sensor CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1206 of 4284

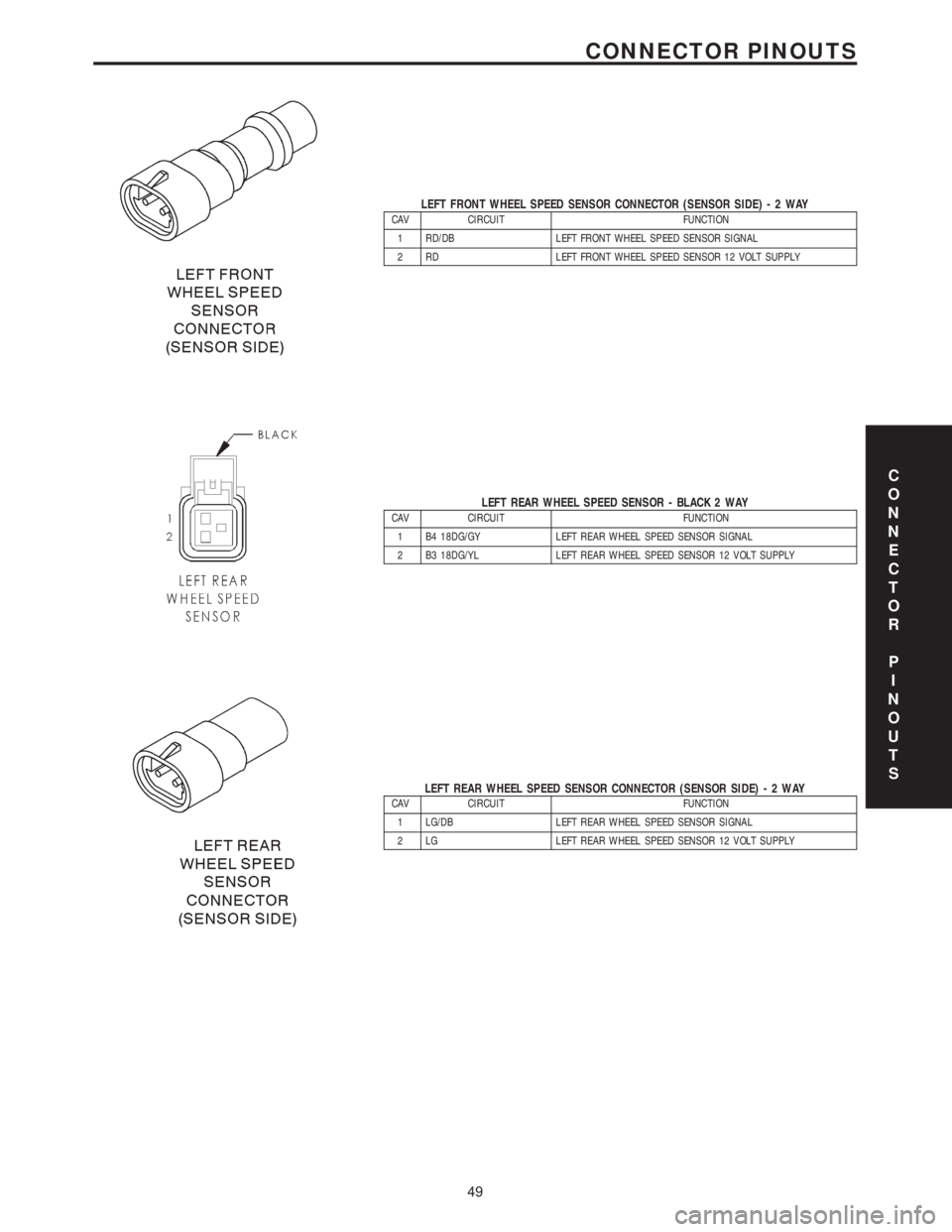

LEFT FRONT WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAYCAV CIRCUIT FUNCTION

1 RD/DB LEFT FRONT WHEEL SPEED SENSOR SIGNAL

2 RD LEFT FRONT WHEEL SPEED SENSOR 12 VOLT SUPPLY

LEFT REAR WHEEL SPEED SENSOR - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 B4 18DG/GY LEFT REAR WHEEL SPEED SENSOR SIGNAL

2 B3 18DG/YL LEFT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

LEFT REAR WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAYCAV CIRCUIT FUNCTION

1 LG/DB LEFT REAR WHEEL SPEED SENSOR SIGNAL

2 LG LEFT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

49

CONNECTOR PINOUTS

Page 1209 of 4284

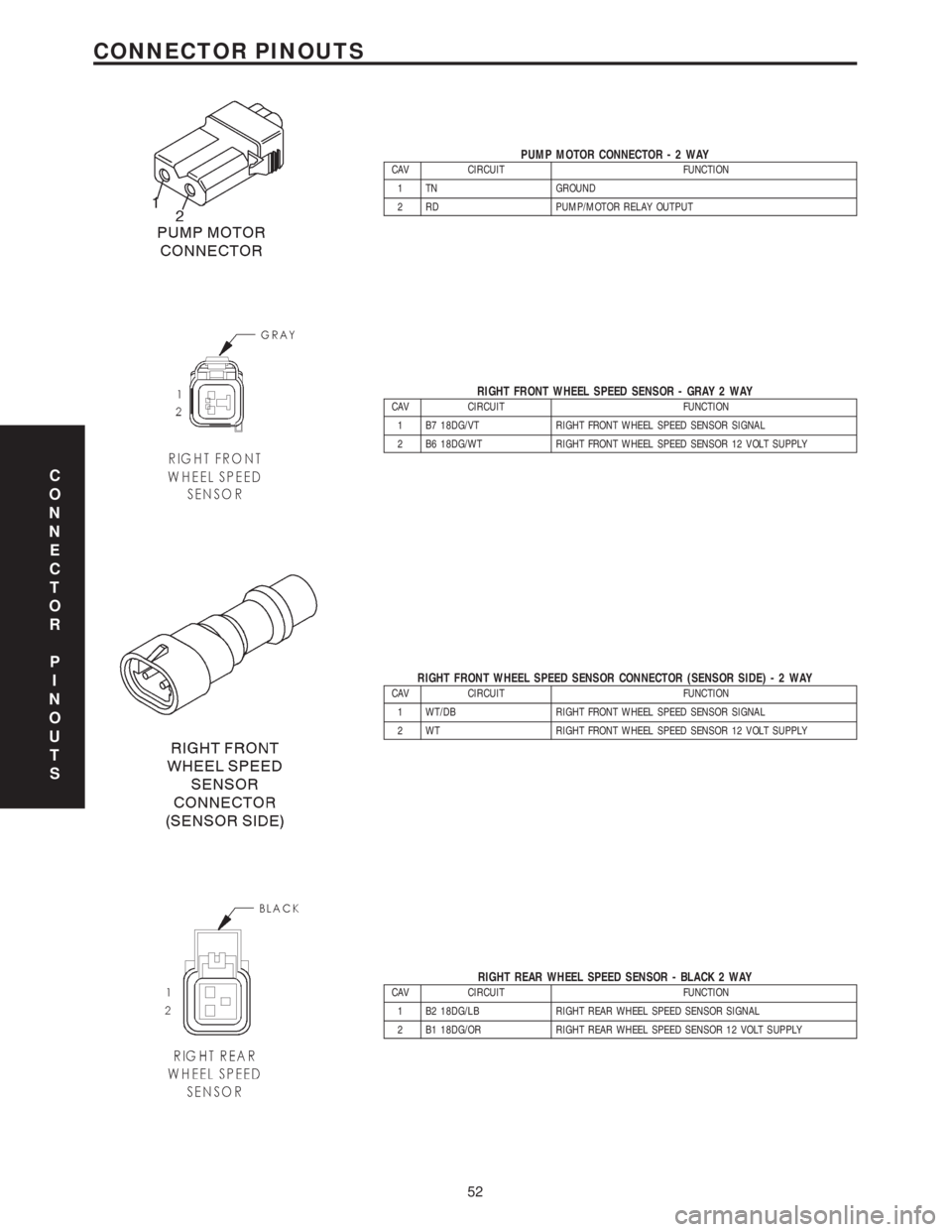

PUMP MOTOR CONNECTOR-2WAYCAV CIRCUIT FUNCTION

1 TN GROUND

2 RD PUMP/MOTOR RELAY OUTPUT

RIGHT FRONT WHEEL SPEED SENSOR - GRAY 2 WAYCAV CIRCUIT FUNCTION

1 B7 18DG/VT RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

2 B6 18DG/WT RIGHT FRONT WHEEL SPEED SENSOR 12 VOLT SUPPLY

RIGHT FRONT WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAYCAV CIRCUIT FUNCTION

1 WT/DB RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

2 WT RIGHT FRONT WHEEL SPEED SENSOR 12 VOLT SUPPLY

RIGHT REAR WHEEL SPEED SENSOR - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 B2 18DG/LB RIGHT REAR WHEEL SPEED SENSOR SIGNAL

2 B1 18DG/OR RIGHT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

52

CONNECTOR PINOUTS

Page 1210 of 4284

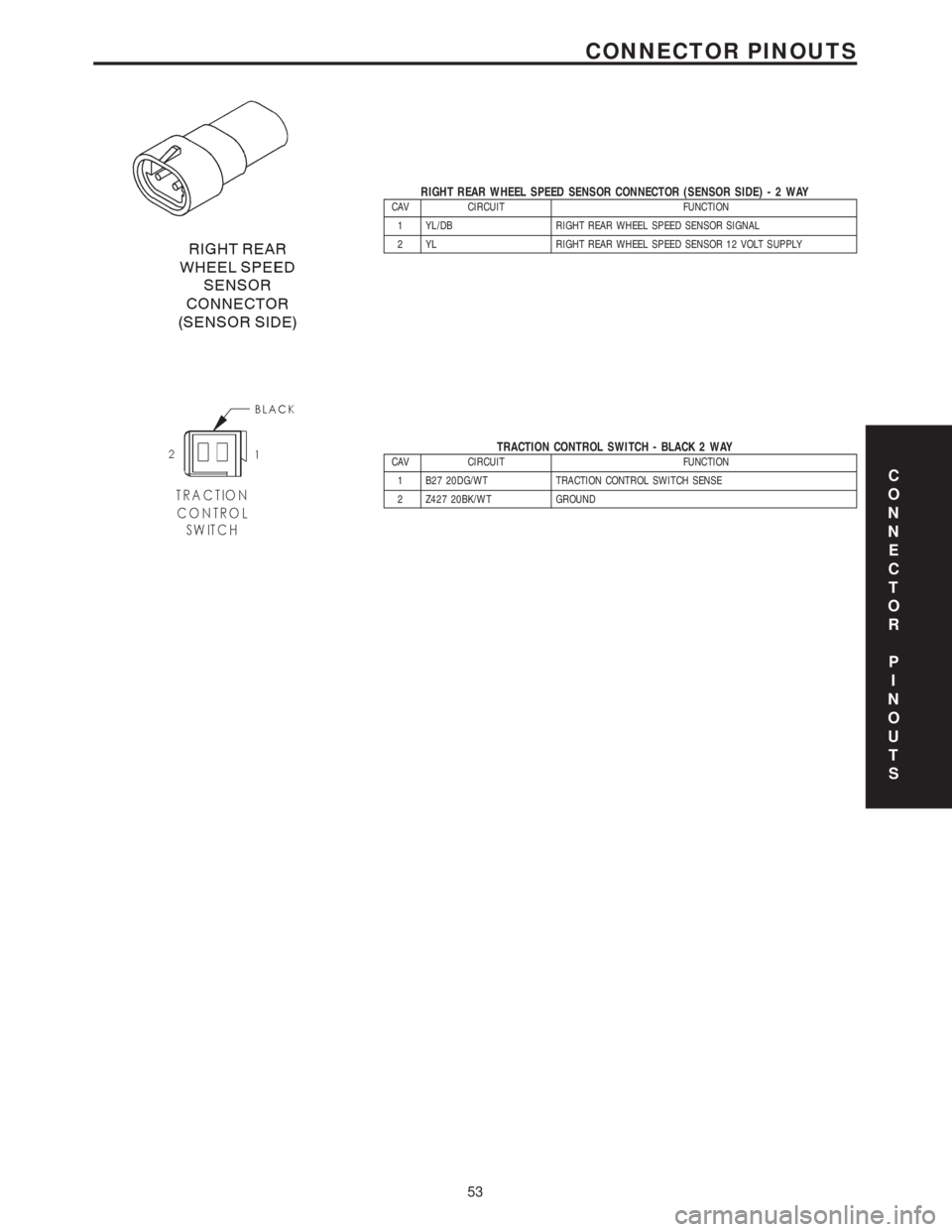

RIGHT REAR WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAYCAV CIRCUIT FUNCTION

1 YL/DB RIGHT REAR WHEEL SPEED SENSOR SIGNAL

2 YL RIGHT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

TRACTION CONTROL SWITCH - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 B27 20DG/WT TRACTION CONTROL SWITCH SENSE

2 Z427 20BK/WT GROUNDC

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

53

CONNECTOR PINOUTS

Page 1214 of 4284

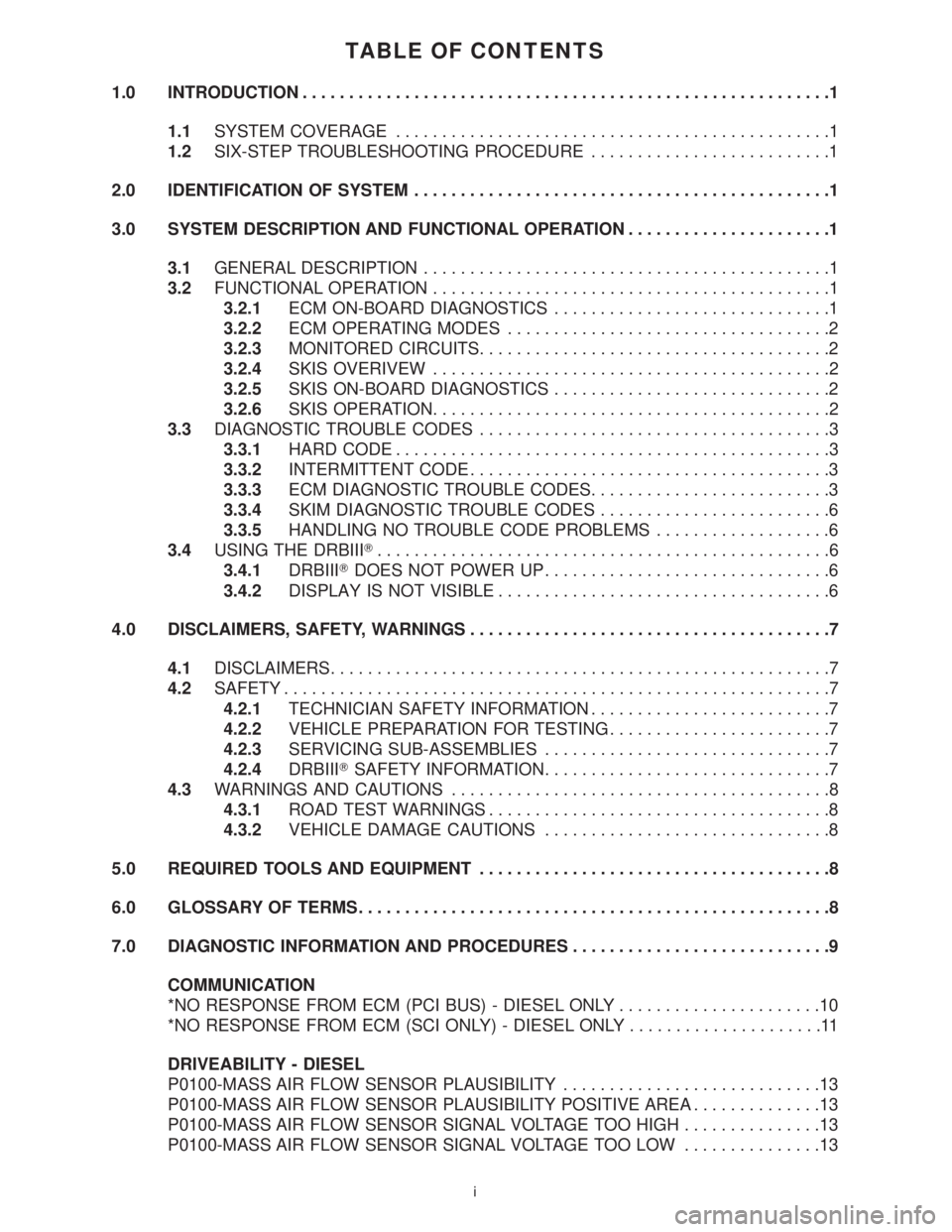

TABLE OF CONTENTS

1.0 INTRODUCTION.........................................................1

1.1SYSTEM COVERAGE...............................................1

1.2SIX-STEP TROUBLESHOOTING PROCEDURE..........................1

2.0 IDENTIFICATION OF SYSTEM.............................................1

3.0 SYSTEM DESCRIPTION AND FUNCTIONAL OPERATION......................1

3.1GENERAL DESCRIPTION............................................1

3.2FUNCTIONAL OPERATION...........................................1

3.2.1ECM ON-BOARD DIAGNOSTICS..............................1

3.2.2ECM OPERATING MODES...................................2

3.2.3MONITORED CIRCUITS......................................2

3.2.4SKIS OVERIVEW...........................................2

3.2.5SKIS ON-BOARD DIAGNOSTICS..............................2

3.2.6SKIS OPERATION...........................................2

3.3DIAGNOSTIC TROUBLE CODES......................................3

3.3.1HARD CODE...............................................3

3.3.2INTERMITTENT CODE.......................................3

3.3.3ECM DIAGNOSTIC TROUBLE CODES..........................3

3.3.4SKIM DIAGNOSTIC TROUBLE CODES.........................6

3.3.5HANDLING NO TROUBLE CODE PROBLEMS...................6

3.4USING THE DRBIIIT.................................................6

3.4.1DRBIIITDOES NOT POWER UP...............................6

3.4.2DISPLAY IS NOT VISIBLE....................................6

4.0 DISCLAIMERS, SAFETY, WARNINGS.......................................7

4.1DISCLAIMERS......................................................7

4.2SAFETY...........................................................7

4.2.1TECHNICIAN SAFETY INFORMATION..........................7

4.2.2VEHICLE PREPARATION FOR TESTING........................7

4.2.3SERVICING SUB-ASSEMBLIES...............................7

4.2.4DRBIIITSAFETY INFORMATION...............................7

4.3WARNINGS AND CAUTIONS.........................................8

4.3.1ROAD TEST WARNINGS.....................................8

4.3.2VEHICLE DAMAGE CAUTIONS...............................8

5.0 REQUIRED TOOLS AND EQUIPMENT......................................8

6.0 GLOSSARY OF TERMS...................................................8

7.0 DIAGNOSTIC INFORMATION AND PROCEDURES............................9

COMMUNICATION

*NO RESPONSE FROM ECM (PCI BUS) - DIESEL ONLY......................10

*NO RESPONSE FROM ECM (SCI ONLY) - DIESEL ONLY.....................11

DRIVEABILITY - DIESEL

P0100-MASS AIR FLOW SENSOR PLAUSIBILITY............................13

P0100-MASS AIR FLOW SENSOR PLAUSIBILITY POSITIVE AREA..............13

P0100-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO HIGH...............13

P0100-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO LOW...............13

i

Page 1215 of 4284

TABLE OF CONTENTS - Continued

P0100-MASS AIR FLOW SENSOR SUPPLY VOLTAGE TOO HIGH OR LOW......13

P0105-BAROMETRIC PRESSURE CIRCUIT SIGNAL VOLTAGE TOO HIGH.......20

P0105-BAROMETRIC PRESSURE CIRCUIT SIGNAL VOLTAGE TOO LOW........20

P0606-ECM ERROR GATE ARRAY - COMMUNICATION.......................20

P0606-ECM ERROR GATE ARRAY - COMMUNICATION NOT VERIFIED..........20

P0606-ECM ERROR GATE ARRAY - QUANTITY STOP........................20

P0606-ECM ERROR RECOVERY HAS OCCURRED..........................20

P0606-ECM ERROR REDUNDANT OVERRUN MONITORING..................20

P1206-CALCULATED INJECTOR VOLTAGE TOO HIGH........................20

P1206-CALCULATED INJECTOR VOLTAGE TOO LOW........................20

P1601-CAPACITOR VOLTAGE 1 VOLTAGE TOO HIGH........................20

P1601-CAPACITOR VOLTAGE 1 VOLTAGE TOO LOW.........................20

P1606-AFTER RUN SHUT OFF ERROR-INJECTION POWERSTAGE............20

P1606-AFTER RUN SHUT OFF ERROR-ZERO QUANTITY.....................20

P1610-VOLTAGE REGULATOR SIGNAL VOLTAGE TOO HIGH..................20

P1610-VOLTAGE REGULATOR SIGNAL VOLTAGE TOO LOW..................20

P1680-EEPROM PLAUSIBILITY CHECKSUM ERROR.........................20

P1680-EEPROM PLAUSIBILITY CODE WORD INCORRECT OR MISSING........20

P1680-EEPROM PLAUSIBILITY COMMUNICATION ERROR....................20

P1680-EEPROM PLAUSIBILITY VARIATION NUMBER ERROR.................20

P1680-EEPROM PLAUSIBILITY VIN CHECKSUM ERROR.....................20

P1680-EEPROM PLAUSIBILITY WRITE ERROR..............................20

P1696-EEPROM MEMORY WRITE DENIED.................................20

P0110-INTAKE AIR TEMP SENSOR CIRCUIT SIGNAL VOLTAGE TOO HIGH......24

P0110-INTAKE AIR TEMP SENSOR CIRCUIT SIGNAL VOLTAGE TOO LOW.......27

P0115-ENGINE COOLANT TEMP SENSOR CIRCUIT SIGNAL

VOLTAGE TOO HIGH....................................................29

P0115-ENGINE COOLANT TEMP SENSOR CIRCUIT SIGNAL

VOLTAGETOO LOW ....................................................32

P0190-FUEL PRESS SENSOR CIRCUIT MALF SIGNAL VOLTAGE TOO HIGH.....34

P0190-FUEL PRESS SENSOR CIRCUIT MALF SIGNAL VOLTAGE TOO LOW.....38

P0190-FUEL PRESS SENSOR CIRCUIT MALF SUPPLY VOLTAGE

TOO HIGH OR LOW.....................................................40

P0195-OIL TEMP SENSOR CIRCUIT MALF SIGNAL VOLTAGE TOO HIGH........41

P0195-OIL TEMP SENSOR CIRCUIT MALF SIGNAL VOLTAGE TOO LOW........44

P0201-CYLINDER 1-INJECTOR CIRCUIT CURRENT DECREASE...............46

P0201-CYLINDER 1-INJECTOR CIRCUIT LOAD DROP........................46

P0201-CYLINDER 1-INJECTOR CIRCUIT OVERCURRENT HIGH SIDE...........46

P0201-CYLINDER 1-INJECTOR CIRCUIT OVERCURRENT LOW SIDE...........46

P0202-CYLINDER 2-INJECTOR CIRCUIT CURRENT DECREASE...............50

P0202-CYLINDER 2-INJECTOR CIRCUIT LOAD DROP........................50

P0202-CYLINDER 2-INJECTOR CIRCUIT OVERCURRENT HIGH SIDE...........50

P0202-CYLINDER 2-INJECTOR CIRCUIT OVERCURRENT LOW SIDE...........50

P0203-CYLINDER 3-INJECTOR CIRCUIT CURRENT DECREASE...............54

P0203-CYLINDER 3-INJECTOR CIRCUIT LOAD DROP........................54

P0203-CYLINDER 3-INJECTOR CIRCUIT OVERCURRENT HIGH SIDE...........54

P0203-CYLINDER 3-INJECTOR CIRCUIT OVERCURRENT LOW SIDE...........54

P0204-CYLINDER 4-INJECTOR CIRCUIT CURRENT DECREASE...............58

P0204-CYLINDER 4-INJECTOR CIRCUIT LOAD DROP........................58

P0204-CYLINDER 4-INJECTOR CIRCUIT OVERCURRENT HIGH SIDE...........58

P0204-CYLINDER 4-INJECTOR CIRCUIT OVERCURRENT LOW SIDE...........58

P0235-BOOST PRESSURE SENSOR PLAUSIBILITY..........................62

P0235-BOOST PRESSURE SENSOR SIGNAL VOLTAGE TOO HIGH.............64

ii

Page 1216 of 4284

TABLE OF CONTENTS - Continued

P0235-BOOST PRESSURE SENSOR SIGNAL VOLTAGE TOO LOW.............67

P0235-BOOST PRESSURE SENSOR SUPPLY VOLTAGE TOO HIGH OR LOW....70

P0335-CKP POSITION SENSOR CIRCUIT OVERSPEED RECOGNITION.........73

P0340-CKP POSITION SENSOR CIRCUIT DYNAMIC PLAUSIBILITY.............75

P0340-CMP POSITION SENSOR CIRCUIT CMP/CKP SYNC FAILURE...........77

P0340-CMP POSITION SENSOR CIRCUIT SIGNAL FREQUENCY TOO HIGH.....80

P0340-CMP POSITION SENSOR CIRCUIT STATIC PLAUSIBILITY...............80

P0380-GLOW PLUG CIRCUIT A OPEN CIRCUIT.............................84

P0380-GLOW PLUG CIRCUIT A SHORT CIRCUIT............................84

P0403-EGR SOLENOID CIRCUIT OPEN CIRCUIT............................87

P0403-EGR SOLENOID CIRCUIT SHORT CIRCUIT...........................90

P0480-FAN 1 CONTROL CIRCUIT OPEN CIRCUIT...........................92

P0480-FAN 1 CONTROL CIRCUIT SHORT CIRCUIT..........................94

P0481-FAN 2 CONTROL CIRCUIT OPEN CIRCUIT...........................96

P0481-FAN 2 CONTROL CIRCUIT SHORT CIRCUIT..........................98

P0500-VEHICLE SPEED SENSOR FREQUENCY TOO HIGH..................100

P0500-VEHICLE SPEED SENSOR HIGH LEVEL DURATION...................100

P0500-VEHICLE SPEED SENSOR PLAUSIBILITY...........................100

P0500-VEHICLE SPEED SENSOR SIGNAL VOLTAGE TOO HIGH..............100

P0514-BATTERY TEMP SENSOR CIRCUIT SIGNAL VOLTAGE TOO HIGH.......104

P0520- OIL PRESS SENSOR CIRCUIT MALF PLAUSIBILITY..................107

P0520-OIL PRESS SENSOR CKT MALF SUPPLY VOLTAGE TOO HIGH OR LOW .110

P0530-A/C PRESSURE SENSOR CIRCUIT PLAUSIBILITY....................112

P0530-A/C PRESSURE SENSOR CIRCUIT SIGNAL VOLTAGE TOO HIGH.......112

P0530-A/C PRESSURE SENSOR CIRCUIT SIGNAL VOLTAGE TOO LOW.......112

P0530-A/C PRESSURE SENSOR CIRCUIT SUPPLY VOLTAGE TOO HIGH OR

LOW.................................................................112

P0560-SYSTEM VOLTAGE TOO HIGH.....................................117

P0560-SYSTEM VOLTAGE TOO LOW.....................................120

*CHECKING THE CHARGING SYSTEM OPERATION - DIESEL................120

P0615-STARTER RELAY CIRCUIT SHORT CIRCUIT.........................124

P0620-GENERATOR FIELD CONTROL MALF BATTERY VOLTAGE

DEVIATION TOO HIGH.................................................126

P0620-GENERATOR FIELD CONTROL MALF BATTERY VOLTAGE

DEVIATION TOO LOW..................................................126

P0620-GENERATOR FIELD CONTROL MALF BATTERY VOLTAGE TOO HIGH . . .126

P0620-GENERATOR FIELD CONTROL MALF BATTERY VOLTAGE TOO LOW. . . .126

P0620-GENERATOR FIELD CONTROL MALF CHARGING VOLTS TOO LOW. . . .126

P0620-GENERATOR FIELD CONTROL MALF OPEN CIRCUIT.................126

P0620-GENERATOR FIELD CONTROL MALF SHORT CIRCUIT................126

P0620-GENERATOR FIELD CONTROL MALF UNSTABLE CURRENT...........126

P0627-FUEL LIFT PUMP RELAY CONTROL CIRCUIT OPEN CIRCUIT..........129

P0627-FUEL LIFT PUMP RELAY CONTROL CIRCUIT SHORT CIRCUIT.........131

P0641-SENSOR REFERENCE VOLTAGE A CKT VOLTAGE TOO HIGH..........133

P0651-SENSOR REFERENCE VOLTAGE B CKT VOLTAGE TOO HIGH..........133

P0641-SENSOR REFERENCE VOLTAGE A CKT VOLTAGE TOO LOW..........136

P0651-SENSOR REFERENCE VOLTAGE B CKT VOLTAGE TOO LOW..........136

P0645-A/C CLUTCH RELAY CIRCUIT OPEN CIRCUIT........................139

P0645-A/C CLUTCH RELAY CIRCUIT SHORT CIRCUIT......................142

P0685-ECM/PCM RELAY CONTROL CIRCUIT SHUTS OFF TOO EARLY........145

P0685-ECM/PCM RELAY CONTROL CIRCUIT SHUTS OFF TOO LATE..........147

P0703-BRAKE SWITCH SIGNAL CIRCUITS PLAUSIBILITY WITH

REDUNDANT CONTACT................................................149

iii

Page 1217 of 4284

TABLE OF CONTENTS - Continued

P0703-BRAKE SWITCH SIGNAL CKTS PLAUS W/REDUNDANT CONTACT

AFTER INITIALIZATION.................................................149

P0833-CLUTCH PEDAL PLAUSIBILITY....................................153

P1130-FUEL RAIL PRESSURE MALFUNCTION LEAKAGE DETECTED..........155

P1130-FUEL RAIL PRESSURE MALFUNCTION PRESSURE TOO HIGH-SHUT

OFF .................................................................155

P1130-FUEL RAIL PRESSURE MALFUNCTION PRESSURE TOO LOW.........155

P1130-FUEL RAIL PRESSURE MALFUNCTION SOLENOID OPEN.............155

P1131-FUEL PRESSURE SOLENOID OPEN CIRCUIT........................158

P1131-FUEL PRESSURE SOLENOID PLAUSIBILITY IN AFTER-RUN............158

P1131-FUEL PRESSURE SOLENOID SHORT CIRCUIT.......................158

P1511-BATTERY SENSE LINE 1 VOLTAGE TOO HIGH.......................162

P1511-BATTERY SENSE LINE 1 VOLTAGE TOO LOW.......................164

P1605-IGNITION SWITCH PLAUSIBILITY..................................166

P1685-SKIM SYSTEM INVALID KEY CODE RECEIVED.......................168

P1685-SKIM SYSTEM INVALID SECRET KEY IN EEPROM....................168

P1685-SKIM SYSTEM KEY COMMUNICATION TIMED OUT...................168

P1685-SKIM SYSTEM SKIM ERROR......................................168

P1685-SKIM SYSTEM WRITE ACCESS TO EEPROM FAILURE................168

P2120-ACC PEDAL POSITION SENSOR 1 CKT PLAUSIBILITY................170

P2120-ACC PEDAL POSITION SENSOR 1 CKT PLAUSIBILITY WITH BRAKE

SWITCH..............................................................170

P2120-ACC PEDAL POSITION SENSOR 1 CKT PLAUSIBILITY WITH

POTENTIOMETER.....................................................170

P2120-ACC PEDAL POSITION SENSOR 1 CKT SIGNAL VOLTAGE TOO HIGH . . .170

P2120-ACC PEDAL POSITION SENSOR 1 CKT SIGNAL VOLTAGE TOO LOW . . .170

P2120-ACC PEDAL POSITION SENSOR 1 CKT SUPPLY VOLTAGE TOO

HIGH OR LOW........................................................170

*CHECKING THE A/C CLUTCH OPERATION...............................179

*CHECKING THE ACCELERATOR PEDAL POSITION SENSOR CALIBRATION . . .181

*CHECKING THE BOOST PRESSURE SENSOR CALIBRATION................182

*CHECKING THE ECM POWER AND GROUND CIRCUITS....................183

*CHECKING THE EGR SYSTEM..........................................185

*CHECKING THE ELECTRIC RADIATOR FAN OPERATION...................186

*CHECKING THE ENGINE COOLANT TEMPERATURE SENSOR CALIBRATION . .193

*CHECKING THE ENGINE MECHANICAL SYSTEMS.........................194

*CHECKING THE GLOW PLUG OPERATION...............................195

*CHECKING THE LIFT PUMP MOTOR OPERATION.........................197

*CHECKING THE MAF SENSOR CALIBRATION.............................200

*CHECKING THE SPEED CONTROL OPERATION...........................201

*CHECKING THE VEHICLE SPEED SIGNAL................................204

*ENGINE CRANKS BUT WILL NOT START.................................207

*ENGINE WILL NOT CRANK.............................................210

VEHICLE THEFT/SECURITY

ANTENNA FAILURE....................................................214

COP FAILURE.........................................................214

EEPROM FAILURE.....................................................214

INTERNAL FAULT......................................................214

RAM FAILURE.........................................................214

SERIAL LINK INTERNAL FAULT..........................................214

STACK OVERFLOW FAILURE............................................214

PCM STATUS FAILURE.................................................216

iv

Page 1218 of 4284

TABLE OF CONTENTS - Continued

SERIAL LINK EXTERNAL FAULT.........................................216

ROLLING CODE FAILURE...............................................218

VIN MISMATCH........................................................218

TRANSPONDER COMMUNICATION FAILURE..............................220

TRANSPONDER CYCLIC REDUNDANCY CHECK (CRC) FAILURE.............220

TRANSPONDER ID MISMATCH..........................................220

TRANSPONDER RESPONSE MISMATCH..................................220

VERIFICATION TESTS

VERIFICATION TESTS..................................................223

8.0 COMPONENT LOCATIONS..............................................227

8.1CONTROL MODULES.............................................227

8.2CONTROLS AND SOLENOIDS......................................227

8.3DATA LINK CONNECTOR..........................................227

8.4FUEL SYSTEM...................................................228

8.5RELAYS.........................................................228

8.6SENSORS.......................................................229

8.7SWITCHES......................................................230

9.0 CONNECTOR PINOUTS................................................231

A/C COMPRESSOR CLUTCH - LT. GRAY 2 WAY............................231

A/C PRESSURE SENSOR - GRAY 4 WAY..................................231

ACCELERATOR PEDAL POSITION SENSOR (DIESEL) - BLACK 10 WAY........231

BATTERY TEMPERATURE SENSOR (DIESEL) - BLACK 2 WAY................231

BOOST PRESSURE SENSOR (DIESEL) - BLACK 4 WAY.....................232

BRAKE LAMP SWITCH - BLACK 6 WAY...................................232

CAMSHAFT POSITION SENSOR (DIESEL) - BLACK 3 WAY...................232

CLUTCH PEDAL UPSTOP SWITCH (DIESEL) - RED 2 WAY...................232

CRANKSHAFT POSITION SENSOR (DIESEL) - BLACK 3 WAY................232

DATA LINK CONNECTOR - BLACK 16 WAY................................233

EGR SOLENOID (DIESEL) - LT. GRAY 2 WAY...............................233

ENGINE CONTROL MODULE C1 (DIESEL) - BLACK 81 WAY..................234

ENGINE CONTROL MODULE C1 (DIESEL) - BLACK 81 WAY..................235

ENGINE CONTROL MODULE C2 (DIESEL) - BLACK 40 WAY..................236

ENGINE COOLANT TEMP SENSOR (DIESEL) - BLUE 2 WAY.................236

ENGINE OIL PRESSURE SENSOR (DIESEL) - BLACK 3 WAY.................237

ENGINE OIL TEMPERATURE SENSOR (DIESEL) - BLACK 2 WAY.............237

FUEL HEATER (DIESEL) - BLACK 2 WAY..................................237

FUEL INJECTOR NO. 1 (DIESEL) - BLACK 2 WAY...........................237

FUEL INJECTOR NO. 2 (DIESEL) - BLACK 2 WAY...........................237

FUEL INJECTOR NO. 3 (DIESEL) - BLACK 2 WAY...........................238

FUEL INJECTOR NO. 4 (DIESEL) - BLACK 2 WAY...........................238

FUEL PRESSURE SENSOR (DIESEL) - BLACK 3 WAY.......................238

FUEL PRESSURE SOLENOID (DIESEL) - BLACK 2 WAY.....................238

GENERATOR - BLACK 2 WAY...........................................238

GLOW PLUG RELAY (DIESEL) - BLACK 4 WAY.............................239

INTELLIGENT POWER MODULE C3 (DIESEL) - YELLOW/RED 20 WAY.........239

LEFT SPEED CONTROL SWITCH - WHITE 2 WAY..........................239

LIFT PUMP MOTOR (DIESEL) - BLACK 2 WAY..............................239

MASS AIR FLOW SENSOR (DIESEL) - ORANGE 5 WAY......................240

v

Page 1219 of 4284

TABLE OF CONTENTS - Continued

A/C COMPRESSOR CLUTCH RELAY......................................242

ECM/PCM RELAY (DIESEL).............................................242

FUEL HEATER RELAY (DIESEL)..........................................242

LIFT PUMP RELAY (DIESEL).............................................242

STARTER MOTOR RELAY...............................................242

RADIATOR FAN NO. 1 (DIESEL) - GRAY 2 WAY.............................242

RADIATOR FAN NO. 2 (DIESEL) - GRAY 2 WAY.............................243

RADIATOR FAN RELAY NO. 1 (DIESEL) - BLUE 9 WAY......................243

RADIATOR FAN RELAY NO. 2 (DIESEL) - BLUE 9 WAY......................243

RADIATOR FAN RELAY NO. 3 (DIESEL) - BLUE 9 WAY......................243

RIGHT SPEED CONTROL SWITCH - WHITE 2 WAY.........................244

SENTRY KEY IMMOBILIZER MODULE - BLACK 6 WAY......................244

VEHICLE SPEED SENSOR (MTX/ATX) - BLACK 3 WAY......................244

WATER IN FUEL SENSOR (DIESEL) - BLACK 2 WAY........................244

10.0 SCHEMATIC DIAGRAMS................................................245

10.12001 RG 2.5L TURBO DIESEL......................................245

11.0 CHARTS AND GRAPHS................................................247

vi

Page 1220 of 4284

1.0 INTRODUCTION

The procedures contained in this manual include

all the specifications, instructions and graphics

needed to diagnose engine control module (ECM)

and sentry key immobilizer system (SKIS) prob-

lems; they are no start, diagnostic trouble code

(DTC), and no trouble code problems for the ECM.

The diagnostics in this manual are based on the

trouble condition or symptom being present at the

time of diagnosis.

When repairs are required, refer to the appropri-

ate service information for the proper removal and

repair procedure.

Diagnostic procedures change every year. New

diagnostic systems may be added; carryover sys-

tems may be enhanced. IT IS RECOMMENDED

THAT YOU REVIEW THE ENTIRE MANUAL TO

BECOME FAMILIAR WITH ALL NEW AND

CHANGED DIAGNOSTIC PROCEDURES.

This manual is designed to begin all diagnosis at

the DTC TEST, which is located at the beginning of

Section 7.0. This will cover all the necessary re-

quirements to begin a logical diagnostic path for

each problem. If there is a diagnostic trouble code

(DTC) detected, it will direct you to the trouble code

test. If there are no DTCs present, it will direct you

by symptom to a no trouble code test.

This book reflects many suggested changes from

readers of past issues. After using this book, if you

have any comments or recommendations, please fill

out the form at the back of the book and mail it back

to us.

1.1 SYSTEM COVERAGE

This diagnostic procedures manual covers all

2001 RG body vehicles equipped with the 2.5L VM

diesel engine.

1.2 SIX-STEP TROUBLESHOOTING

PROCEDURE

Diagnosis of the engine control module (ECM)

and sentry key immobilizer system (SKIS) is done

in six basic steps:

²verification of complaint

²verification of any related symptom

²symptom analysis

²problem isolation

²repair of isolated problem

²verification of proper operation

NOTE: All tests in this manual should be per-

formed with the engine at operating temperature,

unless specified within a particular test.

2.0 IDENTIFICATION OF

SYSTEM

The ECM is located in the left side of the engine

compartment between the left front headlamp and

the intelligent power module. The sentry key immo-

bilizer module (SKIM) is located below the steering

column behind the steering wheel.

3.0 SYSTEM DESCRIPTION AND

FUNCTIONAL OPERATION

3.1 GENERAL DESCRIPTION

The 2.5L VM diesel engine system is equipped

with the latest in technical advances. The on-board

diagnostics incorporated in the engine control mod-

ule and SKIM are intended to assist the field

technician in repairing vehicle problems by the

quickest means.

The engine system incorporates a common rail

fuel delivery design. This design utilizes electroni-

cally controlled solenoid valve type fuel injectors.

Each injector is controlled individually by the ECM.

Injector timing and fuel quantity are controlled by

the ECM based on inputs from the various sensors.

The precision control of the injectors by the ECM

helps to reduce the engine noise, odor and smoke.

3.2 FUNCTIONAL OPERATION

3.2.1 ECM ON-BOARD DIAGNOSTICS

The ECM has been programmed to monitor many

different circuits of the diesel fuel injection system.

This monitoring is called on-board diagnostics.

Certain criteria must be met for a trouble code to

be entered into the ECM memory. The criteria may

be a range of: engine rpm, engine temperature, time

or other input signals to the ECM. If all of the

criteria for monitoring a system or circuit are met,

and a problem is sensed, then a DTC will be stored

in the ECM memory.

It is possible that a DTC for a monitored circuit

may not be entered into the ECM memory, even

though a malfunction has occurred. This may hap-

pen when the monitoring criteria has not been met.

The ECM compares input signal voltages from

each input device with specifications (the estab-

lished high and low limits of the input range) that

are programmed into it for that device. If the input

voltage is not within the specifications and other

trouble code criteria are met, a DTC will be stored

in the ECM memory.

1

GENERAL INFORMATION