sensor CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1221 of 4284

3.2.2 ECM OPERATING MODES

As input signals to the ECM change, the ECM

adjusts its response to the output devices. For

example, the ECM must calculate a different fuel

quantity and fuel timing for engine idle condition

than it would for a wide open throttle condition.

There are several different modes of operation that

determine how the ECM responds to the various

input signals.

Ignition Switch On (Engine Off)

When the ignition switch is turned on, the ECM

activates the glow plug relay for a time period that

is determined by engine coolant temperature, atmo-

spheric temperature and battery voltage. The ECM

also activates the lift pump to prime the fuel sys-

tem.

Engine Start-up Mode

The ECM uses the engine temperature sensor

and the crankshaft position sensor (engine speed)

inputs to determine fuel injection quantity.

Normal Driving Modes

Engine idle, warm-up, acceleration, deceleration

and wide open throttle modes are controlled based

on all of the sensor inputs to the ECM. The ECM

uses these sensor inputs to adjust fuel quantity and

fuel injector timing.

Overheat Protection Mode

If engine temperature is above 106É C (223É F)

and vehicle speed is above 40 km/h (25 MPH) the

ECM will activate the high speed fan and will limit

fuel quantity for engine protection.

Limp-In Mode

If there is a fault detected with the accelerator

pedal position sensor, the ECM will set the engine

speed at 1100 RPM.

Overspeed Detection Mode

If the ECM detects engine RPM that exceeds

5000 RPM, the ECM will set a DTC in memory and

limit engine RPM to no more that 2500 RPM until

the DTC(s) is cleared.

After-Run Mode

The ECM transfers RAM information to ROM

and performs an Input/Output state check.

3.2.3 MONITORED CIRCUITS

The ECM is able to monitor and identify most

driveability related trouble conditions. Some cir-

cuits are directly monitored through ECM feedback

circuitry. In addition, the ECM monitors the voltage

state of some circuits and compares those stateswith expected values. Other systems are monitored

indirectly when the ECM conducts a rationality test

to identify problems.

Although most subsystems of the engine control

module are either directly or indirectly monitored,

there may be occasions when diagnostic trouble

codes are not immediately identified. For a trouble

code to set, a specific set of conditions must occur

and unless these conditions occur, a DTC will not

set.

3.2.4 SKIS OVERIVEW

The sentry key immobilizer system (SKIS) is

designed to prevent unauthorized vehicle opera-

tion. The system consists of a sentry key immobi-

lizer module (SKIM), ignition key(s) equipped with

a transponder chip and the ECM. When the ignition

switch is turned on, the SKIM interrogates the

ignition key. If the ignition key is Valid or Invalid,

the SKIM sends a PCI Bus message to the ECM

indicating ignition key status. Upon receiving this

message the ECM will terminate engine operation

or allow the engine to continue to operate.

3.2.5 SKIS ON-BOARD DIAGNOSTICS

The sentry key immobilizer module (SKIM) has

been programmed to transmit and monitor many

different coded messages as well as PCI Bus mes-

sages. This monitoring is called On-Board Diagnos-

tics. Certain criteria must be met for a DTC to be

entered into SKIM memory. The criteria may be a

range of; input voltage, PCI Bus message or coded

messages to the SKIM. If all of the criteria for

monitoring a circuit or function are met and a fault

is detected, a DTC will be stored in the SKIM

memory.

3.2.6 SKIS OPERATION

When ignition power is supplied to the SKIM, the

SKIM performs an internal self-test. After the self-

test is complete, the SKIM energizes the antenna

(this activates the transponder chip) and sends a

challenge to the transponder chip. The transponder

chip responds to the challenge by generating an

encrypted response message using the following:

Secret Key - This is an electronically stored value

(identification number) that is unique to each SKIS.

The secret key is stored in the SKIM, ECM and all

ignition key transponders.

Challenge - This is a random number that is gen-

erated by the SKIM at each ignition key cycle.

The secret key and challenge are the two vari-

ables used in the algorithm that produces the

encrypted response message. The transponder uses

the crypto algorithm to receive, decode and respond

to the message sent by SKIM. After responding to

the coded message, the transponder sends a tran-

2

GENERAL INFORMATION

Page 1222 of 4284

sponder ID message to the SKIM. The SKIM com-

pares the transponder ID message to the available

valid key codes in SKIM memory (8 key maximum

at any one time). After validating the ignition key,

the SKIM sends a PCI Bus message called a seed

request to the ECM, then waits for the ECM re-

sponse. If the ECM does not respond, the SKIM will

send the seed request again. After three failed

attempts, the SKIM will stop sending the seed

request and store a trouble code in memory. If the

ECM sends a seed response, the SKIM sends a

valid/invalid key message to the ECM. This is an

encrypted message that is generated using the

following:

VIN - Vehicle Identification Number.

Seed - This is a random number that is generated

by the ECM at each ignition key cycle.

The VIN and seed are two variables used in the

rolling code algorithm that encrypts the valid/

invalid key message. The ECM uses the rolling code

algorithm to receive, decode and respond to the

valid/invalid key message sent by the SKIM. After

sending the valid/invalid key message, the SKIM

waits 3.5 seconds for an ECM status message from

the ECM. If the ECM does not respond with a valid

key message to the SKIM, a fault is detected and a

code is stored.

The SKIS incorporates a warning lamp located in

the information center. The lamp receives switched

ignition voltage and is hardwired to the body con-

trol module. The lamp is actuated when the SKIM

sends a PCI Bus message to the body control

module requesting the lamp on. The body control

module then provides the ground for the lamp.

The SKIM will request lamp operation for the

following:

± bulb check at ignition on

± to alert the vehicle operator to a SKIS malfunc-

tion

± when the SKIM is in customer key programming

mode

For all faults except transponder faults the lamp

remains on steady. In the event of a transponder

fault the lamp will flash at a rate of 1Hz (once per

second). If a fault is present, the lamp will remain

on or flashing for the complete ignition cycle. If a

fault is stored in SKIM memory which prevents the

system from operating properly, the ECM will allow

the engine to start and idle for 2 seconds then stall.

This may occur up to six times. After the sixth

attempt, the ECM disables the starter relay until

the fault is corrected.

3.3 DIAGNOSTIC TROUBLE CODES

Each diagnostic trouble code (DTC) is diagnosed

by following a specific procedure. The diagnostic

test procedure contains step-by-step instruction fordetermining the cause of the DTC as well as no

trouble code problems. It is not necessary to per-

form all of the tests in this book to diagnose an

individual code.

Always begin diagnosis by reading the DTC's

using the DRBIIIt.

3.3.1 HARD CODE

A DTC that comes back within one cycle of the

ignition key is a hard code. This means that the

problem is current every time the ECM/SKIM

checks that circuit or function. Procedures in this

manual verify if the DTC is a hard code at the

beginning of each test. When the fault is not a hard

code, an intermittent test must be performed.

NOTE: If the DRBIIItdisplays faults for multiple

components (i.e. ECT, VSS, Oil Temp sensors) iden-

tify and check the shared circuits for possible prob-

lems before continuing (i.e. sensor grounds or 5-volt

supply circuits). Refer to the appropriate schematic

to identify shared circuits.

3.3.2 INTERMITTENT CODE

A DTC that is not current every time the ECM/

SKIM checks the circuit or function is an intermit-

tent code. Most intermittent DTCs are caused by

wiring or connector problems. Problems that come

and go like this are the most difficult to diagnose;

they must be looked for under specific conditions

that cause them. The following checks may assist

you in identifying a possible intermittent problem.

²Visually inspect the related wire harness connec-

tors. Look for broken, bent, pushed out, or cor-

roded terminals.

²Visually inspect the related wire harness. Look

for chafed, pierced, or partially broken wire.

²Refer to hotlines or technical service bulletins

that may apply.

NOTE: Electromagnetic (radio) interference can

cause an intermittent system malfunction. This

interference can interrupt communication between

the ignition key transponder and the SKIM.

3.3.3 ECM DIAGNOSTIC TROUBLE CODES

IMPORTANT NOTE:Before replacing the ECM

for a failed driver, control circuit or ground circuit,

be sure to check the related component/circuit in-

tegrity for failures not detected due to a double fault

in the circuit. Most ECM driver/control circuit fail-

ures are caused by internal failures to components

(i.e. relays and solenoids) and shorted circuits (i.e.

sensor pull-ups, drivers and ground circuits). These

faults are difficult to detect when a double fault has

occurred and only one DTC has set.

If the DRB displays faults for multiple compo-

nents (i.e. VSS, ECT, Batt Temp, etc.), identify and

3

GENERAL INFORMATION

Page 1223 of 4284

check the shared circuits for possible problems

before continuing (i.e. Sensor Grounds or 5-Volt

Supply circuits). Refer to the appropriate wiring

diagrams to identify shared circuits.

MASS AIR FLOW SENSOR SIGNAL VOLTAGE

TOO HIGH

MASS AIR FLOW SENSOR SIGNAL VOLTAGE

TOO LOW

MASS AIR FLOW SENSOR SUPPLY VOLTAGE

TOO HIGH OR LOW

MASS AIR FLOW SENSOR PLAUSIBILITY

MASS AIR FLOW SENSOR SIGNAL PLAUSI-

BILITY POSITIVE AREA

BAROMETRIC PRESSURE CIRCUIT SIGNAL

VOLTAGE TOO HIGH

BAROMETRIC PRESSURE CIRCUIT SIGNAL

VOLTAGE TOO LOW

INTAKE AIR TEMP SENSOR SIGNAL VOLT-

AGE TOO HIGH

INTAKE AIR TEMP SENSOR SIGNAL VOLT-

AGE TOO LOW

ENGINE COOLANT TEMP SENSOR SIGNAL

VOLTAGE TOO HIGH

ENGINE COOLANT TEMP SENSOR SIGNAL

VOLTAGE TOO LOW

FUEL PRESS SENSOR CIRCUIT MALF SIG-

NAL VOLTAGE TOO HIGH

FUEL PRESS SENSOR CIRCUIT MALF SIG-

NAL VOLTAGE TOO LOW

FUEL PRESS SENSOR CIRCUIT MALF SUP-

PLY VOLTAGE TOO HIGH OR LOW

OIL TEMP SENSOR CIRCUIT MALF SIGNAL

VOLTAGE TOO HIGH

OIL TEMP SENSOR CIRCUIT MALF SIGNAL

VOLTAGE TOO LOW

CYLINDER 1-INJECTOR CIRCUIT OVERCUR-

RENT HIGH SIDE

CYLINDER 1-INJECTOR CIRCUIT OVERCUR-

RENT LOW SIDE

CYLINDER 1-INJECTOR CIRCUIT LOAD

DROP

CYLINDER 1-INJECTOR CIRCUIT CURRENT

DECREASE

CYLINDER 2-INJECTOR CIRCUIT OVERCUR-

RENT HIGH SIDE

CYLINDER 2-INJECTOR CIRCUIT OVERCUR-

RENT LOW SIDE

CYLINDER 2-INJECTOR CIRCUIT LOAD

DROP

CYLINDER 2-INJECTOR CIRCUIT CURRENT

DECREASE

CYLINDER 3-INJECTOR CIRCUIT OVERCUR-

RENT HIGH SIDE

CYLINDER 3-INJECTOR CIRCUIT OVERCUR-

RENT LOW SIDE

CYLINDER 3-INJECTOR CIRCUIT LOAD

DROPCYLINDER 3-INJECTOR CIRCUIT CURRENT

DECREASE

CYLINDER 4-INJECTOR CIRCUIT OVERCUR-

RENT HIGH SIDE

CYLINDER 4-INJECTOR CIRCUIT OVERCUR-

RENT LOW SIDE

CYLINDER 4-INJECTOR CIRCUIT LOAD

DROP

CYLINDER 4-INJECTOR CIRCUIT CURRENT

DECREASE

BOOST PRESSURE SENSOR SIGNAL VOLT-

AGE TOO HIGH

BOOST PRESSURE SENSOR SIGNAL VOLT-

AGE TOO LOW

BOOST PRESSURE SENSOR SUPPLY VOLT-

AGE TOO HIGH OR LOW

BOOST PRESSURE SENSOR PLAUSIBILITY

CKP POSITION SENSOR CIRCUIT OVER-

SPEED RECOGNITION

CKP POSITION SENSOR CIRCUIT DYNAMIC

PLAUSIBILITY

CKP POSITION SENSOR CIRCUIT STATIC

PLAUSIBILITY

CMP POSITION SENSOR CIRCUIT CMP/CKP

SYNC FAILURE

CMP POSITION SENSOR CIRCUIT DYNAMIC

PLAUSIBILITY

CMP POSITION SENSOR CIRCUIT STATIC

PLAUSIBILITY

CMP POSITION SENSOR CIRCUIT SIGNAL

FREQUENCY TOO HIGH

CMP POSITION SENSOR CIRCUIT FUEL

SHUT-OFF ACTIVATED

GLOW PLUG CIRCUIT A SHORT CIRCUIT

GLOW PLUG CIRCUIT A OPEN CIRCUIT

EGR SOLENOID CIRCUIT OPEN CIRCUIT

EGR SOLENOID CIRCUIT SHORT CIRCUIT

EGR SOLENOID CIRCUIT IMPROPER FLOW

FAN 1 CONTROL CIRCUIT OPEN CIRCUIT

FAN 1 CONTROL CIRCUIT SHORT CIRCUIT

FAN 2 CONTROL CIRCUIT OPEN CIRCUIT

FAN 2 CONTROL CIRCUIT SHORT CIRCUIT

VEHICLE SPEED SENSOR SIGNAL VOLTAGE

TOO HIGH

VEHICLE SPEED SENSOR FREQUENCY TOO

HIGH

VEHICLE SPEED SENSOR HIGH LEVEL DU-

RATION

VEHICLE SPEED SENSOR PLAUSIBILITY

BATTERY TEMP SENSOR SIGNAL VOLTAGE

TOO HIGH

BATTERY TEMP SENSOR SIGNAL VOLTAGE

TOO LOW

OIL PRESS SENSOR CKT MALF PLAUSIBIL-

ITY

4

GENERAL INFORMATION

Page 1224 of 4284

A/C PRESSURE SENSOR CIRCUIT SIGNAL

VOLTAGE TOO HIGH

A/C PRESSURE SENSOR CIRCUIT SIGNAL

VOLTAGE TOO LOW

A/C PRESSURE SENSOR CIRCUIT SUPPLY

VOLTAGE TOO HIGH OR LOW

A/C PRESSURE SENSOR CIRCUIT PLAUSI-

BILITY

SYSTEM VOLTAGE TOO HIGH

SYSTEM VOLTAGE TOO LOW

S/C SWITCH SIGNAL CIRCUIT SIGNAL VOLT-

AGE TOO HIGH

S/C SWITCH SIGNAL CIRCUIT SIGNAL VOLT-

AGE TOO LOW

S/C SWITCH SIGNAL CIRCUIT PLAUSIBILITY

ECM ERROR RECOVERY HAS OCCURRED

ECM ERROR REDUNDANT OVERRUN MONI-

TORING

ECM ERROR GATE ARRAY - QUANTITY STOP

ECM ERROR GATE ARRAY - COMMUNICA-

TION

ECM ERROR - COMMUNICATION NOT VERI-

FIED

STARTER RELAY CIRCUIT OPEN CIRCUIT

STARTER RELAY CIRCUIT SHORT CIRCUIT

GENERATOR FIELD CONTROL MALF BAT-

TERY VOLTAGE TOO HIGH

GENERATOR FIELD CONTROL MALF BAT-

TERY VOLTAGE TOO LOW

GENERATOR FIELD CONTROL MALF OPEN

CIRCUIT

GENERATOR FIELD CONTROL MALF SHORT

CIRCUIT

GENERATOR FIELD CONTROL MALF

CHARGING VOLTS TOO LOW

GENERATOR FIELD CONTROL MALF BAT-

TERY VOLTAGE DEVIATION TOO HIGH

GENERATOR FIELD CONTROL MALF BAT-

TERY VOLTAGE DEVIATION TOO LOW

GENERATOR FIELD CONTROL MALF UN-

STABLE CURRENT

SENSOR REFERENCE VOLTAGE A CKT VOLT-

AGE TOO HIGH

SENSOR REFERENCE VOLTAGE A CKT VOLT-

AGE TOO LOW

SENSOR REFERENCE VOLTAGE B CKT

VOLTAGE TOO HIGH

SENSOR REFERENCE VOLTAGE B CKT

VOLTAGE TOO LOW

A/C CLUTCH RELAY CIRCUIT OPEN CIRCUIT

A/C CLUTCH RELAY CIRCUIT SHORT CIR-

CUIT

ECM/PCM RELAY CONTROL CIRCUIT SHUTS

OFF TOO EARLY

ECM/PCM RELAY CONTROL CIRCUIT SHUTS

OFF TOO LATE

BRAKE SWITCH SIGNAL CIRCUITS INCOR-

RECT CAN MESSAGEBRAKE SWITCH SIGNAL CIRCUITS PLAUSI-

BILITY WITH REDUNDANT CONTACT

BRAKE SWITCH SIGNAL CIRCUITS PLAUSI-

BILITY WITH REDUNDANT CONTACT AFTER

INITIALIZATION

CLUTCH UPSTOP SWITCH PERF PLAUSIBIL-

ITY

CLUTCH UPSTOP SWITCH PERF PLAUSIBIL-

ITY WITH P/N SWITCH

FUEL RAIL PRESSURE MALFUNCTION

PRESSURE TOO HIGH - LIMITATION

FUEL RAIL PRESSURE MALFUNCTION

PRESSURE TOO LOW

FUEL RAIL PRESSURE MALFUNCTION SO-

LENOID OPEN

FUEL RAIL PRESSURE MALFUNCTION

LEAKAGE DETECTED

FUEL PRESSURE SOLENOID OPEN CIRCUIT

FUEL PRESSURE SOLENOID SHORT CIR-

CUIT

FUEL PRESSURE SOLENOID PLAUSIBILITY

IN AFTER-RUN

CALCULATED INJECTOR VOLTAGE - VOLT-

AGE 1 TOO LOW

CALCULATED INJECTOR VOLTAGE - VOLT-

AGE 2 TOO LOW

BATTERY SENSE LINE 1 VOLTAGE TOO

HIGH

BATTERY SENSE LINE 1 VOLTAGE TOO LOW

FUEL PRESS REG CURRENT CONTROL SIG-

NAL TOO HIGH

FUEL PRESS REG CURRENT CONTROL SIG-

NAL TOO LOW

GENERATOR FIELD CURRENT TOO HIGH

GENERATOR FIELD CURRENT TOO LOW

CAPACITOR VOLTAGE 1 VOLTAGE TOO HIGH

CAPACITOR VOLTAGE 1 VOLTAGE TOO LOW

CAPACITOR VOLTAGE 2 VOLTAGE TOO HIGH

CAPACITOR VOLTAGE 2 VOLTAGE TOO LOW

IGNITION SWITCH PLAUSIBILITY

AFTER RUN SHUT OFF ERROR - ZERO

QUANTITY

AFTERRUN SHUT OFF ERROR - INJ. POWER-

STAGE

VOLTAGE REGULATOR SIGNAL VOLTAGE

TOO HIGH

VOLTAGE REGULATOR SIGNAL VOLTAGE

TOO LOW

MIL/DIAG LAMP VIA J1850 BUS IN FRAME

RESPONSE ERROR

MIL/DIAG LAMP VIA J1850 BUS - STATUS

ERROR

J1850 COMMUNICATION BUS SHORT TO

VOLTAGE

J1850 COMMUNICATION BUS SHORT TO

GROUND

J1850 COMMUNICATION BUS TRANSMIT

BUFFER OVERRUN

5

GENERAL INFORMATION

Page 1225 of 4284

J1850 COMMUNICATION BUS SPI ERROR

J1850 COMMUNICATION BUS RECEIVE TIME-

OUT

J1850 COMMUNICATION BUS UNAUTHO-

RIZED RESET

EEPROM PLAUSIBILITY CHECKSUM ERROR

EEPROM PLAUSIBILITY VIN CHECKSUM

ERROR

EEPROM PLAUSIBILITY COMMUNICATION

ERROR

EEPROM PLAUSIBILITY WRITE ERROR

EEPROM PLAUSIBILITY VARIATION NUM-

BER ERROR

EEPROM PLAUSIBILITY CODE WORD IN-

CORRECT OR MISSING

SKIM SYSTEM SKIM ERROR

SKIM SYSTEM WRITE ACCESS TO EEPROM

FAILURE

SKIM SYSTEM INVALID SECRET KEY IN EE-

PROM

SKIM SYSTEM KEY COMMUNICATION

TIMED OUT

SKIM SYSTEM INVALID KEY CODE RE-

CEIVED

EEPROM RECOVERY OCCURRED

EEPROM REDUNDANT OVERRUN MONI-

TORING

EEPROM QUANTITY STOP

EEPROM COMMUNICATION ERROR

EEPROM COMMUNICATION NOT VERIFIED

ACC PEDAL POSITION SENSOR 1 CKT SIG-

NAL VOLTAGE TOO HIGH

ACC PEDAL POSITION SENSOR 1 CKT SIG-

NAL VOLTAGE TOO LOW

ACC PEDAL POSITION SENSOR 1 CKT SUP-

PLY VOLTAGE TOO HIGH OR LOW

ACC PEDAL POSITION SENSOR 1 CKT PLAU-

SIBILITY WITH POTENTIOMETER

ACC PEDAL POSITION SENSOR 1 CKT PLAU-

SIBILITY WITH BRAKE SWITCH

ACC PEDAL POSITION SENSOR 1 CKT PLAU-

SIBILITY

3.3.4 SKIM DIAGNOSTIC TROUBLE CODES

ANTENNA FAILURE

COP FAILURE

EEPROM FAILURE

PCM STATUS FAILURE

INTERNAL FAULT

RAM FAILURE

ROLLING CODE FAILURE

SERIAL LINK EXTERNAL FAULT

SERIAL LINK INTERNAL FAULT

STACK OVERFLOW FAILURE

TRANSPONDER COMMUNICATION FAILURE

TRANSPONDER CRC (CYCLIC REDUN-

DANCY CHECK) FAILURE

TRANSPONDER ID MISMATCHTRANSPONDER RESPONSE MISMATCH

VIN MISMATCH

3.3.5 HANDLING NO TROUBLE CODE

PROBLEMS

After reading Section 3.0 (System Description

and Functional Operation), you should have a bet-

ter understanding of the theory and operation of the

on-board diagnostics, and how this relates to the

diagnosis of a vehicle that may have a driveability-

related symptom or complaint.

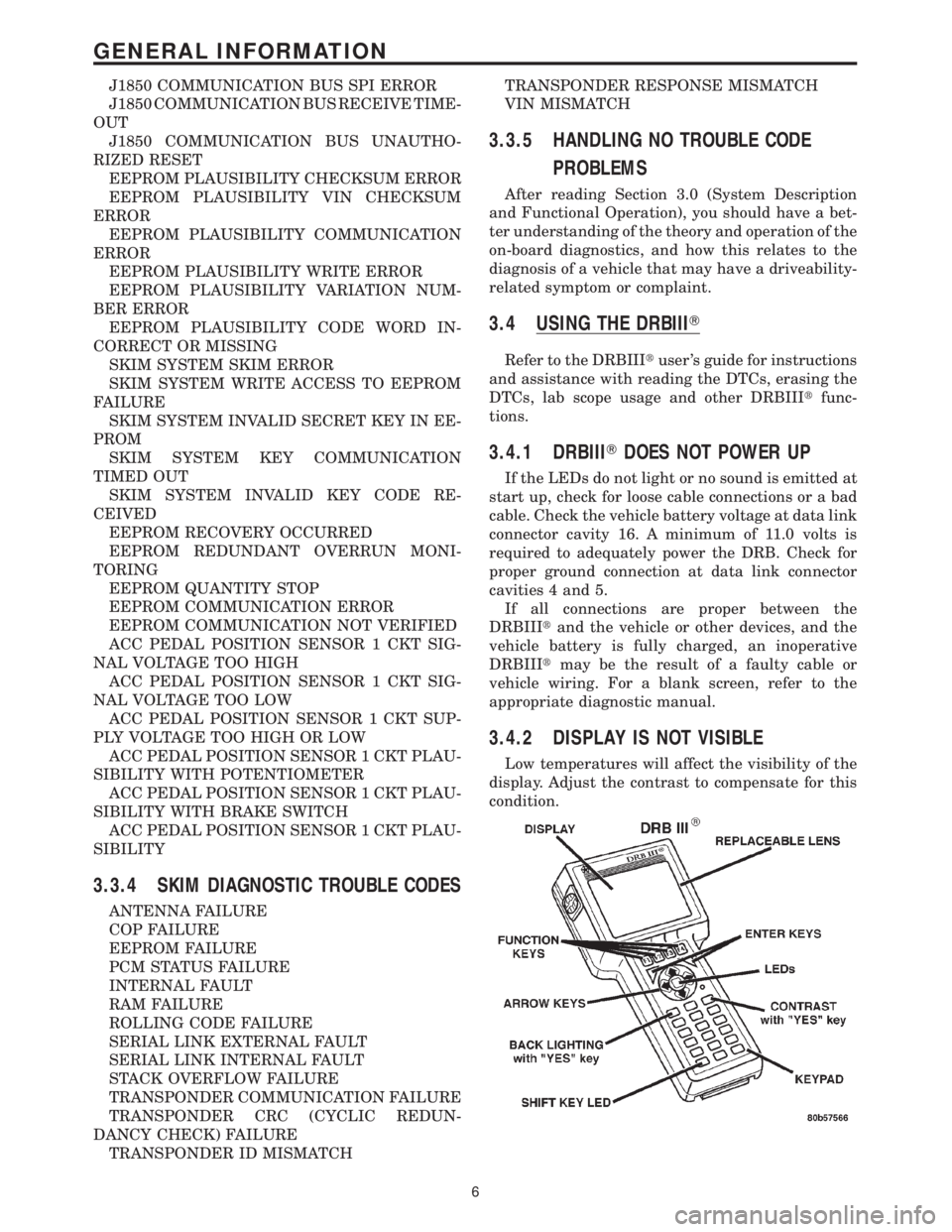

3.4 USING THE DRBIIIT

Refer to the DRBIIItuser 's guide for instructions

and assistance with reading the DTCs, erasing the

DTCs, lab scope usage and other DRBIIItfunc-

tions.

3.4.1 DRBIIITDOES NOT POWER UP

If the LEDs do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage at data link

connector cavity 16. A minimum of 11.0 volts is

required to adequately power the DRB. Check for

proper ground connection at data link connector

cavities 4 and 5.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, an inoperative

DRBIIItmay be the result of a faulty cable or

vehicle wiring. For a blank screen, refer to the

appropriate diagnostic manual.

3.4.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

6

GENERAL INFORMATION

Page 1227 of 4284

4.3 WARNINGS AND CAUTIONS

4.3.1 ROAD TEST WARNINGS

Some complaints will require a test drive as part

of the repair verification procedure. The purpose of

the test drive is to try to duplicate the diagnostic

code or symptom condition.

CAUTION: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED. DUR-

ING THE TEST DRIVE, DO NOT HANG THE

DRBIIITFROM THE REAR VIEW MIRROR. DO

NOT ATTEMPT TO READ THE DRBIIITWHILE

DRIVING. HAVE AN ASSISTANT AVAILABLE

TO OPERATE THE DRBIIIT.

4.3.2 VEHICLE DAMAGE CAUTIONS

Before disconnecting any control module, make

sure the ignition is off. Failure to do so could

damage the module. When testing voltage or circuit

integrity at any control module, use the terminal

side (not the wire end) of the harness connector. Do

not probe through the insulation; this will damage

it and eventually cause it to fail because of corro-

sion.

Be careful when performing electrical test so as to

prevent accidental shorting of terminals. Such a

mistake can damage fuses or components. Also, a

second code could be set, making diagnosis of the

original problem more difficult.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box) scan tool

vacuum gauge

ammeter

ohmmeter

jumper wires and probes

oscilloscope

6.0 GLOSSARY OF TERMS

A/Cair conditioning

APPaccelerator pedal position (sensor)

backfire,

popbackfuel ignites in either the intake or

the exhaust system

BCMbody control module

BPboost pressure (sensor)CKPcrankshaft position (sensor)

CMPcamshaft position (sensor)

cuts out,

missesa steady pulsation or the inability of

the engine to maintain a consistent

rpm

DLCdata link connector

detona-

tion,

spark

knocka mild to severe ping, especially un-

der loaded engine conditions

ECMengine control module

ECTengine coolant temperature (sensor)

EGRexhaust gas recirculation

(solenoid/valve)

hard

startthe engine takes longer than usual

to start, even though it is able to

crank at normal speed.

IATintake air temperature (sensor)

IPMintelligent power module

lack of

power,

sluggishthe engine power output has been

reduced

MAFmass air flow (sensor)

MILmalfunction indicator lamp

msmillisecond(s)

PDCpower distribution center

poor fuel

economythere is significantly less fuel mile-

age than other vehicles of the same

design and configuration

runs

rough/

unstable

idlethe engine runs unevenly at idle

causing the engine to shake if it is

severe enough

S/Cspeed control

SKIMsentry key immobilizer module

SKISsentry key immobilizer system

start and

stallThe engine starts but immediately

dies (stalls)

surgeengine rpm fluctuation without cor-

responding change in accelerator

pedal position

SRCsignal range check

WIFwater in fuel (sensor)

VSSvehicle speed sensor

8

GENERAL INFORMATION

Page 1232 of 4284

Symptom List:

P0100-MASS AIR FLOW SENSOR PLAUSIBILITY

P0100-MASS AIR FLOW SENSOR PLAUSIBILITY POSITIVE AREA

P0100-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO HIGH

P0100-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO LOW

P0100-MASS AIR FLOW SENSOR SUPPLY VOLTAGE TOO HIGH OR

LOW

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0100-MASS AIR FLOW SENSOR

PLAUSIBILITY.

When Monitored and Set Condition:

P0100-MASS AIR FLOW SENSOR PLAUSIBILITY

When Monitored: With the engine running.

Set Condition: The mass airflow measure does not correspond with the enigne load

measurements.

P0100-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO HIGH

When Monitored: With the ignition on.

Set Condition: The Boost Pressure Sensor Signal voltage is above 4.5 volts.

P0100-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO LOW

When Monitored: With the ignition on.

Set Condition: The Mass Air Flow Sensor Signal voltage is below 0.2 volt.

P0100-MASS AIR FLOW SENSOR SUPPLY VOLTAGE TOO HIGH OR LOW

When Monitored: With the ignition on.

Set Condition: The Sensor Reference Voltage9A9voltage to the MAF is below 4.8 volts or

above 5.2 volts for at least 100 ms.

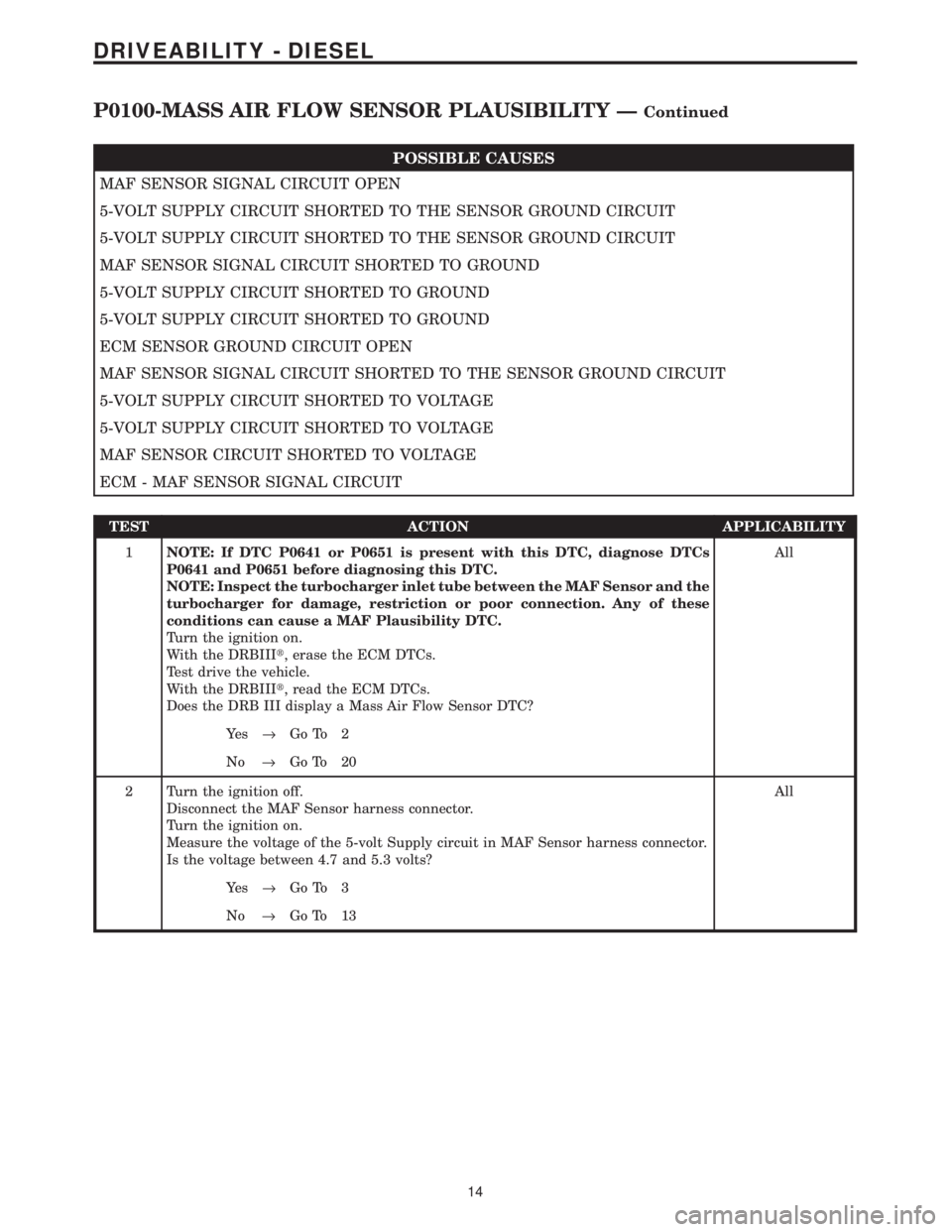

POSSIBLE CAUSES

ECM - 5-VOLT SUPPLY CIRCUIT

ECM/PCM RELAY OUTPUT CIRCUIT OPEN

MAF SENSOR IDLE VOLTAGE

MAF SENSOR SIGNAL - FULL THROTTLE VOLTAGE

SENSOR GROUND OPEN

INTERMITTENT CONDITION

5-VOLT SUPPLY CIRCUIT OPEN

13

DRIVEABILITY - DIESEL

Page 1233 of 4284

POSSIBLE CAUSES

MAF SENSOR SIGNAL CIRCUIT OPEN

5-VOLT SUPPLY CIRCUIT SHORTED TO THE SENSOR GROUND CIRCUIT

5-VOLT SUPPLY CIRCUIT SHORTED TO THE SENSOR GROUND CIRCUIT

MAF SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

ECM SENSOR GROUND CIRCUIT OPEN

MAF SENSOR SIGNAL CIRCUIT SHORTED TO THE SENSOR GROUND CIRCUIT

5-VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

5-VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

MAF SENSOR CIRCUIT SHORTED TO VOLTAGE

ECM - MAF SENSOR SIGNAL CIRCUIT

TEST ACTION APPLICABILITY

1NOTE: If DTC P0641 or P0651 is present with this DTC, diagnose DTCs

P0641 and P0651 before diagnosing this DTC.

NOTE: Inspect the turbocharger inlet tube between the MAF Sensor and the

turbocharger for damage, restriction or poor connection. Any of these

conditions can cause a MAF Plausibility DTC.

Turn the ignition on.

With the DRBIIIt, erase the ECM DTCs.

Test drive the vehicle.

With the DRBIIIt, read the ECM DTCs.

Does the DRB III display a Mass Air Flow Sensor DTC?All

Ye s®Go To 2

No®Go To 20

2 Turn the ignition off.

Disconnect the MAF Sensor harness connector.

Turn the ignition on.

Measure the voltage of the 5-volt Supply circuit in MAF Sensor harness connector.

Is the voltage between 4.7 and 5.3 volts?All

Ye s®Go To 3

No®Go To 13

14

DRIVEABILITY - DIESEL

P0100-MASS AIR FLOW SENSOR PLAUSIBILITY ÐContinued

Page 1234 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the MAF Sensor harness connector.

Disconnect the ECM harness connectors.

Remove the ECM/PCM Relay from the PDC.

Connect a jumper wire between cavity 30 and cavity 87 of the ECM/PCM Relay

connector.

Turn the ignition on.

Measure the voltage of the MAF Sensor Signal circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the MAF Sensor Signal circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 4

4 Turn the ignition off.

Disconnect the MAF Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the MAF Sensor Signal circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 5

No®Repair the MAF Sensor Signal circuit for an open

Perform ROAD TEST VERIFICATION - VER-2.

5 Turn the ignition off.

Disconnect the MAF Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between ground and the MAF Sensor Signal circuit.

Is the resistance below 1000 ohms?All

Ye s®Repair the MAF Sensor Signal circuit for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 6

6 Turn the ignition off.

Disconnect the MAF Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between the MAF Sensor Signal circuit and the Sensor

Ground circuit at of the MAF Sensor harness connector.

Is the resistance below 1000 ohms?All

Ye s®Repair the MAF Sensor Signal for a short to Sensor Ground .

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 7

7 Turn the ignition off.

Disconnect the MAF Sensor harness connector.

Connect a jumper wire between MAF Sensor Signal circuit and the 5-volt supply

circuit at the MAF Sensor harness connector .

With the DRBIII, read the MAF VOLTS.

Does the DRBIII display between 4.0 and 5.5 volts?All

Ye s®Go To 8

No®Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

15

DRIVEABILITY - DIESEL

P0100-MASS AIR FLOW SENSOR PLAUSIBILITY ÐContinued

Page 1235 of 4284

TEST ACTION APPLICABILITY

8 Turn the ignition off.

Disconnect the MAF Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the Sensor Ground circuit between the MAF Sensor and

the ECM.

Is the resistance below 10.0 ohms?All

Ye s®Go To 9

No®Repair the Sensor Ground circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

9 Turn the ignition off.

Disconnect the MAF Sensor harness connector.

Measure the voltage between the 5-volt Supply circuit and the Sensor Ground circuit

at the MAF Sensor harness connector.

Is the voltage above 4.5 volts?All

Ye s®Go To 10

No®Replace and program the ECM in accordance with the Service

Information.

Perform ROAD TEST VERIFICATION - VER-2.

10 Turn the ignition off.

Disconnect the MAF Sensor harness connector.

With the DRBIIIt, actuate the ECM/PCM Relay.

Measure the voltage of the 12-volt Supply circuit at the MAF Sensor harness

connector

Is the voltage above 10.0 volts?All

Ye s®Go To 11

No®Repair the ECM/PCM Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

11 Turn the ignition off.

NOTE: Inspect the turbocharger inlet tube between the MAF Sensor and the

Turbocharger. Ensure the airflow tube properly is secured at each end and

that there is no damage, restrictions or air leaks in the tube.

With a voltmeter, backprobe the MAF Sensor Signal circuit at the MAF Sensor

harness connector.

Allow the engine to idle for at least 2 minutes.

NOTE: The engine speed must be approximately 900 rpm for this test to be

valid.

Is the voltage between 2.1 and 2.7 volts?All

Ye s®Go To 12

No®Replace the Mass Air Flow Sensor in accordance with the Service

Information.

Perform ROAD TEST VERIFICATION - VER-2.

16

DRIVEABILITY - DIESEL

P0100-MASS AIR FLOW SENSOR PLAUSIBILITY ÐContinued