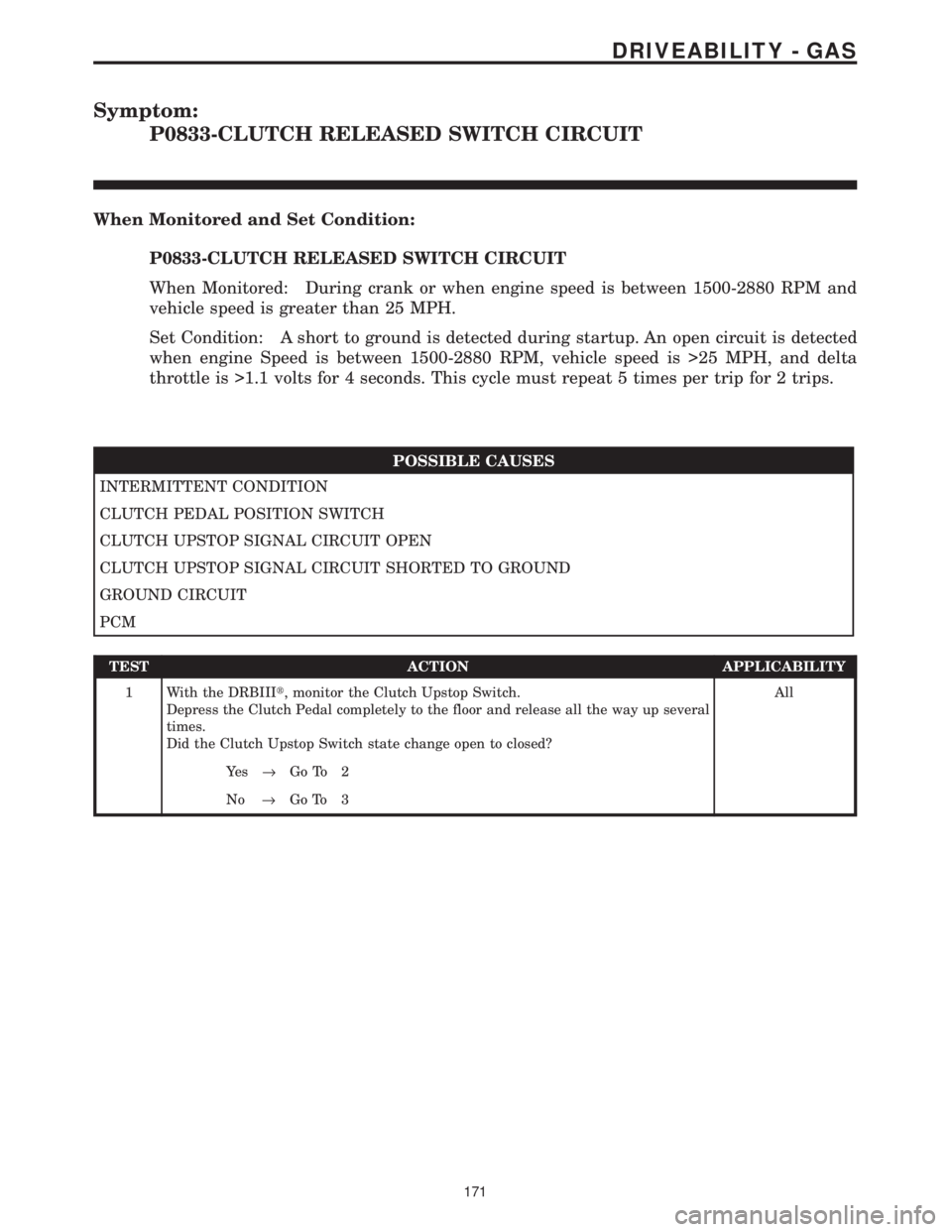

Symptom:

P0833-CLUTCH RELEASED SWITCH CIRCUIT

When Monitored and Set Condition:

P0833-CLUTCH RELEASED SWITCH CIRCUIT

When Monitored: During crank or when engine speed is between 1500-2880 RPM and

vehicle speed is greater than 25 MPH.

Set Condition: A short to ground is detected during startup. An open circuit is detected

when engine Speed is between 1500-2880 RPM, vehicle speed is >25 MPH, and delta

throttle is >1.1 volts for 4 seconds. This cycle must repeat 5 times per trip for 2 trips.

POSSIBLE CAUSES

INTERMITTENT CONDITION

CLUTCH PEDAL POSITION SWITCH

CLUTCH UPSTOP SIGNAL CIRCUIT OPEN

CLUTCH UPSTOP SIGNAL CIRCUIT SHORTED TO GROUND

GROUND CIRCUIT

PCM

TEST ACTION APPLICABILITY

1 With the DRBIIIt, monitor the Clutch Upstop Switch.

Depress the Clutch Pedal completely to the floor and release all the way up several

times.

Did the Clutch Upstop Switch state change open to closed?All

Ye s®Go To 2

No®Go To 3

171

DRIVEABILITY - GAS

Page 3966 of 4284

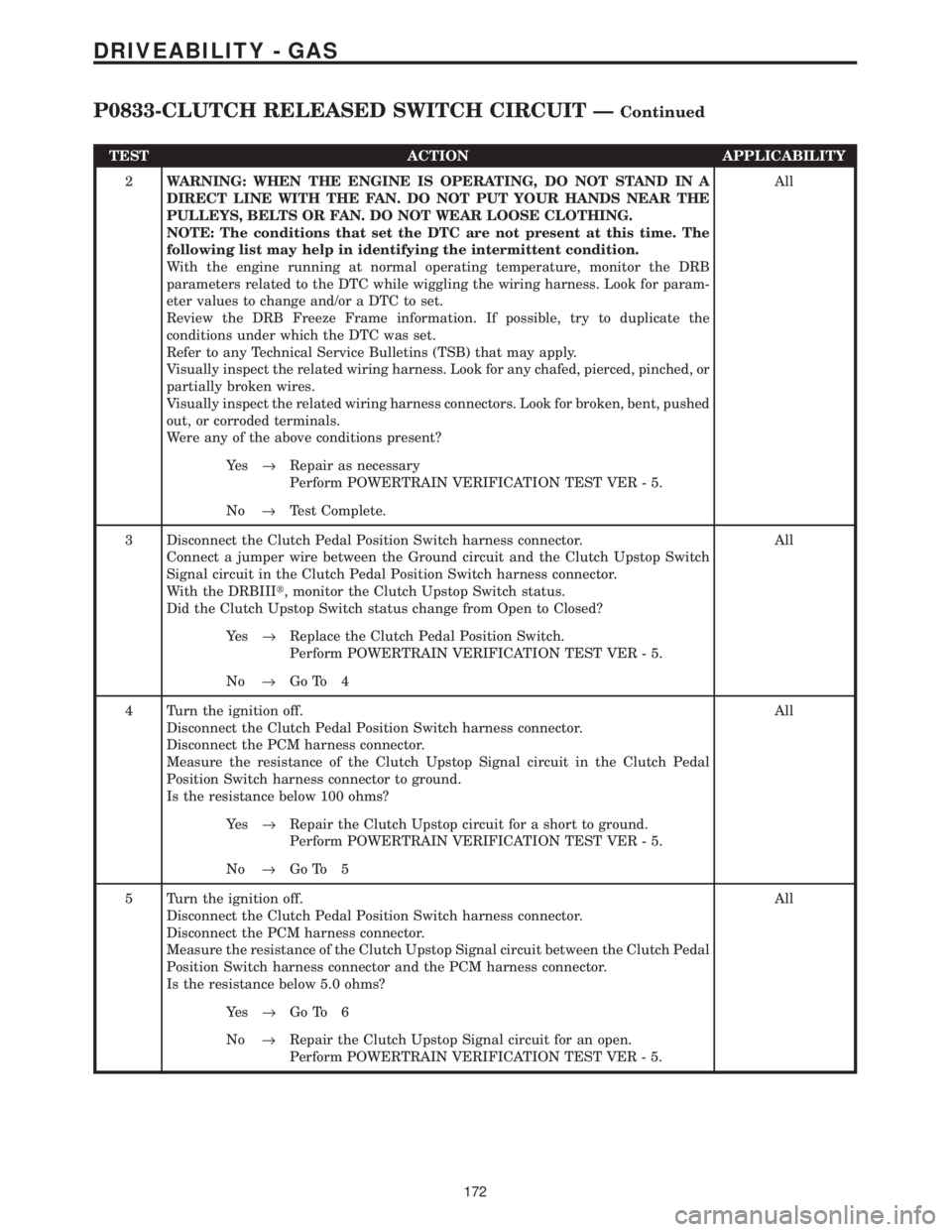

TEST ACTION APPLICABILITY

2WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

3 Disconnect the Clutch Pedal Position Switch harness connector.

Connect a jumper wire between the Ground circuit and the Clutch Upstop Switch

Signal circuit in the Clutch Pedal Position Switch harness connector.

With the DRBIIIt, monitor the Clutch Upstop Switch status.

Did the Clutch Upstop Switch status change from Open to Closed?All

Ye s®Replace the Clutch Pedal Position Switch.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

4 Turn the ignition off.

Disconnect the Clutch Pedal Position Switch harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Clutch Upstop Signal circuit in the Clutch Pedal

Position Switch harness connector to ground.

Is the resistance below 100 ohms?All

Ye s®Repair the Clutch Upstop circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 Turn the ignition off.

Disconnect the Clutch Pedal Position Switch harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Clutch Upstop Signal circuit between the Clutch Pedal

Position Switch harness connector and the PCM harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 6

No®Repair the Clutch Upstop Signal circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

172

DRIVEABILITY - GAS

P0833-CLUTCH RELEASED SWITCH CIRCUIT ÐContinued

Page 3969 of 4284

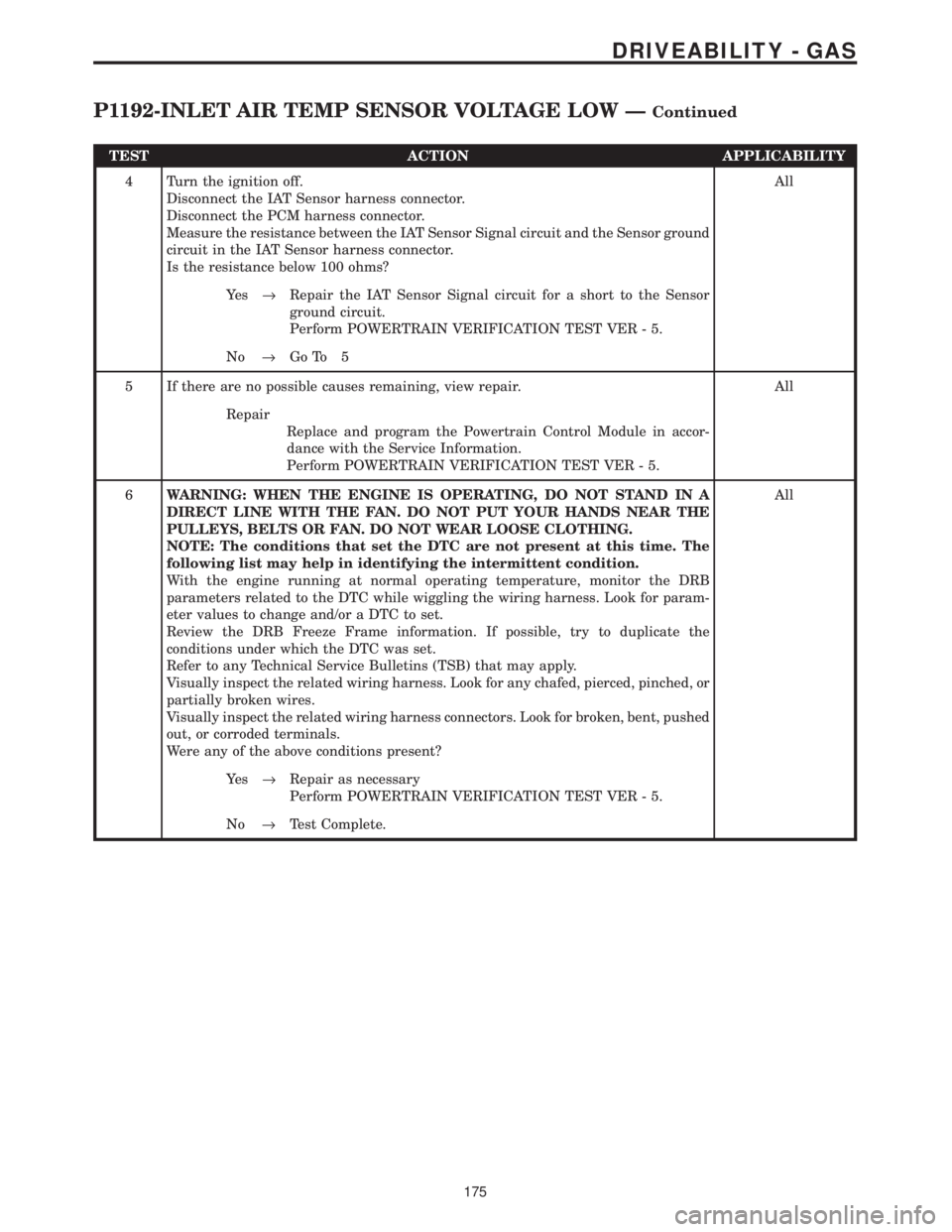

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the IAT Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance between the IAT Sensor Signal circuit and the Sensor ground

circuit in the IAT Sensor harness connector.

Is the resistance below 100 ohms?All

Ye s®Repair the IAT Sensor Signal circuit for a short to the Sensor

ground circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

6WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

175

DRIVEABILITY - GAS

P1192-INLET AIR TEMP SENSOR VOLTAGE LOW ÐContinued

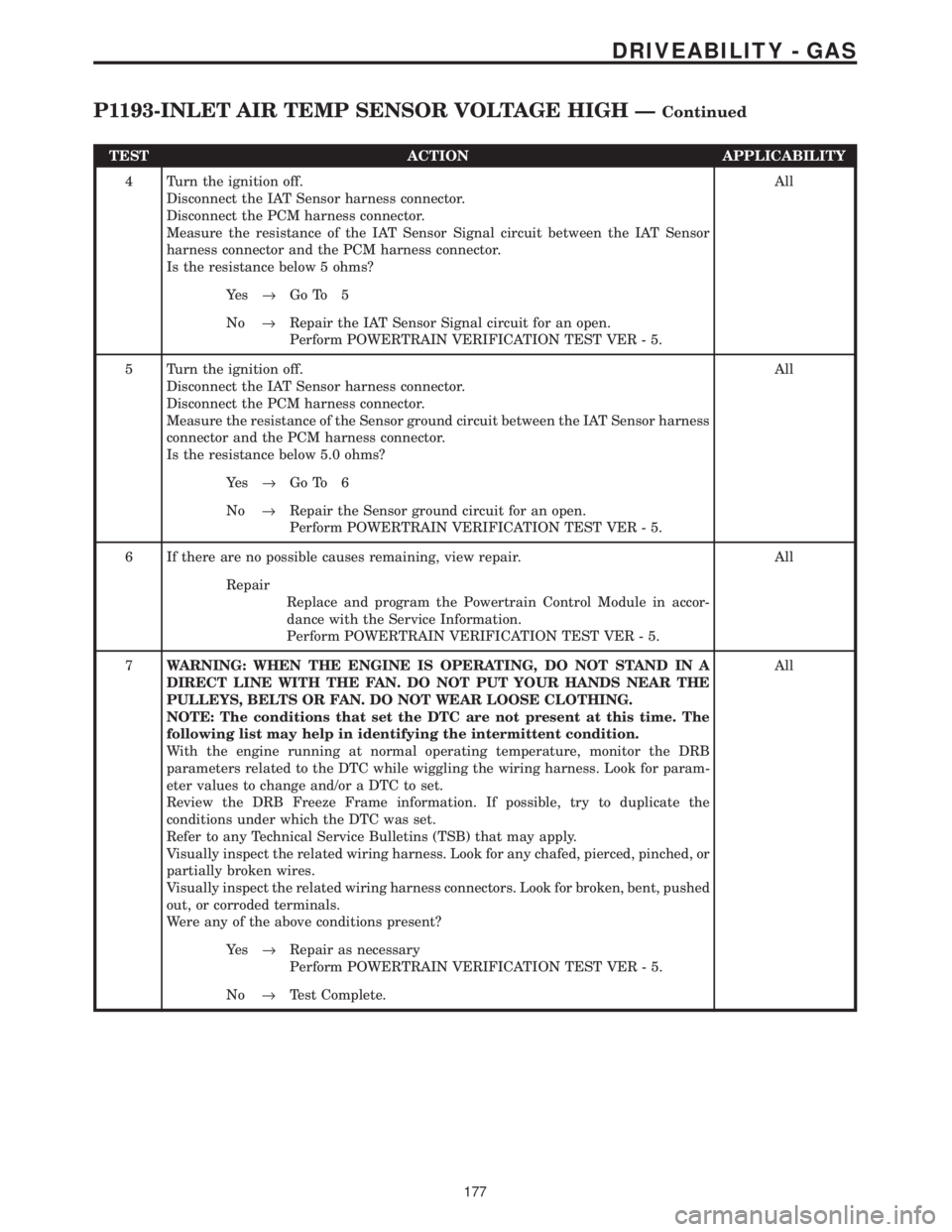

Page 3971 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the IAT Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the IAT Sensor Signal circuit between the IAT Sensor

harness connector and the PCM harness connector.

Is the resistance below 5 ohms?All

Ye s®Go To 5

No®Repair the IAT Sensor Signal circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

5 Turn the ignition off.

Disconnect the IAT Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Sensor ground circuit between the IAT Sensor harness

connector and the PCM harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 6

No®Repair the Sensor ground circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

177

DRIVEABILITY - GAS

P1193-INLET AIR TEMP SENSOR VOLTAGE HIGH ÐContinued