change time CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4113 of 4284

Transmission Effects and possible causes:

Scenario 1)- All PRNDL lights stay illuminated

indefinitely in Park following a Key start.

> Wrong Part Number TCM for application

> TRS connector not plugged in

> C1 through C4 (T1, T3, T41, or T42) circuits are

either open, shorted to ground, or shorted to 12

volts.

> PCI bus failure (Open or shorted resulting in no

communication to BCM or Cluster)

> TRS

> TCM

> BCM

Scenario 2)-9P9is indicated following a key start

but all PRNDL lights illuminate in9N9following a

shift from9R9to9N9. If PRNDL lights illuminate in

9N9and shifter is moved directly into939or9L9

position without pausing in9OD9, then the9OD9

position shift schedule and electronic display will

indicate9OD9until the shifter is shifted into the

9OD9position and held for at least 3 seconds.

> Worn Manual Lever (Rooster Comb). Check for

heavy wearing by TRS switch contacts

> Intermittent C1 through C4 (T1, T3, T41 or T42)

circuits. Check for corrosion, terminal push-outs

or spread terminals at 60-way and/or TRS switch

10-way connector

> TRS

> TCM

> BCM

Scenario 3)- If the invalid code happened while

operating in the939or9L9position, then the939or

9L9shift schedule and electronic display will be

frozen (regardless of whether9OD9,939or9L9is

selected) until the shifter is moved to the9N9

position (all PRNDL lights will illuminate) and

then back to the9OD9position and held there for at

least 3 seconds in order to resume the normal9OD9

shift schedule and electronic display.

> Intermittent C1 through C4 (T1, T3, T41 or T42)

circuits. Check for corrosion, terminal push-outs

or spread terminals at 60-way and/or TRS con-

nector

> TRS

> TCM

> BCM

These same symptoms may occur without the

code P0705(28) getting set. It is possible that the

invalid code that was sensed by the TCM only

occurred once or twice during the given ignition key

start and/or did not last for longer than 0.1 second.Name of code:P0120(29) - Throttle Position Sen-

sor Signal

When monitored:Whenever the engine is run-

ning.

Set condition:This code is set if the throttle angle

goes out of range or if throttle angle changes

abruptly (ie: faster than the throttle body motion

could occur)

Theory of operation:The Transmission Control

Module (TCM) receives the throttle position signal

from the Throttle Position Sensor (TPS) through a

wire spliced into the TPS circuit to the PCM. The

TPS has a 5-volt pull up supplied from the Power-

train Control Module (PCM). The signal is checked

for out-of-range as well as an intermittent (exces-

sive signal changes).

Transmission Effects:Extremely erratic trans-

mission shifting with an intermittent TPS signal

just prior to setting the code. If the intermittent

does not last long enough to set the code, the

customer will say that the transmission violently

hunts between gears. The TCM will use a calcu-

lated throttle angle supplied by the PCM over the

PCI bus. If the PCI bus is unavailable, the TCM will

use a default throttle angle of 24 degrees for the key

start in which the code was set. The TCM will try to

use the TPS signal again on the next key start.

Possible causes:

> Open or shorted TPS signal and/or ground cir-

cuits

> TCM connector problems

> TPS or TPS connector (Check PCM DTC's)

> PCM

> TCM

Name of code:P1787(31) - OD Hydraulic Pressure

Test Failure

P1788(32) - 2-4 Hydraulic Pressure Test Failure

P1789(33) - OD/2-4 Hydraulic Pressure Test Failure

When monitored:In 1st, 2nd, or 3rd gear with

engine speed above 1000 RPM shortly after a shift

and every minute thereafter.

Set condition:Immediately after a shift into 1st,

2nd, or 3rd gear, with engine speed above 1000

RPM, the TCM momentarily turns on element

pressure to the 2-4 and/or OD clutch circuits to

identify that the appropriate pressure switch

closes. If the pressure switch does not close it is

tested again. If the switch does not close the second

time, the appropriate code is set.

Theory of operation:The Transmission Control

Module (TCM) tests the OD and 2-4 pressure

switches when they are off (OD and 2-4 are tested in

1st gear, OD in 2nd gear, and 2-4 in 3rd gear). The

test verifies that the switches are operational. The

TCM verifies that the switch closes when the cor-

9

GENERAL INFORMATION

Page 4116 of 4284

the L-R pressure switch does not indicate pressure.

A second detection of L-R pressure results in setting

the code.

Transmission Effects:At speeds above 72 Km/h

(45 MPH), EMCC is inhibited. Once speed falls

below 72 Km/h (45 MPH), the transmission will go

into relay open limp-in mode and the MIL will

illuminate.

Possible causes:

> Valve body - Solenoid valve stuck in L-R position

> Intermittent short to ground or open circuit in

L-R Pressure Switch Sense circuit (with code 24

only)

> Solenoid pack (with code P1784(24) only)

> TCM (with code P1784(24) only)

Name of Code:P1793(48) - Torque Reduction

(TRD) Link Communication Error

Note: The MIL may set on some engines (3.3L, 3.8L,

3.5L)

When Monitored:Whenever the engine is run-

ning

Set condition:This code is set when the TCM

sends multiple torque reduction messages to the

PCM and the TCM does not receive a response from

the PCM.

Theory of Operation:During high torque shifts

the TCM will send a message requesting that the

PCM reduce engine power until the shift is com-

pleted. This message is sent from the TCM to the

Powertrain Control Module across the Torque Man-

agement Request Sense Circuit. The PCM will

acknowledge the TCM request by sending a mes-

sage across the PCI bus within a specific amount of

time. The TRD Link communication is also tested

periodically for operation whenever the engine is

running and the vehicle is not moving with zero

degrees throttle.

Transmission Effects:Maximum throttle angle

used by TCM will be 54 degrees. As a result a

customer my complain about loss of performance or

of short shifting when driving aggressively.

Possible Causes:

> Sticky Throttle Position Sensor (TPS)

> Wiring or Connector problems in the Torque

Management Request Sense Circuit

> PCM

> TCM

Name of code:P0736(50) - Gear Ratio Error in

Reverse

P0731(51) - Gear Ratio Error in 1st

P0732(52) - Gear Ratio Error in 2nd

P0733(53) - Gear Ratio Error in 3rd

P0734(54) - Gear Ratio Error in 4th

P0715(56) - Input Speed Sensor Error

P0720(57) - Output Speed Sensor Error

P1794(58) - Speed Sensor Ground Error

When monitored:The transmission gear ratio is

monitored continuously while the transmission is in

gear.

Set condition:This code is set if the gear ratio is

not correct for a period of time.

± Codes 50 through 54 sets if the ratio of the

input RPM (Nt) to the output RPM (No) does

not match the given gear ratio.

± Code 56 sets if there is an excessive change in

input RPM in any gear

± Code 57 sets if there is an excessive change in

output RPM in any gear

± Code 58 sets after a TCM reset in neutral and

Nt/No equals a ratio of input to output of 2.50

A hard code sets within 3 seconds, an intermit-

tent code sets within 15 seconds.

Theory of operation:The transmission system

uses two speed sensors, one to measure input RPM

and one to measure output RPM. These inputs are

essential for proper transmission operation. There-

fore, the integrity of this data is verified through

the following checks:

1. When in gear, if the gear ratio does not compare

to a known gear ratio, the corresponding in-gear

trouble code is set (codes 50 through 54).

2. An excessive change in input or output speeds

indicating signal intermittent will result in

codes 56 and/or 57 being set.

3. After a TCM reset in neutral, observing erratic

output and input speed sensor signals indicates

a loss of the common speed sensors ground. This

sets a code 58.

Transmission Effects:The transmission will not

go into relay open limp-in mode until three gear

ratio error events occur in a given key start. This

allows for intermittent problems to correct them-

selves without opening the relay. However, if a gear

ratio error develops, a code is always set, but if the

condition corrects itself the transmission will con-

tinue without requiring the ignition key to be cycled

on and off. Many different events could occur given

the range of failures possible for codes 50 through

58. The following are a few examples:

± Codes 51, 52, 53, 54, 56, and 57 at speeds

above 72 Km/h (45 MPH) - The appropriate

code is set, EMCC is aborted and current gear

is maintained. If while still traveling above 72

Km/h (45 MPH), the gear ratio becomes valid

again, EMCC will reengage and normal oper-

ation will resume. If the gear ratio becomes

intermittent and recovers three times in a

given key start, the current gear will be main-

tained and EMCC inhibited, then the trans-

mission will go into relay open limp-in mode if

12

GENERAL INFORMATION

Page 4123 of 4284

information at the time of publication. The right is

reserved to make changes at any time without

notice.

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: ENGINES PRODUCE CARBON

MONOXIDE THAT IS ODORLESS, CAUSES

SLOWER REACTION TIMES AND CAN LEAD

TO SERIOUS INJURY. WHEN THE ENGINE IS

OPERATING, KEEP SERVICE AREAS WELL

VENTILATED OR ATTACH THE VEHICLE

EXHAUST SYSTEM TO THE SHOP EXHAUST

REMOVAL SYSTEM.

Some operations in this manual require that

hydraulic tubes, hoses, and fittings, disconnected

for inspection or testing purposes. These systems,

when fully charged contains fluid at high pressure.

Before disconnecting any hydraulic tubes, hoses or

fittings, be sure that the system is fully depressur-

ized.

When servicing a vehicle, always wear eye pro-

tection and remove any metal jewelry such as

watchbands or bracelets that might make an inad-

vertent electrical contact.

When diagnosing a transmission system problem,

it is important to follow approved procedures where

applicable. Following these procedures is very im-

portant to the safety of individuals performing

diagnostic tests.

4.2.2 VEHICLE PREPARATION FOR

TESTING

Make sure the vehicle being tested has a fully

charged battery. If it does not, false diagnostic codes

or error messages may occur. It is extremely impor-

tant that accurate shift lever position data be avail-

able to the TCM. The accuracy of any diagnostic

trouble code found in memory is doubtful unless the

Shift Lever Test, performed on the DRBtScan Tool,

passes.

4.2.3 SERVICING SUB-ASSEMBLIES

Some components of the powertrain system are

intended to be serviced in assembly only. Attempt-

ing to remove or repair certain system subcompo-

nents may result in personal injury and/or im-

proper system operation. Only those components

with approved repair and installation procedures in

the service instructions should be serviced.

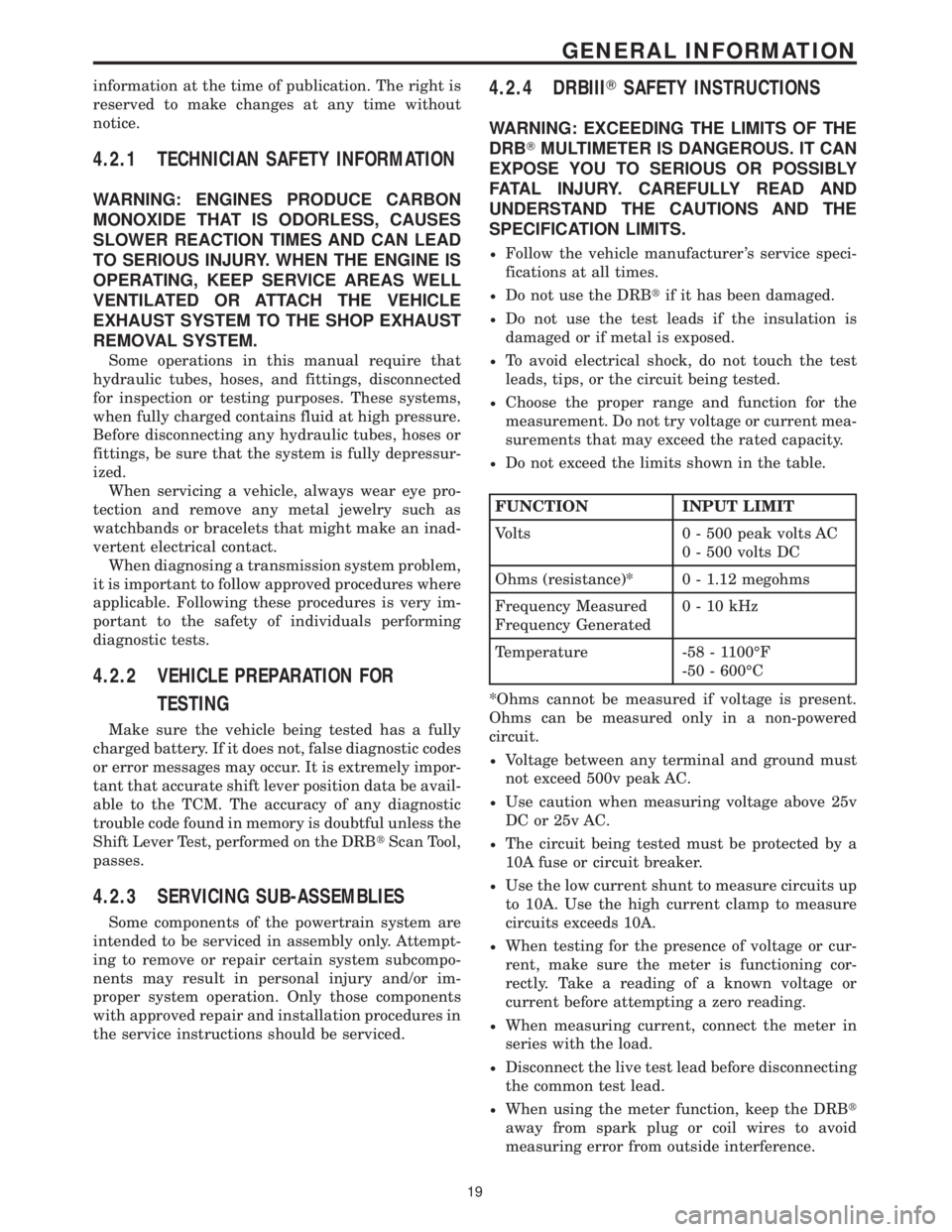

4.2.4 DRBIIITSAFETY INSTRUCTIONS

WARNING: EXCEEDING THE LIMITS OF THE

DRBTMULTIMETER IS DANGEROUS. IT CAN

EXPOSE YOU TO SERIOUS OR POSSIBLY

FATAL INJURY. CAREFULLY READ AND

UNDERSTAND THE CAUTIONS AND THE

SPECIFICATION LIMITS.

²Follow the vehicle manufacturer 's service speci-

fications at all times.

²Do not use the DRBtif it has been damaged.

²Do not use the test leads if the insulation is

damaged or if metal is exposed.

²To avoid electrical shock, do not touch the test

leads, tips, or the circuit being tested.

²Choose the proper range and function for the

measurement. Do not try voltage or current mea-

surements that may exceed the rated capacity.

²Do not exceed the limits shown in the table.

FUNCTION INPUT LIMIT

Volts 0 - 500 peak volts AC

0 - 500 volts DC

Ohms (resistance)* 0 - 1.12 megohms

Frequency Measured

Frequency Generated0-10kHz

Temperature -58 - 1100ÉF

-50 - 600ÉC

*Ohms cannot be measured if voltage is present.

Ohms can be measured only in a non-powered

circuit.

²Voltage between any terminal and ground must

not exceed 500v peak AC.

²Use caution when measuring voltage above 25v

DC or 25v AC.

²The circuit being tested must be protected by a

10A fuse or circuit breaker.

²Use the low current shunt to measure circuits up

to 10A. Use the high current clamp to measure

circuits exceeds 10A.

²When testing for the presence of voltage or cur-

rent, make sure the meter is functioning cor-

rectly. Take a reading of a known voltage or

current before attempting a zero reading.

²When measuring current, connect the meter in

series with the load.

²Disconnect the live test lead before disconnecting

the common test lead.

²When using the meter function, keep the DRBt

away from spark plug or coil wires to avoid

measuring error from outside interference.

19

GENERAL INFORMATION

Page 4129 of 4284

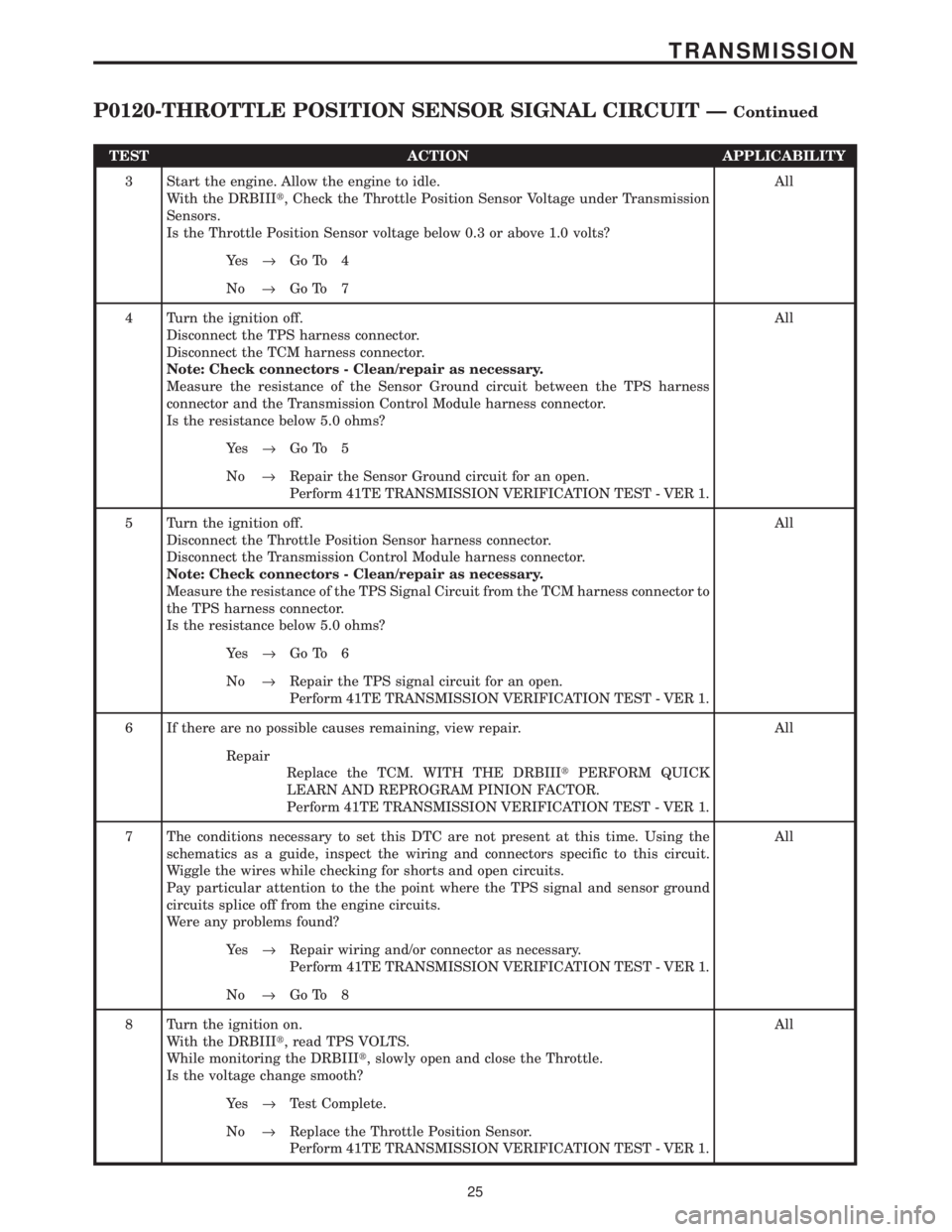

TEST ACTION APPLICABILITY

3 Start the engine. Allow the engine to idle.

With the DRBIIIt, Check the Throttle Position Sensor Voltage under Transmission

Sensors.

Is the Throttle Position Sensor voltage below 0.3 or above 1.0 volts?All

Ye s®Go To 4

No®Go To 7

4 Turn the ignition off.

Disconnect the TPS harness connector.

Disconnect the TCM harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Sensor Ground circuit between the TPS harness

connector and the Transmission Control Module harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 5

No®Repair the Sensor Ground circuit for an open.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

5 Turn the ignition off.

Disconnect the Throttle Position Sensor harness connector.

Disconnect the Transmission Control Module harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the TPS Signal Circuit from the TCM harness connector to

the TPS harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 6

No®Repair the TPS signal circuit for an open.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

6 If there are no possible causes remaining, view repair. All

Repair

Replace the TCM. WITH THE DRBIIItPERFORM QUICK

LEARN AND REPROGRAM PINION FACTOR.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

7 The conditions necessary to set this DTC are not present at this time. Using the

schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle the wires while checking for shorts and open circuits.

Pay particular attention to the the point where the TPS signal and sensor ground

circuits splice off from the engine circuits.

Were any problems found?All

Ye s®Repair wiring and/or connector as necessary.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

No®Go To 8

8 Turn the ignition on.

With the DRBIIIt, read TPS VOLTS.

While monitoring the DRBIIIt, slowly open and close the Throttle.

Is the voltage change smooth?All

Ye s®Test Complete.

No®Replace the Throttle Position Sensor.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

25

TRANSMISSION

P0120-THROTTLE POSITION SENSOR SIGNAL CIRCUIT ÐContinued

Page 4151 of 4284

TEST ACTION APPLICABILITY

3 With the DRBIIIt, Check the STARTS SINCE SET counter.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter set at 0?All

Ye s®Go To 4

No®Go To 7

4 Turn the ignition off to the lock position.

Disconnect the TCM harness connector.

Disconnect the Crank Position Sensor harness connector.

Measure the resistance of the Crank Position Sensor Ground circuit between the

TCM harness connector and the CKP harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Crank Position Sensor Ground circuit for an open.

No®Go To 5

5 Turn the ignition off to the lock position.

Disconnect the TCM harness connector.

Disconnect the Crank Position Sensor harness connector.

Measure the resistance of the Crank Position Sensor Signal circuit between the TCM

harness connector and the CKP harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the open Crank Position Sensor Signal circuit.

No®Go To 6

6 If there are no possible causes remaining, view repair. All

Repair

Replace the TCM. WITH THE DRBIIItPERFORM QUICK

LEARN AND REPROGRAM PINION FACTOR.

7 The conditions necessary to set the DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this

circuit.

Check the power and ground circuits of the Transmission Control Module.

Start the engine.

With the DRBIIIt, monitor the Engine RPM.

Wiggle the wire harness between the TCM and CKP.

Were any problems found and/or did the Engine RPM change while wiggling the

harness?All

Ye s®Repair wiring and/or connectors as necessary.

No®Test Complete.

47

TRANSMISSION

P0725-ENGINE SPEED SENSOR CIRCUIT (3.3L/3.8L) ÐContinued